High-activity MgO roasting technology and special device thereof

A roasting process and special device technology, which is applied in the field of high-activity MgO roasting process and its special device, can solve the problems of large fluctuations in product quality, short operation period, and high maintenance intensity, and achieve good product quality, low maintenance difficulty, and equipment The effect of less total investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention more obvious and understandable, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

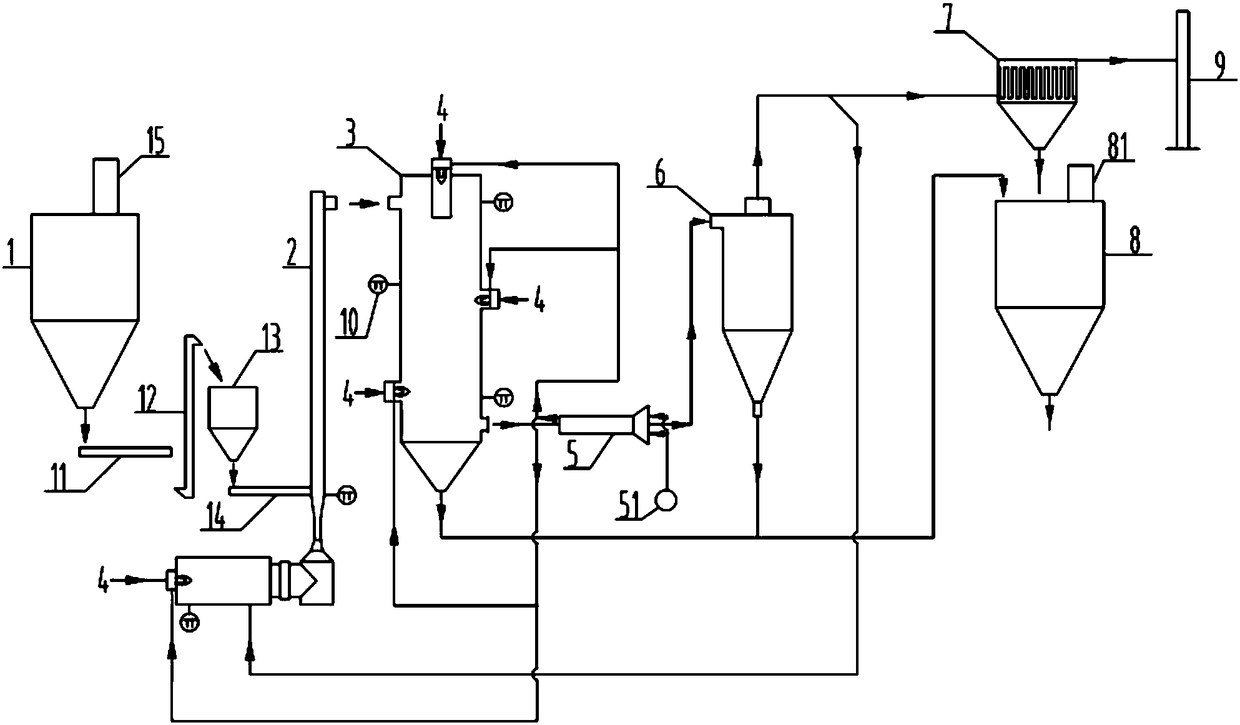

[0030] A special device for high-activity MgO roasting, such as figure 1 As shown, it includes raw material bin (1), airflow preheating furnace (2), swirl calciner (3), multi-channel combustion system (4), cooling device (5), separation device (6), waste gas treatment device ( 7), the finished product warehouse (8), the chimney (9) and the temperature detector (10), wherein the raw material warehouse (1) is connected to the feed port at the bottom of the airflow preheating furnace (2) through the conveying equipment, and the airflow preheating furnace (2) ) discharge port is connected with the feed port at the top of the swirl calciner (3), the discharge port at the bottom of the swirl calciner (3) is connected with the hot side feed port of the cooling devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com