Black resin composition, prepreg and laminated plate

A technology of black resin and composition, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of increasing product time and difficulty, poor insulation performance of laminated boards, and limiting the application of high-end products, etc. Achieve the effects of good color consistency, excellent insulation and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

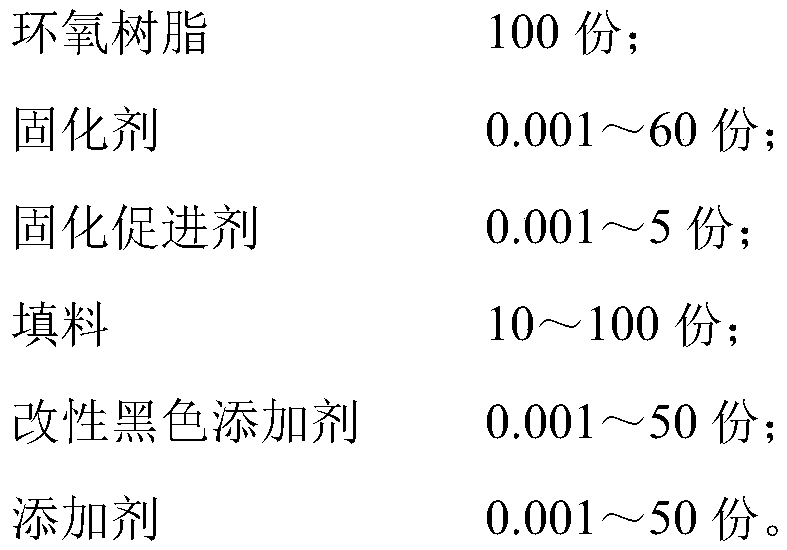

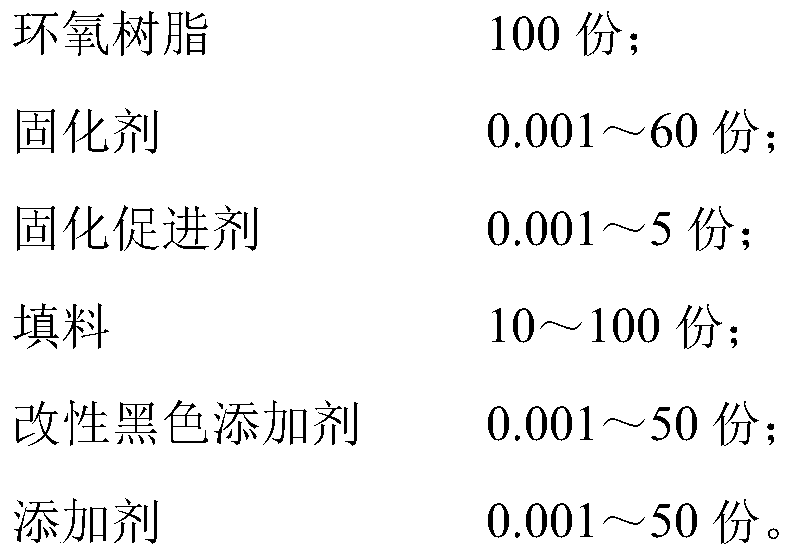

Method used

Image

Examples

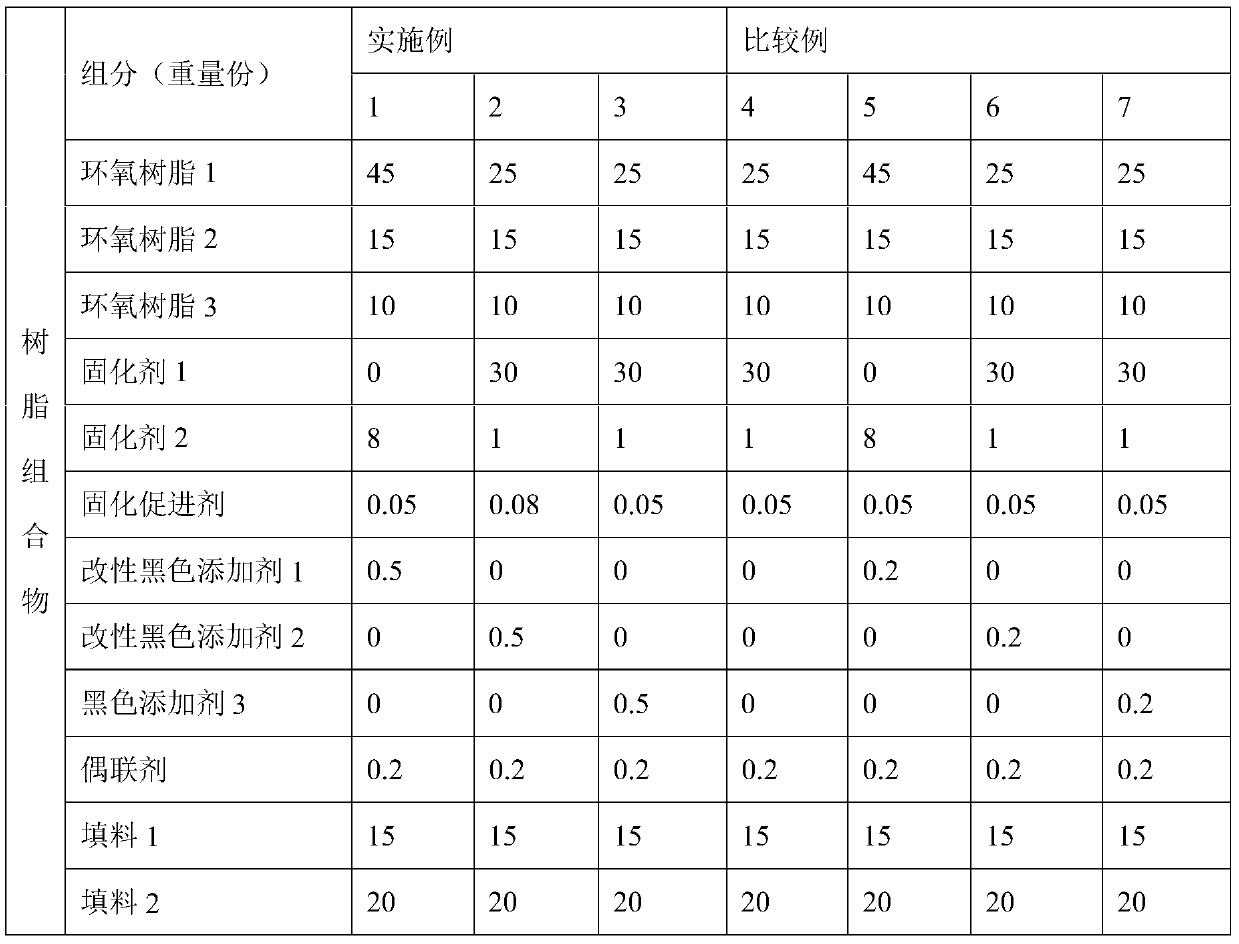

Embodiment 1

[0037] 1. Preparation of black resin composition

[0038] In parts by weight, get 45 parts of epoxy resin 1, 15 parts of epoxy resin 2, 10 parts of epoxy resin 3, 0 parts of curing agent 1, 8 parts of curing agent 2, 0.05 part of curing accelerator, 0.5 part of modified black Additive 1, 0 parts of modified black additive 2, 0 parts of black additive 3, 0.2 part of silane coupling agent, 15 parts of filler 1, 20 parts of filler 2, dissolved in an organic solvent, stirred evenly, and the solid content of the resin composition was adjusted to 60 wt%, to prepare a black resin combination liquid.

[0039] 2. Preparation of prepreg

[0040] The above-mentioned black resin combination solution is impregnated or fully evenly coated on the reinforcing material, such as E-type glass cloth, and baked in an oven at 150°C to obtain a prepreg.

[0041] 3. Preparation of copper clad laminate

[0042] Take the six prepregs prepared above and stack them together, place a piece of copper fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com