Patents

Literature

55results about How to "No increase in size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

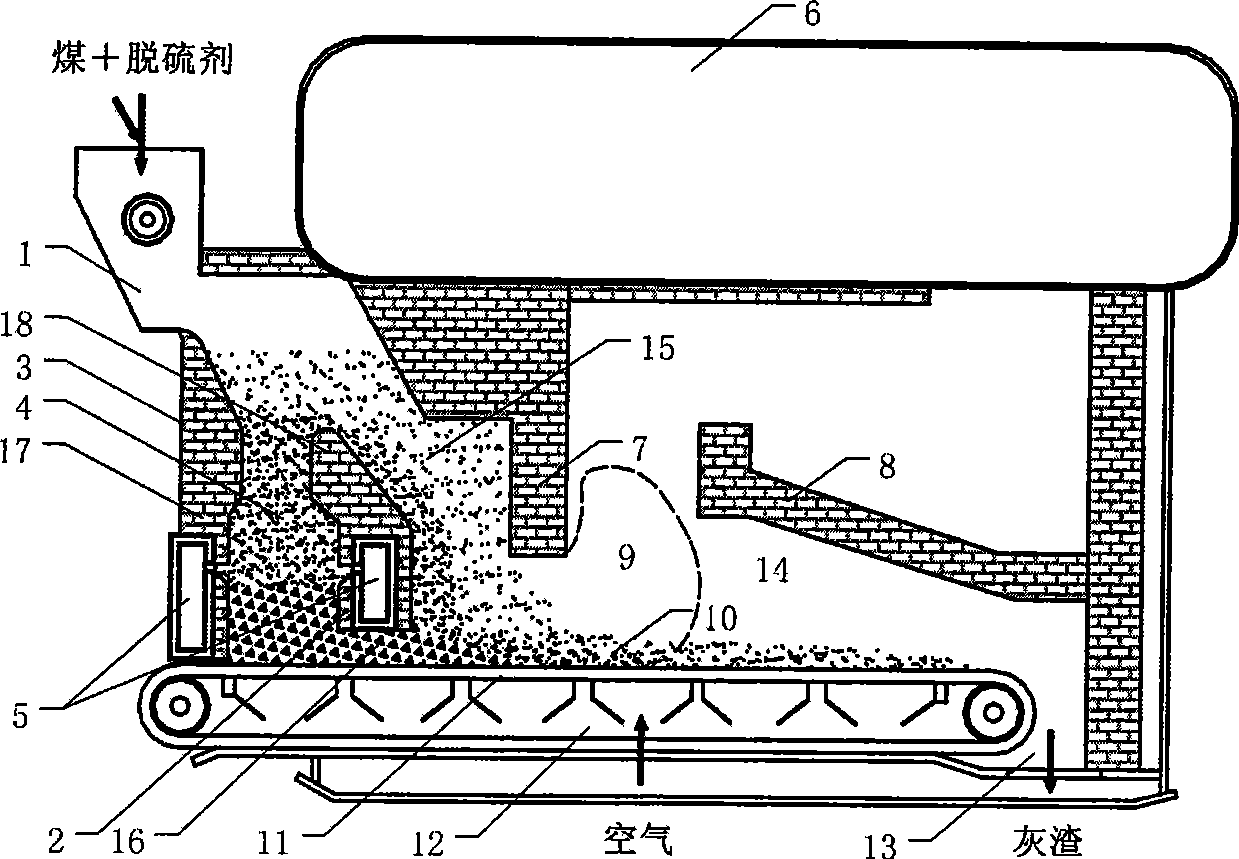

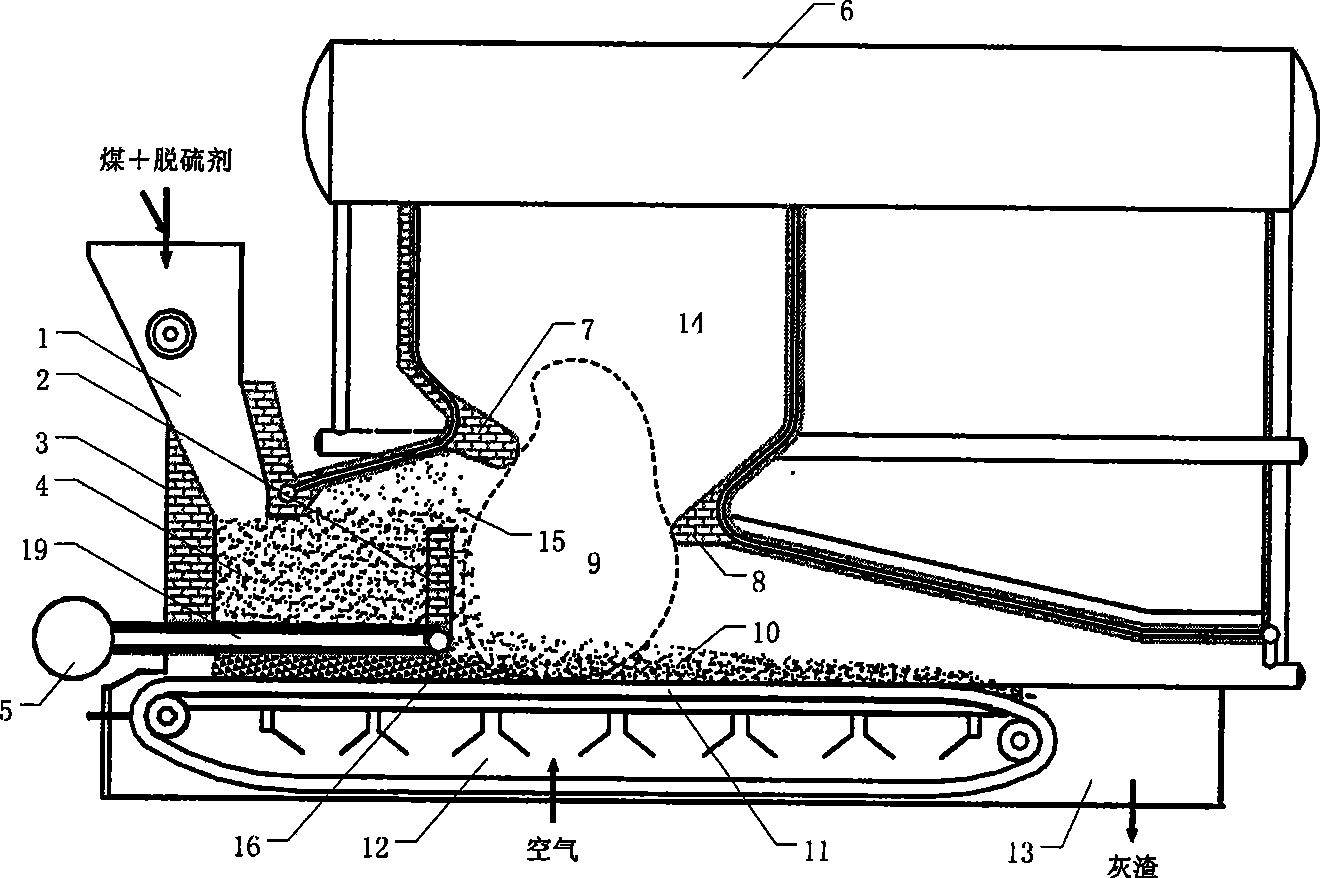

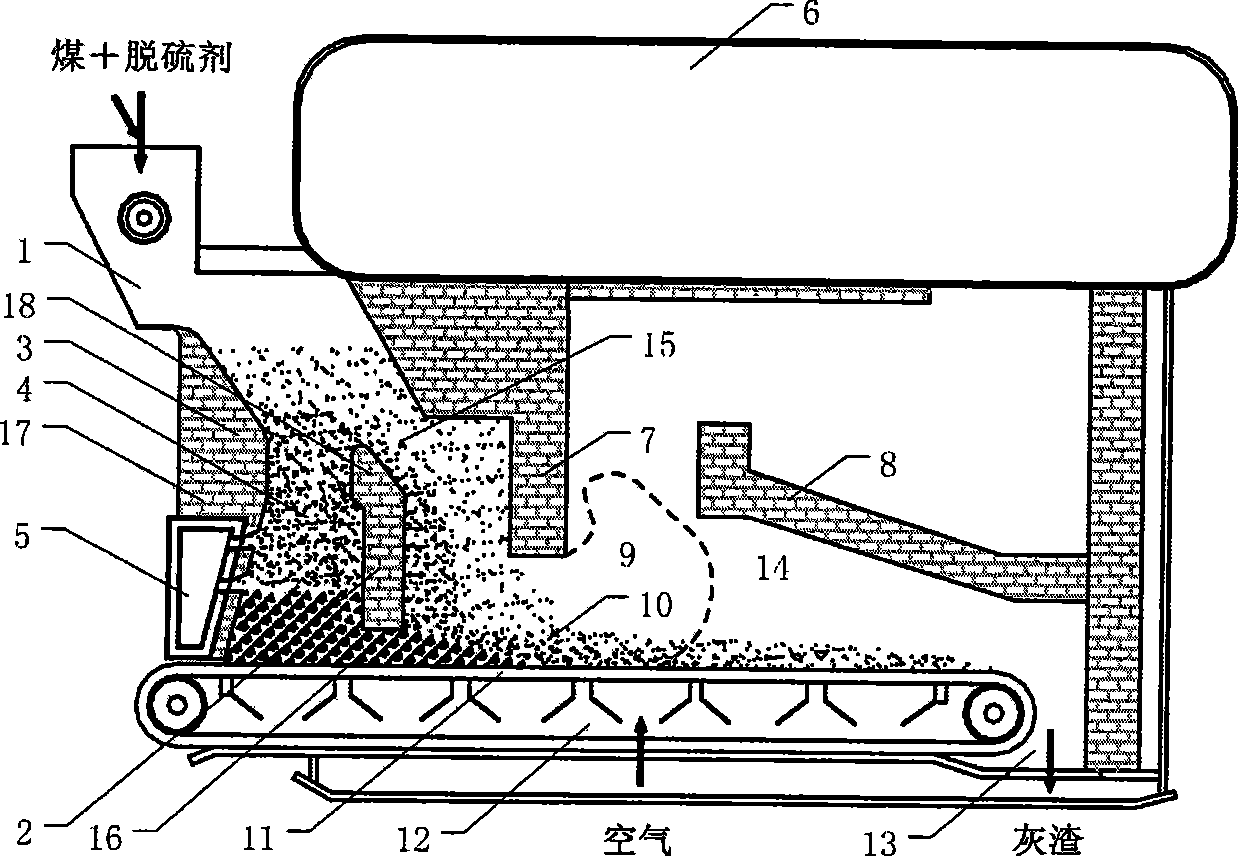

Coal thermal decomposition grate firing apparatus and its combustion method

InactiveCN101368724ASimple structureNo increase in sizeSolid fuel combustionCombustion apparatusCombustion chamberCombustible gas

The invention relates to a coal pyrolysis layer combustion device and the combustion method thereof, including that the furnace body interior of the first layer combustion furnace is divided into an upper oxidation pyrolysis chamber and a lower fire grate layer combustion chamber which is communicated with each other; the coal and desulfurizer are mixed to be fed into the middle part of the oxidation pyrolysis for oxidation pyrolysis through a hopper; the generated combustible gas and the smaller semi-coke particles are overflowed through the upper-connected through port or are carried in the airflow to be fed into the mechanical fire grate layer combustion chamber; the bigger semi-coke particles fall on the mechanical fire grate and are fed into the layer combustion layer for combustion; the mechanical fire grate layer combustion chamber is provided with a front arch and a back arch for organizing the airflow field inside the furnace; the coal pyrolysis layer combustion device and the combustion method thereof adopt the fluidization characteristics of the coal particles with different particle diameters and the high thermal capacity characteristic inside the oxidation pyrolysis chamber to realize the natural separation of the coal particles with different particle diameters and the rapid oxidation pyrolysis of coal, reduce the fire grate coal leakage loss and the incomplete combustion loss caused by the front segment low temperature of the fire grate and reduce the emission of the SOx and NOx pollutant through the combination of the pyrolysis desulfurization and the combustion desulfurization, and the reburning denitration formed by the coal pyrolysis product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

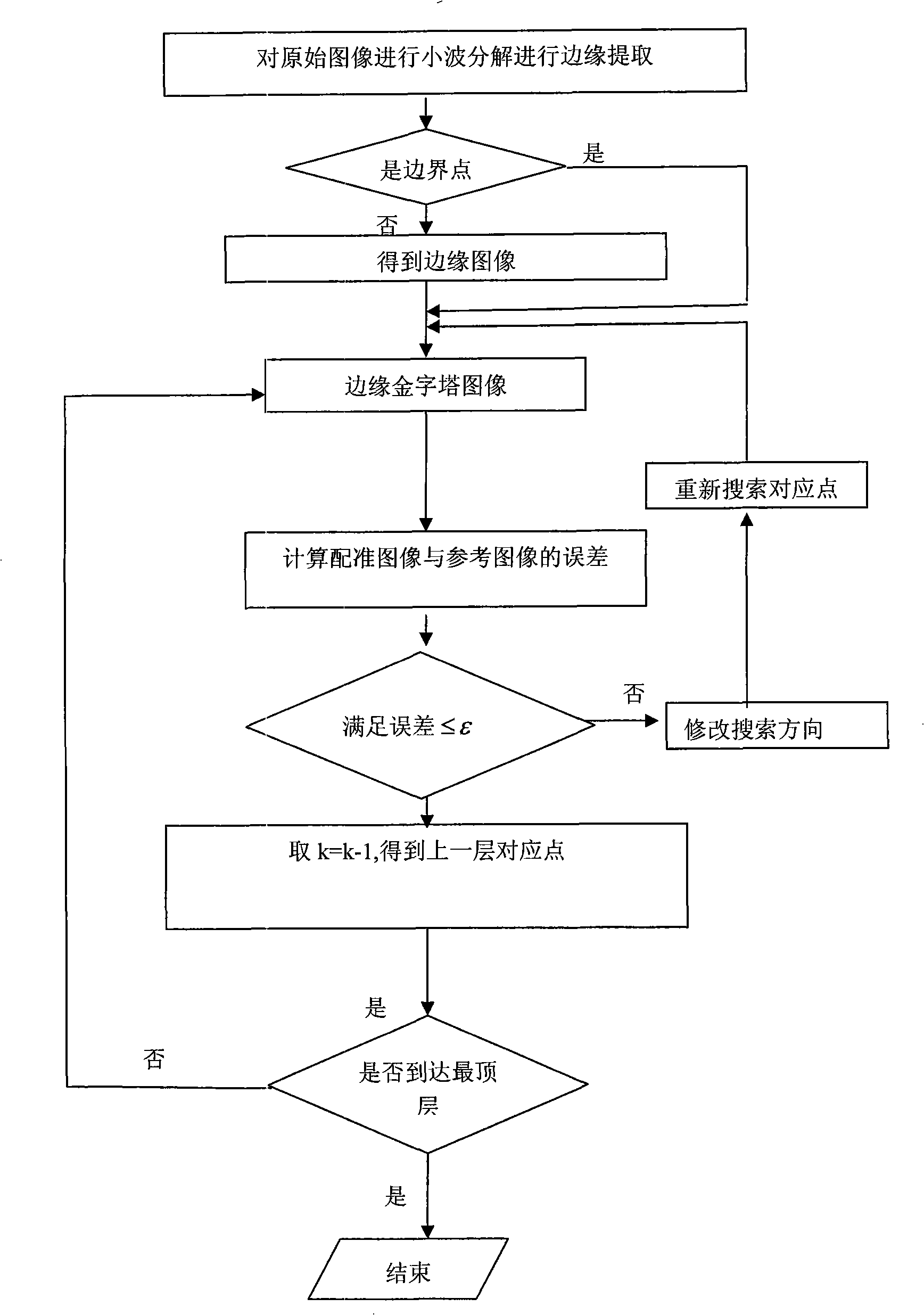

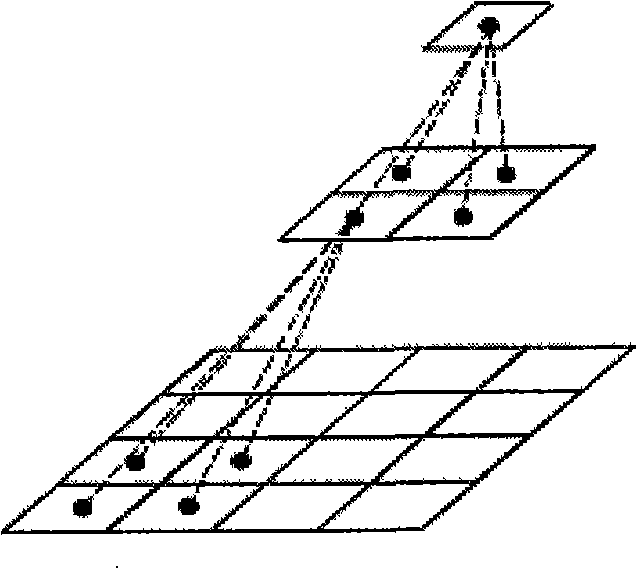

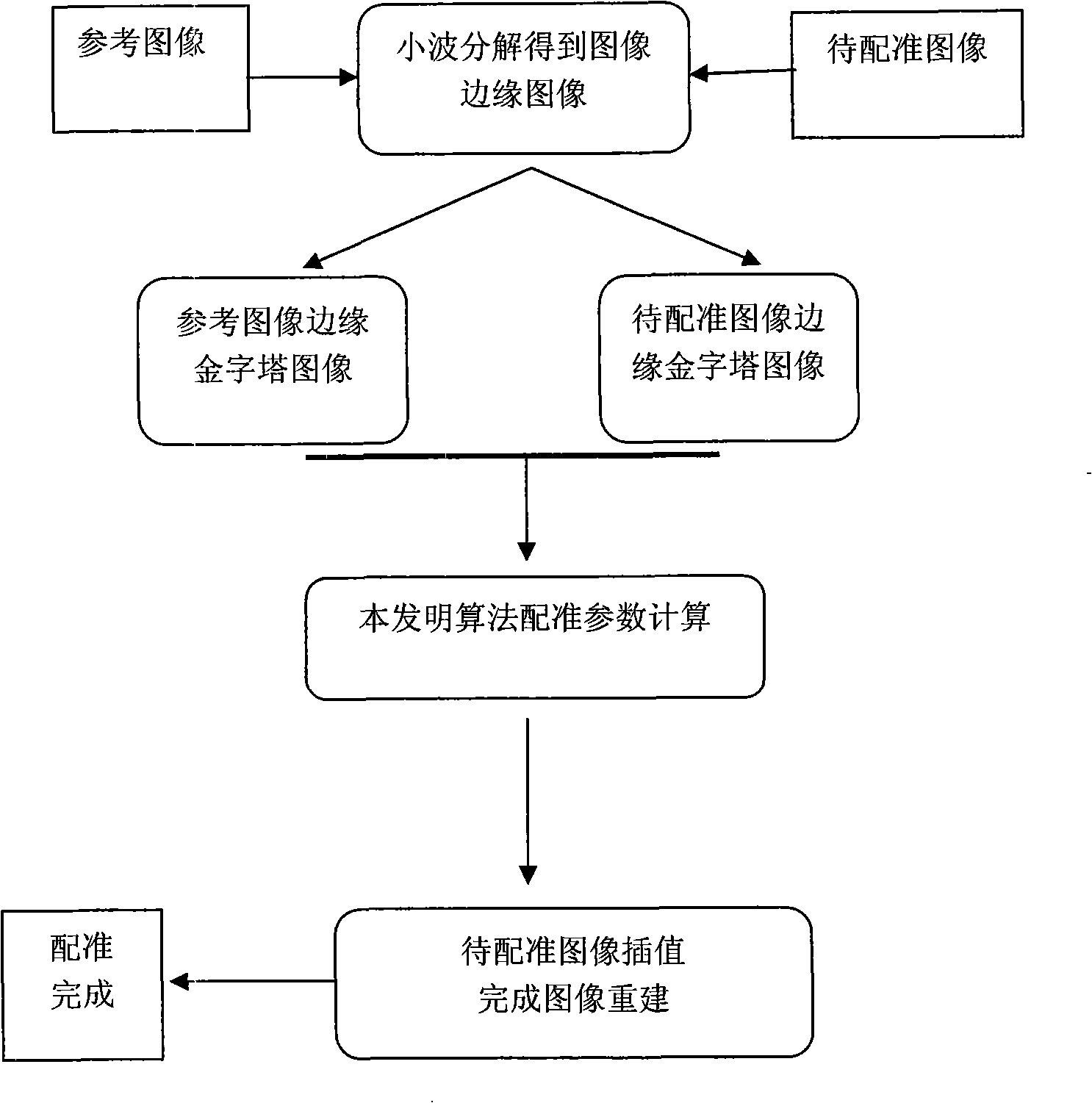

Multi- resolution non-rigid head medicine image registration method based on image edge

InactiveCN101493936AExact matchReduce matching errorImage analysisImage resolutionInformation integration

The invention relates to a multi-resolution non-rigid head medical image registration method on the basis of image edges, which pertains to the field of information fusion. The method utilizes searches gradually becoming accurate to transform parameters during the registration process. At first, wavelet transformation is used for detecting the edge of an image; a edge pyramid image is formed on the basis of an edge image; then relatively wide search is carried out in the lowest scale level (the roughest level) of the edge pyramid image; the best transformation for registering the two images is found; each subsequent level takes the search result of the former level as a center; and search scope is reduced to continually search until the search in the highest scale level is carried out. Compared with the registration directly using the original image, the method can reduce calculated amount, improve accuracy and can register images of different spatial resolution.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

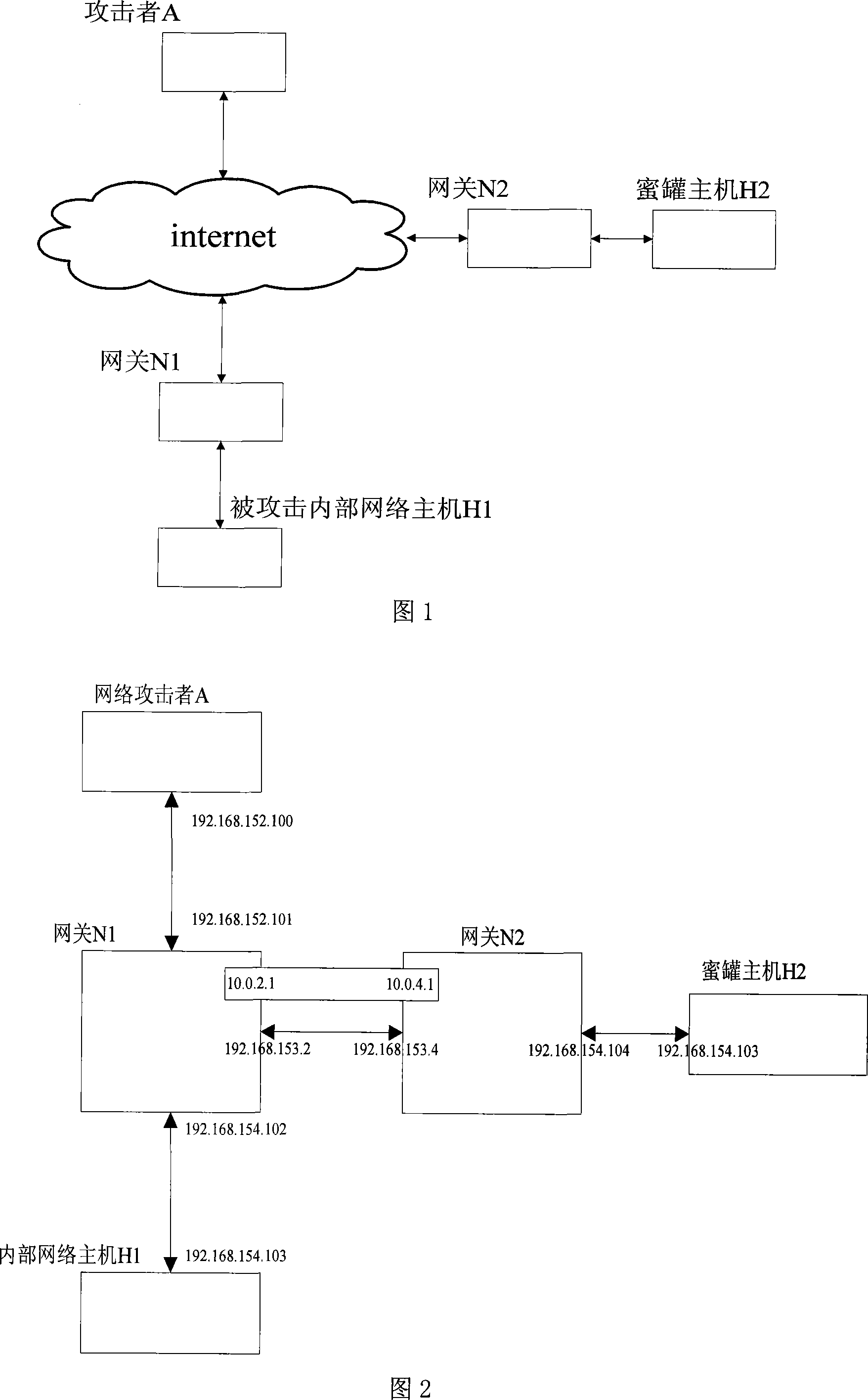

A method for redirecting network attack by combining route with the tunnel

InactiveCN101188613AAvoid the risks of running third-party softwareSpeed has no effectNetworks interconnectionNetwork attackManet routing

The invention discloses a method for network attack redirection by combining route and a tunnel. The network attack is redirected to a honeypot host computer with identical subnetwork address at a far end through arranging the tunnel and configuring a second routing list between a gateway N1 and a gateway N2 connected with the honeypot host computer, and marking a network attack IP package in order to realize the network attack redirection. The method of the invention is easy to be carried out, quick and highly effective, and is especially suitable for the condition of temporary network attack redirection on an important gateway; simultaneously, the method of the invention has the advantages that the risk is low, and the problems of minimum MTU or IP package fragmentation of the network are not required to be worried.

Owner:PEKING UNIV

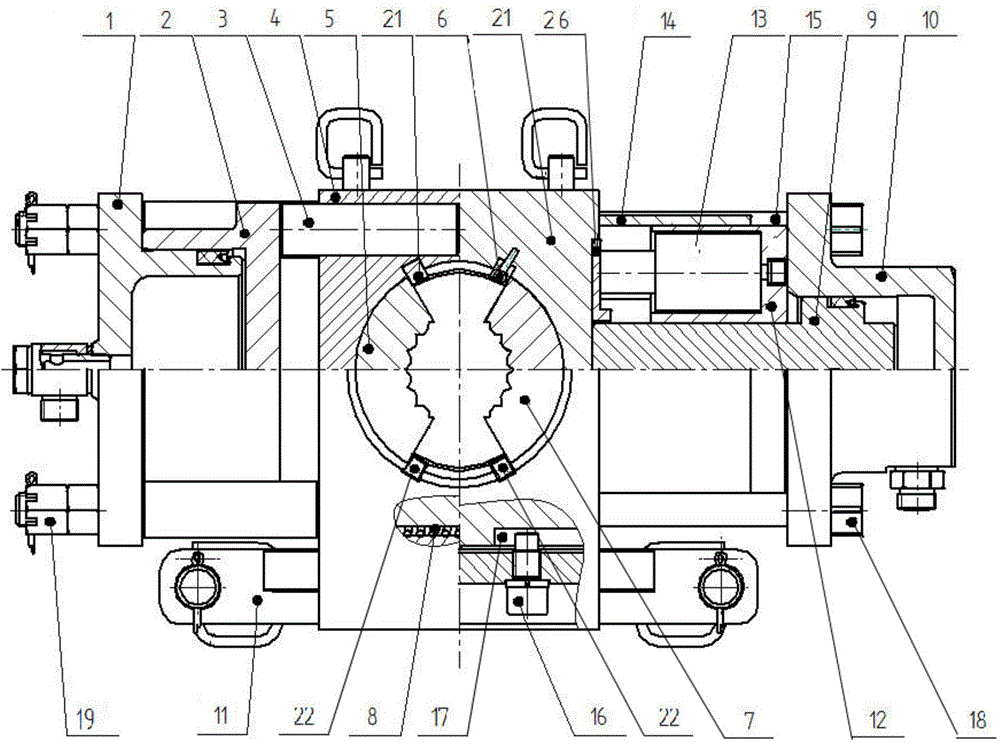

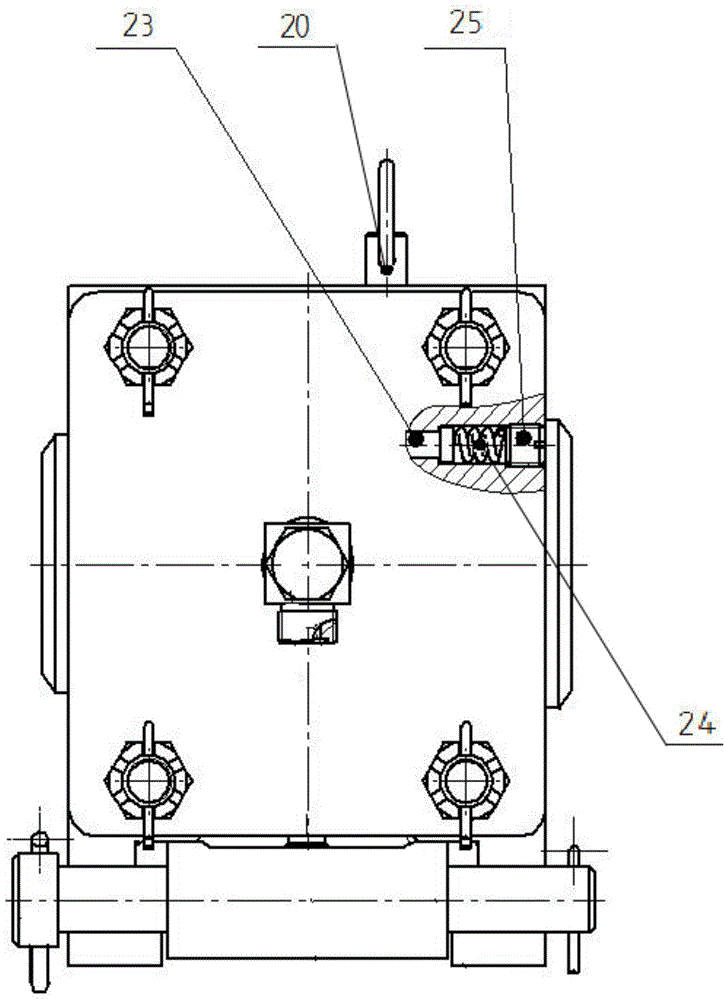

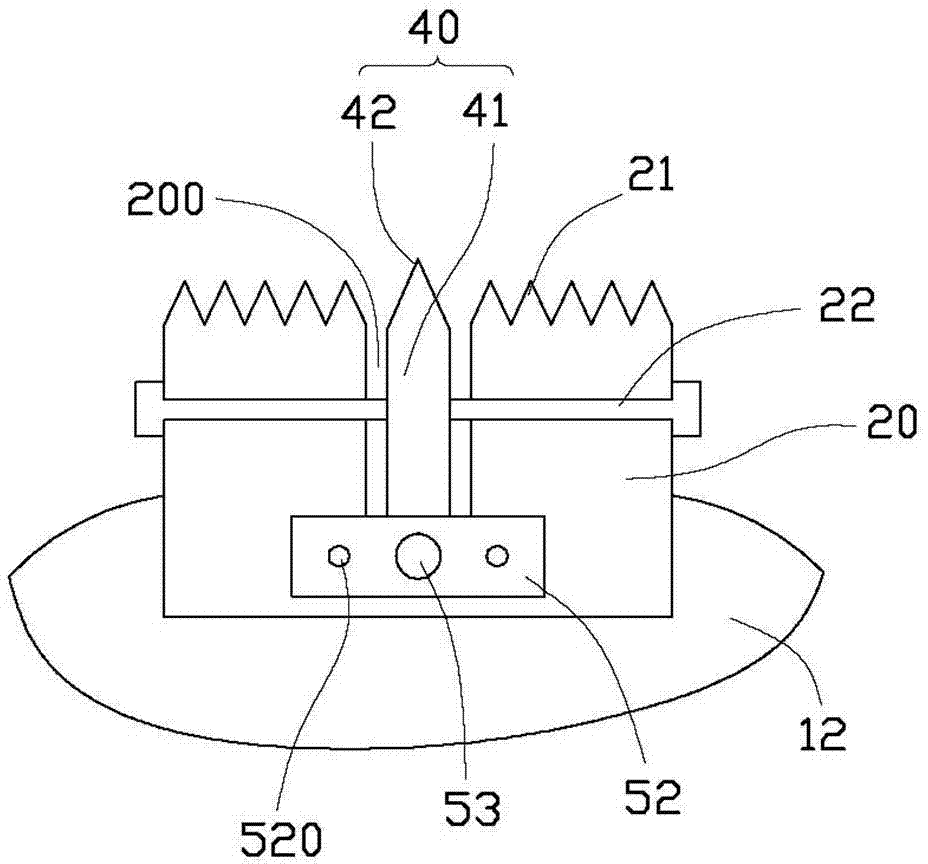

Clamp

ActiveCN103821466ANo increase in sizeNo serious lossDrilling rodsDrilling casingsEngineeringNitrogen gas

The invention provides a clamp which comprises a left oil cylinder piston, a left oil cylinder body, a jack column, a left slip bowl, a left slip, a right slip bowl, a right slip, a slip bowl spring, a right oil cylinder piston, a right oil cylinder body, a guide rail, a nitrogen spring seat and a nitrogen spring. The left end of the nitrogen spring seat is provided with a nitrogen spring countersink. The right end of the nitrogen spring seat is abutted against the left end of the right oil cylinder body. The ejecting end of the right oil cylinder piston penetrates the central hole of the nitrogen spring seat. The cylinder body of the nitrogen spring is inserted into the nitrogen spring countersink and fixedly connected with nitrogen spring seat. The extending end of the piston of the nitrogen spring is abutted against the right end of the right slip bowl. The clamp is large in opening amount, large in clamping force and small in size, and severe loss of clamping force can be avoided when the slips are abraded after long term use.

Owner:HUAINAN MINING IND GRP +1

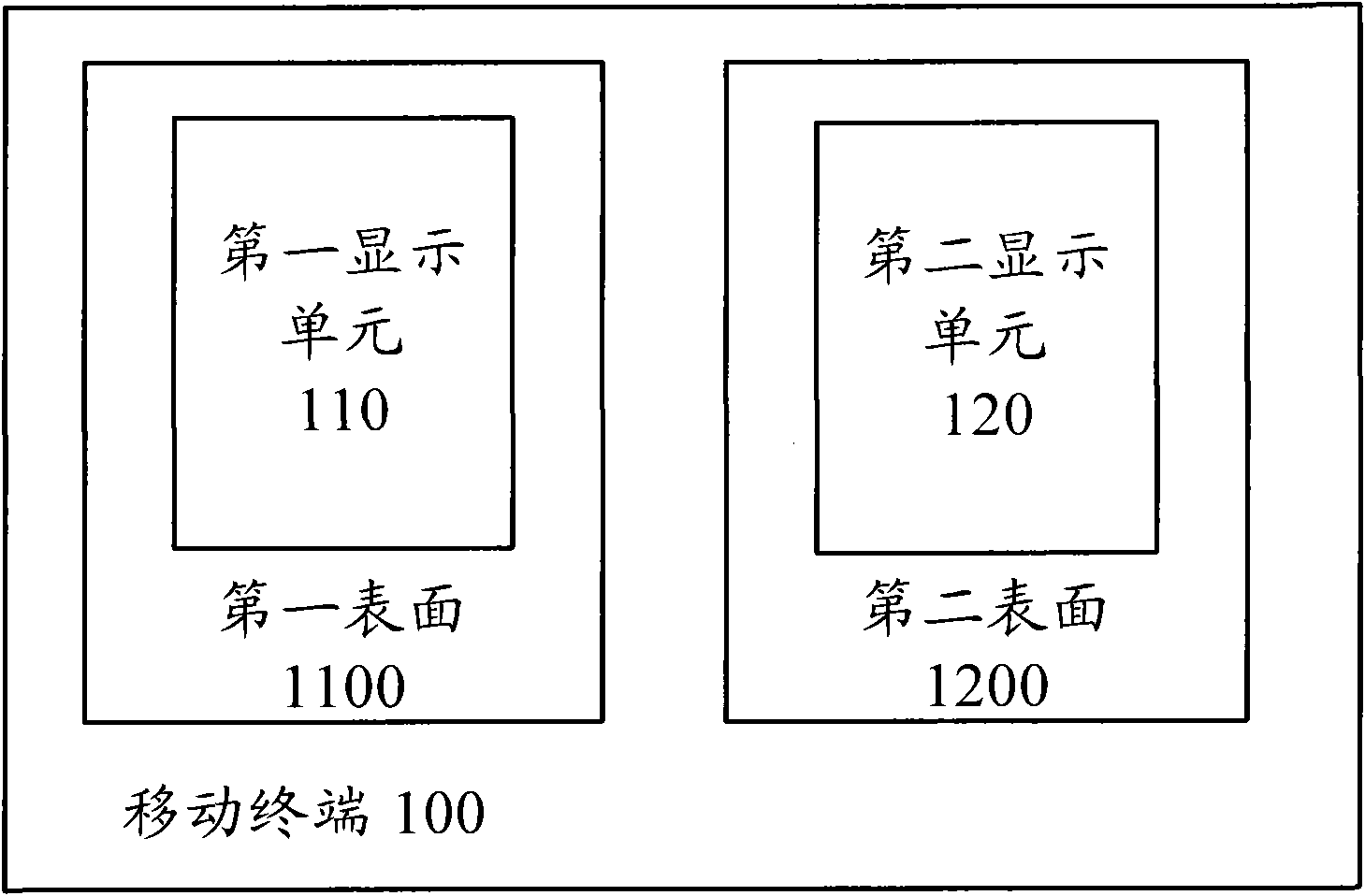

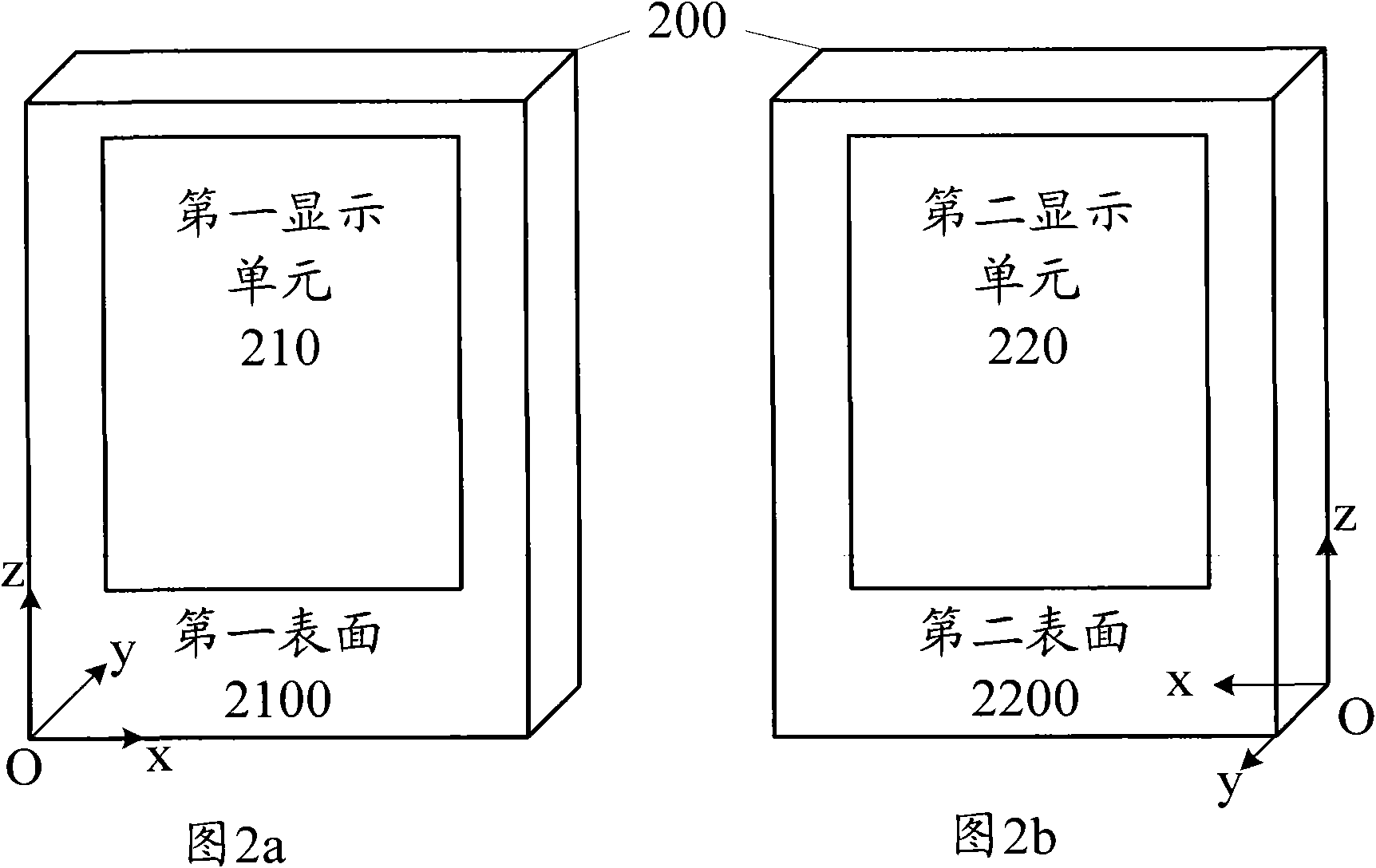

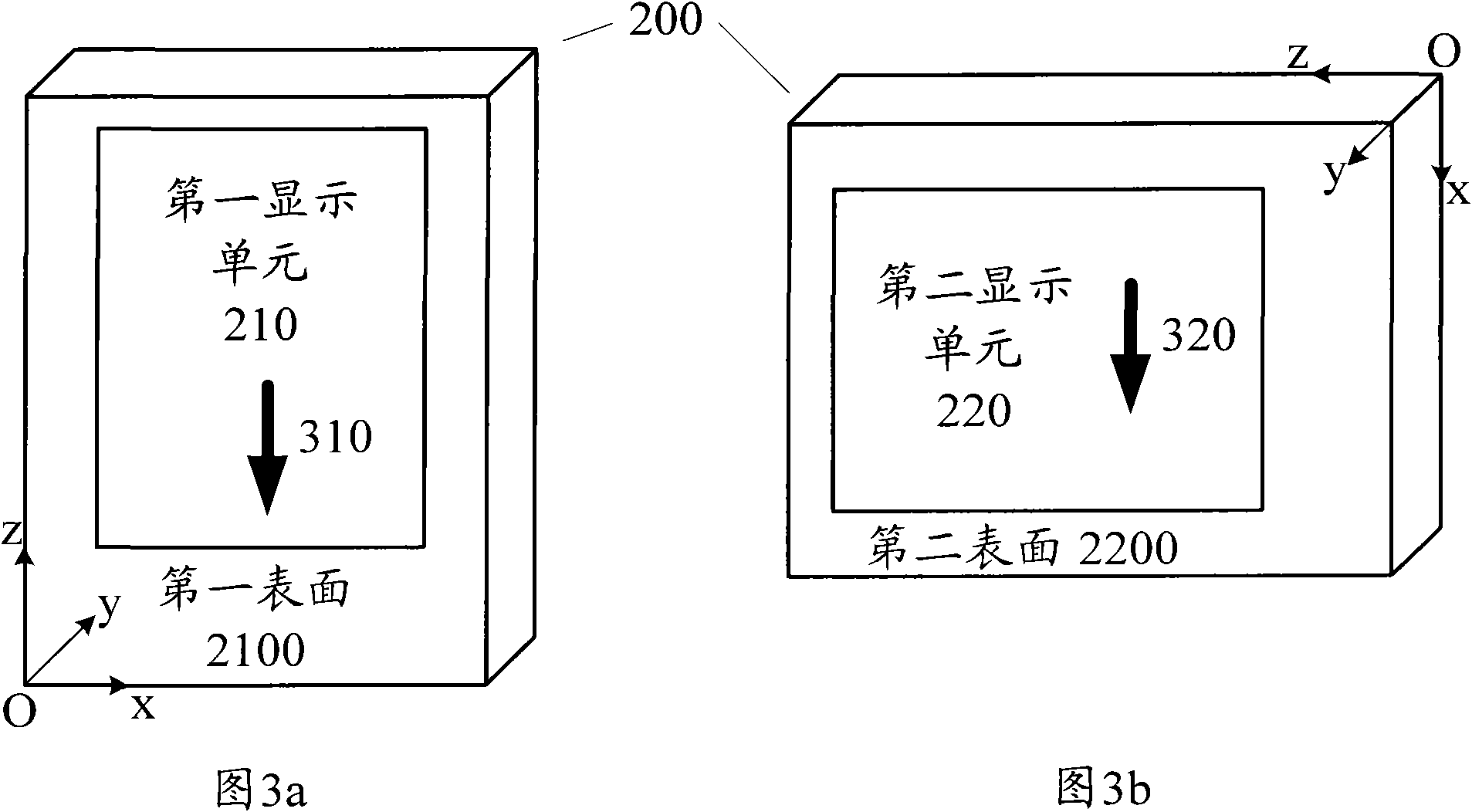

Mobile terminal and display method for mobile terminal

ActiveCN102339194AIncrease the display areaAvoid dropping your phoneStatic indicating devicesDigital data processing detailsComputer scienceComputer terminal

Owner:LENOVO (BEIJING) CO LTD

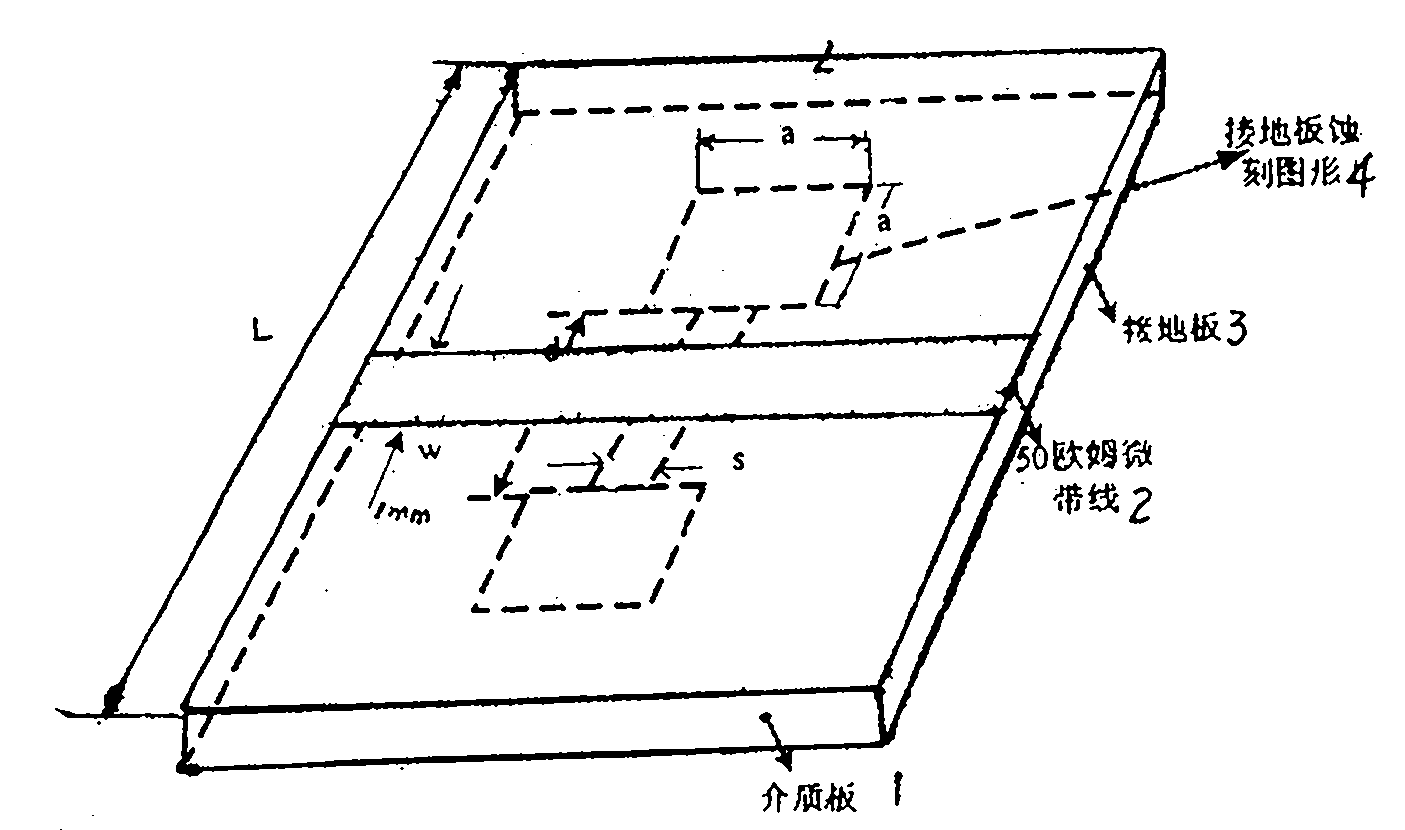

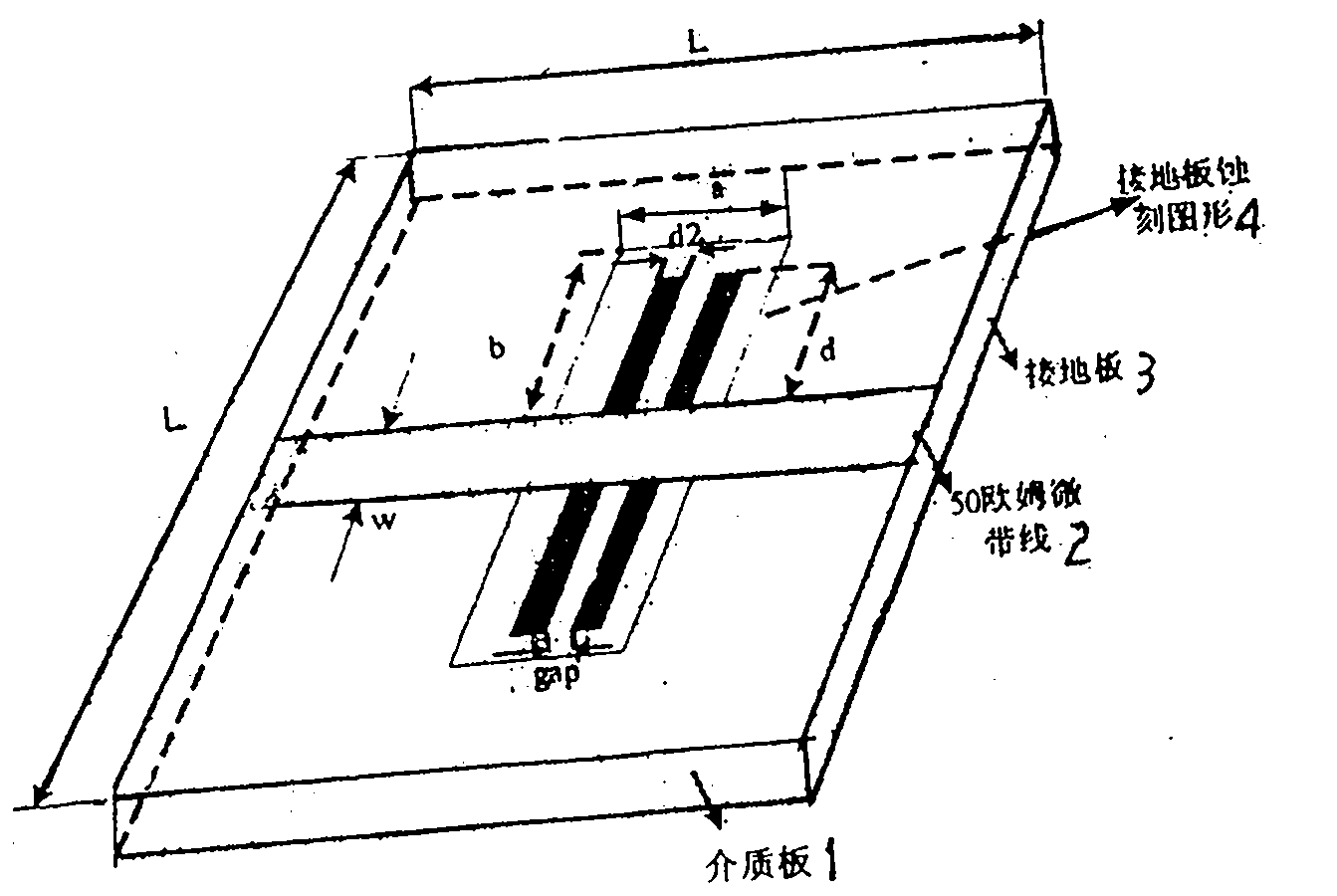

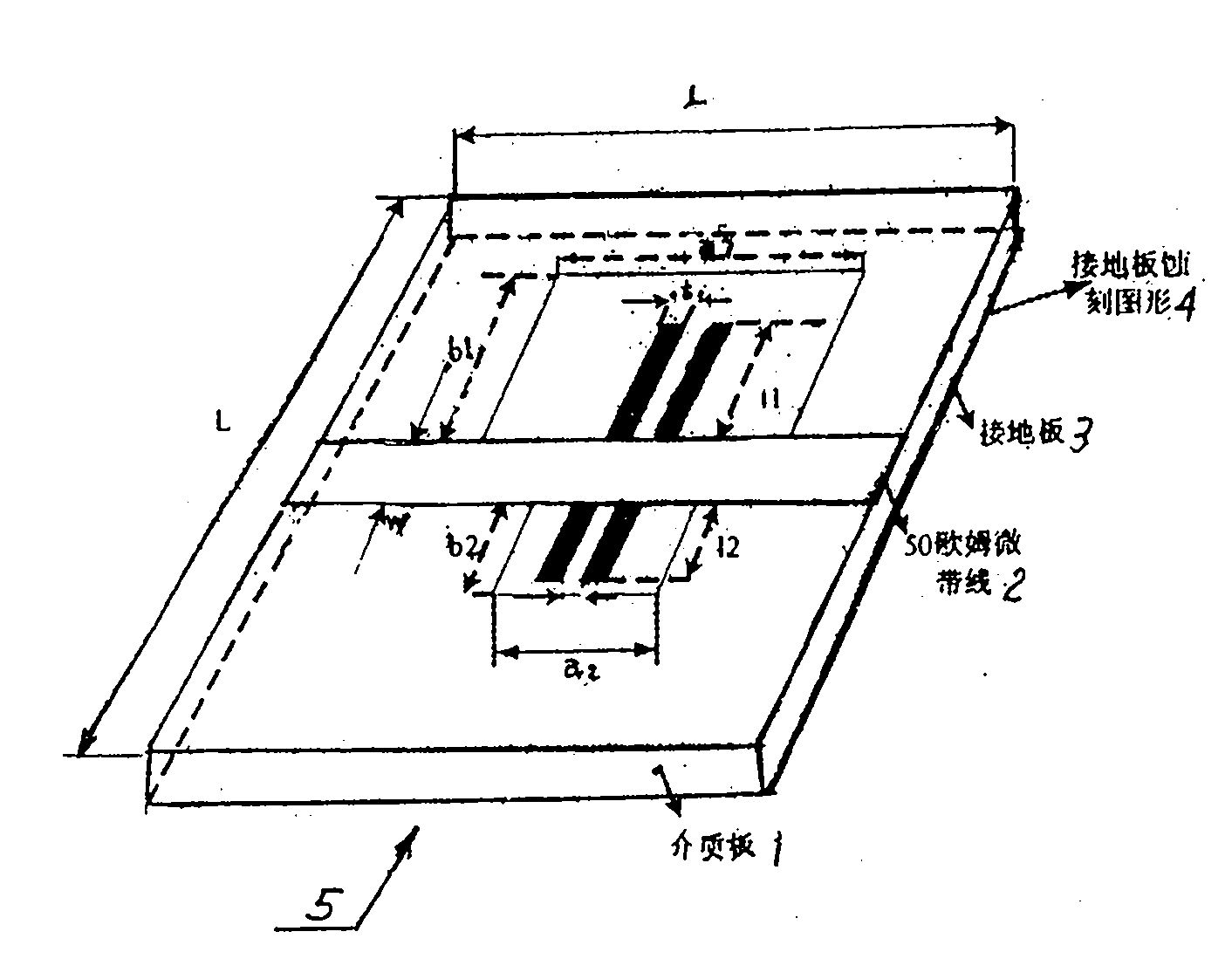

Asymmetric DGS (Defected Ground Structure) structure cascaded filter

InactiveCN101931114AStop band depthSuppresses higher harmonicsWaveguide type devicesFrequency bandPhysics

The invention relates to an asymmetric DGS (Defected Ground Structure) structure cascaded filter, belonging to the field of microwave devices. A T-shaped defected grounding structure asymmetric to a microstrip line is etched on a rectangular dielectric slab as an asymmetric T-shaped DGS structure of a single unit, and the asymmetric T-shaped DGS structures of two or three single units are cascaded in parallel to form the filter. Compared with the traditional dumbbell and T-shaped DGS structures, the asymmetric DGS structure filter can effectively inhibit secondary harmonic waves and third harmonic waves of the microwave devices in a specific frequency range, and the volume of the filter is not increased greatly. Multiple symmetric and asymmetric DGSs can be cascaded, and the cascaded product can obtain higher inhibition action on wide stopband of secondary harmonic waves and third harmonic waves of the microwave devices.

Owner:BEIJING UNIV OF POSTS & TELECOMM

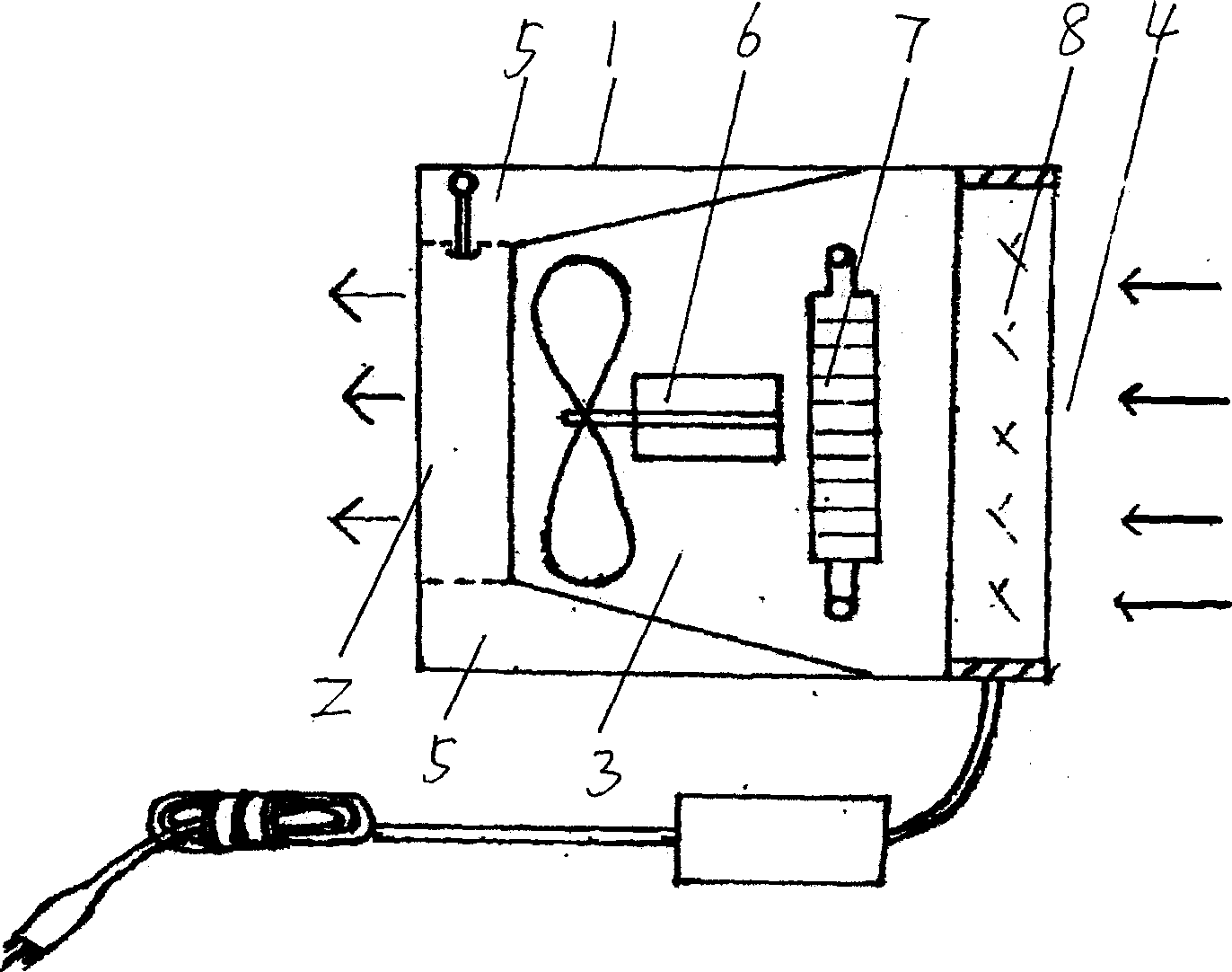

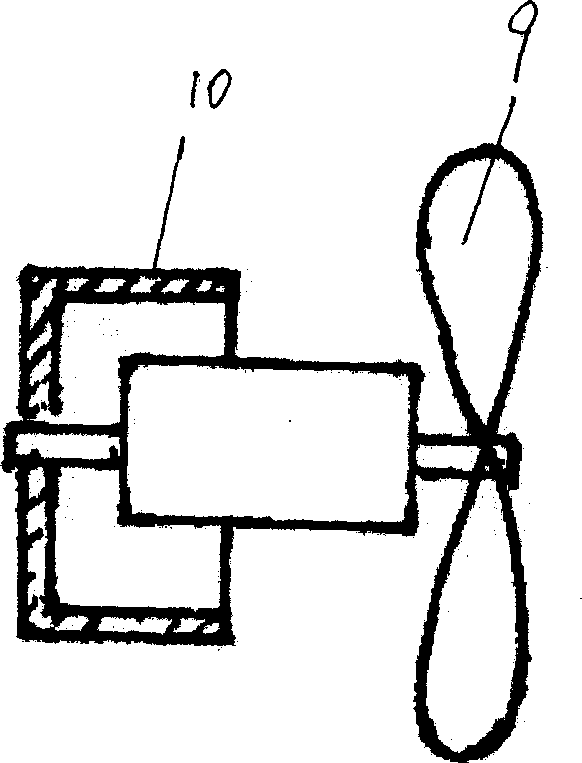

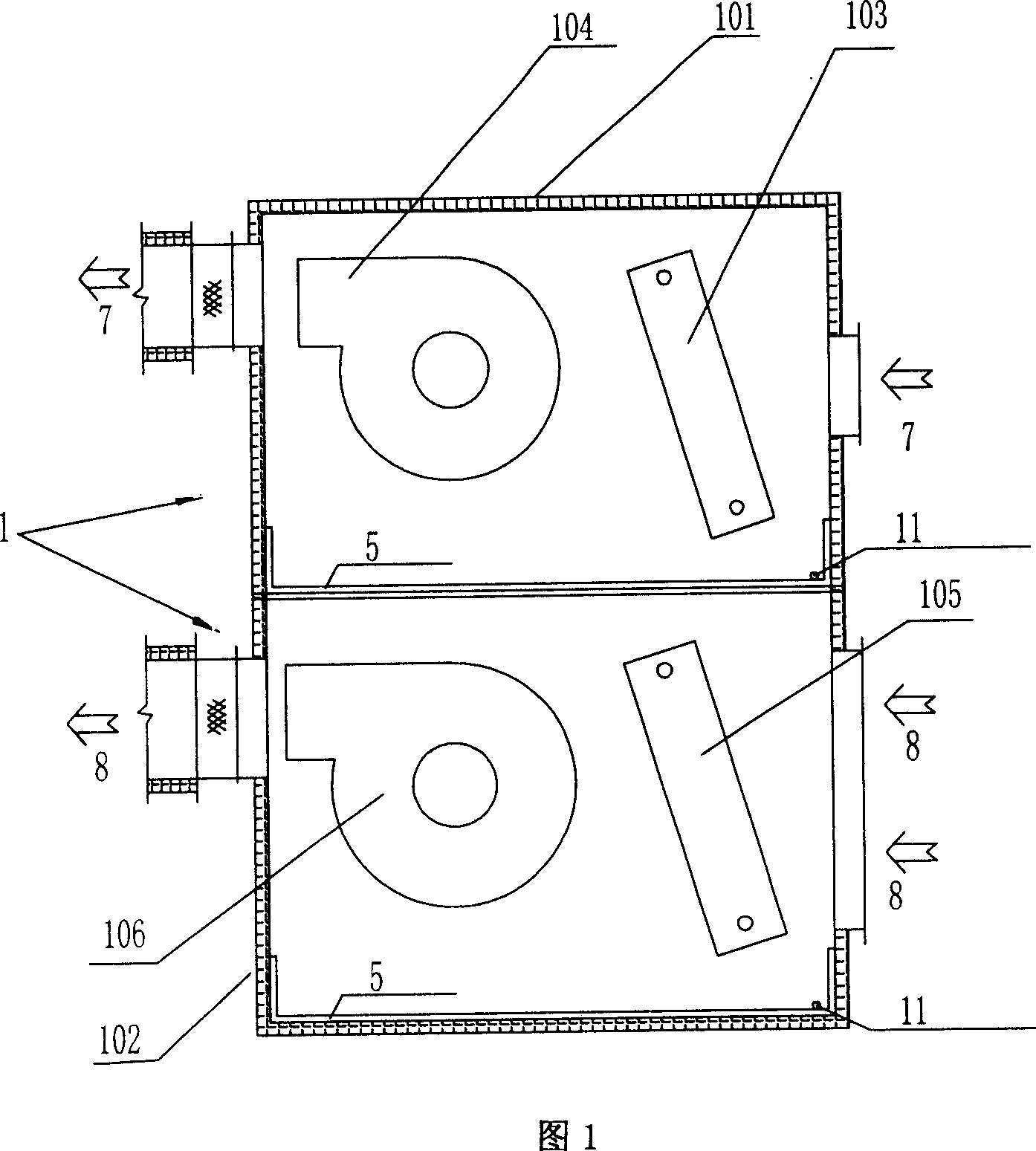

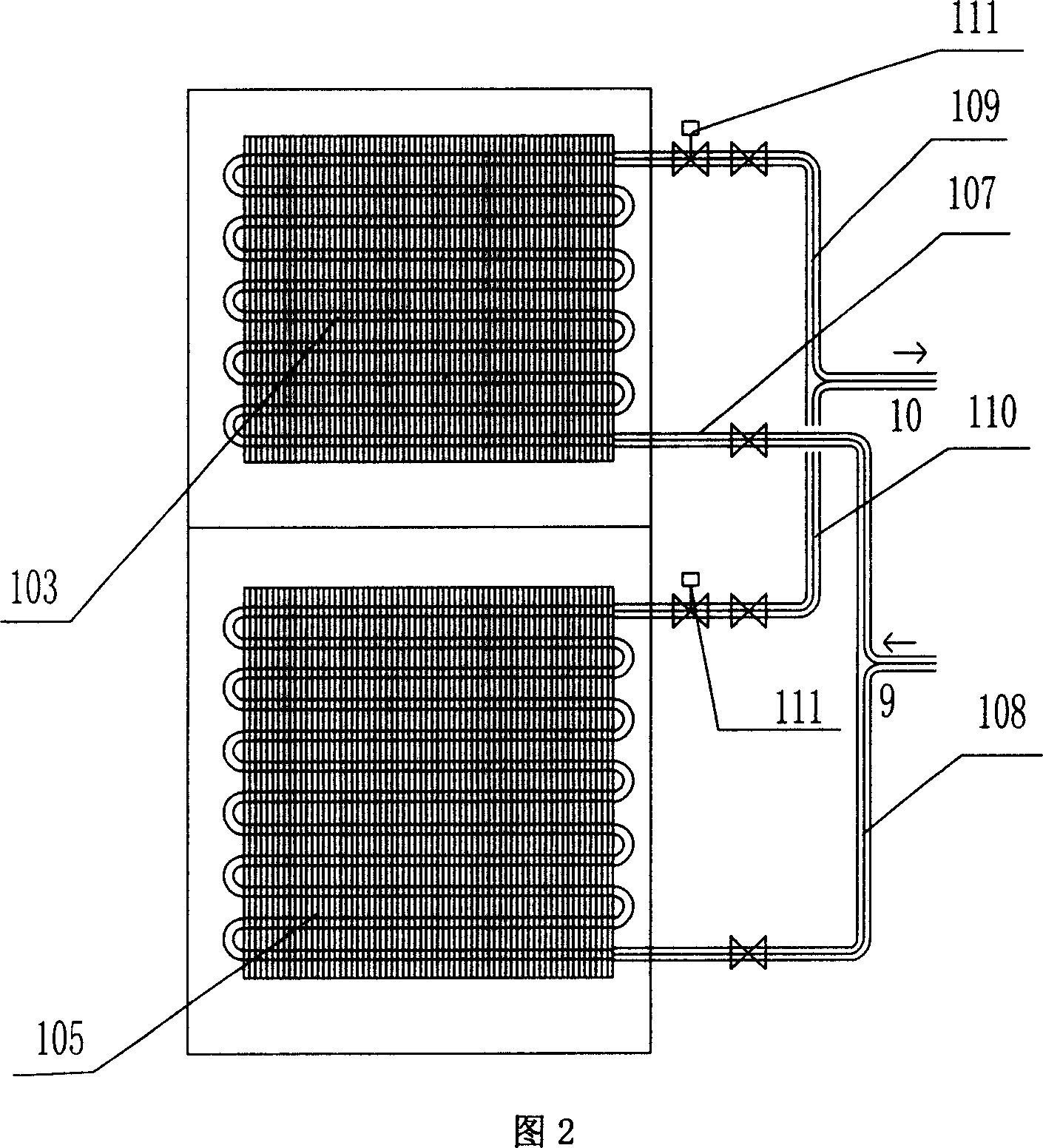

Automatic dedusting, heating, moistening and air exchanging machine

InactiveCN1421647ANo increase in sizeNo reduction in efficacyLighting and heating apparatusAir conditioning systemsAir pumpEngineering

The automatic dedusting, heating, moistening and air exchanging machine is used in room air exchange and kitchen ventilation. The machine includes casing with air inlet, air channel and air outlet; electric fan in the air channel; filtering to purify input air; moistener to moisten output air; air heater and controller. The electric fan is an efficient axial flow and centrifugal one and has two vanes; the filter has filter element, pressure sensor and element protector; the moistener includes water tank, water mist generator, water level tester, air pump, etc; the heater is finned electric heating pipe; and the controller has setting, alarm and other functions. The present invention has compact structure and several functions.

Owner:武雄

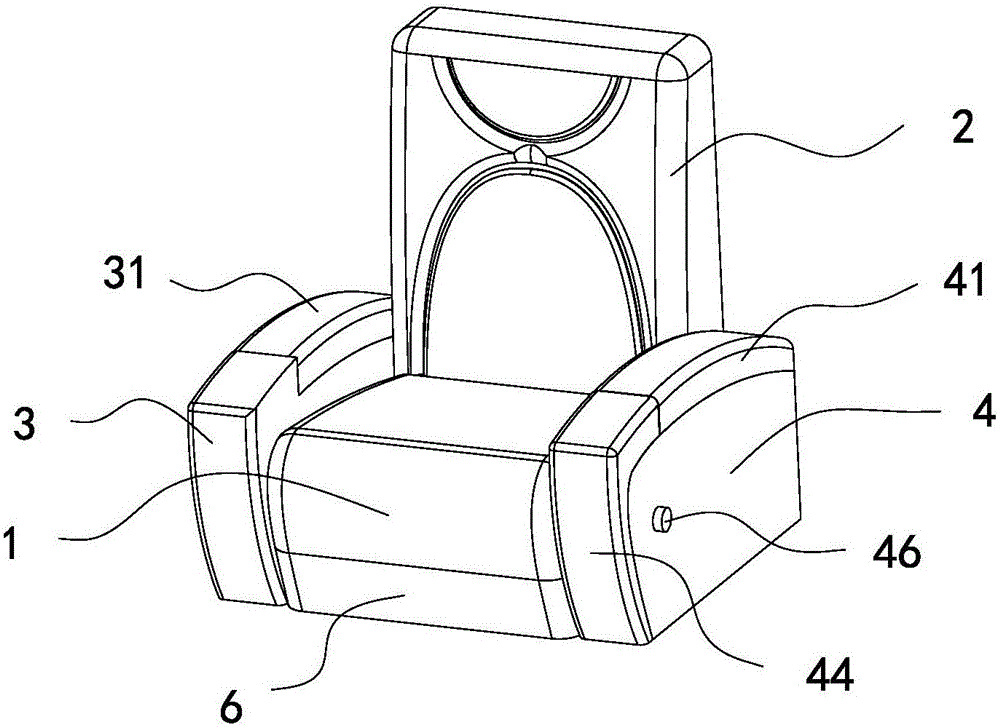

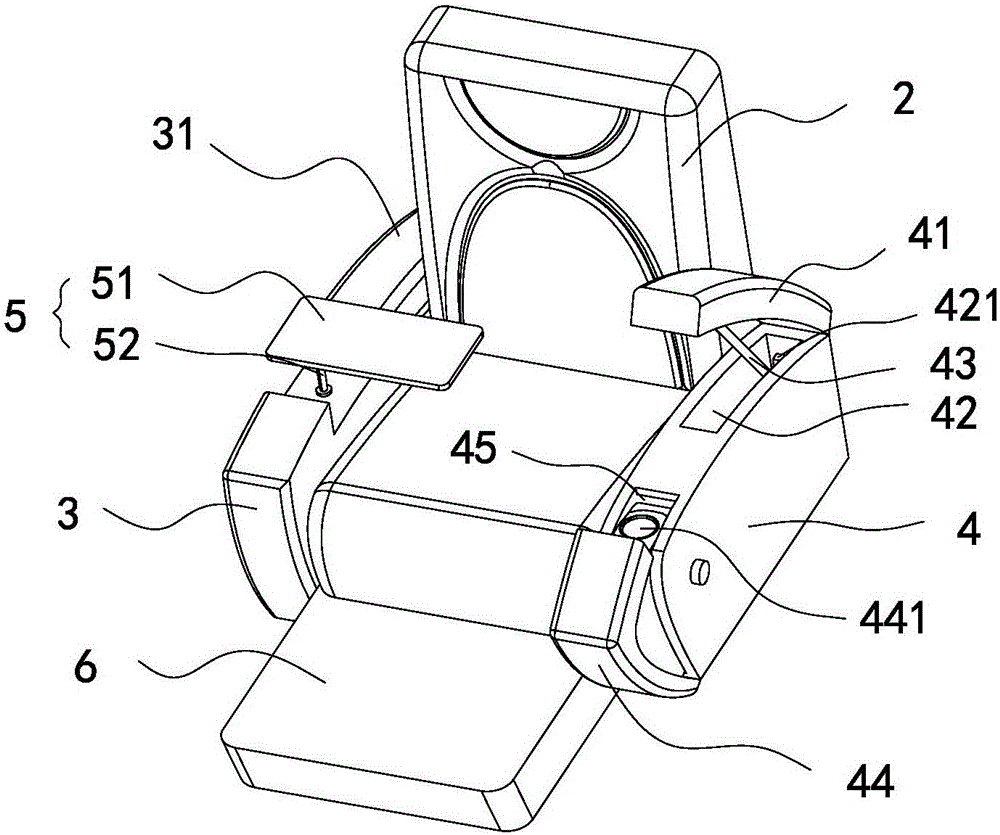

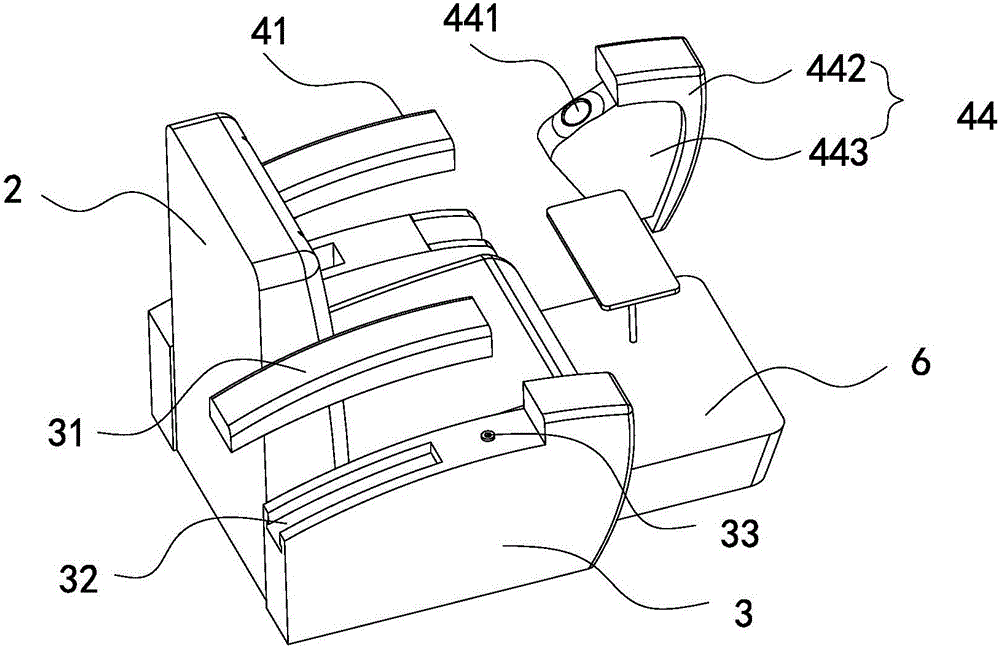

Multifunctional armchair

The invention discloses a multifunctional armchair and belongs to the field of furniture. The multifunctional armchair comprises a cushion, a backrest, a left armrest and a right armrest, wherein the left armrest and the right armrest are respectively arranged on two sides of the cushion, one of the left armrest and the right armrest is provided with a storage groove, a first armrest cover for covering the storage groove is movably connected above the storage groove, the other one of the left armrest and the right armrest is provided with a second armrest cover, a connecting part is correspondingly arranged below the second armrest cover, an object placing platform is detachably connected to the connecting part, a lateral armrest table is arranged on one of the left armrest and the right armrest, can be retracted into the corresponding armrest and is provided with a cup holder, and the cup holder is positioned outside the left armrest or the right armrest when the lateral armrest table is spread. The multifunctional armchair is convenient in object placing, good in object storage performance and good in user experience.

Owner:HAINING GELIN FURNITURE +1

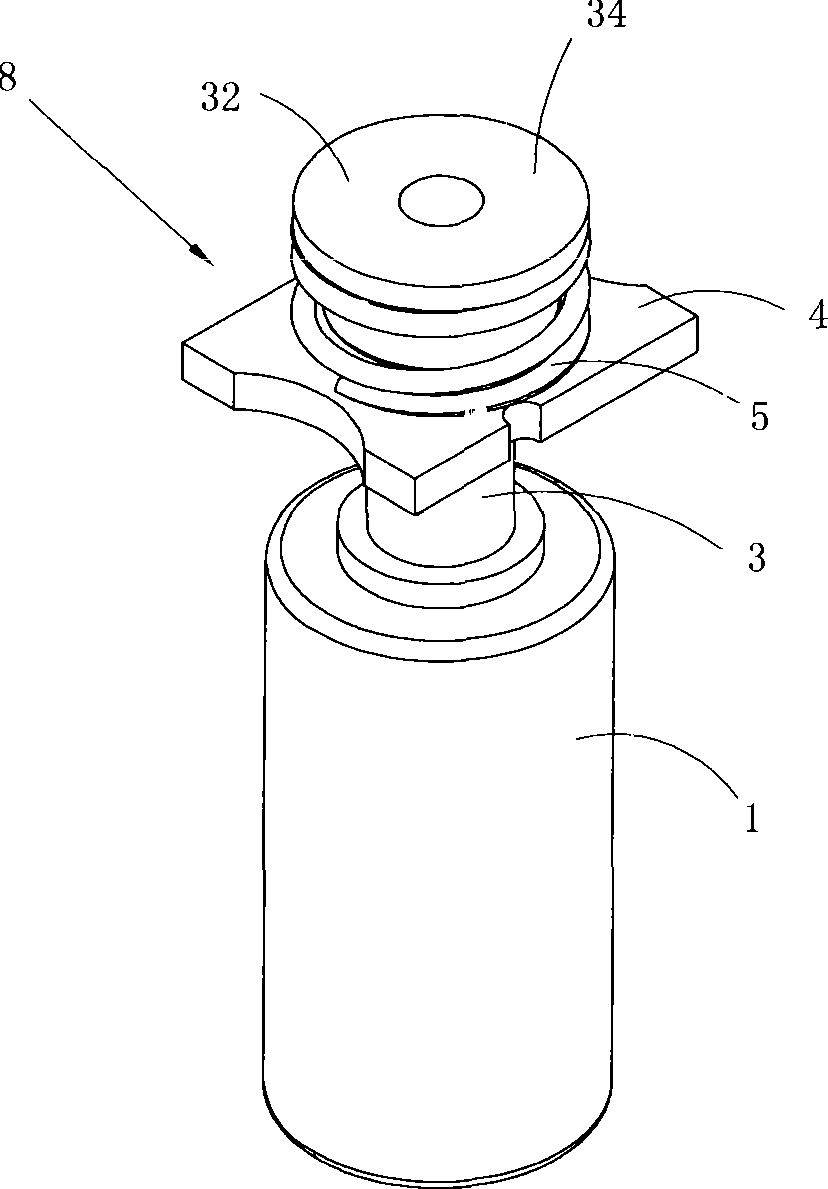

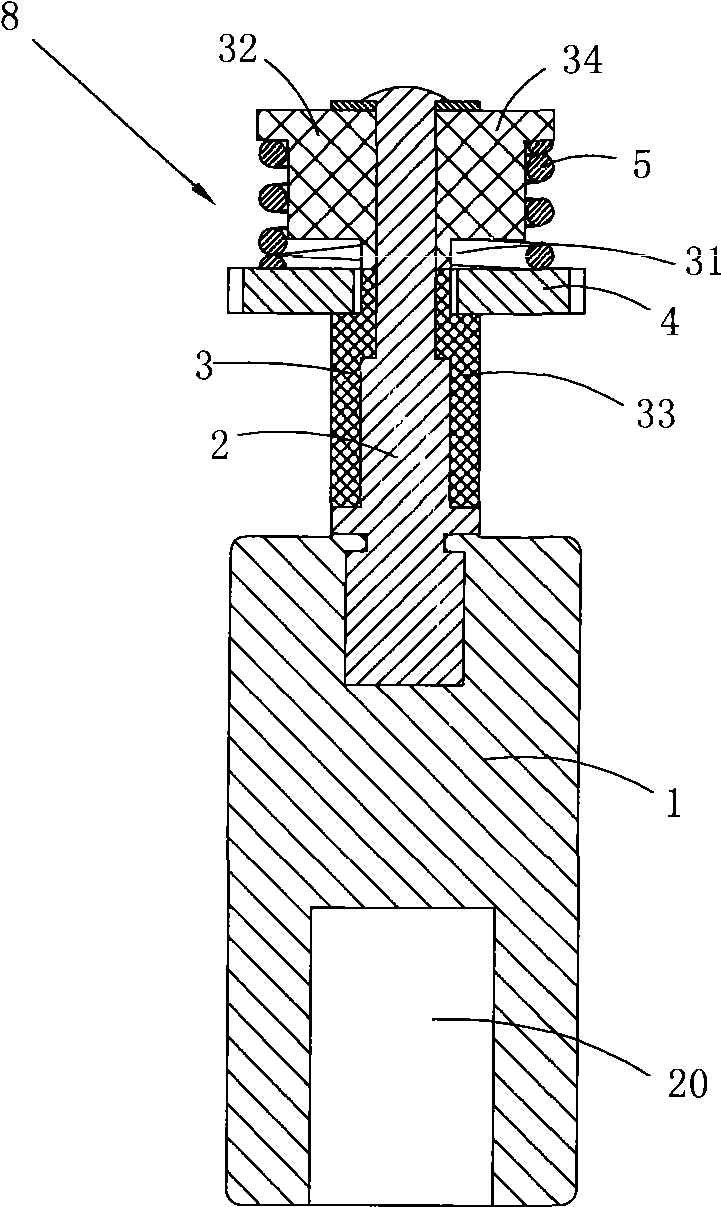

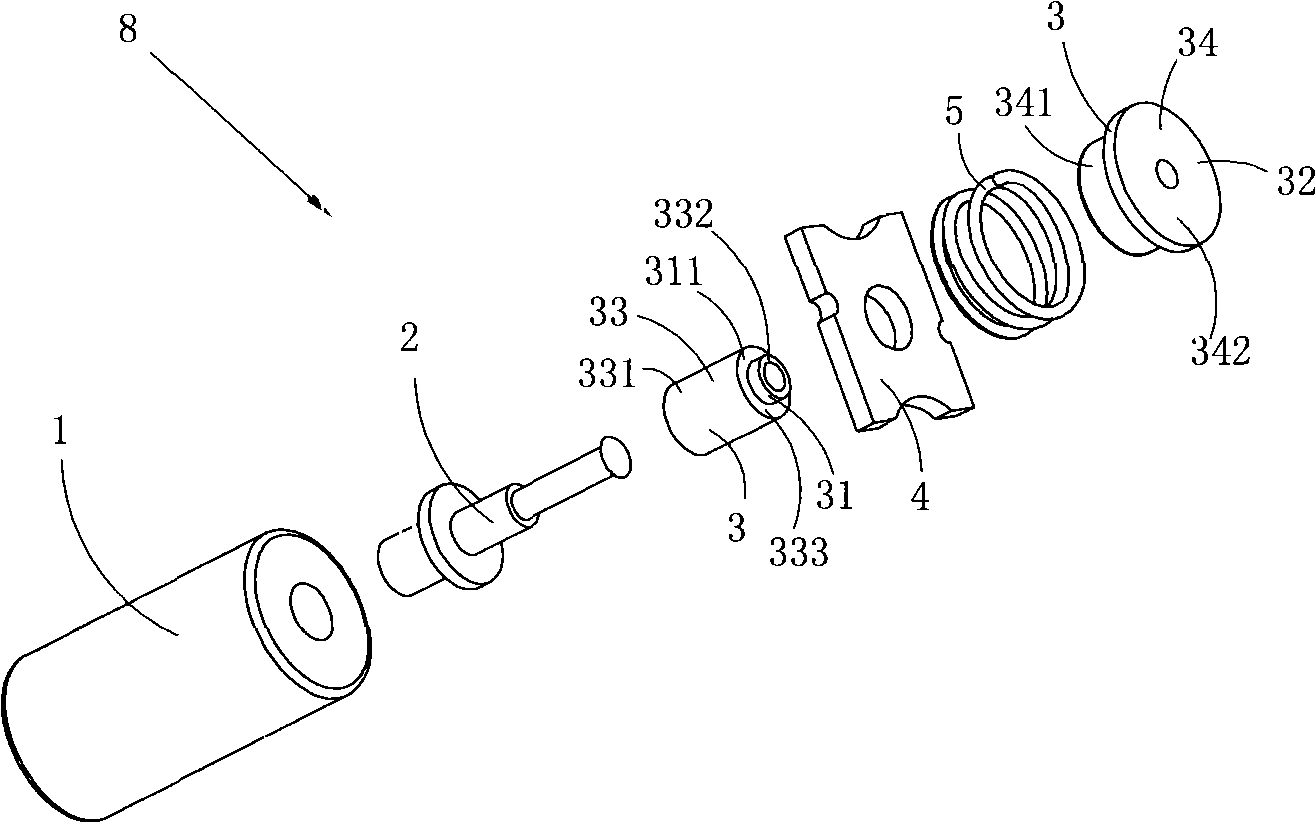

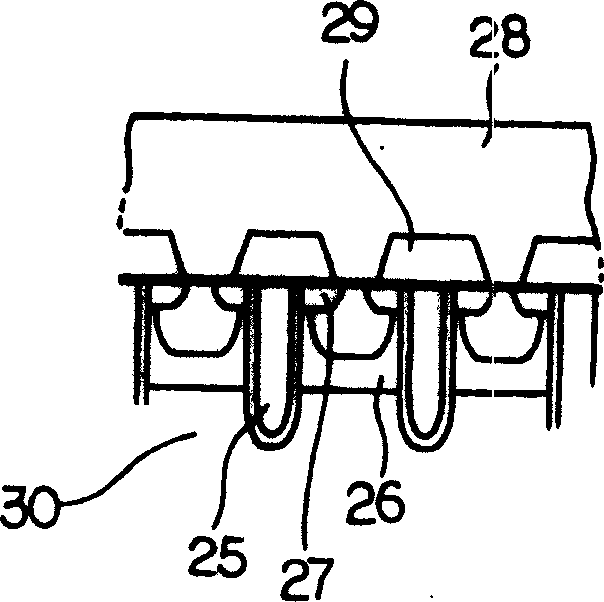

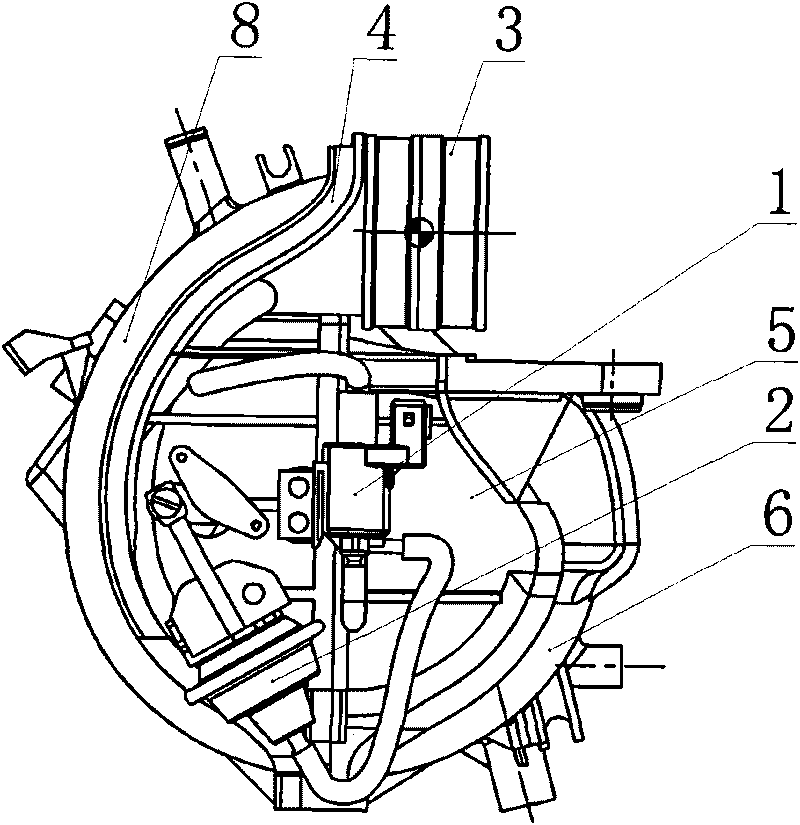

Moving contact component and startup relay

InactiveCN101533739AEasy to maintainStable working performanceElectric switchesElectromagnetic relay detailsEngineeringMechanical engineering

The invention discloses a moving contact component and a startup relay. The moving contact component comprises a moving iron core, a locating rod, an insulated jacket sleeved on the locating rod and a moving contact piece and a buffer spring sleeved on the insulated jacket, wherein the moving contact piece and the buffer spring are arranged in turn in a direction far away from the moving iron core; the insulated jacket is provided with a sliding area; and the moving contact piece can move to and fro within the sliding area under the action of outside force and the restore elastic force of the buffer spring. The startup relay comprises a shell, a coil component, a moving contact component of the structure, a fixed contact component and a restore spring providing the restore elastic force for the moving contact component. The moving contact piece and two fixed contact pieces can be closed in the process that the moving contact piece moves along with the moving iron core. The moving contact component and the startup relay have the advantages that the moving contact piece is directly arranged on the moving iron core, so that the overall structure is integrated and the installation and the maintenance is convenient; and the buffer spring effectively reduces abrasion caused by collision when the moving contact piece and the fixed contact pieces are closed, and ensures the service life of the moving contact piece.

Owner:浙江致威电子科技有限公司

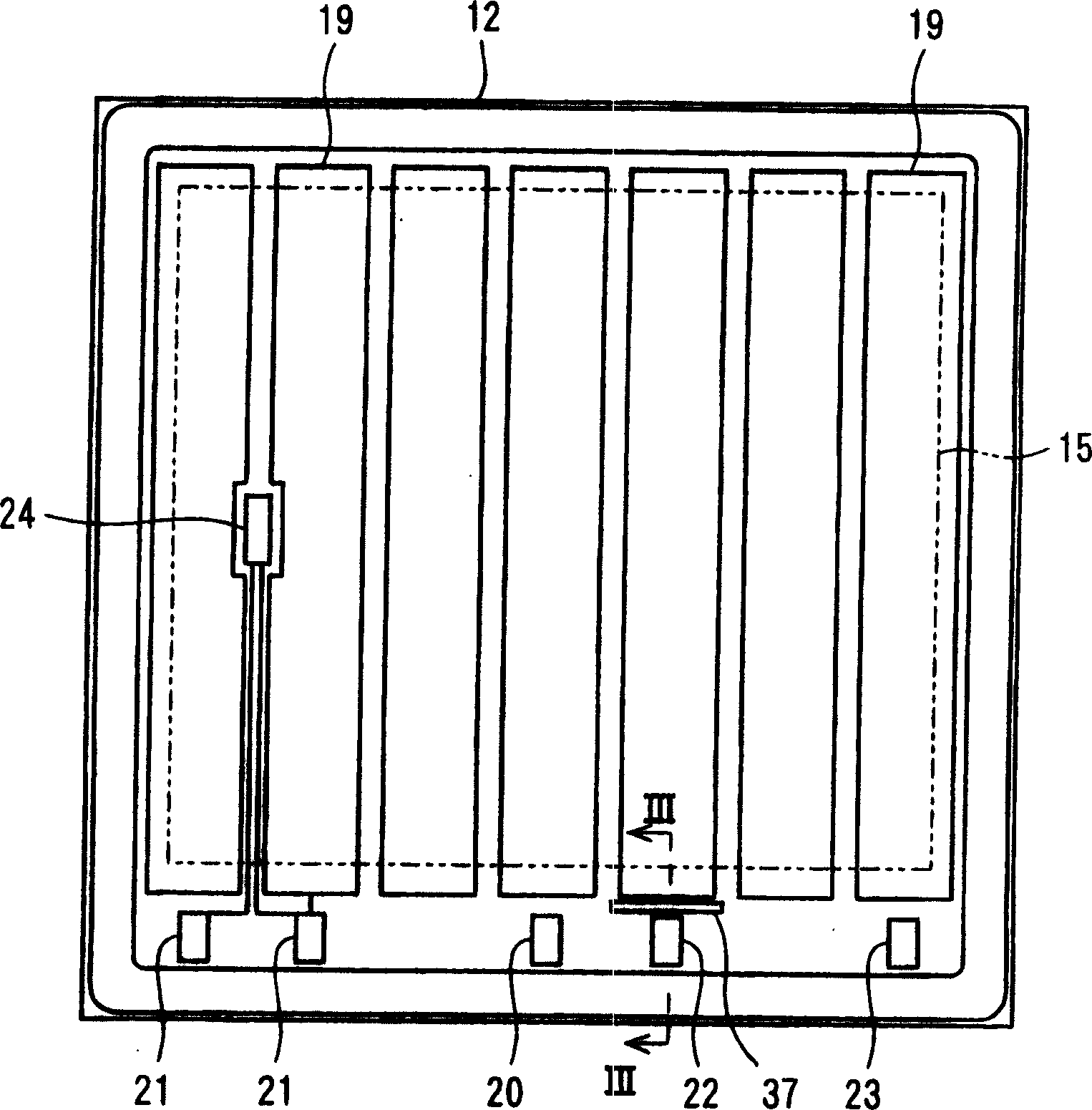

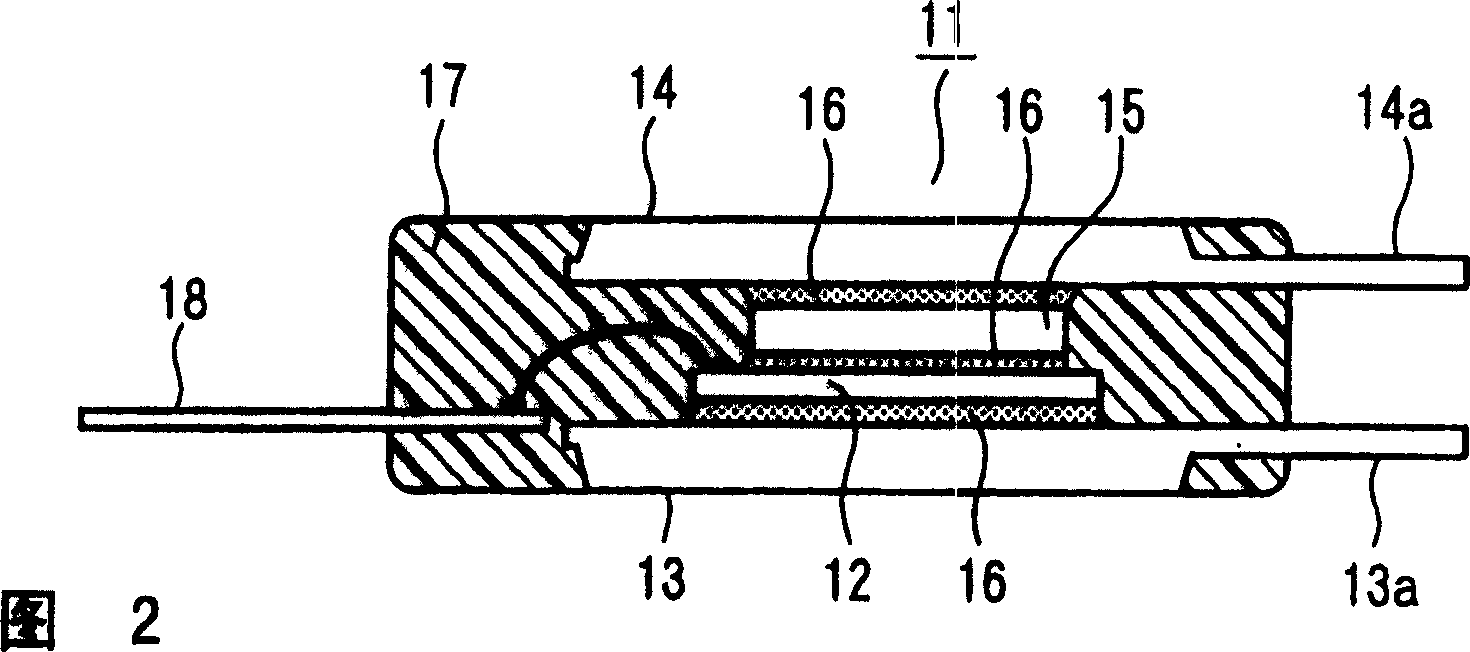

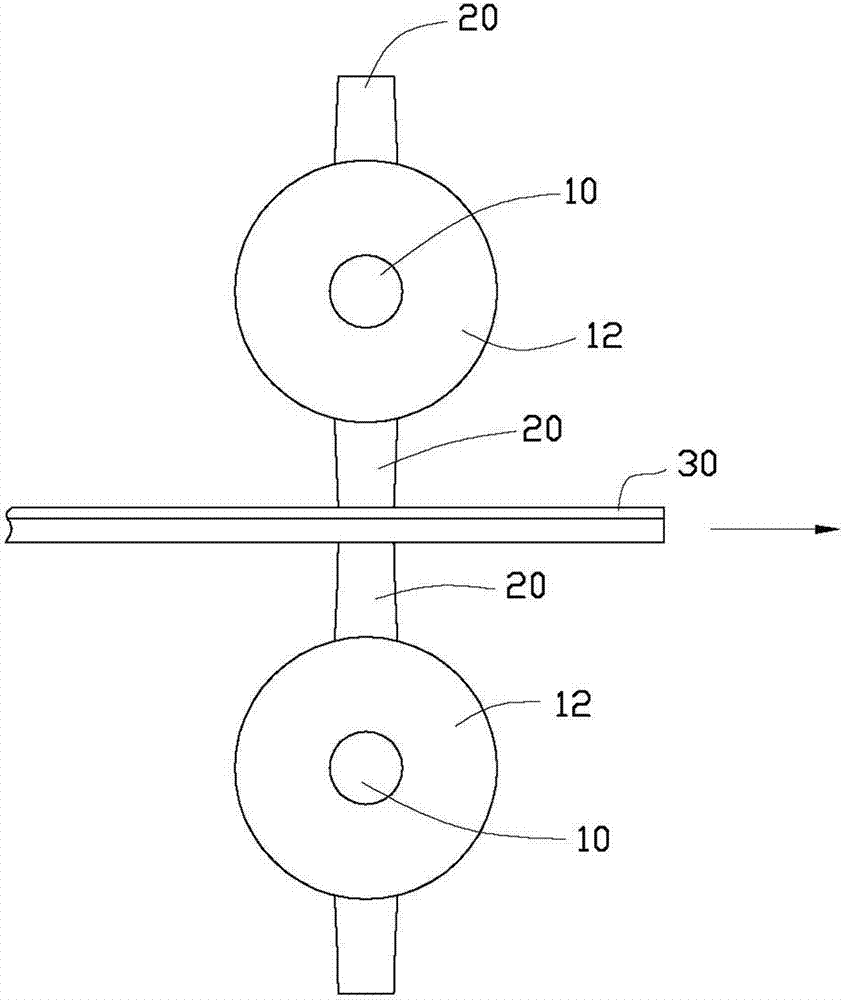

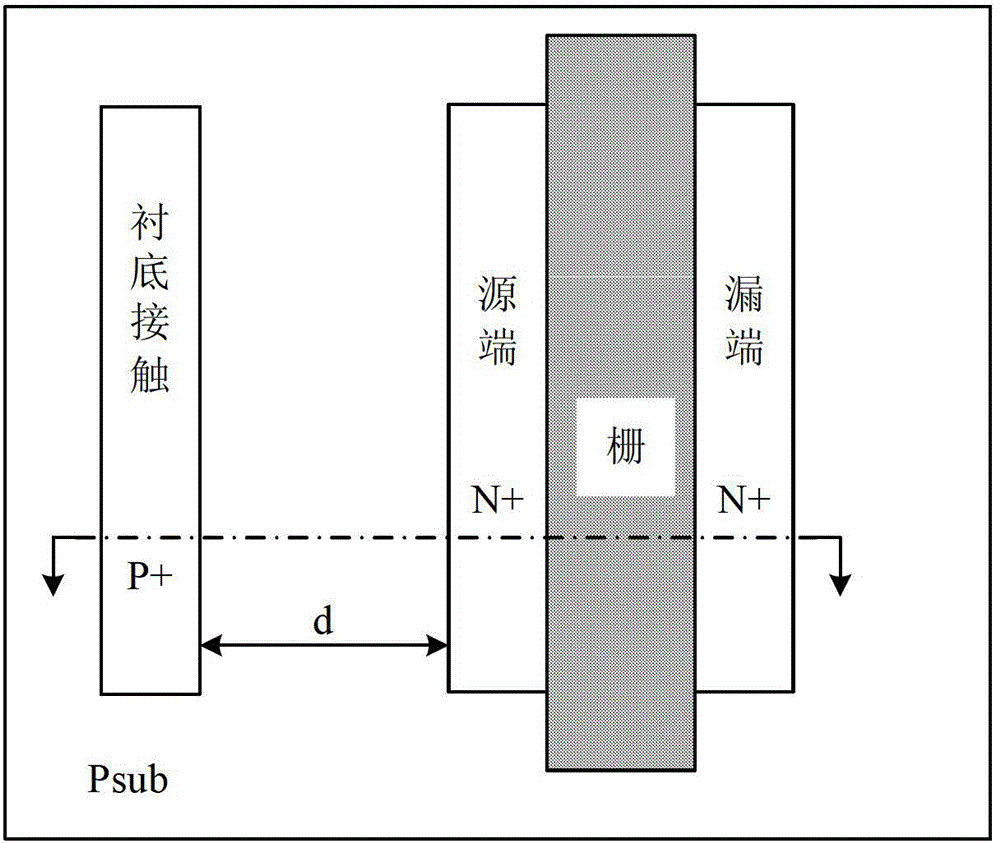

Semiconductor device with a pair of radiating fan

InactiveCN1619799AGuaranteed insulation performanceNo increase in sizeSemiconductor/solid-state device detailsSolid-state devicesHeat sinkSemiconductor device

The semiconductor device is composed of a semiconductor element (12), a pair of upper and lower cooling fins (13, 14) and a cooling block (15). The heat slug (15) has a planar shape smaller than that of the semiconductor element (12). The semiconductor element (12) has a heat generating portion (19) facing the heat dissipation block (15). The heating part (19) has an outer peripheral edge, and the distance (d) between the outer peripheral edge of the heating part (19) and the outer peripheral edge of the heat dissipation block (15) is less than 1.0 mm.

Owner:DENSO CORP

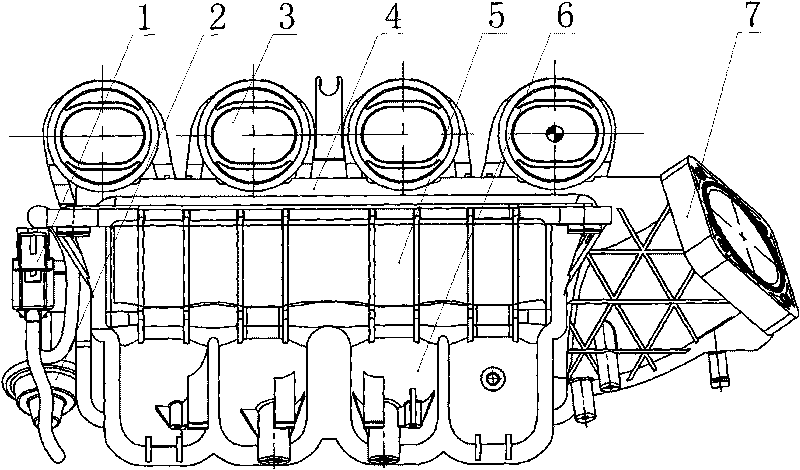

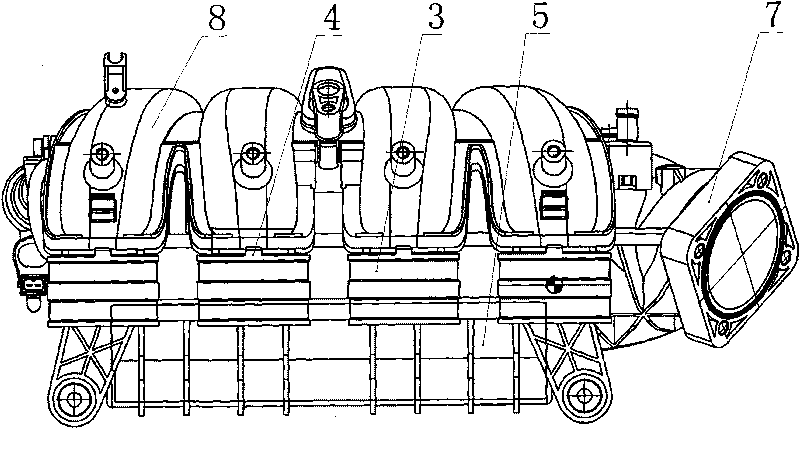

Variable air volume type air intake branch pipe

InactiveCN101699047AReduce intake resistanceAir intake increasedCombustion-air/fuel-air treatmentEngine controllersVariable air volumeAir volume

The invention relates to variable air volume type air intake branch pipe. Air intake ports communicated with air exhaust pipes are made directly on an intermediate plate in a pressure stabilizing cavity in a way of corresponding to the air exhaust pipes; exchange-over valves are sealed and arranged on the air intake ports; the valve plates of the exchange-over valves are jointly arranged on the same transmission shaft which is driven by a vacuum valve arranged at the input end on the lateral side of the air intake branch pipe to swing; and the vacuum valve is controlled to act by an electromagnetic valve arranged on the lateral side of the intermediate plate of the air intake branch pipe. The electrical control mode adopted in the invention is quick in response, ensures that the most proper air amount is supplied under a corresponding working condition in time, achieves high air volume control accuracy and stability, improves the dynamic property of an engine and increases the air flow rate in a cylinder by improving the air intake speed of the engine at a high rotation speed, so a sub-combustion process is improved and the economy of low-speed fuel oil in the engine is improved.

Owner:TIANJIN HUIDE AUTOMOBILE INDUCTION SYST

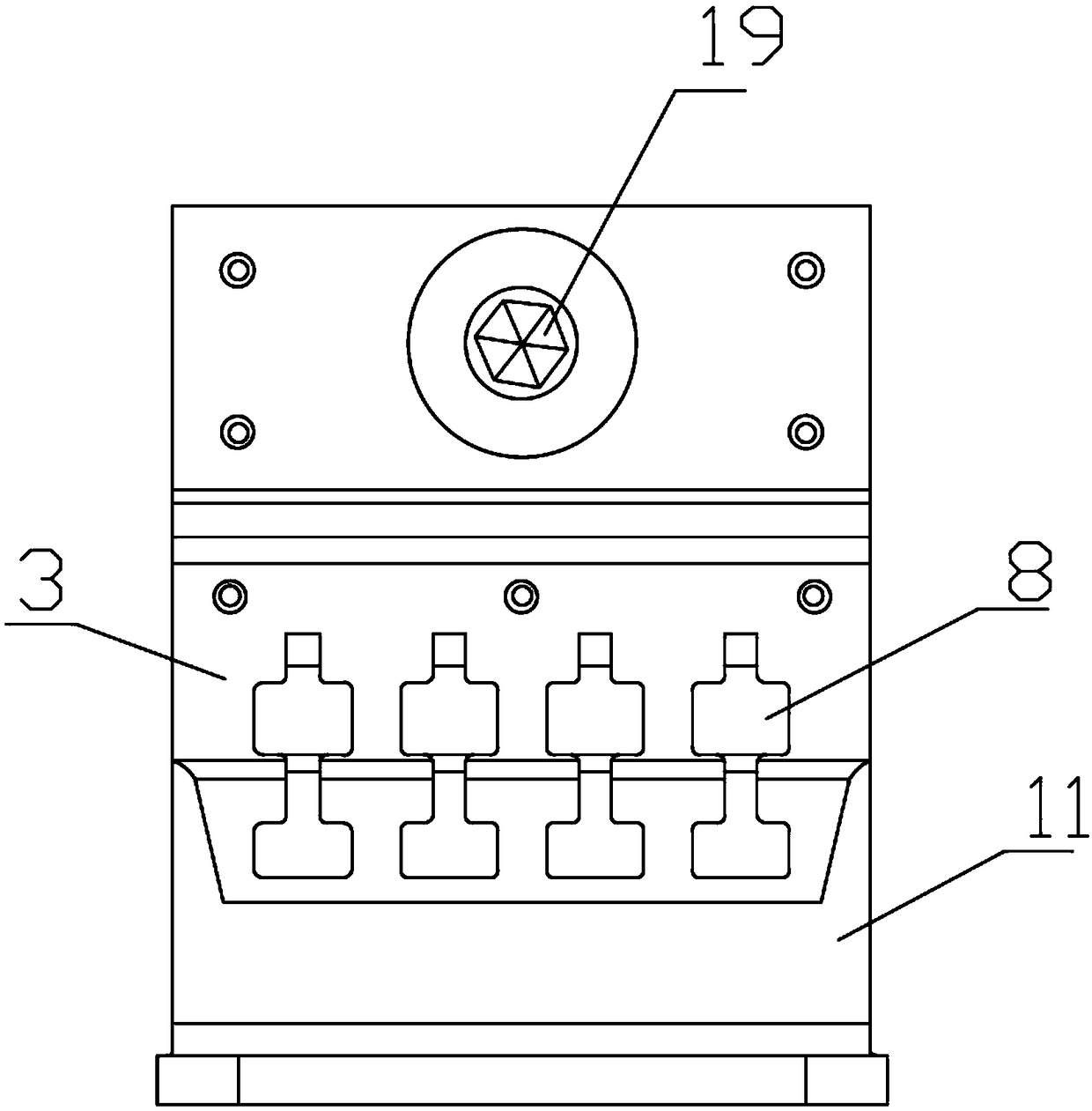

Heat-sealing packaging device and transverse sealing cutting unit thereof

A transverse sealing cutting unit comprises a pruning shear, a plurality of hot-pressing glands arranged on the pruning shear, cutters correspondingly arranged on each hot-pressing gland, and pairs of regulating mechanisms arranged on each hot-pressing gland, wherein cutter grooves are arranged in the hot-pressing glands; each cutter comprises a cutter body and a cutter blade point; and each regulating mechanism comprises a regulating block arranged in each cutter groove, a fixing block arranged at one end of each hot-pressing gland, and a screw rod nut penetrating through the fixing block and in a threaded connection with the regulating block. The section of the bottom surface of each cutter body is in an arc shape along the extending direction of the cutter groove, the section of the top surface of each regulating block is in an arc shape along the extending direction of the cutter groove, the top surface of the regulating block abuts against the bottom surface of the cutter body, and the bottom surface of the regulating bock is in a surface contact with the bottom of the cutter groove. The invention further provides a heat-sealing packaging device provided with the transverse sealing cutting unit. The regulating mechanisms are small in abrasion and long in service life, the volume of the pruning shear is not occupied, and the cost can be reduced.

Owner:GOLD HONG YE PAPER

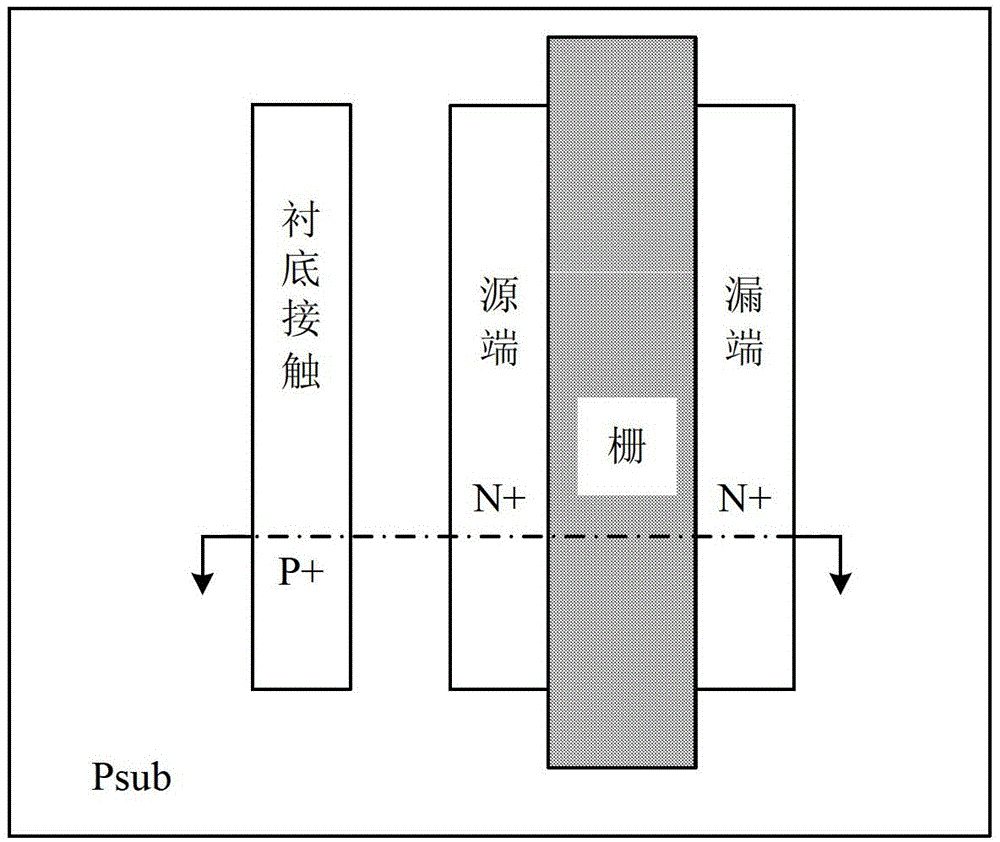

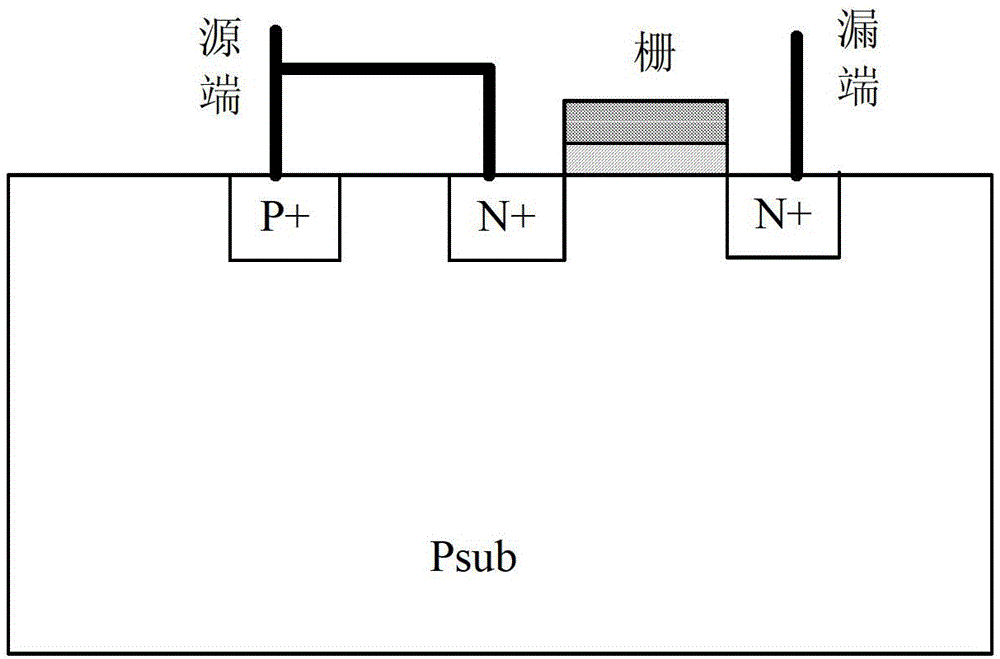

A mos device for integrated circuit chip esd protection

InactiveCN103280458BImprove turn-on uniformityIncrease the secondary breakdown currentSemiconductor devicesElectrical resistance and conductancePower flow

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

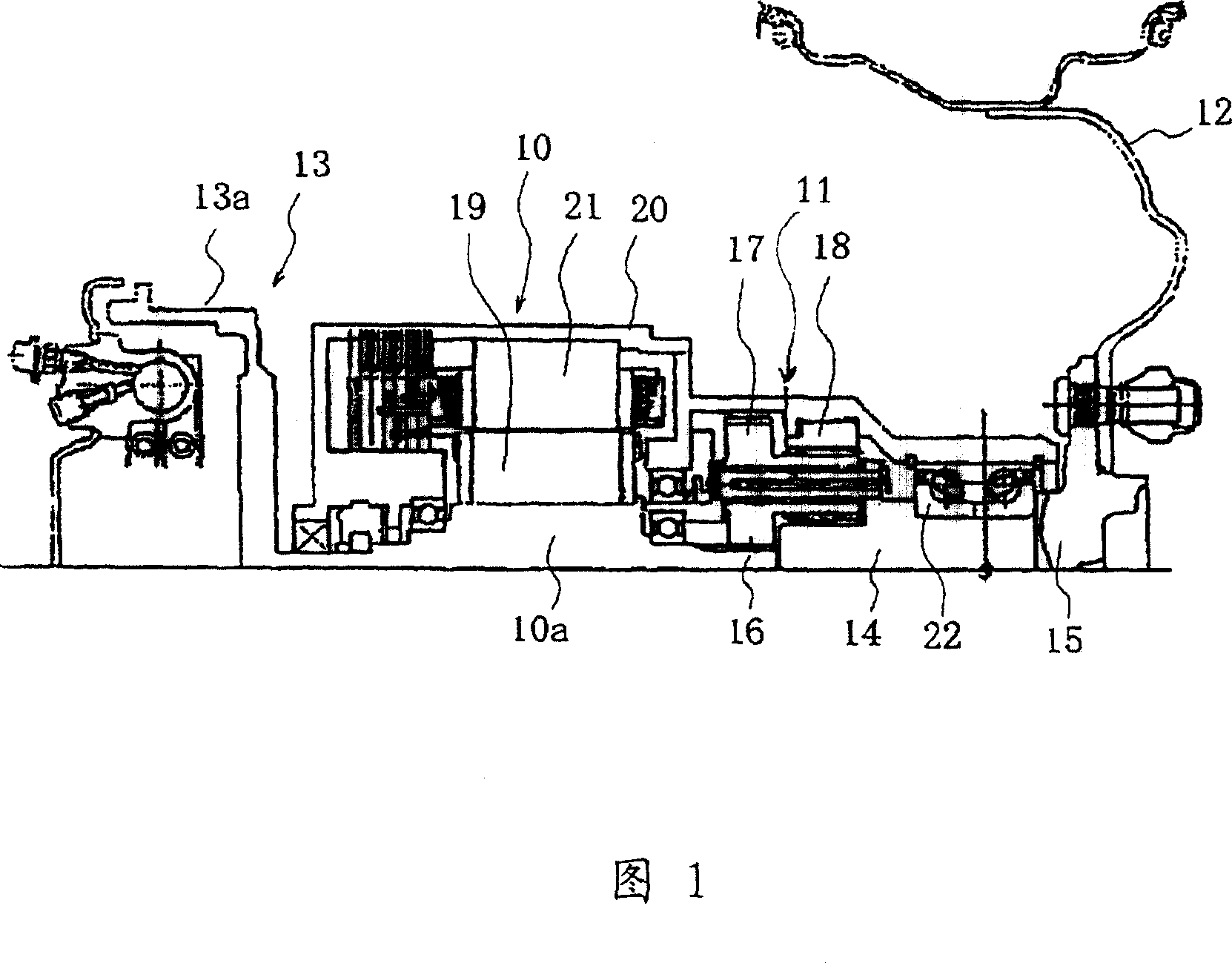

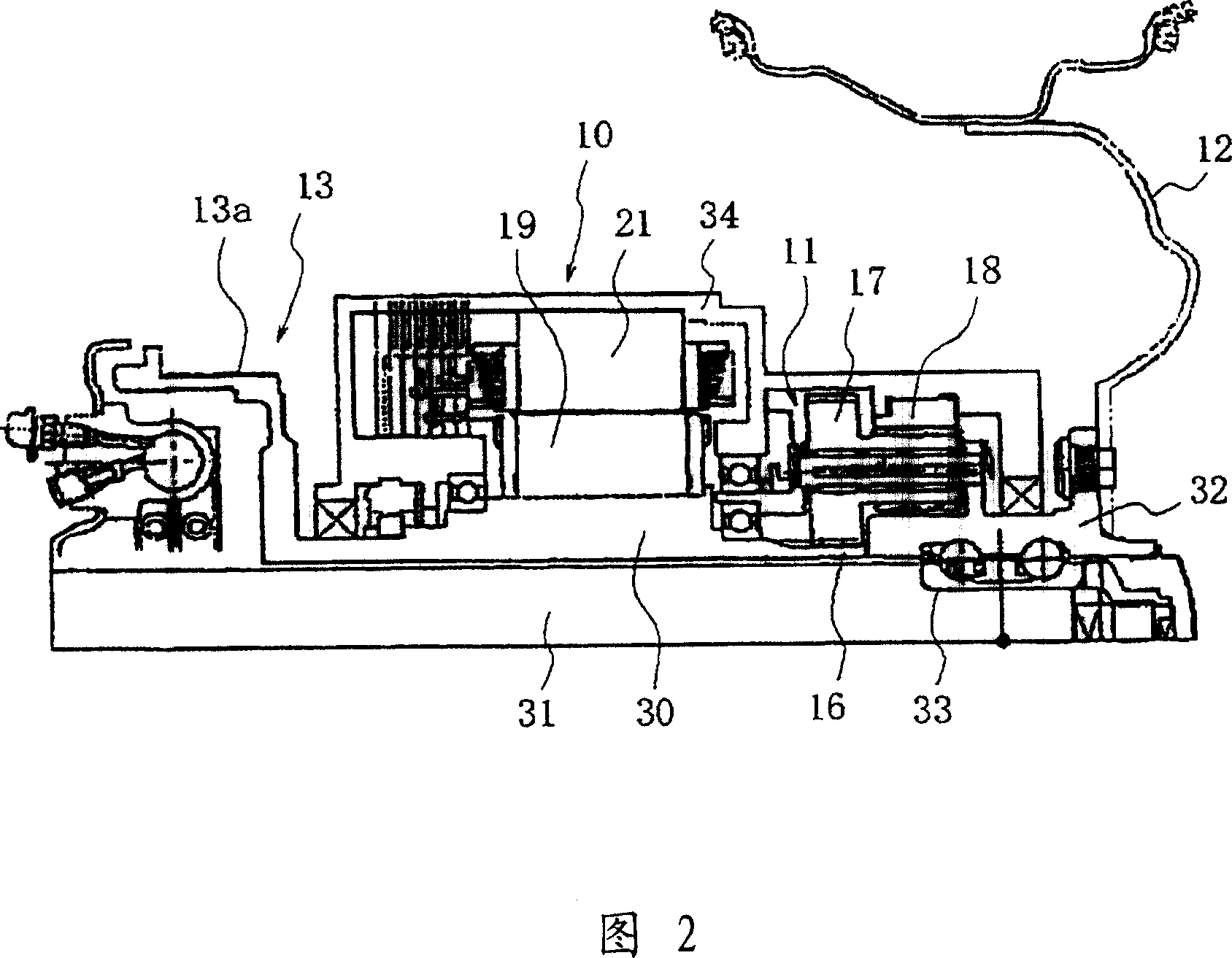

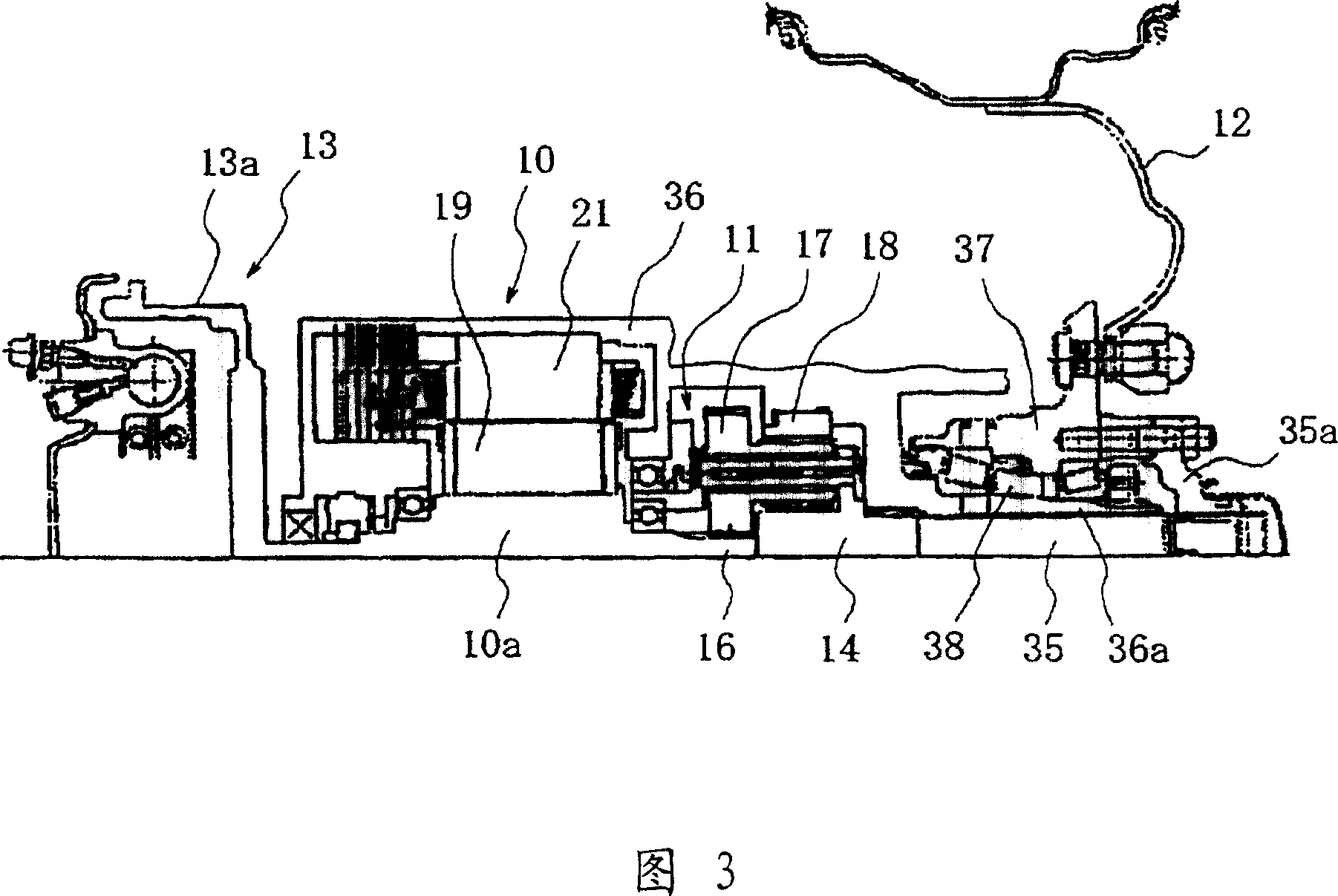

Vehicle drive

InactiveCN101032920ANo increase in sizeEasy to carryBraking element arrangementsElectric propulsion mountingRotational axisElectric machine

A drive unit is provided for driving a wheel (12) installed on a vehicle. The drive unit includes a driving source (10) equipped with a rotary shaft (10a). A speed reducer (11) is connected between the driving source and the wheel so as to reduce the rotational speed of the rotary shaft and transmit the reduced rotational speed to the wheel. A brake unit (13) is provided having a rotary member (13a) rotationally connected to the speed reducer on a side of the speed reducer opposite from the wheel so as to brake the rotation of the wheel through the speed reducer.

Owner:NISSAN MOTOR CO LTD

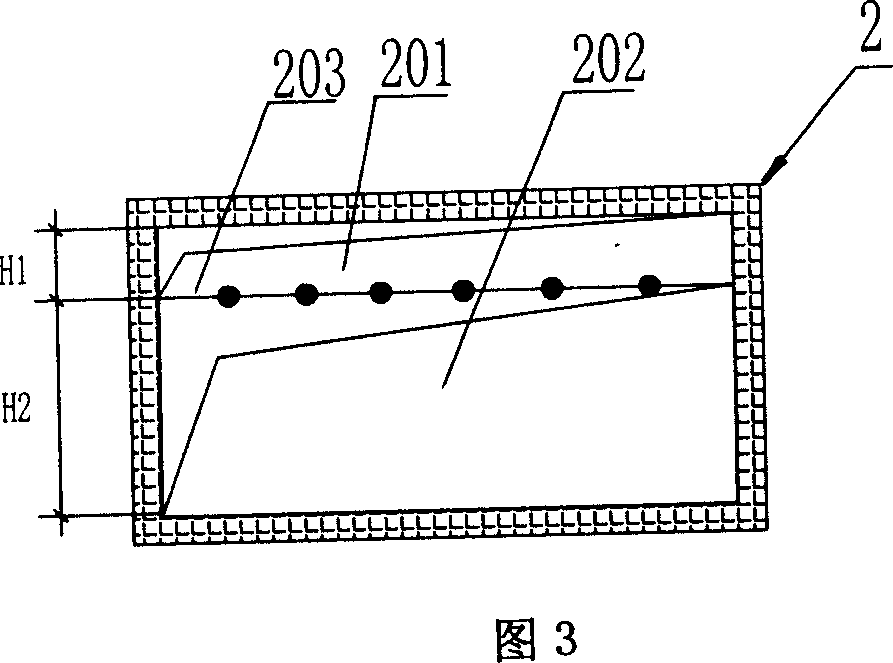

Method for realizing certain fresh-air quantity temperature regulation at end pant of air-conditioning system and VAN air-conditioner system with centain fresh-air quantity

ActiveCN1936438ASolve the problem of insufficient fresh air volumeSimple structureLighting and heating apparatusAir conditioning systemsAir volumeFresh air

This invention discloses a method for providing definite new air volume to a VAV system and a new VAV air conditioning system matched to said method, which keeps the new air entering into the end unchanged by setting an independent new air processor set and realizes the aim of determining new air value by adjusting circular air value to realize the air variance.

Owner:杨建宁

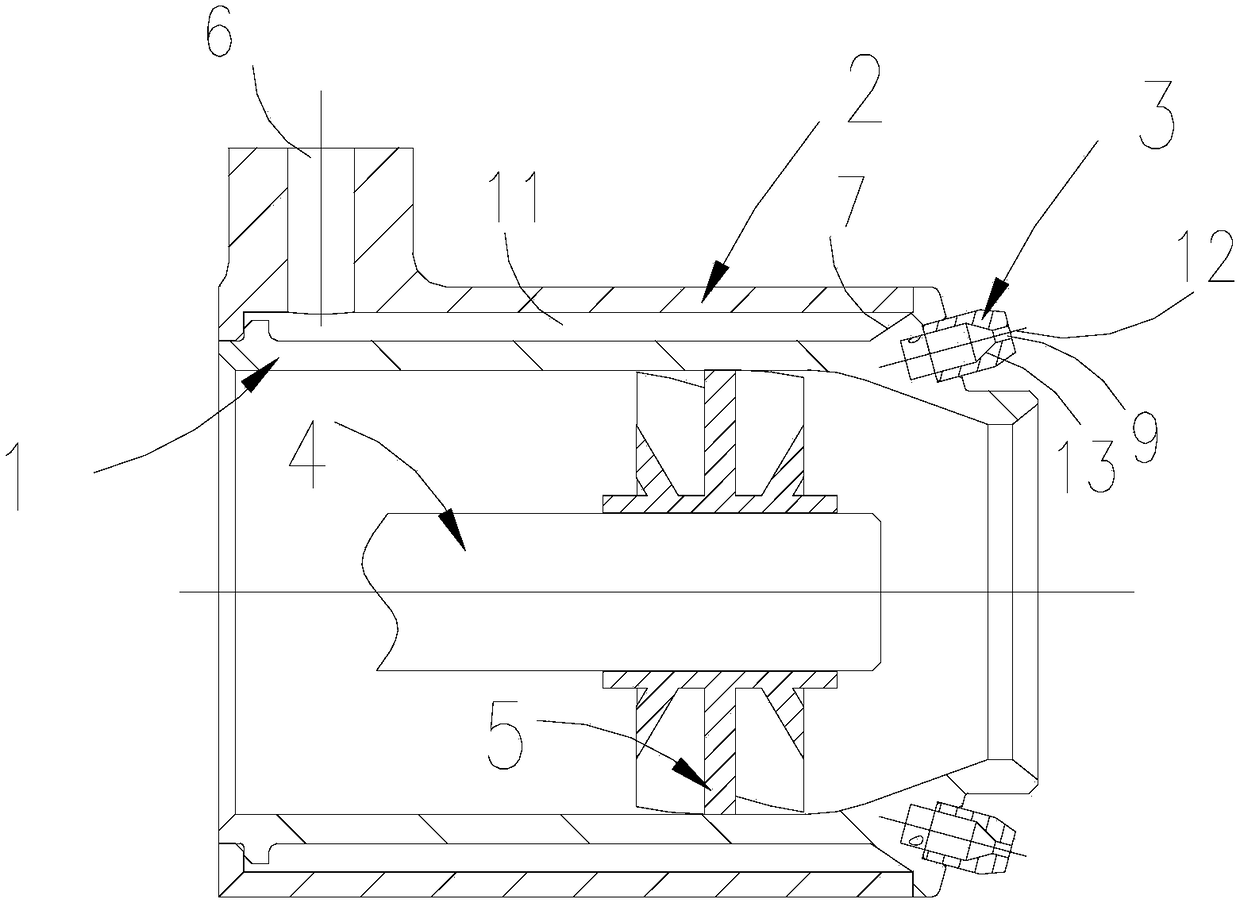

Multi-point jetting device for reinforcing atomization

InactiveCN108252811AImprove combustion efficiencyImprove atomization effectTurbine/propulsion fuel valvesThroatSpray nozzle

The invention relates to a multi-point jetting device for reinforcing atomization. The multi-point jetting device comprises a throat channel (1), a shell (2), a main spout (3), an auxiliary nozzle (4)and a swirler (5); and eccentric holes (10) are formed in the conical face (7) of the throat channel (1), and an annular cavity (11) communicates with the main spout (3) through the eccentric holes (10). By utilizing forming of the eccentric holes in the conical face at an inlet of each jetting point, fuel oil enters a swirling flow chamber to generate centrifugal rotation, atomization is reinforced due to the effect of centrifugal force, the burning efficiency is improved under the medium and small working conditions of an engine, and the size of the nozzle is not increased.

Owner:AECC SICHUAN GAS TURBINE RES INST

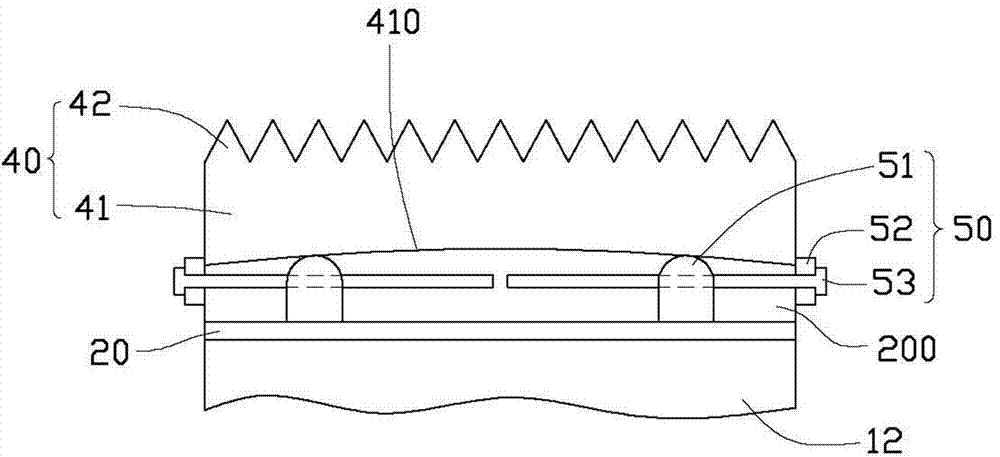

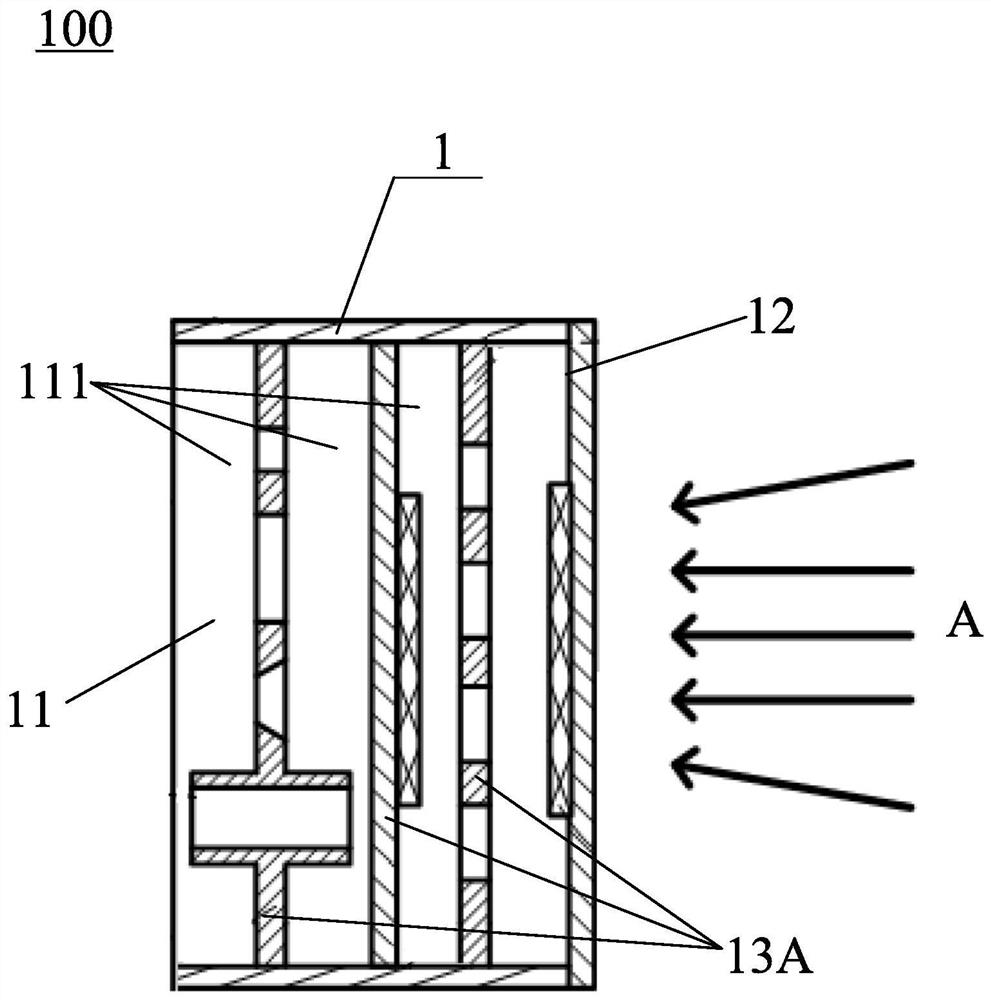

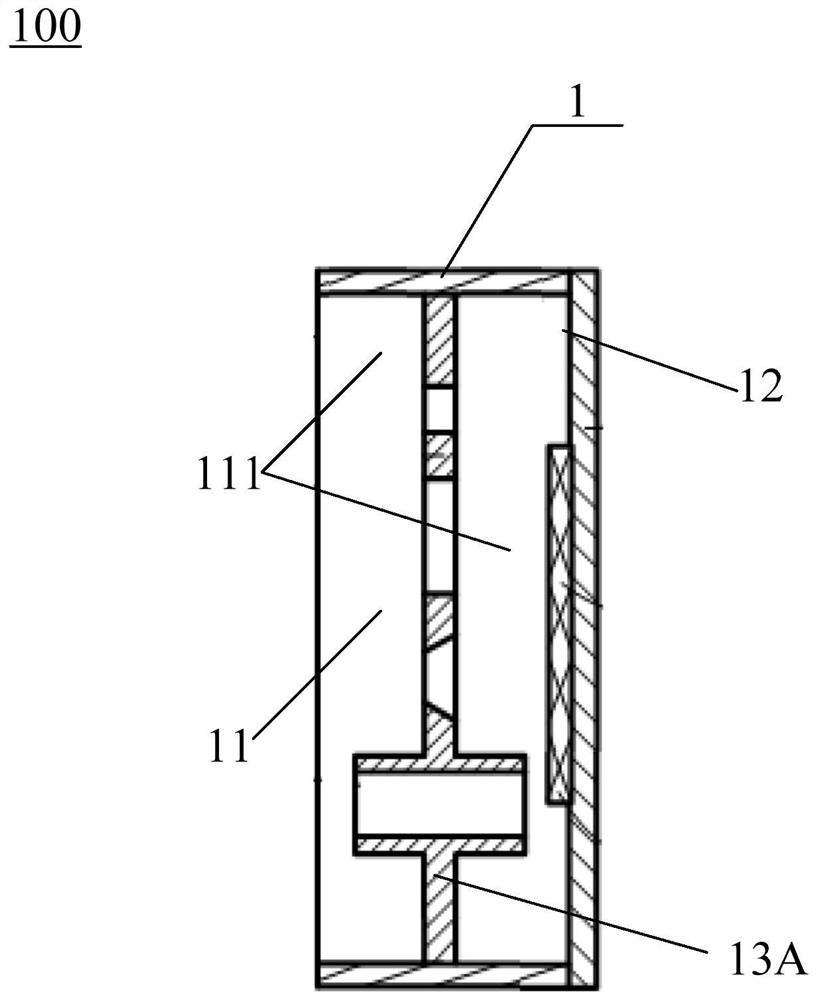

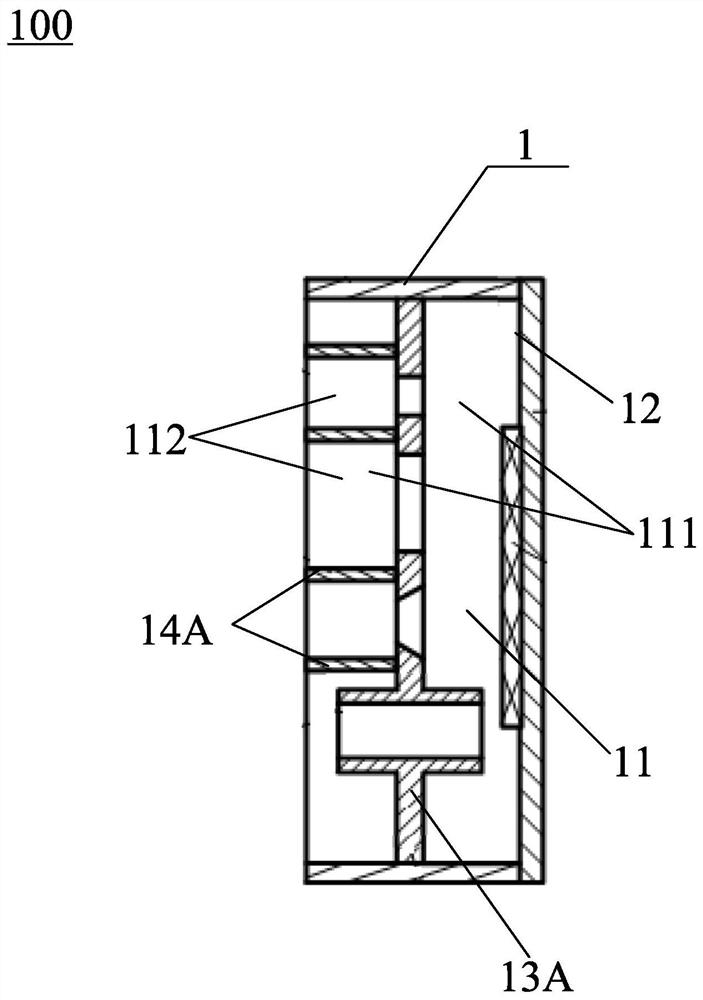

Broadband sound absorption structure

PendingCN112382264ARealization of broadband sound absorptionIncrease widthSound producing devicesNoiseThin membrane

The invention belongs to the technical field of sound absorption, and discloses a broadband sound absorption structure. The broadband sound absorption structure comprises a shell, a sound absorption cavity is formed in the shell, an opening communicated with the sound absorption cavity and the external environment is formed in the shell, and a perforated plate or a thin film used for noise input is fixed to the opening in a sealed mode; the structure also comprises independent sub sound absorption cavities which are formed in the sound absorption cavity, and each sub sound absorption cavity isprovided with a perforated plate or a film for inputting noise in the sound absorption cavity; the sub sound absorption cavities are constructed to be different in cavity size, so that noise of the external environment enters the sound absorption cavities, and after the noise enters the sub sound absorption cavities, the noise of the corresponding frequency band can be absorbed through the cavities, with different sizes, of the sub sound absorption cavities, and broadband sound absorption of the noise is achieved. The broadband sound absorption structure is small in size and good in sound absorption effect on low-frequency noise.

Owner:上海超颖声学科技有限公司

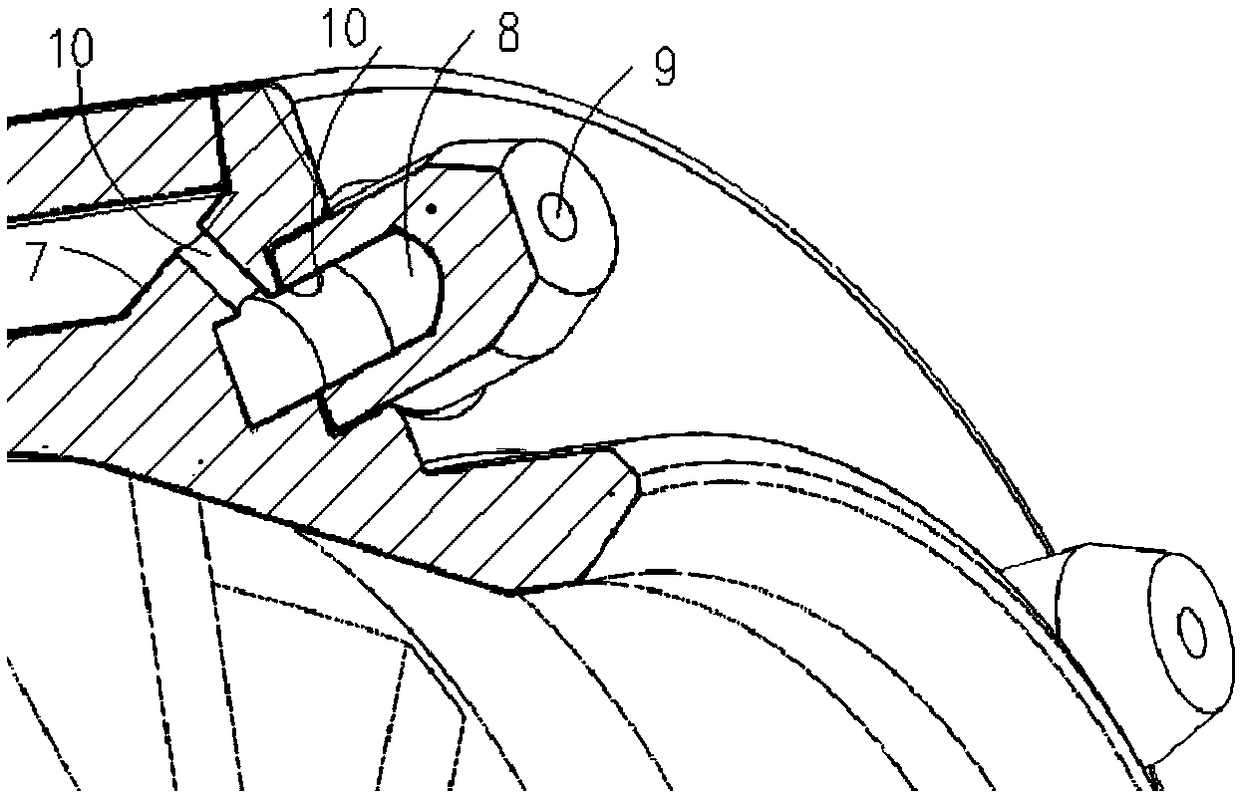

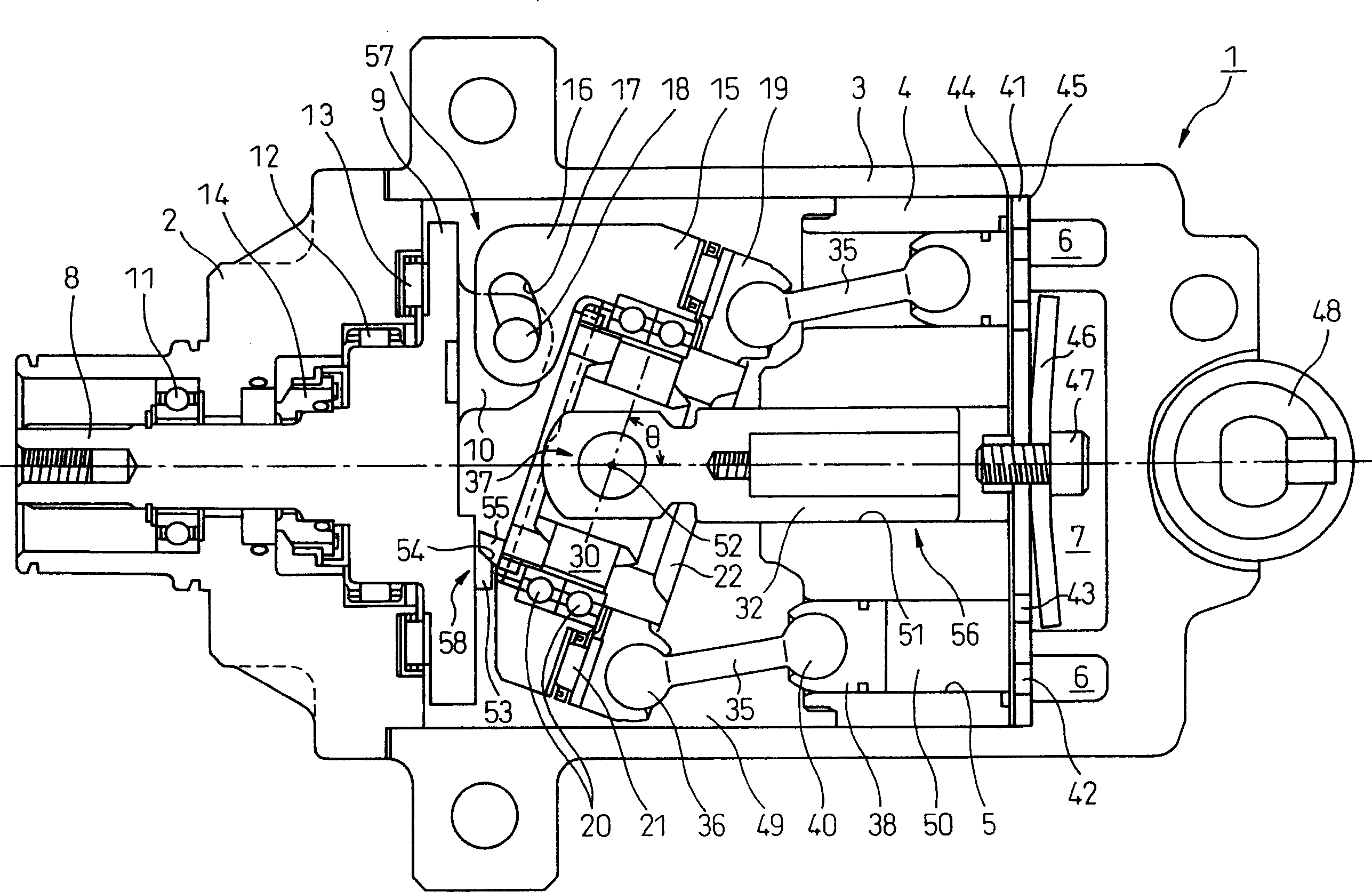

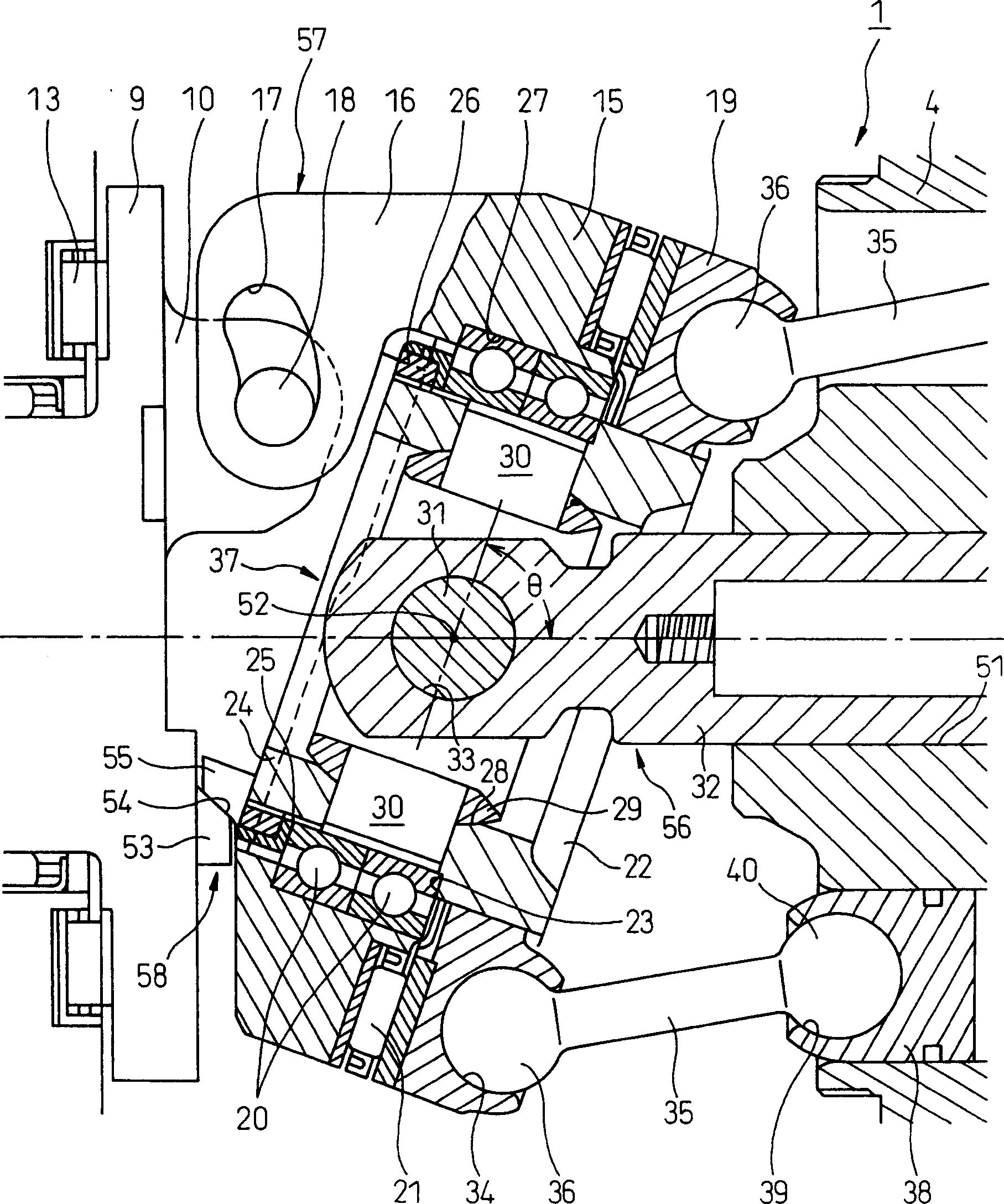

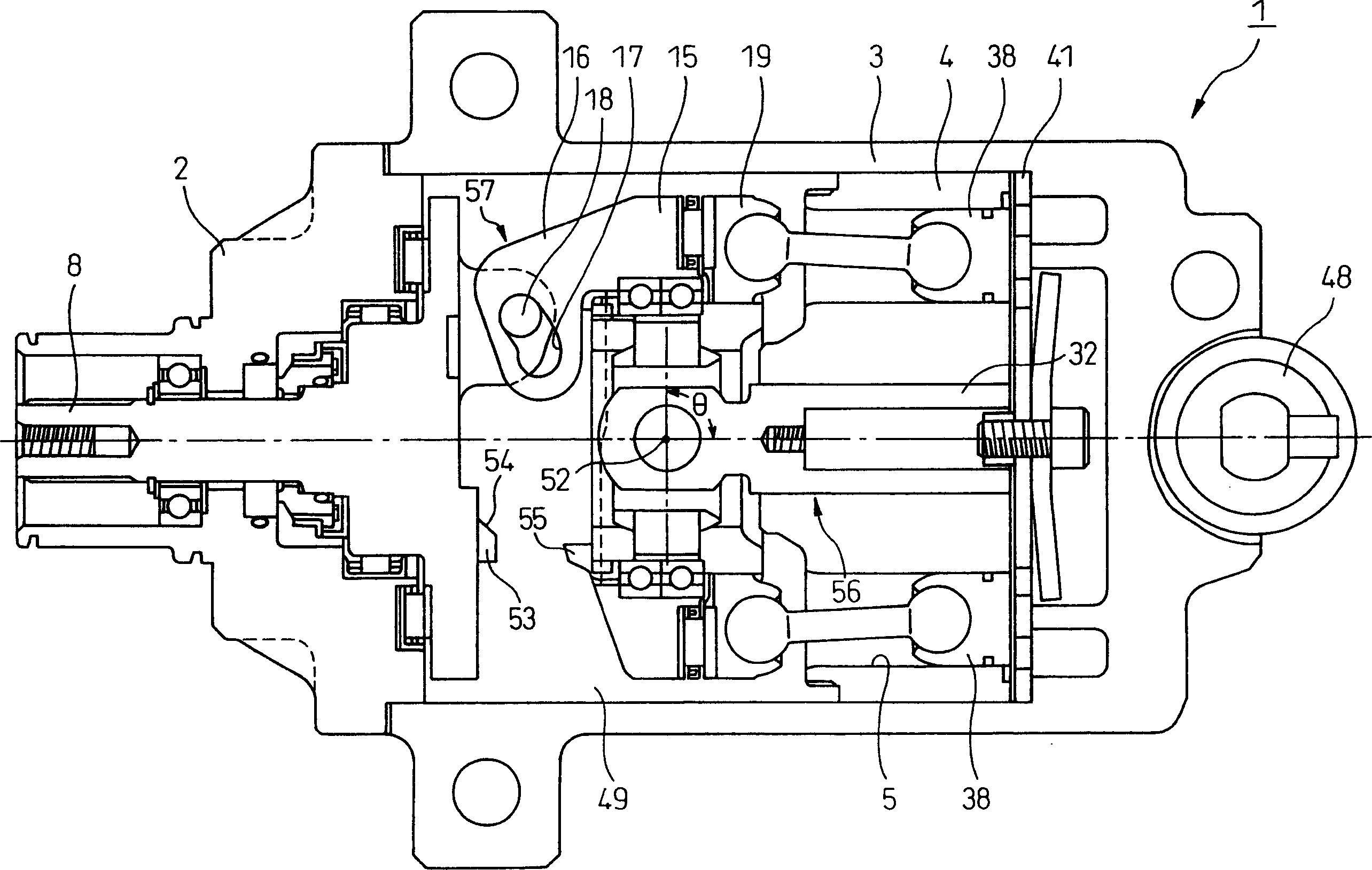

Taumelscheiben-verstellkompressor

InactiveCN1690414AIncrease its sizeNo increase in outer ring sizeMulti-stage pumpsPositive-displacement liquid enginesUniversal jointDrive shaft

In a configuration in which a driving shaft 8 supported in a cantilever manner is connected with a drive plate 15 through a link mechanism 57 and a wobble plate 19 capable of rotating relatively for it is connected with the central shaft 32 through a rotation stopping mechanism 56 including the universal joint 37, load in the radial direction which is component of force of compression reaction force acts on the rotation stopping mechanism 56. By providing projections 53 and 55 which can be mutually engaged between the driving shaft 8 and the drive plate 15 and a special load supporting part composed of an inclined face 54 and engaging the load supporting part in the vicinity of operation region for bringing the maximum discharge capacity, load in the radial direction is supported by the driving shaft 8.

Owner:DENSO CORP +1

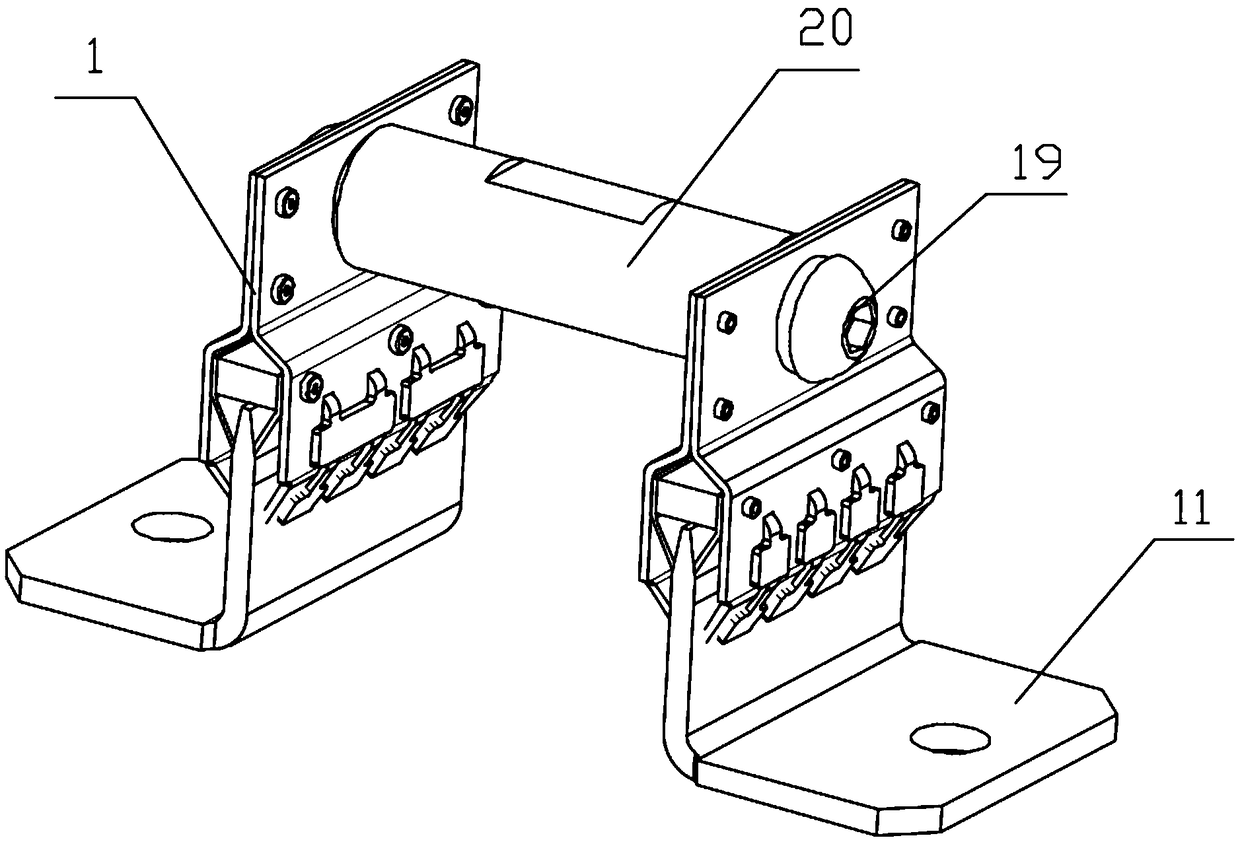

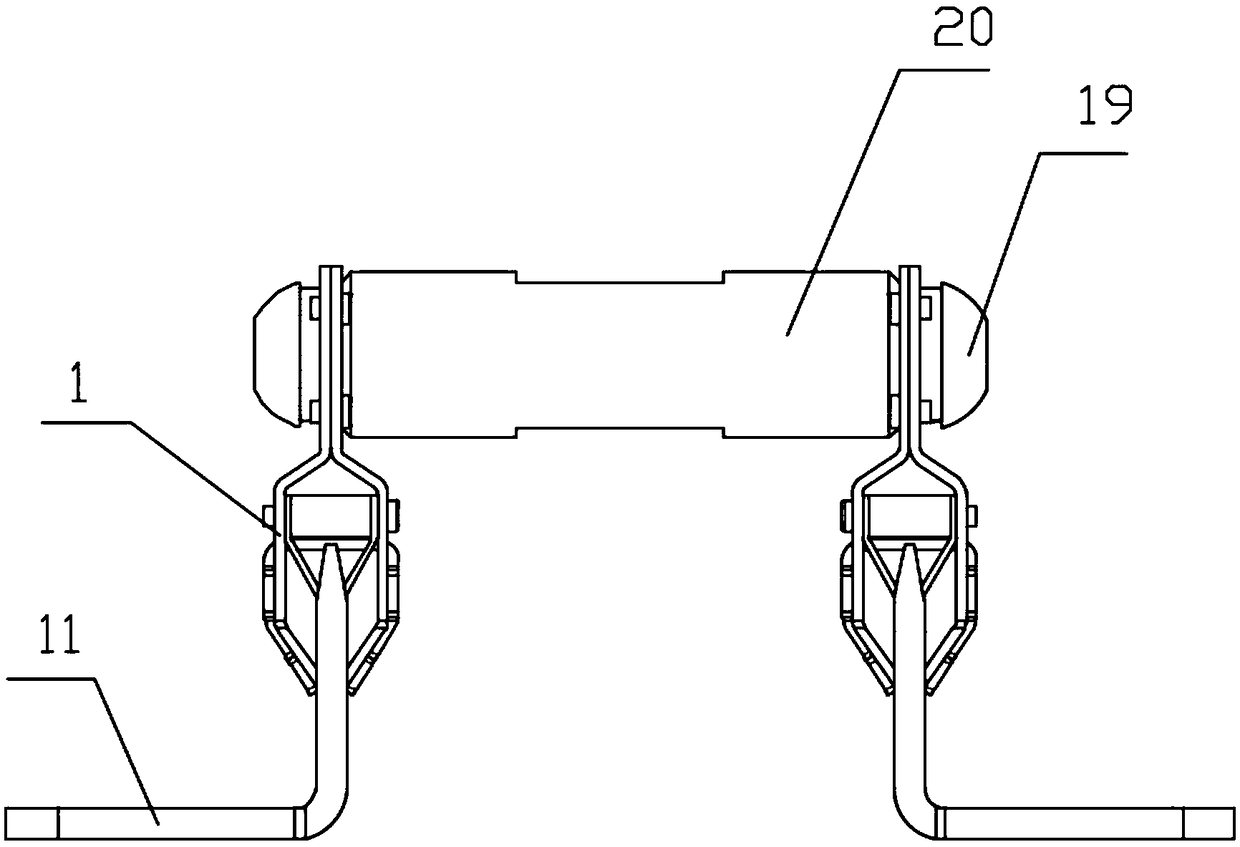

Electrical connector seat

PendingCN109103651AIncrease surface areaImprove cooling efficiencySecuring/insulating coupling contact membersElectricityEngineering

An electrical connector seat comprises a first group of contact pieces, wherein the first group of contact pieces is composed of two rows of oppositely arranged contact pieces, the upper ends of the two rows of contact pieces are connected and the lower ends form sockets; at least one group of contact pieces is added to the electric connector base, and the added contact piece group is arranged inthe first group of contact pieces, and the added contact piece group comprises two rows of oppositely arranged added contact pieces, and the lower ends of the two rows of added contact pieces of the added contact piece group form sockets, and the sockets face the same direction as the sockets of the first group of contact pieces; in accordance with the prior art, so that the connection between theinsert piece and the contact piece is more reliable. At the same time, the contact area between the plug and the contact piece is increased, so that the contact resistance and the heat generation amount are reduced, and the surface area of the contact piece is increased by the double-layer contact piece, the heat dissipation efficiency of the contact surface is improved, the hidden danger of safety is reduced, the size of the structure is not increased by the double-layer contact piece, and the cost is effectively controlled.

Owner:ZHEJIANG ZHONGHANG ELECTRONICS

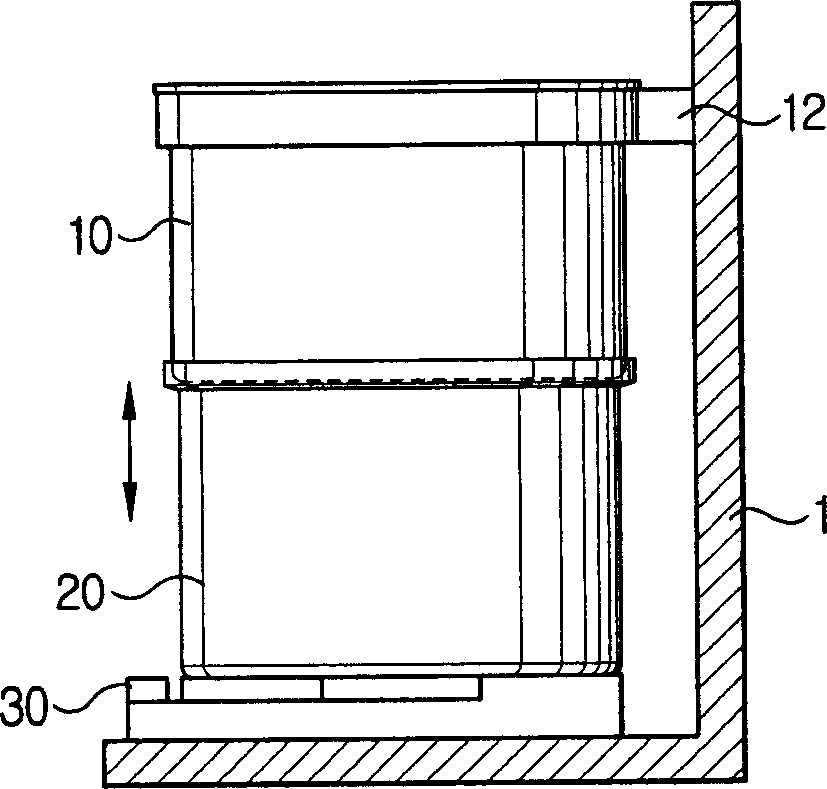

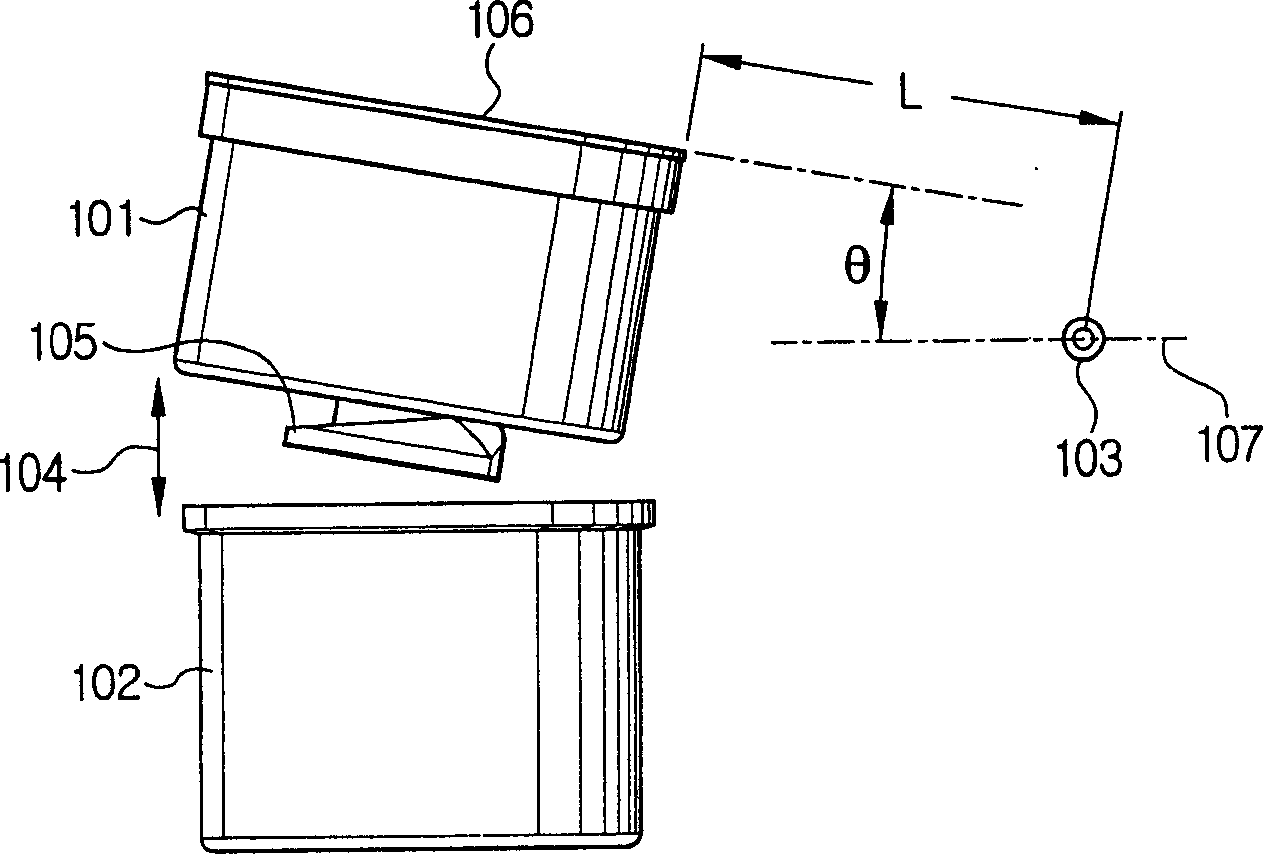

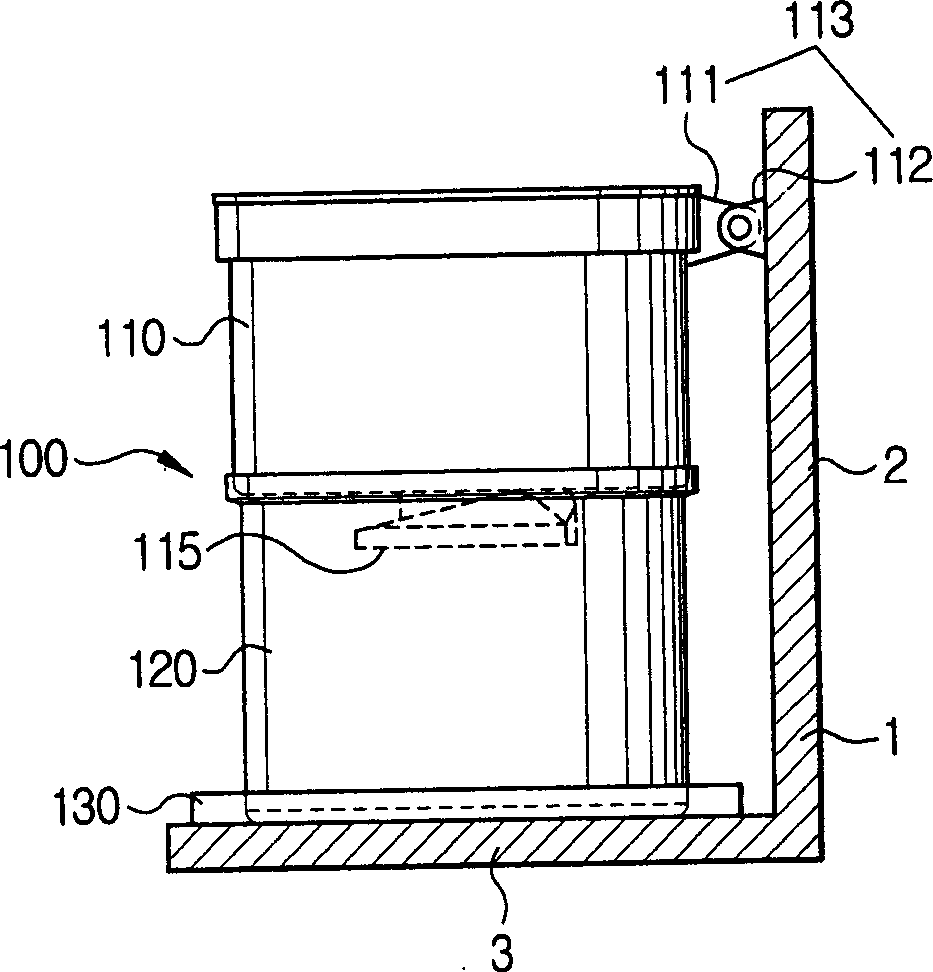

Cyclonic vacuum cleaner

Cyclonic vacuum cleaners provide an increased volume dust container by configuring the cyclonic body of the vacuum cleaner to be pivotally mounted to the vacuum cleaner body. By rotating it about the pivot seat, the cyclone body is disconnected from the dust container by rotating or "opening" the cyclone body. The dust container removably installed in the cleaner body and the cyclone body hinged on the upper part of the cleaner body are selectively detached and connected with respect to the dust container.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

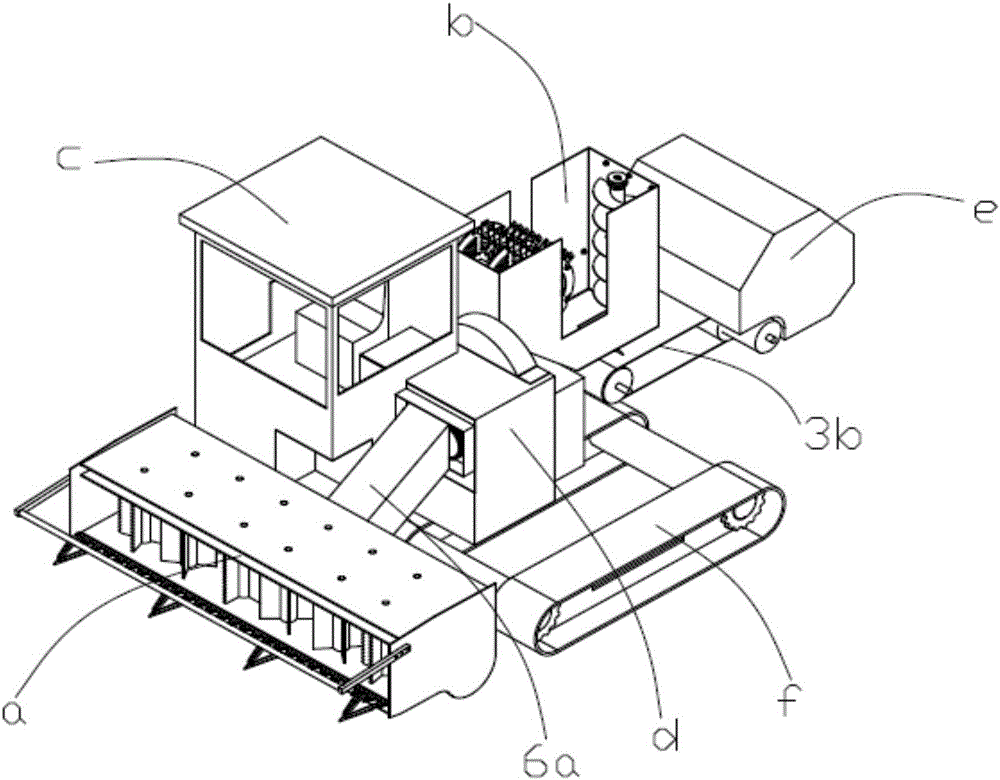

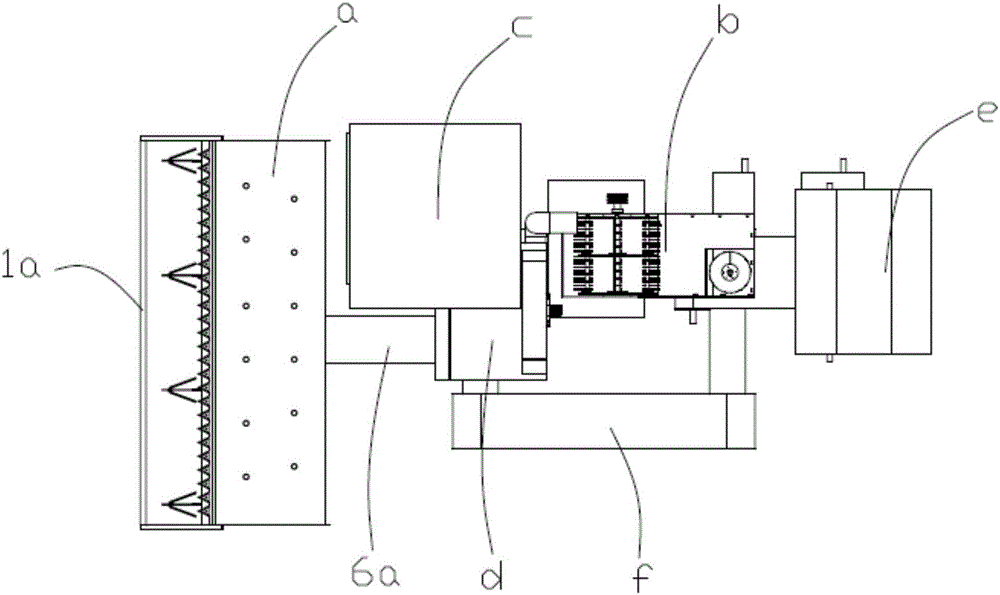

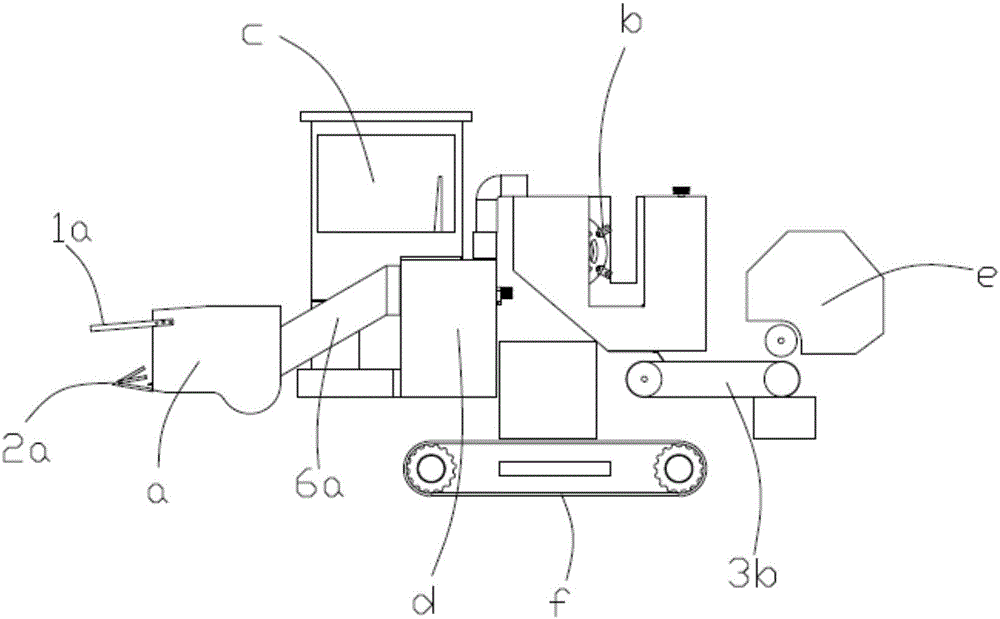

Paper mulberry ensilage direct harvesting baler

InactiveCN106717483AFast feedingFeed wheel assembly feeds quicklyMowersAgricultural undercarriagesPulp and paper industryFan blade

The invention provides a paper mulberry ensilage direct harvesting baler which comprises a cutting table assembly, a secondary rubbing conveying mechanism, a cab assembly, a fan assembly, a baler assembly and a crawler-type walking assembly. Paper mulberries are harvested through the cutting table assembly, fed through a feeding wheel assembly, and extruded through a bridging assembly to enter the fan assembly; paper mulberry stems are subjected to primary cutting of a cutter I of the fan assembly and then finely cut through a cutter II, the paper mulberry stems are rubbed by fan blades and then fed into the secondary rubbing conveying mechanism through a fan, the paper mulberry stems are rubbed by a rubbing box in the secondary rubbing conveying mechanism, then a feed additive is sprayed to the paper mulberry stems in a spraying box, the paper mulberry stems are pushed to a conveying belt, and ensilage feed is conveyed to the baler assembly through the conveying belt for baling. The paper mulberry ensilage direct harvesting baler is compact and light in structure and facilitates work, and integrated work of harvesting, conveying, cutting, rubbing and balking of the paper mulberries is achieved. The blank of paper mulberry integrated harvesting work machines at home and abroad is filled up.

Owner:LINYI YINXIN ENG MACHINERY CO LTD

Compact air-cooled unit

PendingCN108242867AReduce volumeReduce quality problemsMagnetic circuit stationary partsCooling/ventillation arrangementCooling effectEngineering

The invention discloses a compact air-cooled unit, which comprises a cabinet, a power device and a generator, wherein the power device and the generator are arranged in the cabinet and are adjacentlyand coaxially connected; one end, far away from the power device, of the generator motor shaft extends out of the generator but does not pass through the cabinet; a cabinet cooling fan is fixed on a motor shaft extending section extending out of the generator; and the generator comprises a PCB stator coaxially arranged with the motor shaft and an electronic module. According to the compact air-cooled unit disclosed in the invention, the PCB generator with a small size and a small mass is adopted, the generator unit with the same size thus internally has the space for enabling the motor shaft to extend out of the generator, mounting of the cabinet cooling fan is thus facilitated, on the basis of the existing generator set, the whole size of the generator set does not need to be increased, the cabinet cooling fan can be mounted on the generator motor shaft, and the cooling effects in the cabinet are improved.

Owner:WERNERFUJIAN POWER CO LTD

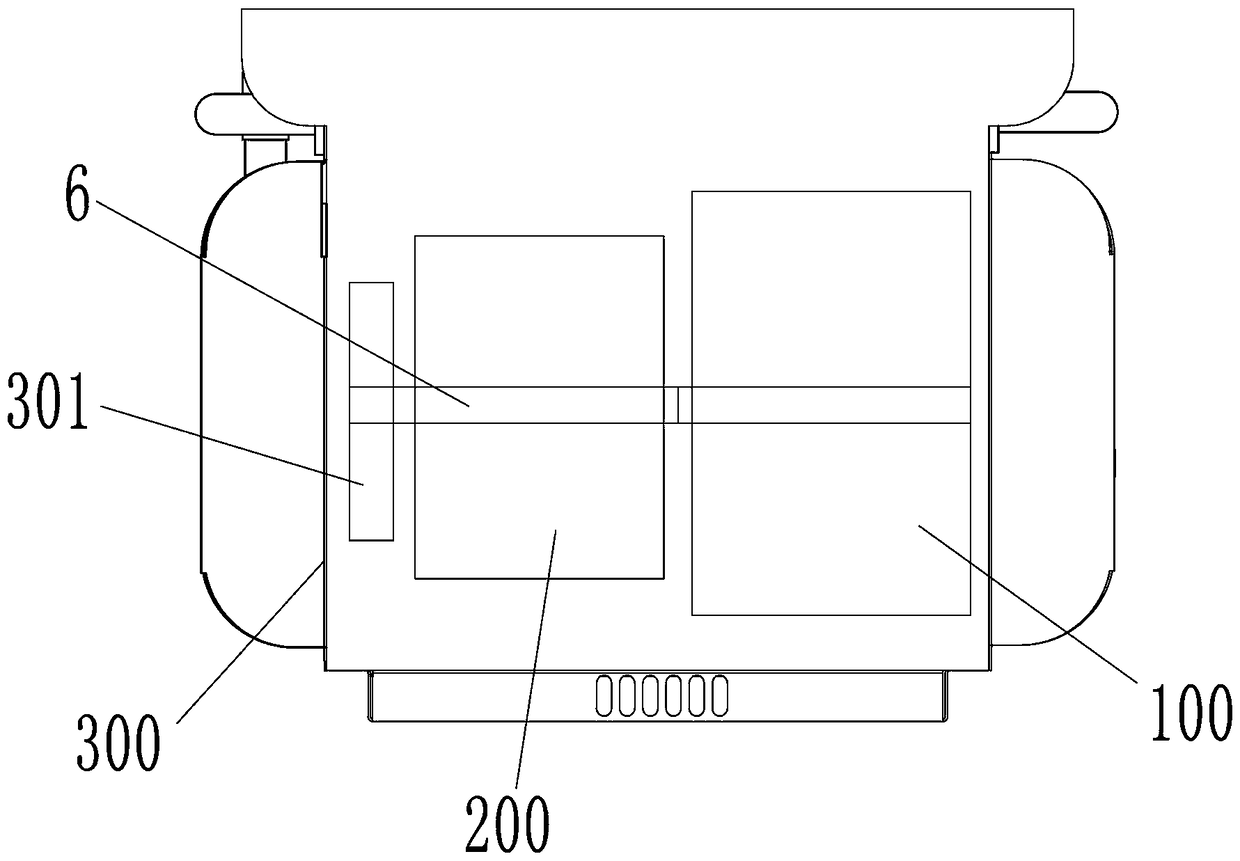

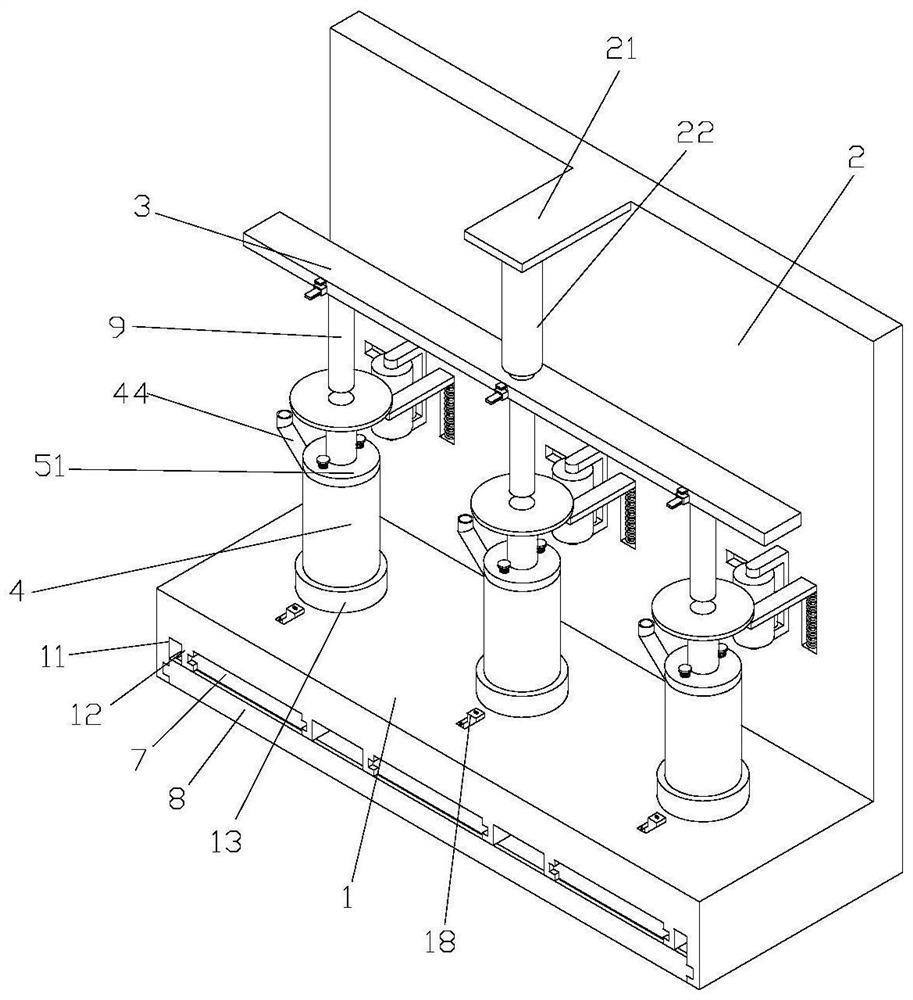

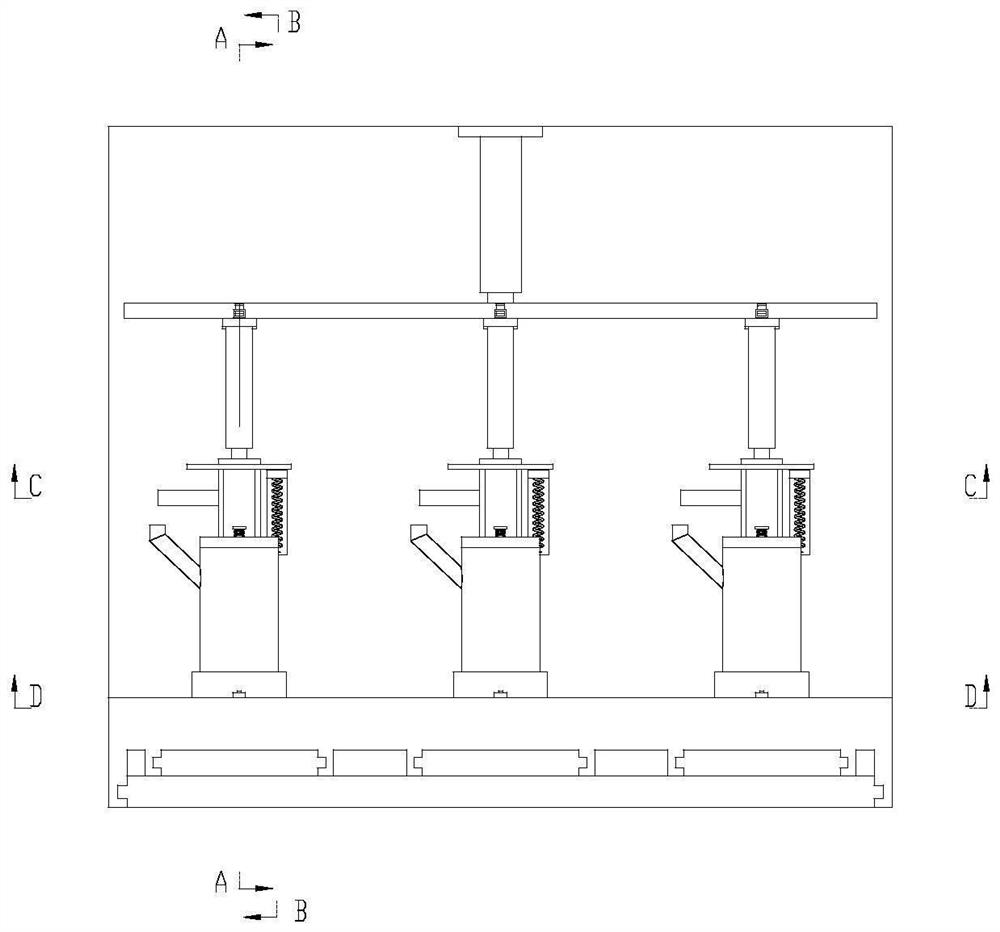

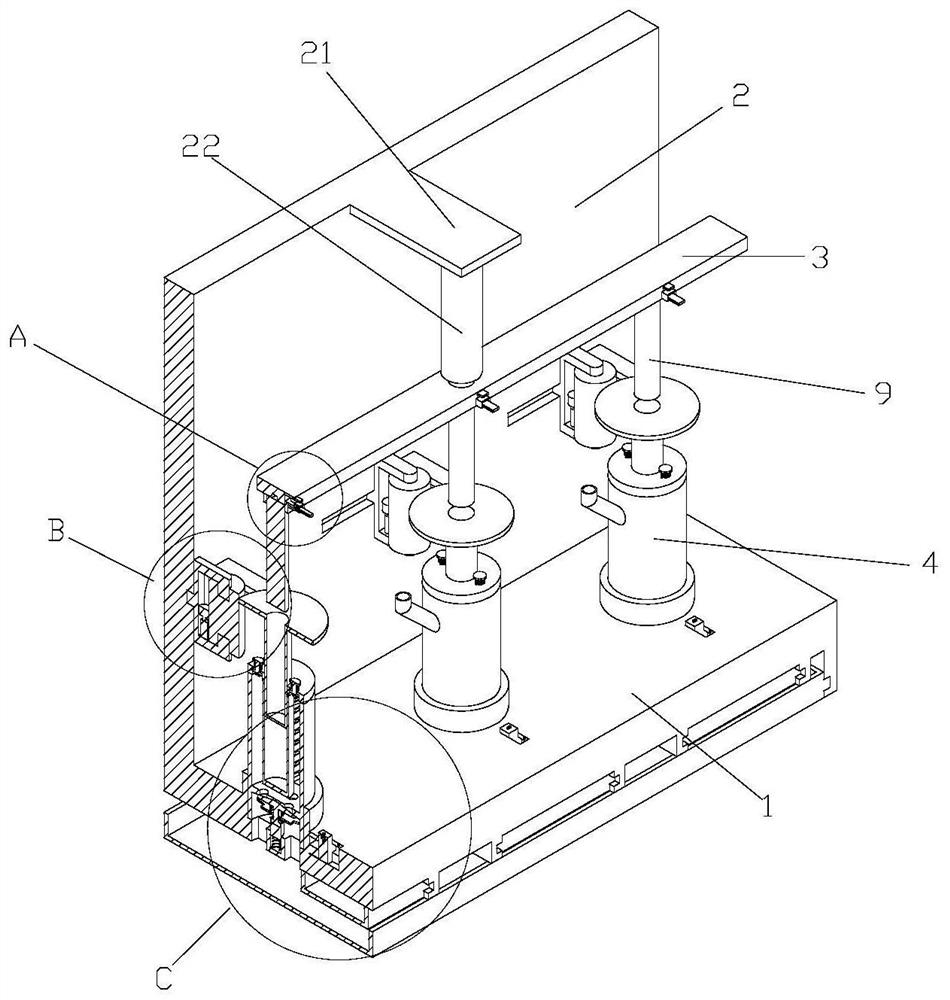

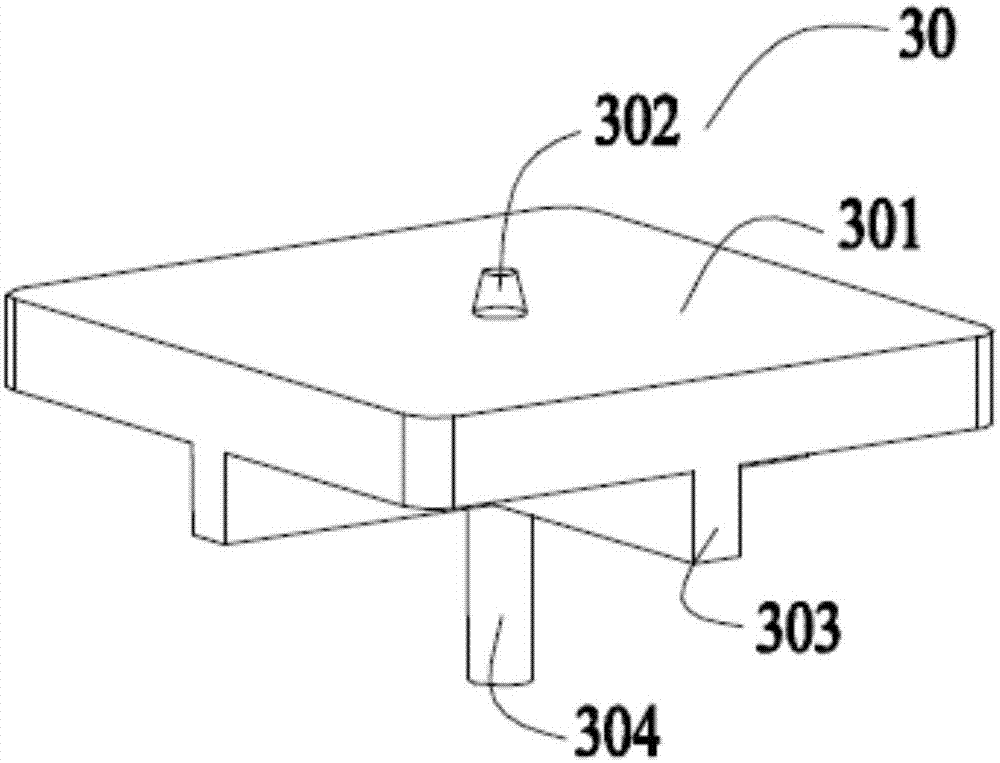

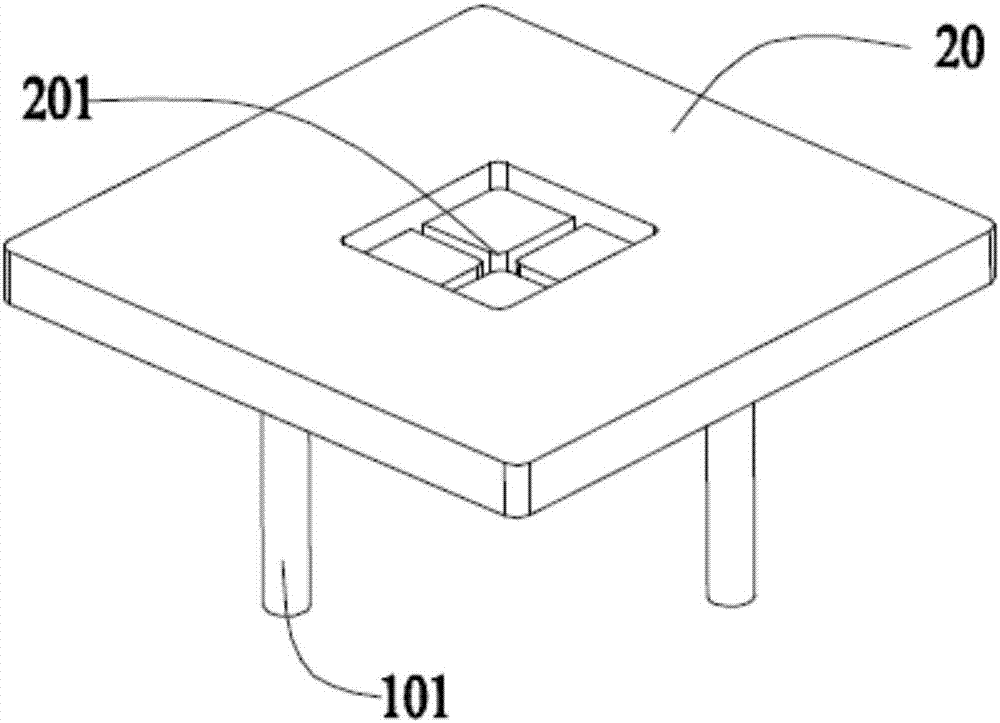

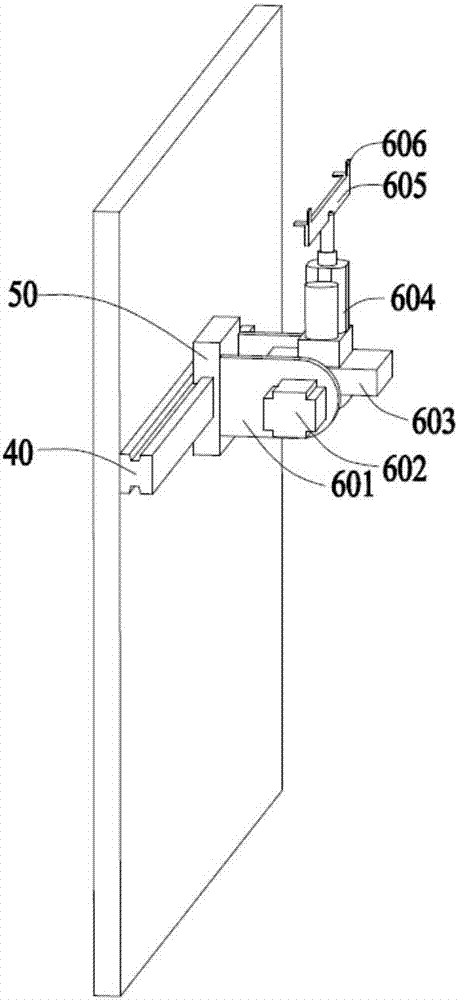

Magnetic bead method nucleic acid extraction equipment

ActiveCN112358965AReduce volumeNo increase in sizeBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadElectric machinery

The invention discloses magnetic bead method nucleic acid extraction equipment, which comprises a bottom plate, a vertical plate arranged on the bottom plate and an extraction pipe arranged on the bottom plate, a mounting groove is formed in the bottom plate, the extraction pipe is inserted into the mounting groove, a plurality of liquid outlet holes are formed in the bottom of the extraction pipe, a liquid inlet pipe is arranged on the side wall of the extraction pipe, and a sealing plate matched with the liquid outlet hole is further arranged at the bottom of the extraction pipe; wherein a first sleeve is arranged in the extraction pipe in a penetrating manner, a first push plate is arranged on the first sleeve, a plurality of through grooves are formed in the first push plate, and a plurality of first baffle plates matched with the through grooves are arranged on the first push plate; a magnetic rod is arranged on the vertical plate, and a driving motor used for driving the first sleeve to rotate is further arranged on the vertical plate.

Owner:CHINA JILIANG UNIV

Conveying mechanism for carriers

ActiveCN107963453AEasy to replaceNo increase in sizeConveyor partsOperation safetyIndustrial engineering

The invention discloses a conveying mechanism for carriers. The conveying mechanism comprises a machine table, a fixed table and two grabbing mechanisms. The fixed table is arranged at the bottom endof the machine table and used for bearing the carriers, the center of the fixed table is provided with a groove, a movable plate matched with the groove is movably arranged in the groove in the longitudinal direction, the two grabbing mechanisms are movably arranged on the two sides of the machine table correspondingly, and the grabbing mechanisms are provided with clamping claws used for grabbingthe carriers. According to the conveying mechanism, the carries are supported to the certain height through the movable plate, then, the carriers are directly conveyed to the position outside the machine table through the grabbing mechanisms, workers can replace the carriers conveniently, the automation degree is improved, and operation safety is ensured.

Owner:FLEXSINE IND TECH SUZHOU CO LTD

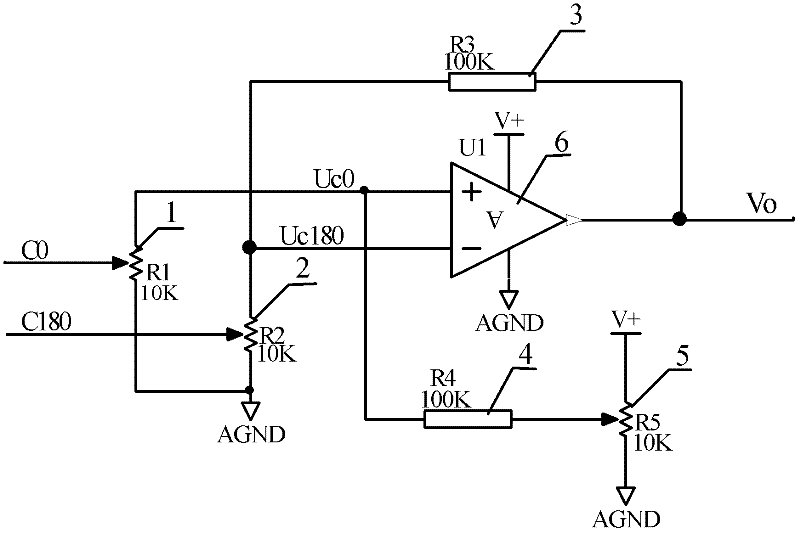

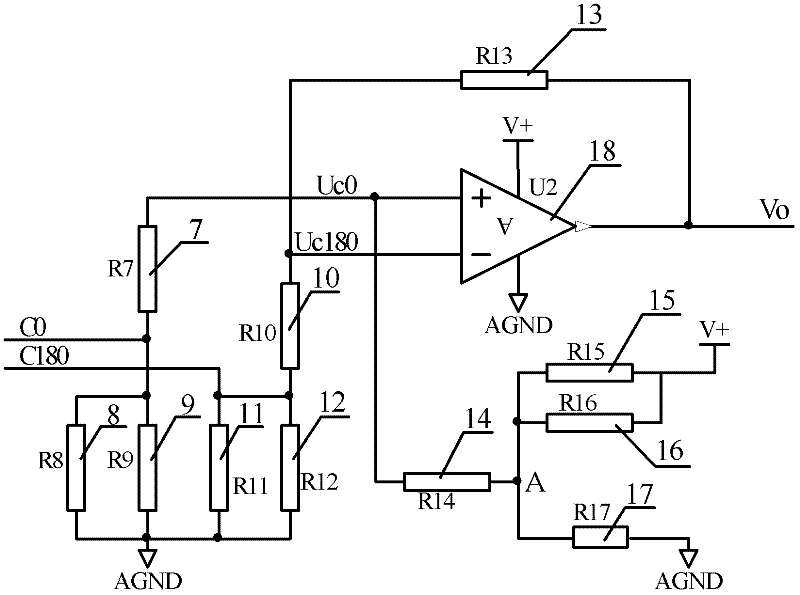

Signal pre-amplifier circuit of aerospace-grade photoelectric encoder

InactiveCN102355211AImprove reliabilityEasy to adjustDifferential amplifiersDc-amplifiers with dc-coupled stagesNegative feedbackAudio power amplifier

The invention relates to a signal pre-amplifier circuit of an aerospace-grade photoelectric encoder, belonging to a signal amplifier circuit involved in the technical field of photoelectric encoders and aiming at solving the technical problem of providing the signal amplifier circuit of the aerospace-grade photoelectric encoder. The technical scheme of the invention is that: the signal pre-amplifier circuit comprises a first to a third input resistors, a first to a third inverted input resistors, a negative feedback resistor, a first to a fourth bias resistors and an amplifier; after the second positive input resistor and the third positive input resistor are connected in parallel, one end is grounded and the other end is connected with the first positive input resistor, and the other end of the first positive input resistor is connected with a positive input pin of the amplifier; after the second inverted input resistor and the third inverted input resistor are connected in parallel, one end is grounded and the other end is connected with the first inverted input resistor, and the other end of the first inverted input resistor is connected with the negative input pin of the amplifier; one end of the negative feedback resistor is connected with an output pin of the amplifier, and the other end of the negative feedback resistor is connected with the nvegative input pin of the amplifier; after the second bias resistor and the third bias resistor are connected in parallel, one end is connected with a positive power supply V+, the other end is connected with the fourth bias resistor in series, and the other end of the fourth bias resistor is grounded; and one end of the first bias resistor is connected with the positive input pin of the amplifier, and the other end of the first bias resistor is connected with a connection point A of the second bias resistor, the third bias resistor and the fourth bias resistor.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

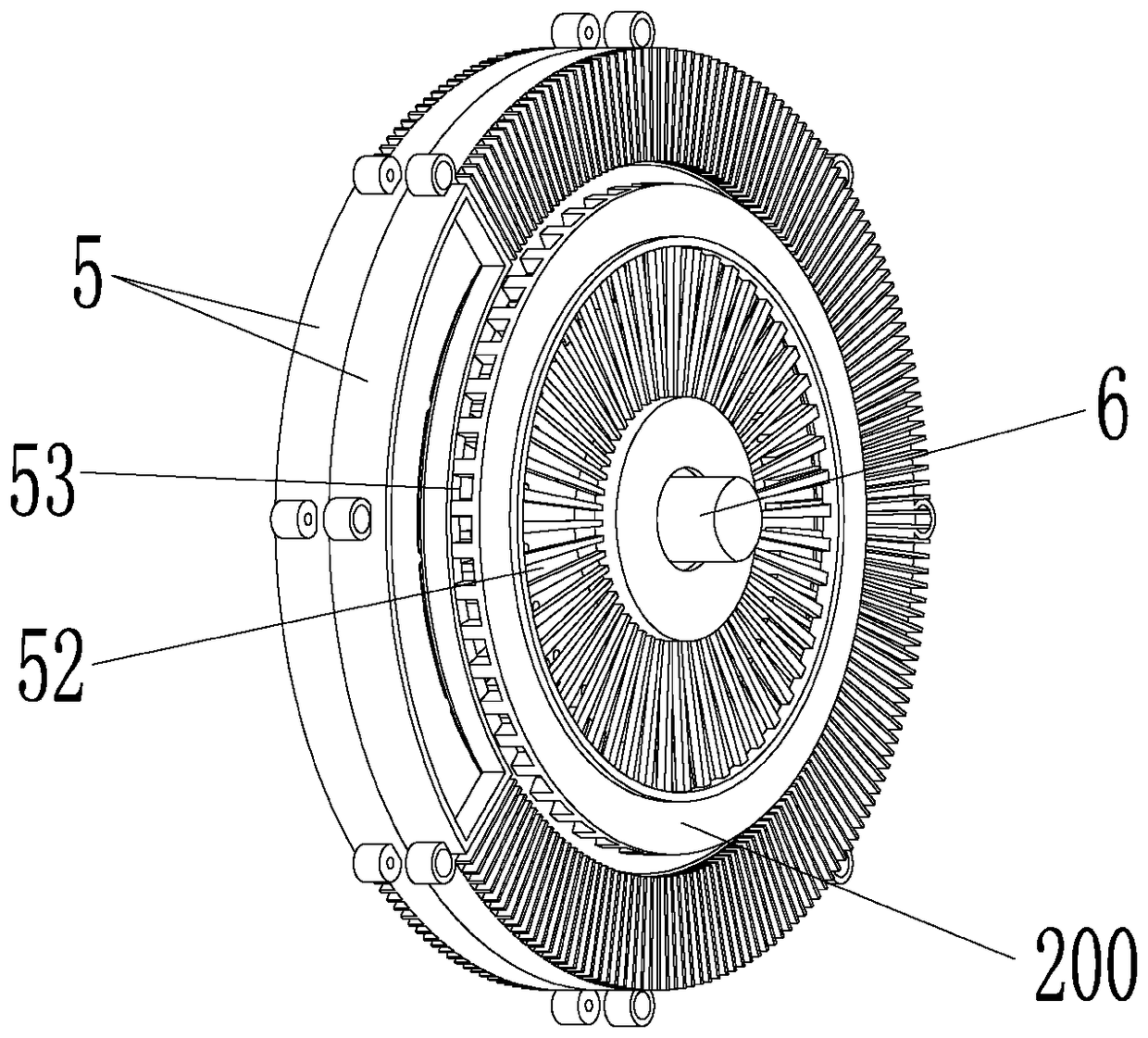

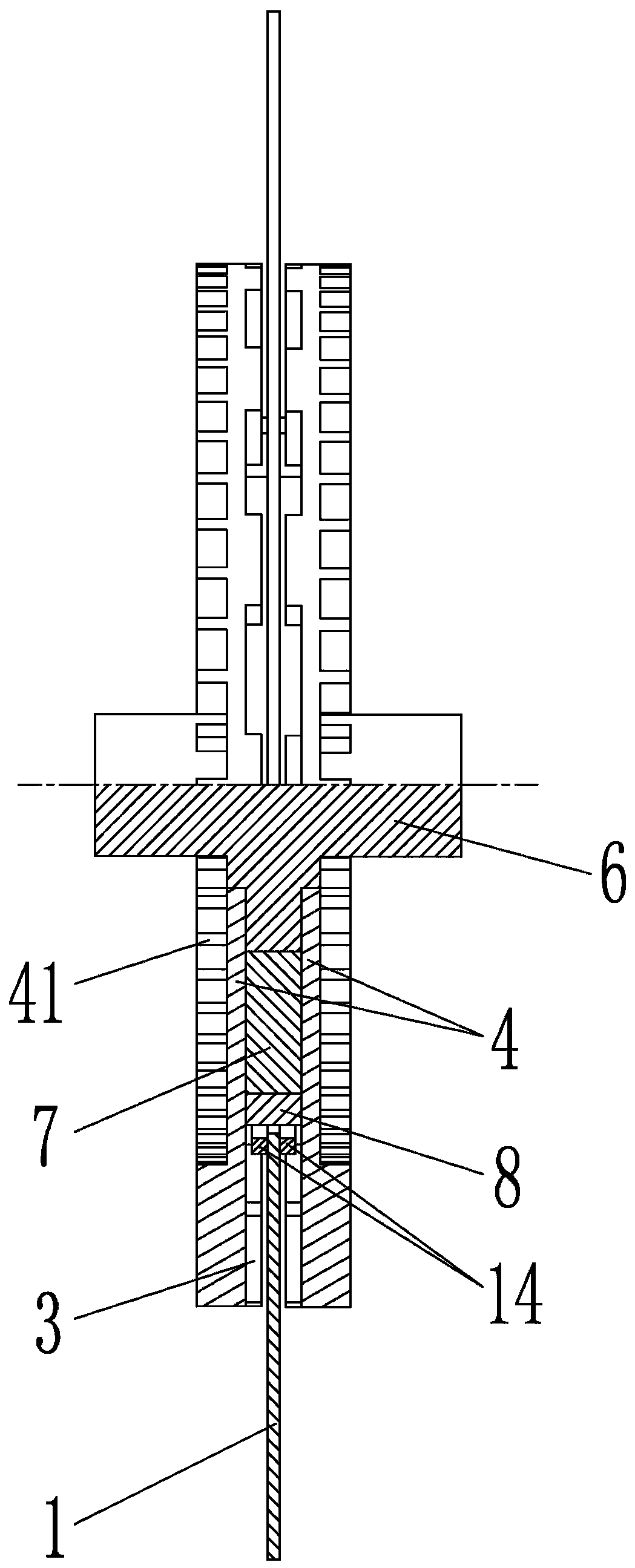

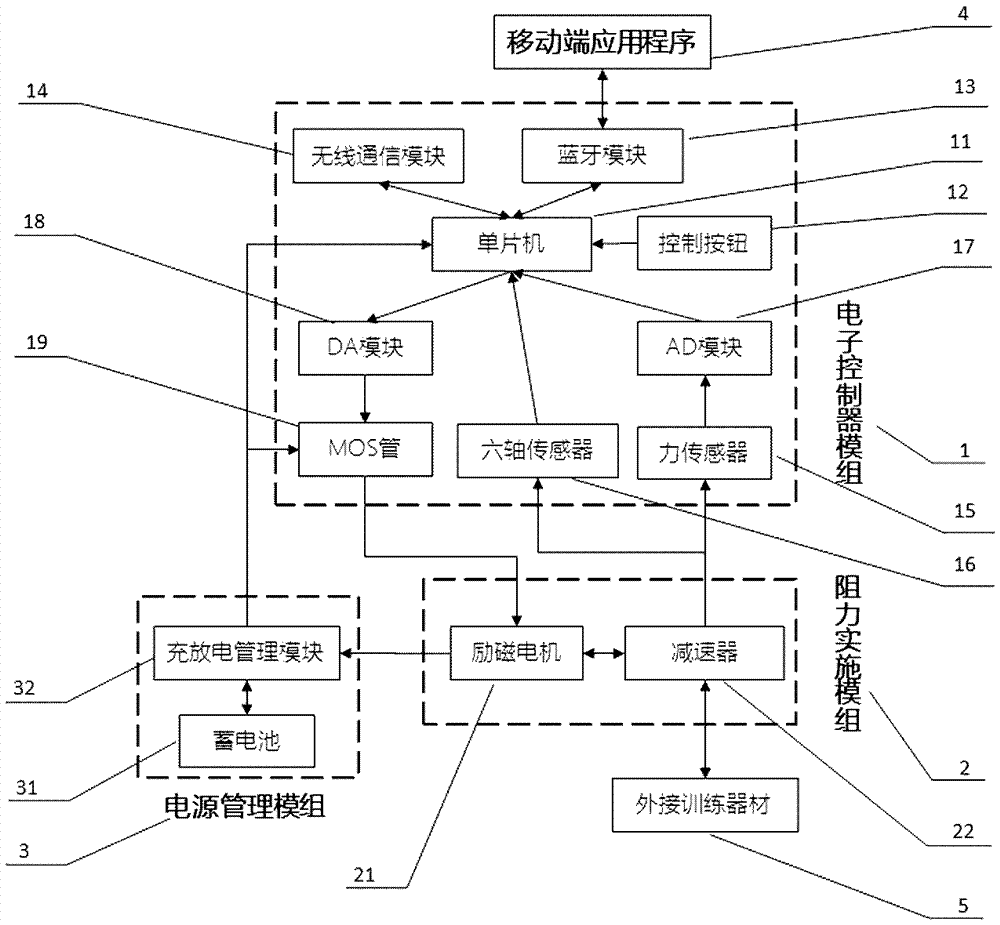

Multifunctional intelligent resistance device applied to exercise equipment

InactiveCN107998585ALow costImprove efficiencySubstation equipmentMuscle exercising devicesElectronic controllerThe Internet

The invention relates to sports exercise equipment, in particular to a device with a measuring device and an electronic controller, using electromagnetic resistance and having an isokinetic training function. The device structurally comprises an electronic controller module (1), a resistance implementing module (2), a power source management module (3) and a mobile terminal application program (4). A user can set training modes including three main modes of being isotonic, isometric and isokinetic through the mobile terminal application program (4) or a control button (12), and the electroniccontroller module (1) adopts different implementation schemes according to different training modes. Under control of the electronic controller module (1), resistance when an excitation motor generates power is used as a resistance source, power generated by the resistance is reutilized, the device is enabled to be in the Internet of Things and intelligent, isokinetic motion is realized with low cost, and the device is safe, efficient, environment-friendly and low in cost.

Owner:卢夫龙

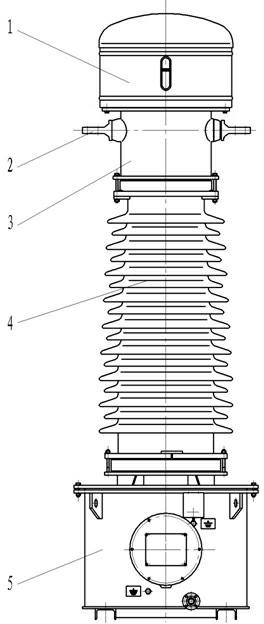

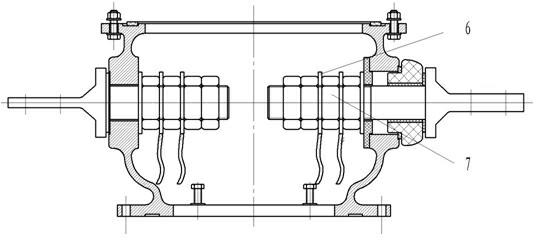

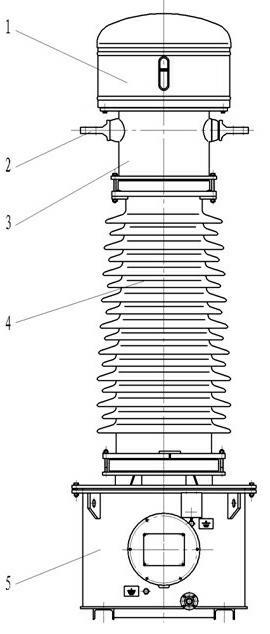

Current transformer with one-circle primary winding

InactiveCN102360890AIncrease contact areaReduce electricity densityTransformers/inductances coolingTransformersIncrease sizeFuel tank

The invention relates to a current transformer with a one-circle primary winding, belonging to the technical field of a transformer. The technical scheme provided by the invention is as follows: the current transformer comprises an expander (1), a conductive rod (2), an oil conservator (3), an insulator (4) and an oil tank (5); the expander is arranged above the oil conservator; the insulator is arranged below the oil conservator; the conductive rod is arranged on the oil conservator; the insulator is arranged on the oil tank; the conductive rod is connected with the primary winding; the primary winding is provided with two semicircular tubes; wiring pieces (6) are welded at the upper ends of the two semicircular tubes, respectively; the two wiring pieces are commonly connected to the conductive rod; a nut is arranged between the two wiring pieces, and the two wiring pieces are arranged by means of being separated by the nut (7); and the two wiring pieces are fastened on the conductive rod. The current transformer provided by the invention is used for overcoming the problem that the unqualified temperature rise is easily caused when the traditional current transformer with the large current ratio takes the primary winding as one circle; meanwhile, the current transformer is simple in operation, and is economic and practical without increasing sizes of parts and expanding the space of the oil conservator.

Owner:BAODING TIANWEI GRP CO LTD

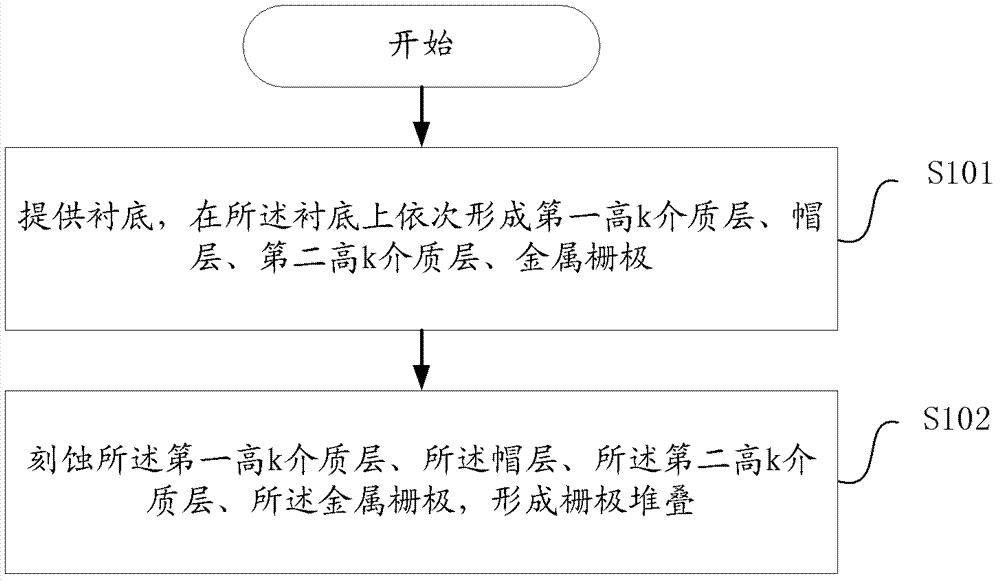

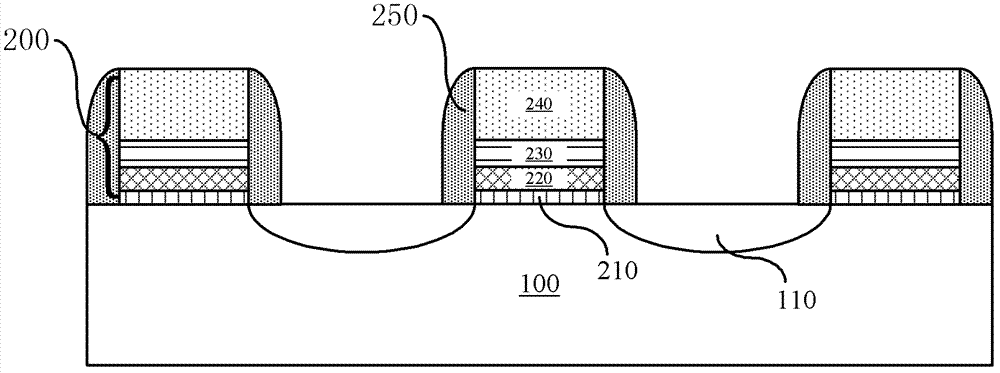

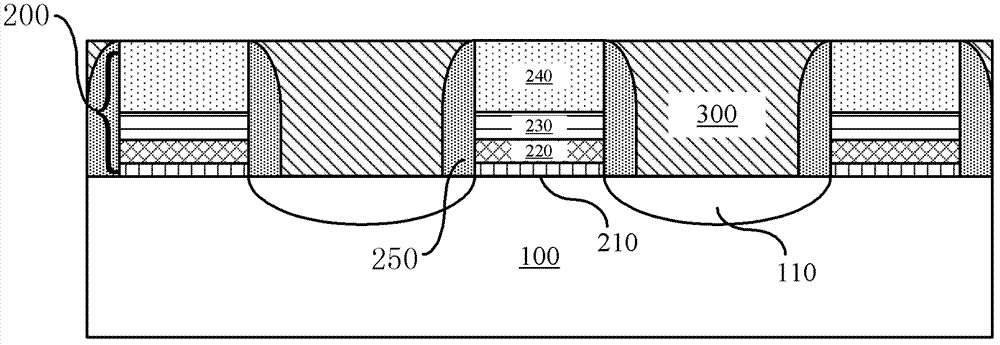

Semiconductor structure and method for manufacturing same

InactiveCN102820327AAdvantage structureMerit methodSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureDielectric layer

The invention provides a semiconductor structure and a method for manufacturing the same. The method includes steps of providing a substrate and sequentially forming a first high-k dielectric layer, an adjusting layer, a second high-k dielectric layer and a metal grid electrode; and etching the first high-k dielectric layer, the adjusting layer, the second high-k dielectric layer and the metal grid electrode to form grid electrode stacks. Correspondingly, the invention further provides the semiconductor structure. The adjusting layer is formed between the two high-k dielectric layers, so that the adjusting layer is effectively prevented from being in direct contact with the metal grid electrode to degrade the performance of a semiconductor device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

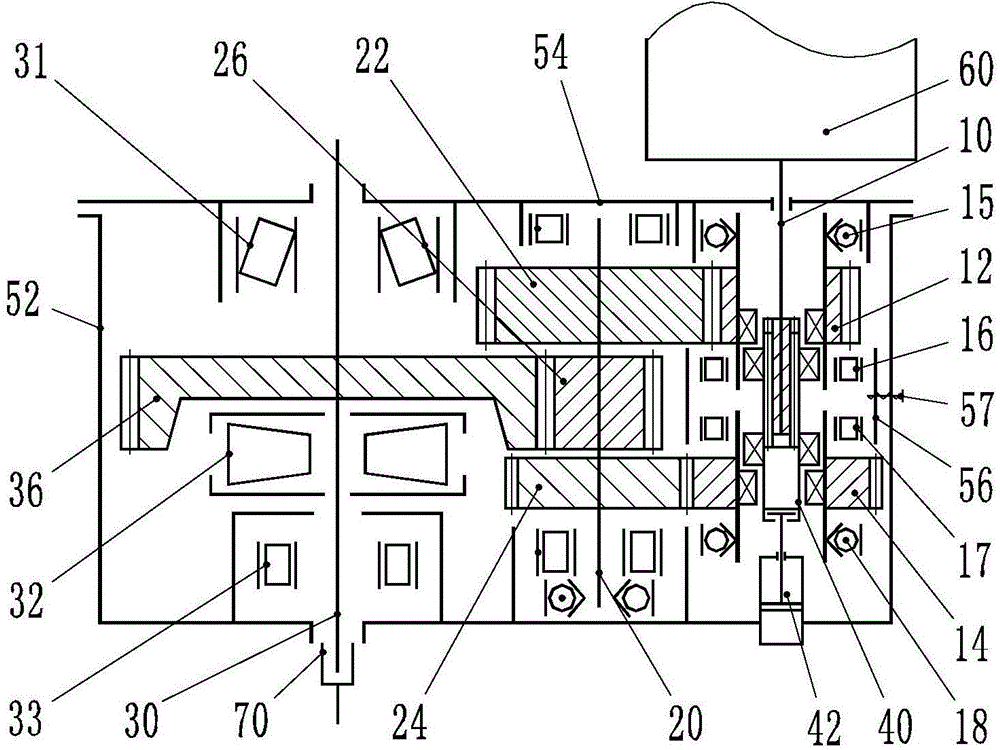

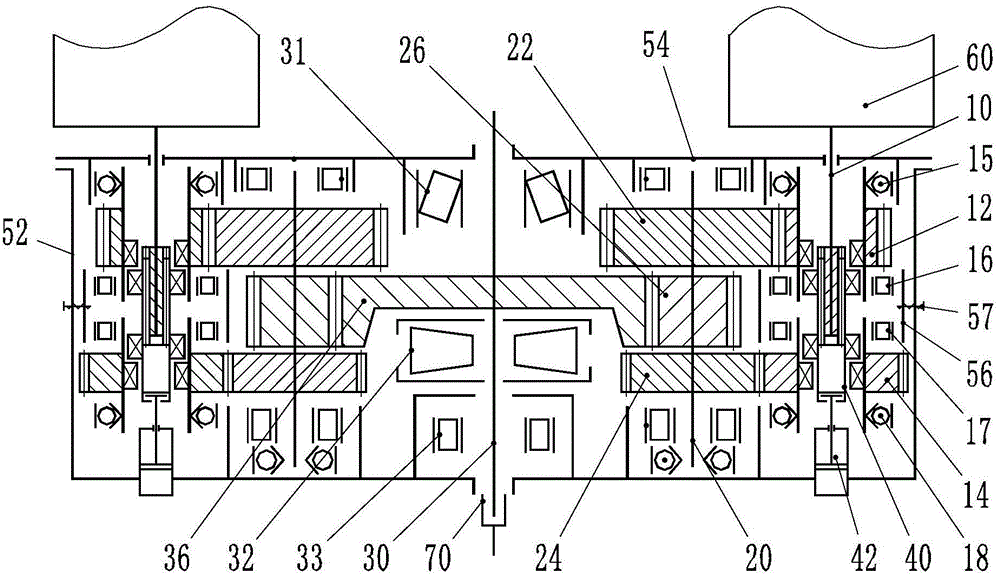

Two-gear gear speed reducing box used for top driving well drilling device

InactiveCN104595423AReduce contact stressReduce extrusion stressToothed gearingsTransmission elementsGear driveLow speed

The invention provides a two-gear gear speed reducing box used for a top driving well drilling device. The two-gear gear speed reducing box comprises a box body and mechanisms arranged in the box body, wherein each input mechanism comprises an input shaft and a grade-I low-speed gear driving gear and a grade-I high-speed gear driving gear which sleeve the periphery of the input shaft; each middle transmission mechanism comprises a middle shaft, and a grade-I low-speed gear driven gear, a grade-I high-speed gear driven gear and a grade-II driving gear which sleeve the middle shaft; an output mechanism comprises an output shaft and a grade-II driven gear which sleeves the output shaft; each speed changing mechanism comprises a sliding sleeve sleeving the input shaft; the sliding sleeves are mounted among the peripheries of the input shafts, and the inner walls of central holes of the grade-I low-speed gear driving gears and the grade-I high-speed gear driving gears respectively, slide along the input shafts, are matched with the inner walls of the central holes of the grade-I low-speed gear driving gears and the grade-I high-speed gear driving gears, and drive the grade-I low-speed gear driven gear pair and the grade-I high-speed gear driven gear pair to rotate. Compared with the prior art, the rotary speed output range can be improved by more than 2-3 times.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

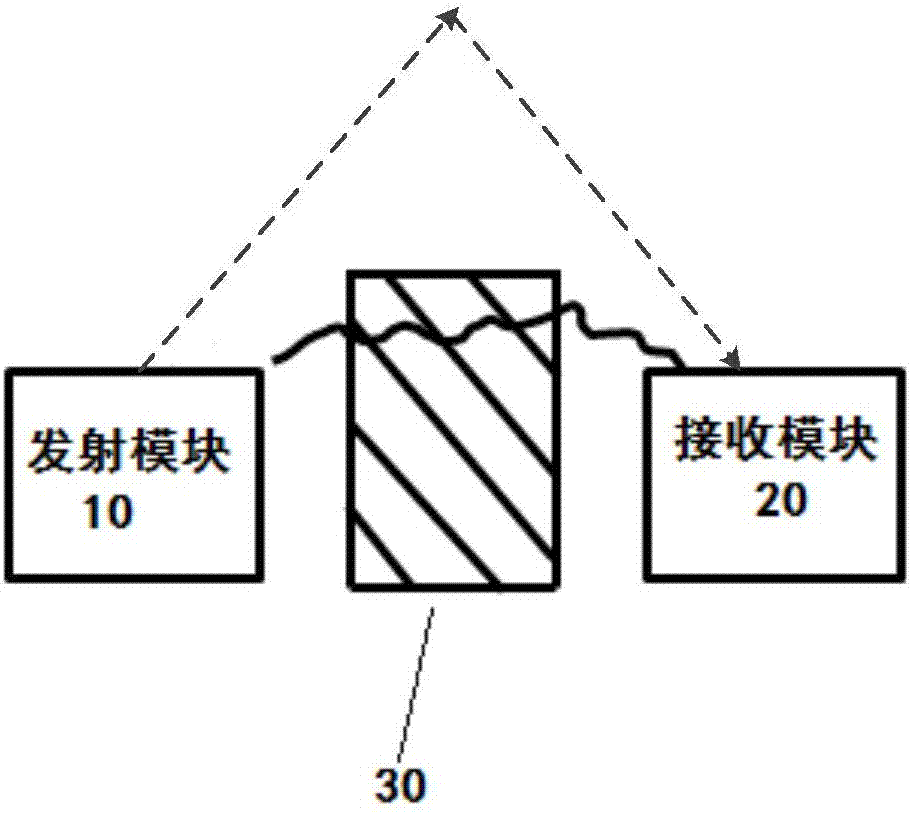

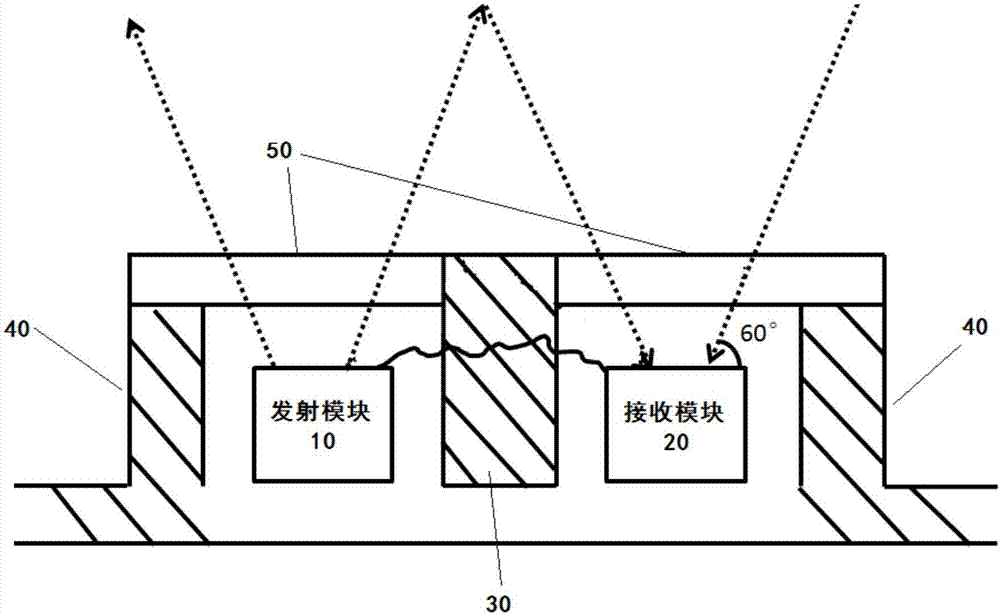

Light sensing device, display control device and household appliance

InactiveCN107481656ANo increase in sizeGuaranteed sensing accuracyCathode-ray tube indicatorsElectricityUser needs

The embodiments of the invention provide a light sensing device, a display control device and a household appliance, which belong to the field of household appliances. The light sensing device includes a light sensor module and a first light blocking film. The light sensor module includes an emitting module and a receiving module. The receiving module is used for receiving light emitted by the emitting module and reflected, and generating an electrical signal according to the light received. The first light blocking film is disposed between the emitting module and the receiving module, and is used for preventing the diffused light of the emitting module from reaching the receiving module. The light sensing device is small in size, and thus the design space of the household appliance is greatly saved. The other objective of the invention is to provide a display control device and a household appliance. According to the display control device and the household appliance, a display module can be turned on in time when users need to watch the display module and can be turned off in time when users leave, and therefore, the electric energy consumed by the display module is significantly reduced.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com