Combustion system and method of inverted-alpha shaped flame air distribution type layered boiler

A combustion system and air distribution system technology, applied in the boiler field, can solve problems such as large excess air coefficient, uneven furnace temperature distribution, difficult formation of α flame, etc., to increase combustion temperature, reduce carbon content and solid phase in ash Effect of incomplete combustion loss and reduction of nitrogen oxide generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

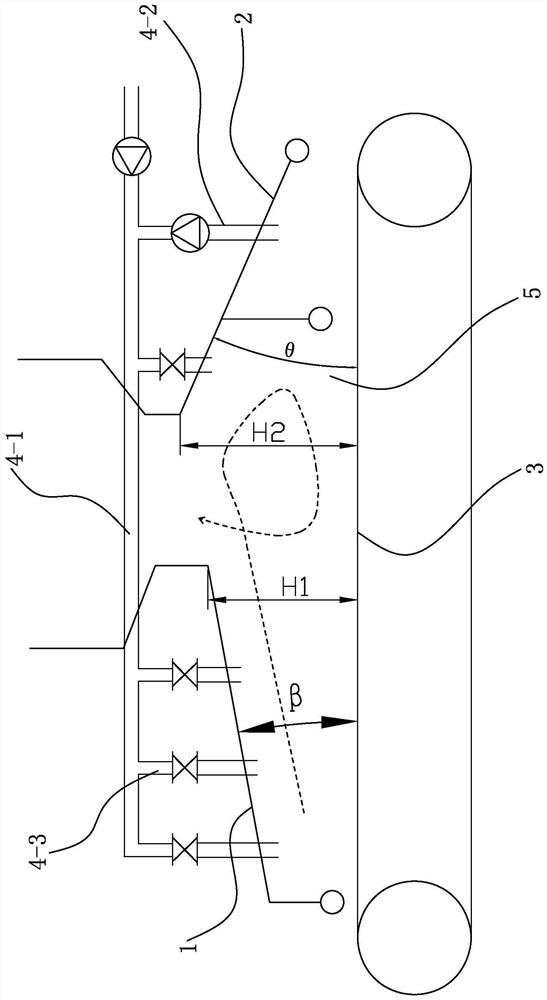

[0015] Specific implementation mode one: combine figure 1 Explain that this embodiment is a large anti-α-shaped flame distribution type layer combustion furnace combustion system, which includes a front arch 1, a rear arch 2 and a fire grate 3; the bottom of the front arch 1 and the rear arch 2 is provided with a fire grate 3 ; also includes the air distribution system 4; the front arch 1 and the rear arch 2 are arranged obliquely respectively, the top height HA of the front arch 1 is smaller than the top height HB of the rear arch 2, the length of the rear arch 2 is smaller than the length of the front arch 1, and the front arch 1 The angle between arch 1 and rear arch 2 is an obtuse angle. The front arch, rear arch and partition plate are divided into front area and rear area. The front area is the combustion area, and the rear area is the cooling area. The combustion zone can produce anti-α-shaped flames; the air distribution system 4 includes a main pipe 4-1, a fan, a smok...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Note that one of the multiple air distribution pipes 4-3 in this embodiment extends into the pyrolysis zone below the front arch 1 . Below the front arch, from left to right are the preheating zone, pyrolysis zone and ignition zone respectively, the main combustion zone in the middle, and the burnout zone 5 on the right. The high-temperature mixed flue gas is introduced into the pyrolysis zone of the forward arch 1 to solve the problem of difficulty in ignition of the pyrolysis zone of the forward arch 1 . The high-temperature gas is introduced into the pyrolysis zone of the front arch to ignite the hot gas, thereby solving the ignition problem; the cooling zone is used to reduce the temperature of the ash discharged from the grate, reducing the physical heat loss of the ash, and at the same time, the oxygen-enriched high-temperature flue gas discharged from the cooling zone The front and rear arches are introduced...

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 To illustrate, the included angle β between the front arch 1 and the horizontal plane in this embodiment is 25°-30°. In this way, the length of the front arch 1 can be increased as much as possible, so that the burning flame can form anti-α flames at the front arch 1 and the rear arch 2 . Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com