Compact air-cooled unit

A compact, air-cooled technology, applied in the direction of electromechanical devices, electric components, cooling/ventilation devices, etc., can solve the problems of exhaust fan volume, small power, poor heat dissipation effect of the chassis, damage to generators and power devices, etc., to achieve reduction The overall volume and quality, the effect of improving heat dissipation and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

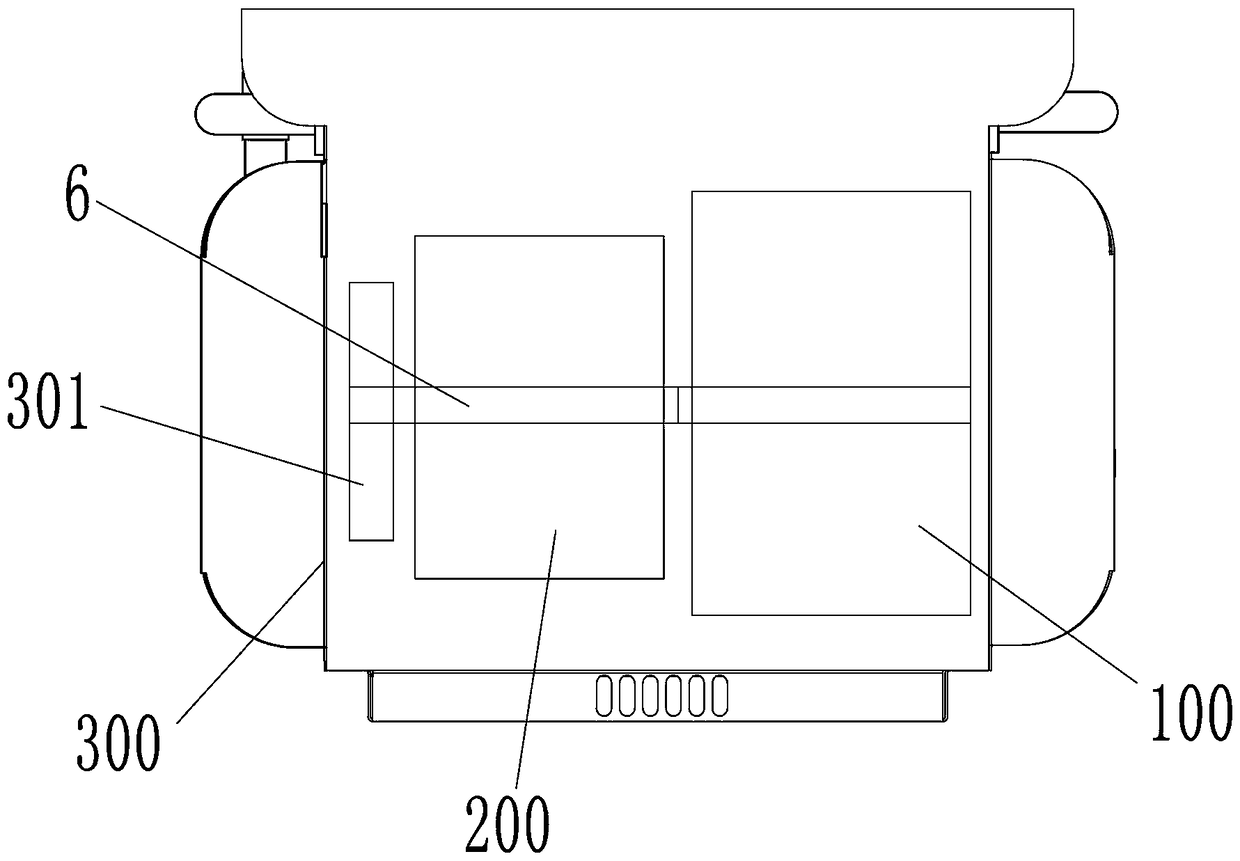

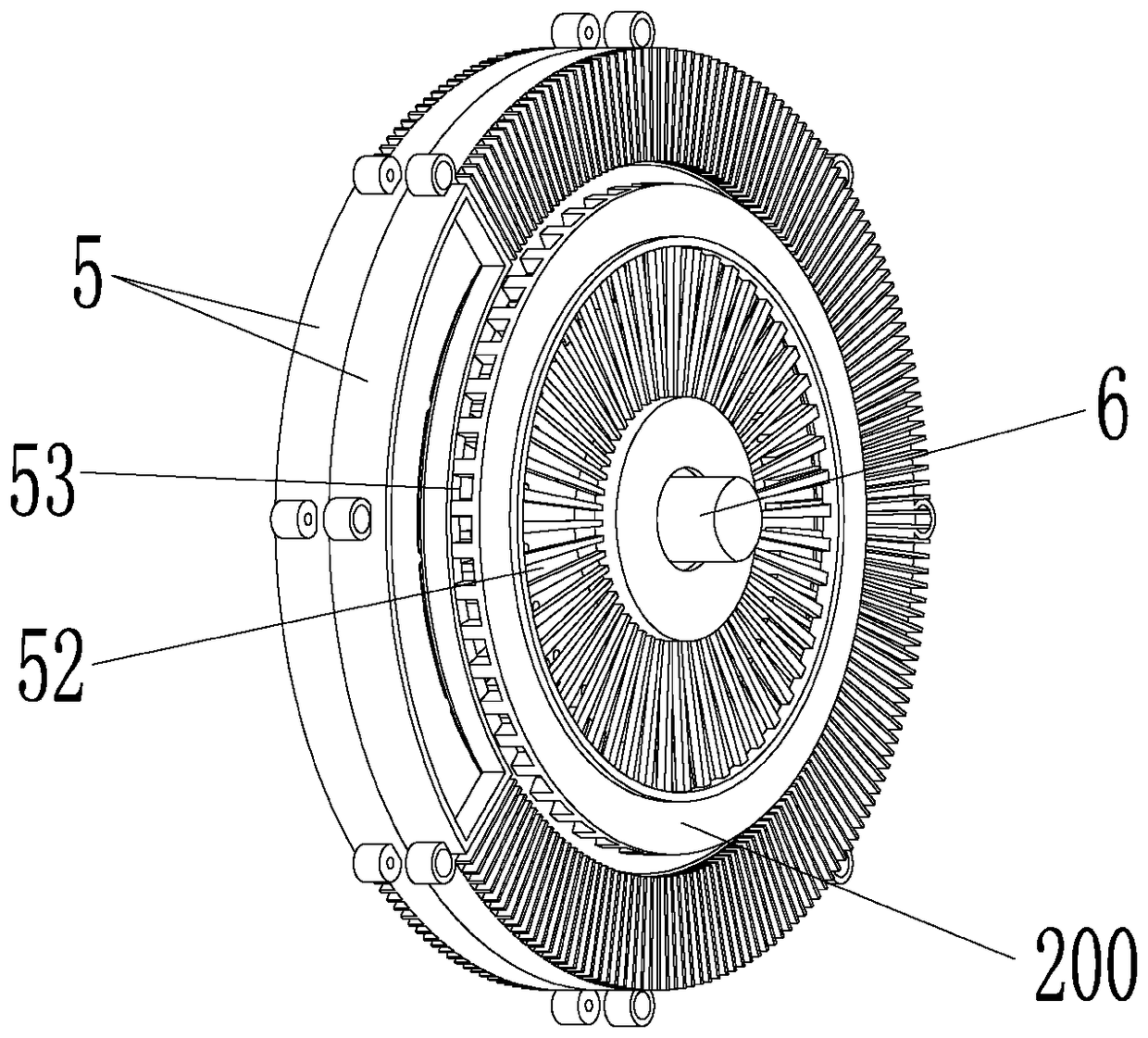

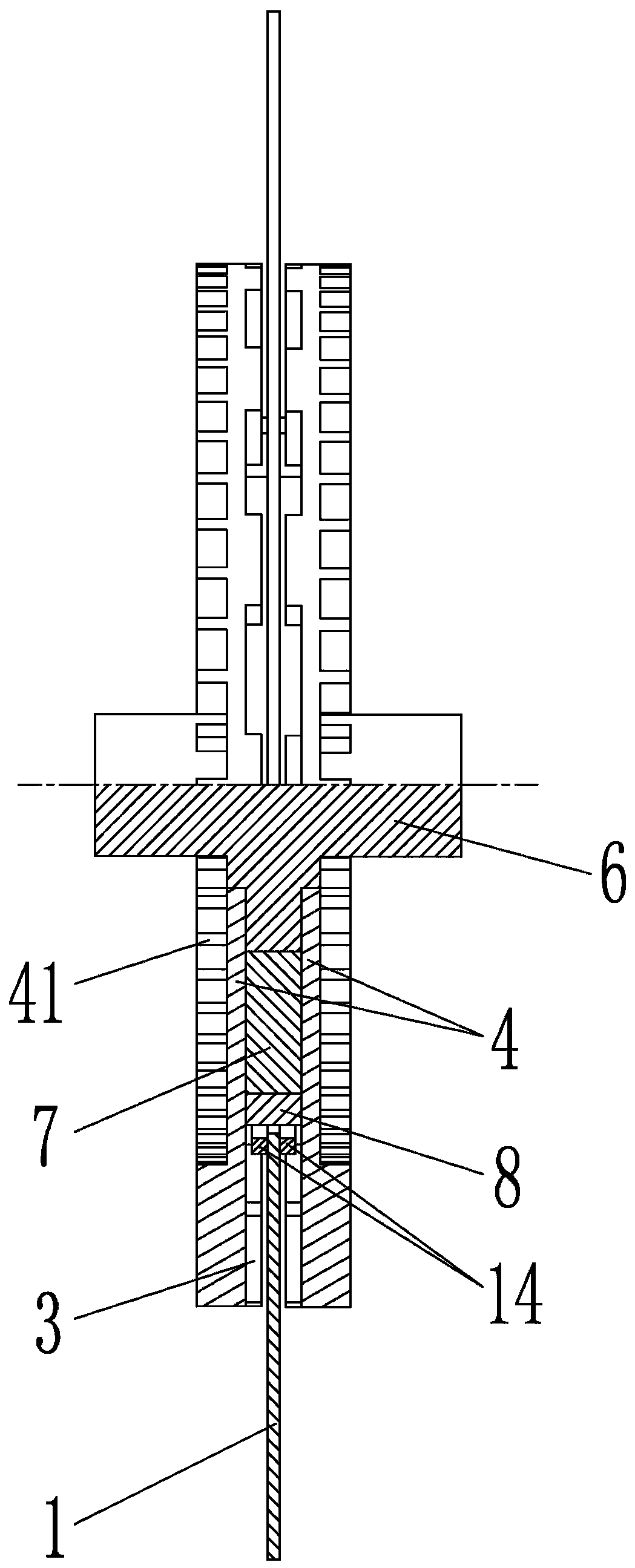

[0024] Figure 1 to Figure 9 The first embodiment of the light-weight and compact electromechanical integrated machine of the present invention is shown. Such as Figure 1 to Figure 4 As shown, the compact air-cooled unit of the present invention includes a chassis 300, a power unit 100 and a generator 200 that are adjacently connected coaxially in the chassis 300, and the end of the generator motor shaft 6 away from the power unit 100 extends to the generator 200 but does not go out of the chassis 300, extending to the outer motor shaft extension of the generator 200 and fixing a chassis cooling fan 301, the generator 200 includes a PCB stator 1 coaxially arranged with the motor shaft 6, and an electronic module 2 The two sides of the PCB stator 1 are symmetrical and outwardly provided with a magnetic steel rotor 3, a heat dissipation shell 4 and an end cover 5 respectively, the heat dissipation shell 4 is sleeved on the motor shaft 6, and the end cover 5 is rotatable. Slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com