Device for NOx reduction and grate firing by stokehold screening, gasifying and reburning

An equipment and sorting technology, applied in combustion equipment, lighting and heating equipment, combustion of solid fuel, etc., can solve the problems of industrial boilers not receiving sufficient attention, not enough attention, reducing NOx emission technology, etc., to reduce solid Effects of incomplete combustion loss, reduction of NOx emissions, and improvement of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

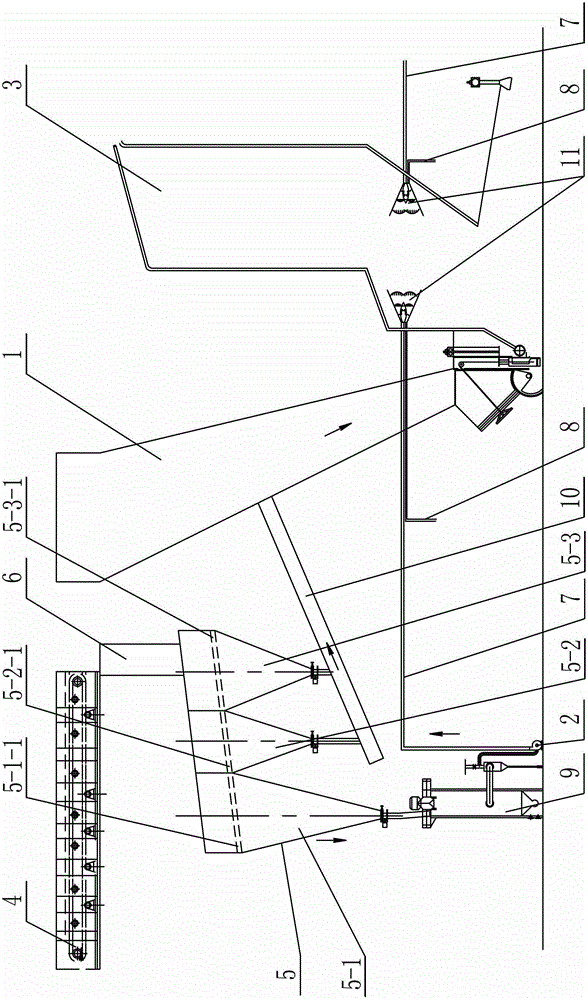

[0014] Specific implementation mode one: combine figure 1 Explain, a kind of pre-furnace sorting, gasification and recombustion equipment for reducing NOx layer combustion in this embodiment, the equipment includes boiler coal hopper 1, fan 2 and coal-fired conveying device 4, and the equipment also includes pre-furnace screening and sorting Device 5, transition pipe 6, gasification gas pipeline 7, combustion air pipeline 8, fixed bed gasifier 9, screw material conveyor 10 and gasification gas nozzle 11;

[0015] The screening and sorting device 5 in front of the furnace includes a large particle coal hopper 5-1, a medium particle coal hopper 5-2 and a small particle coal hopper 5-3, and the medium particle coal hopper 5-2 is arranged on the large particle coal hopper 5- 1 and the small particle coal hopper 5-3, the feeding chambers of the large particle coal hopper 5-1, the medium particle coal hopper 5-2 and the small particle coal hopper 5-3 are connected and arranged, and ...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Illustrate, the aperture of the small sieve sieve 5-3-1 of the present embodiment<6mm, the aperture of the middle sieve 5-2-1 is 6-15mm, the aperture of the large sieve 5-1-1 15-25mm. Suitable for screening lump coal. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Illustrate, the aperture of the small sieve sieve 5-3-1 of the present embodiment<6mm, the aperture of the middle sieve 5-2-1 is 6-20mm, the aperture of the large sieve 5-1-1 20-50mm. Suitable for screening mixed coal. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com