Powdery straw cleaning combustor

A burner and straw technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problems of incomplete combustion loss of solids, large and complex feeding system, slagging and contamination of heating surfaces, etc., to achieve The effect of increasing the volumetric thermal strength, alleviating slagging and contamination, and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention rather than limit the scope of the present invention, and those skilled in the art can make some non-essential improvements and adjustments based on the content of the above invention.

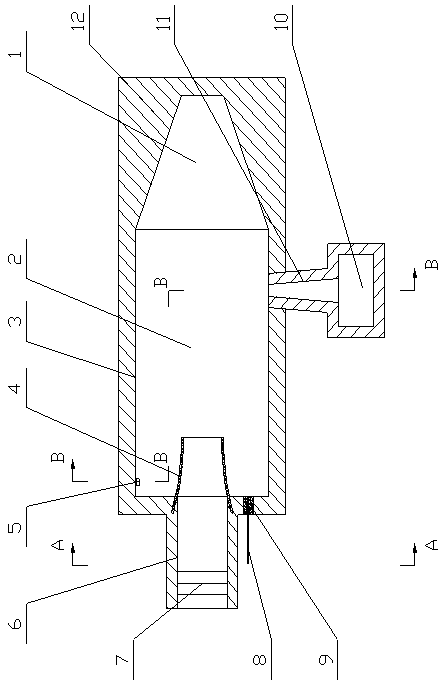

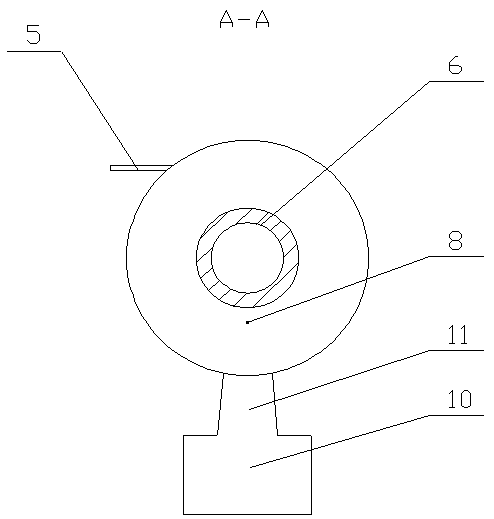

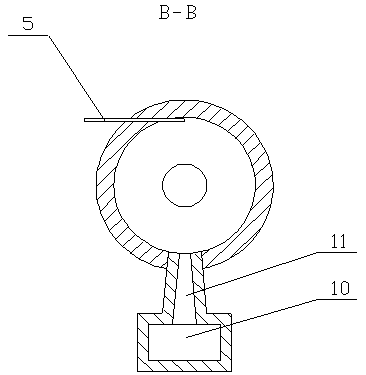

[0041] like Figure 1-3 As shown, the powdered straw cleaning burner of the present invention includes a burner body, and the burner body includes a burner casing 12, a combustion chamber located in the burner casing 12 and a flue gas outlet 6, and the combustion chamber includes a circular The cylinder part 2 and the conical part 1, the burner casing near the flue gas outlet 6 of the combustion chamber is provided with a primary air inlet pipe 8 and a secondary air inlet pipe 5, and the primary air inlet pipe 8 is in contact with the burner casing 12 The burner brick 9 is set; the primary a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com