Atmospheric gas radiation heating device

A radiant heating and atmospheric technology, which is applied in lighting and heating equipment, gas fuel burners, and the combustion of block fuels and gaseous fuels, etc., can solve the problem of affecting the service life and use effect of gas radiant tubes, and air/gas mixing The ratio is not easy to control, the connection between the burner and the radiant tube is complicated, etc., to achieve the effects of uniform temperature distribution in the circumferential direction, improved fuel utilization rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

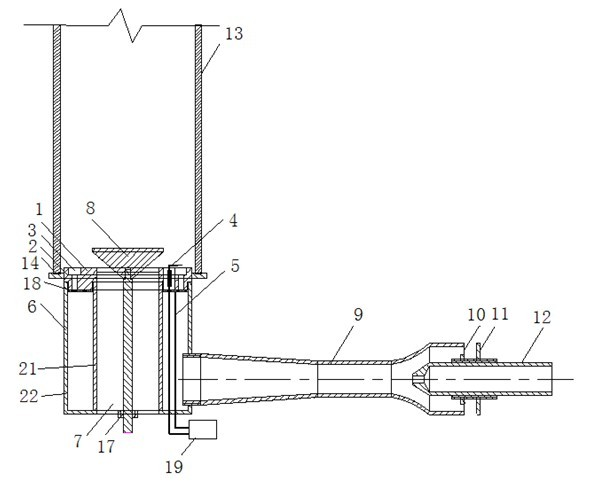

[0040] The present invention will be further described below in conjunction with accompanying drawing.

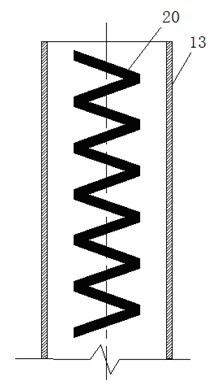

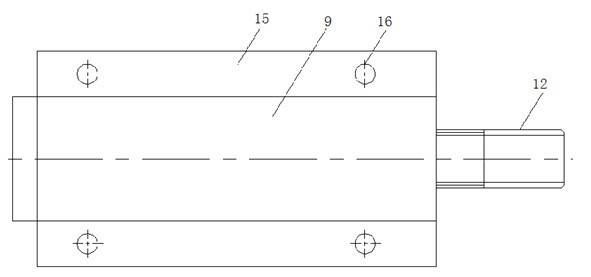

[0041] see figure 1 , as can be seen from the figure, the atmospheric gas radiation heating device of the present invention is composed of three parts: a burner, a radiant tube 13 and an igniter, wherein the burner is mainly composed of a nozzle 12, an injection pipe 9 and a burner head 6 composition. The nozzle 12 is inserted from one end of the injection pipe 9 , and a primary air inlet 10 is formed between the outer wall of the nozzle 12 and the inner wall of the injection pipe 9 . The lower end of the radiant tube 13 is connected with the burner head 6, and the upper end is fixed on the furnace wall with a tube clip. The burner head 6 of the present invention is composed of a concentric and equal-height inner pipe 21 and an outer pipe 22, one end of the ring between the inner pipe 21 and the outer pipe 22 is closed, and the other end of the injection pipe 9 is threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com