Coal thermal decomposition grate firing apparatus and its combustion method

A technology of coal pyrolysis and pyrolysis chamber, which is applied in the field of coal pyrolysis layer combustion devices, can solve the problems of increasing the complexity of the overall equipment volume, the influence of semi-coke fluidity and fluidization, poor economy and popularization, etc., to achieve Avoid desulfurization agent deactivation, simple structure, reduce the effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

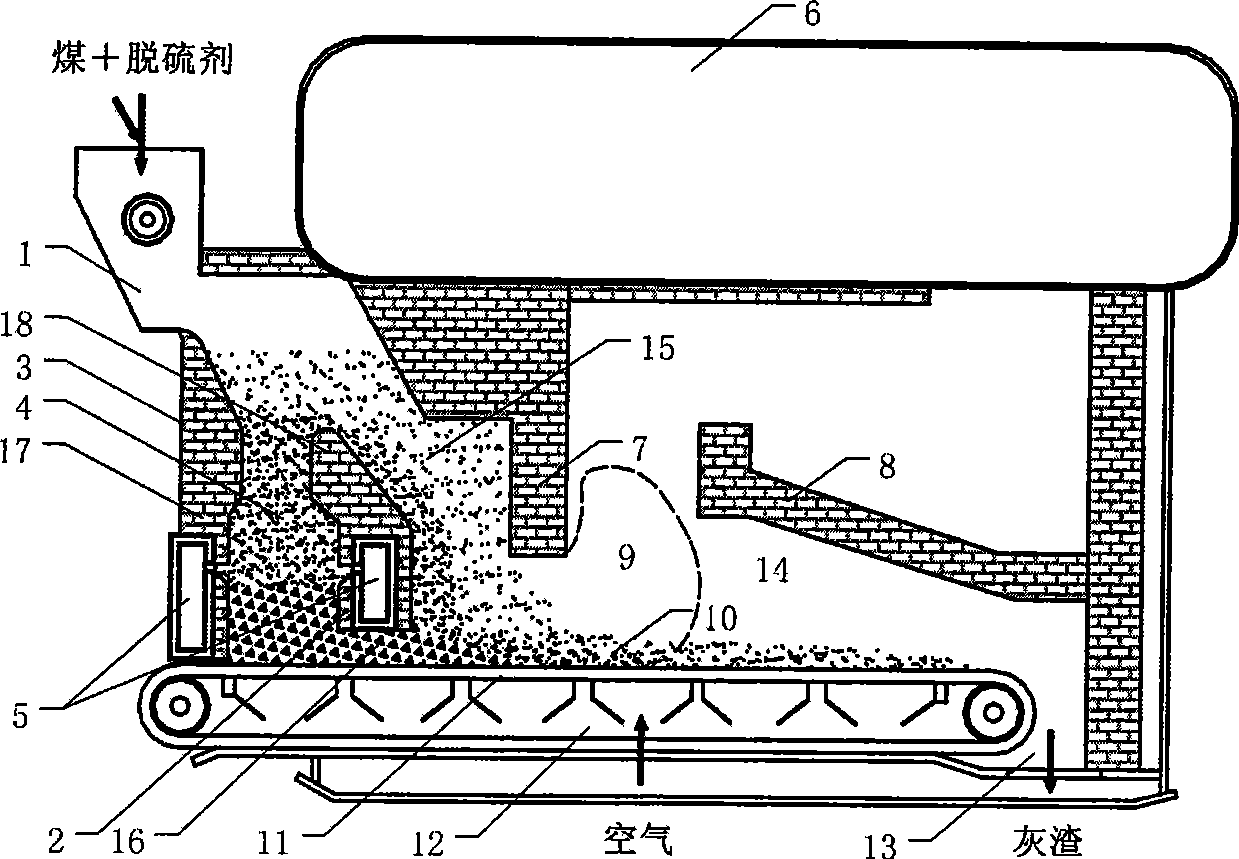

[0042] The coal pyrolysis layer combustion device of the present embodiment is as figure 1As shown, it includes: a layer of combustion furnace body 3, the interior of the furnace body 3 is divided into an upstream oxidation pyrolysis chamber 4 and a downstream layer combustion chamber 14 by a partition wall 2, and the oxidation pyrolysis chamber 4 is located at the front section of the mechanical grate 11 Above, it communicates with the layer combustion chamber 14 through the upper communication port 15 and the lower communication port 16, and the lower part of the oxidation pyrolysis chamber 4 is provided with an air supply device 5 arranged in the double-sided wall, and the air supply device 5 is respectively arranged in front of the layer combustion furnace. Two in-wall air chambers in the wall 17 and the partition wall 2 form. The partition wall 2 is provided with a reduced diameter 18 above the air supply device 5 to enhance the gas-solid mixing effect in the oxidation py...

Embodiment 2

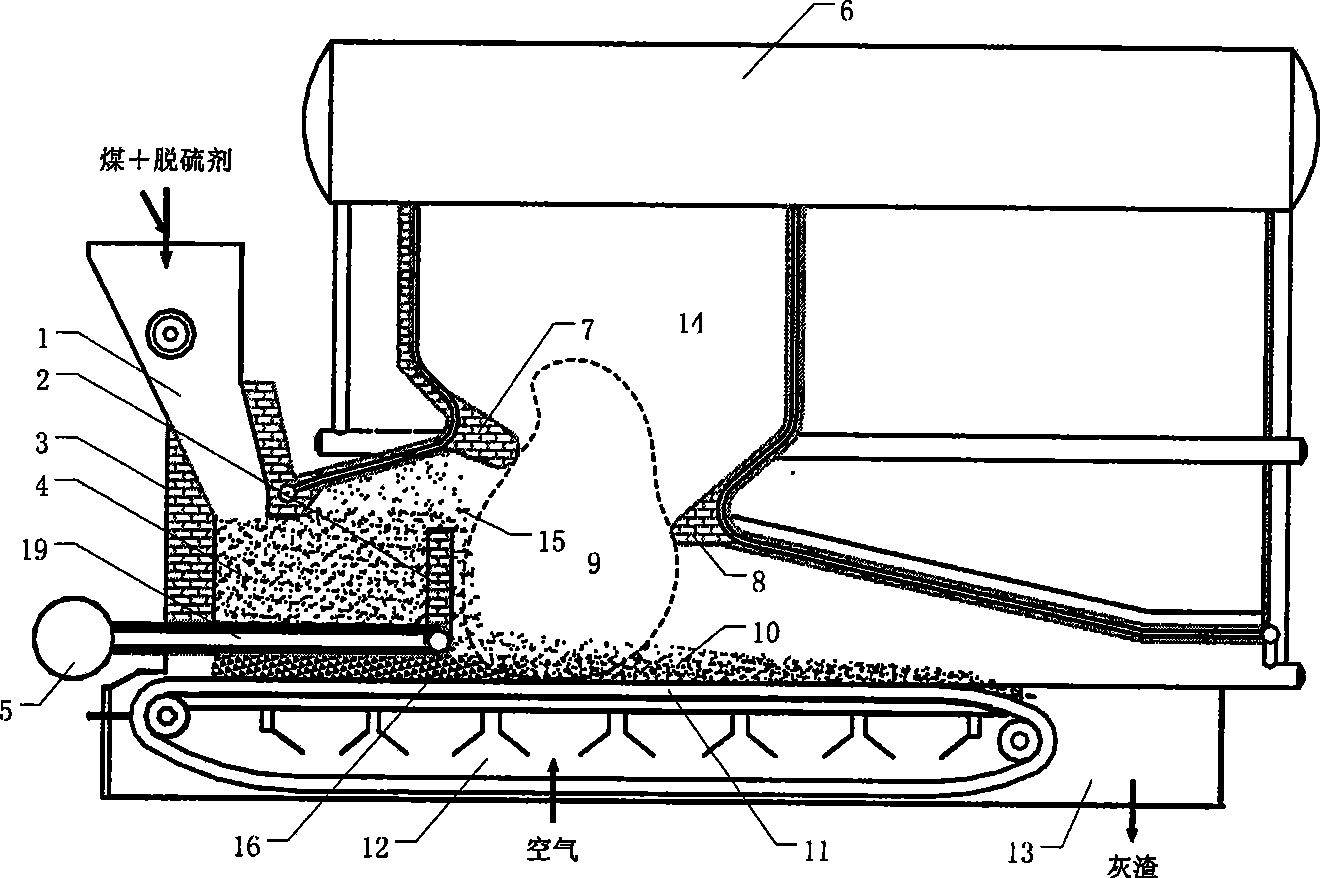

[0049] The coal pyrolysis layer combustion equipment of this embodiment is as figure 2 As shown, it includes a furnace body 3 and a hopper 1, the bottom of the furnace body 3 is provided with a mechanical fire grate 11 and an air chamber 12, the rear section of the fire grate 11 is covered with a semi-coke layer 10, and the inside of the furnace body 3 is covered by a partition wall 2 is divided into an oxidation pyrolysis chamber 4 and a layer combustion chamber 14, the lower part of the hopper 1 communicates with the oxidation pyrolysis chamber 4, and the oxidation pyrolysis chamber 4 communicates with the layer through the upper communication port 15 and the lower communication port 16 Combustion chamber 14 communicates, is provided with front arch 7 near described upper communication port 15 in layer combustion chamber 14, and described front arch 7 becomes 45 ° with horizontal direction, and also is provided with and horizontal direction in layer combustion chamber 14 and...

Embodiment 3

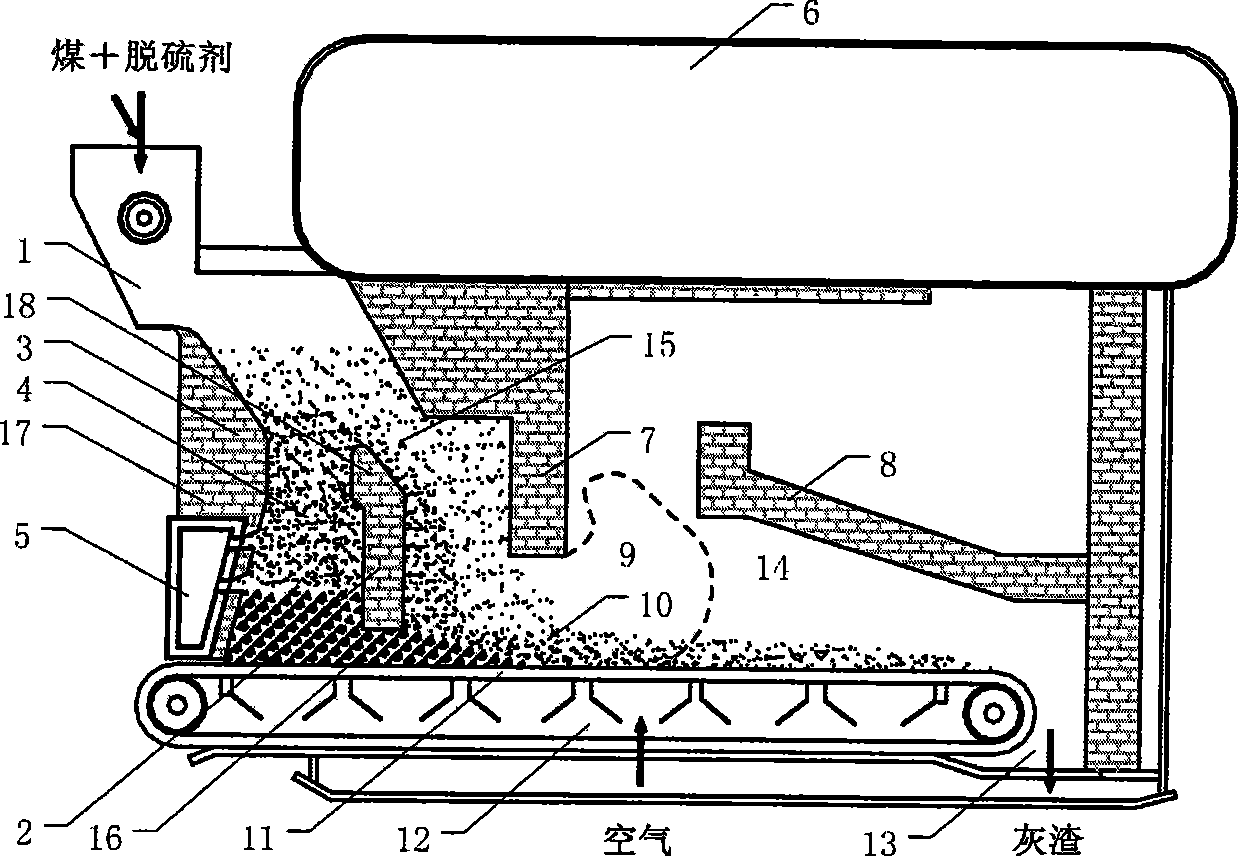

[0051] The oxidation pyrolysis chamber 4 of the coal pyrolysis layer combustion equipment of the present embodiment is a fixed bed, adopts the air supply device 5 arranged in the single wall, such as image 3 As shown, the air supply device 5 is composed of an in-wall air chamber arranged in the front wall 17 of the layered combustion furnace, and other structures are the same as in Embodiment 1. The air supply device arranged in a single wall is suitable for smaller-scale layer-fired furnaces, and has a simple structure. During the combustion process, the smaller semi-coke particles and combustible gas generated by the pyrolysis of coal in the oxidation pyrolysis chamber overflow from the upper communication port 15 or are entrained by the air flow into the layer combustion chamber 14, while the generated large-size semi-coke particles pass through The peroxidation pyrolysis chamber falls behind the front section of the mechanical grate 11 below, and along with the movement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com