Full-premixing type condensation type steam generator

A fully premixed condensing type, steam generator technology, applied in the direction of steam generation, steam generation methods, steam boilers, etc., can solve the problems of low combustion efficiency and environmental protection, achieve high combustion temperature, reduce emissions, and flame propagation speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

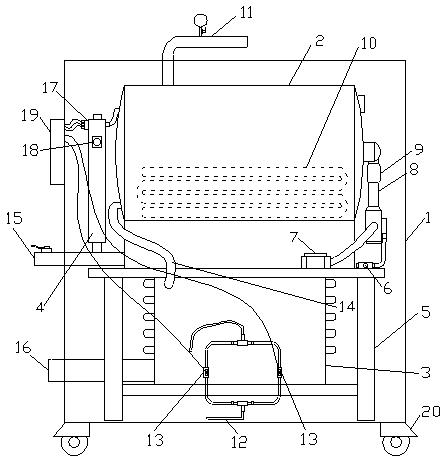

[0011] As shown in the figure, a fully premixed condensing steam generator includes a shell 1, a combustion cylinder 2, a secondary heat exchanger 3 and an auxiliary water tank 4, a combustion cylinder 2, a secondary heat exchanger 3 and an auxiliary The water tank 4 is built in the frame 5 in the shell 1, the secondary heat exchanger 3 is located under the combustion cylinder 2, the gas communicates with the gas inlet of the premix chamber through the proportional valve 6, and the air passes through the air filter 7 to communicate with the premix chamber. The air inlet of the mixing chamber is connected, the premixing chamber is connected to the inlet of the fan 8, and the outlet of the fan 8 is connected to the mixer 9. After being ignited, the mixed gas at the outlet of the mixer 9 enters the serpentine heat exchange coil 10 built in the combustion cylinder 2, and replenishes water. The pipe 15 communicates with the combustion cylinder 2, and the steam outlet pipe 11 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com