Patents

Literature

34results about How to "Reduce incomplete combustion losses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

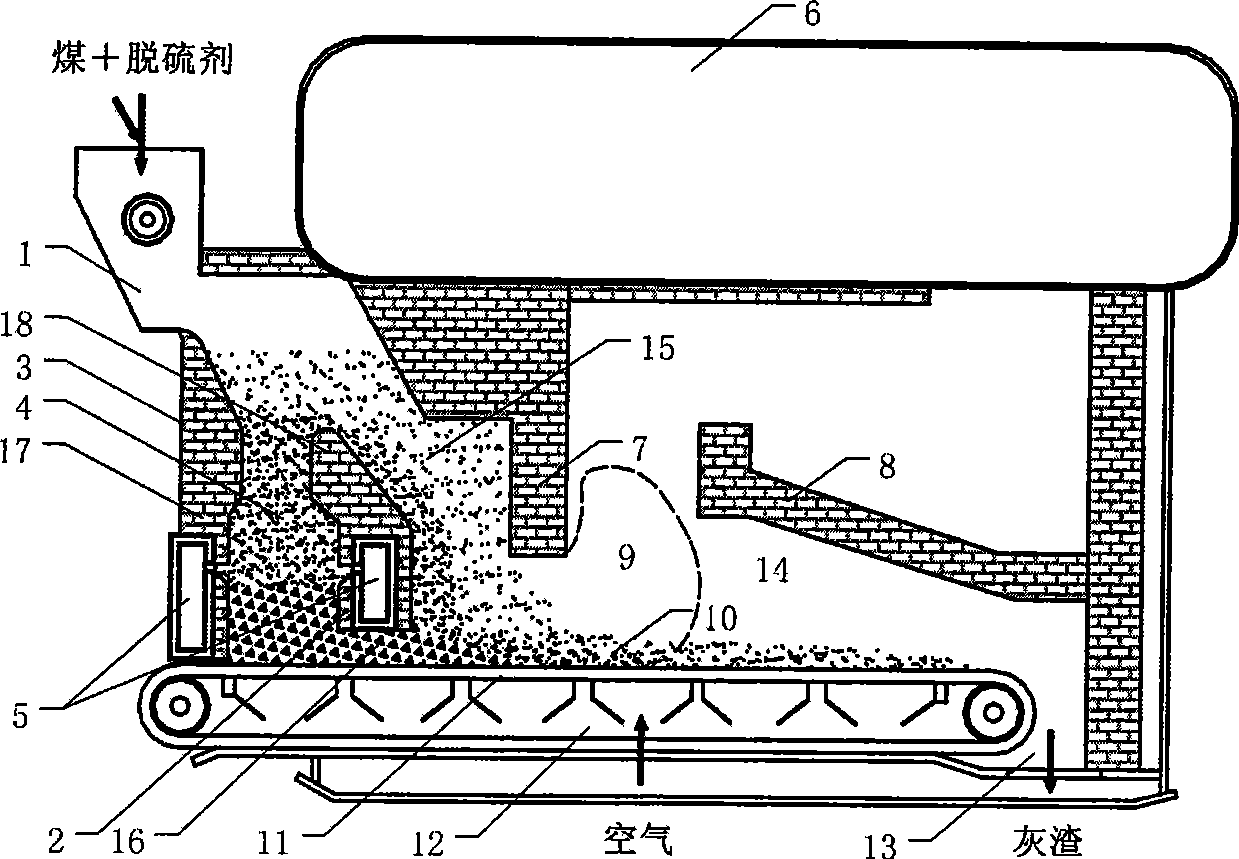

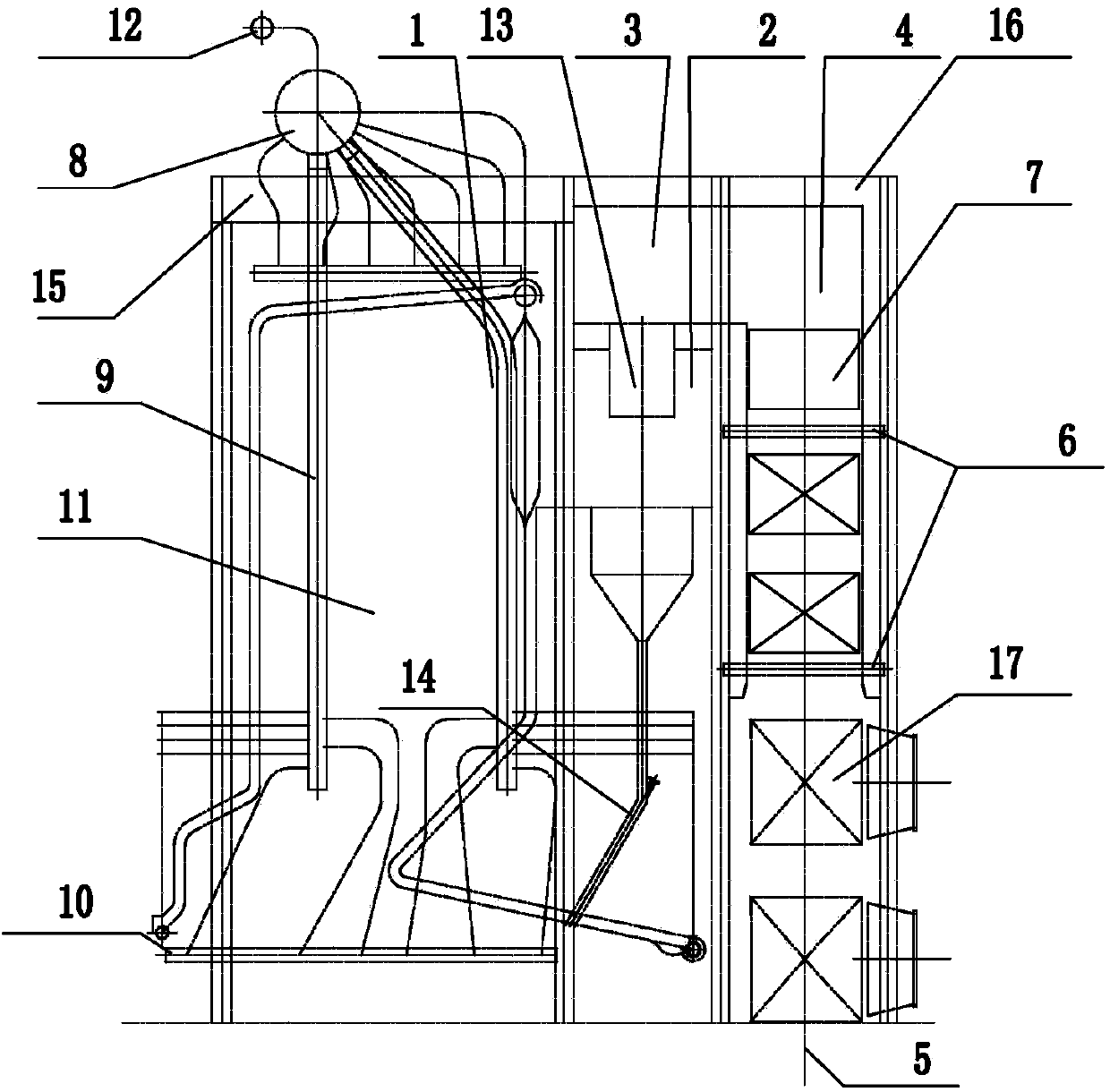

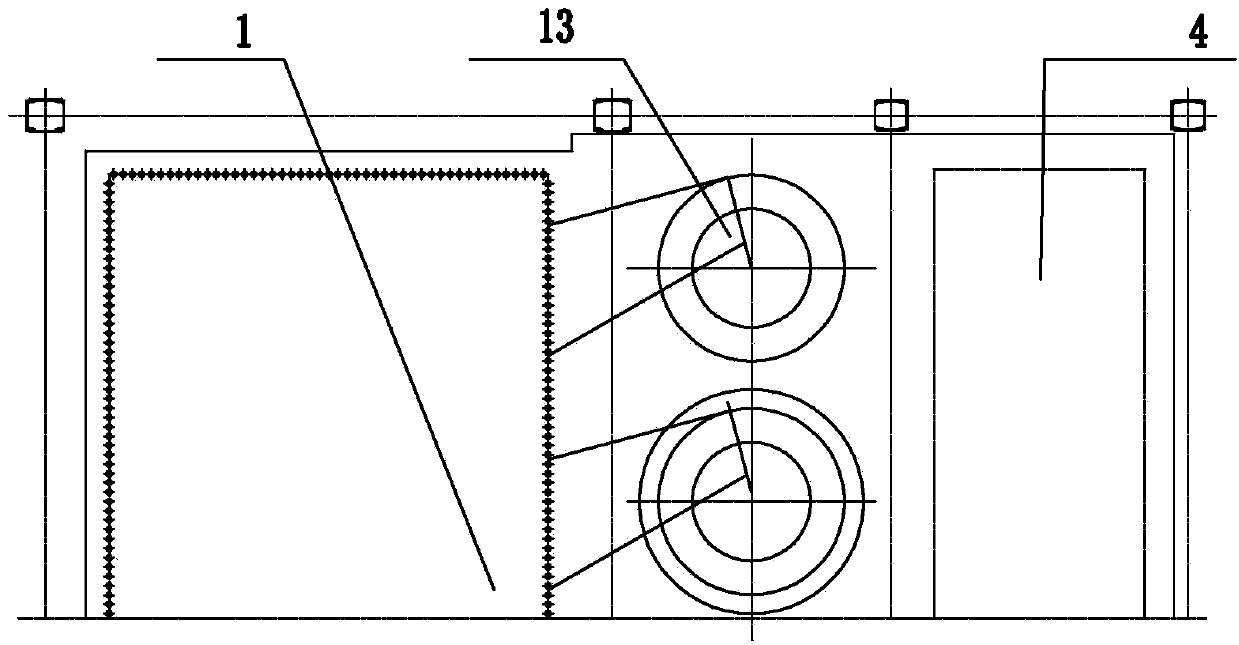

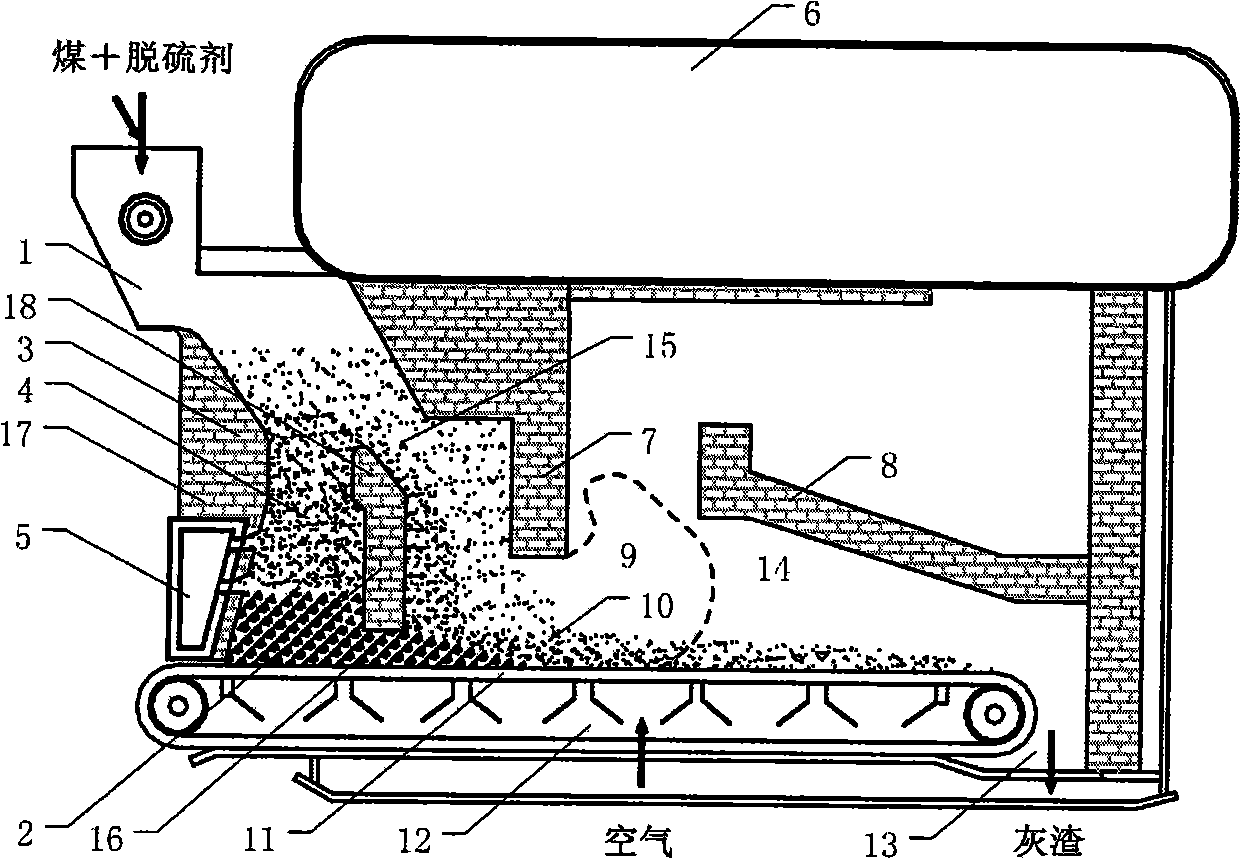

Coal thermal decomposition grate firing apparatus and its combustion method

InactiveCN101368724ASimple structureNo increase in sizeSolid fuel combustionCombustion apparatusCombustion chamberCombustible gas

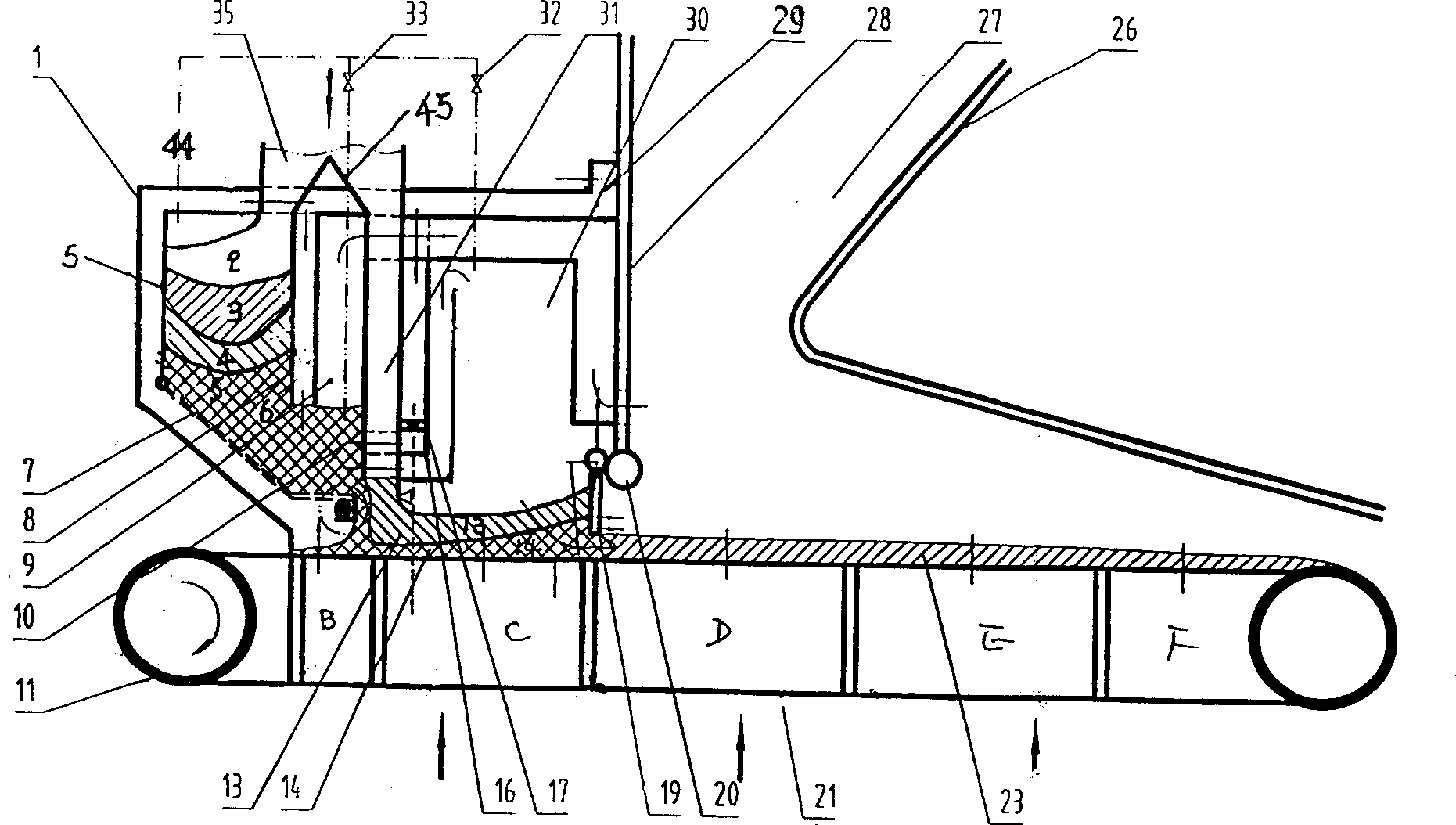

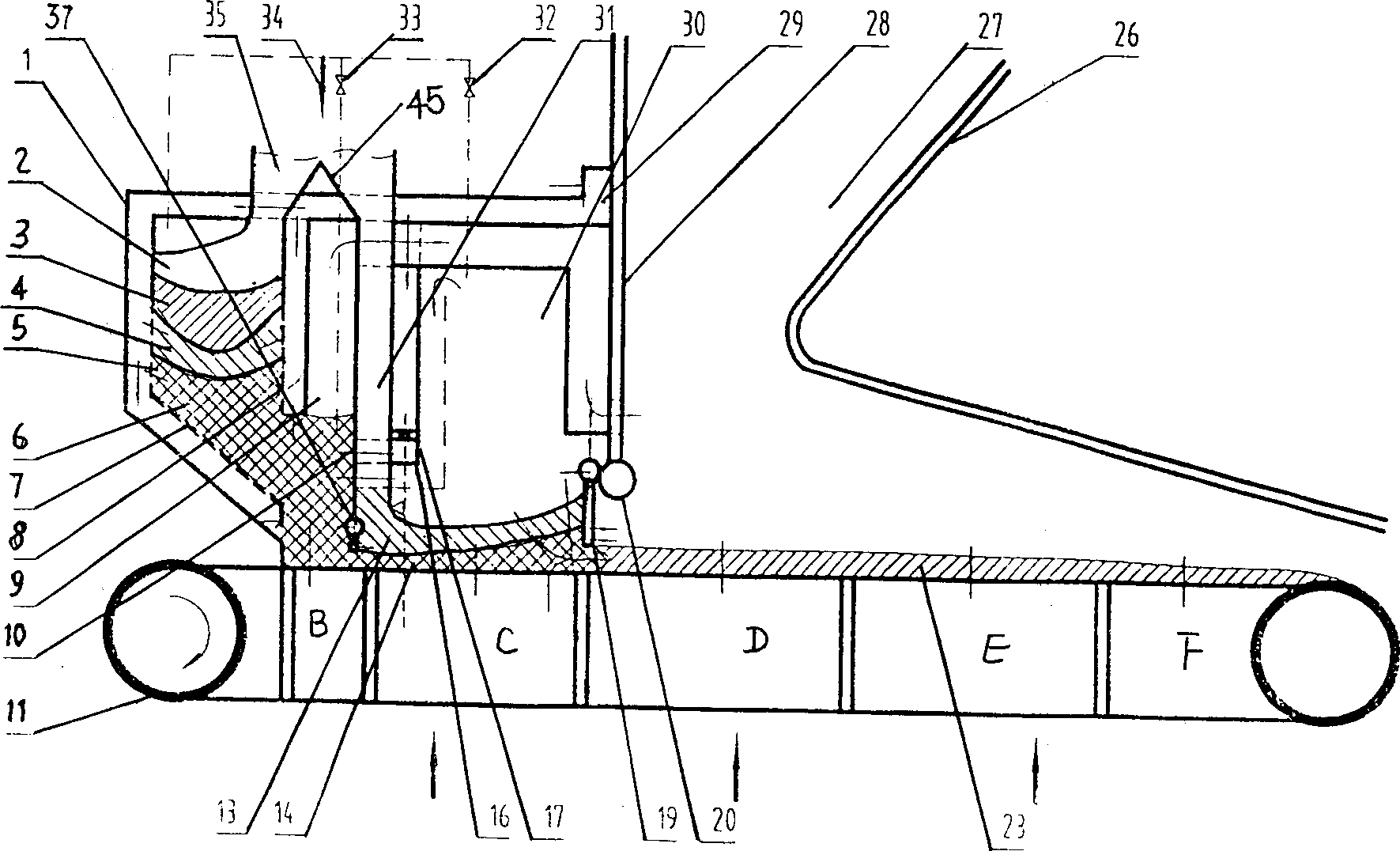

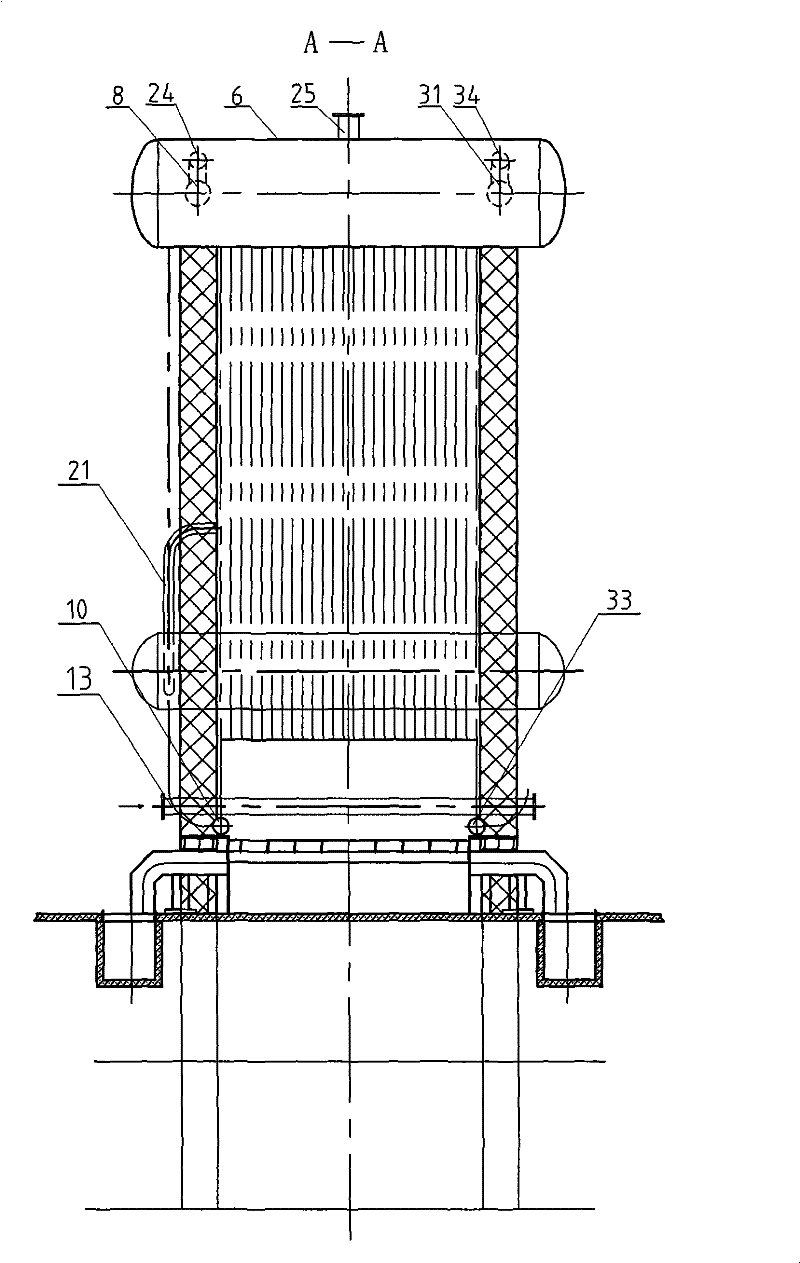

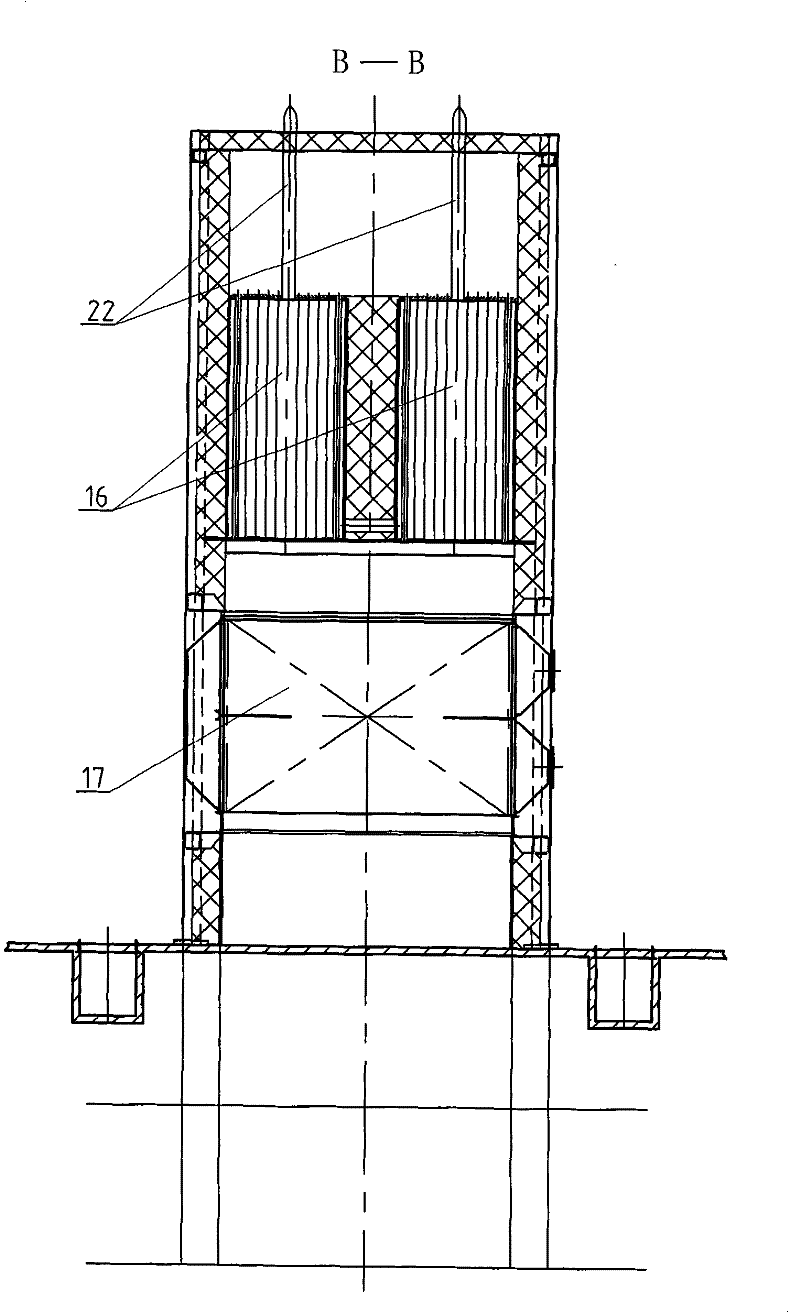

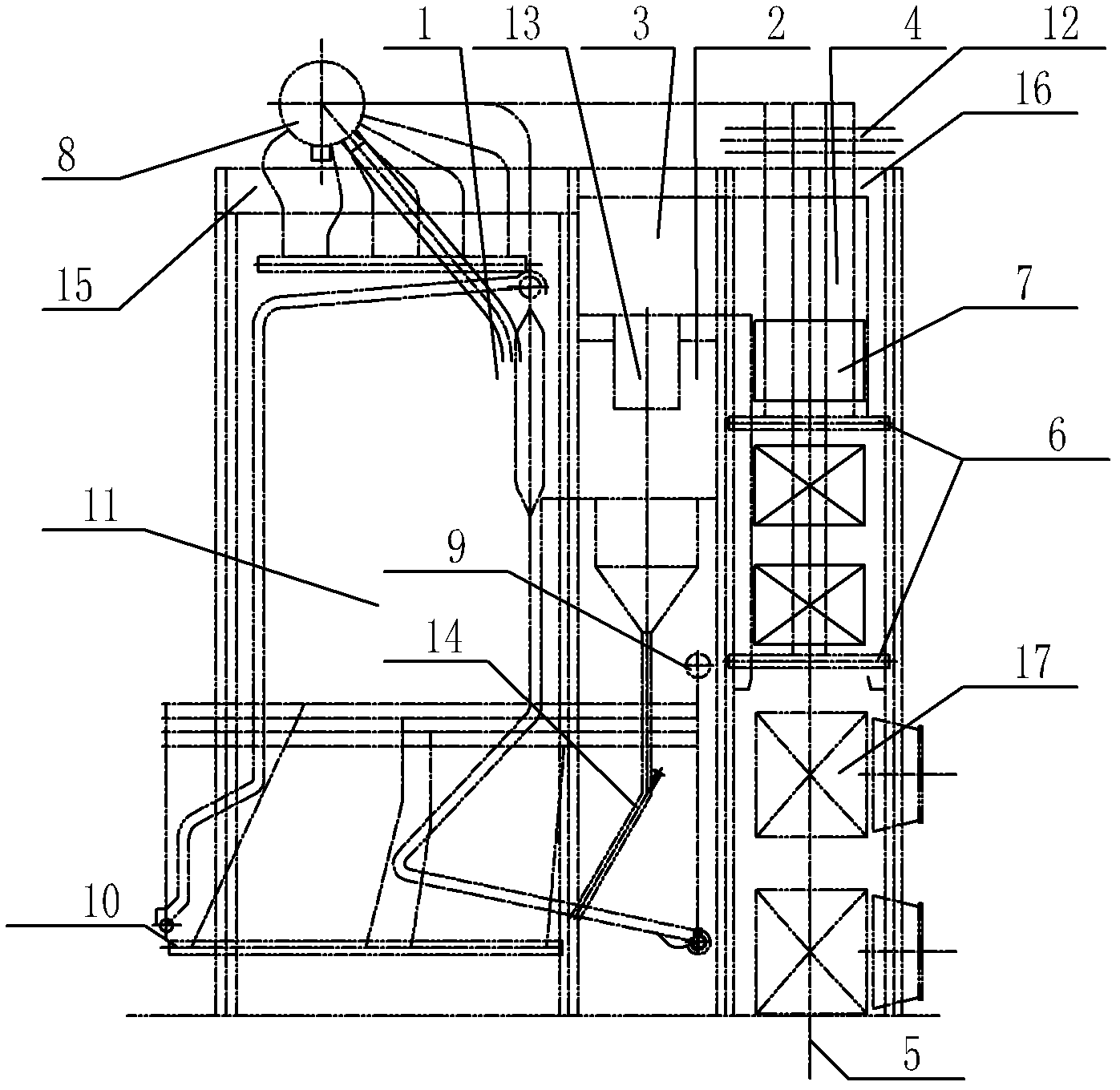

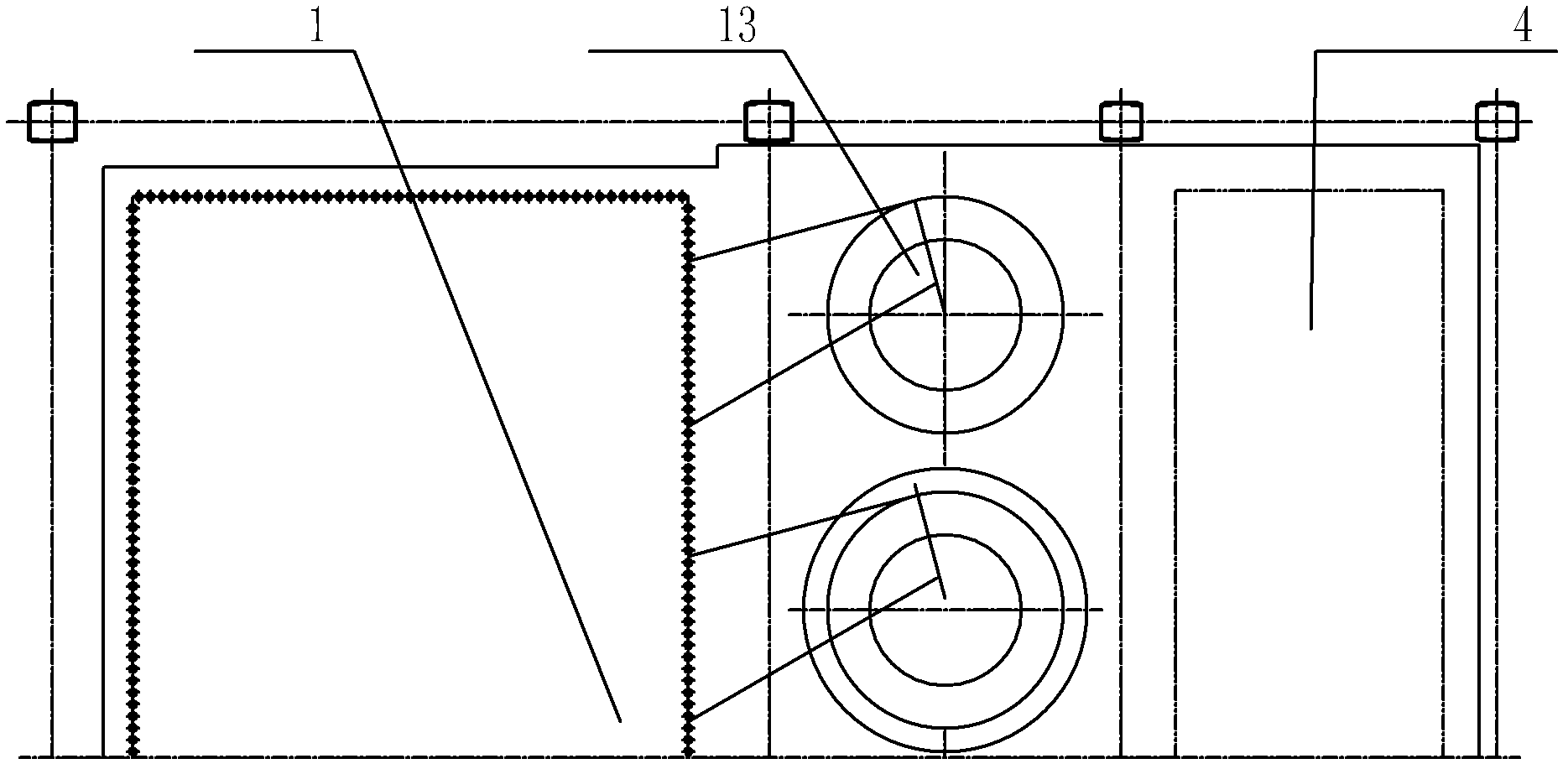

The invention relates to a coal pyrolysis layer combustion device and the combustion method thereof, including that the furnace body interior of the first layer combustion furnace is divided into an upper oxidation pyrolysis chamber and a lower fire grate layer combustion chamber which is communicated with each other; the coal and desulfurizer are mixed to be fed into the middle part of the oxidation pyrolysis for oxidation pyrolysis through a hopper; the generated combustible gas and the smaller semi-coke particles are overflowed through the upper-connected through port or are carried in the airflow to be fed into the mechanical fire grate layer combustion chamber; the bigger semi-coke particles fall on the mechanical fire grate and are fed into the layer combustion layer for combustion; the mechanical fire grate layer combustion chamber is provided with a front arch and a back arch for organizing the airflow field inside the furnace; the coal pyrolysis layer combustion device and the combustion method thereof adopt the fluidization characteristics of the coal particles with different particle diameters and the high thermal capacity characteristic inside the oxidation pyrolysis chamber to realize the natural separation of the coal particles with different particle diameters and the rapid oxidation pyrolysis of coal, reduce the fire grate coal leakage loss and the incomplete combustion loss caused by the front segment low temperature of the fire grate and reduce the emission of the SOx and NOx pollutant through the combination of the pyrolysis desulfurization and the combustion desulfurization, and the reburning denitration formed by the coal pyrolysis product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

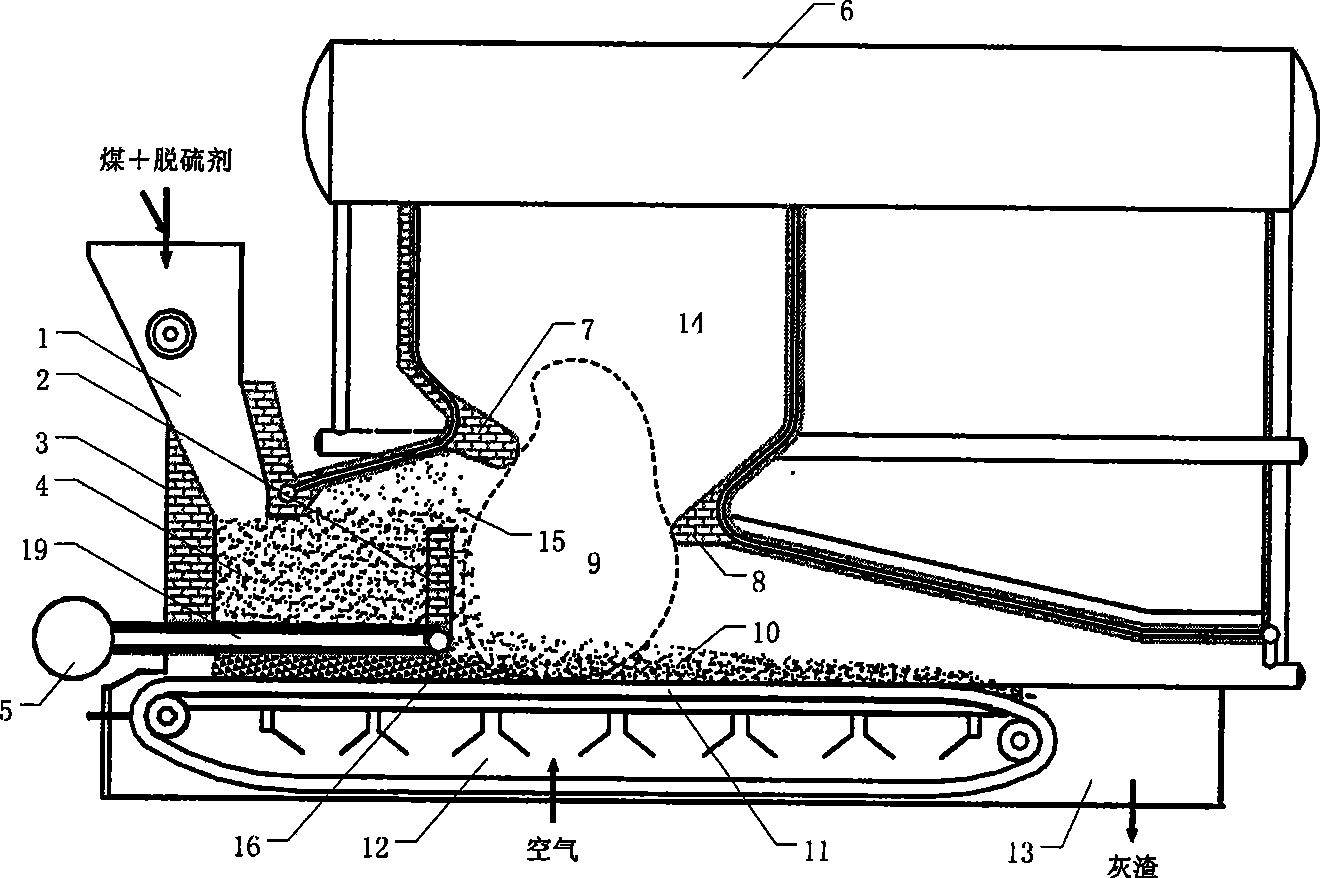

Layered decoupling coal-burning technology and mechanical layered decoupling furnace

InactiveCN1403737AEmission reductionReduce incomplete combustion lossesSolid fuel combustionCombustion apparatus

The present invention relates to the layered decoupling coal buring technological and mechanical layered decoupling furnace. Coal is burned in the combustion chamber to produce fume exhausted to gasifying chamber or flue and semi-coke conveyed to the mechanical grate of gasifying chamber; the coal on the semi-coke layer is ignited from the bottom, burnt in anoxic condition and gasifying pyrolyzed; NOx in the fume is reduced into N2; and after being mixed with the second draft, CO and smoke black are burnt out. The separated burning in the mechanical layered decoupling furnace produces lowered pollutant exhaust and high burning efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

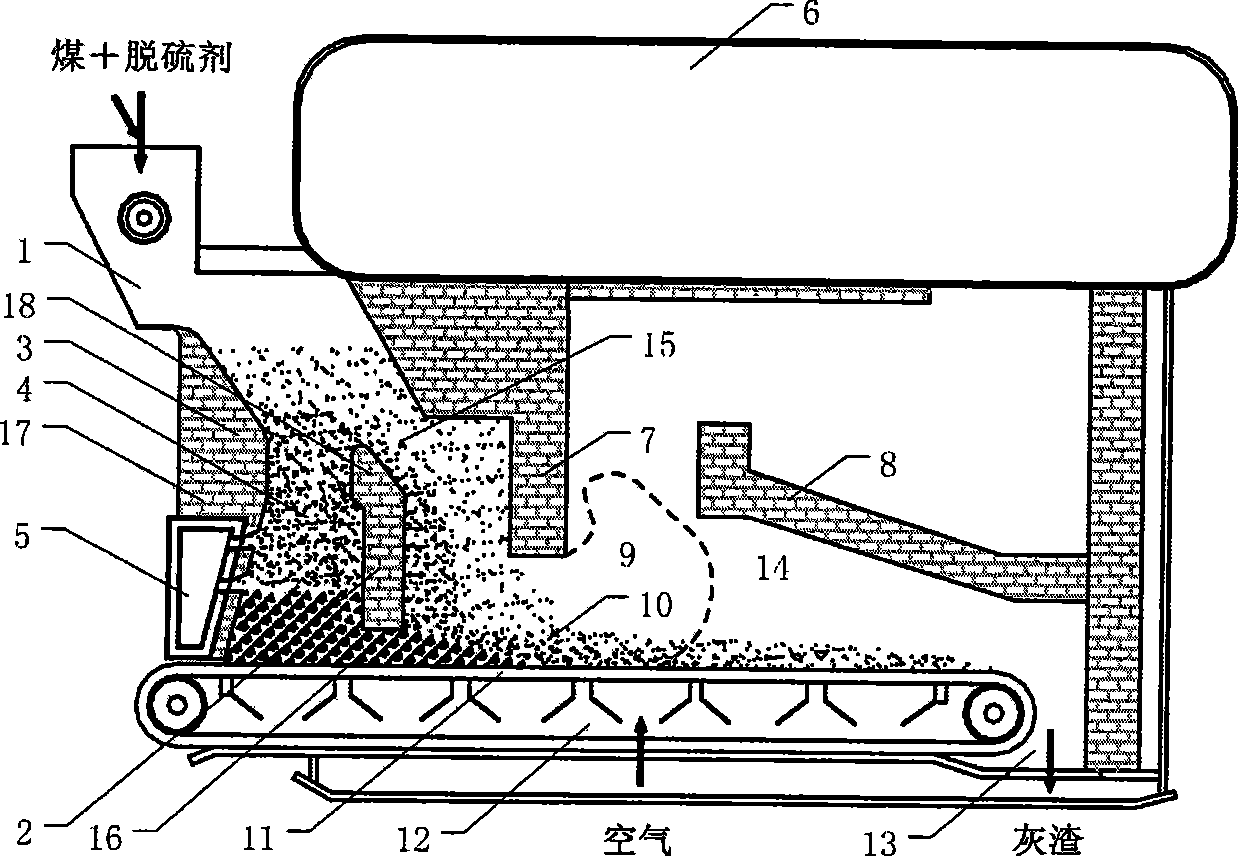

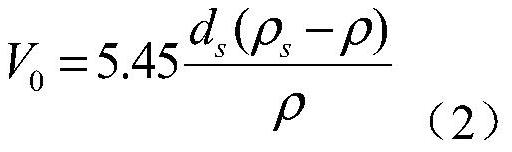

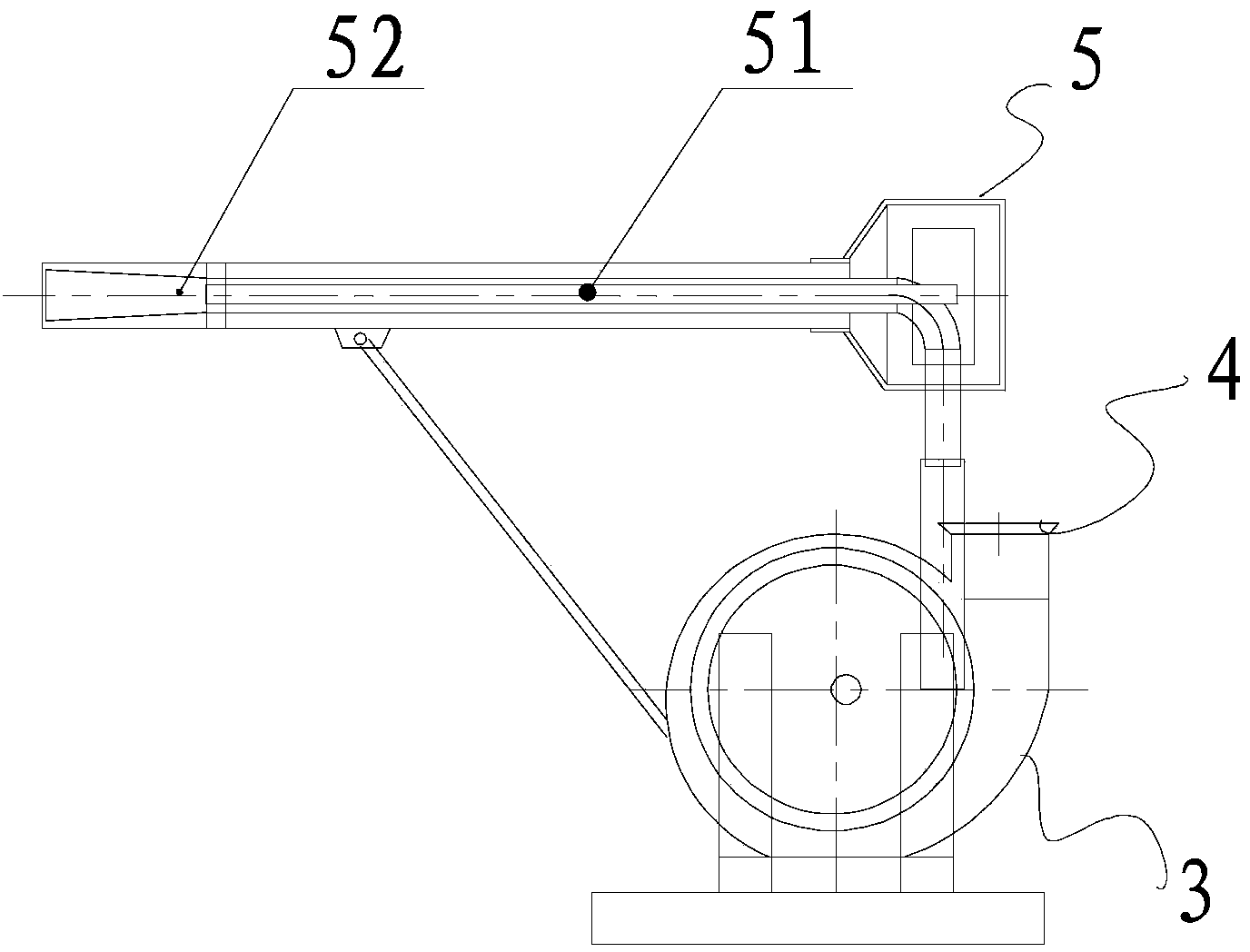

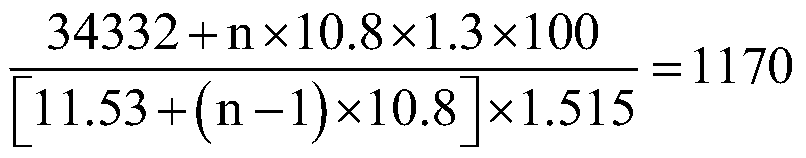

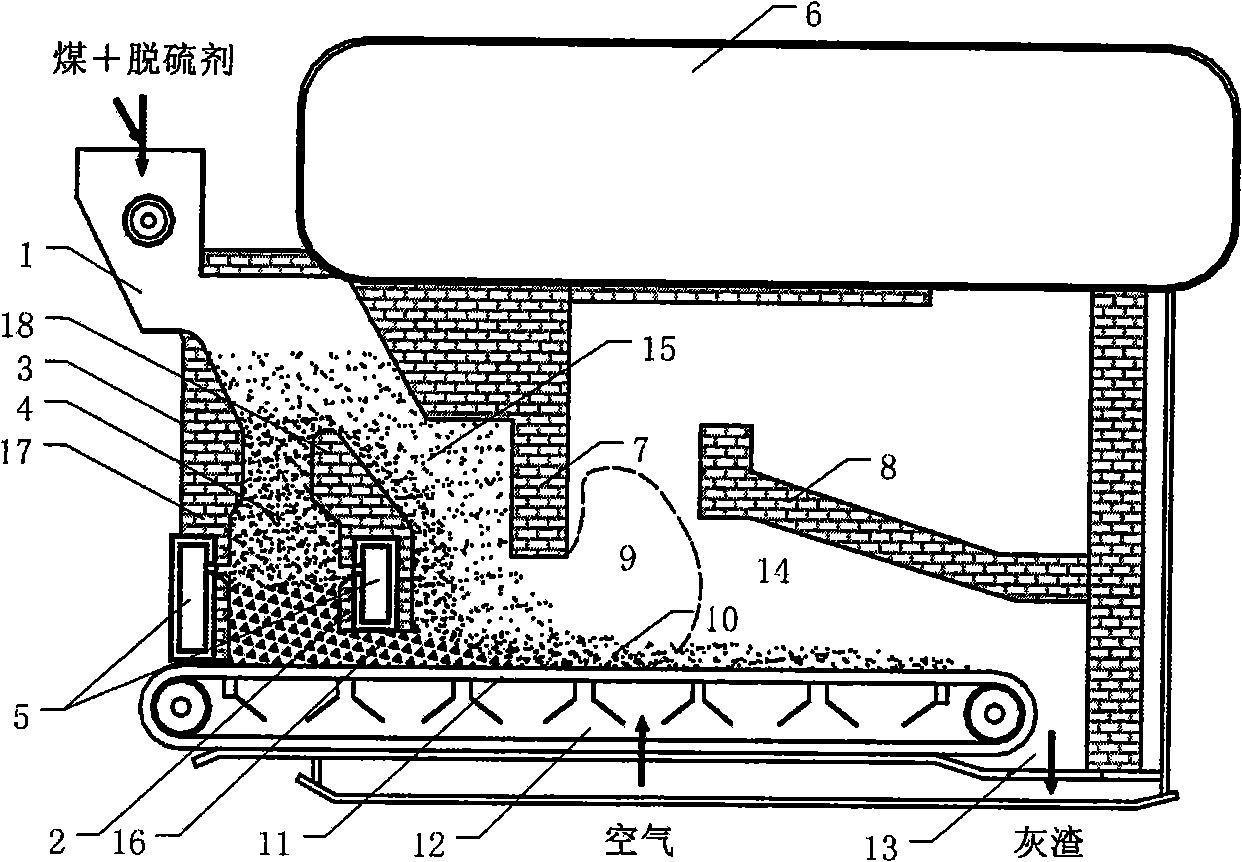

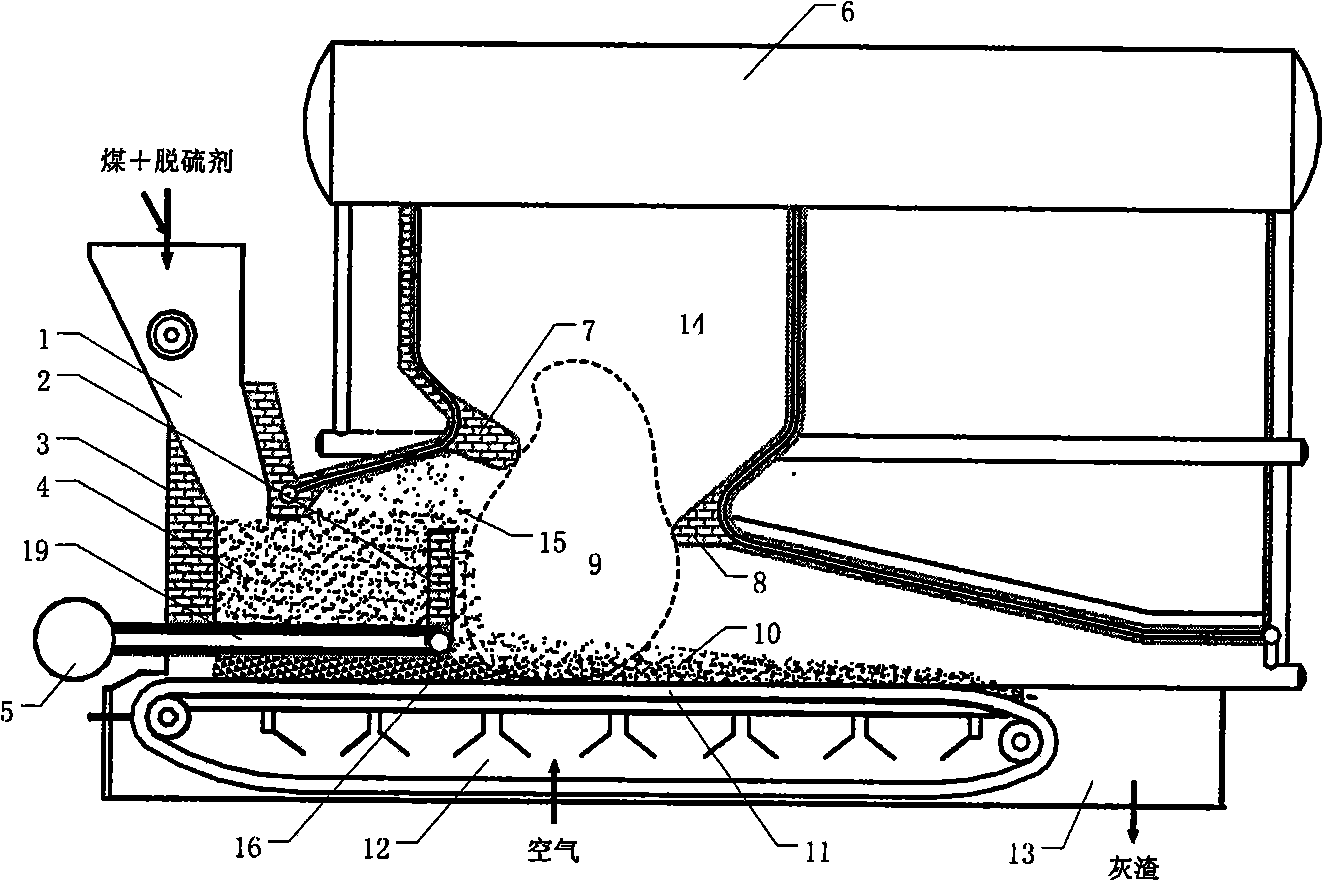

Front coal gasification grate-firing device and combustion method thereof

InactiveCN103234196ASpeed up the drying and heating processReduce incomplete combustion lossesSolid fuel combustionCombustion apparatusHearthGrate firing

The invention discloses a front coal gasification grate-firing device and a combustion method thereof. By the aid of the front coal gasification grate-firing device and the combustion method thereof, the problems of emission of the high NOx content and the high SOx content of traditional chain layer burners are solved, and the boiler efficiency is improved. The front coal gasification grate-firing device comprises a coal bucket, a coal gasification chamber and a coke discharge pipe which are communicated sequentially, a gas pipe is arranged at the top of the coal gasification chamber, an injection nozzle is arranged inside the gas pipe, communicated with a secondary air pipeline through an injection air pipeline and parallel with the secondary air pipeline, an opening of the injection nozzle faces towards a hearth, the secondary air pipeline and the gas pipe are arranged in parallel in an up-and-down mode and communicated with the hearth, a bottom bellows is installed at the bottom of the coal gasification chamber, communicated with a gasification air pipeline and communicated with the coal gasification chamber through a fire grate I, the fire grate I is inclined towards the inlet direction of the coke discharge pipe, a coke breaking machine is installed at the position of an inlet of the coke discharge pipe, and an outlet of the coke discharge pipe is located above a fire grate II at the bottom of the hearth.

Owner:SHANDONG UNIV

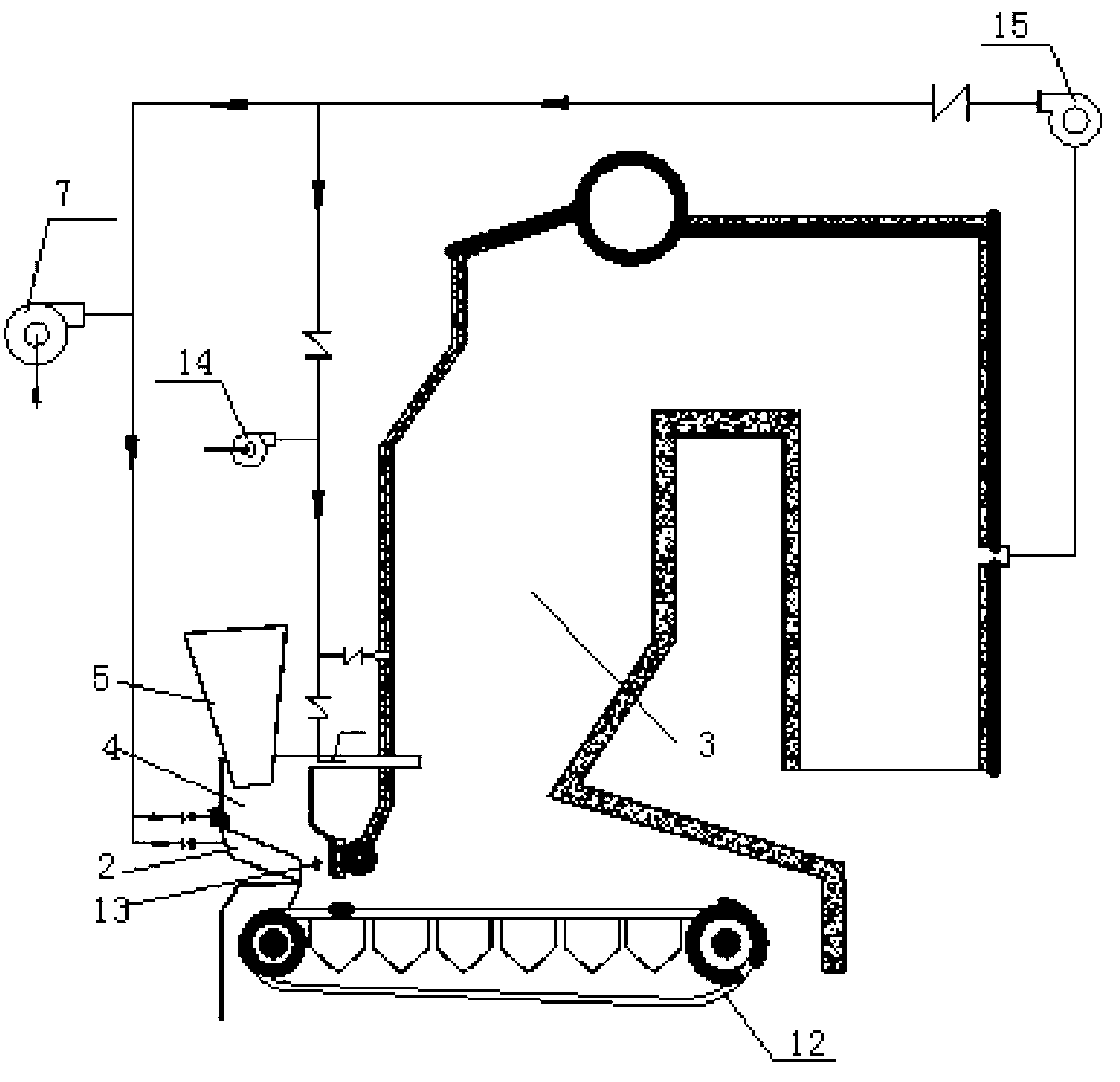

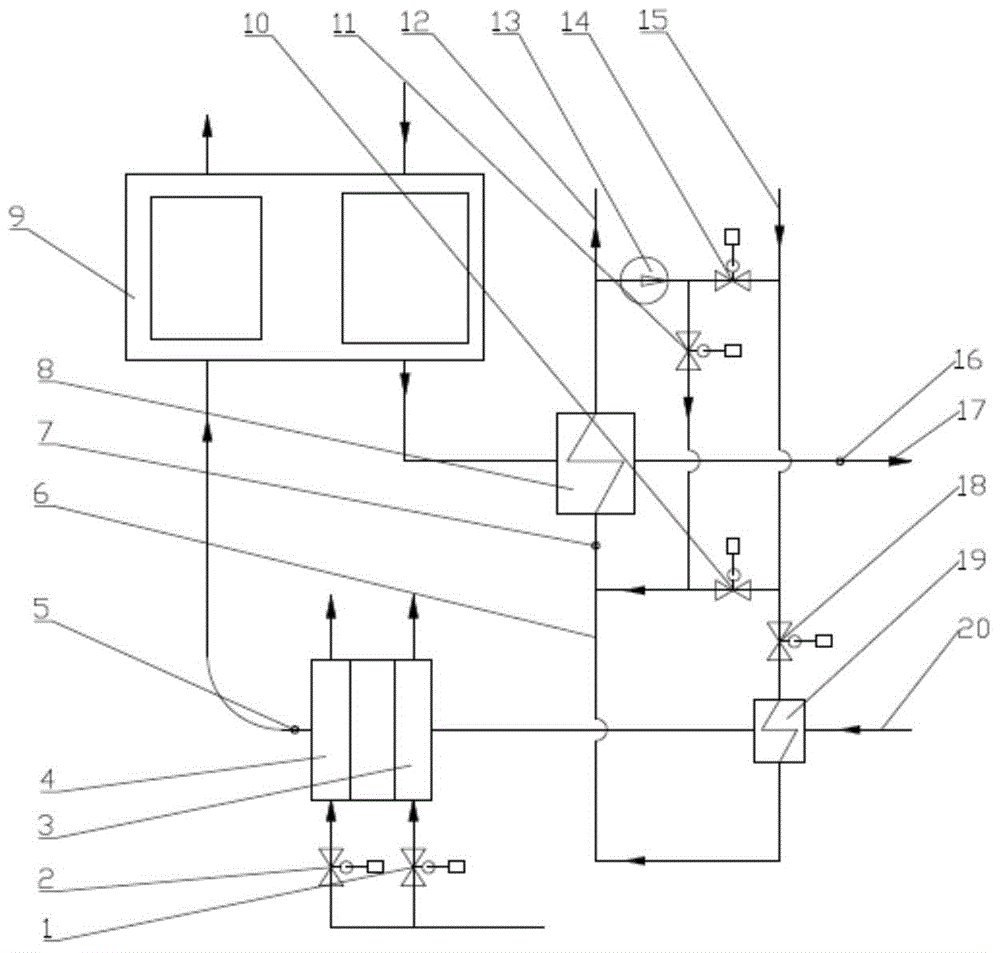

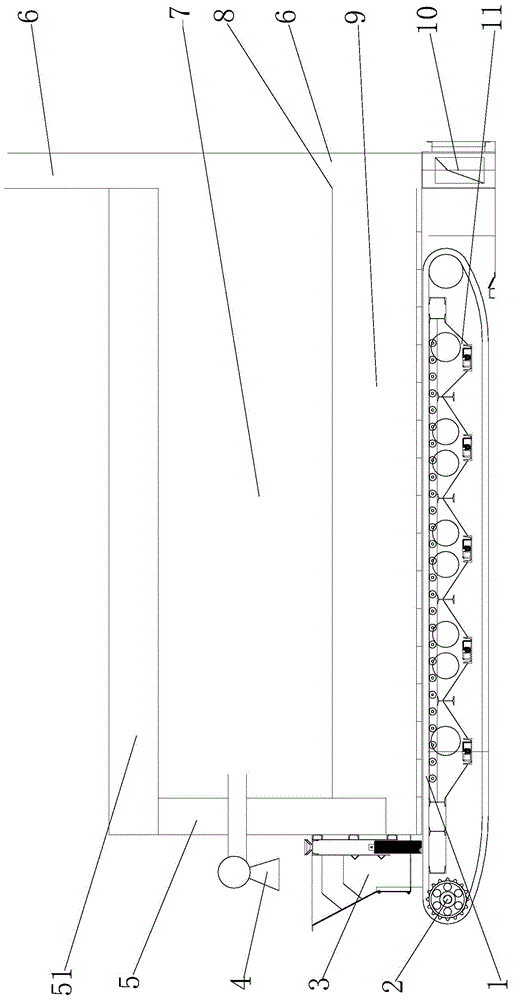

Air preheating and flue gas waste heat utilizing system and method

InactiveCN104807035ASolve the existing disadvantagesRaise the inlet air temperatureFeed water supplyCombustion processAir preheaterFlue gas

The invention particularly aims to the technical field of boiler air preheating. A disclosed air preheating and flue gas waste heat utilizing system comprises a flue gas channel (17), an air channel (20), an air preheater (9), a condensed water flue heat exchanger (8) and a condensed water air channel heat exchanger (19), and further comprises a condensed water feeding main pipe (15) and a condensed water returning main pipe (12); the flue gas channel (17) and the air channel (20) are connected with the air preheater (9); the condensed water flue heat exchanger (8) is arranged on the flue gas channel (17) at the back of the air preheater (9) in a flue gas flowing direction; the condensed water air channel heat exchanger (19) is arranged on the air channel (20) at the front of the air preheater (9) in an air flowing direction. According to the air preheating and flue gas waste heat utilizing system, flue gas discharge and heat exchange can be automatically adjusted according to change of operation conditions; on the premise of ensuring the safety of a heated surface and the regular operation of the system, the maximization of the heat circulation efficiency and the system economical efficiency is ensured.

Owner:郝江平

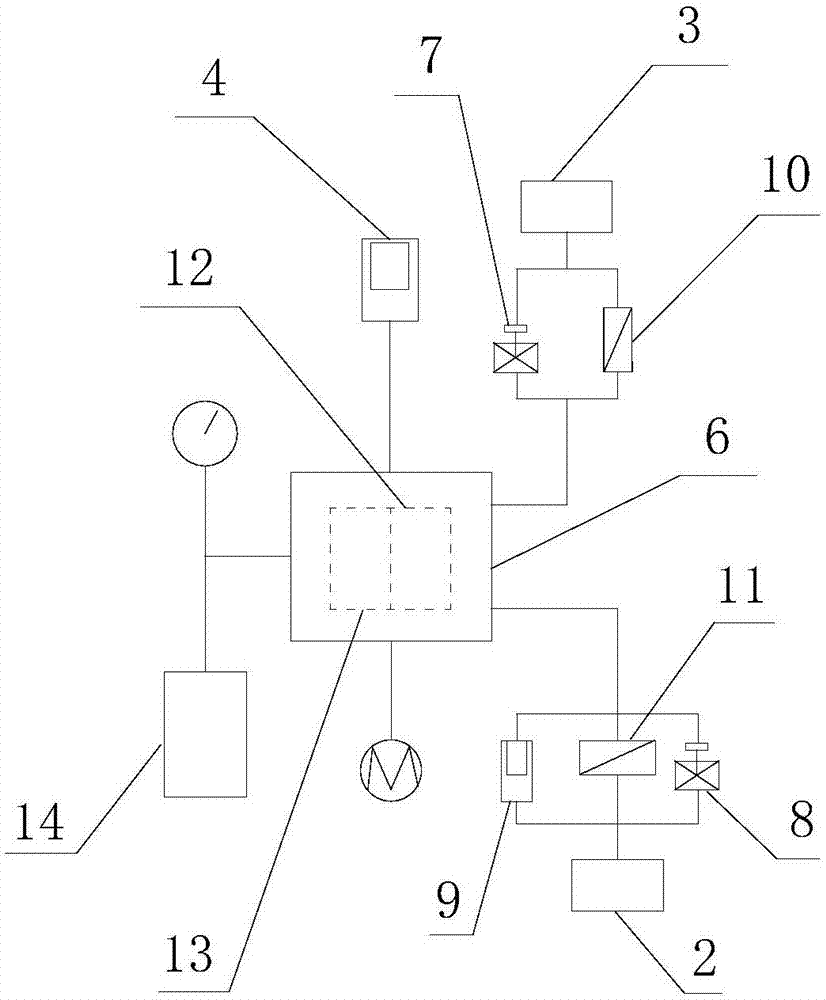

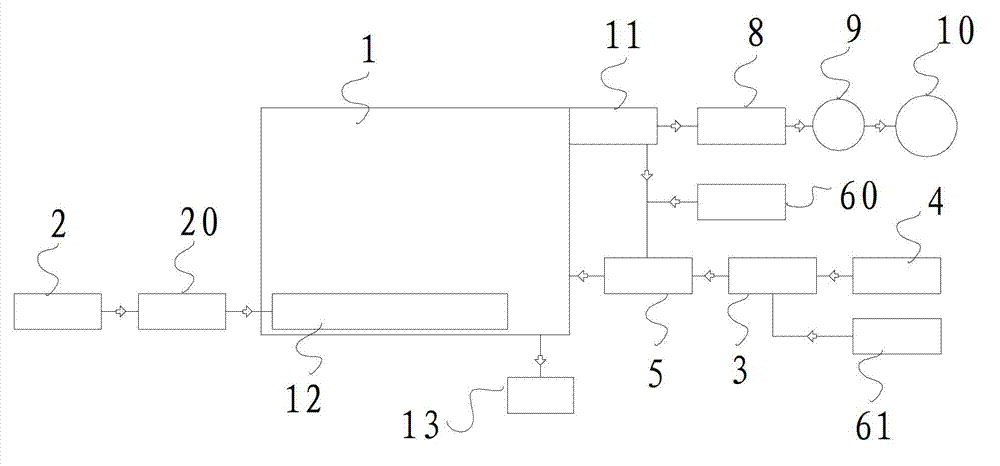

Control system for flue gas oxygen content of layer combustion boiler based on flue gas recirculation

ActiveCN107166428AReduce the intensity of manual operationImprove accuracyAir supply regulationSolid fuel combustionControl systemFlue gas

The invention provides a control system for the flue gas oxygen content of a layer combustion boiler based on flue gas recirculation. The control system is mainly composed of the layer combustion boiler, a blower, a flue gas recirculation fan, a zirconium oxide analyzer, an air pipe, a DCS system (or a PLC system) and the like, and can be widely applied to the field of combustion control and combustion optimization of layer combustion boilers. The control system adopts conventional equipment, performance is reliable and stable, stable operation of the boiler under the very low load (the 30% rated load) can be achieved, ash accumulating of the heating surface of the tail of the boiler is reduced, the initial discharge concentration of boiler nitrogen and oxygen compounds can be reduced by 15-20%, and the heat efficiency of the boiler under the low load is improved by 5% or more.

Owner:廊坊市华源盛世热力有限公司

Burning device and process for oil shale fluidized bed

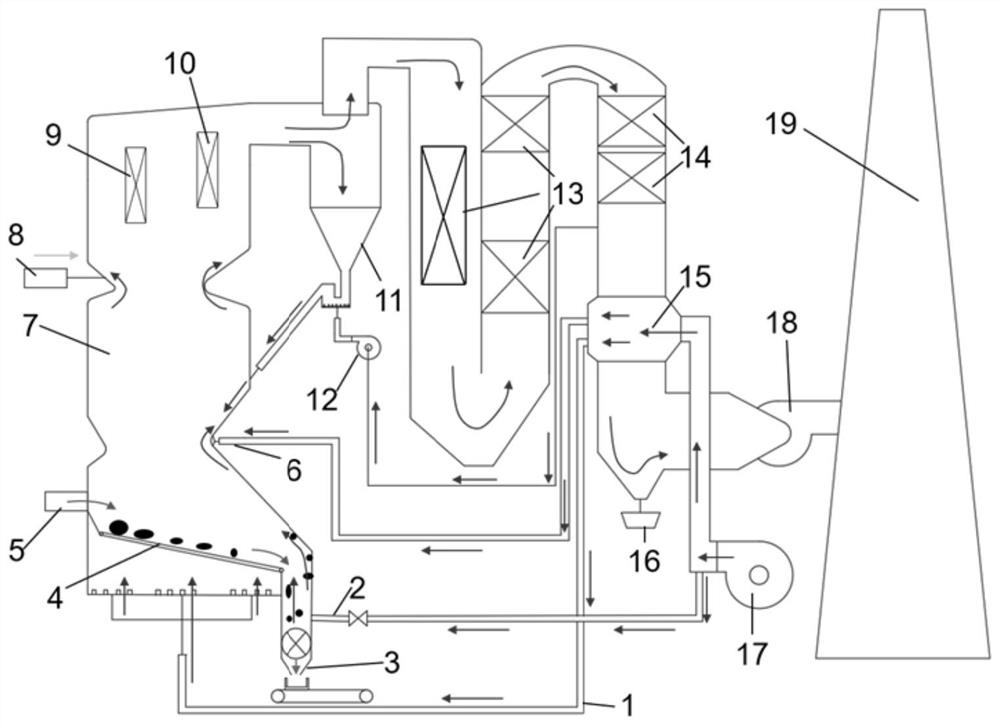

InactiveCN1253673CWide adaptabilityAvoid depositionFluidized bed combustionCement productionAir volumeParticle combustion

The invention relates to a device and craft for using fluidized bed to burn kerogen. The raw oil and kerogen are transmitted into the boiler combustion device through the transmission system. The device includes fluidized bed boiler, vortex separator, and ash particle combustion system and ash dredge reclaiming device. In the boiler, the hot wind enters with small aperture speed and hot fluidized speed through the directional cap, the wind is divided into the first wind and the secondary wind; the wind quantity can be adjusted, maintains the stability of the bed and homogeneity of temperature, the temperature is maintained between 850deg.C-920deg.C. The smoke is separated through the separator, the raw particle returns into the furnace to be burned, the residue tail gas reclaims heat through several heat exchangers, and the ash dredge in the furnace is discharged out of the dredge colder with high wind quantity and pressure through the electric dust eliminator, which can be used as cement mixing material. The combustion intensity and efficiency are high, the contamination is little.

Owner:广东亨达利水泥厂有限公司

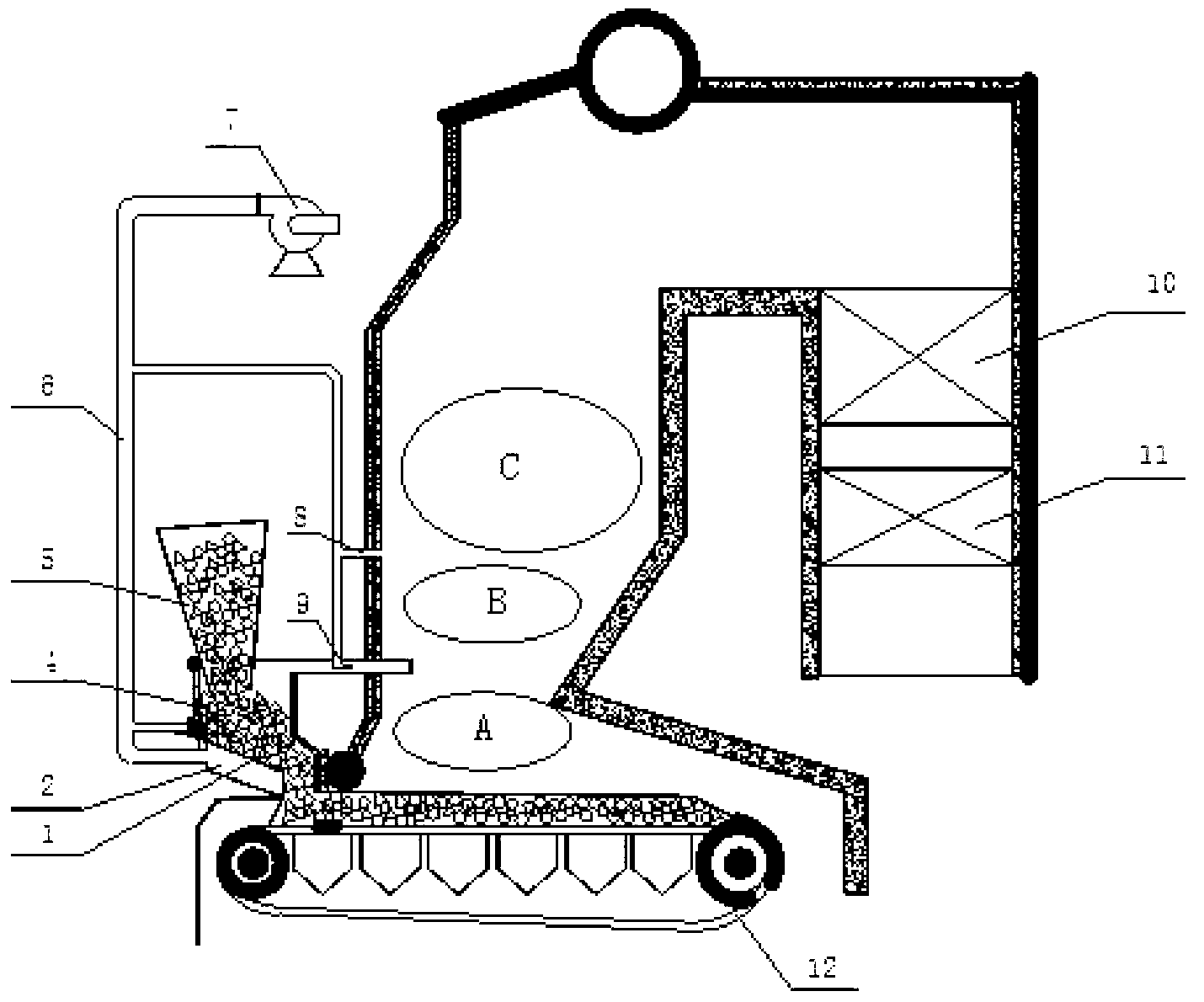

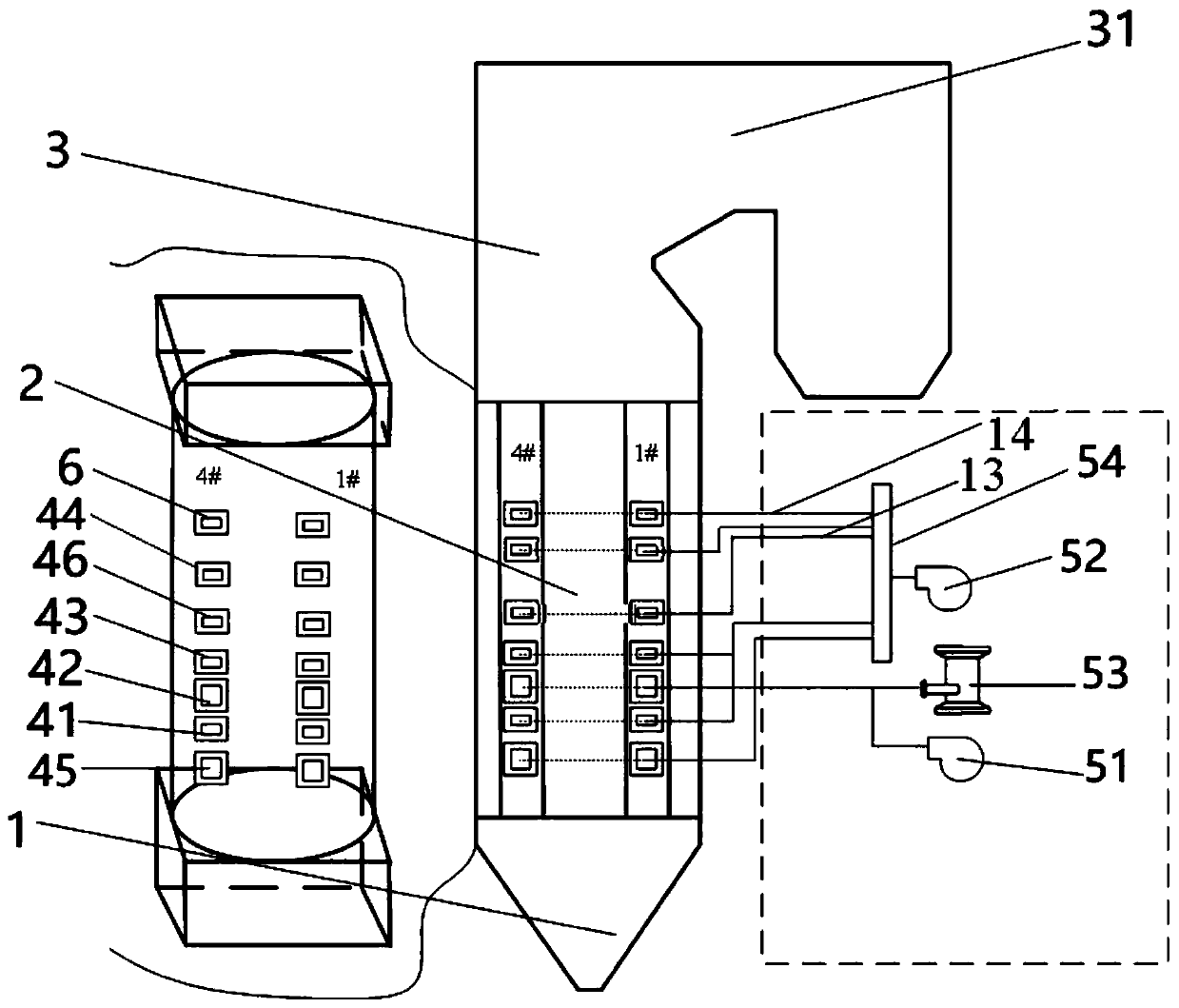

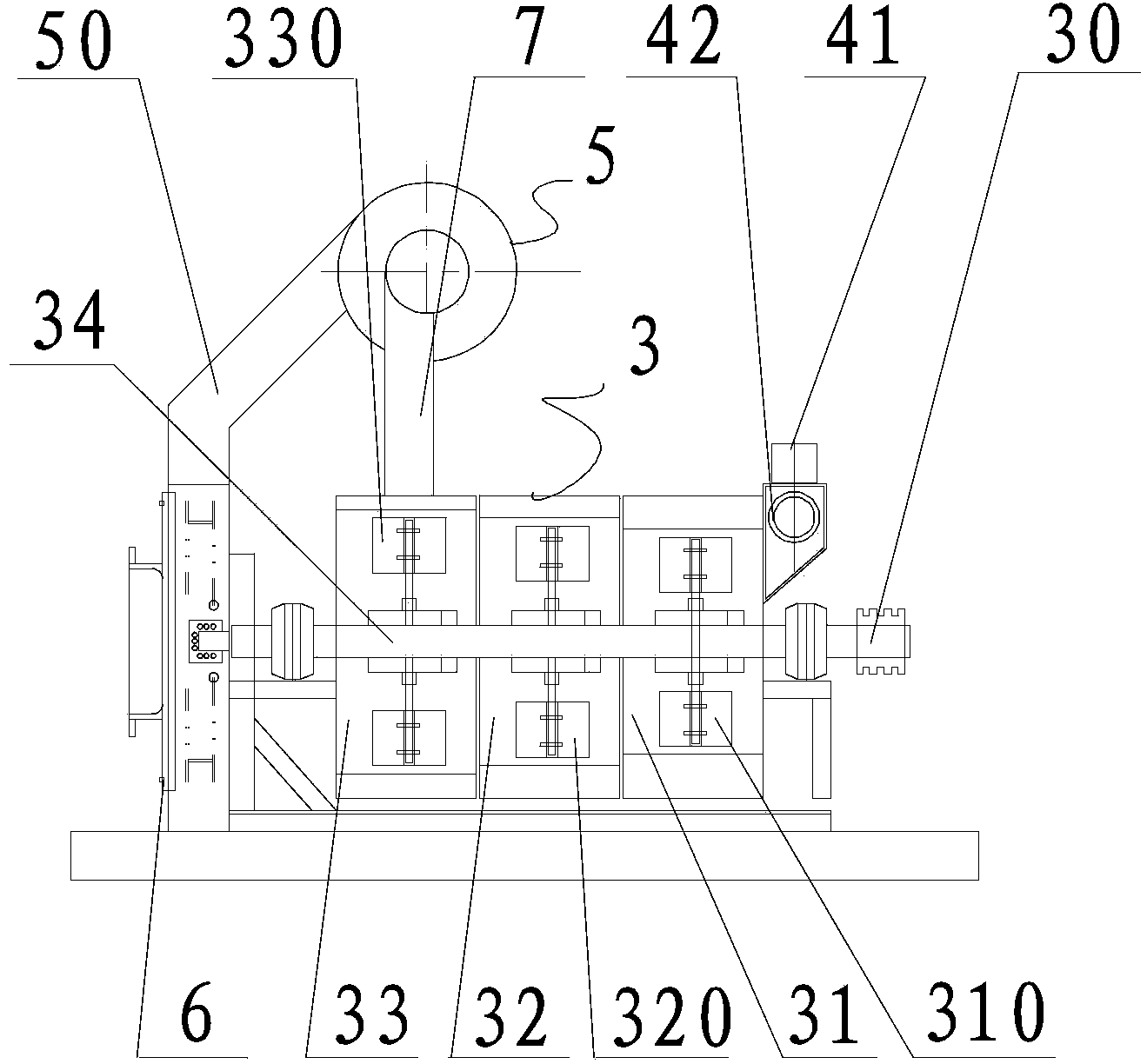

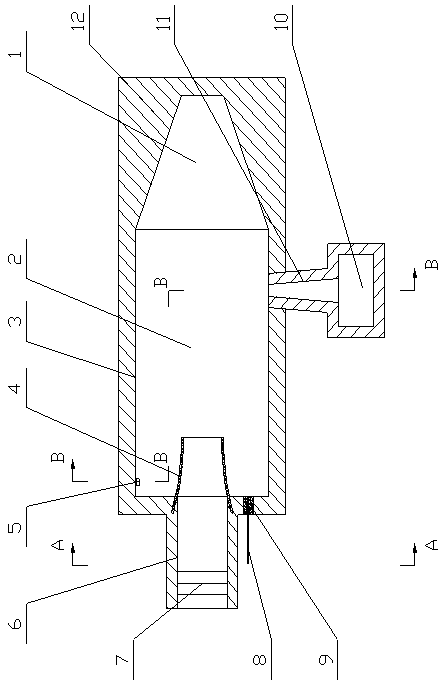

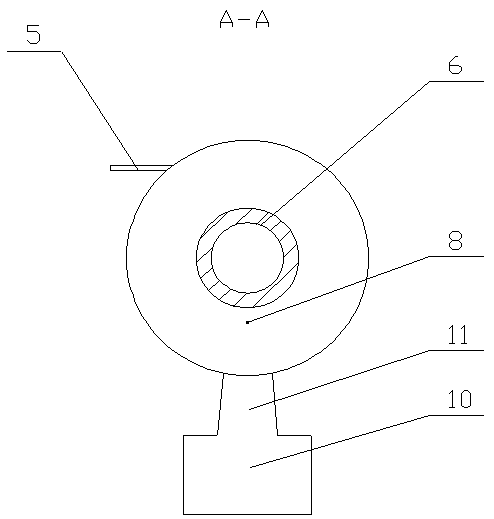

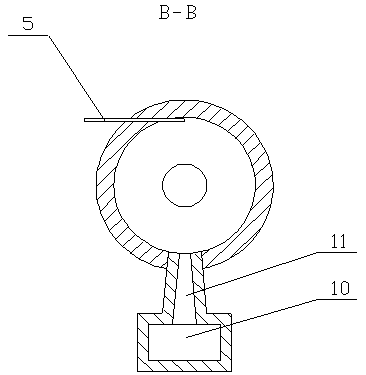

Pulverized coal co-combustion system of industrial boiler

ActiveCN102901089AHigh flame temperatureImprove burnout ratePulverulent fuel combustion burnersLump/pulverulent fuel preparationCombustion systemImpeller

The invention discloses a pulverized coal co-combustion system of an industrial boiler. With the system, layer combustion and suspension combustion can form in a furnace. The system includes a boiler, a raw coal supply device and a co-combustion device. The boiler comprises a furnace, a coal inlet located at the lower part of a front end wall, and a chain grate disposed at the lower part of a furnace inner chamber. The raw coal supply device is connected to the coal inlet through a coal hopper. The co-combustion device is arranged at the boiler tail, and is composed of a boiler-front mill, a pulverized coal combustor and a pulverized coal conveying pipe. The boiler-front mill includes a rotation shaft running through a primary milling chamber, an intermediate milling chamber and a fine milling chamber connected in order, a primary hammer type impeller, an intermediate hammer type impeller and a final hammer type impeller. The front end wall upper part of the primary milling chamber is provided with a coal inlet, and the chamber wall upper part of the fine milling chamber is provided with a pulverized coal nozzle. The pulverized coal combustor includes a combustor body and a combustion nozzle. The combustor body is equipped with a secondary air inlet and a pulverized coal inlet. And the pulverized coal conveying pipe connects the pulverized coal inlet of the combustor body and the pulverized coal nozzle of the boiler-front mill.

Owner:SHANGHAI INDAL BOILER RES INST

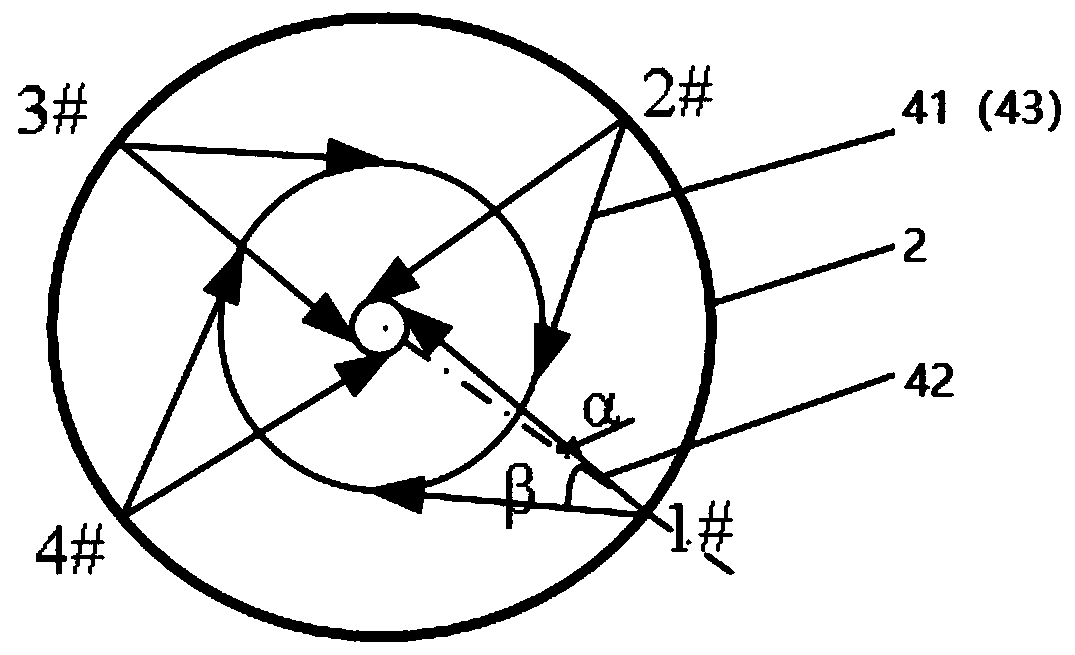

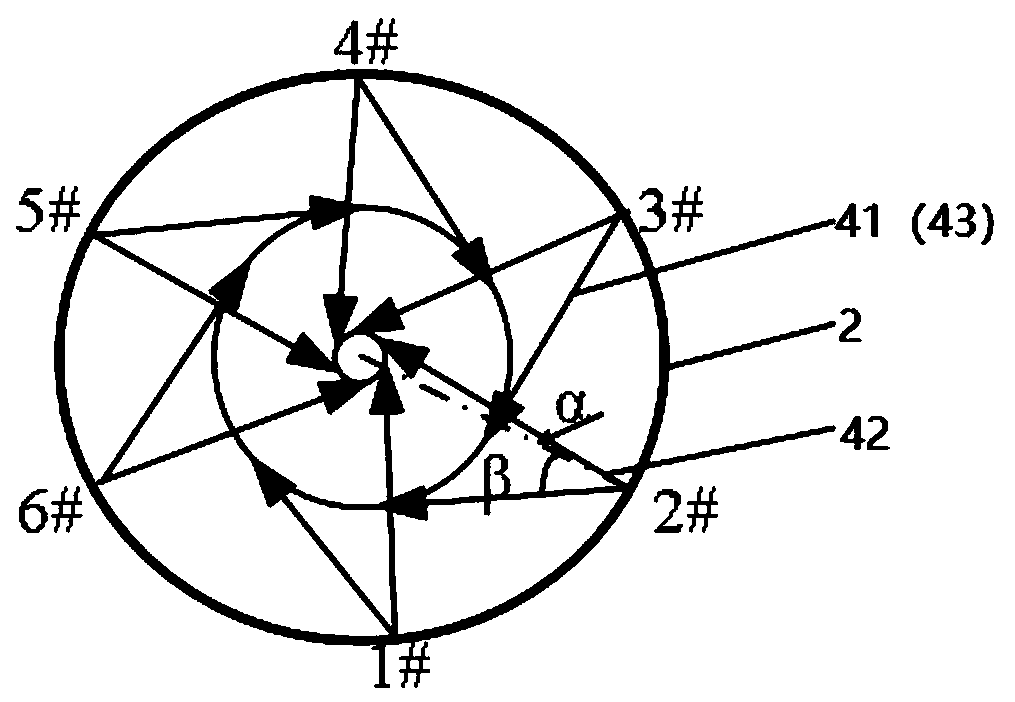

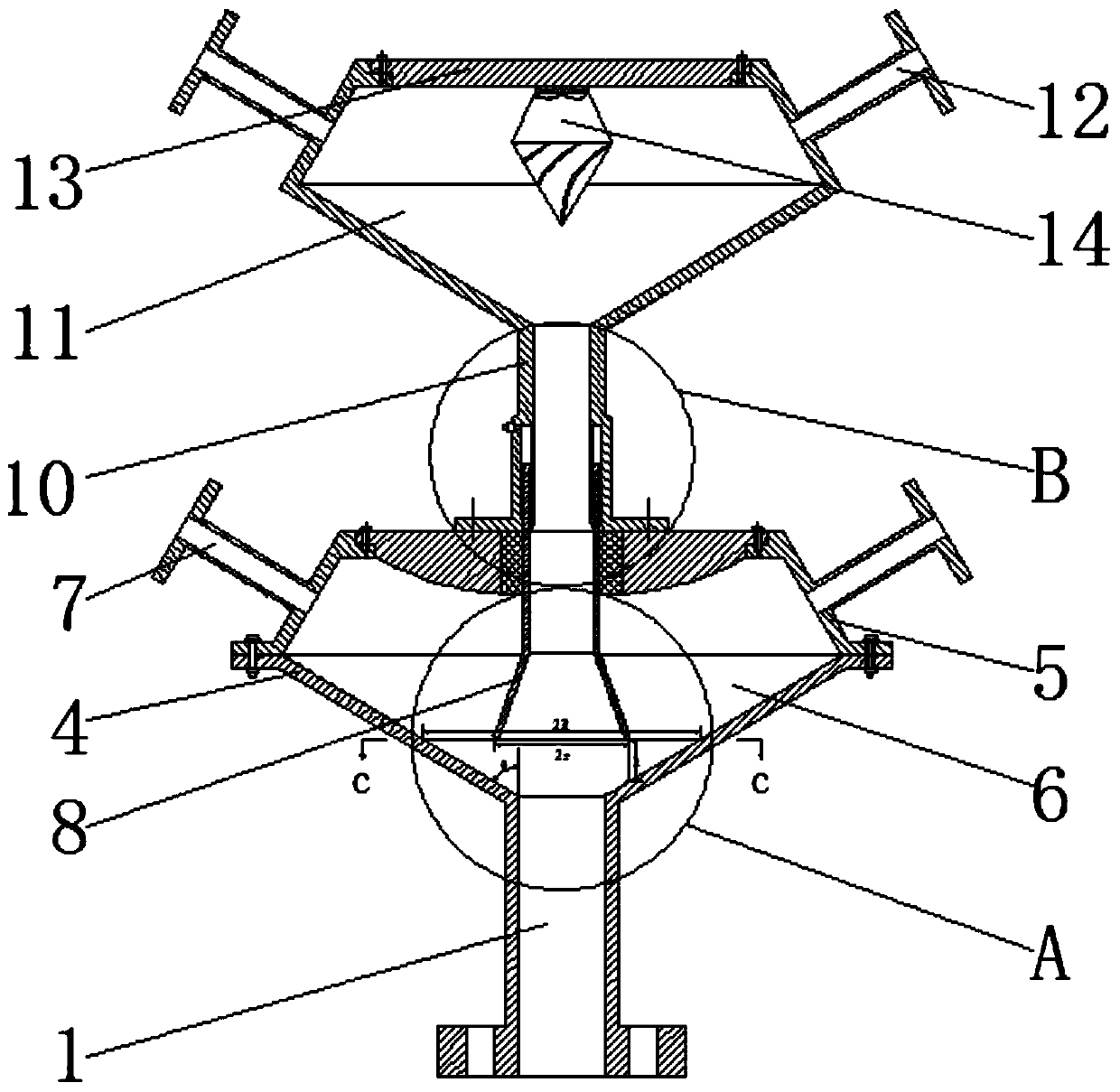

Supercritical CO2 circular and elliptical tangential boiler furnace body with uniform thermal loads

InactiveCN111550771AEnsure safe and economical operationAvoid overheatingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsBoiler furnace

The invention relates to a supercritical CO2 circular and elliptical tangential boiler furnace body with uniform thermal loads. A furnace hearth comprises a burner cavity. The cross section of an inner cavity of the burner cavity is circular or elliptical. At least one burner assembly is axially arranged in the burner cavity, and the burner assembly comprises a first deflection secondary air nozzle, a primary air nozzle, a second deflection secondary air nozzle and a direct current secondary air nozzle which are arranged in a spaced manner from bottom to top successively. A SOFA air nozzle isarranged on a cavity wall of the burner cavity. An air path system comprises a primary air fan, a secondary air fan, a coal mill and a secondary air distributor. An outlet of the primary air fan and apulverized coal outlet of the coal mill are connected to the primary air nozzle through a primary air pipe. An air outlet of the secondary air fan is connected to the first deflection secondary air nozzle, the second deflection secondary air nozzle, the direct current secondary air nozzle and the SOFA air nozzle separately. The supercritical CO2 circular and elliptical tangential boiler furnace body has the advantages that the thermal loads in the furnace hearth are uniformly distributed axially and radially, so that overtemperature of a heated surface of the boiler furnace is avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

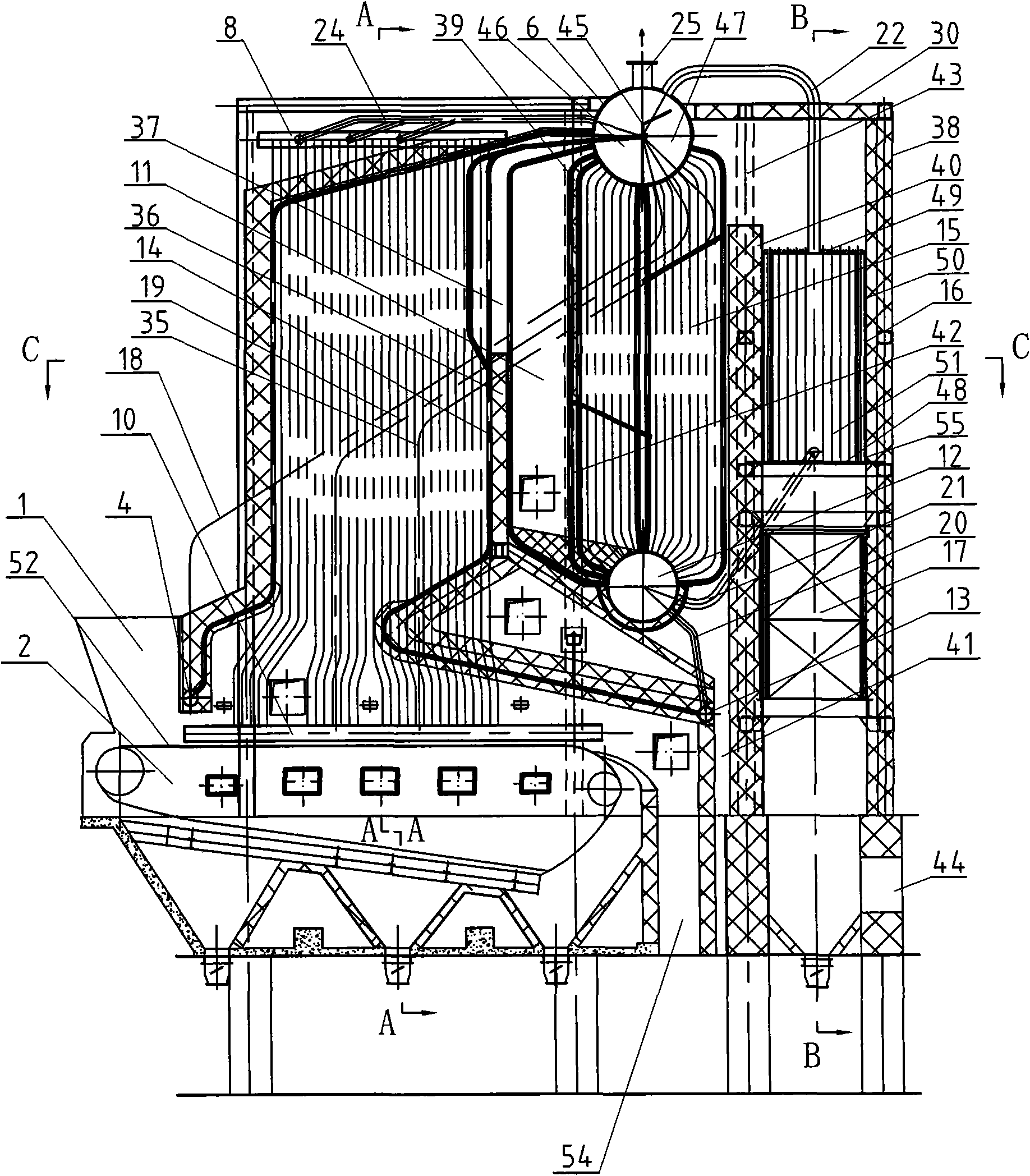

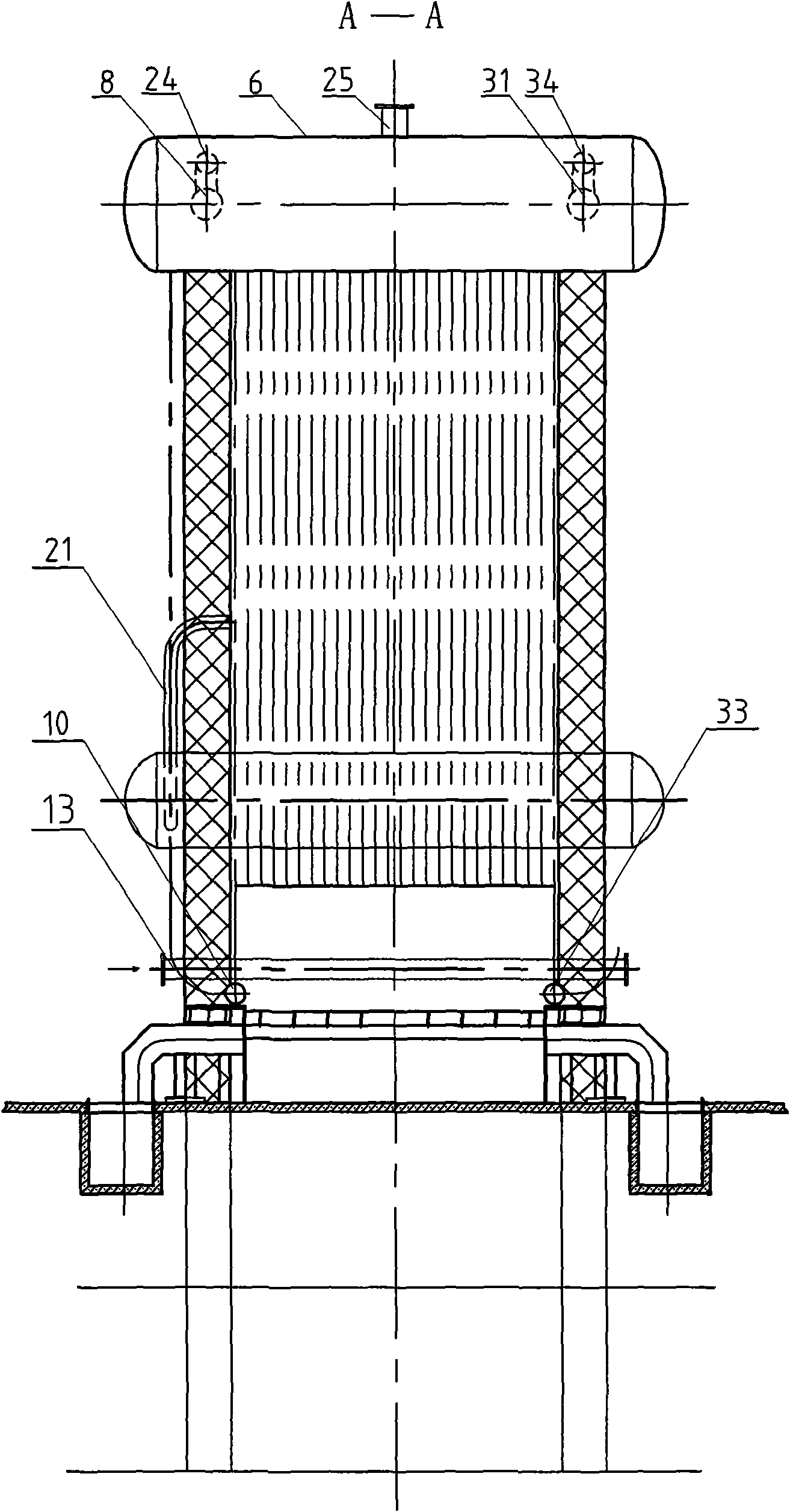

Large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue

A large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue relates to a water-fire tube hot water boiler. The aim of the invention is to settle the problems of ash accumulation, hard ash elimination, and reduced thermal efficiency of boiler in the prior water-fire tube hot water boiler. A burnout chamber, a convection calandria and a vertical threaded flue coal economizer are provided in the boiler body. The convection calandria is communicated with the upper barrel and the lower barrel. A warm water area and a hot warm water area are installed in the upper barrel. A first connecting pipe is communicated with a lower box of water cooled wall of back wall and the lower drum. A second connecting pipe is communicated with a lower drum and a vertical threaded flue coal economizer. A third connecting pipe is communicated with a hot water area and the vertical threaded flue coal economizer. The down pipe of water cooled wall of front wall is communicated with a lower collection box of water cooled wall of front wall and the cold water area. The down pipe of left wall is communicated with a lower collection box of water cooled wall of left wall. The down pipe of right wall is communicated with a lower collection box of water cooled box of water cooled wall of right wall. The large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue according to the invention adopts the vertical threaded flue coal economizer and has the advantages of no ash accumulation in the threaded flue, easy ash elimination and high thermal efficiency of boiler.

Owner:HARBIN INST OF TECH

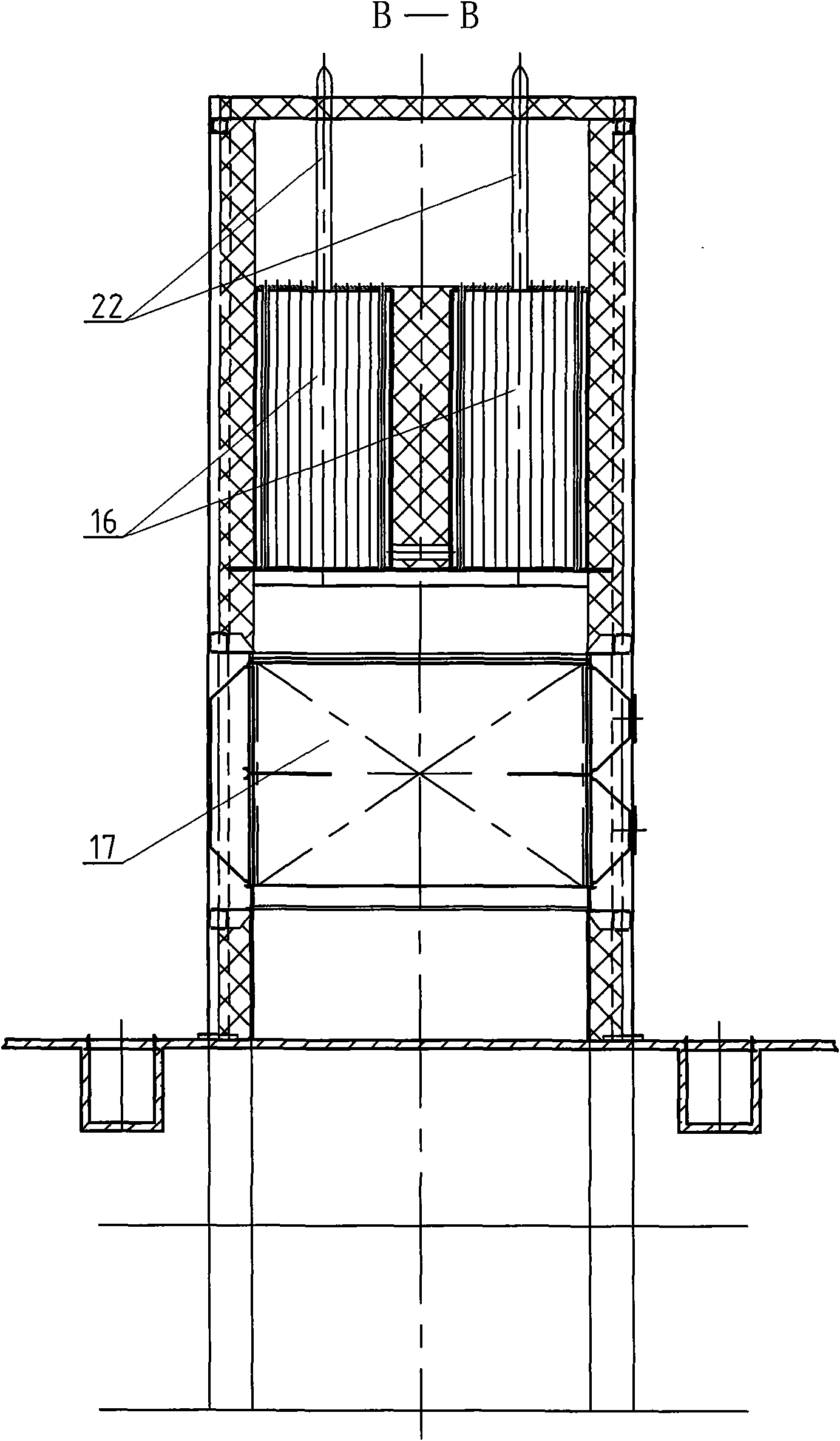

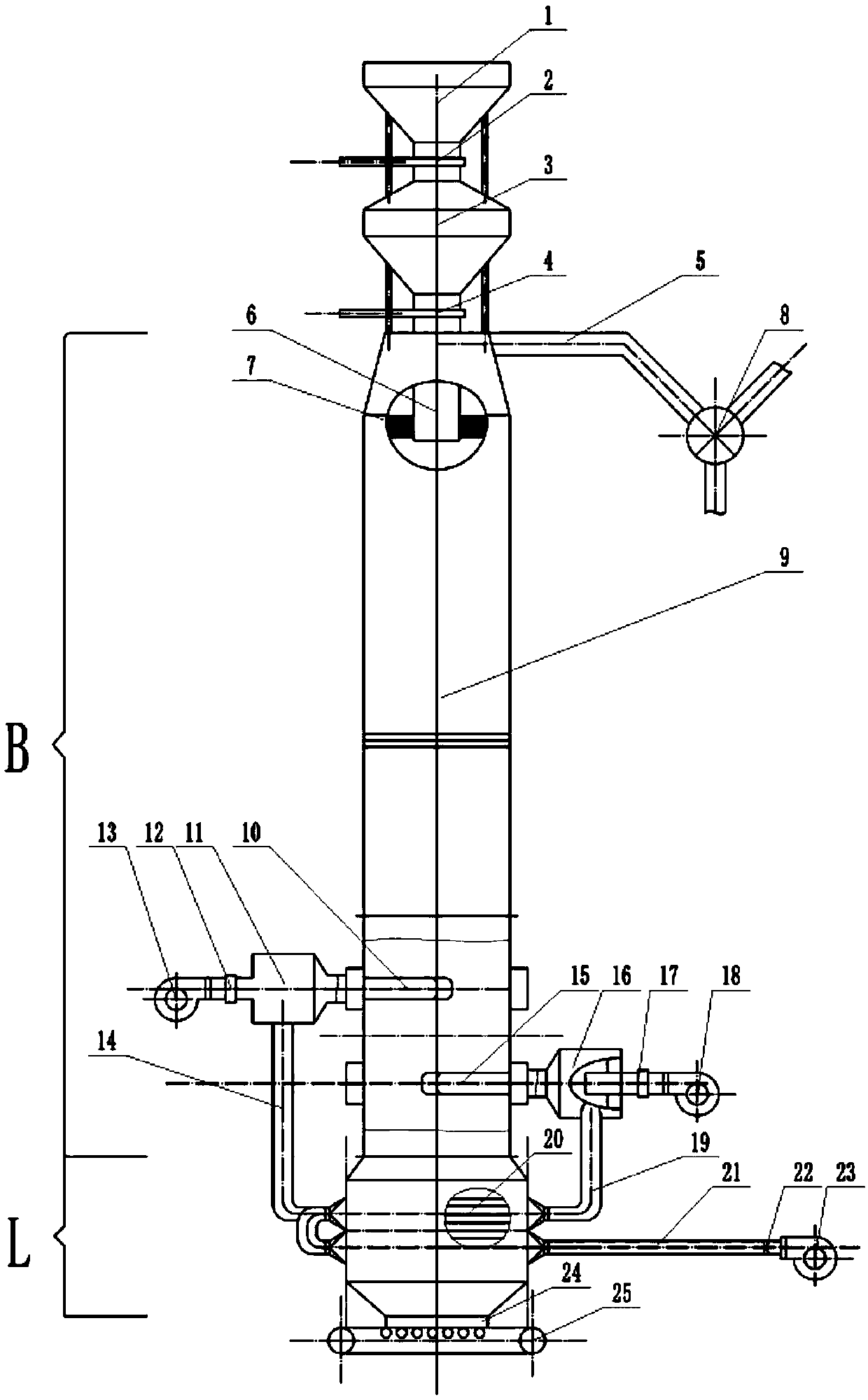

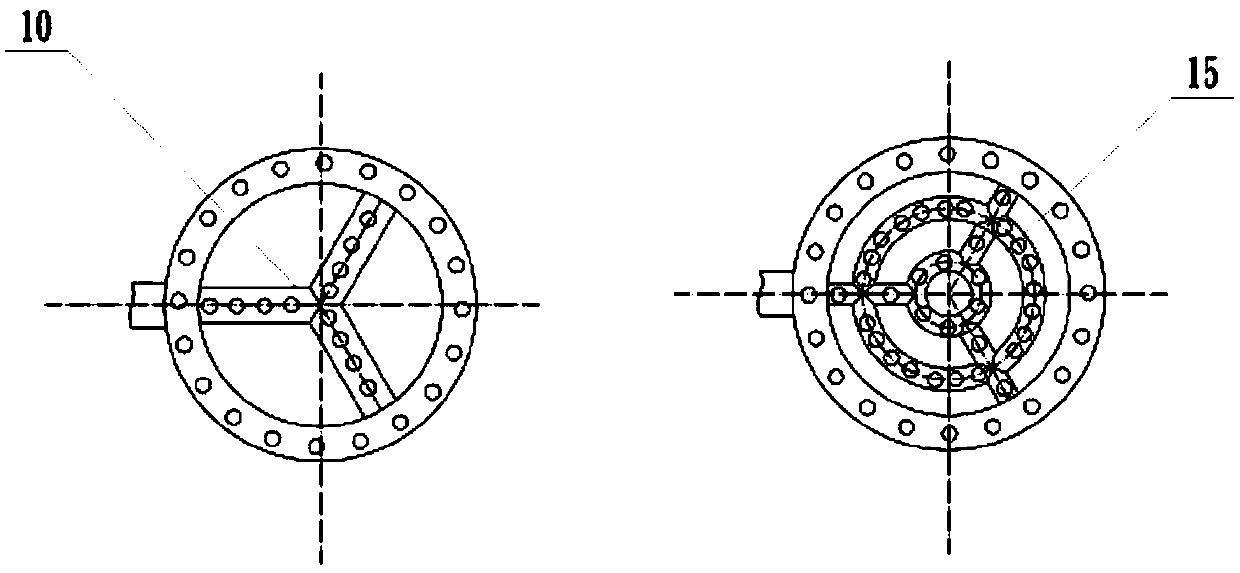

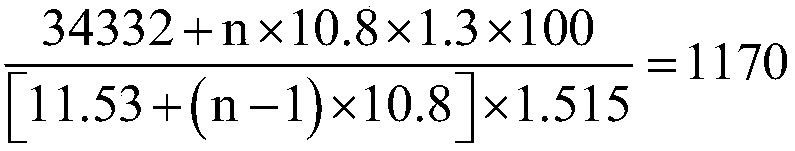

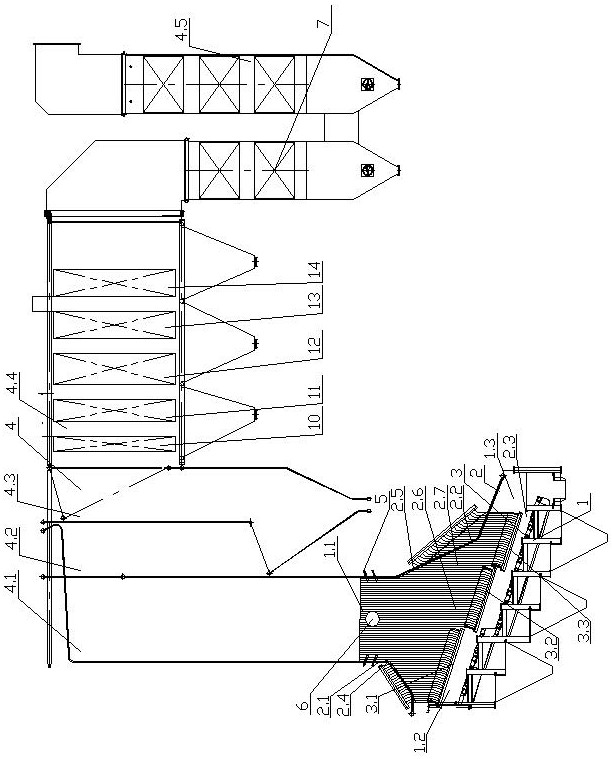

Novel aluminium oxide vertical activation roasting device and roasting method

ActiveCN109654874AReduce energy consumptionQuality improvementCharge composition/stateIncreasing energy efficiencyCombustion chamberFlue gas

The invention relates to the technical field of activated aluminium oxide prepared by non-ferrous metal, specifically a novel aluminium oxide vertical activation roasting device and a roasting method.Aluminium oxide pellets move from top to bottom in a vertical roasting furnace, and are discharged from a discharging valve at the bottom of the furnace body after pre-storage, roasting and cooling processes. Flue gas generated by natural gas combustion roasts aluminium oxide pellets from bottom to top, and then is discharged after primary and secondary dust removal from the top of the furnace body. A cooling heat exchange pipe is arranged at the lower part of the furnace body, cooling gas is introduced into the pipe, the roasted high-temperature aluminium oxide pellets are cooled when flowing outside the pipe; after being heated, the cooling gas in the heat exchange pipe is sent into a combustion chamber through an air pipe to be used as combustion-supporting gas of natural gas, therefore, the waste heat recovery of the aluminium oxide pellets is realized. The roasting device provided by the invention has higher waste heat recovery utilization rate, full heat exchange between combustion flue gas and aluminium oxide pellets, and effectively reduces the natural gas energy consumption; and the method is reasonable, efficient, simple and easy to operate.

Owner:NORTHEASTERN UNIV

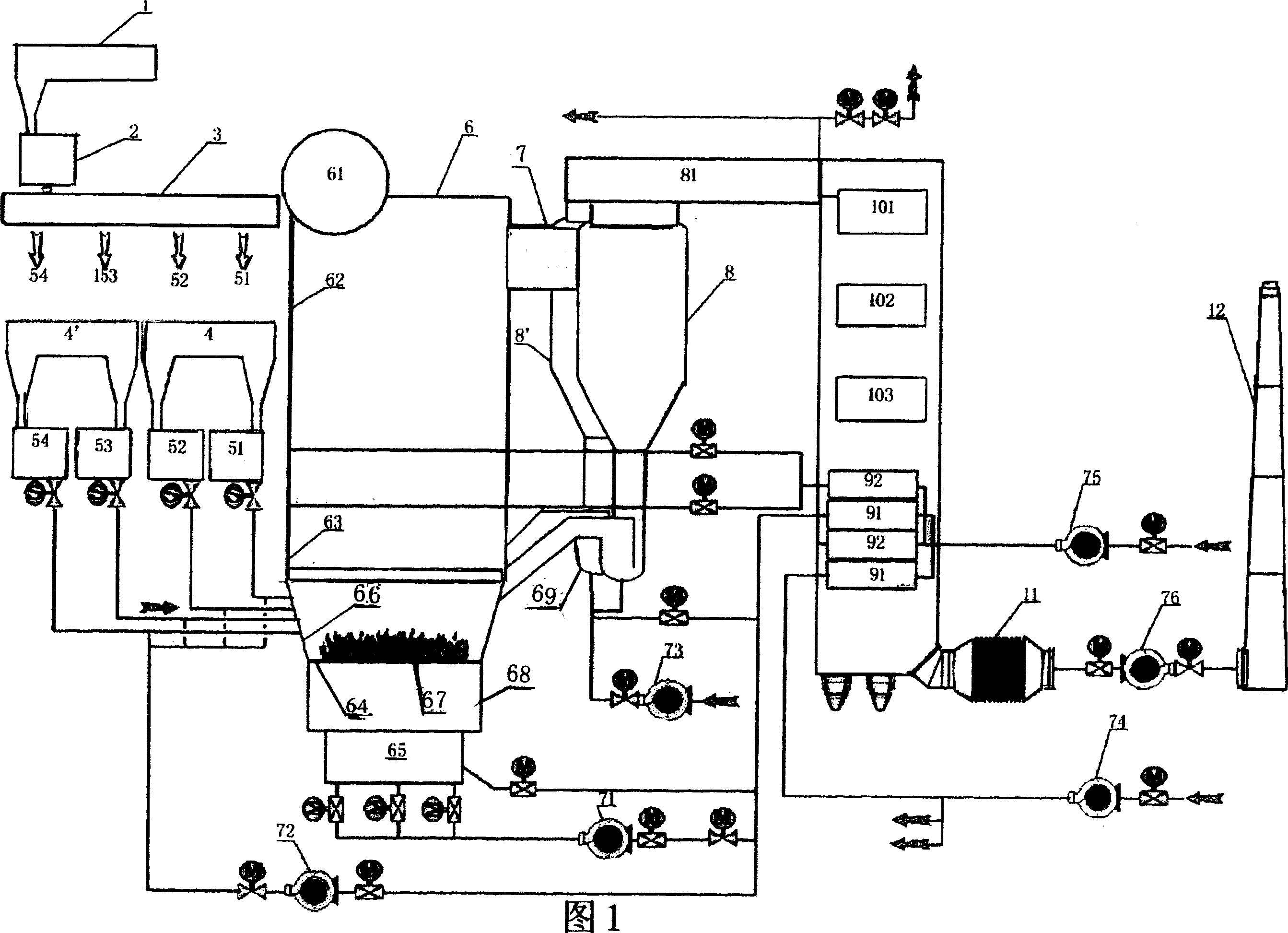

Slag burnout system and method of biomass boiler

PendingCN111981473AHigh thermal efficiencyGood for burnoutFluidized bed combustionApparatus for fluidised bed combustionAir preheaterSlag

The invention discloses a slag burnout system and method of a biomass boiler. The slag burnout system comprises a boiler body, a cyclone separator, an ash cooling air pipeline and denitration equipment, wherein a water cooling wall and a first superheater are arranged in the boiler body; an inlet of the cyclone separator communicates with an exhaust port of the boiler body; a slag outlet of the cyclone separator communicates with a first necking structure of the boiler body through a return pipeline; an air outlet of the cyclone separator communicates with a flue gas pipeline; a second superheater, a coal economizer and an air preheater are sequentially arranged in the flue gas pipeline in the flue gas flowing direction; an inlet of the air preheater communicates with an air feeder throughan air feeding pipeline; and an outlet of the air preheater communicates with a primary air pipeline and a secondary air pipeline. According to the slag burnout system and method, through circulatingfluidization and keeping of upward ash cooling air in a slag well, boiler ash can be fully burnt out, sensible heat of the ash is fully utilized, the boiler efficiency can be improved, and ash deposition corrosion is reduced.

Owner:南方电网综合能源(广州)有限公司赤水分公司 +3

Large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue

A large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue relates to a water-fire tube hot water boiler. The aim of the invention is to settle the problemsof ash accumulation, hard ash elimination, and reduced thermal efficiency of boiler in the prior water-fire tube hot water boiler. A burnout chamber, a convection calandria and a vertical threaded flue coal economizer are provided in the boiler body. The convection calandria is communicated with the upper barrel and the lower barrel. A warm water area and a hot warm water area are installed in the upper barrel. A first connecting pipe is communicated with a lower box of water cooled wall of back wall and the lower drum. A second connecting pipe is communicated with a lower drum and a verticalthreaded flue coal economizer. A third connecting pipe is communicated with a hot water area and the vertical threaded flue coal economizer. The down pipe of water cooled wall of front wall is communicated with a lower collection box of water cooled wall of front wall and the cold water area. The down pipe of left wall is communicated with a lower collection box of water cooled wall of left wall.The down pipe of right wall is communicated with a lower collection box of water cooled box of water cooled wall of right wall. The large-scale water-fire tube hot water boiler of double-barrel transverse vertical type threaded flue according to the invention adopts the vertical threaded flue coal economizer and has the advantages of no ash accumulation in the threaded flue, easy ash eliminationand high thermal efficiency of boiler.

Owner:HARBIN INST OF TECH

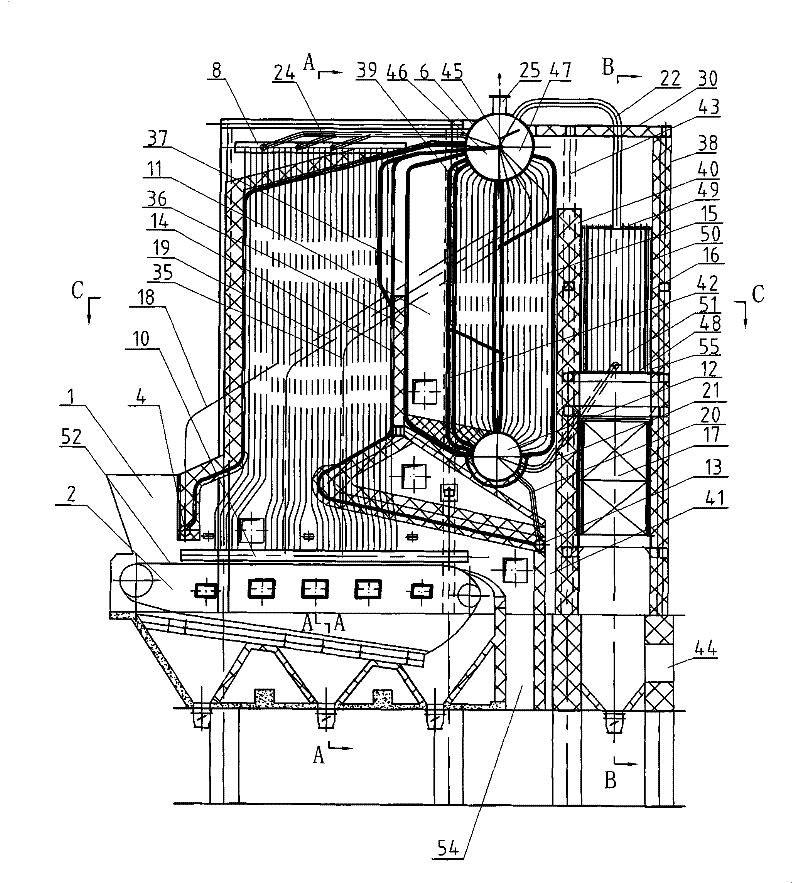

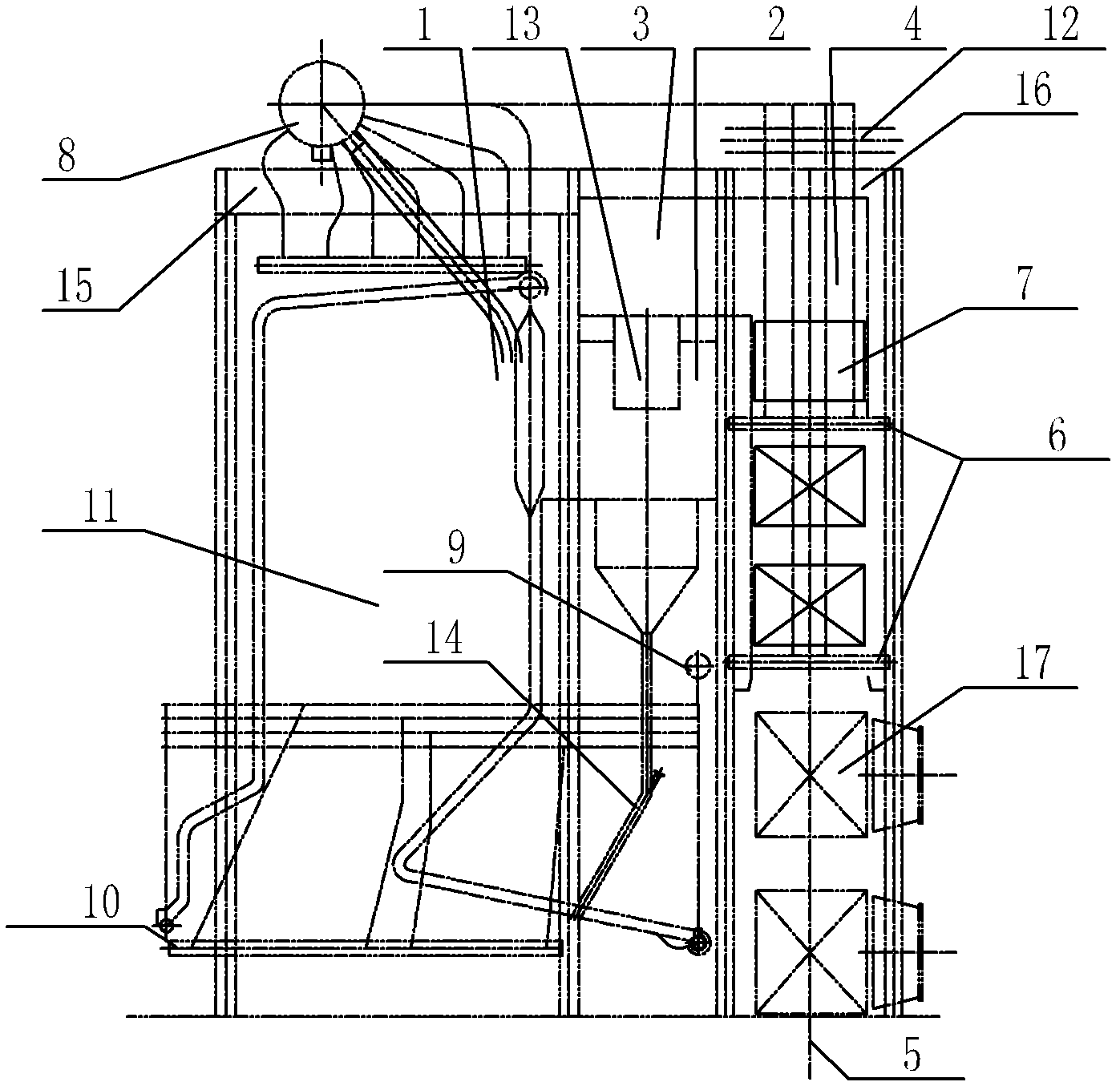

Forced circulation type hot water boiler structure

The invention relates to a forced circulation type hot water boiler structure which comprises a hearth and is characterized in that a cyclone separator is arranged at the outlet of the hearth, the outlet end of the cyclone separator is communicated with a horizontal flue, a tail vertical shaft is arranged at one side of the horizontal flue, an economizer is installed in the tail vertical shaft, an air preheater is installed at the bottom part of the tail vertical shaft, and a flue gas outlet is arranged at the lower part of the air preheater; and a water cooling wall is arranged at the periphery of the hearth, a water inlet of the water cooling wall is connected with a water cooling wall header at the lower part of the water cooling wall, the water cooling wall header is connected with a backwater distribution header via a connecting pipe, a water outlet at the upper end of the water cooling wall is connected with a boiler barrel at the upper end of the hearth, the boiler barrel is connected with an economizer header at the lower part of the economizer by a connecting pipe, and the economizer header is connected with a hot water outlet header at the top end of the tail vertical shaft via a connecting pipe. According to the forced circulation type hot water boiler structure, the height of the tail vertical shaft is decreased, the height of the hearth is decreased, the metal consumption quantity of the boiler main body is reduced, the imperfect combustion loss of the boiler machinery is reduced, and the boiler efficiency is improved.

Owner:WUXI HUAGUANG IND BOILER

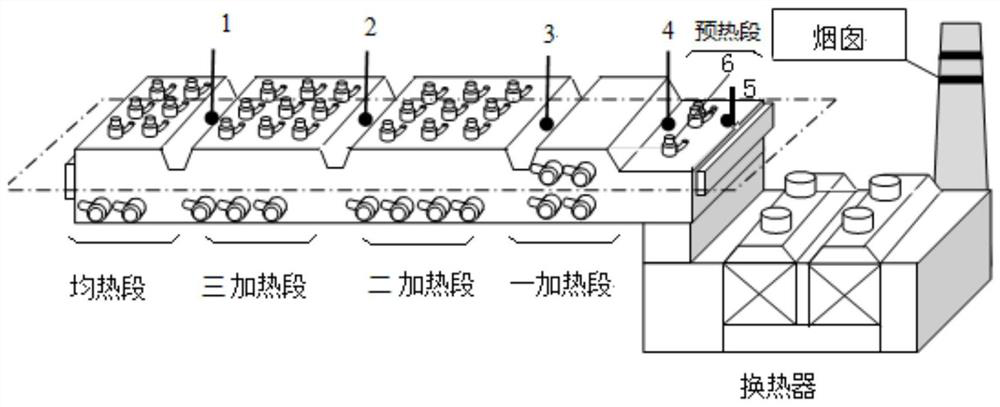

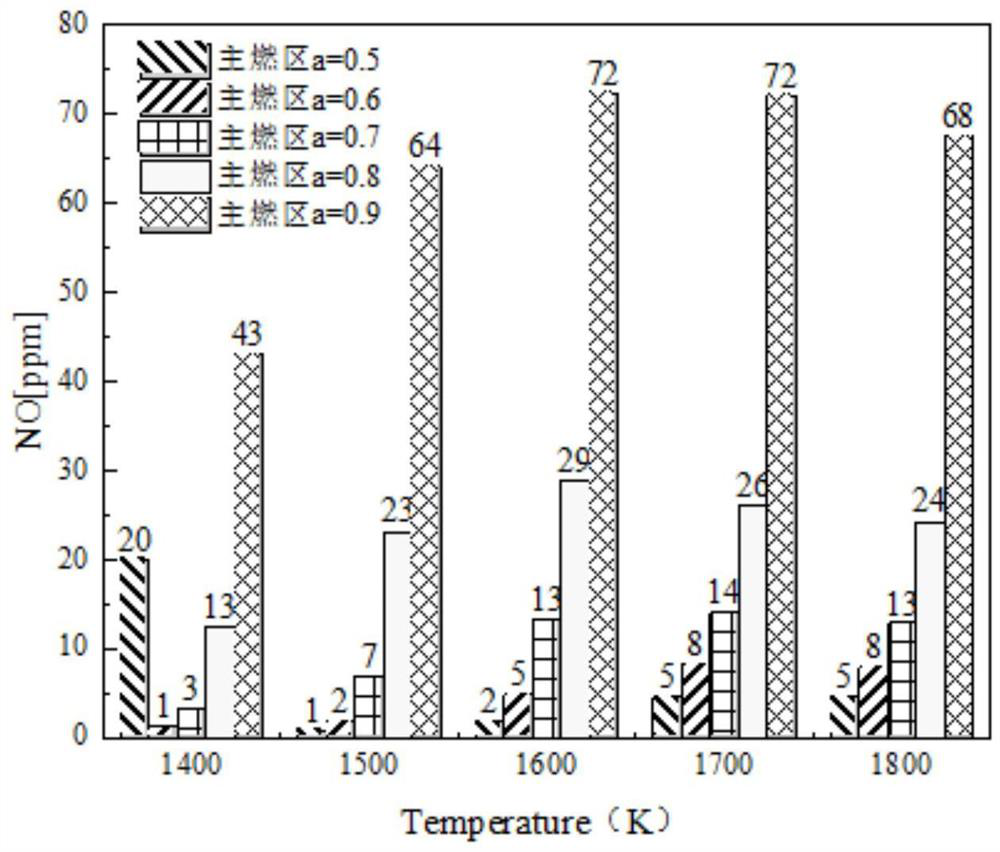

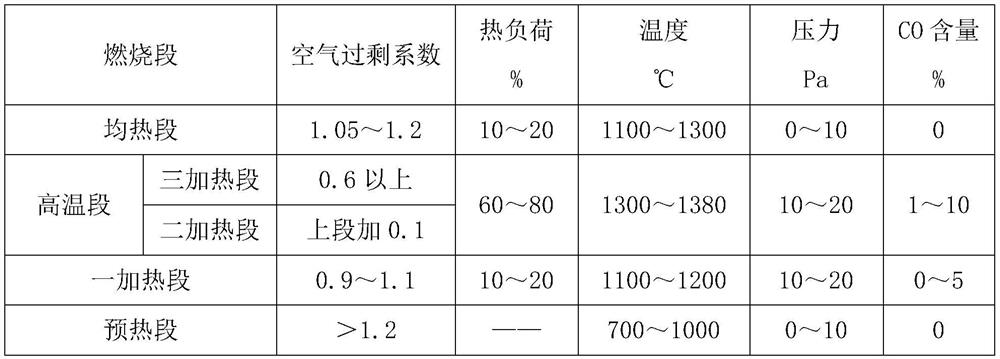

Heating furnace low-NOx combustion control method based on gas fuel

ActiveCN113154874AReduce incomplete combustion lossesRealize energy saving and environmental protection combustion control technologyFurnace typesThermodynamicsFlue gas

The invention relates to a heating furnace low-NOx combustion control method based on a gas fuel, which comprises the following steps: 1) controlling the hearth atmosphere of a soaking section to be weak oxidizing atmosphere, so that the fuel is completely combusted in the soaking section, and the flue gas does not contain CO; 2) controlling the hearth atmosphere of each heating section in a high-temperature section to be a reducing atmosphere, so that the CO content in the flue gas entering a low-temperature heating section from the high-temperature section is 3-10%; 3) controlling the hearth atmosphere of the heating section to be a reducing atmosphere, so that the CO content in the flue gas of the low-temperature heating section is not more than 1.5%; and (4) an air nozzle is additionally arranged on a preheating section, when the CO content in the flue gas of the preheating section is larger than 1%, an air nozzle is opened to burn residual CO, the air nozzle is closed until the CO content is zero, and it is guaranteed that an air excess coefficient of the preheating section is larger than 1.2. Generation of flue gas NOx in the high-temperature section is reduced, meanwhile, residual fuel is combusted through the low-temperature section, and the heat absorption efficiency of a steel billet is improved.

Owner:ANGANG STEEL CO LTD

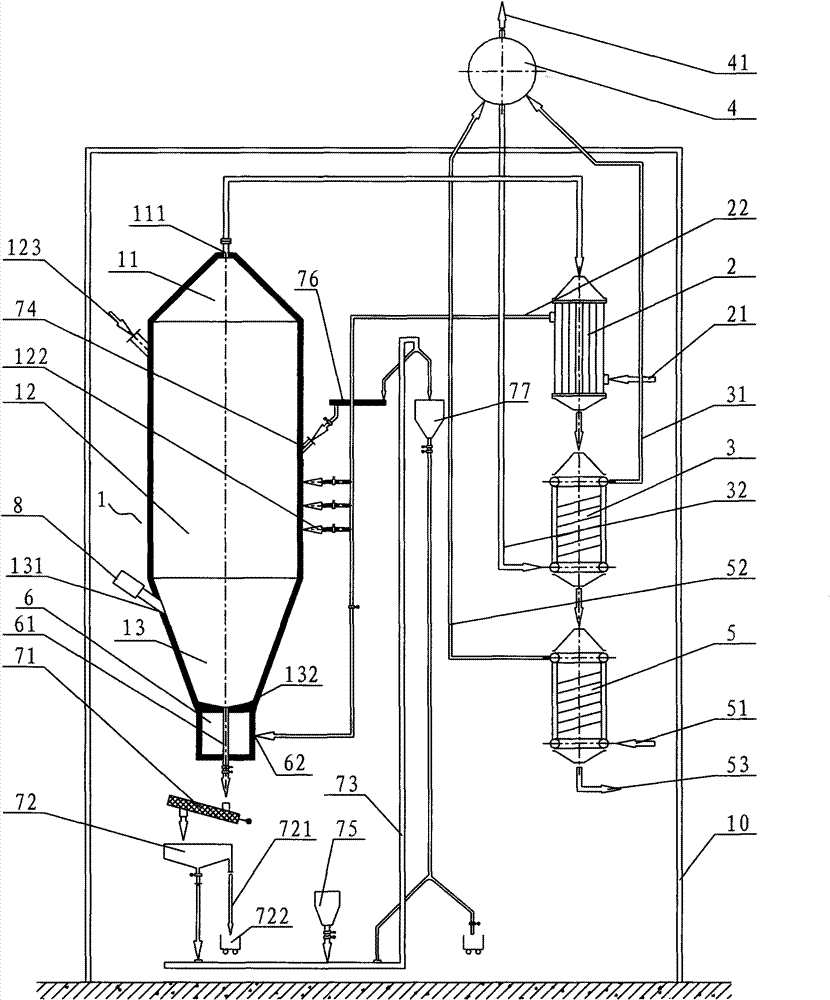

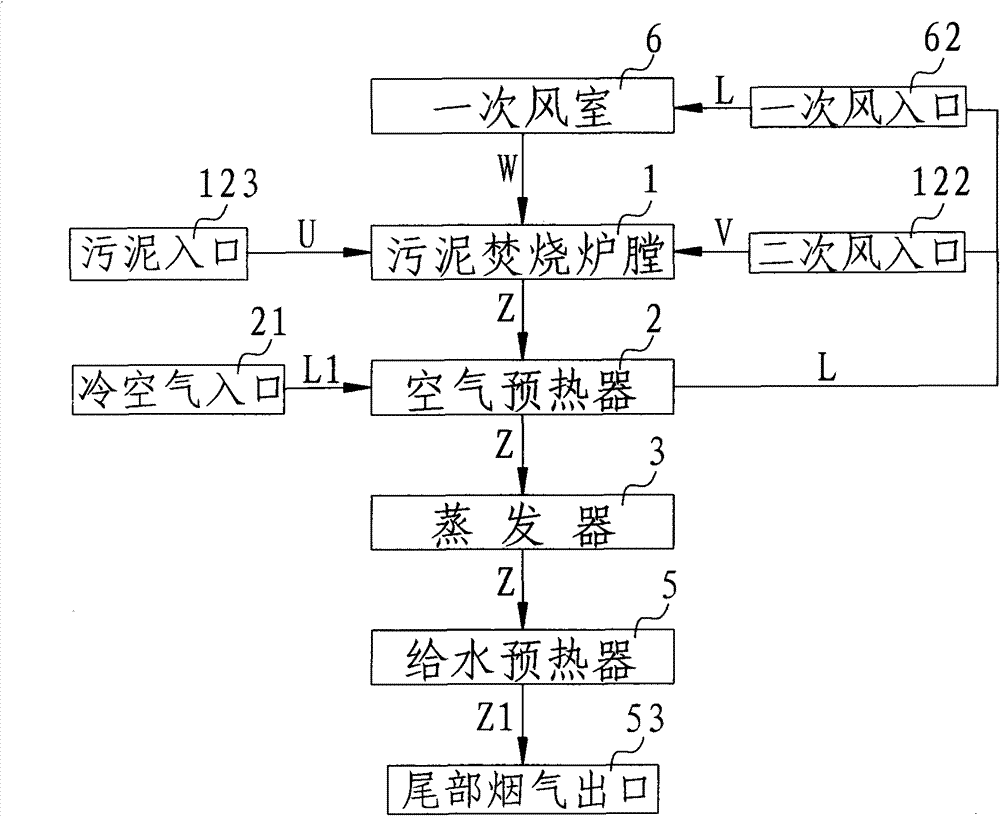

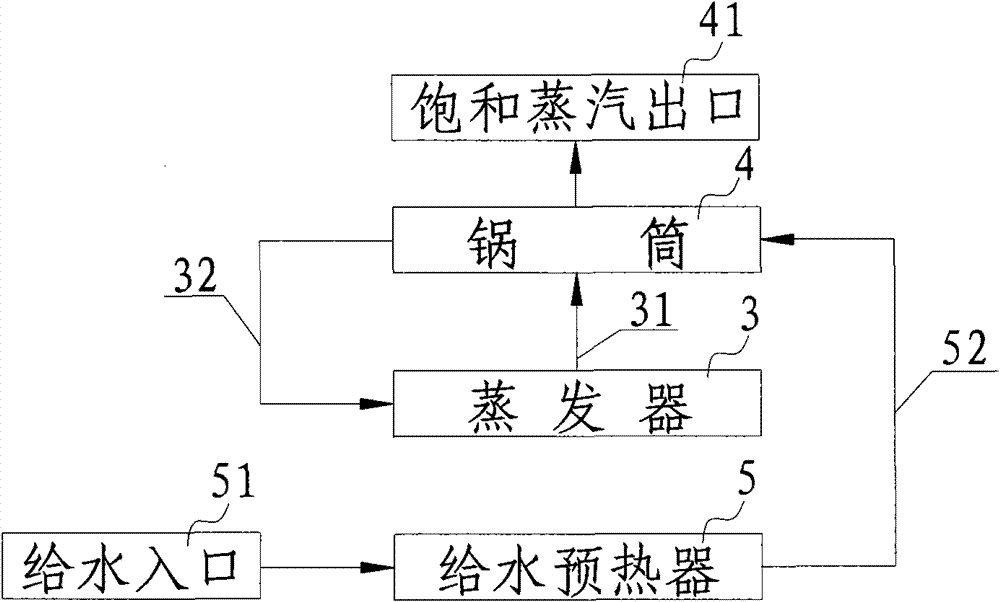

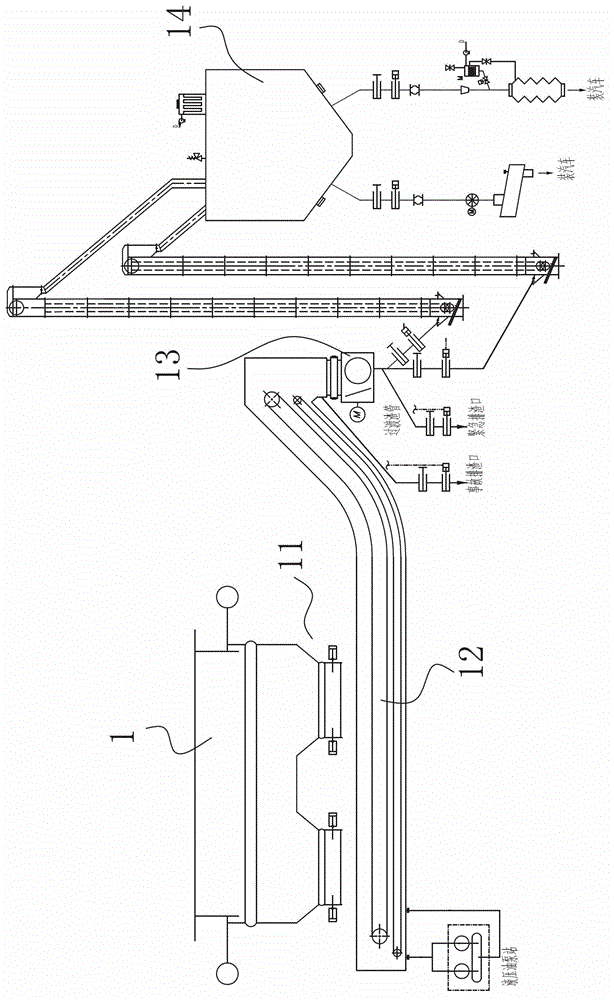

Bubbling bed sludge incineration boiler and sludge incineration method

ActiveCN102235677BImprove efficiencyGuaranteed afterburnIncinerator apparatusAir preheaterCombustion

The invention relates to a bubbling bed sludge incineration boiler and a sludge incineration method. The bubbling bed sludge incineration boiler comprises a steel framework, and a sludge incineration hearth, an air preheater, an evaporator, a feed water preheater, a primary air chamber and a boiler barrel which are arranged on the steel framework, wherein the primary air chamber is connected withthe lower port of the sludge incineration hearth; the sludge incineration hearth is a heat-insulating hearth, so that heat generated by sludge incineration is completely used for drying sludge; the air preheater is communicated with a flue gas outlet and a secondary air inlet of the hearth and the primary air chamber through a pipeline respectively, and is used for generating high-temperature airto supplement heat required by drying the sludge and providing oxygen required by ignition and preliminary combustion; the evaporator is connected with the air preheater; the feed water preheater is connected with the evaporator; and the evaporator and the feed water preheater are connected with the boiler barrel respectively to generate saturated steam for drying the sludge.

Owner:烟台鑫丰源电站设备有限公司

Pulverized coal co-combustion system of industrial boiler

ActiveCN102901089BHigh flame temperatureImprove burnout ratePulverulent fuel combustion burnersLump/pulverulent fuel preparationCombustion systemImpeller

The invention discloses a pulverized coal co-combustion system of an industrial boiler. With the system, layer combustion and suspension combustion can form in a furnace. The system includes a boiler, a raw coal supply device and a co-combustion device. The boiler comprises a furnace, a coal inlet located at the lower part of a front end wall, and a chain grate disposed at the lower part of a furnace inner chamber. The raw coal supply device is connected to the coal inlet through a coal hopper. The co-combustion device is arranged at the boiler tail, and is composed of a boiler-front mill, a pulverized coal combustor and a pulverized coal conveying pipe. The boiler-front mill includes a rotation shaft running through a primary milling chamber, an intermediate milling chamber and a fine milling chamber connected in order, a primary hammer type impeller, an intermediate hammer type impeller and a final hammer type impeller. The front end wall upper part of the primary milling chamber is provided with a coal inlet, and the chamber wall upper part of the fine milling chamber is provided with a pulverized coal nozzle. The pulverized coal combustor includes a combustor body and a combustion nozzle. The combustor body is equipped with a secondary air inlet and a pulverized coal inlet. And the pulverized coal conveying pipe connects the pulverized coal inlet of the combustor body and the pulverized coal nozzle of the boiler-front mill.

Owner:SHANGHAI INDAL BOILER RES INST

A new type of alumina vertical activated roasting device and roasting method

ActiveCN109654874BReduce energy consumptionQuality improvementCharge composition/stateIncreasing energy efficiencyCombustion chamberFlue gas

The invention relates to the technical field of preparing activated alumina from non-ferrous metals, and specifically to a new type of alumina vertical activation roasting device and method. Alumina pellets move from top to bottom in the vertical roasting furnace. After pre-storage, roasting and cooling processes, they are discharged from the discharge valve at the bottom of the furnace body. The flue gas generated by the combustion of natural gas is roasted into alumina pellets from bottom to top, and then discharged from the top of the furnace body after primary and secondary dust removal. There is a cooling heat exchange tube arranged in the lower part of the furnace body. Cooling gas flows through the tube. The roasted high-temperature alumina pellets are cooled when flowing out of the tube. The cooling gas in the heat exchange tube is heated and sent to the combustion chamber through the air duct as a combustion support for natural gas. Gas, thereby realizing waste heat recovery of alumina pellets. The invention has a high waste heat recovery rate, sufficient heat exchange between combustion flue gas and alumina pellets, and effectively reduces natural gas energy consumption. The method is reasonable and efficient, and the equipment is simple and easy to operate.

Owner:NORTHEASTERN UNIV LIAONING

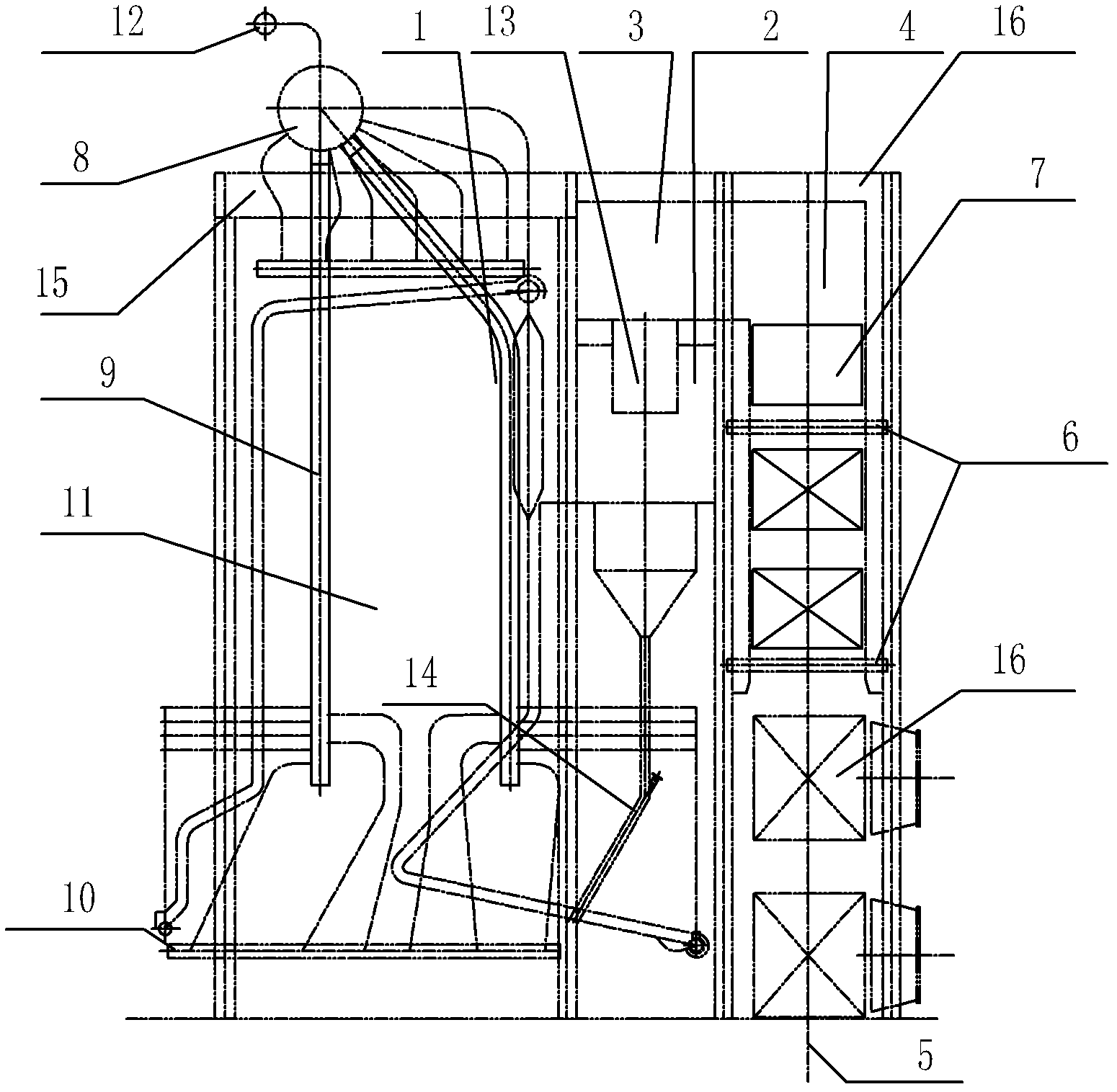

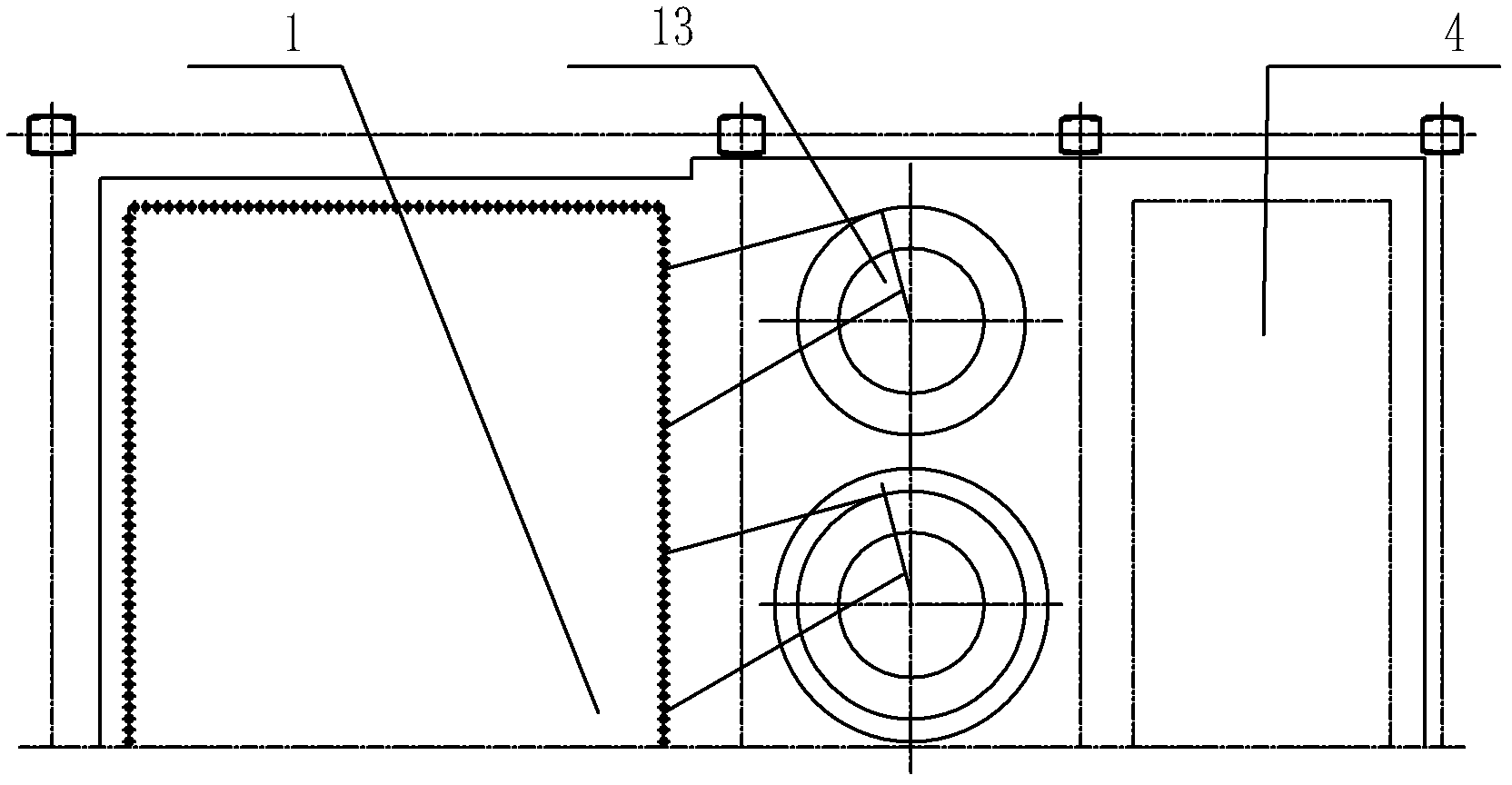

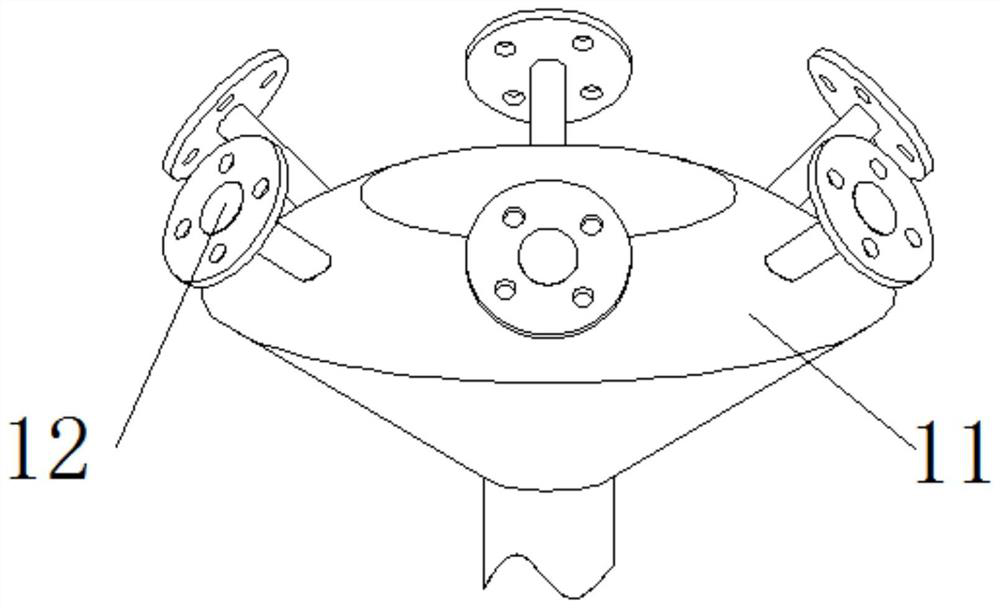

Gas-liquid-solid fuel hybrid combustion furnace

InactiveCN104832911APromote combustionReduce incomplete combustion lossesBurnersSolid fuel combustionCombustorCombustion chamber

The invention provides a gas-liquid-solid fuel hybrid combustion furnace, and relates to the technical field of combustion furnaces. The furnace device mainly comprises a front shaft assembly, a chain fire grate, a feed hopper, a hot air outlet, a refractory furnace wall, an ash collecting hopper, an oil or gas fired combustor, a solid fuel combustion hearth, an oil or gas fired combustion hearth and a special refractory material combustion cover, wherein the feed hopper and the chain fire grate form a solid fuel supply device; the special refractory material combustion cover and the chain fire grate form a solid fuel combustion chamber in an enclosing manner; a primary air supply outlet is positioned below the chain fire grate, and is used for supplying air required by solid fuel combustion; the oil or gas fired combustor, a furnace top and the special refractory material combustion cover form an oil or gas fired combustion chamber; the two combustion chambers are isolated through the special refractory material combustion cover. Under the action of the refractory material combustion cover, full heat exchange is performed, so that the temperature fields in the combustion chambers are kept stable, the generation of pollutants is reduced, the combustion efficiency is increased, and the heat efficiency is increased.

Owner:邢献军

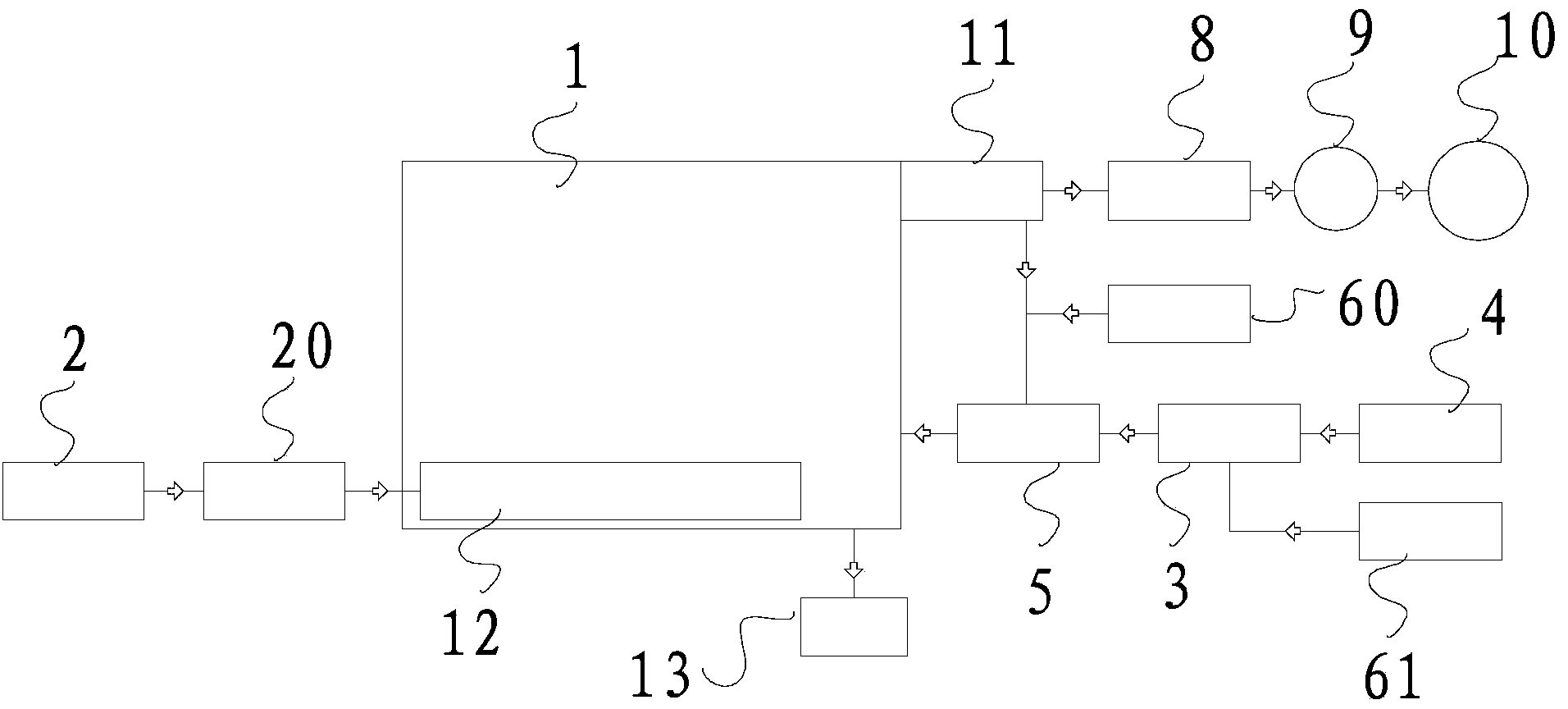

A system and method for air preheating and flue gas waste heat utilization

InactiveCN104807035BSolve the existing disadvantagesRaise the inlet air temperatureCombustion processFeed water supplyAir preheaterFlue gas

The invention particularly aims to the technical field of boiler air preheating. A disclosed air preheating and flue gas waste heat utilizing system comprises a flue gas channel (17), an air channel (20), an air preheater (9), a condensed water flue heat exchanger (8) and a condensed water air channel heat exchanger (19), and further comprises a condensed water feeding main pipe (15) and a condensed water returning main pipe (12); the flue gas channel (17) and the air channel (20) are connected with the air preheater (9); the condensed water flue heat exchanger (8) is arranged on the flue gas channel (17) at the back of the air preheater (9) in a flue gas flowing direction; the condensed water air channel heat exchanger (19) is arranged on the air channel (20) at the front of the air preheater (9) in an air flowing direction. According to the air preheating and flue gas waste heat utilizing system, flue gas discharge and heat exchange can be automatically adjusted according to change of operation conditions; on the premise of ensuring the safety of a heated surface and the regular operation of the system, the maximization of the heat circulation efficiency and the system economical efficiency is ensured.

Owner:郝江平

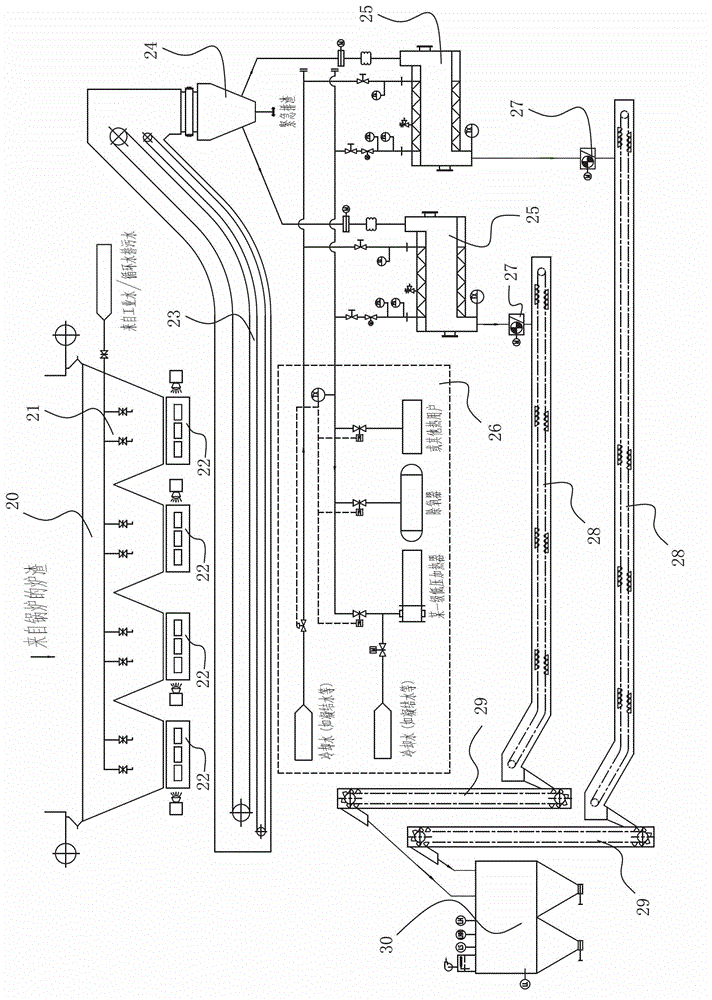

Incineration boiler integrated system for efficiently treating high-calorific-value garbage

InactiveCN112212344AMaximize utilizationImprove thermal efficiencyCombustion technology mitigationSteam superheatersProcess engineeringHearth

The invention discloses an incineration boiler integrated system for efficiently treating high-calorific-value garbage, and relates to the technical field of garbage incineration equipment. The systemcomprises a fire grate frame, the fire grate frame is provided with a water-cooling hearth, a fire grate arranged on the fire grate frame is arranged in the water-cooling hearth, the upper end of thewater-cooling hearth is provided with a smoke outlet, a garbage inlet is arranged at the front end of the water-cooling hearth, a slag outlet is arranged at the rear end of the water-cooling hearth,and the smoke outlet of the water-cooling hearth is connected with a flue set. The fire grate frame is provided with the water-cooling hearth so that the high-calorific-value household garbage can betreated, a scheme is provided for the treatment of the high-calorific-value garbage at present, the heat of the garbage can be utilized to the maximum, and the heat efficiency is high.

Owner:CHINA TIANYING +1

Forced circulation type hot water boiler structure

The invention relates to a forced circulation type hot water boiler structure which comprises a hearth and is characterized in that a cyclone separator is arranged at the outlet of the hearth, the outlet end of the cyclone separator is communicated with a horizontal flue, a tail vertical shaft is arranged at one side of the horizontal flue, an economizer is installed in the tail vertical shaft, an air preheater is installed at the bottom part of the tail vertical shaft, and a flue gas outlet is arranged at the lower part of the air preheater; and a water cooling wall is arranged at the periphery of the hearth, a water inlet of the water cooling wall is connected with a water cooling wall header at the lower part of the water cooling wall, the water cooling wall header is connected with a backwater distribution header via a connecting pipe, a water outlet at the upper end of the water cooling wall is connected with a boiler barrel at the upper end of the hearth, the boiler barrel is connected with an economizer header at the lower part of the economizer by a connecting pipe, and the economizer header is connected with a hot water outlet header at the top end of the tail vertical shaft via a connecting pipe. According to the forced circulation type hot water boiler structure, the height of the tail vertical shaft is decreased, the height of the hearth is decreased, the metal consumption quantity of the boiler main body is reduced, the imperfect combustion loss of the boiler machinery is reduced, and the boiler efficiency is improved.

Owner:WUXI HUAGUANG IND BOILER

Natural circulation type hot water boiler structure

The invention relates to a natural circulation type hot water boiler structure comprising a hearth. The natural circulation type hot water boiler structure is characterized in that a cyclone separator is arranged at an outlet of the hearth, the outlet end of the cyclone separator is communicated with a horizontal flue, a tail vertical shaft is arranged at one side of the horizontal flue, an economizer is installed in the tail vertical shaft, an air preheater is installed at the bottom part of the tail vertical shaft, and a flue gas outlet is arranged at the lower part of the air preheater; and an economizer header is installed at the lower part of the economizer, the economizer header is connected with a boiler barrel at the upper end of the hearth by a connecting pipe, a boiler pipe is connected with a lower header of a water cooling wall by a centralized downcomer at the outside of the hearth, the lower header of the water cooling wall is connected with a water inlet of the water cooling wall, a water outlet at the upper end of the water cooling wall is connected with the boiler barrel, and a water outlet of the boiler barrel is connected with the hot water outlet header at the top part of the tail vertical shaft. According to the natural circulation type hot water boiler structure, the height of the tail vertical shaft is decreased, the height of the hearth is decreased, the metal consumption quantity of the boiler main body is reduced, the imperfect combustion loss of the boiler machinery is reduced, and the boiler efficiency is improved.

Owner:WUXI HUAGUANG IND BOILER

Coal thermal decomposition grate firing apparatus and its combustion method

InactiveCN101368724BSimple structureNo increase in sizeSolid fuel combustionCombustion apparatusCombustion chamberCombustible gas

The invention relates to a coal pyrolysis layer combustion device and the combustion method thereof, including that the furnace body interior of the first layer combustion furnace is divided into an upper oxidation pyrolysis chamber and a lower fire grate layer combustion chamber which is communicated with each other; the coal and desulfurizer are mixed to be fed into the middle part of the oxidation pyrolysis for oxidation pyrolysis through a hopper; the generated combustible gas and the smaller semi-coke particles are overflowed through the upper-connected through port or are carried in theairflow to be fed into the mechanical fire grate layer combustion chamber; the bigger semi-coke particles fall on the mechanical fire grate and are fed into the layer combustion layer for combustion;the mechanical fire grate layer combustion chamber is provided with a front arch and a back arch for organizing the airflow field inside the furnace; the coal pyrolysis layer combustion device and the combustion method thereof adopt the fluidization characteristics of the coal particles with different particle diameters and the high thermal capacity characteristic inside the oxidation pyrolysis chamber to realize the natural separation of the coal particles with different particle diameters and the rapid oxidation pyrolysis of coal, reduce the fire grate coal leakage loss and the incomplete combustion loss caused by the front segment low temperature of the fire grate and reduce the emission of the SOx and NOx pollutant through the combination of the pyrolysis desulfurization and the combustion desulfurization, and the reburning denitration formed by the coal pyrolysis product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

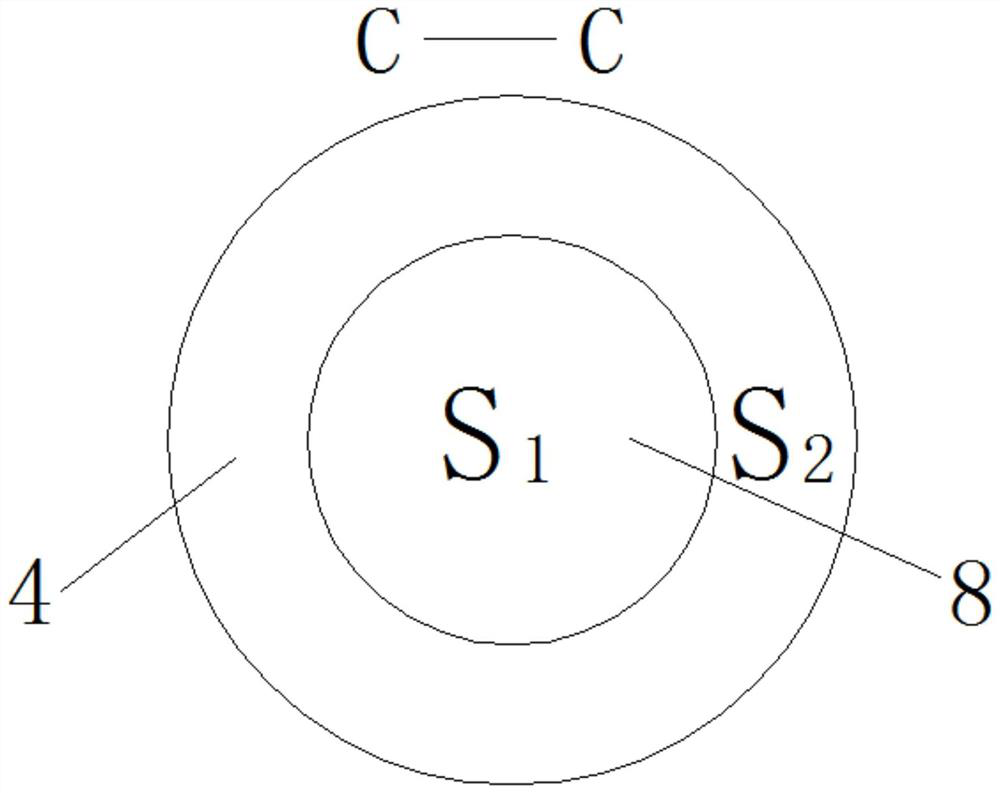

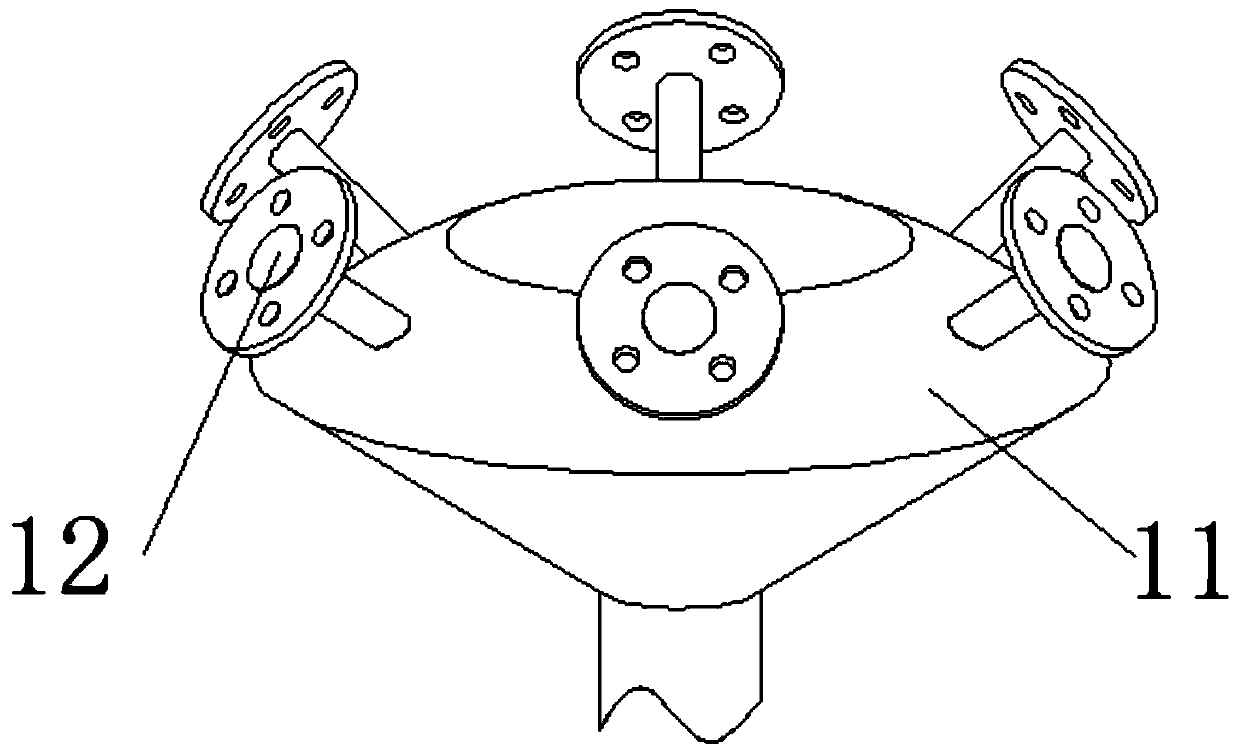

Powdery straw cleaning combustor

ActiveCN110043897AIncrease volumetric heat intensityExtended stayPulverulent fuel combustion burnersNon-combustible gases/liquids supplyParticulatesCombustion chamber

The invention discloses a powdery straw cleaning combustor. The combustor comprises a combustor body, wherein the combustor body comprises a combustor shell, a combustion chamber and a flue gas outlet, wherein the combustion chamber and the flue gas outlet are positioned in the combustor shell; the combustion chamber comprises a cylindrical part and a conical part, the combustion chamber is near to the flue gas outlet, the combustor shell is provided with a primary air inlet pipeline and a secondary air inlet pipeline, the primary air inlet pipeline is axially parallel to the combustion chamber, the secondary air inlet pipeline is tangent to the cylindrical part of the combustion chamber, a nozzle of the secondary air inlet pipeline is located on the inner wall of the combustion chamber oris close to the inner wall of the combustion chamber, and a cylindrical backflow cone is arranged at the junction of the flue gas outlet of the combustion chamber and the cylindrical part of the combustion chamber. The powdery straw cleaning combustor has the advantages of lean combustion and liquid slag discharge, the combustor is compact in structure, high in outlet smoke cleanliness and uniform in temperature field, good in combustion stability, small in solid incomplete combustion loss, less in emission of Nox and particulate matters, and the powdery straw cleaning combustor has importantsignificance in promoting the development of renewable energy sources and reducing the emission of pollutants.

Owner:ZHONGYUAN ENGINEERING COLLEGE

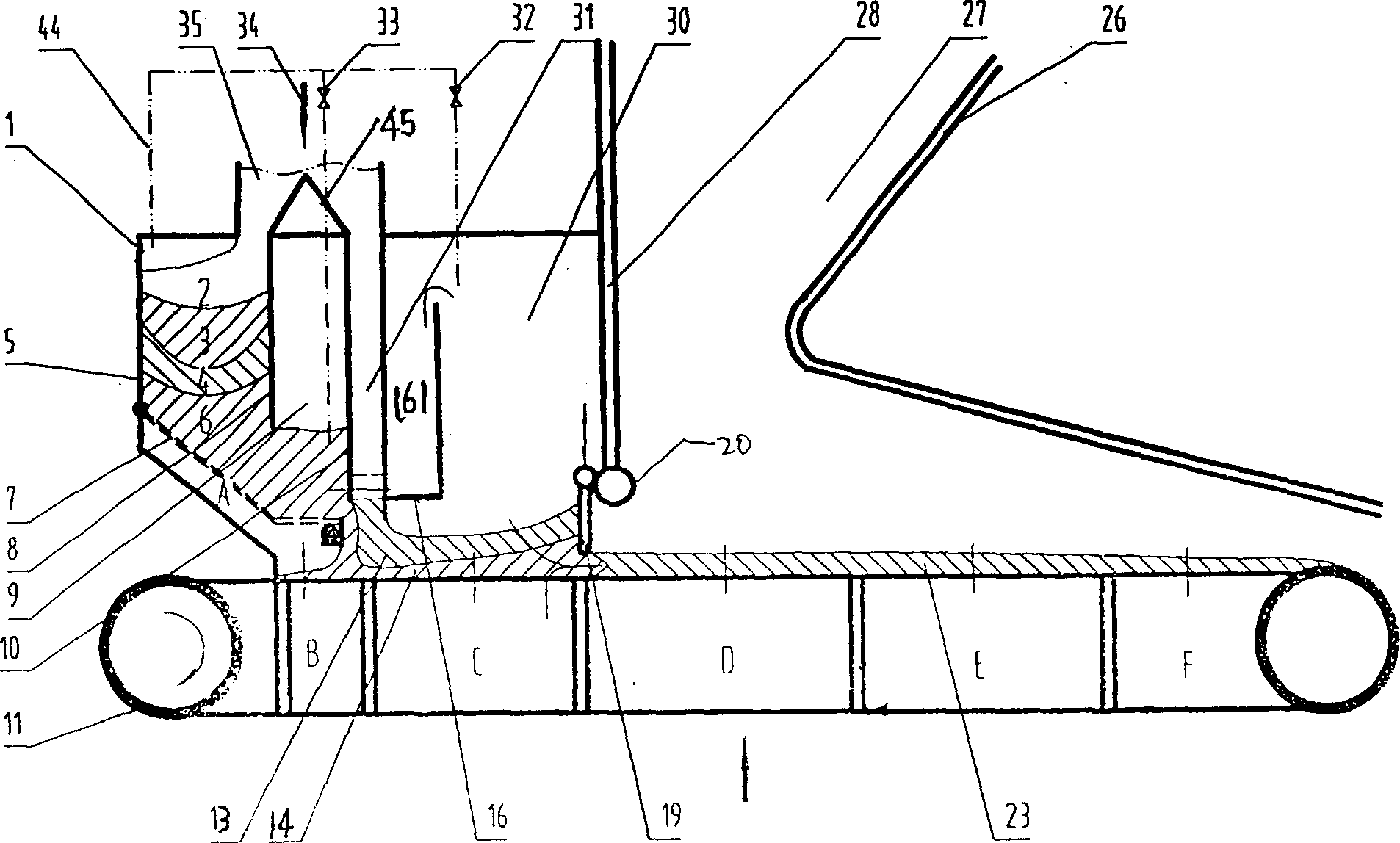

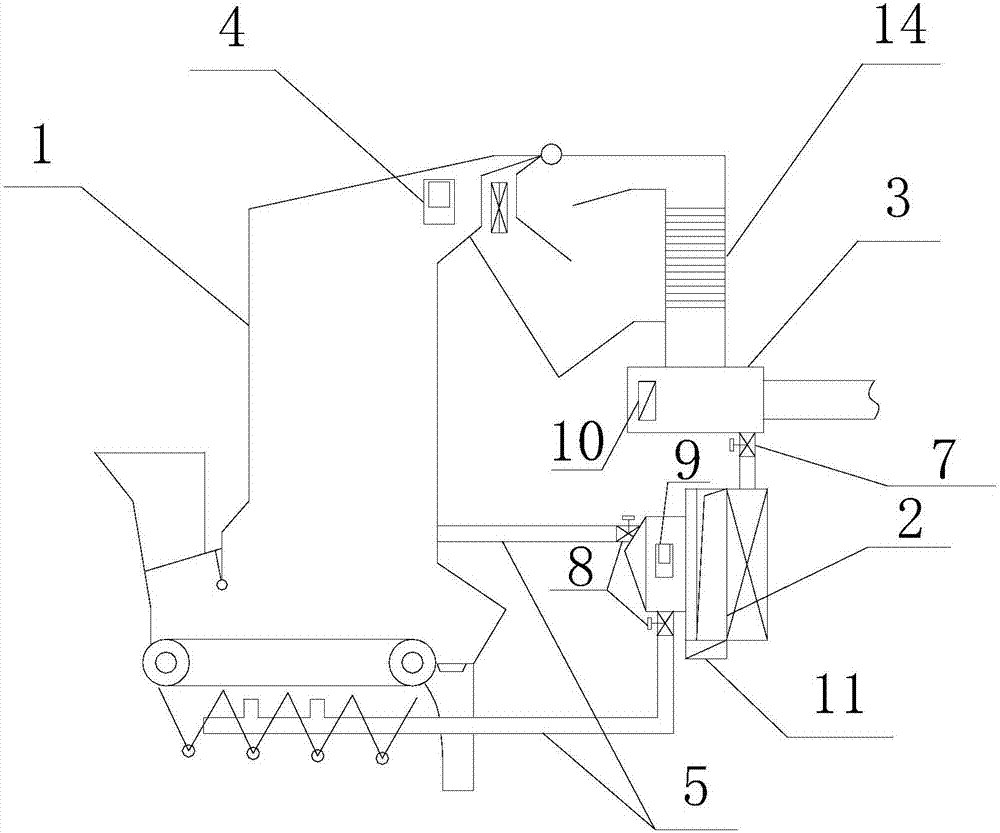

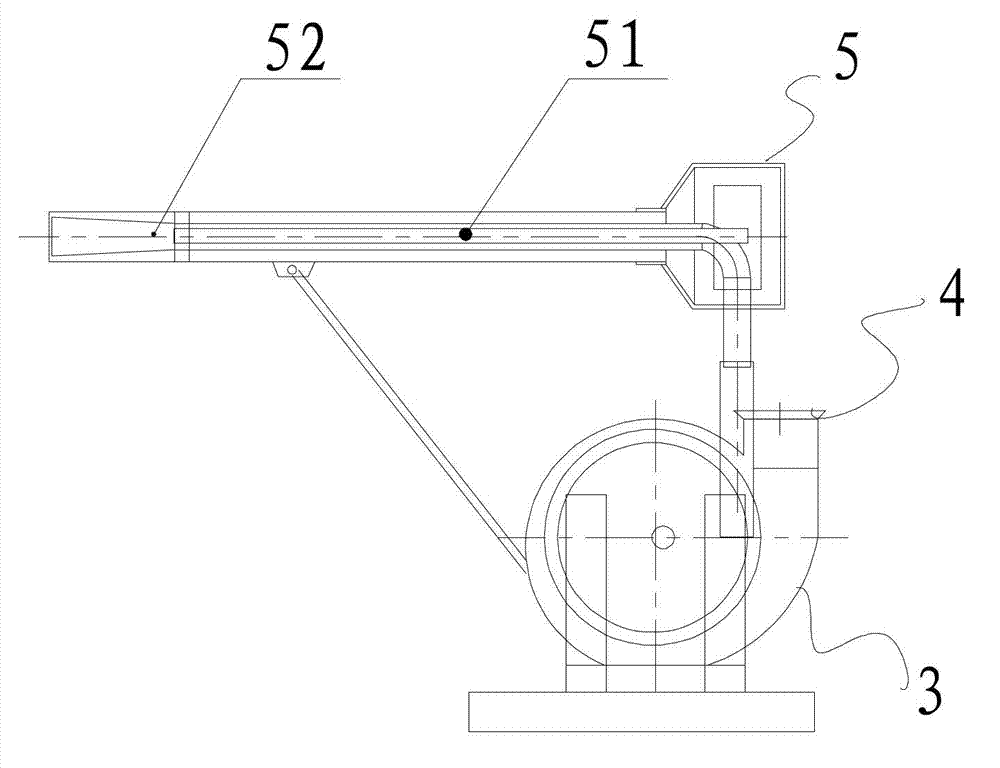

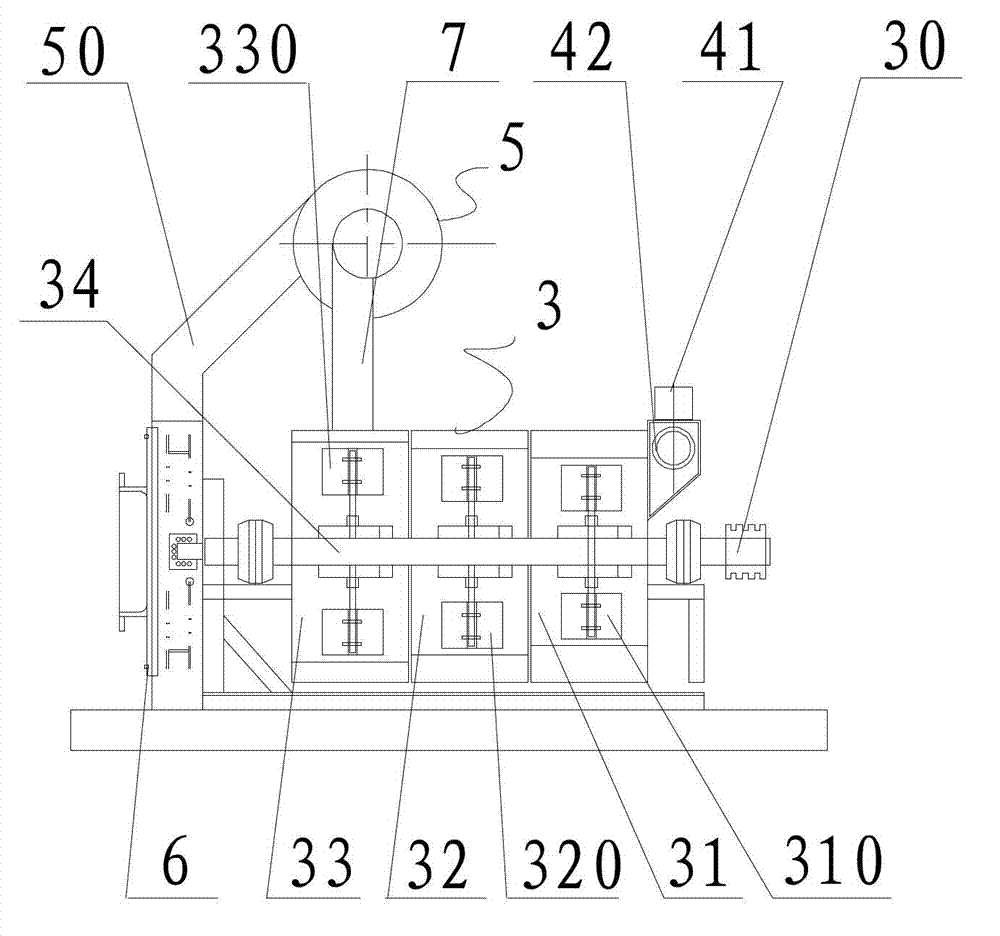

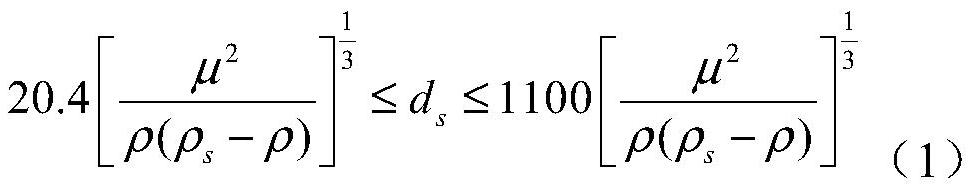

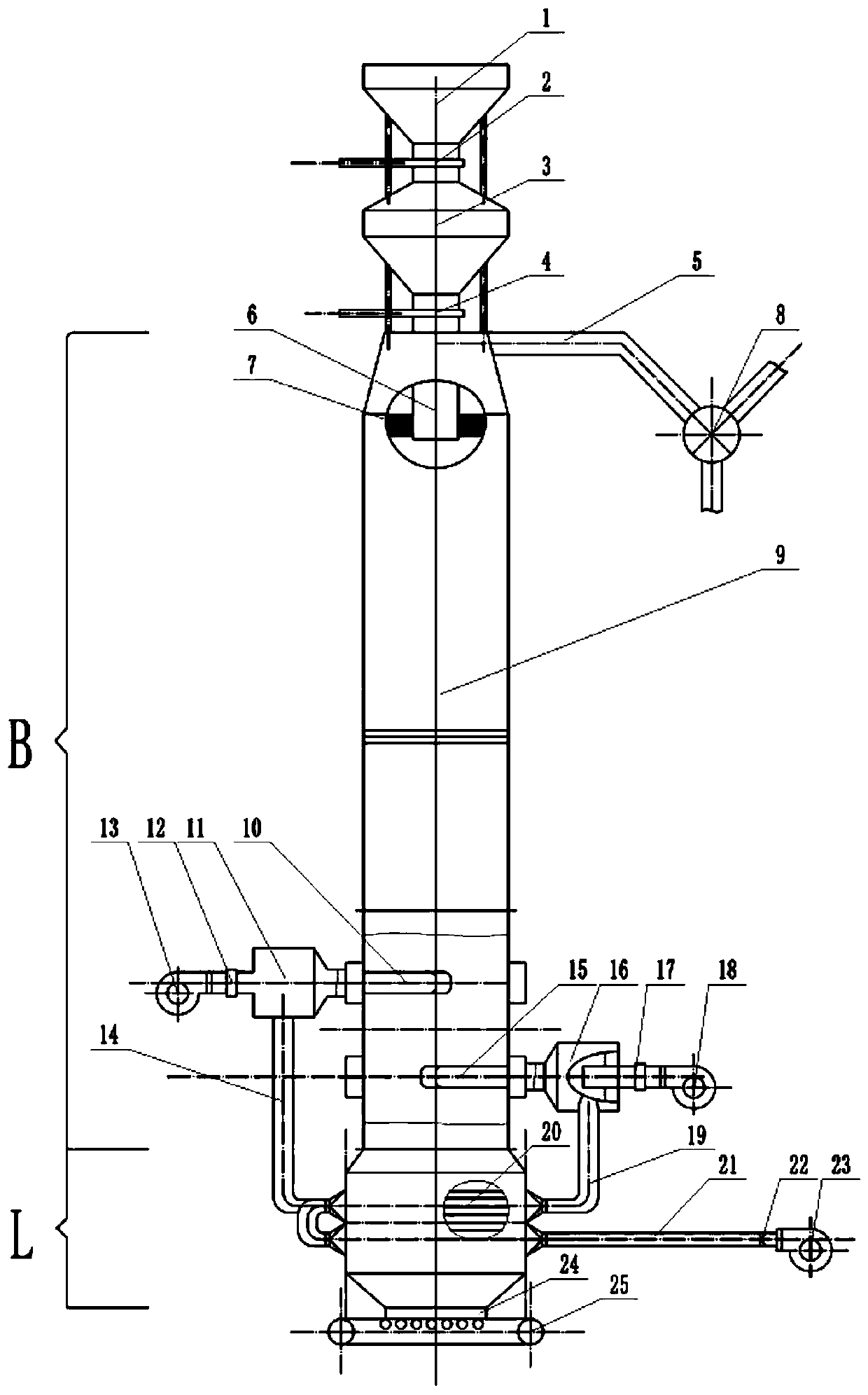

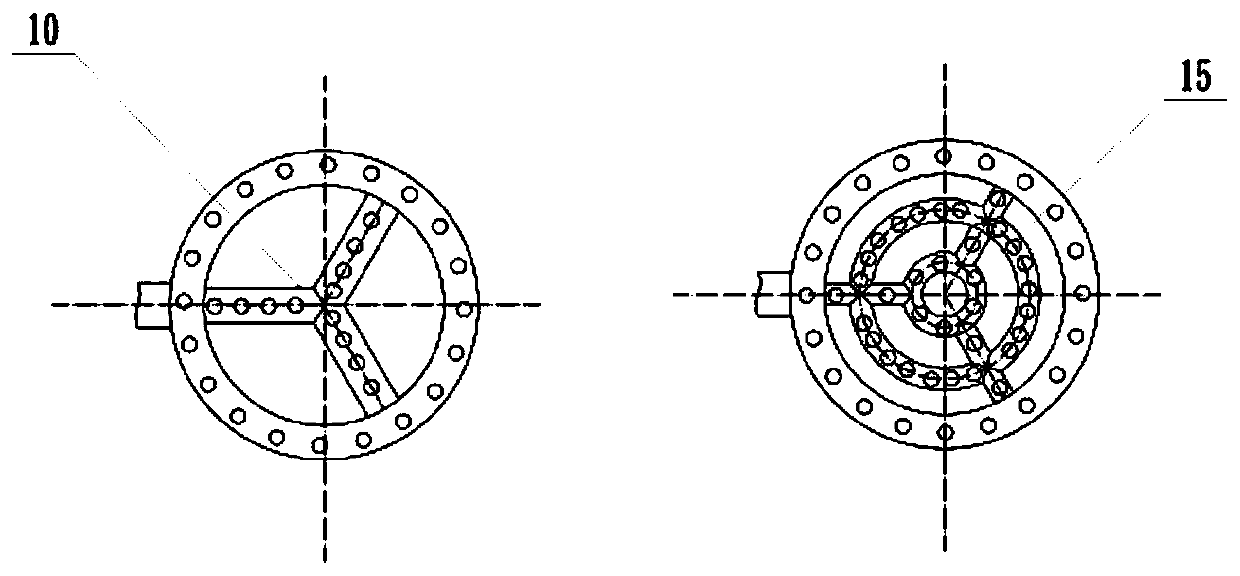

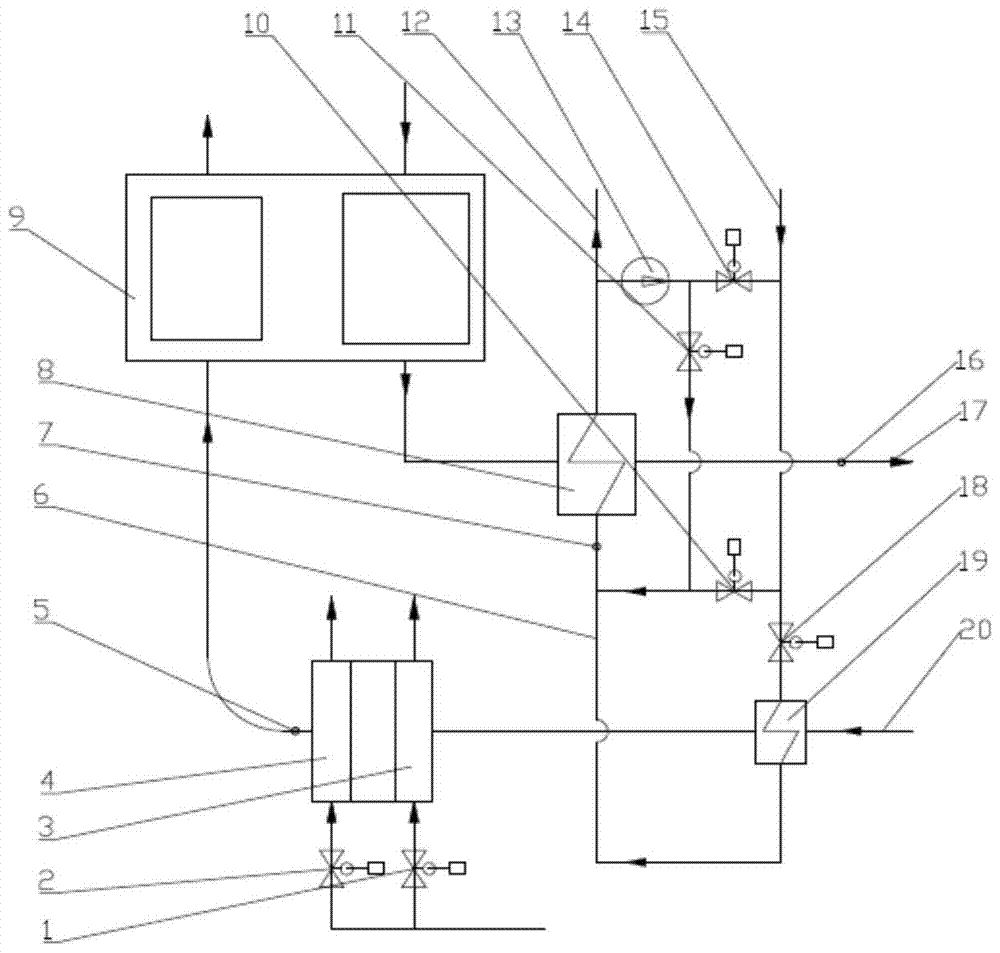

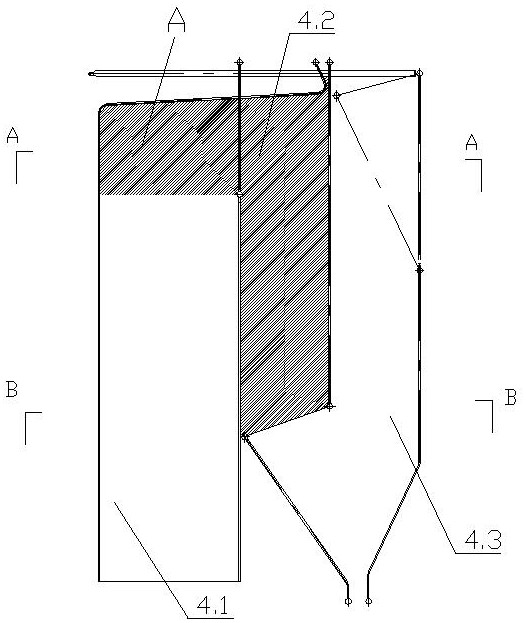

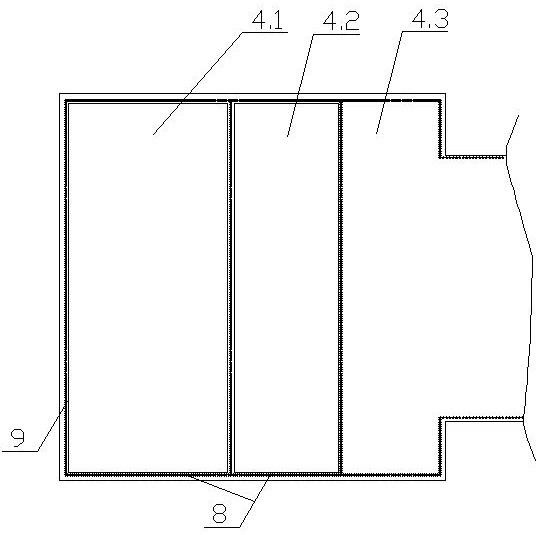

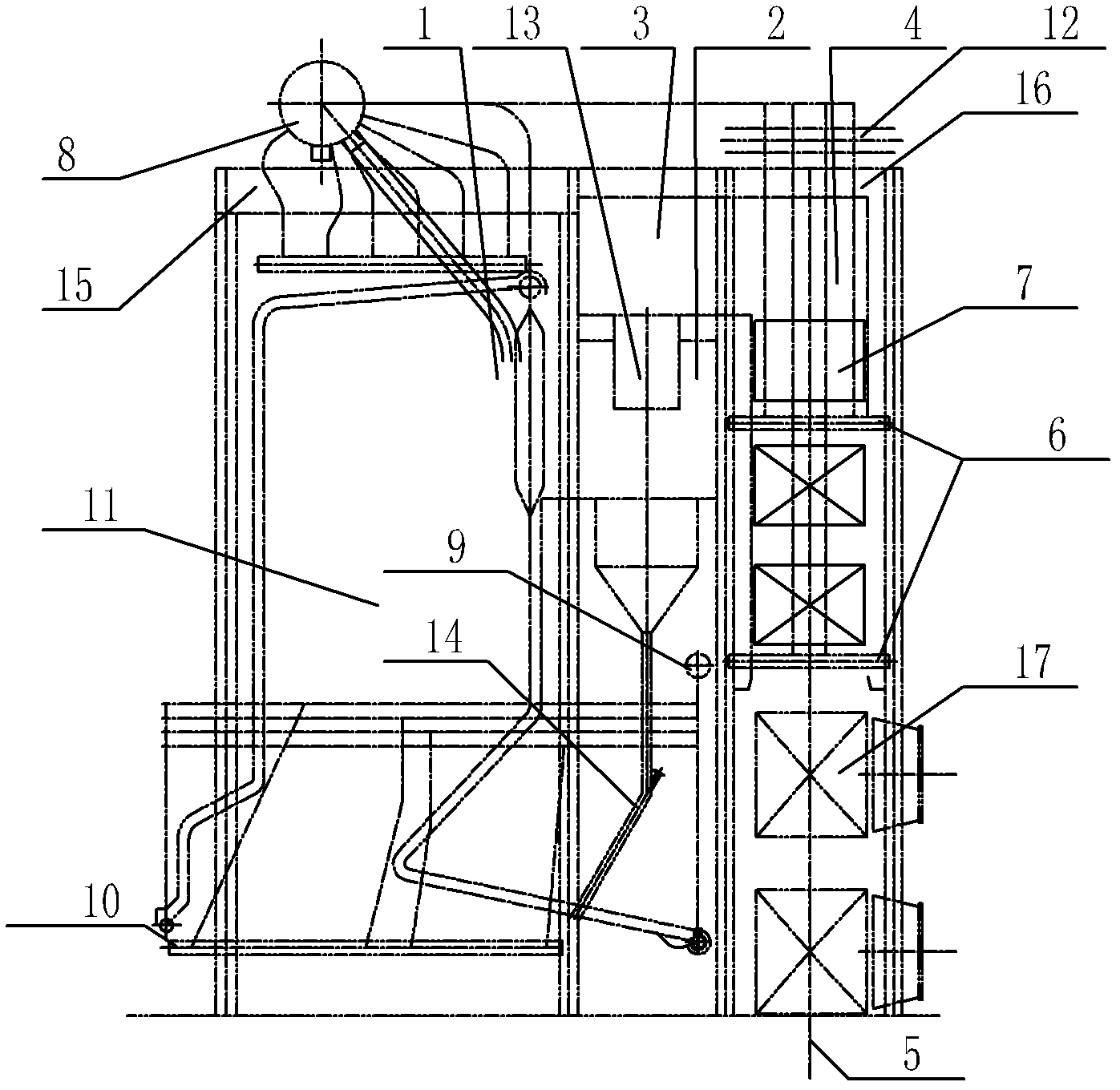

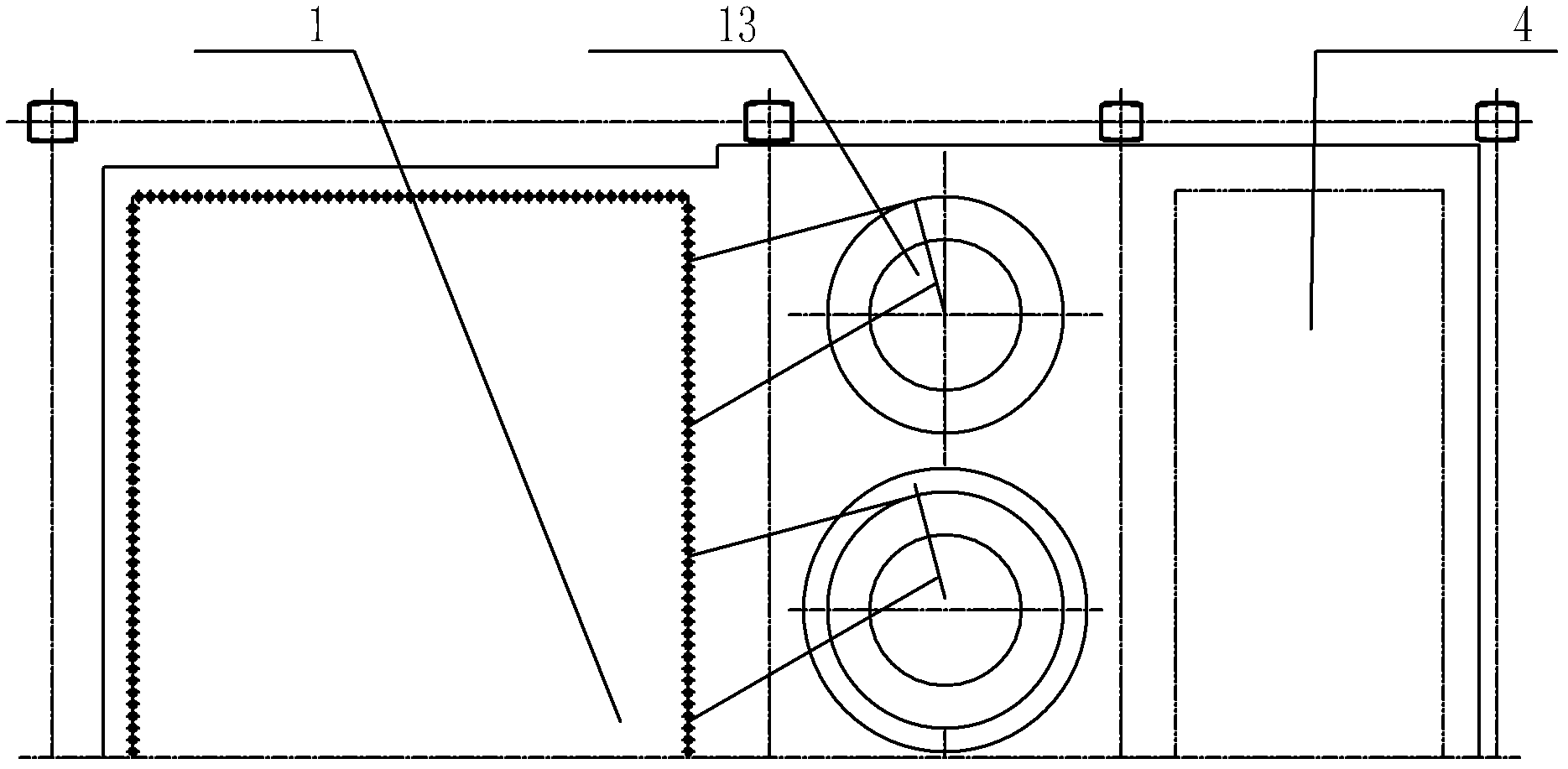

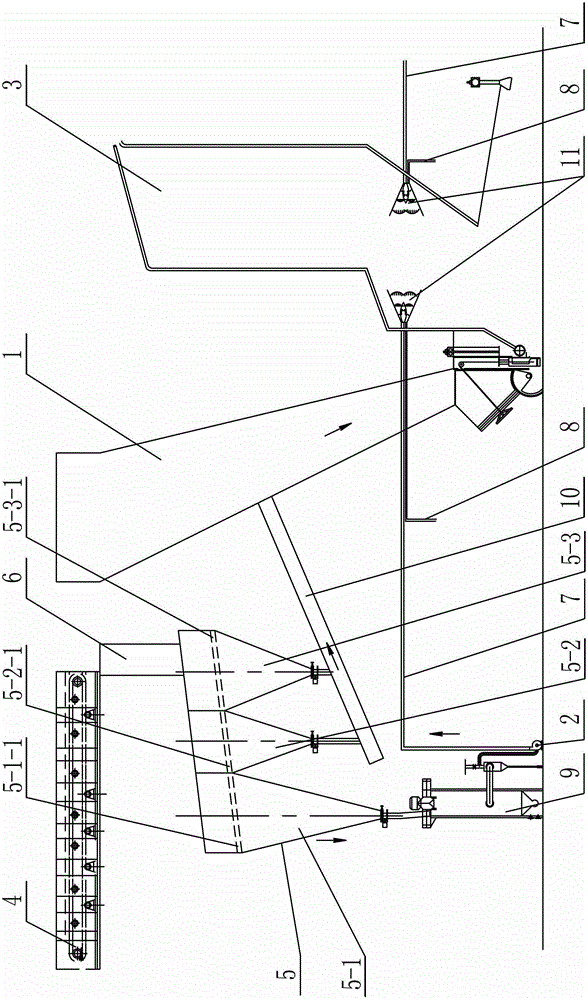

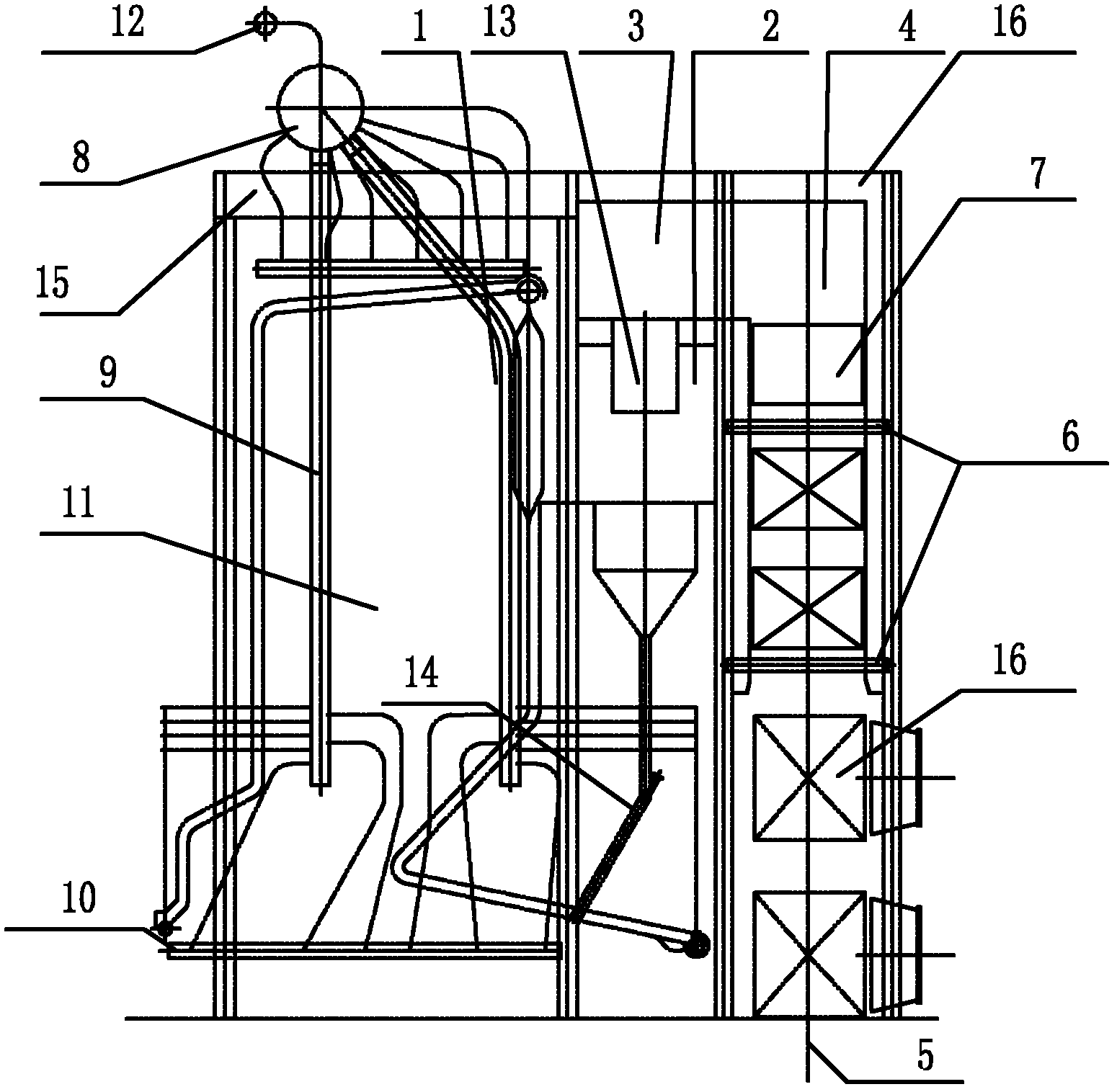

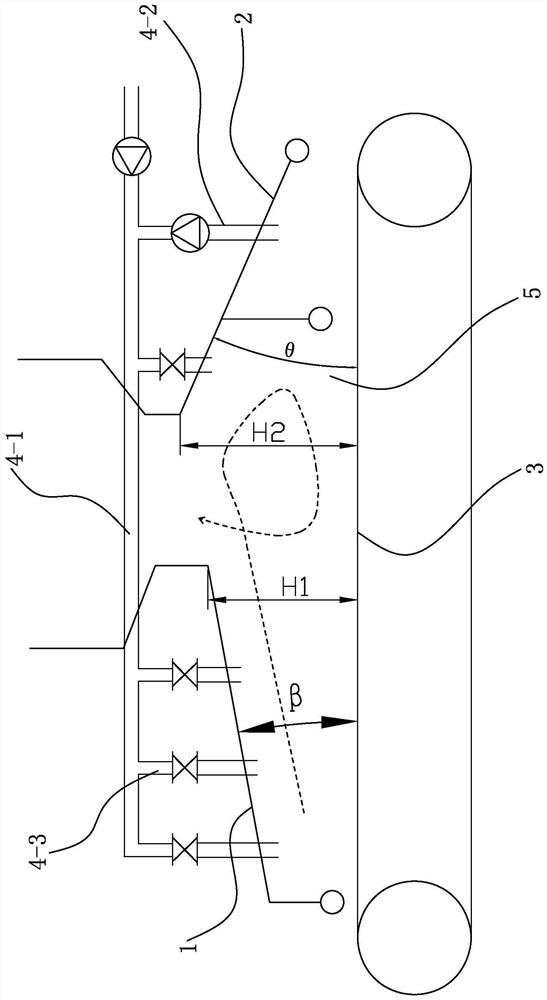

Device for NOx reduction and grate firing by stokehold screening, gasifying and reburning

ActiveCN102721040BReduce incomplete combustion lossesAchieve restorationSolid fuel combustionLump/pulverulent fuel preparationFixed bedSpray nozzle

A device for NOx reducing and grate firing by stokehold screening, gasifying and reburning belongs to the technical field of environment-friendly equipment and aims to realize the low NOx discharge amount and high efficiency burning of a grate firing industrial boiler. A stokehold screening and sorting device comprises a large-particle coal hopper, a medium-particle coal hopper and a small-particle coal hopper, wherein the medium-particle coal hopper is arranged between the large-particle coal hopper and the small-particle coal hopper, material inlet cavities of the large-particle coal hopper, the medium-particle coal hopper and the small-particle coal hopper are communicated with each other, a large-mesh screen is arranged in the large-particle coal hopper, a medium-mesh screen is arranged in the medium-particle coal hopper, the small-mesh screen is arranged in the small-particle coal hopper, a fire coal conveyer device is communicated with the small-particle coal hopper, the small-particle coal hopper and the medium-particle coal hopper are communicated with a spiral material conveyer which is communicated with a boiler coal hopper, the boiler coal hopper is communicated with a boiler, the large-particle coal hopper is communicated with a fixed bed gasification furnace, a gasifying gas outlet of the fixed bed gasification furnace is communicated with a gasifying gas spray nozzle by a fan and a gasifying gas pipeline, combustion air pipeline is communicated with the gasifying gas spray nozzle which is arranged in the boiler. The device is matched with the boiler for use.

Owner:HARBIN INST OF TECH

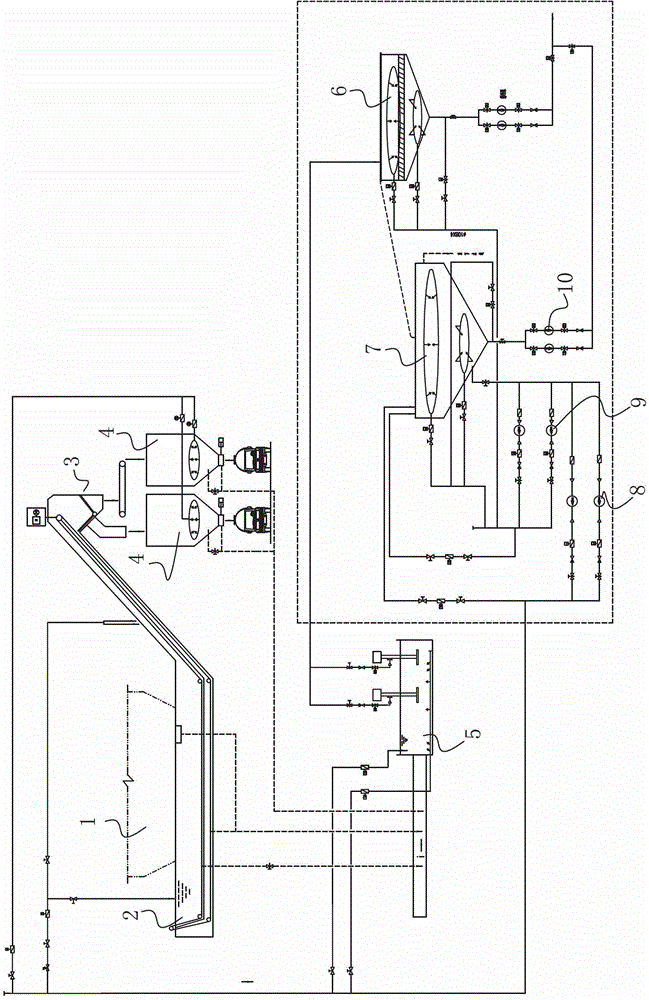

Air-water combined cooling and dry slag removal method and system for pulverized coal boiler

ActiveCN102954478BReduce incomplete combustion lossesImprove efficiencyLighting and heating apparatusAir volumePower station

The invention relates to an air-water combined cooling dry slagging method and a system of a pulverized coal boiler. The method comprises the following steps of primarily adopting an air-cooling steel-strip (chain plate) slag cooling machine to pre-cool and withdraw the slag of the boiler; adopting a roller-type slag cooler to further cool the slag after precooling; and finally directly transporting or conveying the slag after being cooled through the roller-type slag cooler to a slag cabin. The slag from the boiler is conveyed to a transitional slag bucket through the air-cooling steel-strip slag cooling machine, then the slag enters the roller-type slag cooler, and finally the hot air being heated by the slag enters a boiler hearth to be burned. The cooling water of the rotary-type slag cooler is from a condensed water (or other cooling medium) system in a power plant, and the cooling water is returned to a heat power system of the power plant after being heated by the slag. Due to the adoption of the method and the system, the problems that the air volume of a dry slagging system is difficult to control and side effect is produced on the burning of the boiler can be solved, the waste heat of the slag can be recycled, the unit efficiency can be improved, and the power generation coal consumption can be reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

Natural circulation type hot water boiler structure

The invention relates to a natural circulation type hot water boiler structure comprising a hearth. The natural circulation type hot water boiler structure is characterized in that a cyclone separator is arranged at an outlet of the hearth, the outlet end of the cyclone separator is communicated with a horizontal flue, a tail vertical shaft is arranged at one side of the horizontal flue, an economizer is installed in the tail vertical shaft, an air preheater is installed at the bottom part of the tail vertical shaft, and a flue gas outlet is arranged at the lower part of the air preheater; and an economizer header is installed at the lower part of the economizer, the economizer header is connected with a boiler barrel at the upper end of the hearth by a connecting pipe, a boiler pipe is connected with a lower header of a water cooling wall by a centralized downcomer at the outside of the hearth, the lower header of the water cooling wall is connected with a water inlet of the water cooling wall, a water outlet at the upper end of the water cooling wall is connected with the boiler barrel, and a water outlet of the boiler barrel is connected with the hot water outlet header at the top part of the tail vertical shaft. According to the natural circulation type hot water boiler structure, the height of the tail vertical shaft is decreased, the height of the hearth is decreased, the metal consumption quantity of the boiler main body is reduced, the imperfect combustion loss of the boiler machinery is reduced, and the boiler efficiency is improved.

Owner:WUXI HUAGUANG IND BOILER

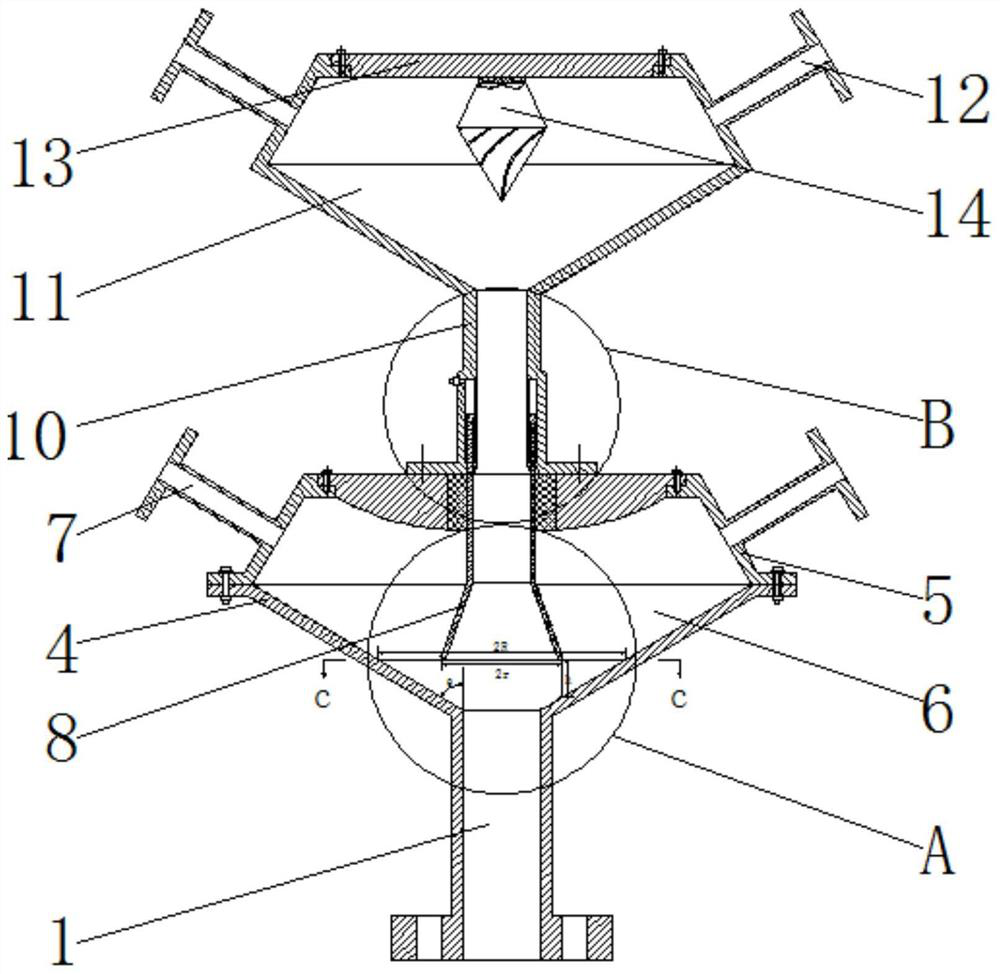

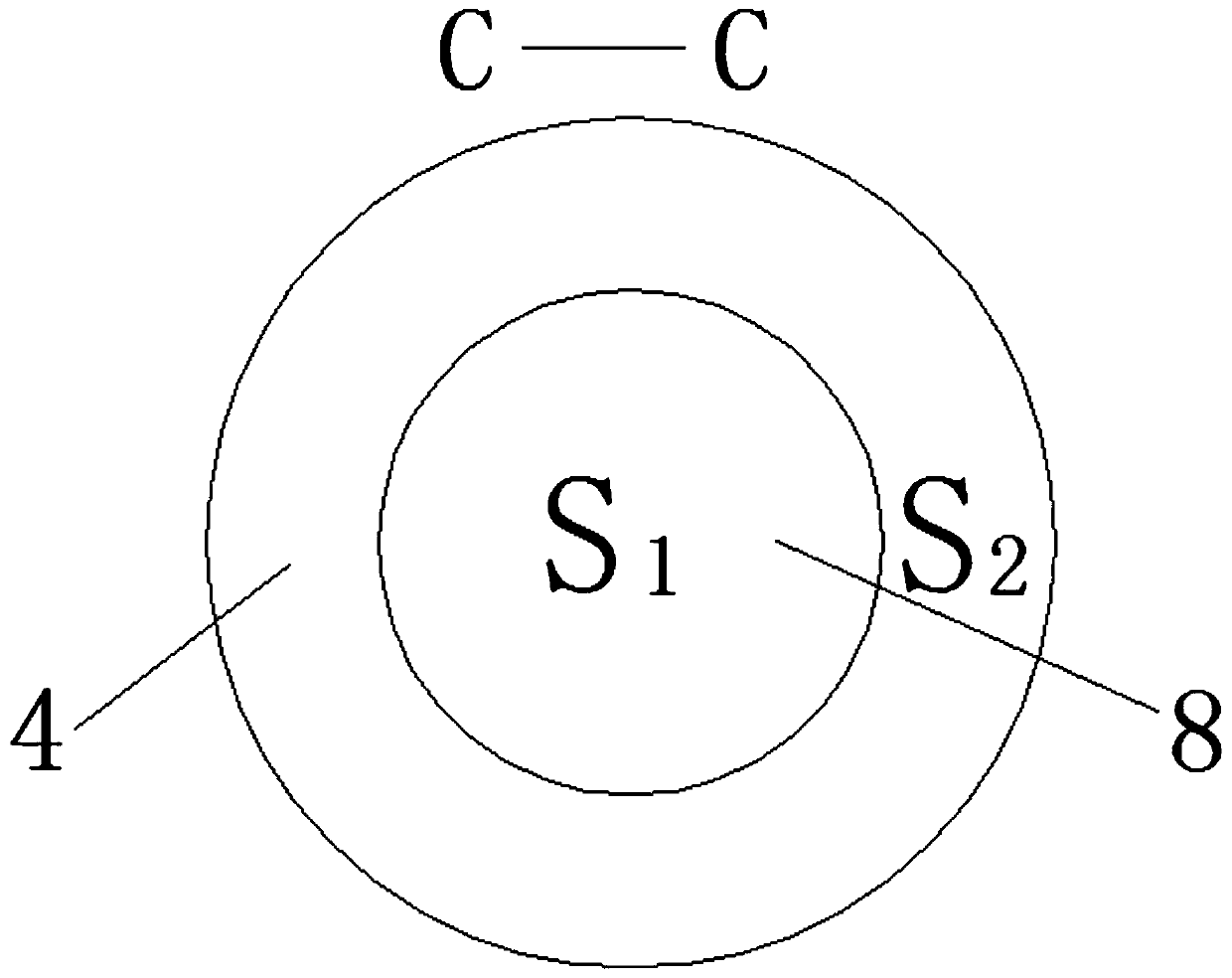

Coal powder distributor for coal-fired blast furnace

ActiveCN111174227BRealize the separation of thick and lightLow running costFuel feeding arrangementsLump/pulverulent fuel feeder/distributionThermodynamicsCombustion

The invention relates to the technical field of coal-fired blast furnaces, and discloses a pulverized coal distributor for a coal-fired blast furnace. The upper cover is installed. Through the arrangement of the first distribution chamber, the movable standpipe and the second distribution chamber, the primary air entering from the air inlet main pipe and the pulverized coal carried by it are divided into two parts with different concentrations, so as to realize the separation of the concentration of the pulverized coal, and then The first distribution chamber and the second distribution chamber are evenly distributed and then transferred from the first distribution air duct and the second distribution air duct to the boiler respectively. Concentration of pulverized coal is ignited to improve the low-load and warm combustion capacity of combustion, and at the same time, it can achieve stable ignition of inferior coal, improve combustion efficiency, reduce blast furnace operating costs, and improve the utilization rate of inferior coal.

Owner:山西晋钢智造科技实业有限公司

Combustion system and method of inverted-alpha shaped flame air distribution type layered boiler

ActiveCN112432159APrevent getting involvedRaise the combustion temperatureSolid fuel combustionIndirect carbon-dioxide mitigationCombustion systemAir preheater

The invention discloses a combustion system and method of an inverted-alpha shaped flame air distribution type layered boiler, and belongs to the technical field of boilers. The combustion system comprises a front arch, a rear arch, a fire grate and an air distribution system, wherein the front arch and the rear arch are separately arranged aslant; the top height of the front arch is less than that of the rear arch; the rear arch is shorter than the front arch; an included angle of the front arch and the rear arch is an obtuse angle; the front arch, the rear arch and a partitioning plate are divided into a front zone and a rear zone, the front zone is a combustion zone and the rear zone is a cooling area; the air distribution system comprises a main pipe, air blowers, a fume exhaust pipe and a plurality of air distribution pipes; the fume exhaust pipe and one end of each of the plurality of air distribution pipes are connected with the main pipe; the other end of each of the pluralityof air distribution pipes extends into a combustion chamber from the front arch or the rear arch; an adjusting valve is arranged on the each air distribution pipe; the other end of the fume exhaust pipe extends into a cooling fume exhaust zone, the main pipe communicates with an air pre-heater of an existing boiler; and the air blowers are separately arranged on the main pipe and the fume exhaustpipe. According to the system and the method disclosed by the invention, generation of nitrogen oxide can be reduced, and fume exhaustion loss is reduced.

Owner:HARBIN INST OF TECH

Pulverized coal distributor for coal-fired blast furnace

ActiveCN111174227ARealize the separation of thick and lightLow running costFuel feeding arrangementsLump/pulverulent fuel feeder/distributionThermodynamicsCombustion

The invention relates to the technical field of coal-fired blast furnaces, and discloses a pulverized coal distributor for a coal-fired blast furnace. The pulverized coal distributor comprises an airinlet main pipe, wherein a bottom inclined body is fixedly mounted at the top of the air inlet main pipe, and an upper sealing cover is fixedly mounted at the top of the bottom inclined body through bolts. Through the arrangement of a first distribution chamber, a movable vertical pipe and a second distribution chamber, primary air entering from the air inlet main pipe and pulverized coal carriedby the primary air are divided into two parts with different concentrations, concentration separation of the pulverized coal is achieved, after the pulverized coal is uniformly distributed in the first distribution chamber and the second distribution chamber, the pulverized coal is conveyed into a boiler from a first distribution air pipe and a second distribution air pipe, the ignition temperature and the ignition heat of the concentrated pulverized coal are low, so that the concentrated pulverized coal is ignited firstly and then the low-concentration pulverized coal is ignited, and the low-load warm combustion capacity of combustion is improved; and meanwhile, stable ignition of inferior coal can be realized, the combustion efficiency is improved, the blast furnace operation cost is reduced, and the utilization rate of inferior coal is increased.

Owner:山西晋钢智造科技实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com