Patents

Literature

72results about How to "Raise the temperature level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method

ActiveCN107971330AReduce consumptionEmission reductionCombination devicesDispersed particle filtrationAir preheaterThermal desorption

The invention relates to an efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method. A burner is communicated with a high temperature oxidizingchamber, a high temperature smoke pipe of the high temperature oxidizing chamber is communicated with a rotary kiln heating processing system and an air heat exchanger, a high temperature air outletof the air heat exchanger is communicated with the burner, a smoke pipe of the air preheater is communicated with an inlet of a quench tower, an outlet of the quench tower is communicated with an inlet of a bag-type dust collector, an outlet of the bag-type dust collector is communicated with an inlet of a deacidification tower, an outlet of the deacidification tower is communicated with an air inlet of a second induced draft fan, and an outlet of the second induced draft fan is communicated with a chimney. A part of high temperature flue gas generated by the burner enters a rotary kiln thermal desorption reactor to achieve desorption of organic pollutant and soil drying pretreatment, organic matter enters the high temperature oxidizing chamber through a backflow pipe for burning treatment, and thorough oxidative degradation removal is achieved; and the other part of high temperature flue gas is used for increasing the temperature of combustion air through the air heat exchanger.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

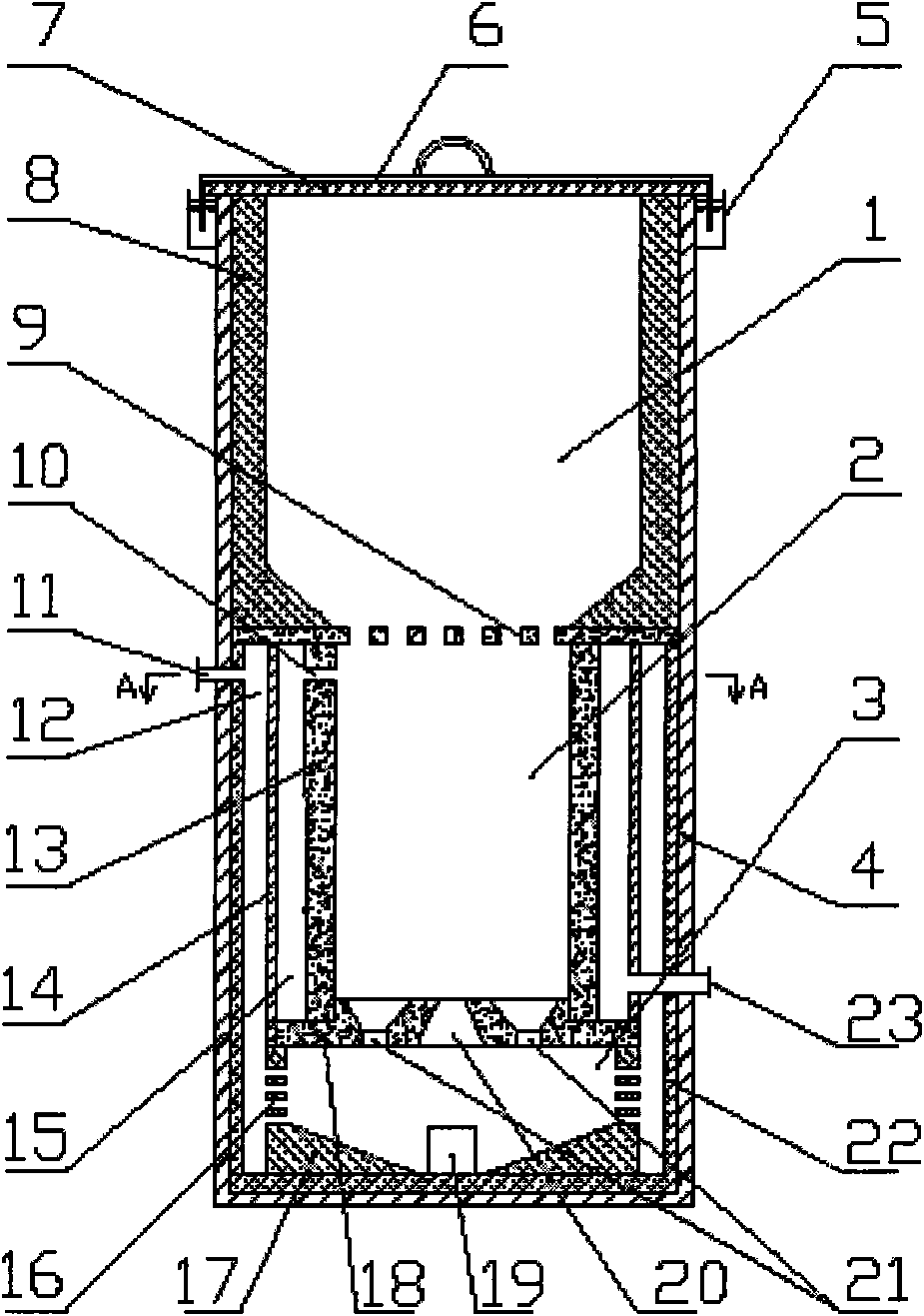

Household up-draft biomass gasification device

InactiveCN101560411ASettlement requires ignition,Resolution timeCombined combustion mitigationGasification with fuel pre-distillationRadiation lossTar

The invention discloses a household up-draft biomass gasification device, which has an upright cylinder structure and is characterized in that the household up-draft biomass gasification device comprises a destructive distillation chamber arranged at the upper section thereof, a main gasification chamber arranged at the middle section thereof and an ash chamber arranged at the lower section thereof; all the sections are respectively separated by a heat storage grille and a heat storage grate; and the main gasification chamber is enclosed by a radiation cylinder on the periphery. The household up-draft biomass gasification device has no need of an external firing heat source, fast firing speed and high temperature of the gasification center, remarkably reduces tar content, reduces radiation loss of a furnace body, and has high gasification efficiency, long fire banking time of the gasification furnace, simple and compact structure, convenient operation and low operating cost.

Owner:安徽喜阳阳新能源科技有限公司

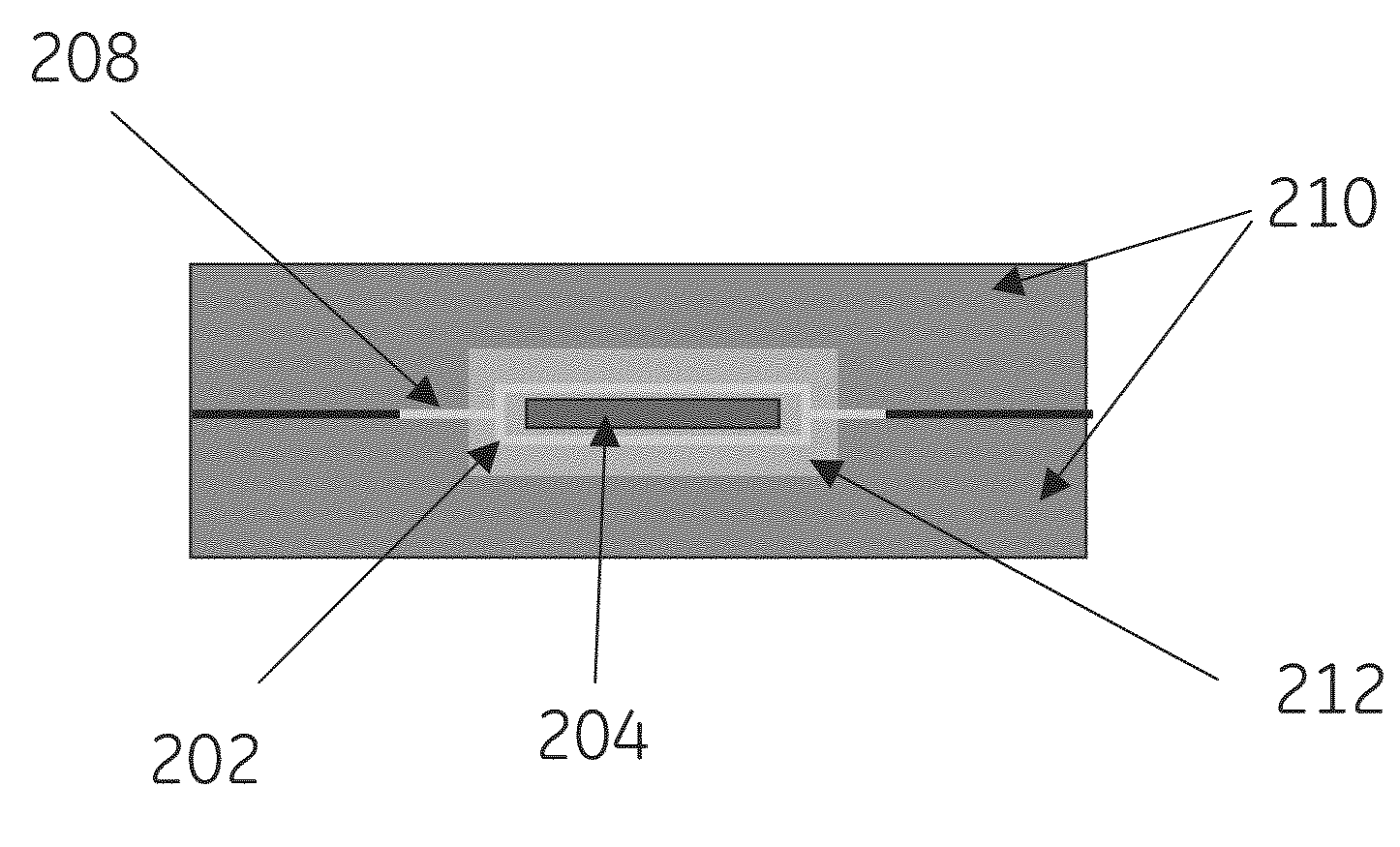

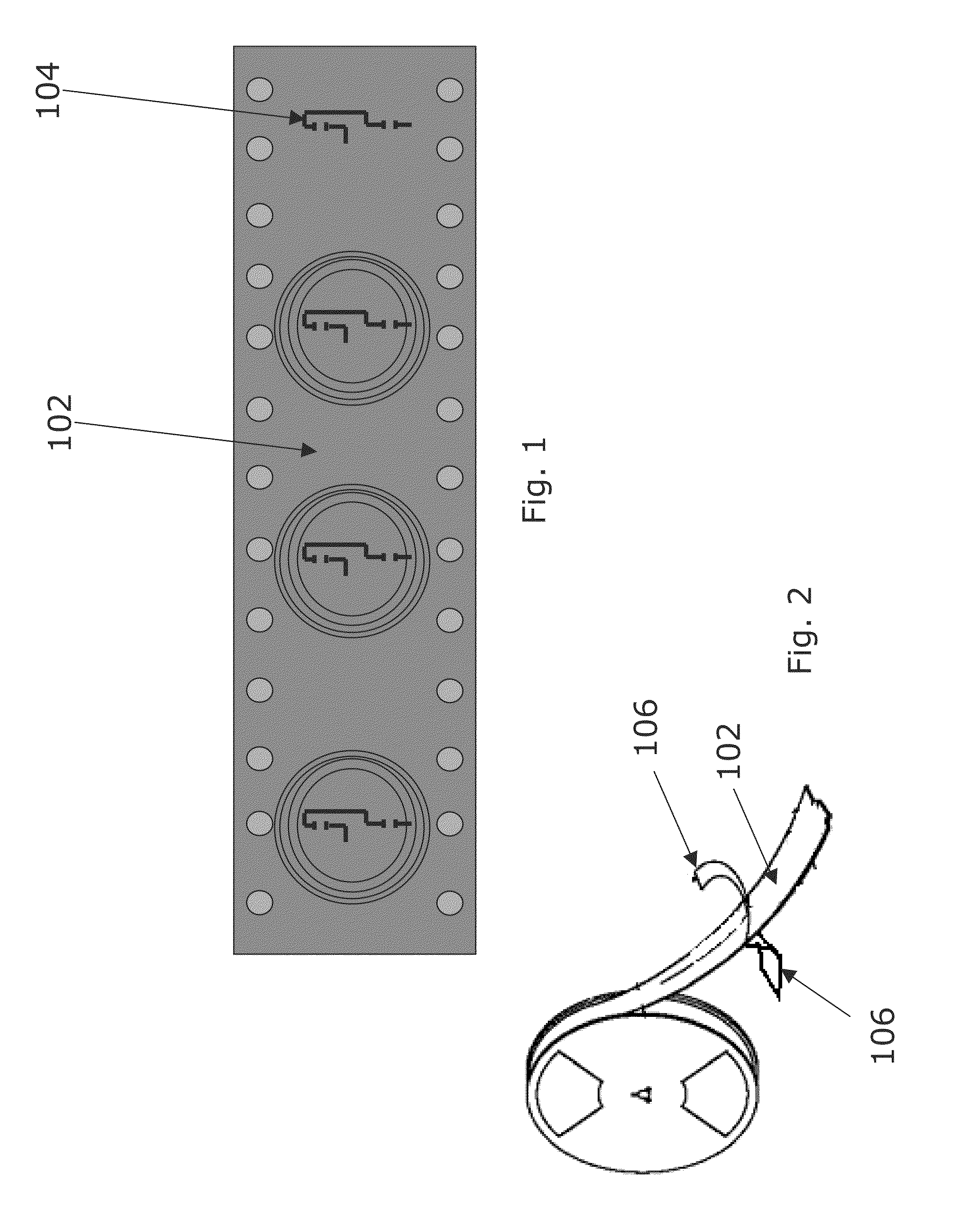

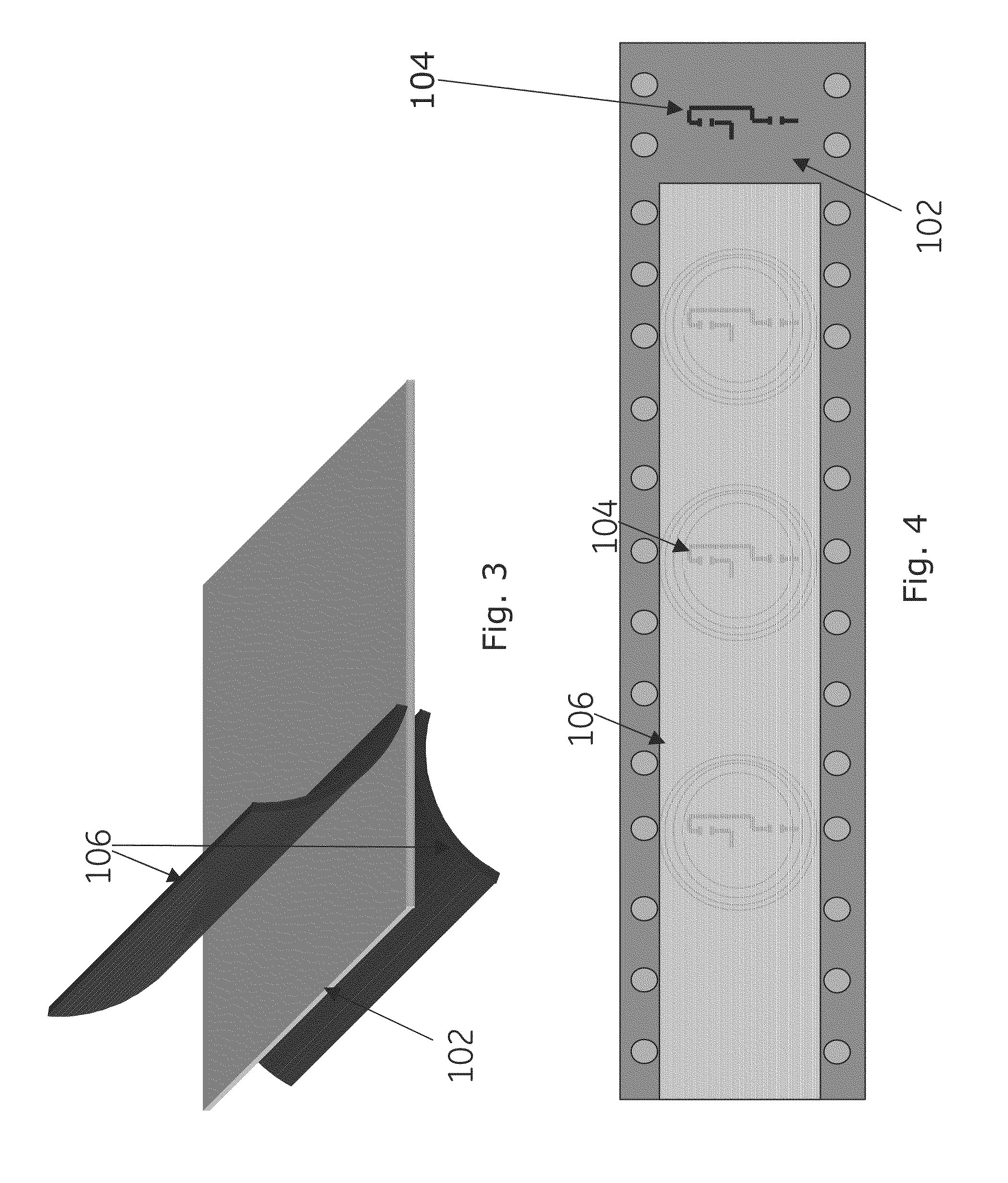

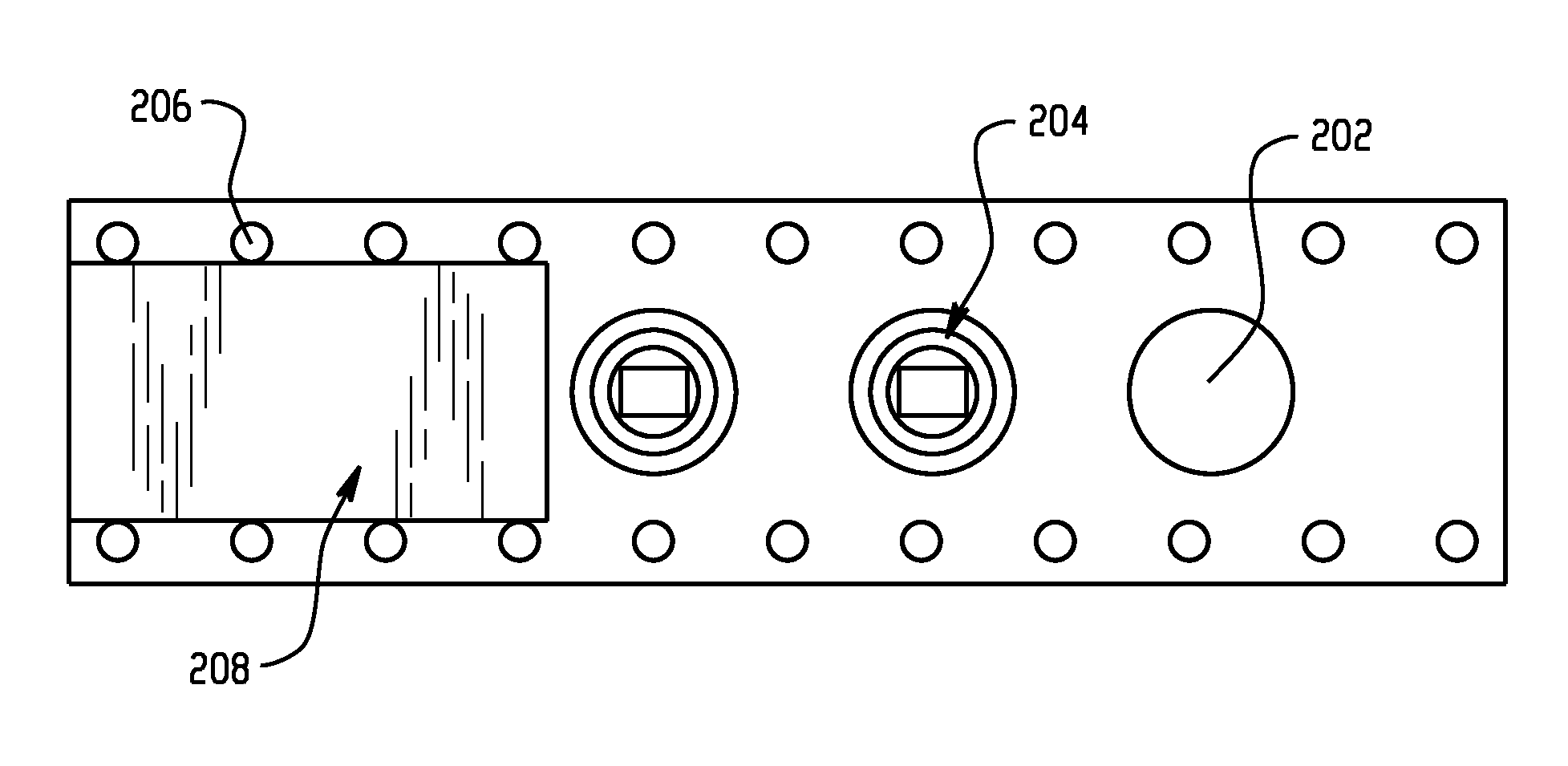

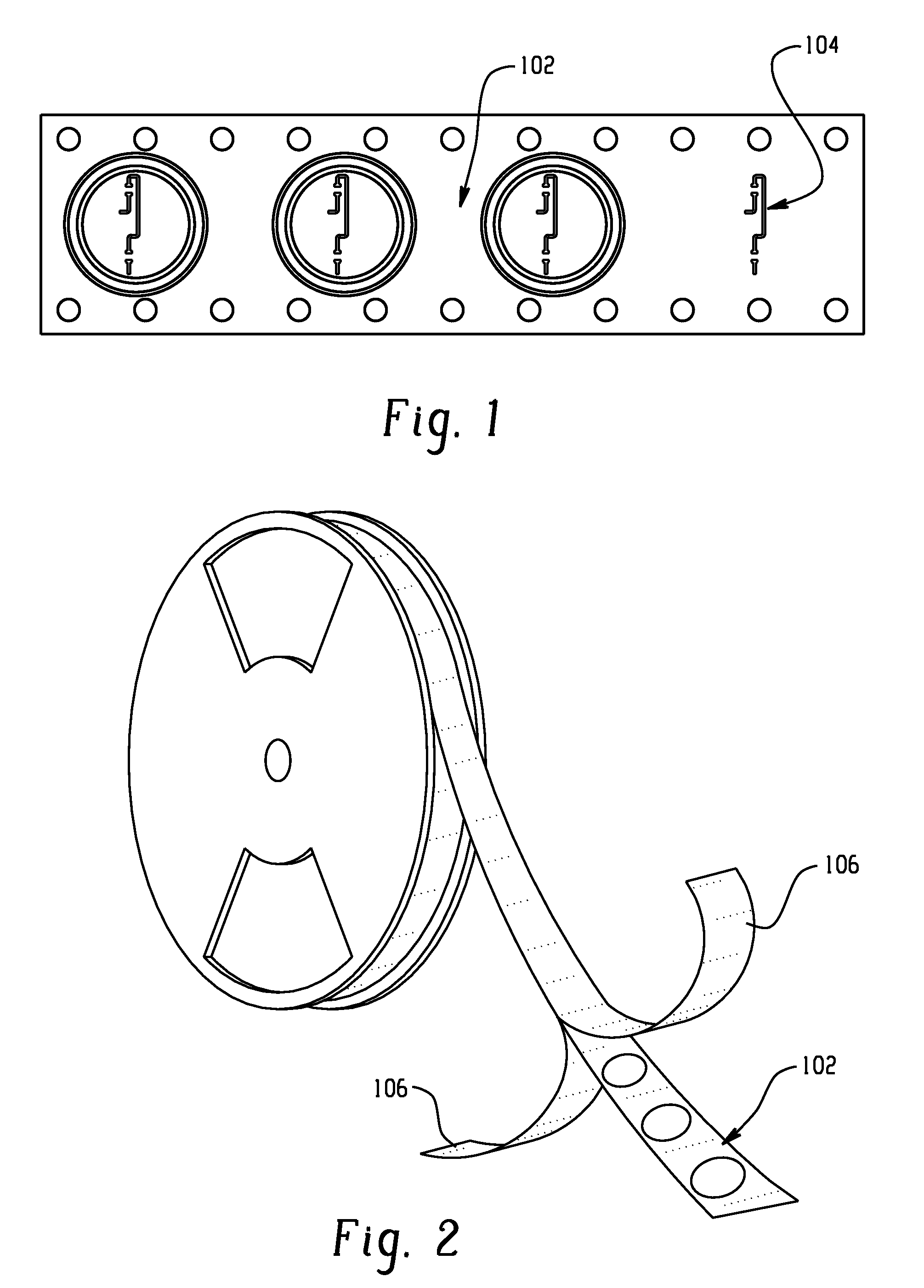

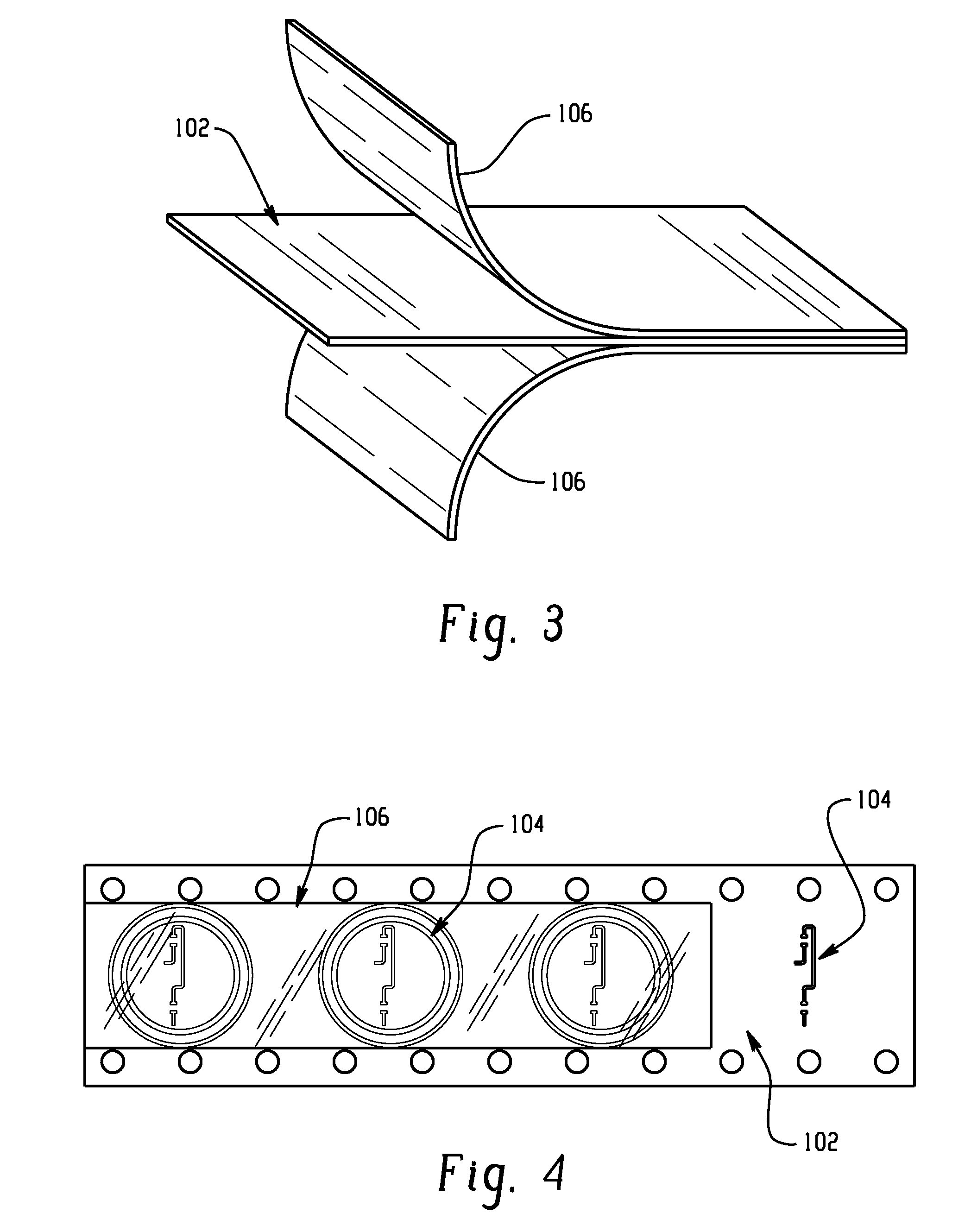

Encapsulated RFID tags and methods of making same

InactiveUS20100259393A1Increase resistanceHigh strengthSemiconductor/solid-state device detailsSynthetic resin layered productsBreaking strengthInjection molding process

Encapsulated radio frequency identification (RFID) articles having enhanced break strength and / or temperature resistance and methods of making these articles. The RFID articles include an RFID tag embedded within a thermoplastic substrate to form the RFID article. In one embodiment, the RFID article includes an over-molded barrier material that enables the RFID article to have enhanced temperature resistance such that the articles are able to sustain repeated exposure to high temperatures and / or sterilization procedures, thereby enabling the RFID articles to be utilized in applications heretofore unavailable. In other embodiments, the RFID articles are made using an injection molding process that provides very thin encapsulated RFID tags that also exhibit an increased level of temperature resistance.

Owner:SABIC GLOBAL TECH BV

Encapsulated RFID tags and methods of making same

InactiveUS8325047B2Increase resistanceHigh strengthSemiconductor/solid-state device detailsSynthetic resin layered productsBreaking strengthEngineering

Encapsulated radio frequency identification (RFID) articles having enhanced break strength and / or temperature resistance and methods of making these articles. The RFID articles include an RFID tag embedded within a thermoplastic substrate to form the RFID article. In one embodiment, the RFID article includes an over-molded barrier material that enables the RFID article to have enhanced temperature resistance such that the articles are able to sustain repeated exposure to high temperatures and / or sterilization procedures, thereby enabling the RFID articles to be utilized in applications heretofore unavailable. In other embodiments, the RFID articles are made using an injection molding process that provides very thin encapsulated RFID tags that also exhibit an increased level of temperature resistance.

Owner:SABIC GLOBAL TECH BV

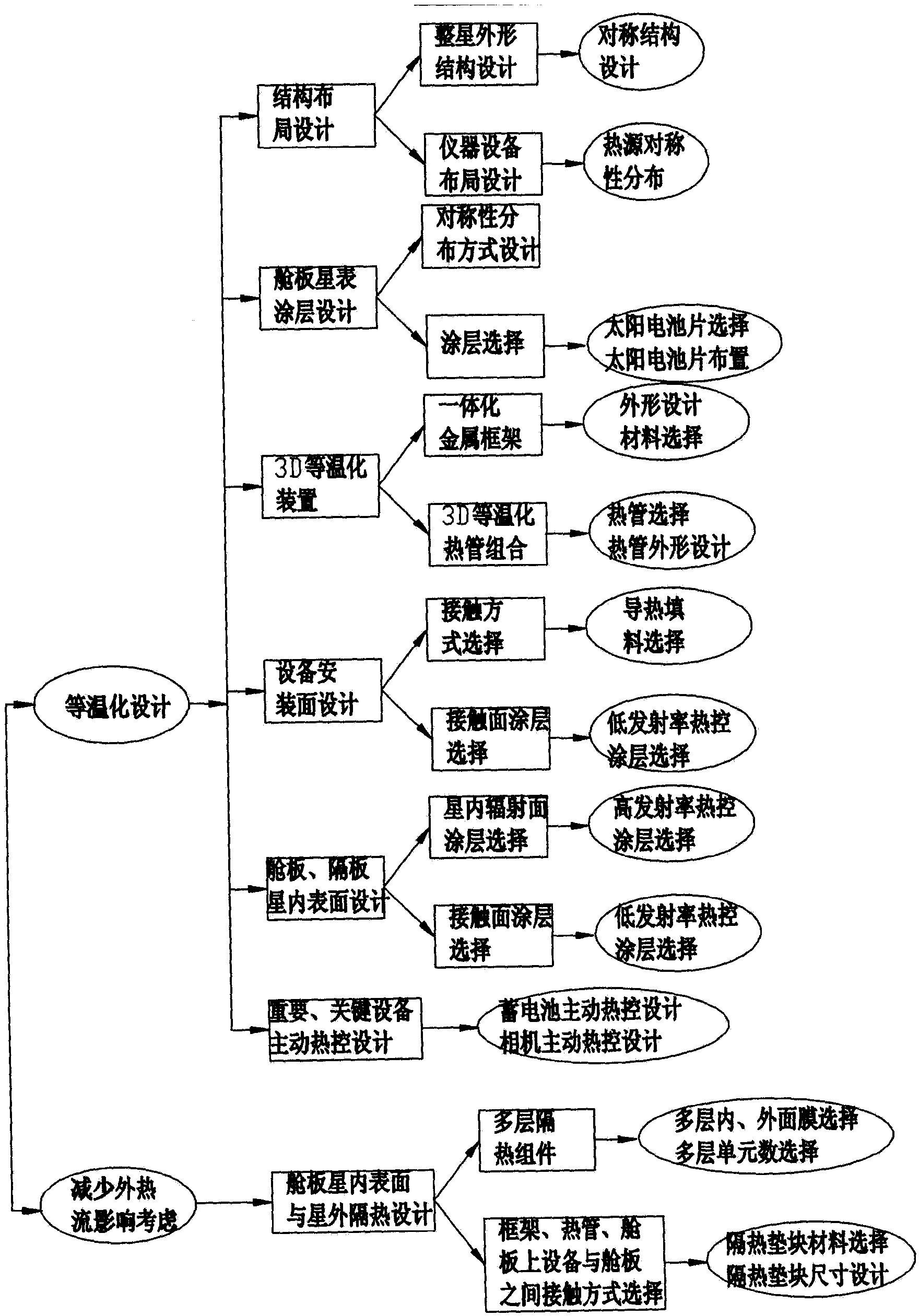

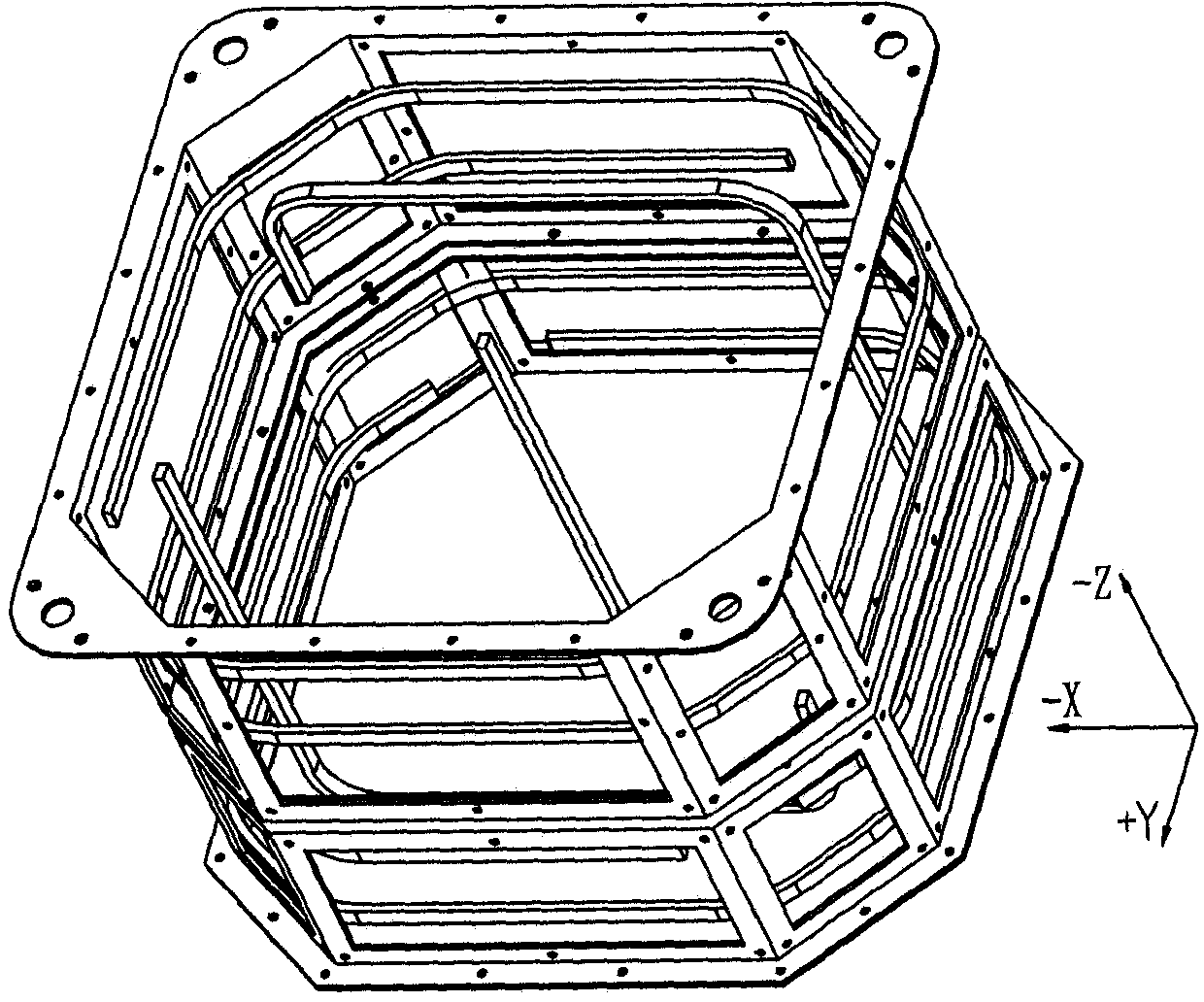

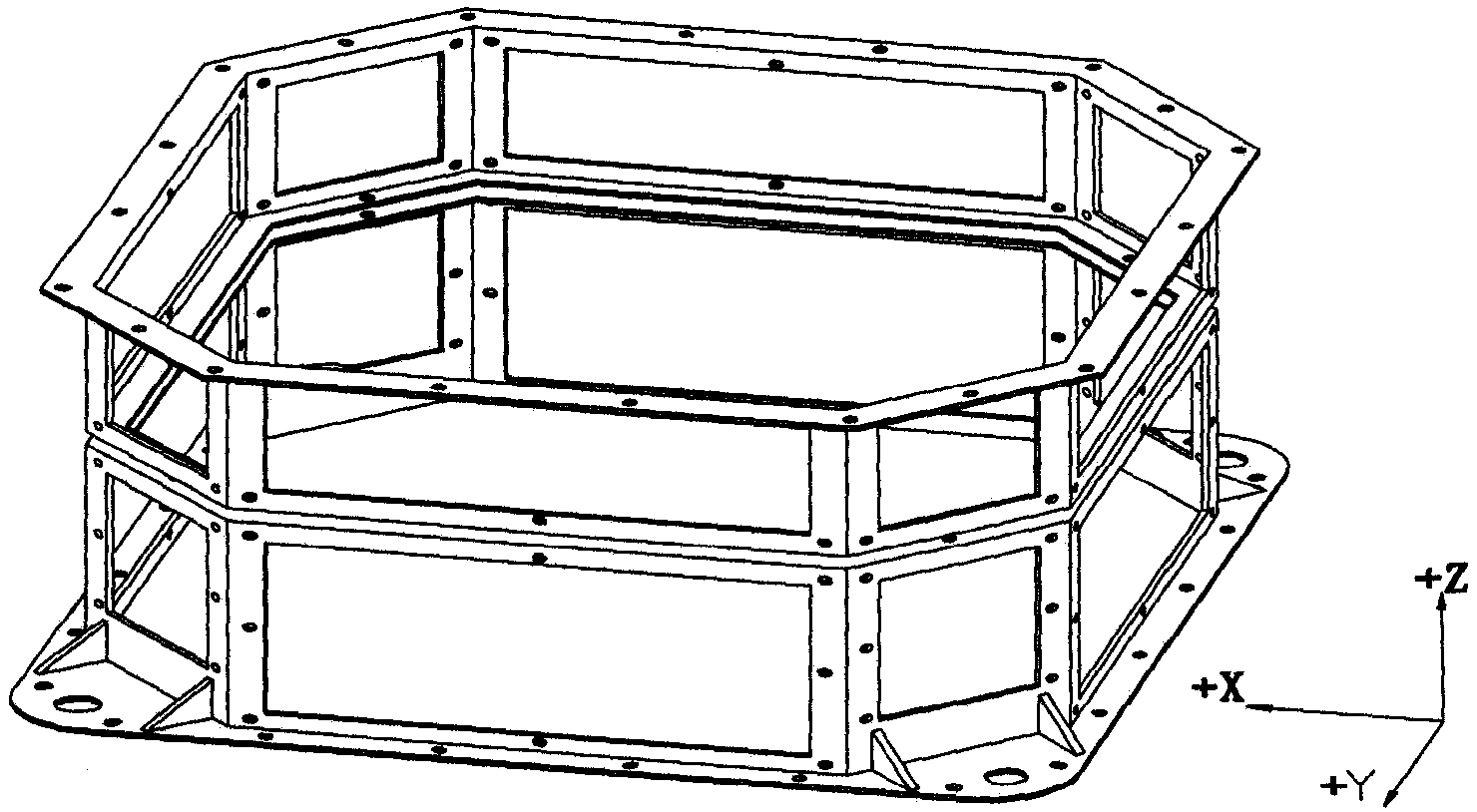

Thermal Control Method for Attitudeless Satellite

ActiveCN105659752BSolve the problem of guaranteeing temperature levelsEnhanced radiation heat transferCosmonautic environmental control arrangementSystems designGallium arsenate

The thermal control method of the non-attitude satellite, paste or spray the high-emissivity thermal control coating on the equipment in the star, fill the thermal conductive filler between the equipment installed on the partition and the installation surface, and spray the high-emissivity thermal control coating on the inner surface of the rest of the structure star Floor. The inner surface of the cabin board is covered with multi-layer heat insulation components to reduce the impact of drastic changes in heat flow outside the outer orbit of the star. Except for the installation surface of the instrument and equipment, the structural star module is pasted with third-order gallium arsenide solar cells. From the perspective of top-level system design, the present invention is based on the whole star isothermal design idea, fully utilizes the whole star structure heat storage, and utilizes solar cells as energy supply equipment and temperature control means at the same time, and adopts three-dimensional direction 3D isothermal heat pipe combination and integration The 3D isothermal device composed of a metal frame solves the problem of ensuring the temperature level of the entire satellite when there is no attitude control.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

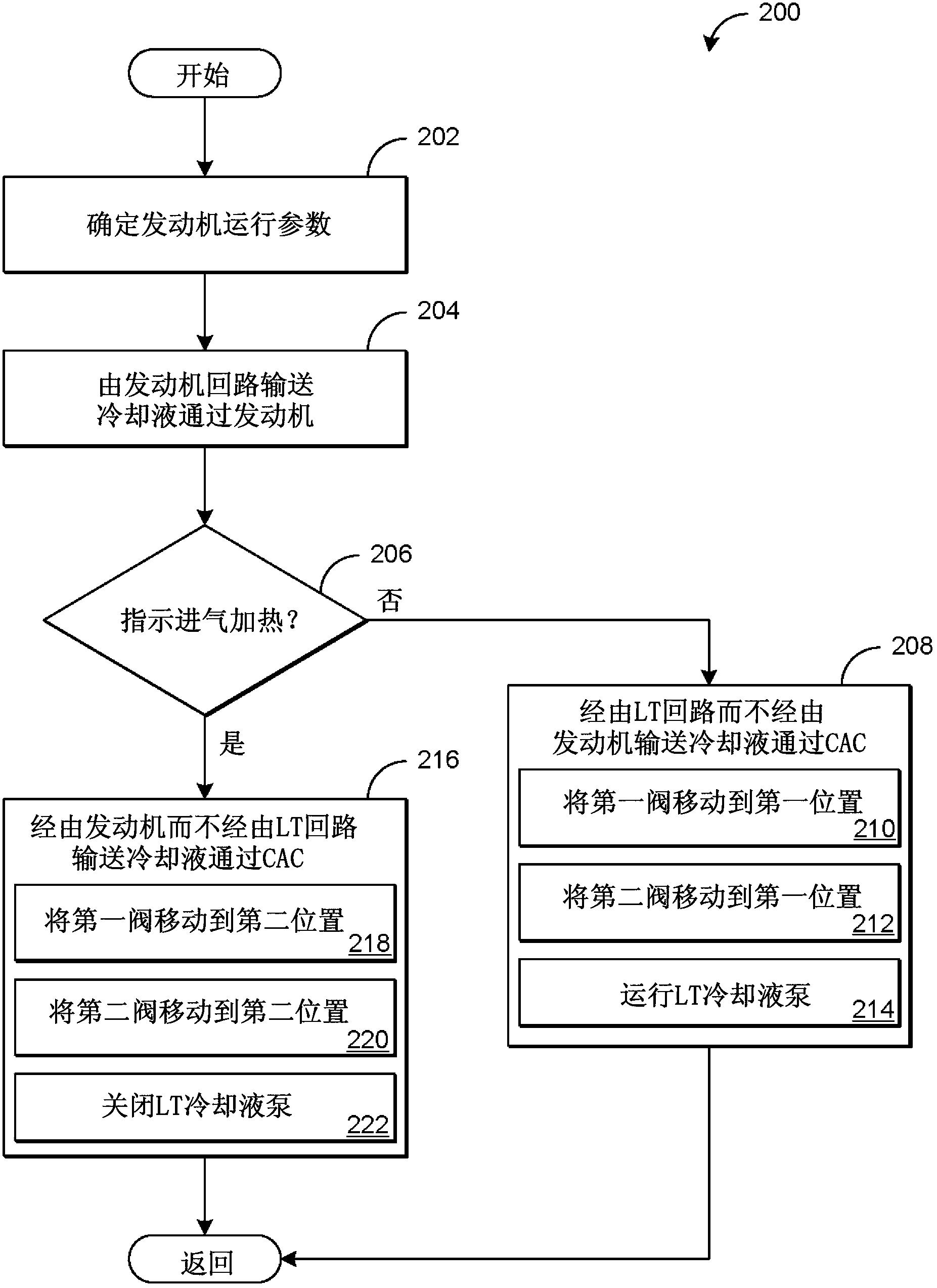

Cooling arrangement for a chargeable internal combustion engine

InactiveCN102797551AShorten the warm-up periodChange operating parametersLiquid coolingCoolant flow controlTurbochargerEngineering

Embodiments for a cooling arrangement are provided. In one example, a cooling arrangement comprises a low-temperature circuit for charge-air cooling of a turbocharger of an internal combustion engine, an engine cooling circuit for cooling the internal combustion engine, and a charge-air cooler arranged in the low-temperature circuit and connected in a fluid-conducting manner on a coolant inlet side, via a first valve device, to the low-temperature circuit and to the engine cooling circuit, and on a coolant outlet side, via a second valve device, to the low-temperature circuit and to the engine cooling circuit. In this way, coolant from the engine may heat the charge-air cooler under certain conditions.

Owner:FORD GLOBAL TECH LLC

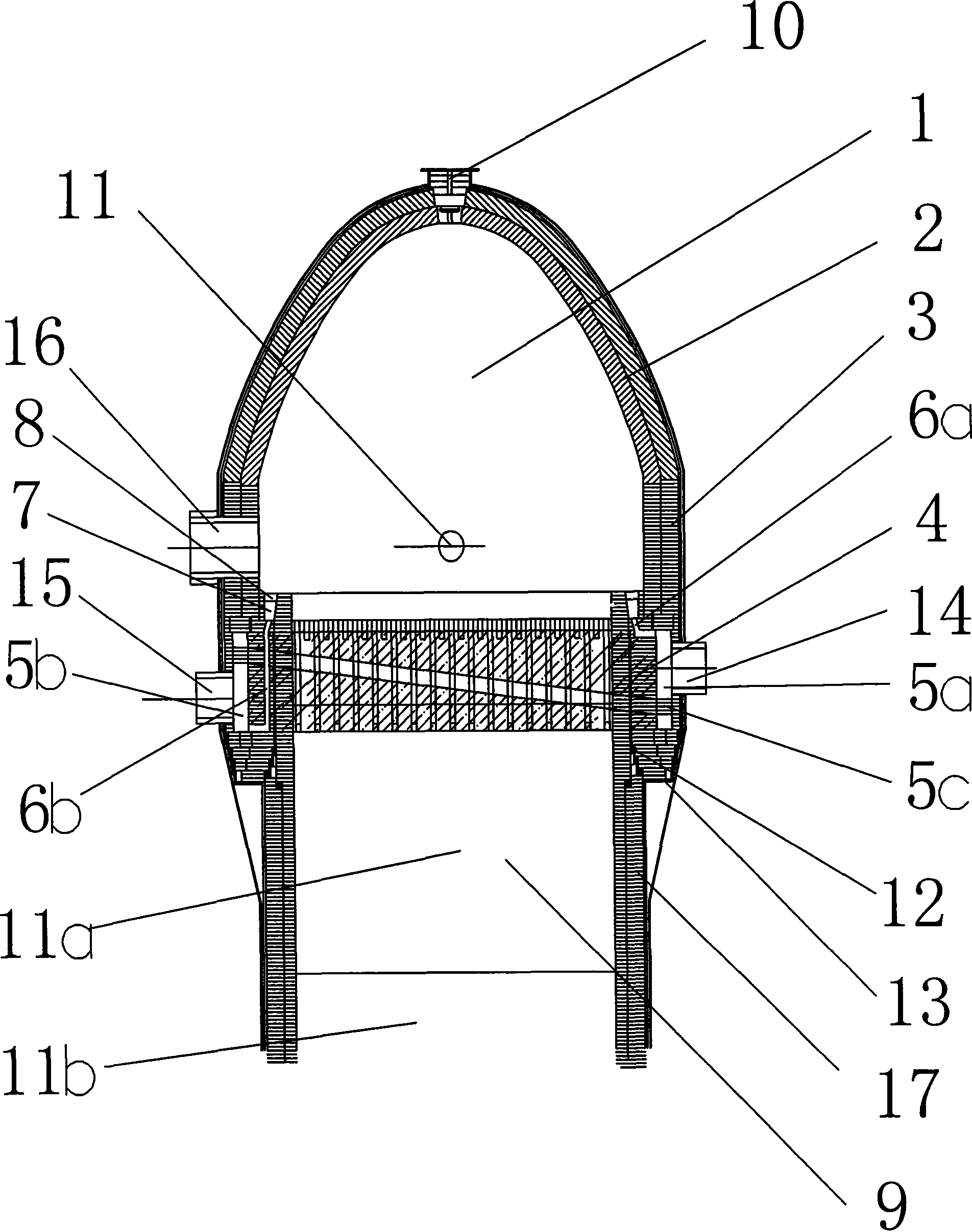

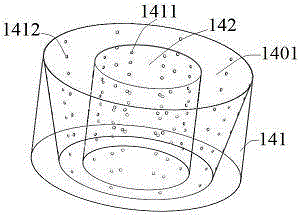

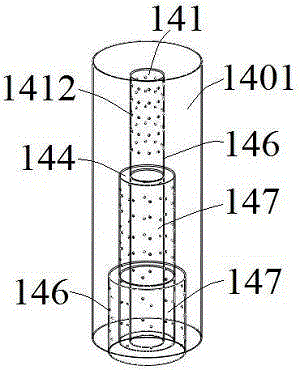

Top burning hot blast stove using annular airflow spray upward with premixing combustion and reflux heating

ActiveCN101381786AFixing Poor MixingResolve Insufficient CombustionBrick-hot blast stovesCombustion processSocial benefitsCombustor

The invention relates to a top-firing hot blast furnace which adopts upper spraying, premixing, firing, reflux and heating by annular airflow and effectively solves the problems of the rationality and stability of the fluid flow in the hot blast furnace and the sufficiency and uniformity of the mixing of different fluids. The top-firing hot blast furnace has the following structure: a vault is positioned on a burner of the upper part of a furnace body; the lower part of a furnace grate under the furnace body is provided with a cold wind chamber; a flue gas outlet pipe and a cold wind inlet pipe are arranged on the sidewall of the cold wind chamber; a combustion chamber is formed between a straight cylinder part on the upper part of the burner and the vault; a hot blast outlet pipe is arranged on the straight cylinder part; the lower part of the burner is provided with a heat storage chamber; the outer wall of the burner is positioned on an outer supporting annular plate of the upper part of the furnace body; the inside of the burner is separated into a coal gas distribution circuit and an air distribution circuit by a partition wall of an oblique circuit; the outer ends of the coal gas distribution circuit and the air distribution circuit are provided with a coal gas inlet pipe and an air inlet pipe respectively; a conduit is formed between the upper parts of the outer wall and the inner wall of the burner; the coal gas distribution circuit and the air distribution circuit are connected with an annular airflow premixing conduit through the respective nozzle tube distributed on the peripheral wall of the burner; and a flow equalizing and obstructing baffle plate is formed between the upper part of the conduit and the combustion chamber. The top-firing hot blast furnace has good economical and social benefits.

Owner:河南省豫兴热风炉工程技术有限公司

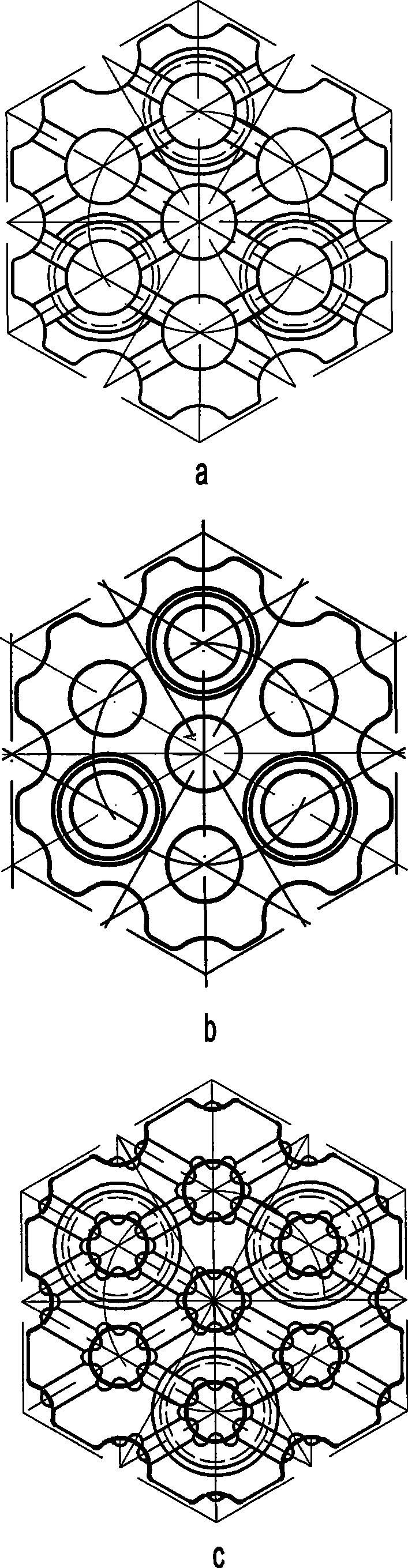

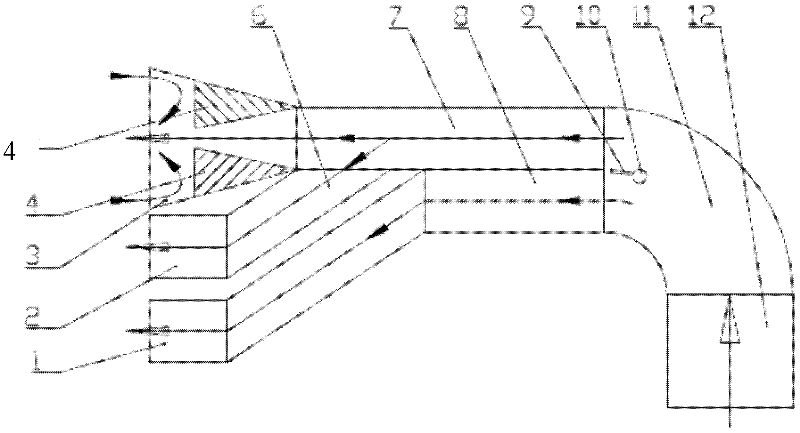

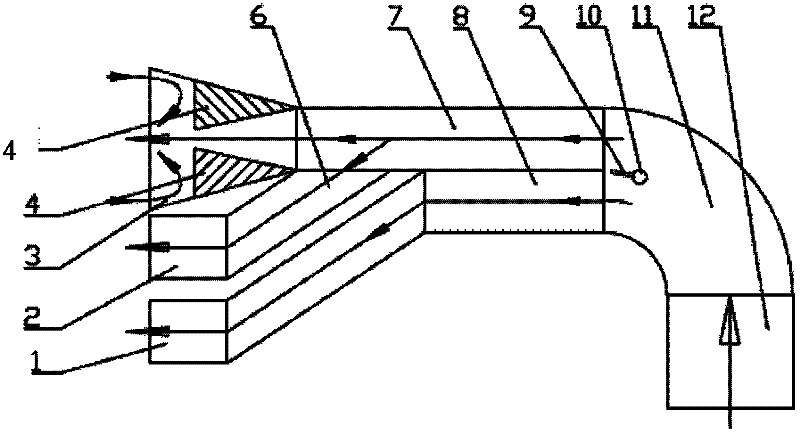

Pulverized coal decoupling combustor and decoupling combustion method thereof

InactiveCN102297425AMeet or exceed concentration efficiencyOver concentration efficiencyPulverulent fuel combustion burnersCombustorGuide tube

The invention relates to a pulverized coal decoupling combustor and a decoupling combustion method thereof. The decoupling combustor comprises a first-stage air duct (12), an inertia separator (11), air current conduits and a spout which are sequentially connected along the air current direction, wherein the air current conduits comprise a dense side air current conduit (7) and a fresh side air current conduit (8); the fresh side air current conduit (8) is communicated with a third-stage spout (1); the dense side air current conduit (7) is connected with a first-stage spout (3); a second-stage spout conduit (6) communicated with the dense side air current conduit (7) is led out of a pipeline between the dense side air current conduit (7) and the first-stage spout (3) on the dense side aircurrent conduit (7); the second-stage spout conduit (6) is communicated with a second-stage spout (2); the first-stage spout (3) is a gradually-increasing spout; a pair of pulverized coal collecting flame stabilizing devices (4) is oppositely arranged at the upper side and the lower side inside the front end of the first-stage spout (3); the cross sections of the pulverized coal collecting flame stabilizing devices (4) along the air current direction is gradually increased; and the area of the cross section of an air current channel is decreased along the air current direction, thus the coupling combustion is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

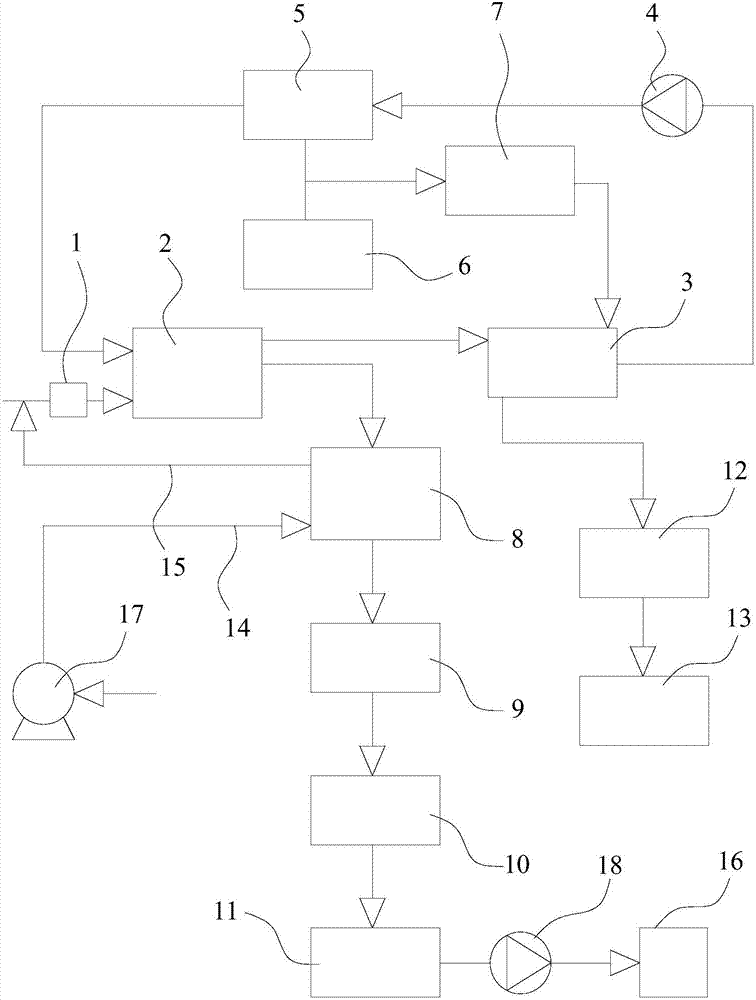

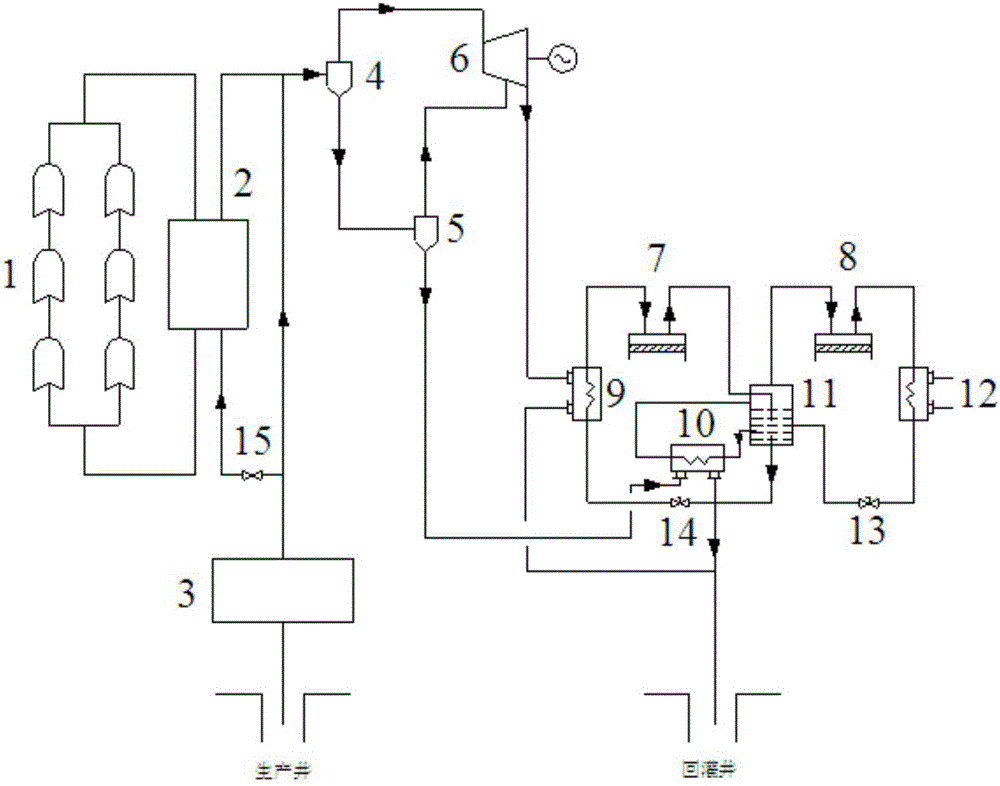

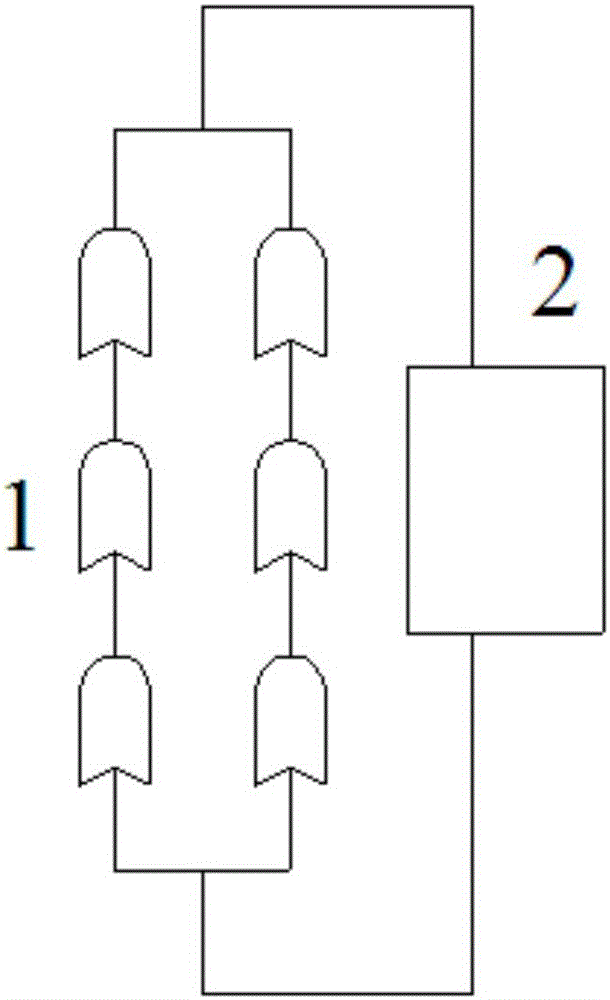

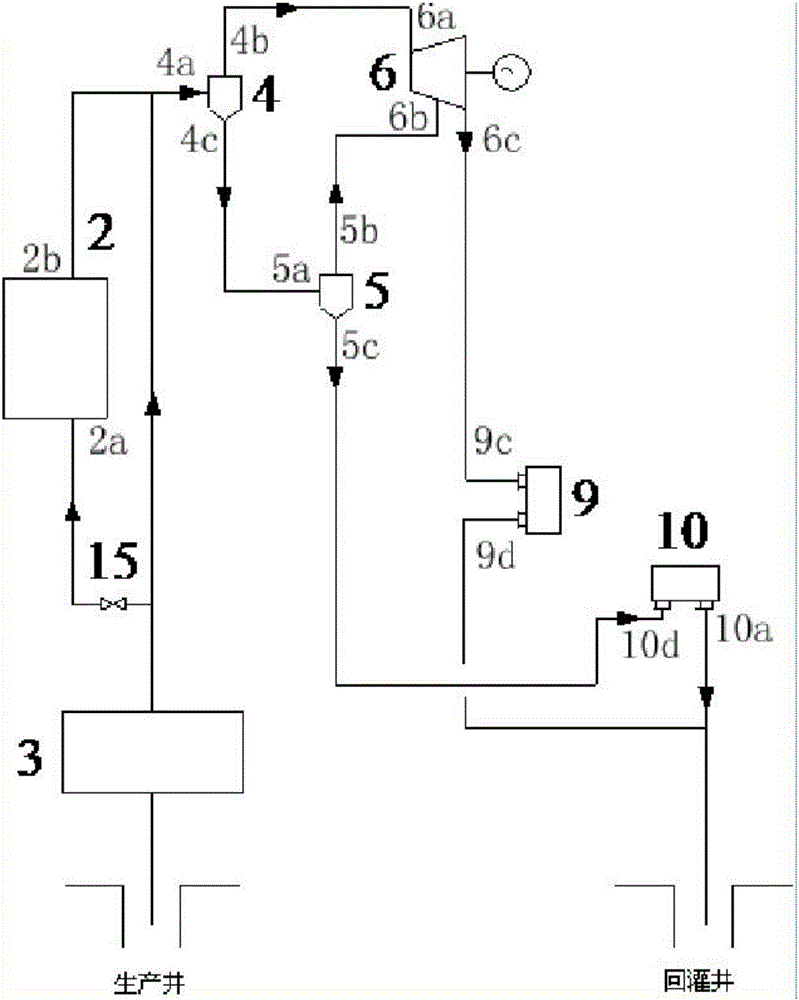

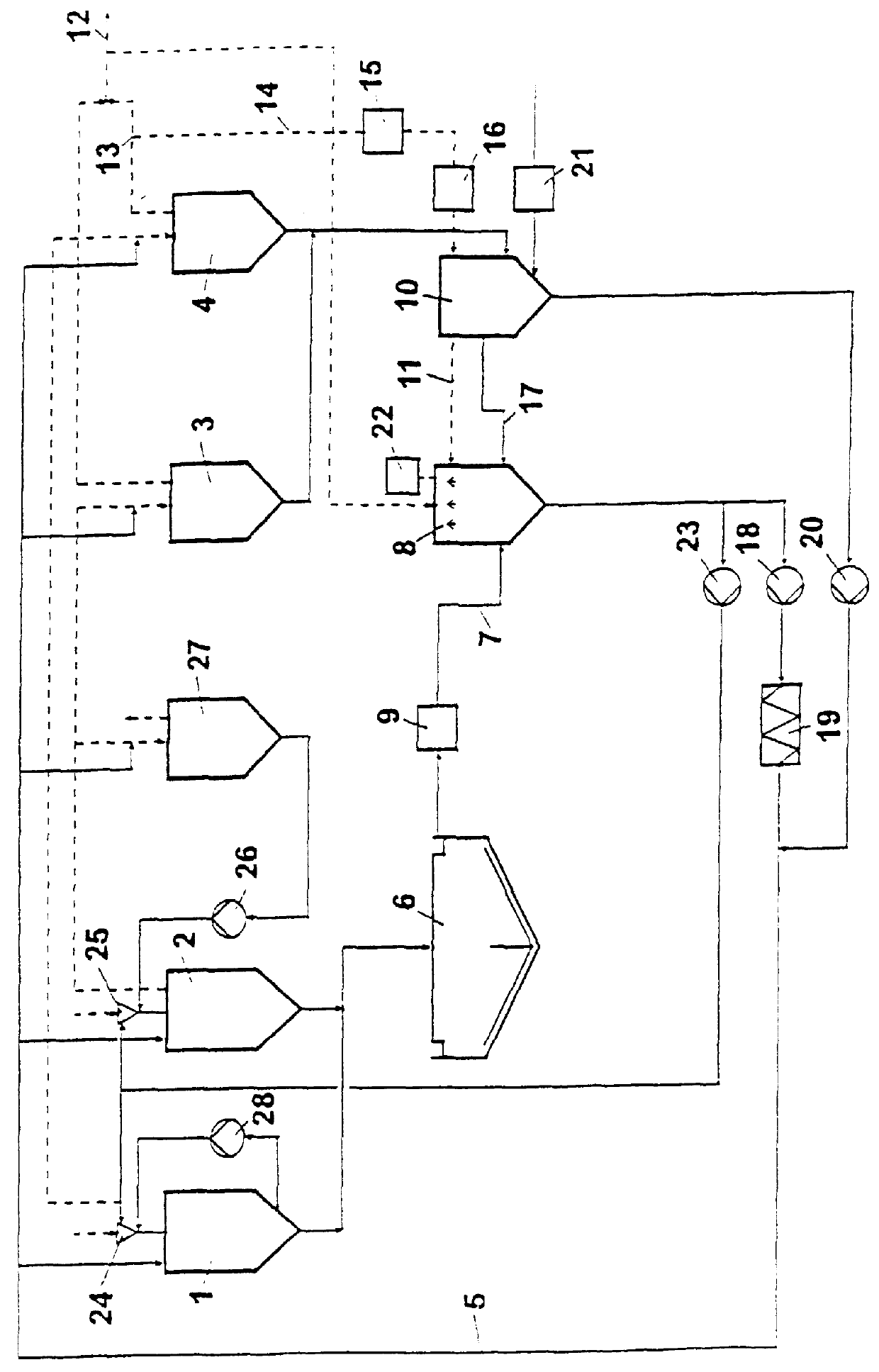

Solar energy and terrestrial heat combination two-level flash double-working-medium cycle power generation hot water system

ActiveCN105888992AImprove working abilityImprove system efficiency and power generationSolar heating energyFrom solar energyChillerEvaporator

The invention provides a solar energy and terrestrial heat combination two-level flash double-working-medium cycle power generation hot water system. The solar energy and terrestrial heat combination two-level flash double-working-medium cycle power generation hot water system comprises a groove type solar energy heat collector, a heat storage device, a terrestrial heat processing device, a first-level flash vessel, a second-level flash vessel, a steam turbine, a low-pressure compressor, a high-pressure compressor, an evaporator, a middle evaporator, a middle cooler and a condenser, wherein the terrestrial heat processing device, the first-level flash vessel, the second-level flash vessel, the steam turbine, the low-pressure compressor, the high-pressure compressor, the evaporator communicate to a production well, the middle evaporator, the middle cooler and the condenser communicate to a recharge well, and the heat storage device and the groove type solar energy heat collector communicate with each other and form a closed cycle.

Owner:SOUTHEAST UNIV

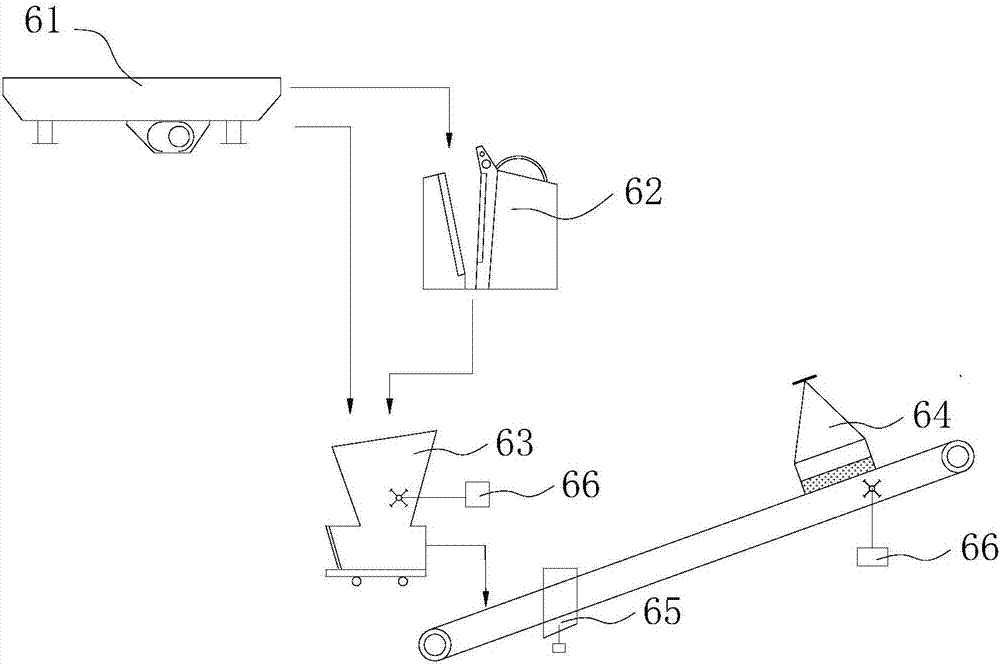

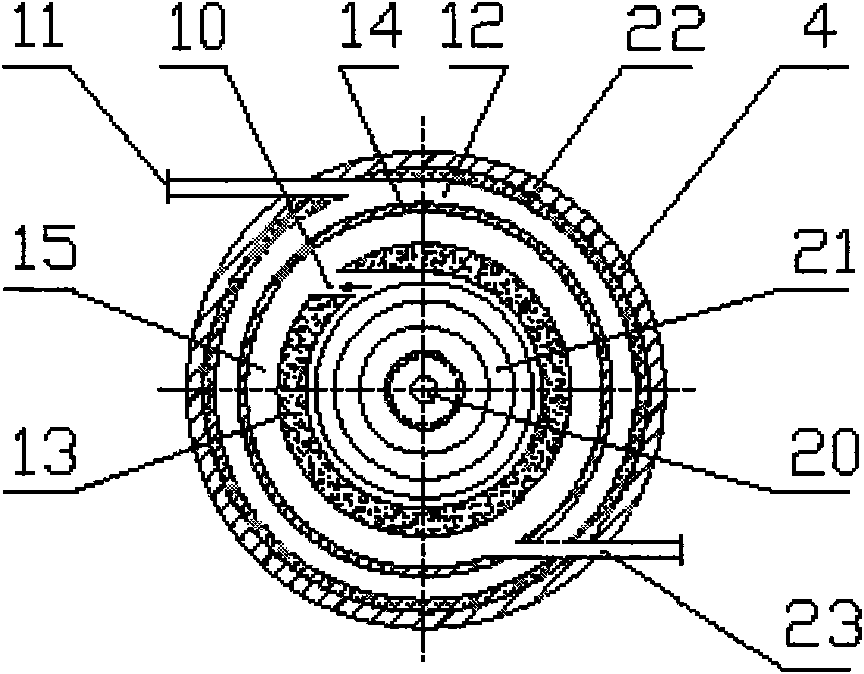

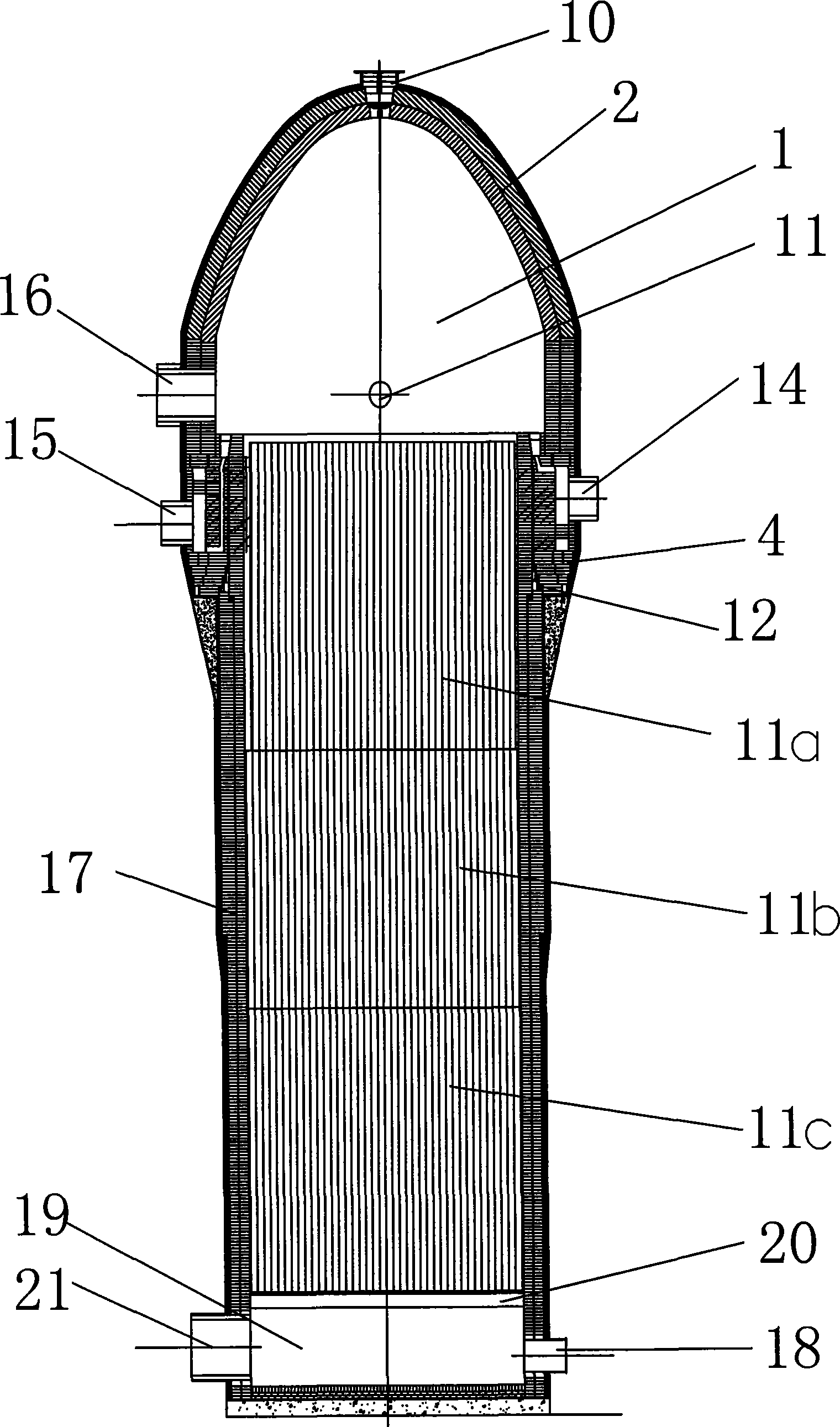

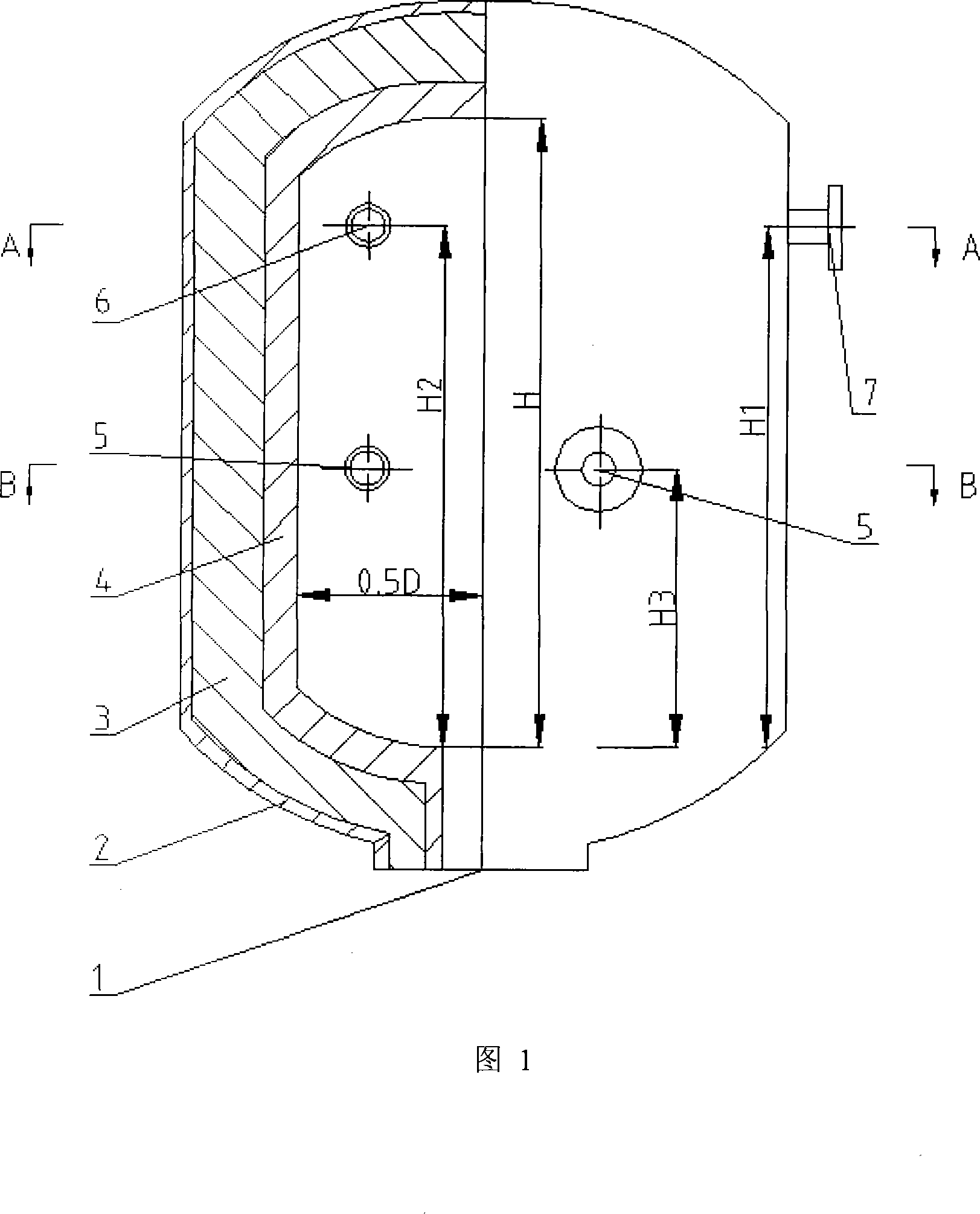

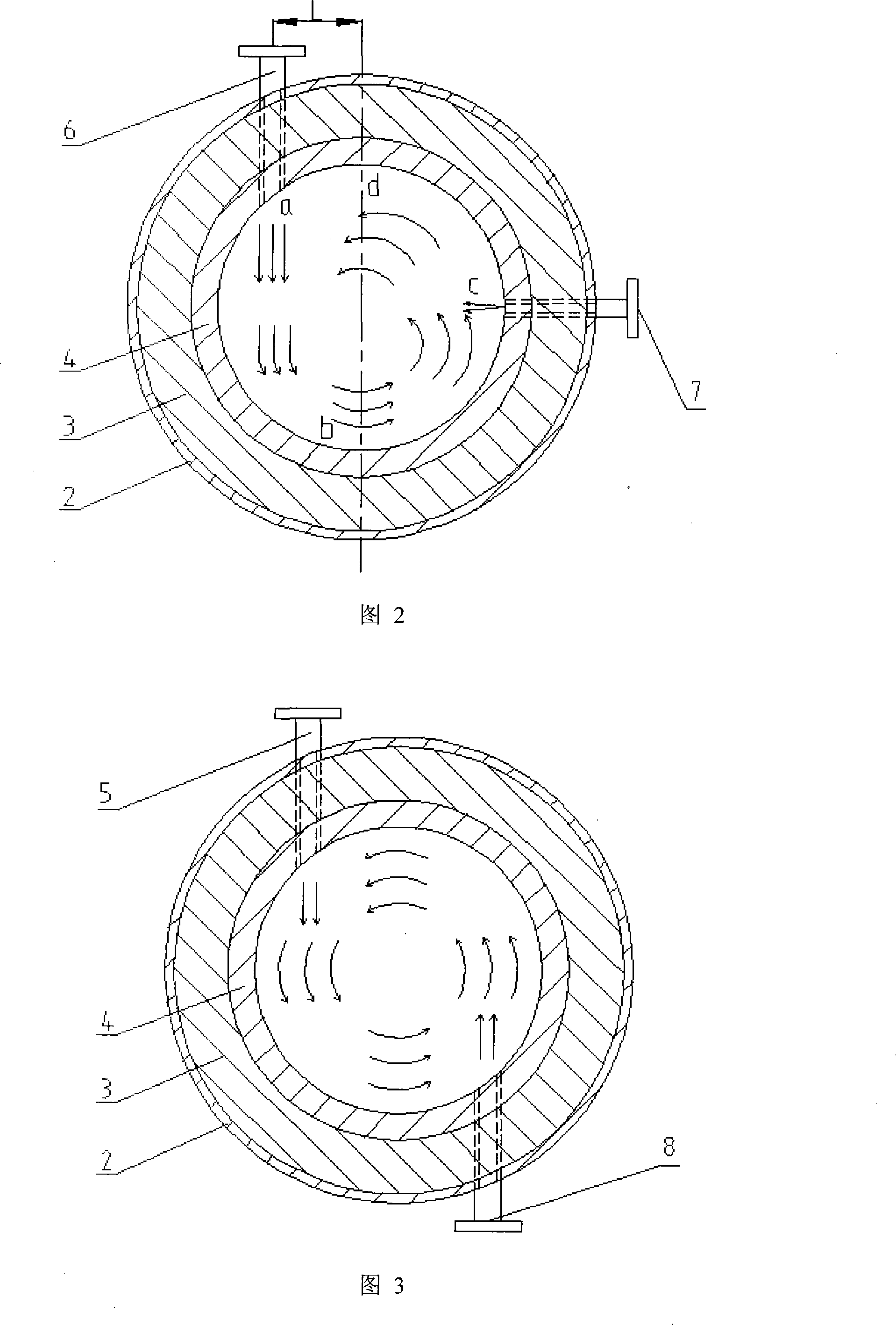

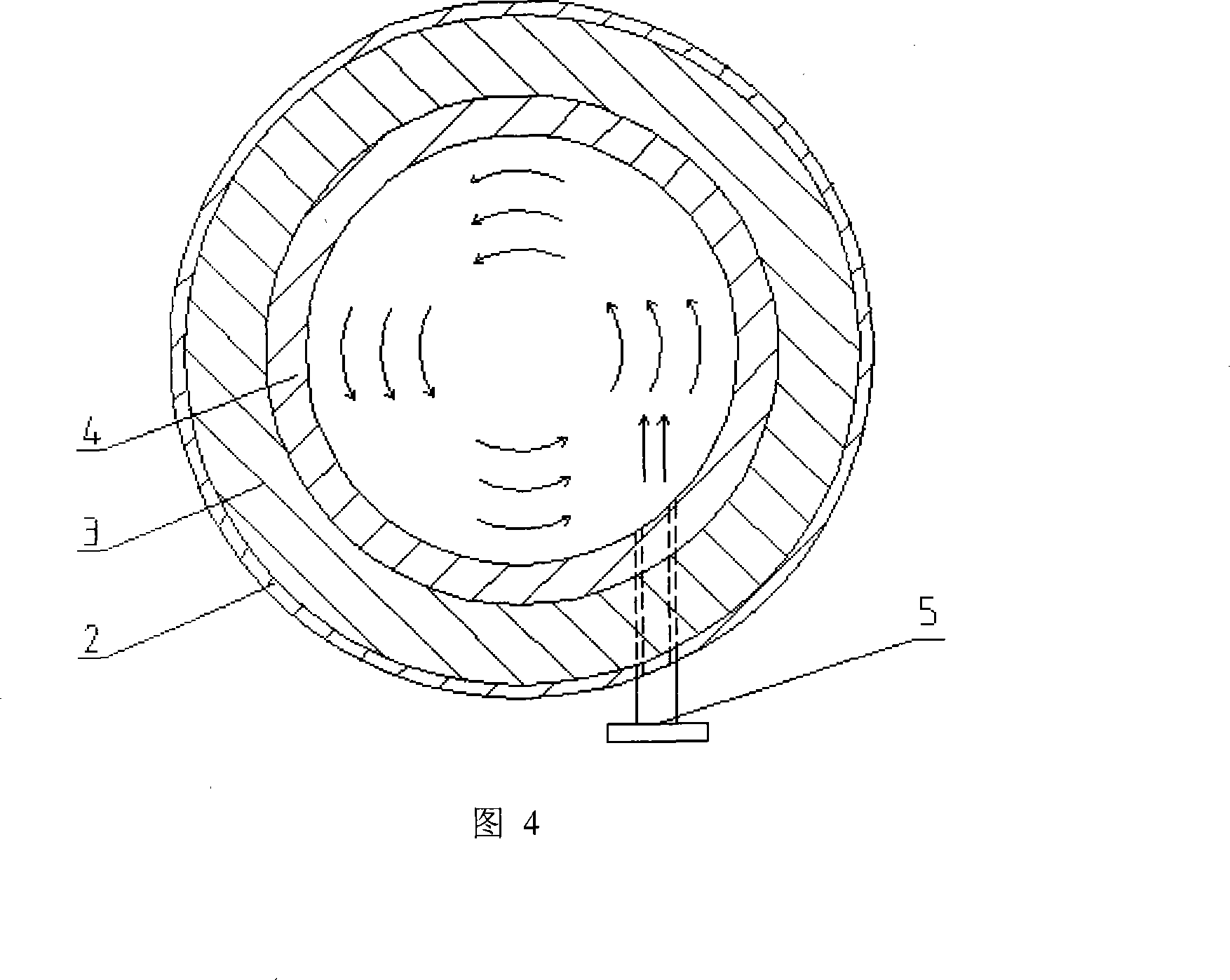

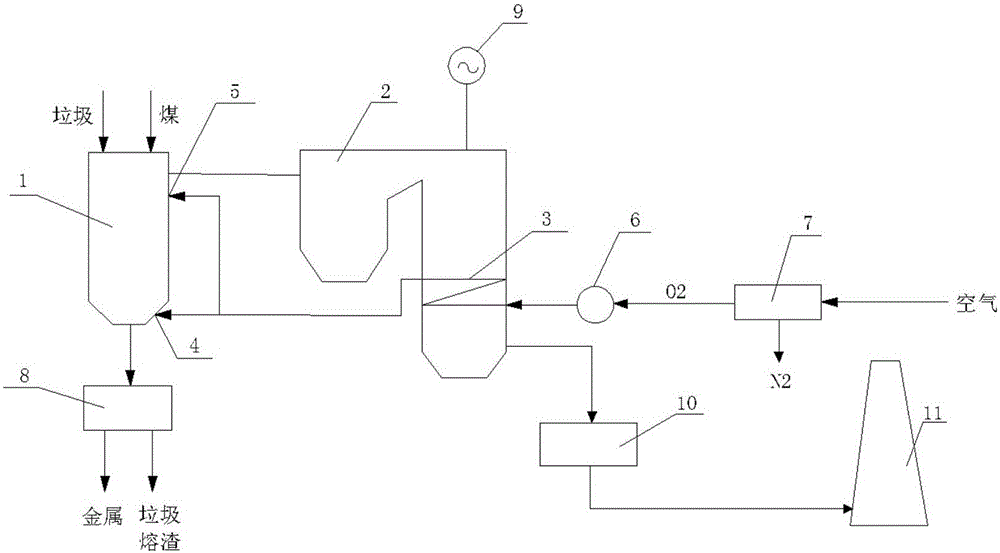

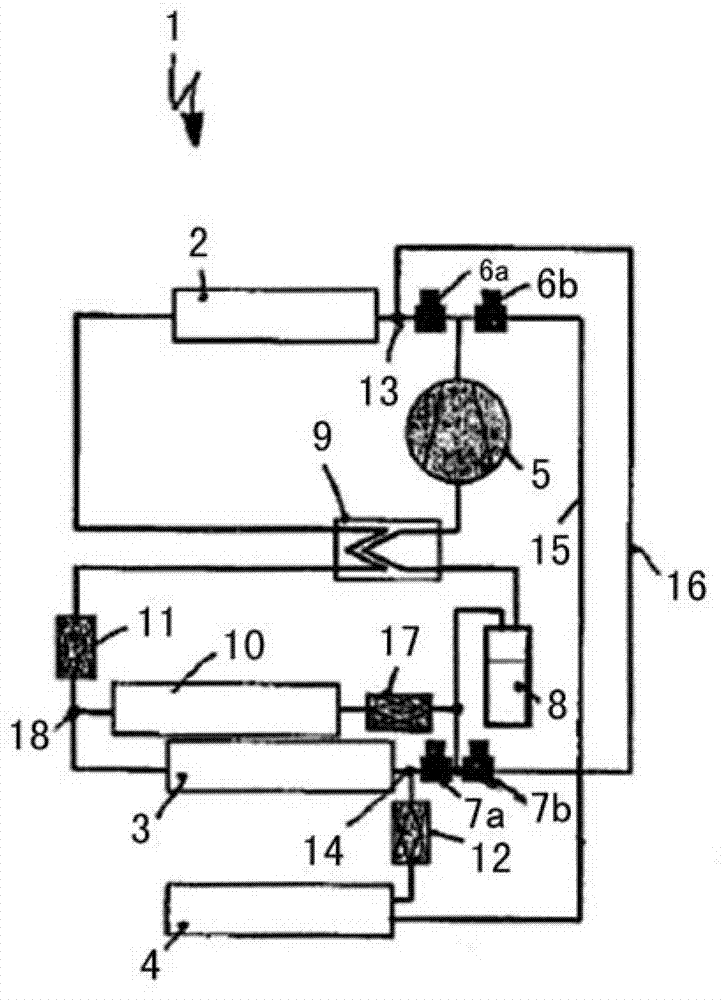

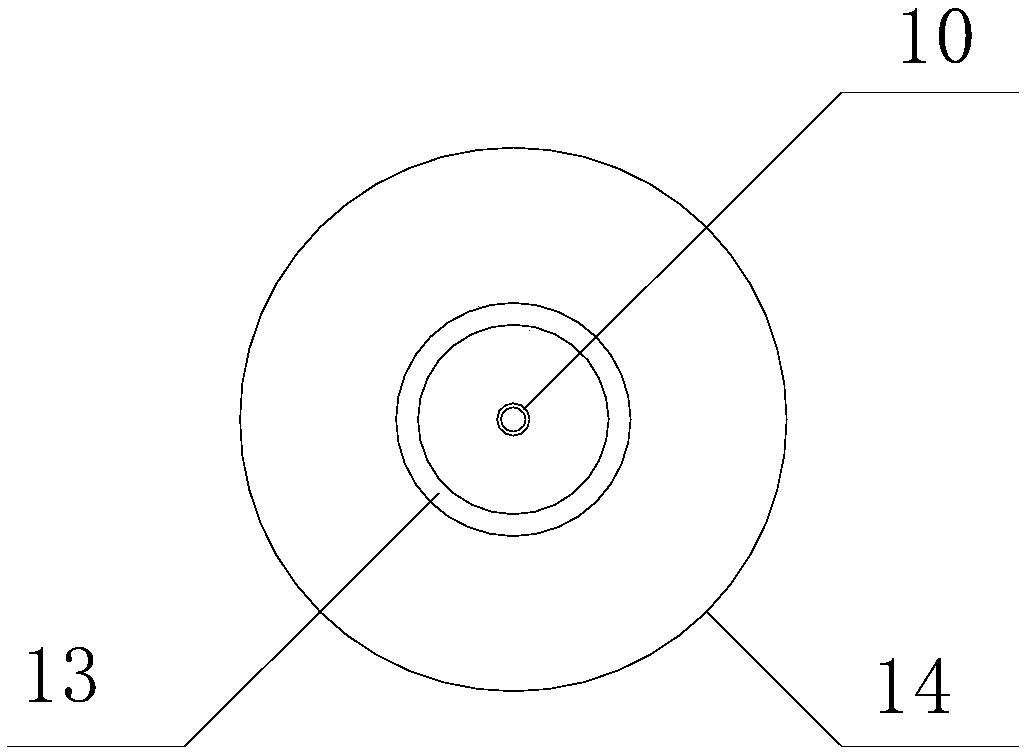

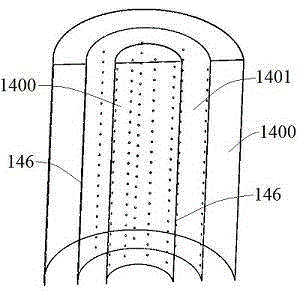

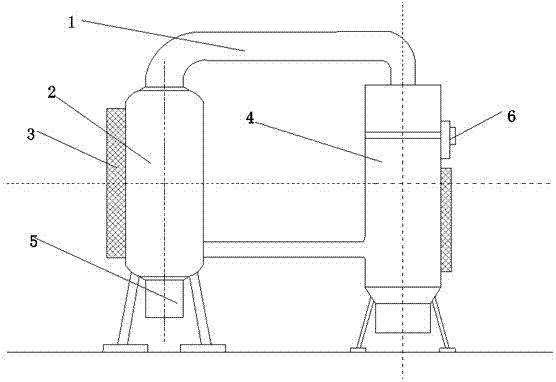

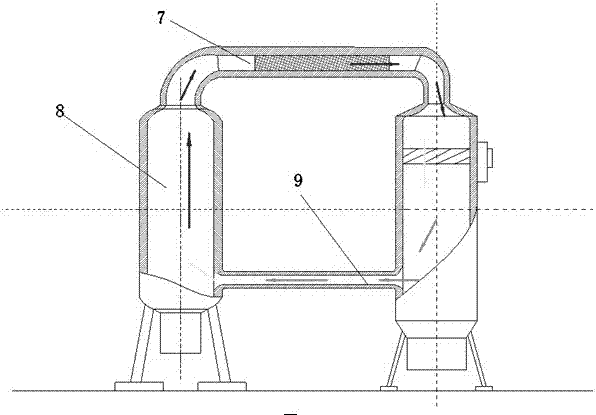

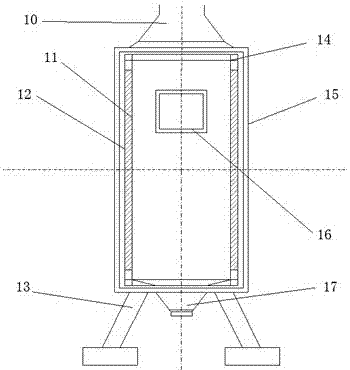

High ash melting point coal seed gasification method and device thereof

InactiveCN101235320AReduce the maximum temperatureRaise the temperature levelGranular/pulverulent flues gasificationWater vaporSlag

The invention discloses a vertical pressurization entrained flow gasification method and a device which is suitable for dust coal with high ash fusion point, slag tapping, synthesis gas and liquid slag and flows to a slag hole of down stream, the device comprises a metal casing 2 of a gasification stove, a thermal-insulating heat-insulating layer 3, a flame-proof inner container 4, a oxidize nozzle 6, a dust coal nozzle 7, a water vapor nozzle 5 and a water vapor nozzle 8. The invention is characterized in that dust coals and gasifying agents are sprayed into a gasification stove through nozzles on different heights on stove walls in different stove inlet mode, dust coal is radially sprayed through a nozzle on the upper portion of a stove body under the conveying of carrier gas, oxidizing agent is injected with high speed through a nozzle 6 on another different on the upper portion of the stove body along the direction which is parallel to the circular cross section tangent of the stove body, water vapor is injected with high speed through nozzles 7 and 8 on the lower part of the stove body along the direction which is parallel to the circular cross section tangent of the stove body, and the rotating directions of the gasifying agents on the upper portion and the lower portion are the same. Contact and reaction time of dust coal and gasifying agents in the stove is increased, gasification reaction is led to be more complete, which is beneficial further improving gasification efficiency. And the method adopts a downwards parallel current model of synthesis gas and liquid slag, which smoothly achieve slag tapping of dust coal with high ash fusion point.

Owner:UNIV OF SCI & TECH OF CHINA

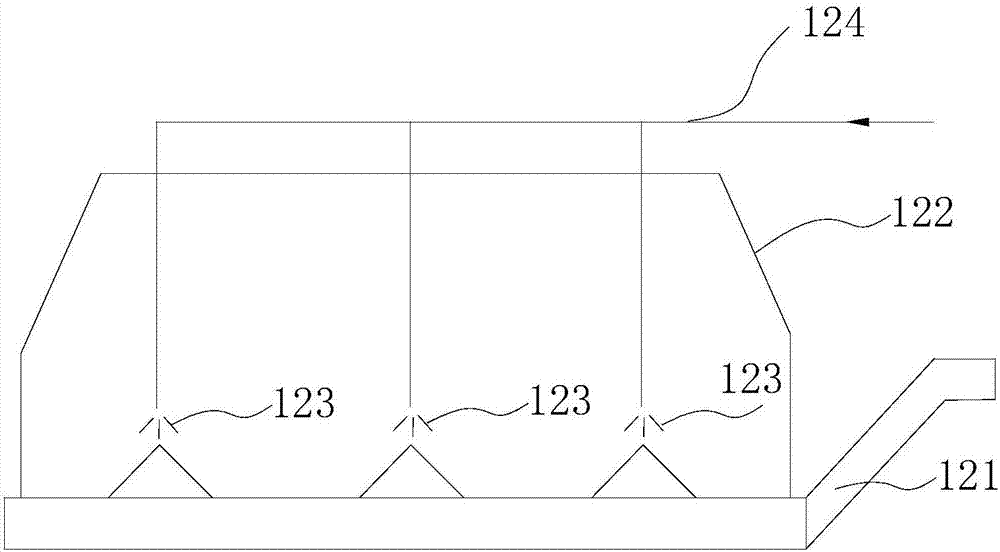

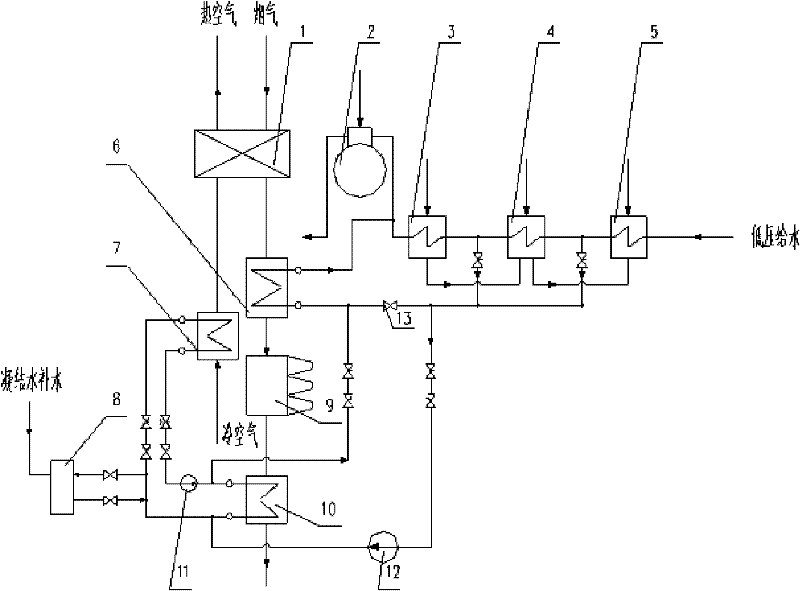

Combined type flue gas residual heat comprehensive utilization system

ActiveCN102230615AReduce corrosionReduce riskCombustion technology mitigationFeed-water heatersCold airFlue gas

The invention discloses a combined type flue gas residual heat comprehensive utilization system. A first-stage flue gas cooler and a second-stage flue gas cooler are arranged in front of and behind a dust collector respectively to realize stepped utilization of residual heat of exhaust smoke; condensed water with high entropy is heated at a flue gas high-temperature section; cold air with low entropy is heated in a flue gas low-temperature section; and a flue gas low-temperature section cooler and a flue gas high-temperature section cooler run in series. By adopting the comprehensive utilization system, the inlet water temperature level and the closed circulation water temperature level of the second-stage flue gas cooler are raised, and the risks of low-temperature corrosion and closed circulating water freezing in the flue gas cooler are decreased.

Owner:HUANENG CLEAN ENERGY RES INST

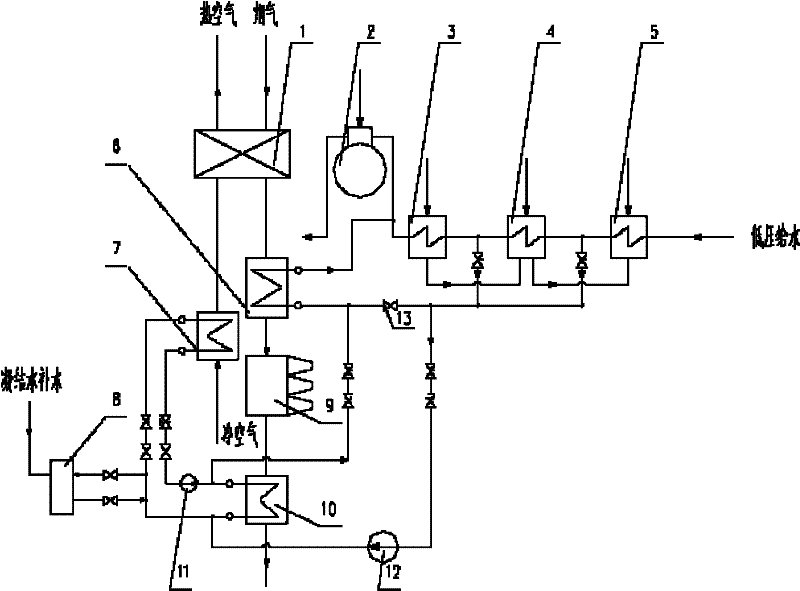

Device and method for heating and melting rubbish under oxygen-rich condition

InactiveCN105864782ALow ignition temperatureReduce usageIndirect carbon-dioxide mitigationIncinerator apparatusAir preheaterCombustion

The invention discloses a device and method for heating and melting rubbish under the oxygen-rich condition. The device comprises a rubbish melting furnace. The rubbish melting furnace is connected with an oxygen supply system. The bottom of the rubbish melting furnace is connected with a cooling device. The oxygen supply system comprises an air separation device, an air feeder and an air preheater which are connected sequentially. A first air blowing opening is formed in the upper portion of the rubbish melting furnace. A second air blowing opening is formed in the bottom of the rubbish melting furnace. Both the first air blowing opening and the second air blowing opening communicate with the air preheater. The oxygen supply system supplies separated oxygen-rich gas to the rubbish melting furnace, and the oxygen-rich gas is used as an oxidizing agent for melting the rubbish. The beneficial effects of the oxygen-rich combustion and melting treatment are used, combustion heat of fuel is used, fly ash of the rubbish is molten at the high temperature, stable glassy state slag is formed after cooling, organic components of Dioxin and the like are destroyed, and most of heavy metals are solidified in the glassy state slag.

Owner:SHANDONG UNIV

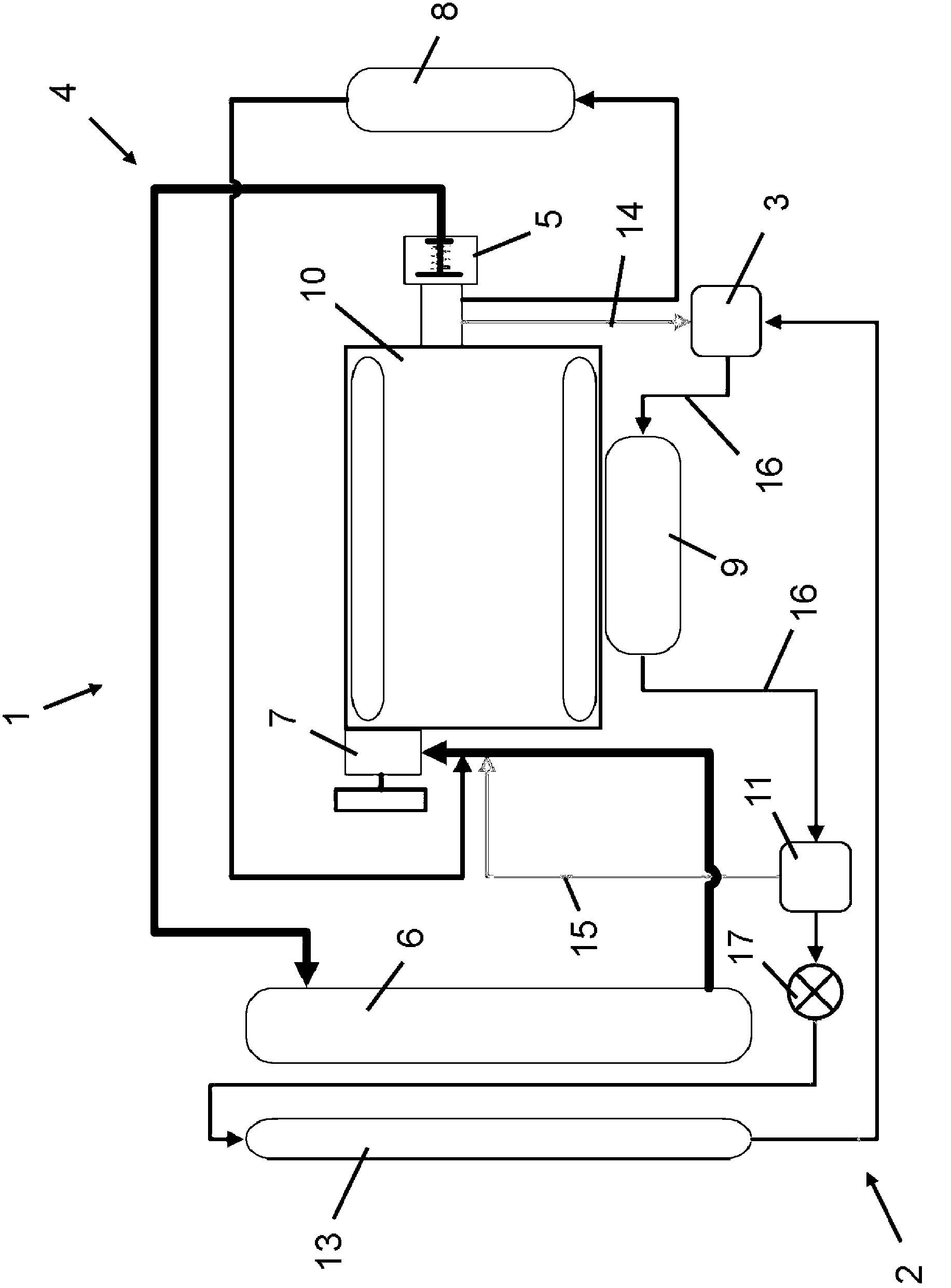

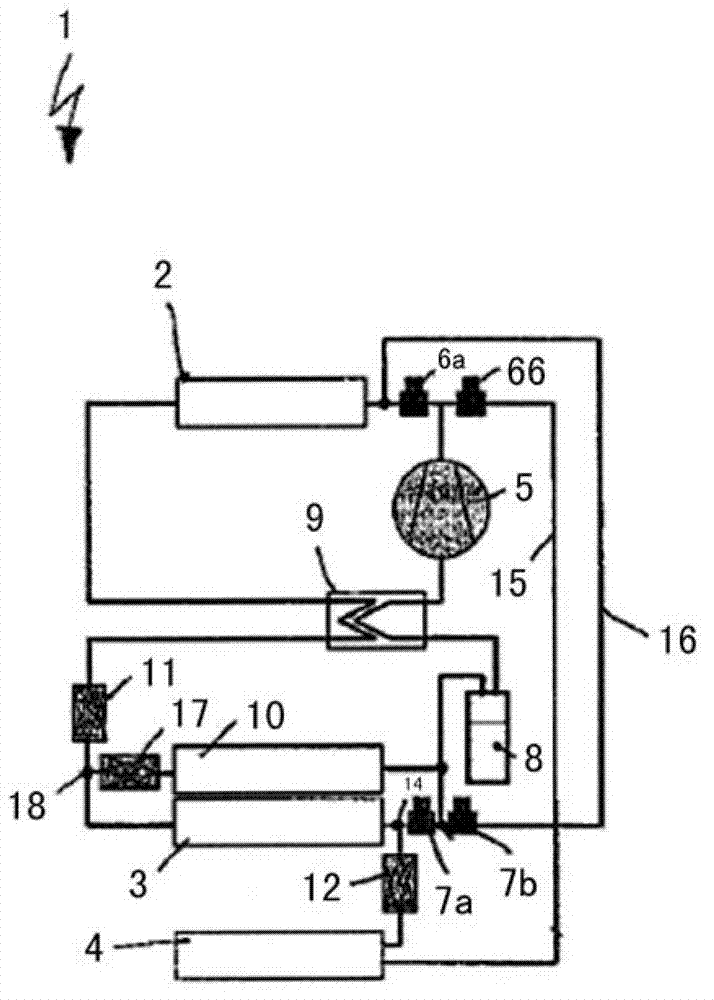

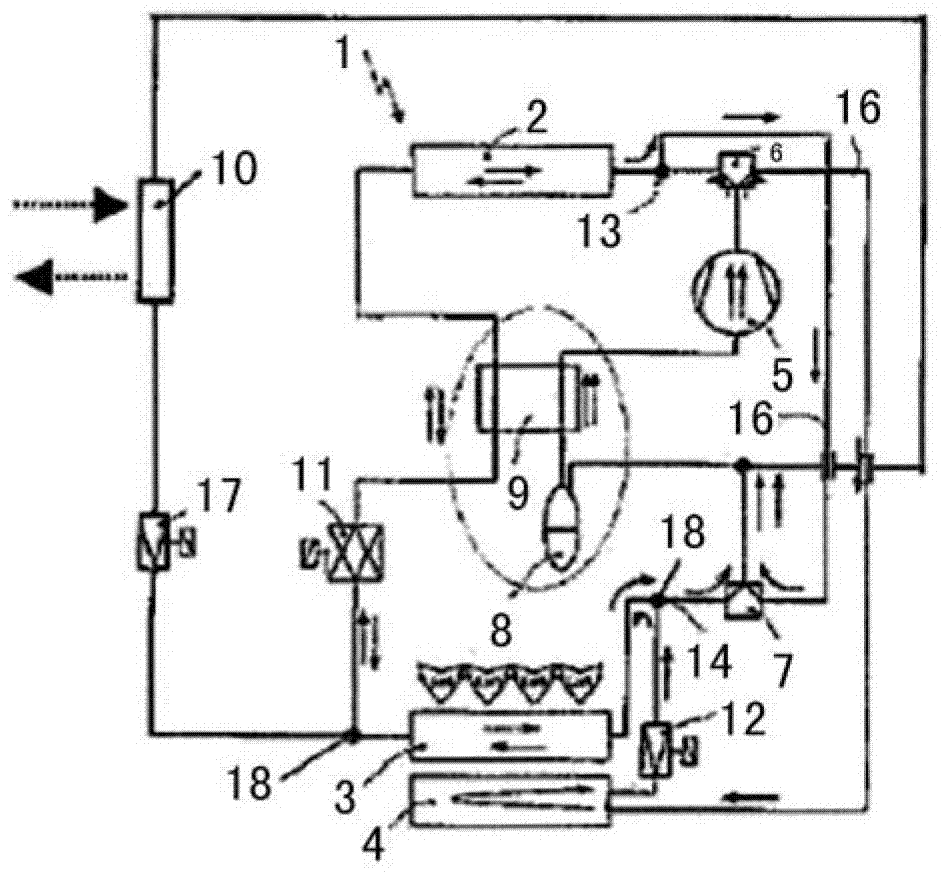

Motor vehicle refrigerant circuit with a refrigeration system circuit and a heat pump circuit

ActiveCN102897002ARaise the temperature levelIncrease the itineraryAir-treating devicesHeat pumpsAir conditioningRefrigerant

The invention relates to a motor vehicle refrigerant circuit provided with a refrigeration system circuit and a heat pump circuit which are used for air conditioning and heating of a motor vehicle, wherein heat pump condenser (4), a refrigeration system and a heat pump evaporator (3), and a chiller (10) in a coolant circuit are configured to serve as extra heat pump evaporators in the heat pump circuit and are in serial connection, and an expansion member (17) is connected with the chiller (10) at a coolant side and disposed in the coolant circuit by serving as a member for heating the coolant.

Owner:HANON SYST

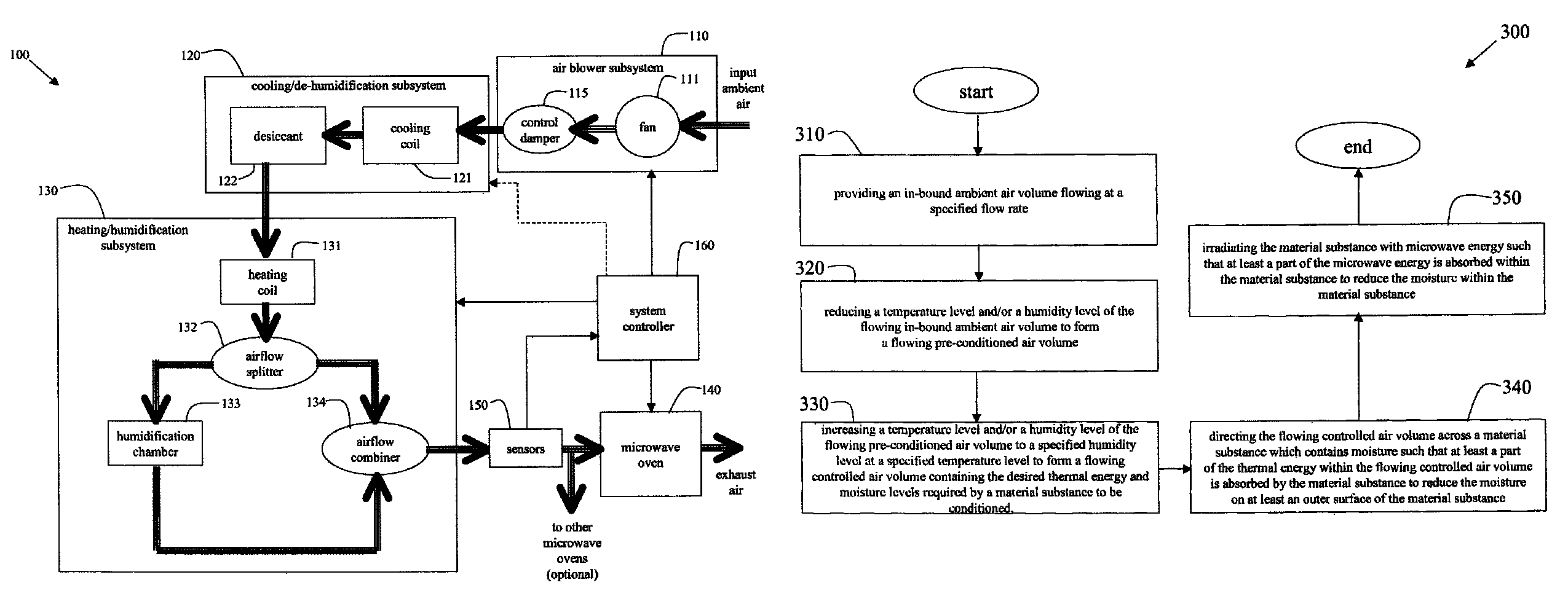

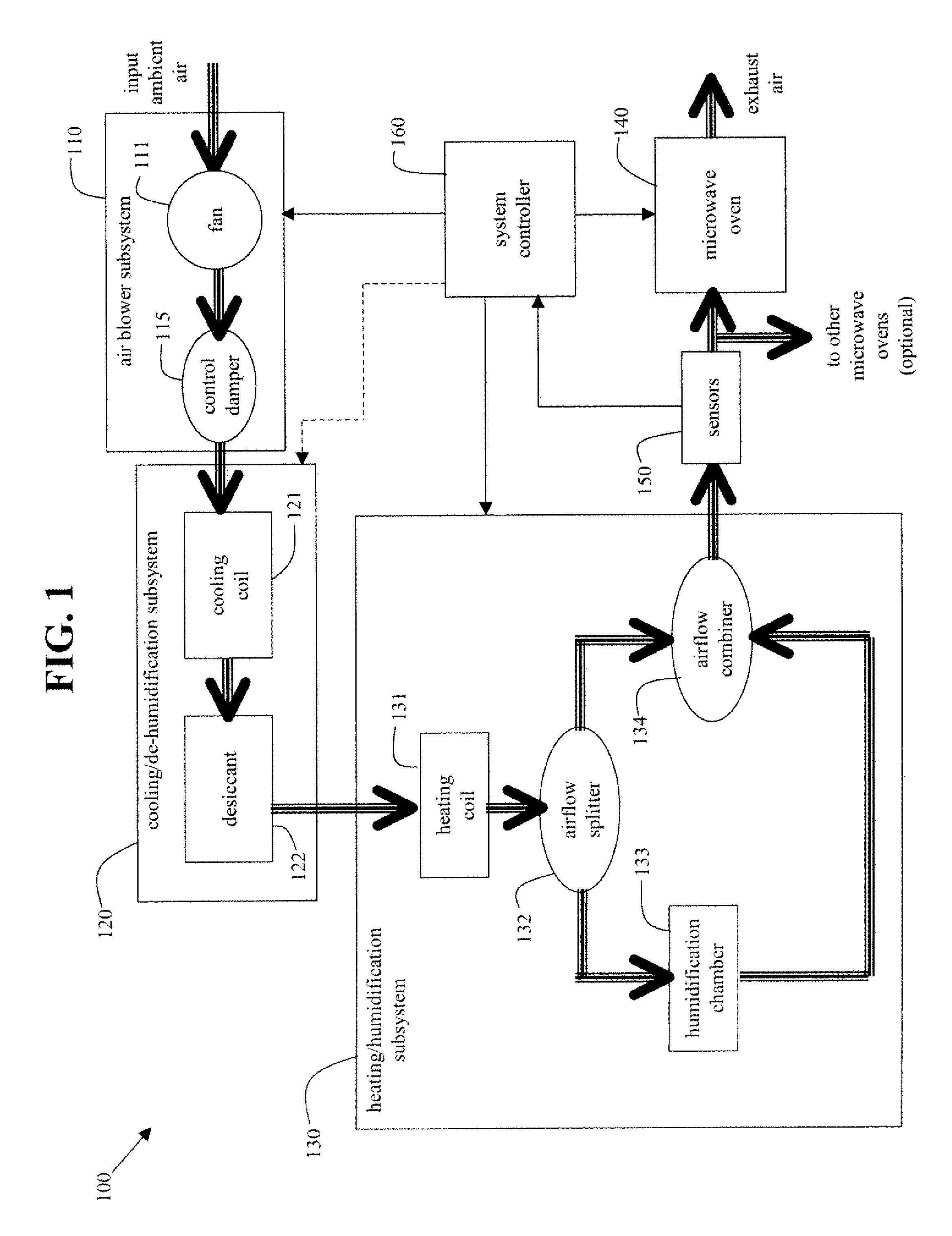

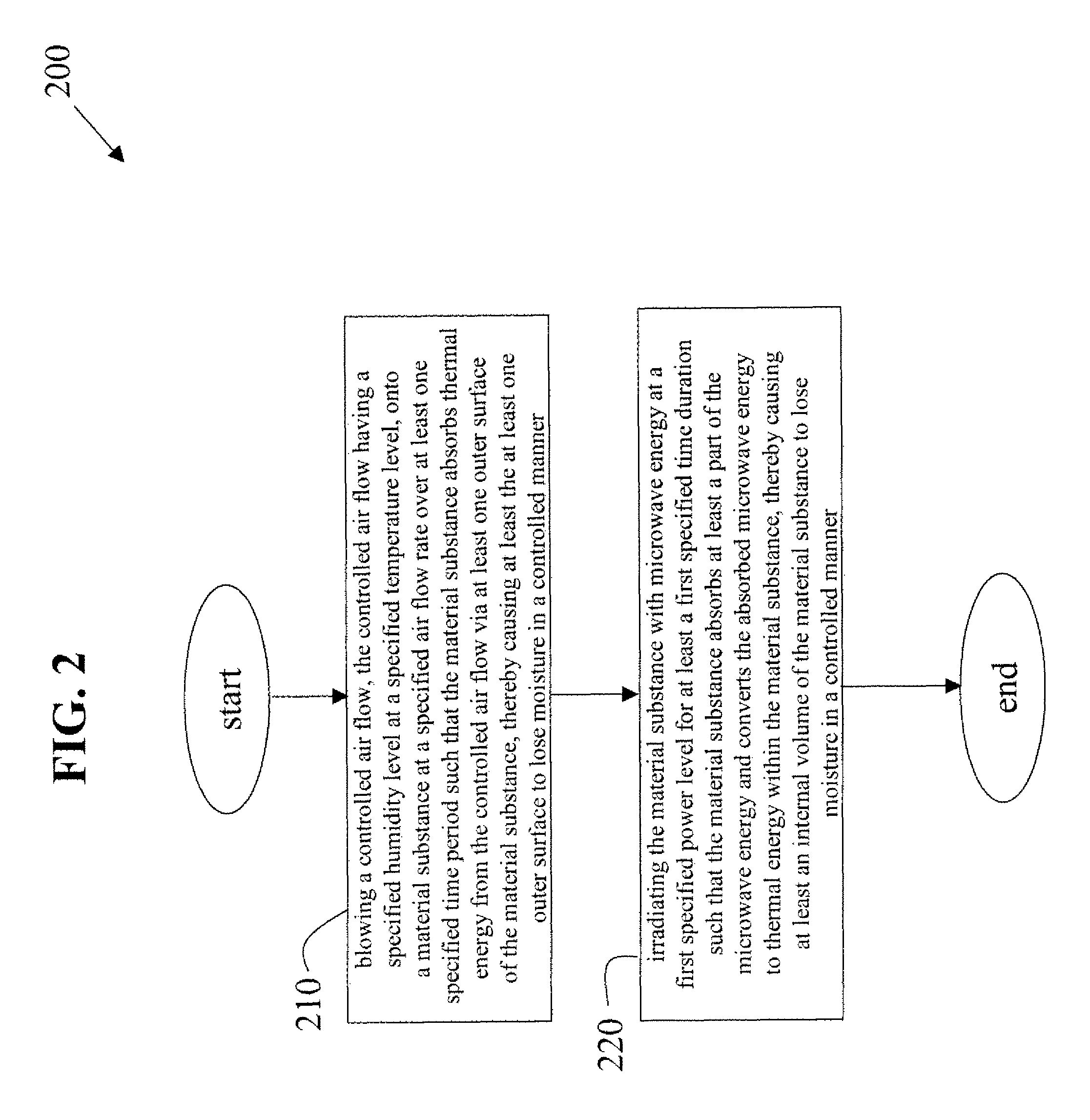

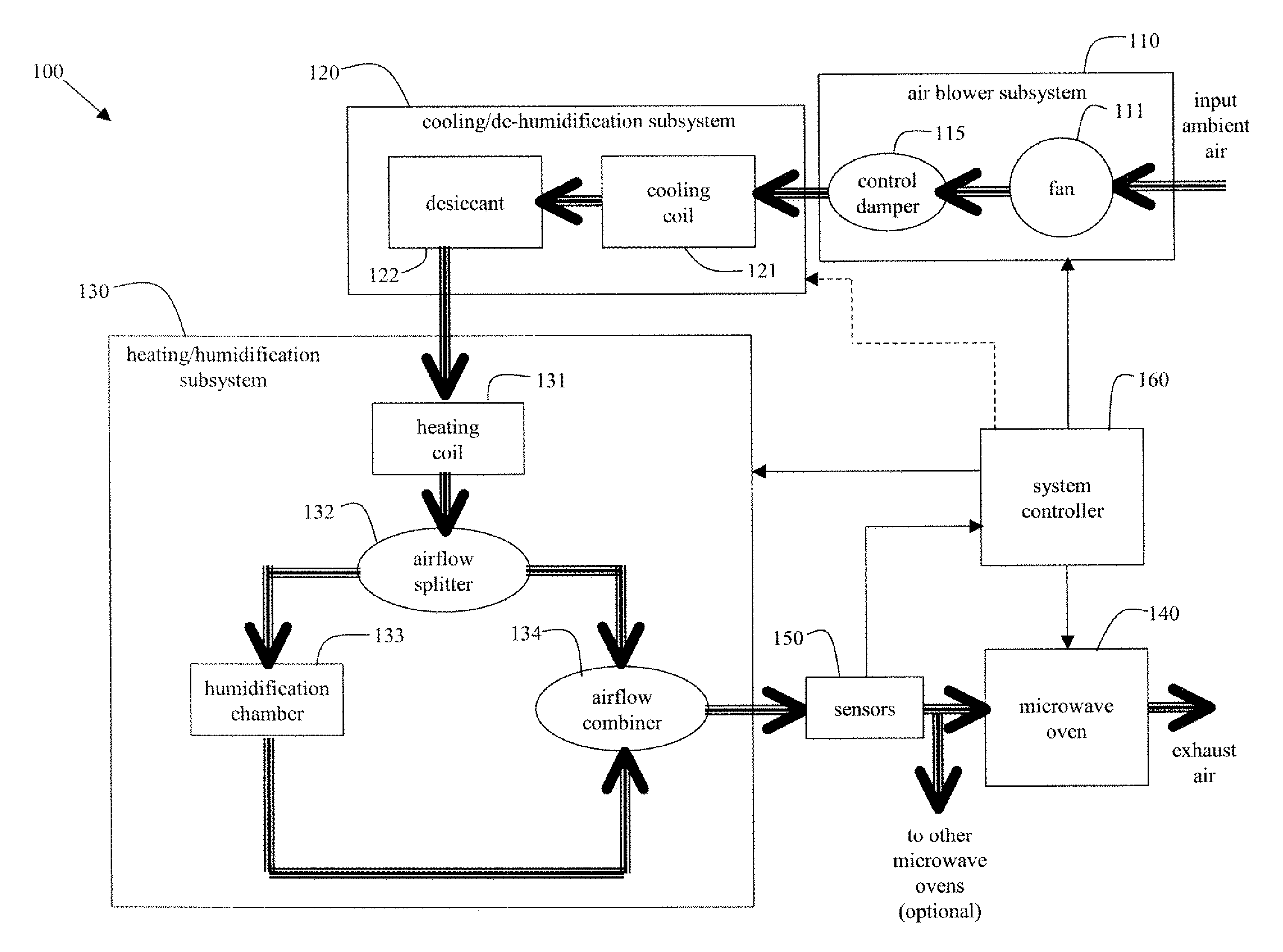

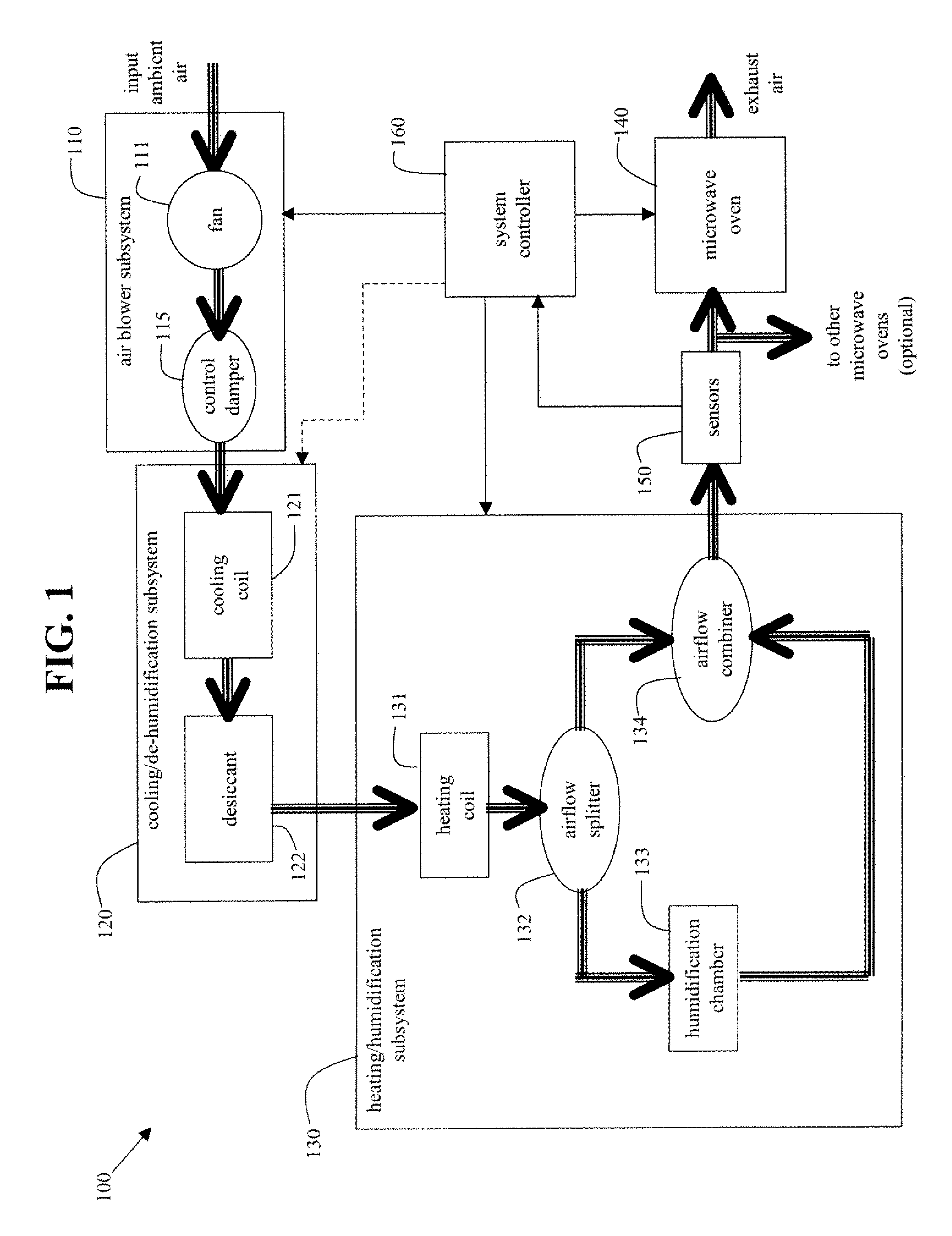

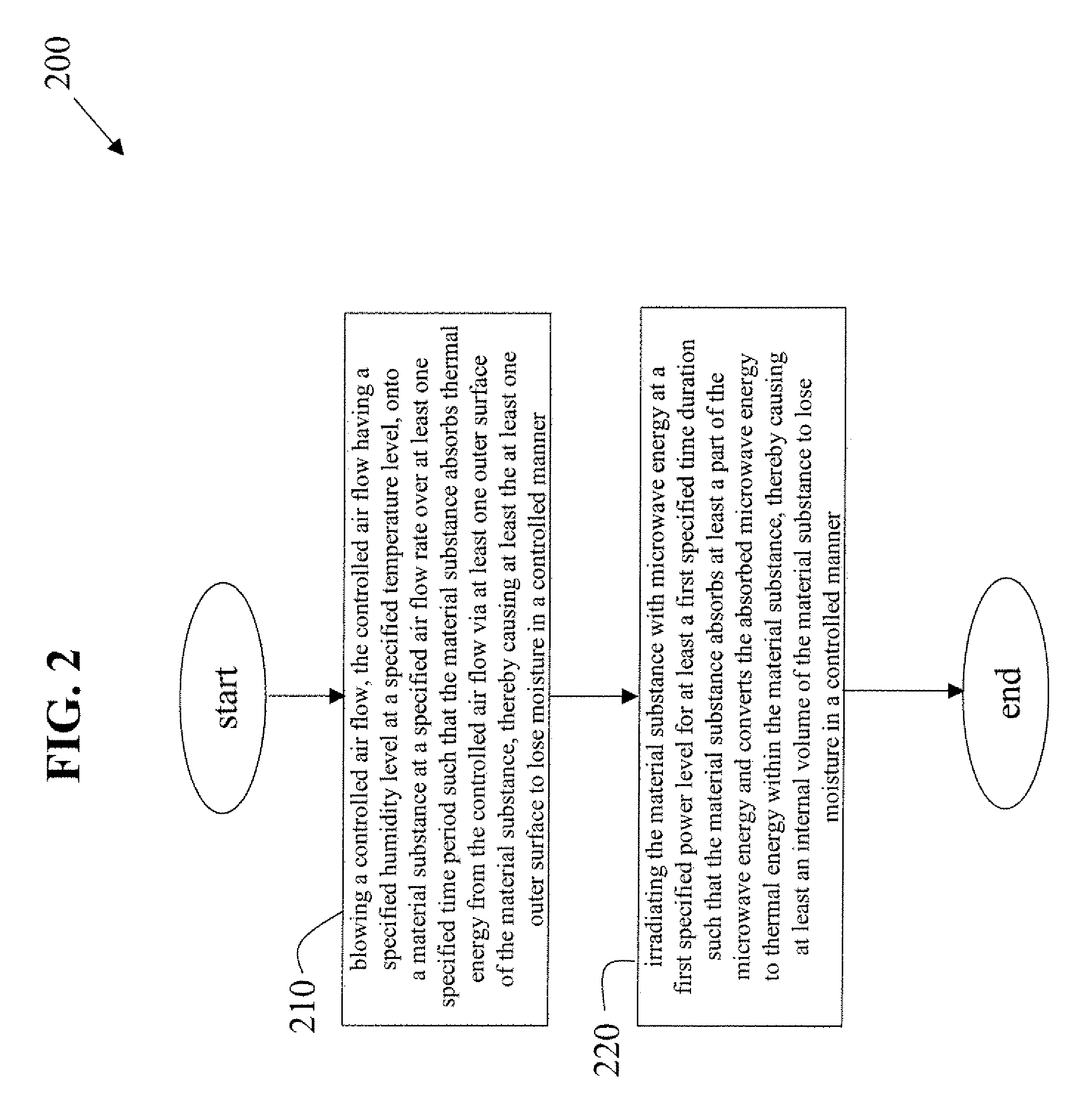

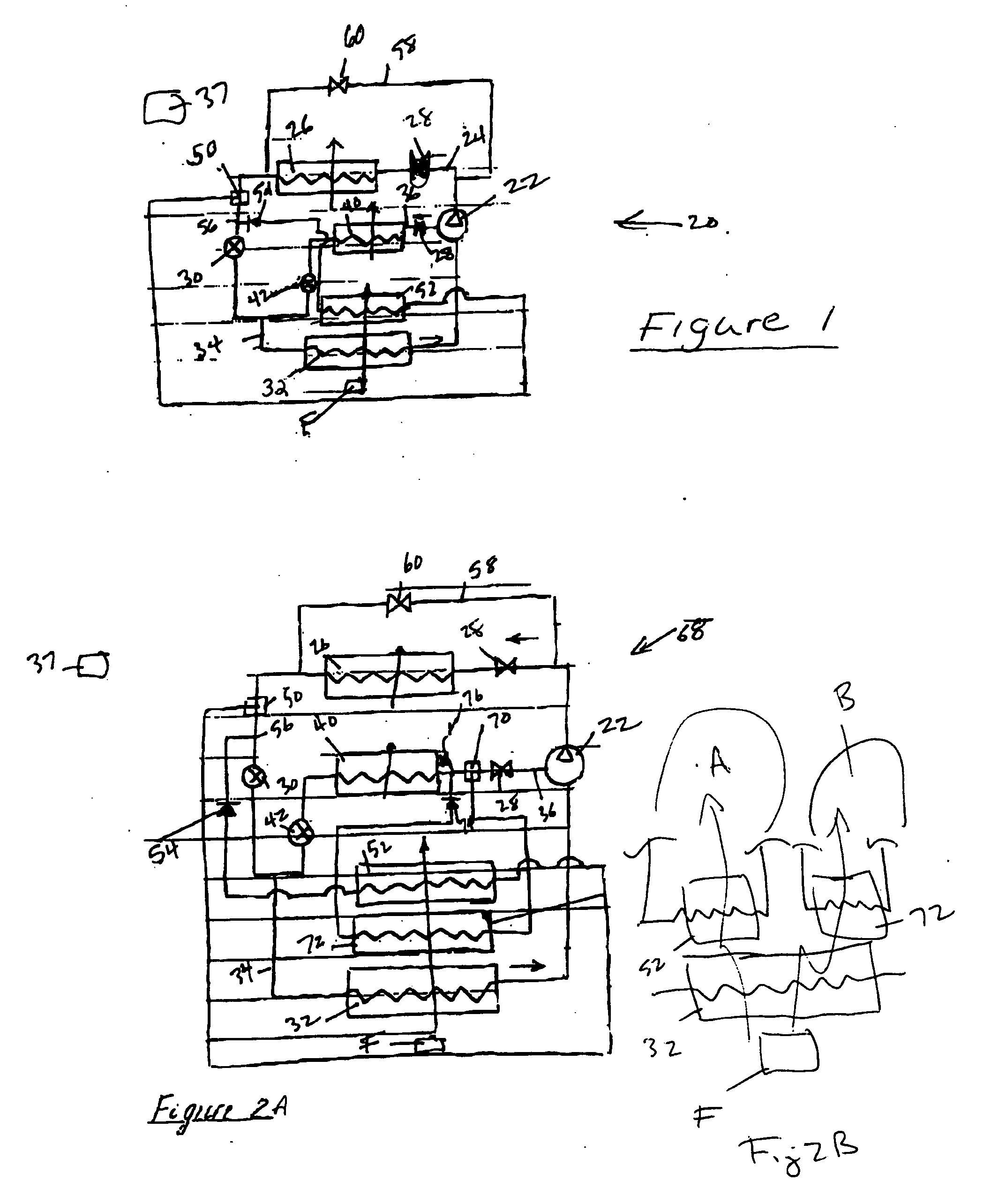

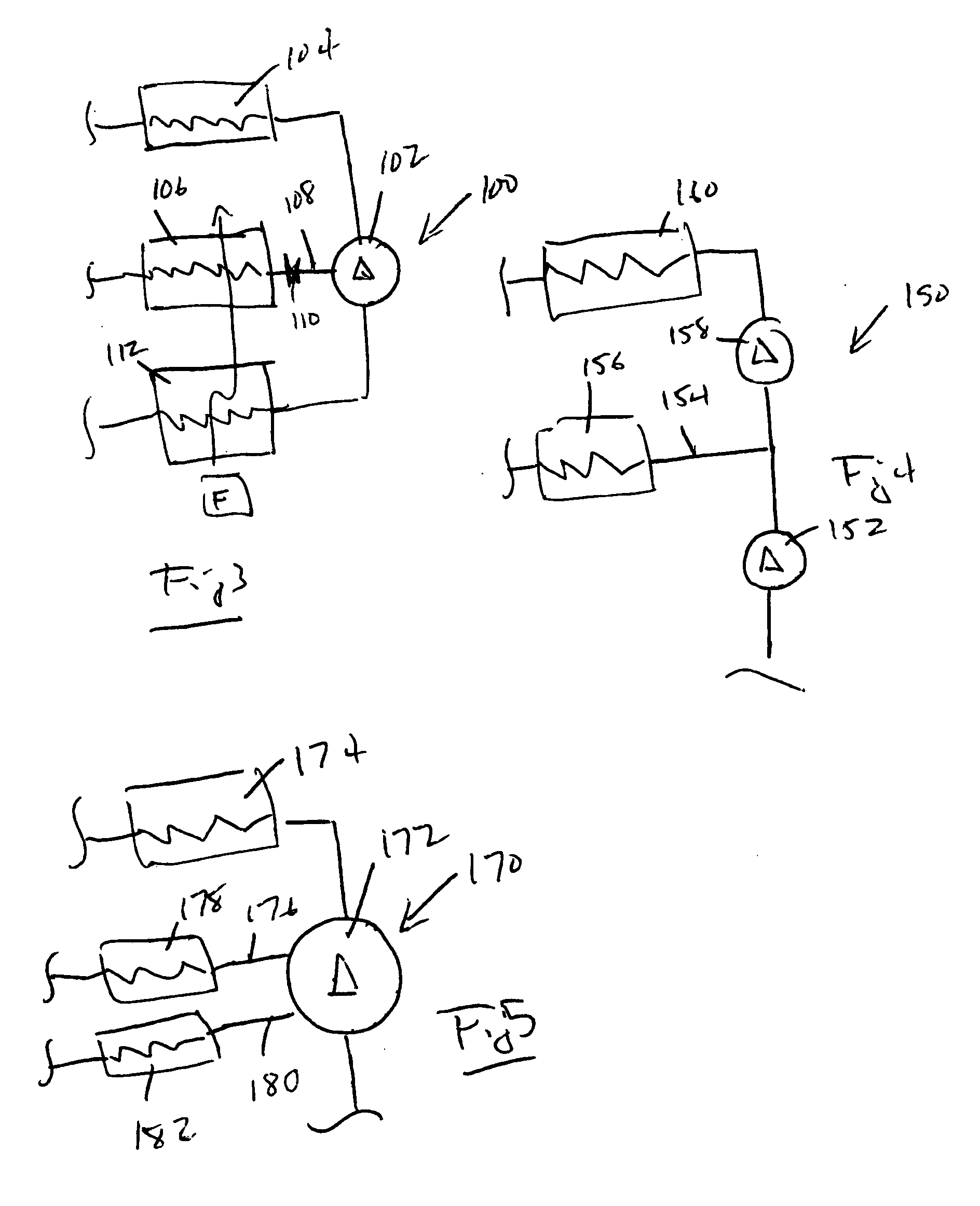

System and method to control energy input to a material

InactiveUS7913417B2Decreasing temperature level and humidity levelLower Level RequirementsDough treatmentDrying solid materials with heatThermal energyMicrowave

A system and method of controlling energy that is input to a material substance, for the controlled removal of moisture from the material substance, is disclosed. A controlled air flow is blown onto the material substance at a specified air flow rate over at least one specified time period such that the material substance absorbs thermal energy from the controlled air flow via at least one outer surface of the material substance. The controlled air flow is of a specified humidity level at a specified temperature level. The material substance is also irradiated with microwave energy at a first specified power level for at least a first specified time duration such that the material substance absorbs at least a part of the microwave energy and converts the absorbed microwave energy to thermal energy within the material substance. As a result, moisture is removed from the material substance in a controlled manner.

Owner:THE SHERWIN-WILLIAMS CO

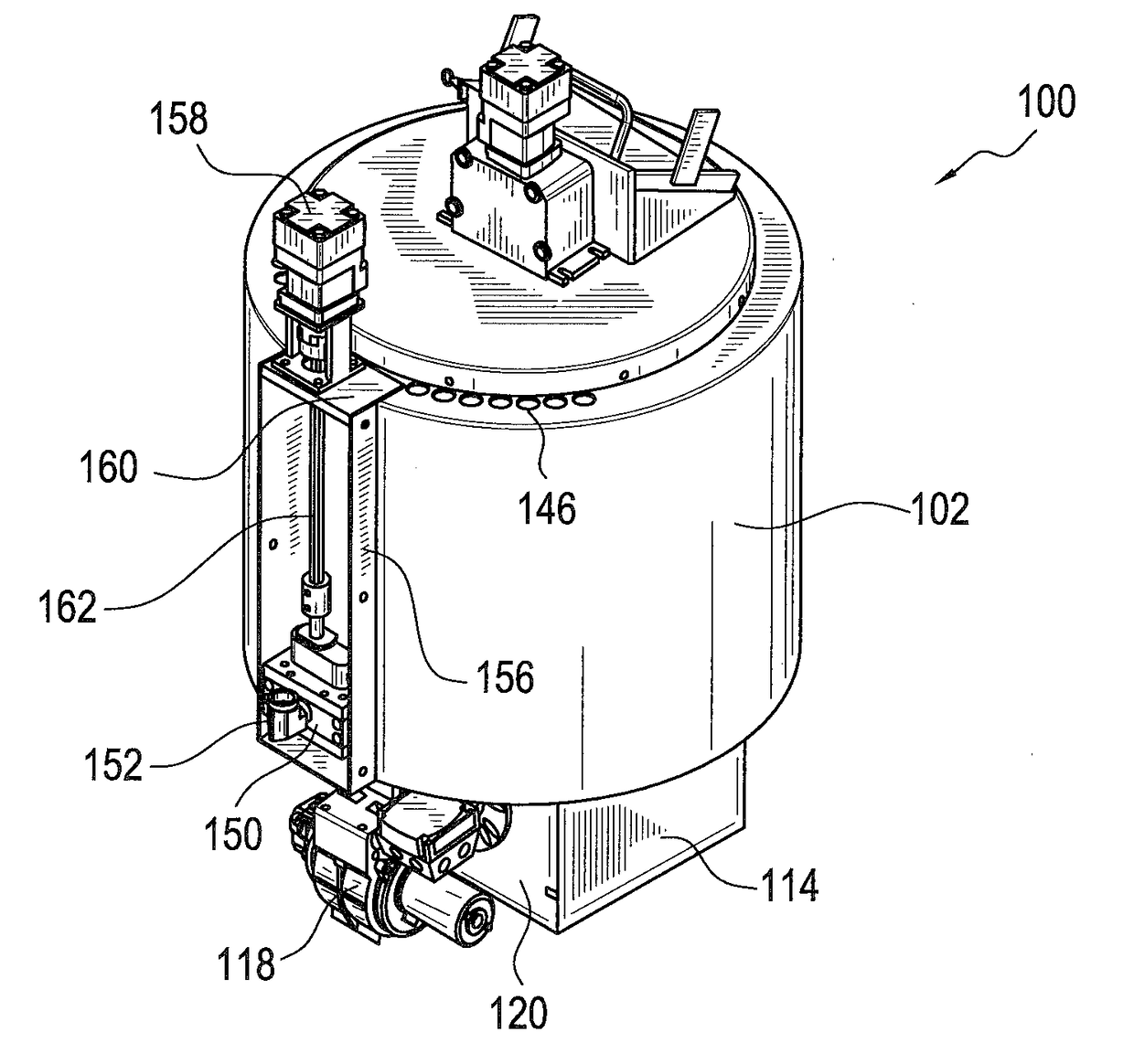

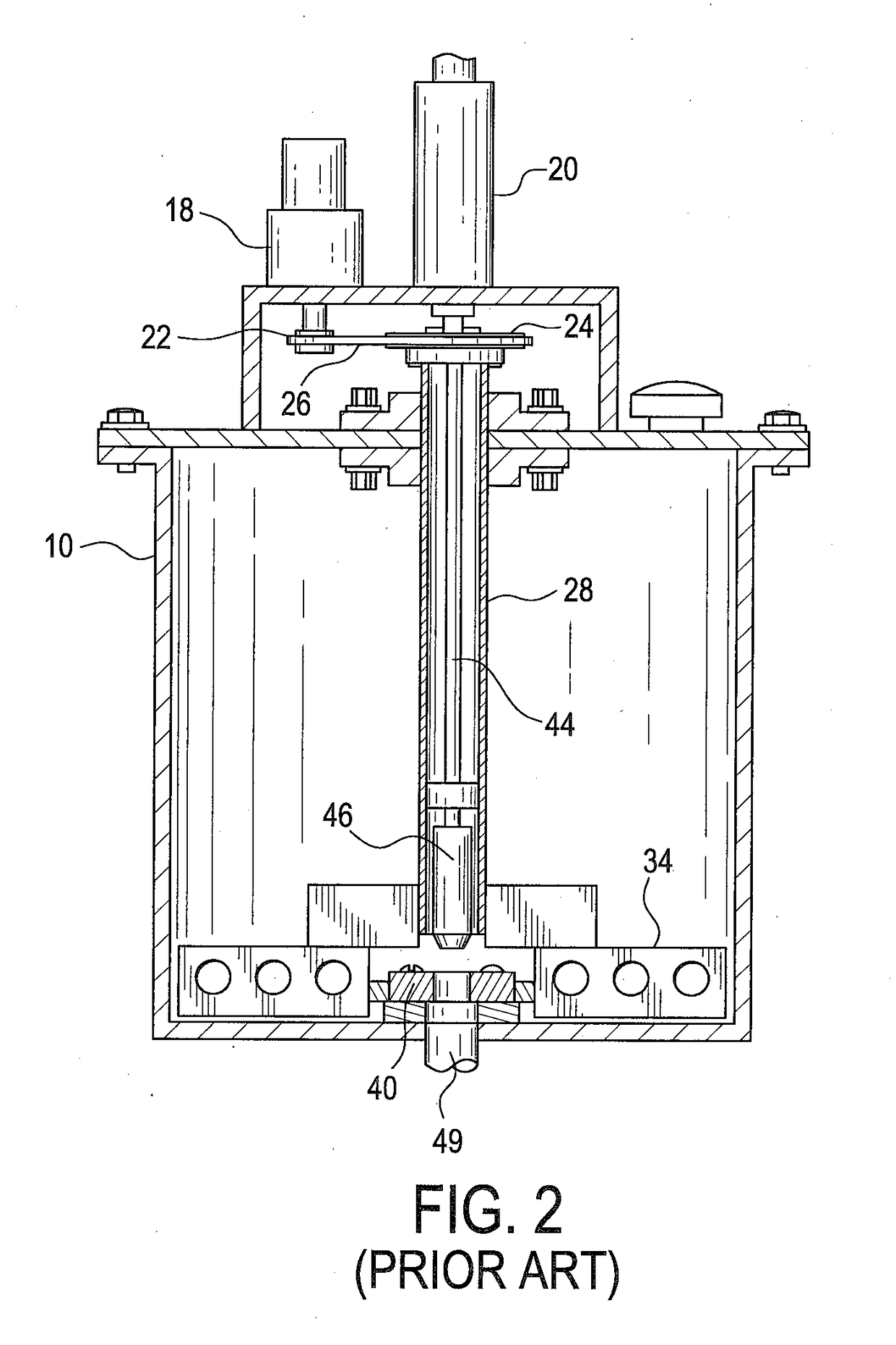

Integral melter and pump system for the application of bituminous adhesives and highway crack-sealing materials, and a method of making the same

ActiveUS9771691B2Efficient transferRaise the temperature levelLiquid surface applicatorsLiquid transferring devicesAdhesiveEngineering

Owner:DISPENSING TECH CORP

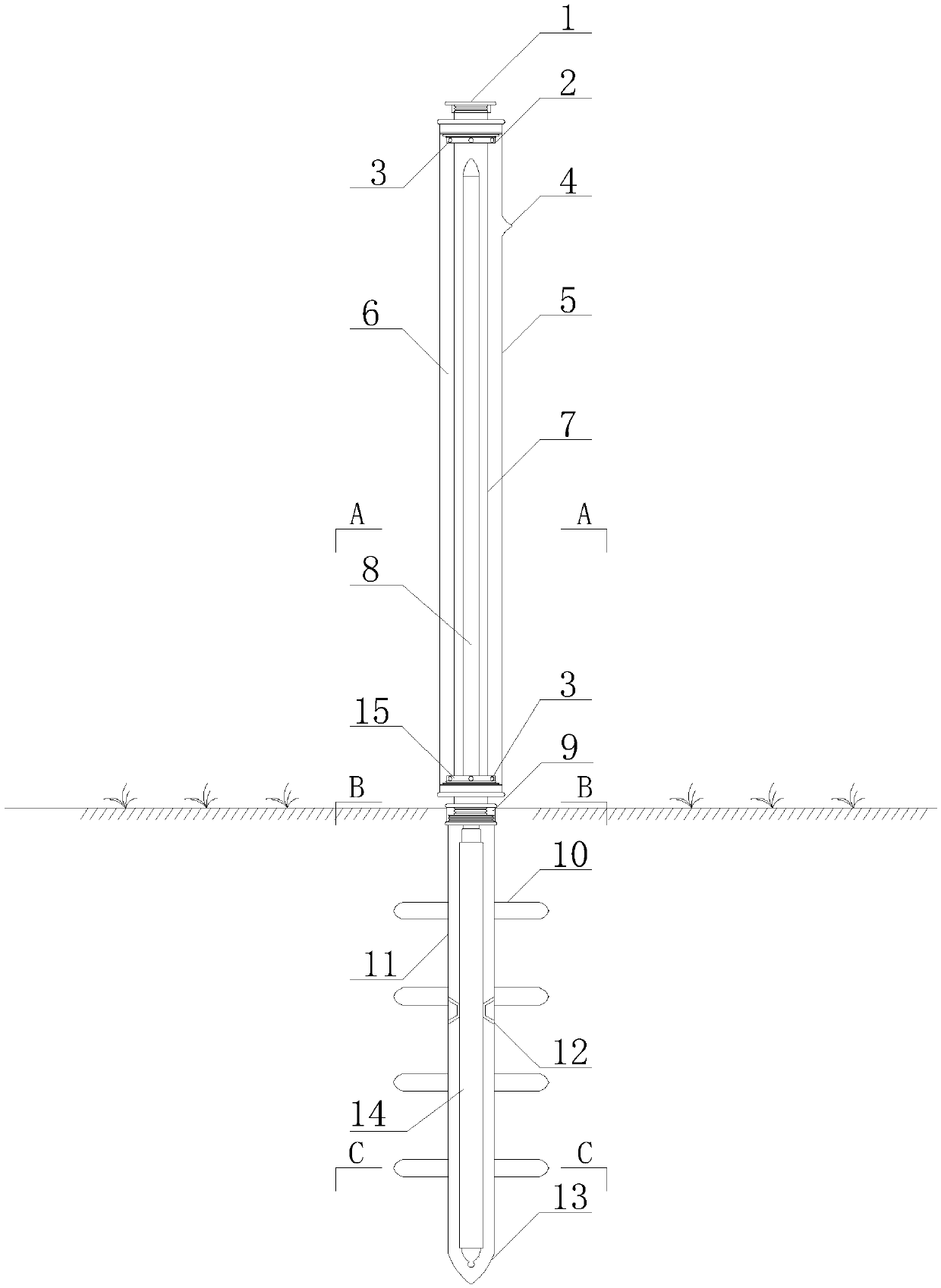

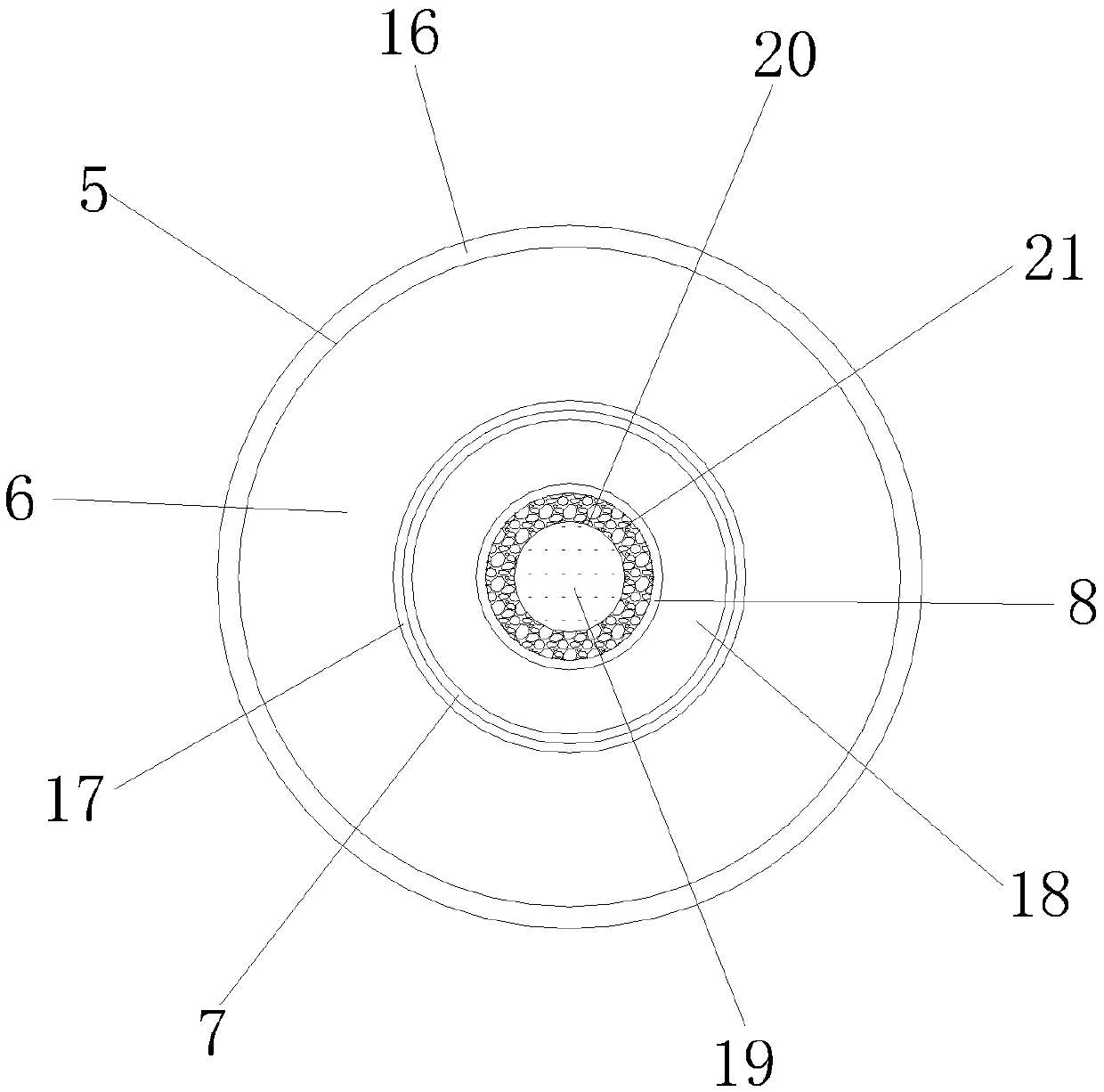

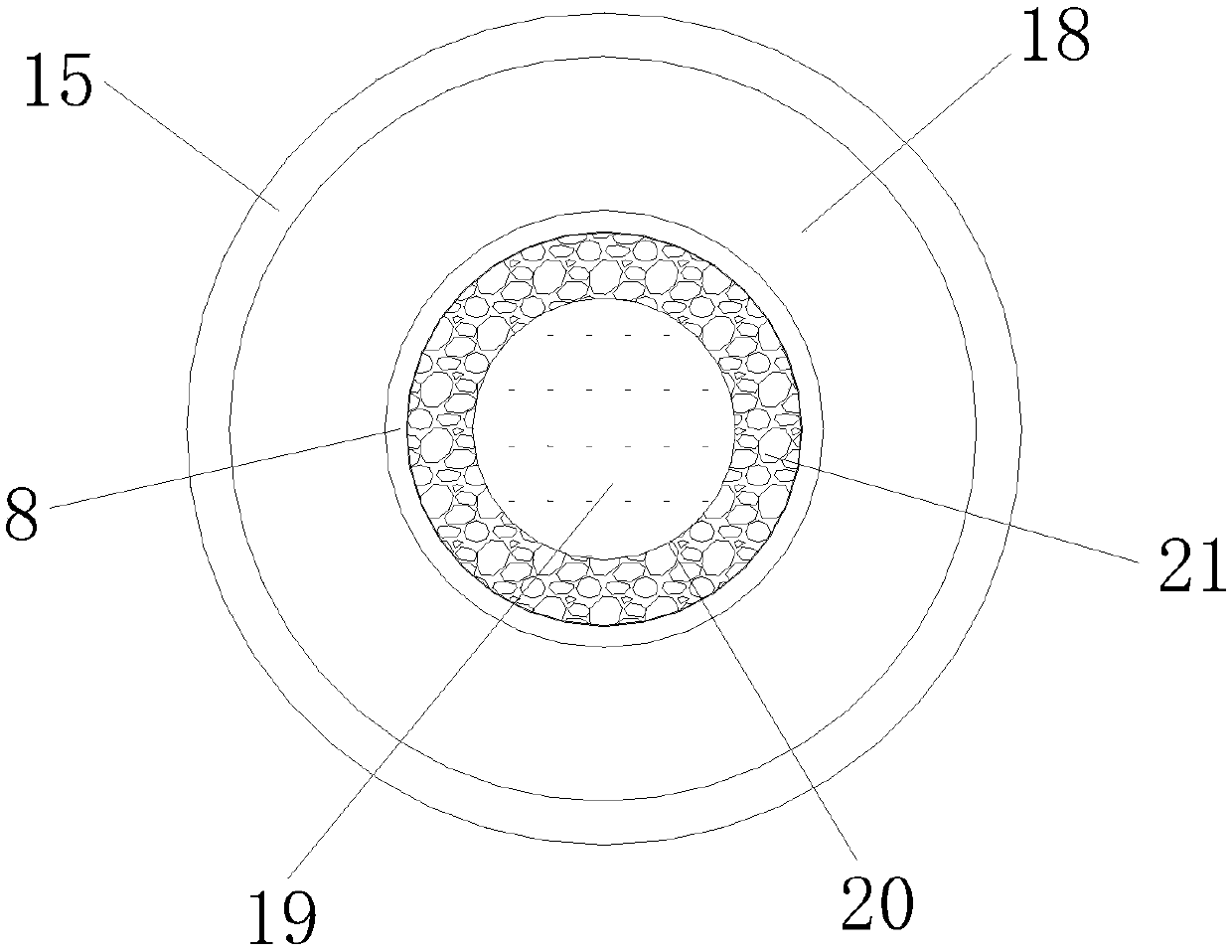

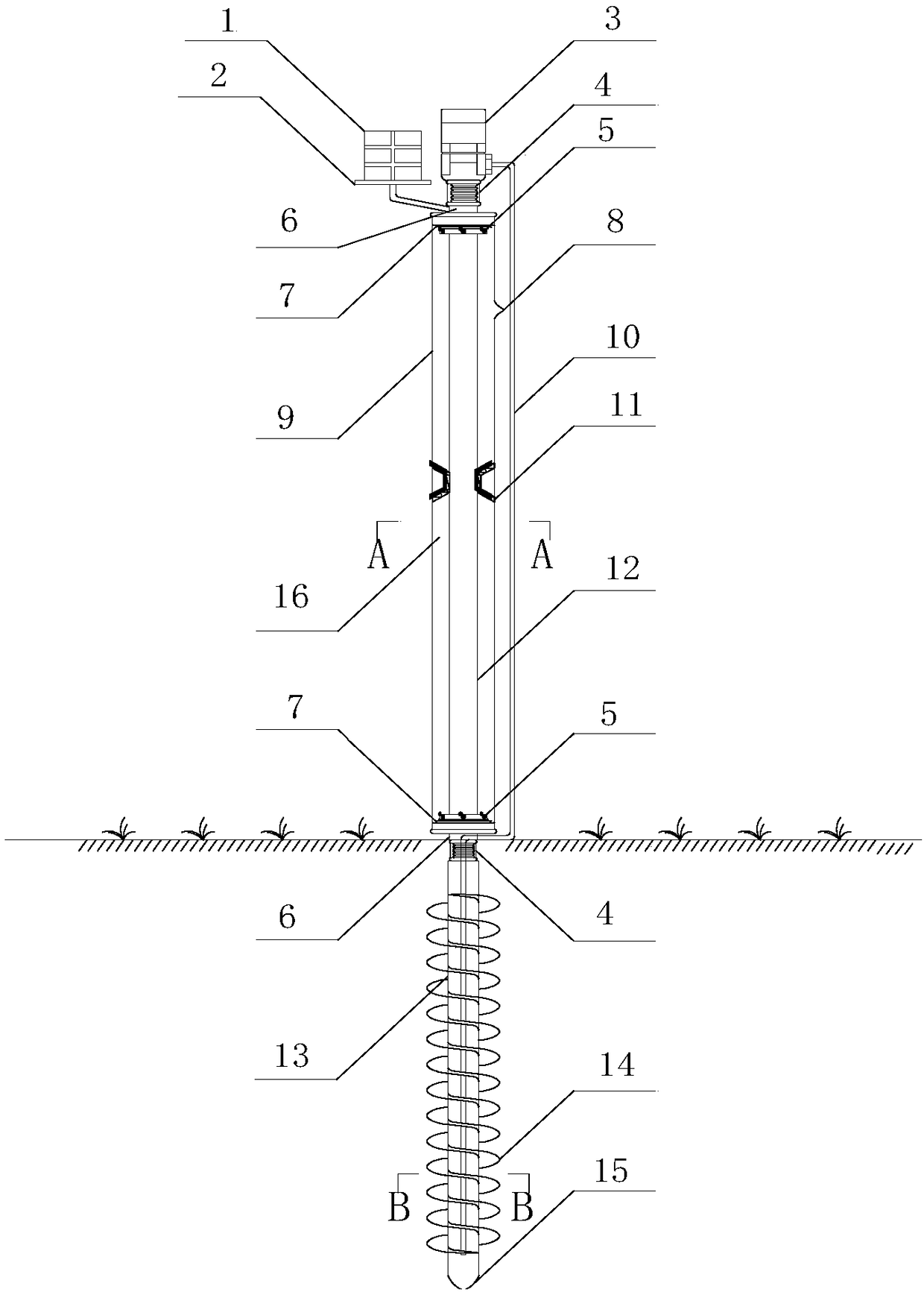

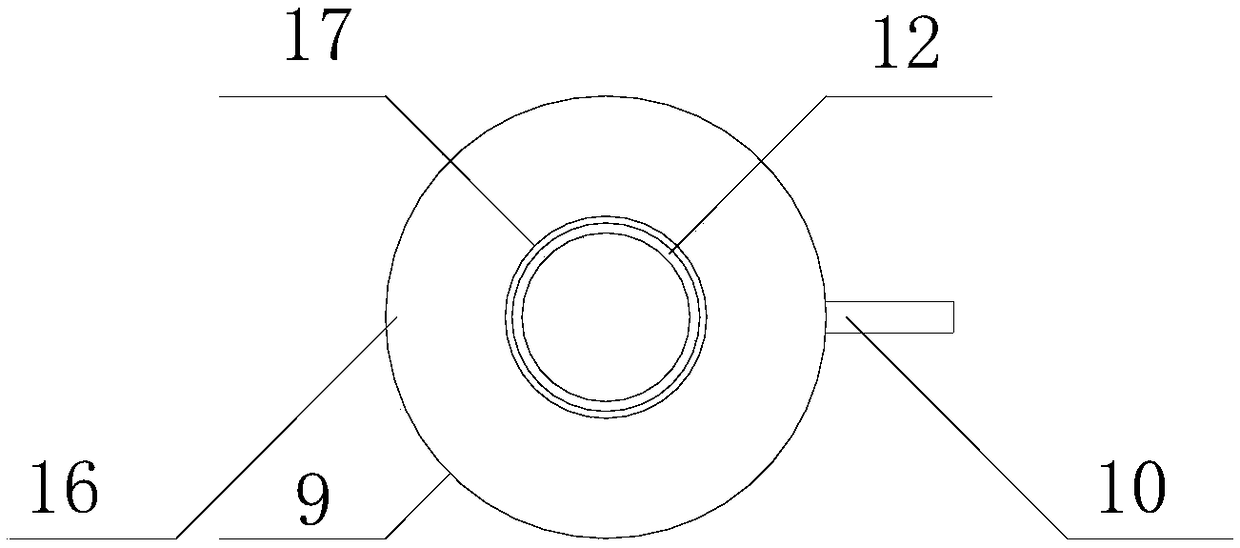

Heat pipe type solar photothermal device aiming at roadbed frost heave and roadbed frost heave prevention method

PendingCN109577126AIncrease heat inputRaise the temperature levelSolar heating energySolar heat collector detailsPhotothermal conversionEngineering

The invention is applicable to the technical field of roadbed engineering construction and maintenance, and provides a heat pipe type solar photothermal device aiming at roadbed frost heave, comprising a photothermal conversion tube, the photothermal conversion tube is sleeved with a light transmission tube, a vacuum cavity is formed between the photothermal conversion tube and the light transmission tube, two ends of the photothermal conversion tube are respectively connected with a first joint and a second joint, and an end cap is arranged on the first joint to form a seal at one end of thephotothermal conversion tube; one end of a thermal dissipation tube is connected with the second joint and is in communication with the photothermal conversion tube, the other end of the thermal dissipation tube is provided with a tapered guide cap, and the inside of the photothermal conversion tube and the inside of the thermal dissipation tube are filled with a first heat transfer medium; a first tube shell is located inside the photothermal conversion tube, a second tube shell is fixed in the inside of the thermal dissipation tube through a bracket, one end of the first tube shell and one end of the second tube shell are connected through a sealing piece, the inside of the first tube shell and the inside of the second tube shell are in conduction, and a second heat transfer medium is infused into the first tube shell and the second tube shell, so as to solve the problem that the effect of the frost heave prevention measures for the roadbed is not ideal.

Owner:SHIJIAZHUANG TIEDAO UNIV

System and Method to Control Energy Input to a Material

InactiveUS20070175061A1Decrease temperature level and humidity levelReduce temperature level and humidity levelDough treatmentDrying solid materials with heatAirflowEngineering

A system and method of controlling energy that is input to a material substance, for the controlled removal of moisture from the material substance, is disclosed. A controlled air flow is blown onto the material substance at a specified air flow rate over at least one specified time period such that the material substance absorbs thermal energy from the controlled air flow via at least one outer surface of the material substance. The controlled air flow is of a specified humidity level at a specified temperature level. The material substance is also irradiated with microwave energy at a first specified power level for at least a first specified time duration such that the material substance absorbs at least a part of the microwave energy and converts the absorbed microwave energy to thermal energy within the material substance. As a result, moisture is removed from the material substance in a controlled manner.

Owner:THE SHERWIN-WILLIAMS CO

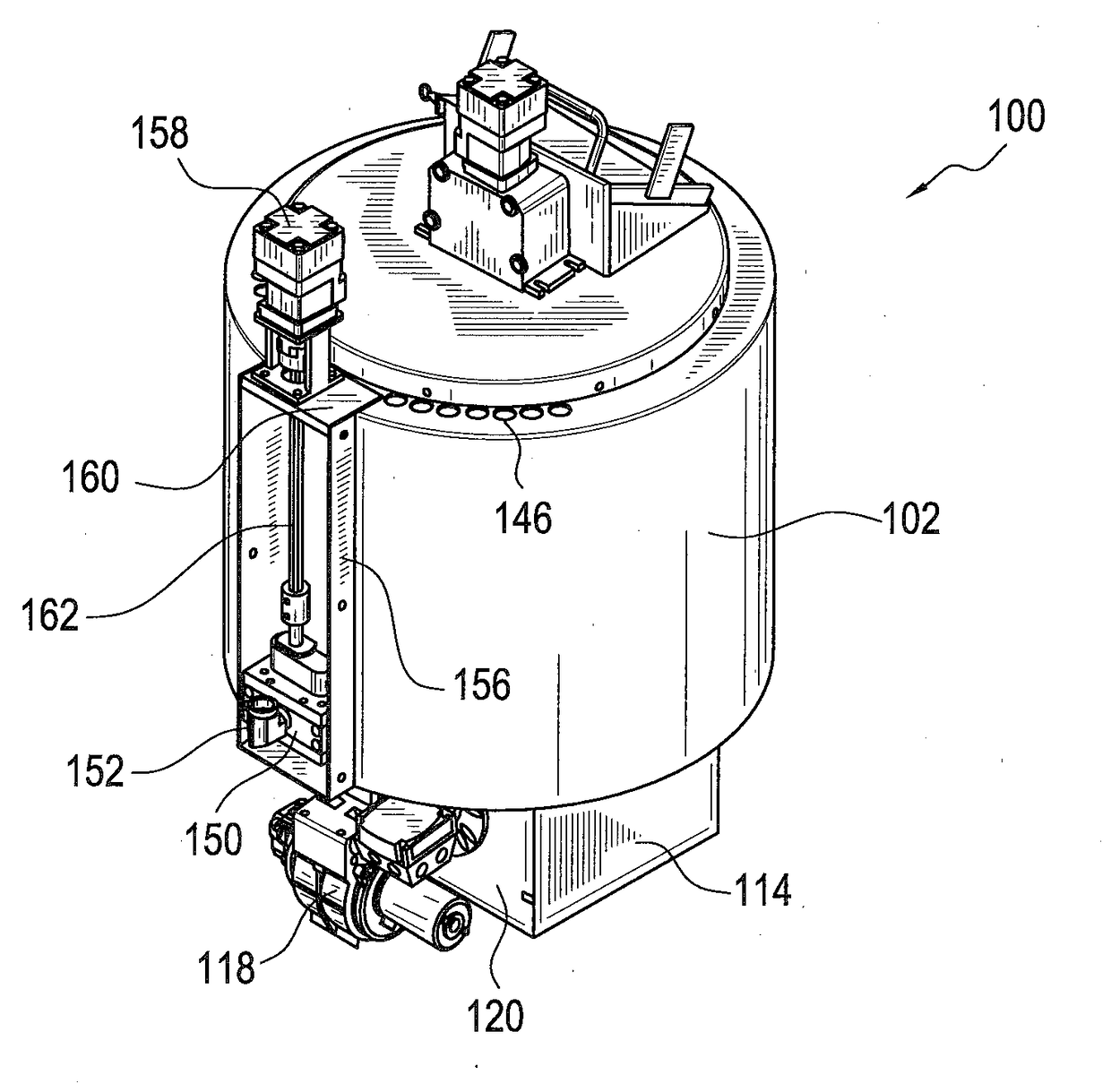

Integral melter and pump system for the application of bituminous adhesives and highway crack-sealing materials, and a method of making the same

ActiveUS20170218575A1Efficient transferRaise the temperature levelLiquid surface applicatorsPaving detailsAdhesiveMaterial supply

An integral melter and pump assembly or system, and a method of making the same, is disclosed wherein the pump assembly comprises a melter housing having a melter container defined within the melter housing. A pump mounting plate is integrally mounted within a side wall portion of the melter container and an output dispensing supply pump is mounted directly upon an external surface portion of the pump mounting plate in a surface-to-surface manner such that heat generated internally within the melter container is effectively transferred by conduction from the melter container and through the pump mounting plate such that the temperature level of the output pump is elevated to, and maintained at, a predeterminedly desired level even when the pump, is not disposed in its output dispensing mode. In addition, since the output dispensing or material supply pump is disposed externally of the melter container and the melter housing, the output dispensing or material supply pump is easily and readily accessible in case maintenance becomes necessary. Optionally, an oil jacket or chamber can surround the melter container so as to more evenly or consistently provide heating of the melter container.

Owner:DISPENSING TECH CORP

Process for treating the scrubbing water from the gas scrubbing process in an iron ore reduction plant

InactiveUS6120582AReduce transferLow investment costProductsLiquid degasificationWarm waterFlash-gas

PCT No. PCT / DE97 / 00895 Sec. 371 Date Jun. 3, 1999 Sec. 102(e) Date Nov. 9, 1998 PCT Filed Apr. 30, 1997 PCT Pub. No. WO97 / 43221 PCT Pub. Date Nov. 20, 1997A process is disclosed for treating the scrubbing water from the gas scrubbing process in an iron ore reduction plant. The scrubbing water is brought into direct contact with the gas in two gas scrubbers arranged in two successive scrubbing stages at the gas-side, is withdrawn from the gas scrubbers and is supplied again to the gas scrubbers after the solids it contains are separated, and after it is treated and cooled. The scrubbing water is separately withdrawn from the two scrubbing stages and only the scrubbing water from the first scrubbing stage is largely freed from solids in a thickener, then led into a warm water container. The scrubbing water from the second scrubbing stage is directly led into a return water container in which it releases carbon dioxide-rich flash gas led into the scrubbing water in the warm water container to enrich it with carbon dioxide. The scrubbing water from the warm water container is cooled in a heat exchanger, then fed back to the gas scrubbers of the two scrubbing stages together with the scrubbing water from the return water container. Moreover, part of the carbon dioxide-rich scrubbed gas or part of the carbon dioxide-rich water contained in the return water container may also be led into the warm water container to enrich the scrubbing water in the warm water container with carbon dioxide.

Owner:VOEST ALPINE AG

Internal circulation type solar heating device and anti-frost heaving method for subgrade

PendingCN109440559APrevent statePrevent frost heaveSolar heating energyBatteries circuit arrangementsEngineeringExpansion joint

The invention is applied to the technical field of subgrade engineering and provides an internal circulation type solar heating device for a subgrade. The axis of a metal heat collecting pipe is superposed with that of a glass tube; two ends of the metal heat collecting pipe and two ends of the glass tube are all connected by bellow expansion joints in a sealing manner; each of the two ends of themetal heat collecting pipe is respectively connected with a metal heat collecting pipe joint; the metal heat collecting pipe joints extend to the outer sides of the bellow expansion joints; the top end of a metal heat supply pipe is communicated with the metal heat collecting pipe joint at the bottom end of the metal heat collecting pipe through a threaded connector; a cone head guiding cap is arranged at the bottom end of the metal heat supply pipe; a circulating pump is driven by a solar cell to operate; an inlet of the circulating pump is communicated with the metal heat collecting pipe joint at the top end of the metal heat collecting pipe; an outlet of the circulating pump is communicated with an inlet of a circulating pipeline; an outlet of the circulating pipeline penetrates through the threaded connector and extends to the bottom of the metal heat supply pipe; the metal heat supply pipe and the metal heat collecting pipe are internally filled with heat transfer fluid. The problem of poor anti-frost heaving effect of the subgrade in the prior art is solved.

Owner:SHIJIAZHUANG TIEDAO UNIV

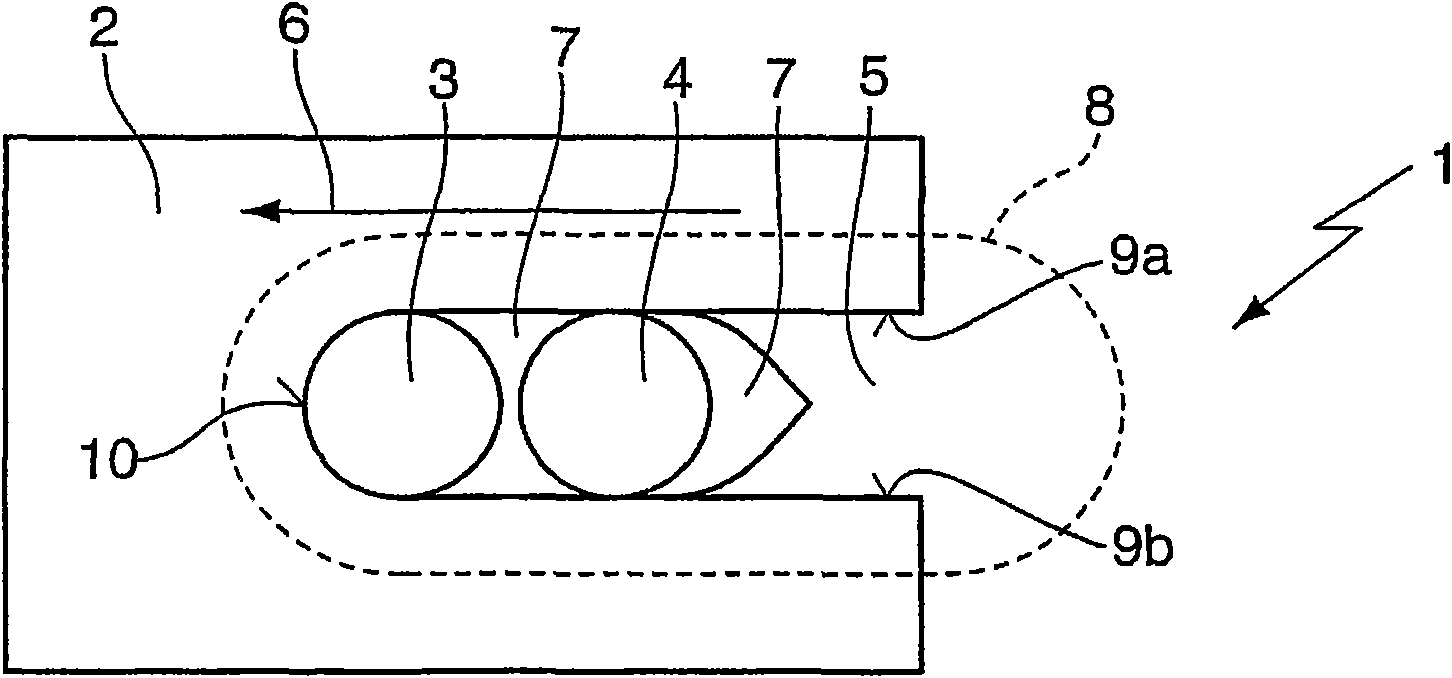

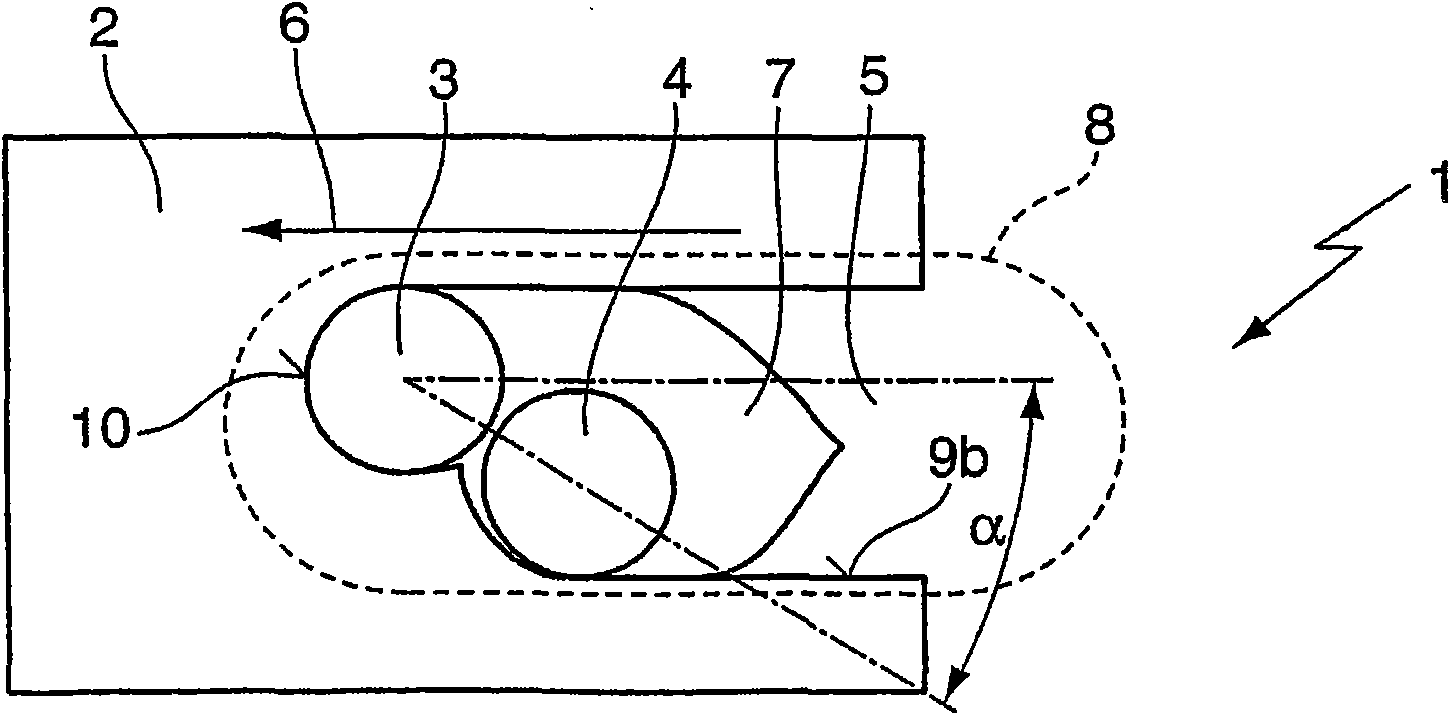

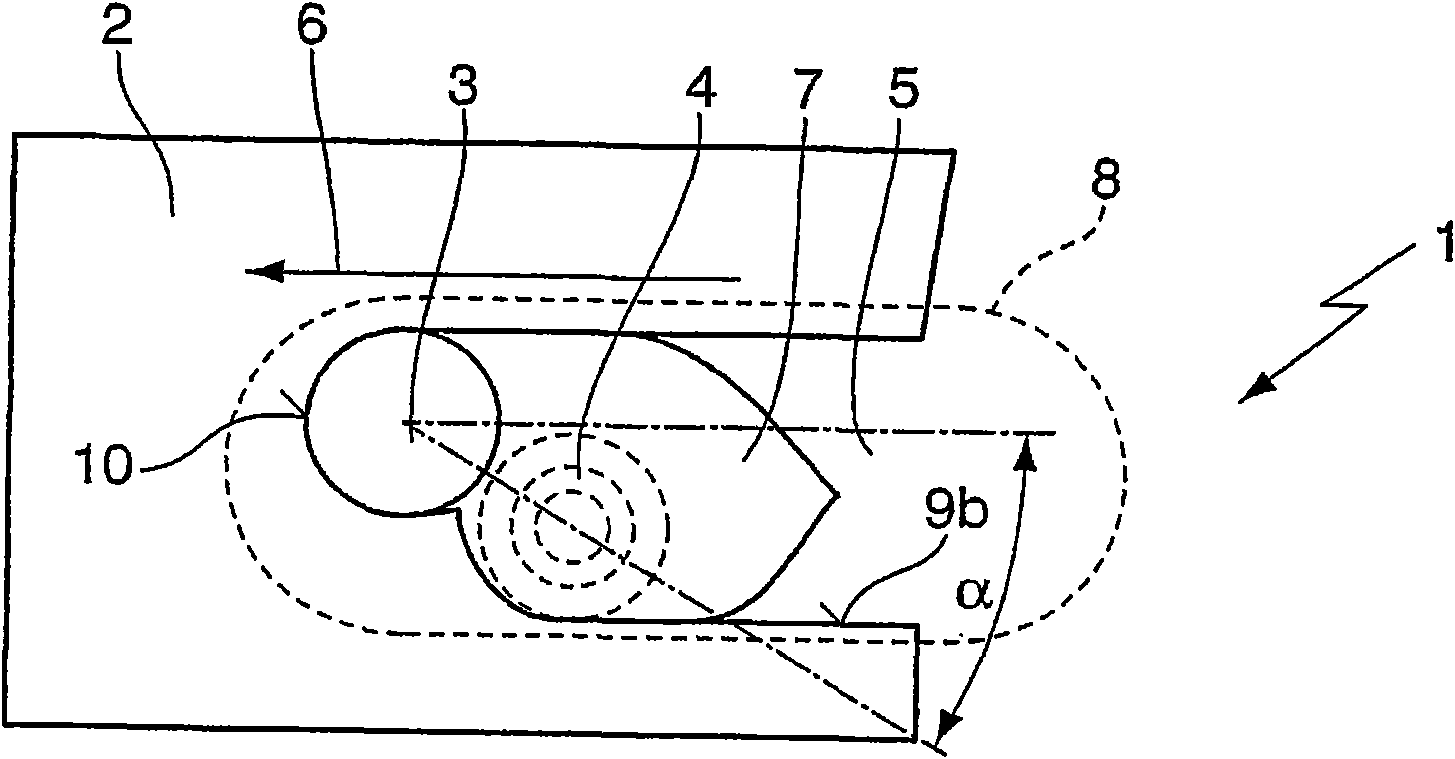

Method for the keyhole-free laser fusion cutting using leading and trailing laser beams

ActiveCN101896308ADischarge has little effectAverage roughness value reductionLaser beam welding apparatusLight beamOptoelectronics

In a method for the keyhole-free fusion cutting of a workpiece (2), wherein the workpiece (2) is fused by a laser beam (3) along a kerf (5) to be produced and the resulting melt (7) is driven out of the produced kerf (5) by a gas jet with high pressure, according to the invention at least one laser beam (4) trails the laser beam (3) in the cutting direction (6) and influences the melt (7) such that at least one of the two cutting flanks (9a, 9b) of the workpiece (2) has a better cutting quality than without the trailing laser beam (4).

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

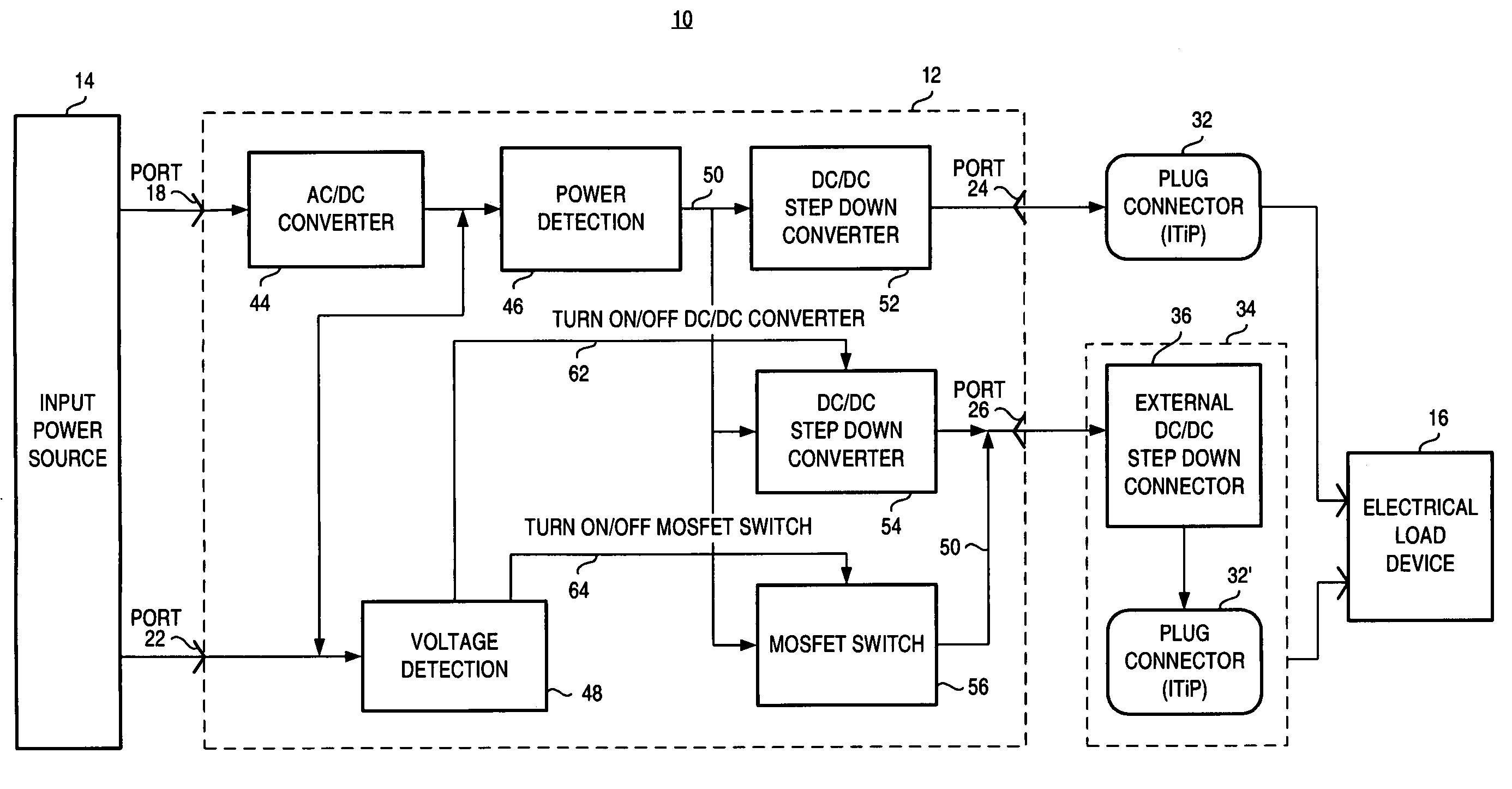

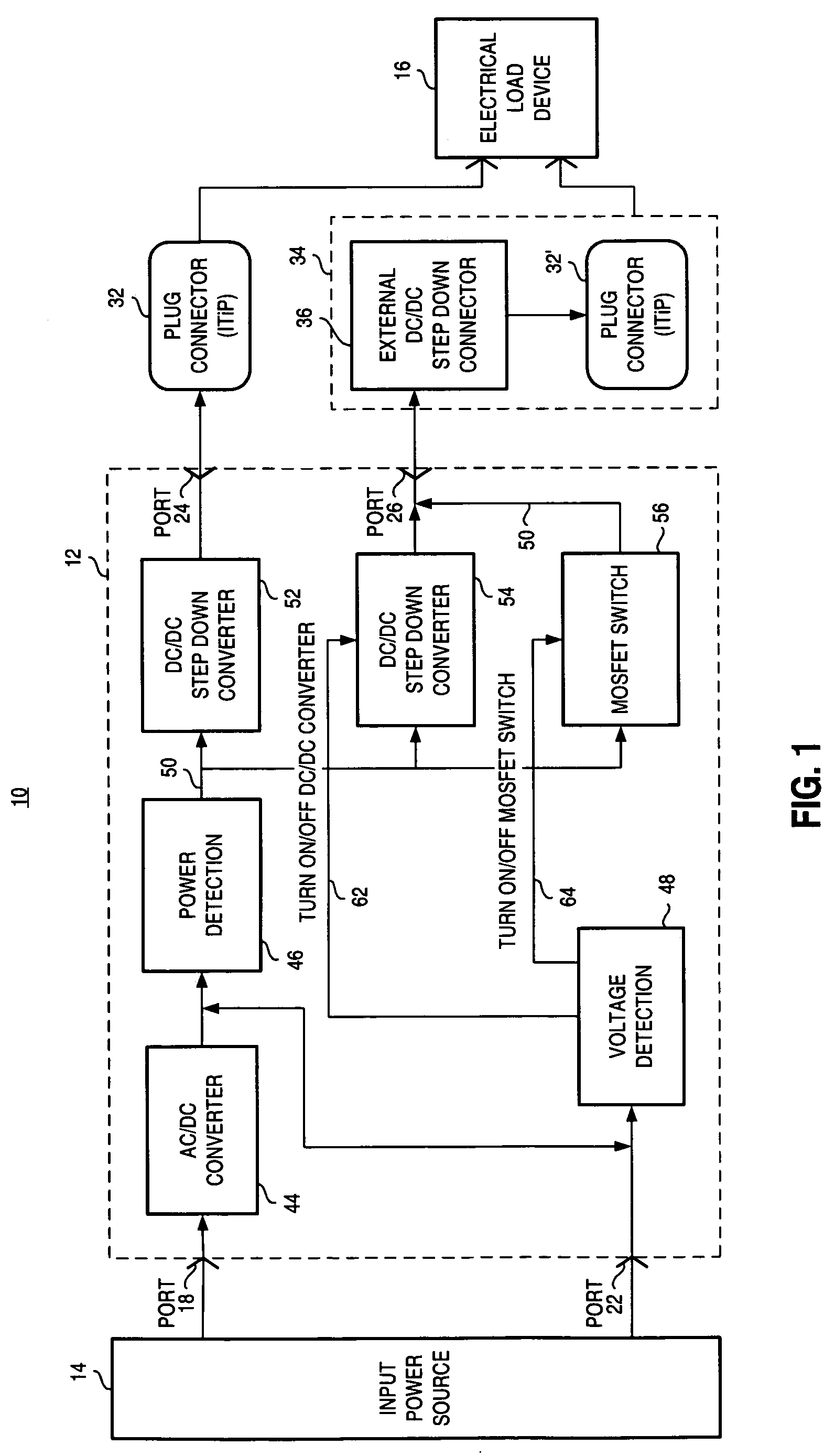

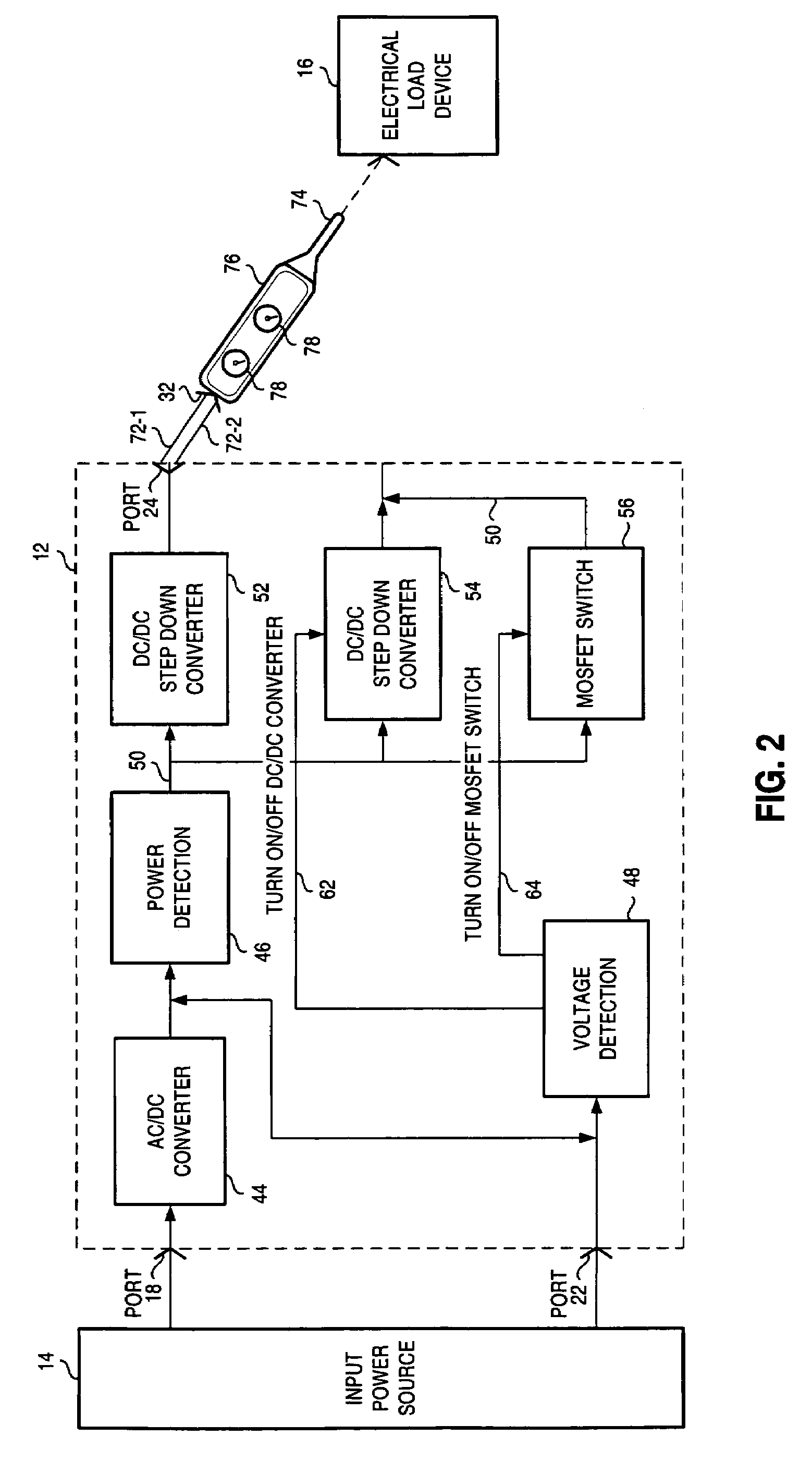

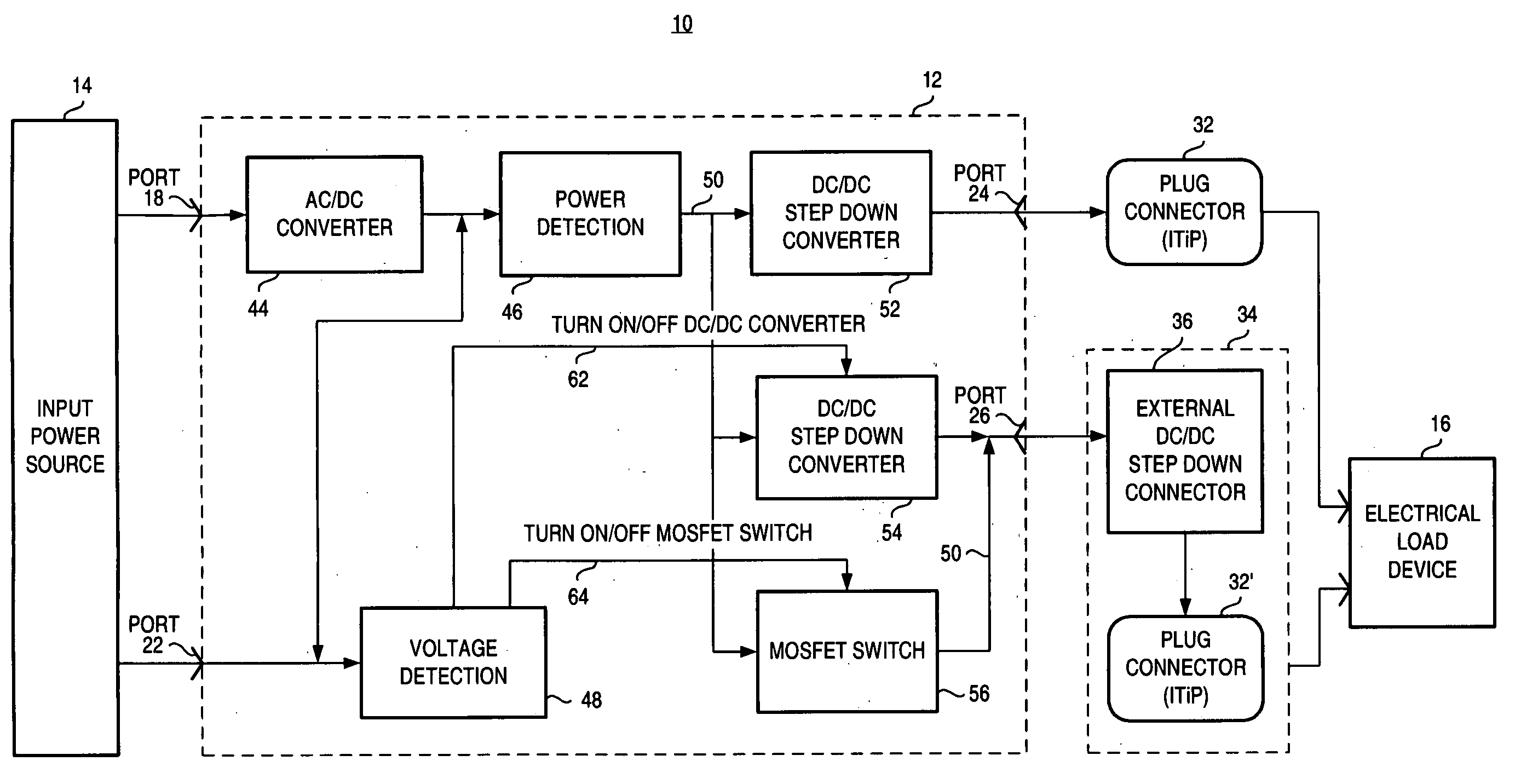

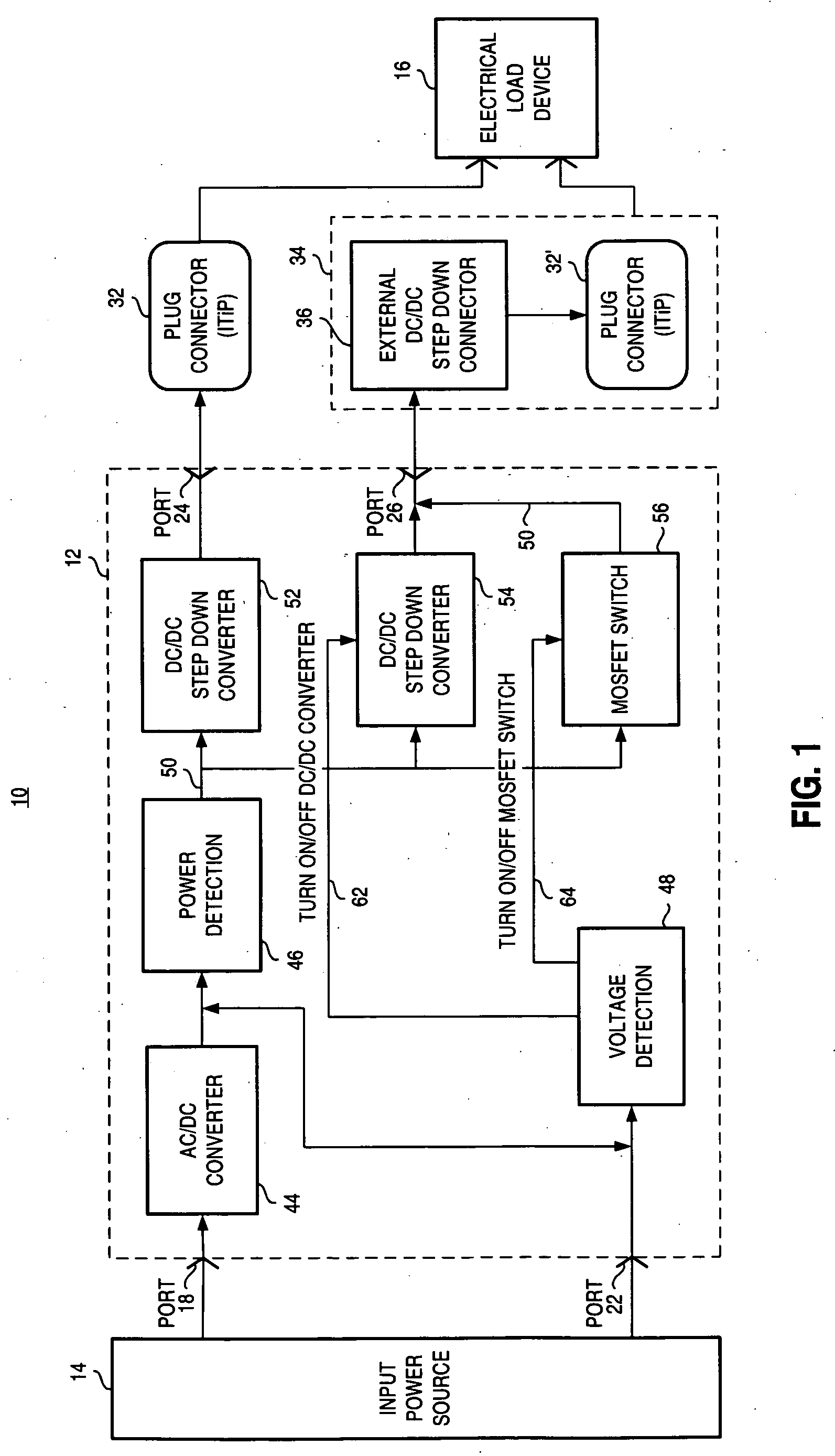

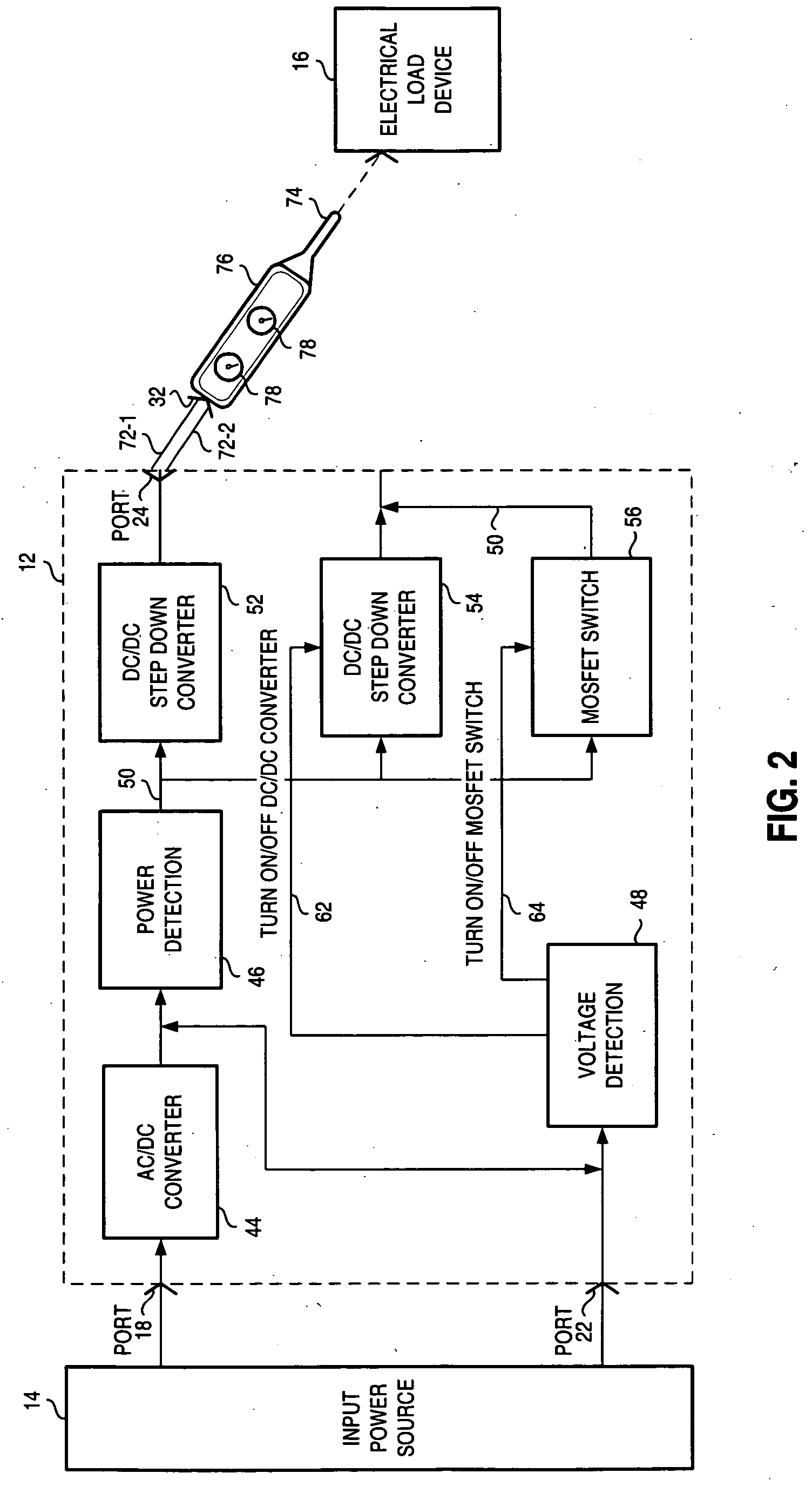

Apparatus, and associated method, for converting electrical power into form for powering a load device

InactiveUS7298120B2Improve conversion efficiencyReduce harmful effectsAc-dc conversionDc source parallel operationElectricityThermal energy

A power converter, and an associated method, for converting input power into output power. The power converter is capable of converting direct current input power as well as alternating current input power into direct current output power available for use to power an electrical load device, such as a consumer electronic device. The power conversion is performed at improved levels of efficiency, and less input power is dissipated as thermal energy.

Owner:THE SOURCE

Mixed combustion device and combustion equipment utilizing same

InactiveCN105276583AExtended service lifeReduce volumeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFirewoodSolid fuel

The invention discloses a mixed combustion device and combustion equipment utilizing same, and belongs to the technical field of combustion equipment. The mixed combustion device comprises a to-be-sprayed medium channel and a mixed combustion channel, wherein a reaction space wall for spacing the to-be-sprayed medium and the mixed combustion channel is provided with an orifice; and a combustion medium is sprayed from the to-be-sprayed medium channel to the mixed combustion channel through the orifice. From a combustion initial end of the mixed combustion channel to a combustion exhaustion end of the mixed combustion channel, combustion conditions are optimized along with progress of a combustion process; and different matching proportions of the to-be-sprayed medium are realized according to needs of different combustion stages, mixing uniformity of different media is realized to the greatest extent to facilitate combustion. The mixed combustion device is suitable for combustion of gas fuels, can be applied to combustion of liquid and solid fuels, and is especially suitable for combustion of fuels such as natural gas, coal gas, biogas, biomass cracking fuel gas, fuel oil, methanol, pulverized coal, biomass micro powder, straws, firewood, biomass forming fuels, block-shaped coals and the like.

Owner:庄彦峰

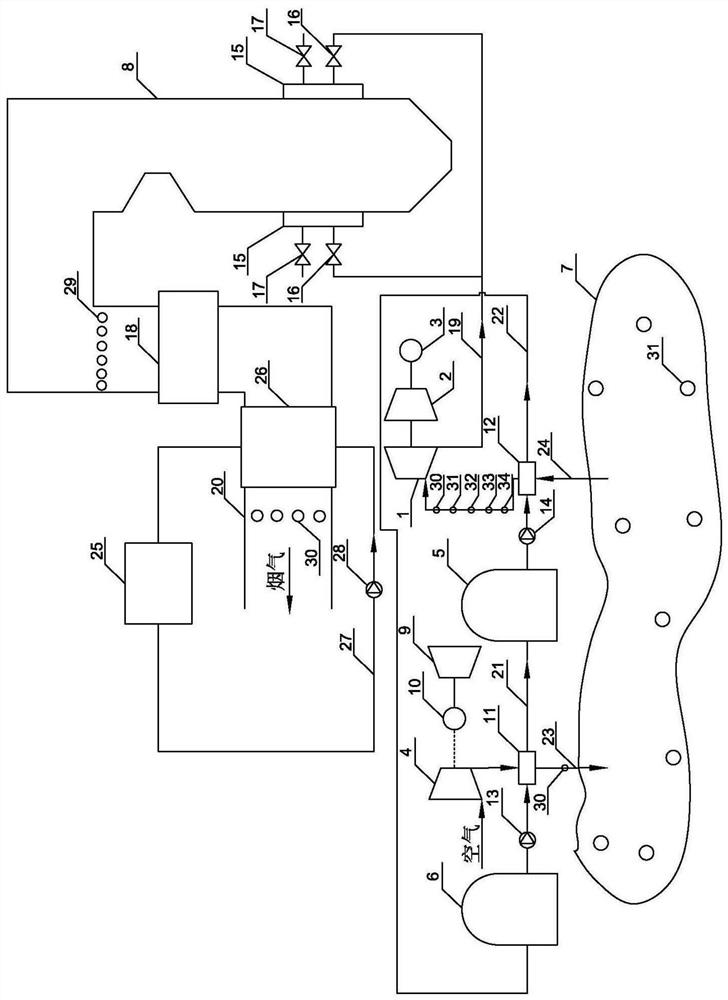

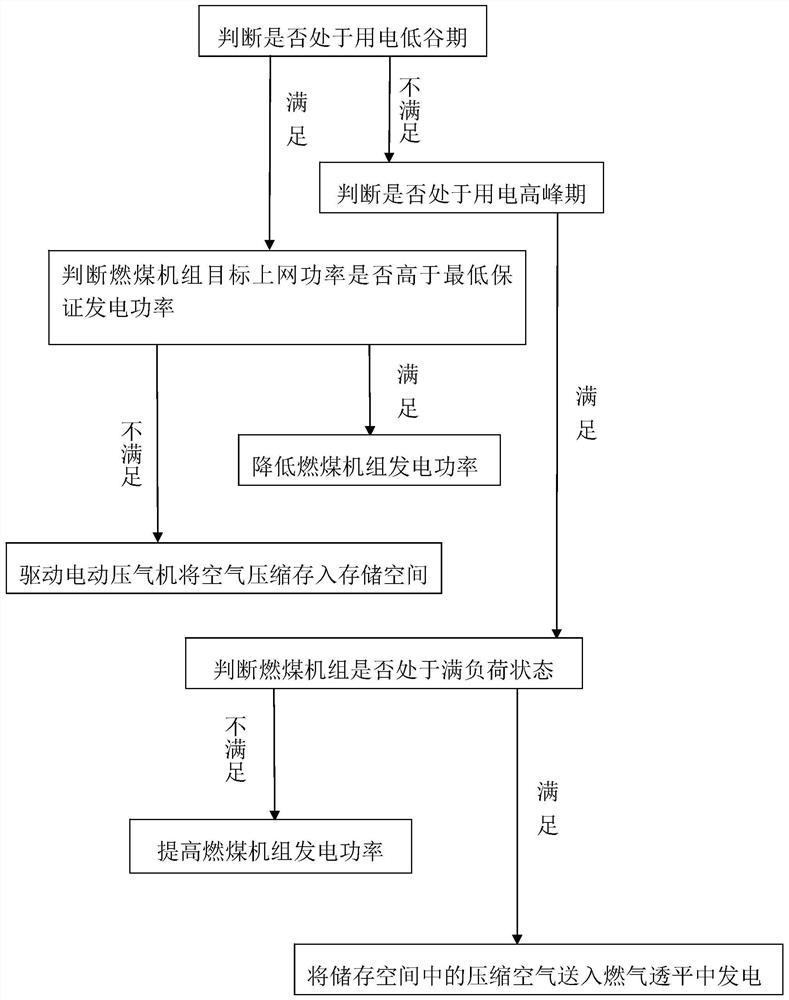

Peak regulation power generation system and method coupled with compressed air energy storage

ActiveCN113202574AIncrease power generationReduce internet powerPumpsSteam engine plantsNatural gas consumptionAir compression

The invention discloses a peak regulation power generation system and method coupled with compressed air energy storage. With the development and utilization of large-scale renewable energy sources, the peak-valley difference of a power grid is increasingly increased, and the bearing capacity is also limited. According to the technical scheme, when the power grid is in a power consumption valley period, air is compressed through power generated by a coal-fired unit and then stored in a storage space, and on the premise that it is guaranteed that the actual generation power of the coal-fired unit is higher than the minimum guaranteed generation power, the on-grid power of the coal-fired unit is effectively reduced; and when the power grid is in a power consumption peak period, the compressed air in the storage space is fed into a gas turbine for power generation, so that the power consumption of a main compressor is reduced, the on-grid power of the gas turbine is improved, and the natural gas consumption is reduced. According to the peak regulation power generation system and method coupled with compressed air energy storage, support can be provided for peak load shifting of the power grid, so that the renewable energy consumption capability is improved, and the usage amount of high-grade energy such as natural gas can be reduced on the premise that the on-grid power of the system meets the power grid adjustment requirement.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Apparatus, and associated method, for converting electrical power into form for powering a load device

InactiveUS20060256594A1Improve conversion efficiencyReduce harmful effectsAc-dc conversionDc source parallel operationThermal energyElectric force

A power converter, and an associated method, for converting input power into output power. The power converter is capable of converting direct current input power as well as alternating current input power into direct current output power available for use to power an electrical load device, such as a consumer electronic device. The power conversion is performed at improved levels of efficiency, and less input power is dissipated as thermal energy.

Owner:THE SOURCE

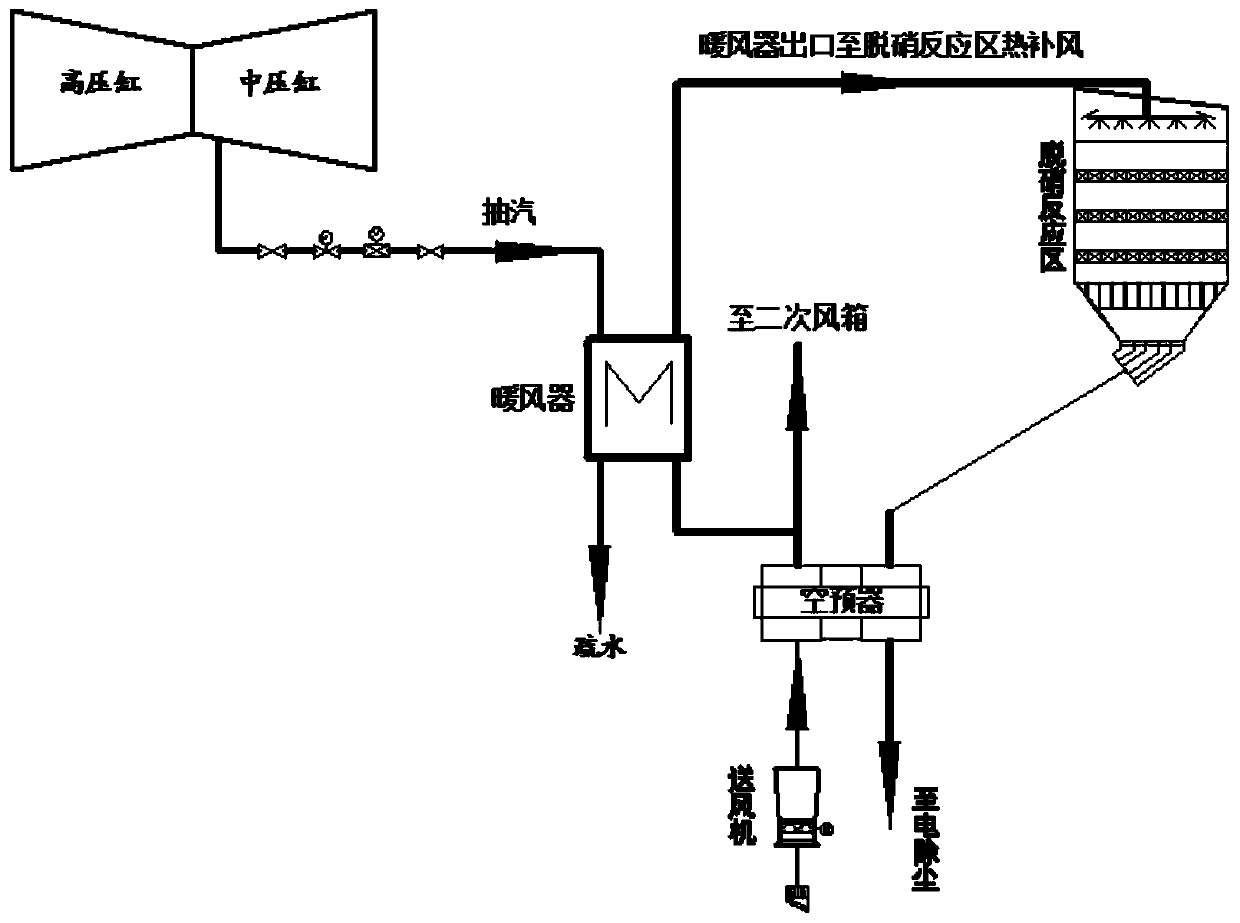

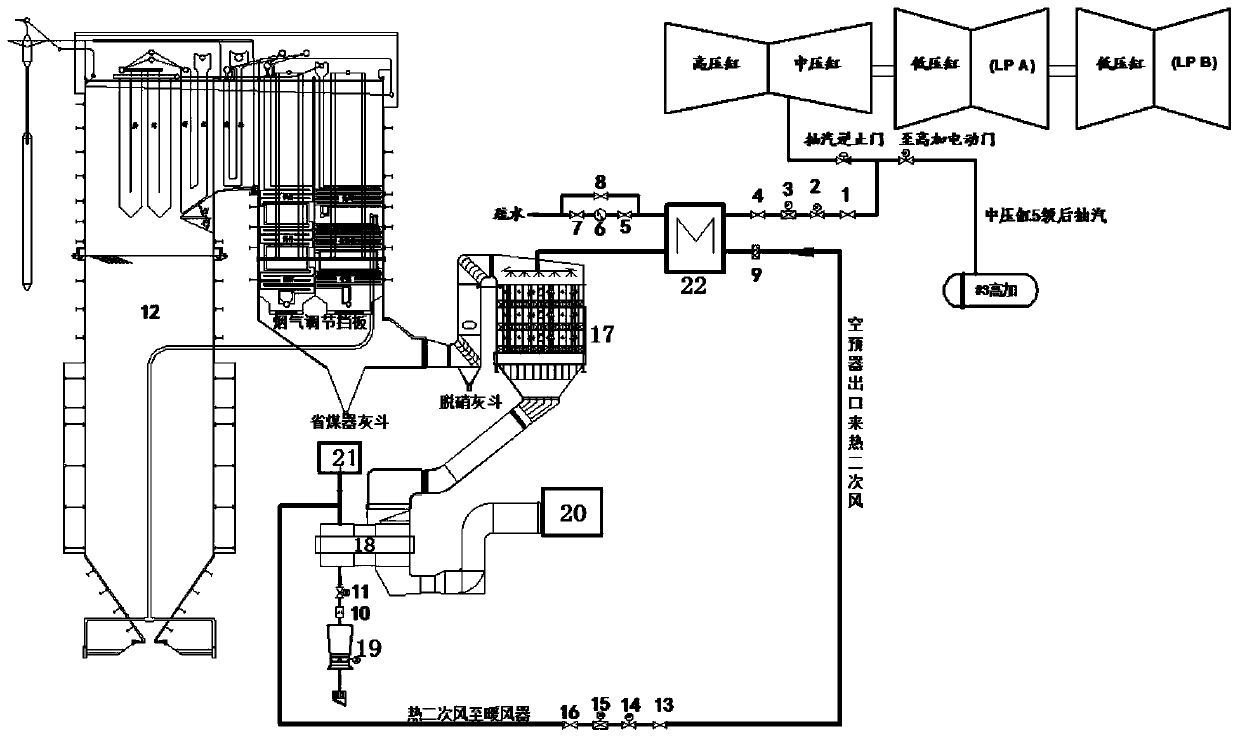

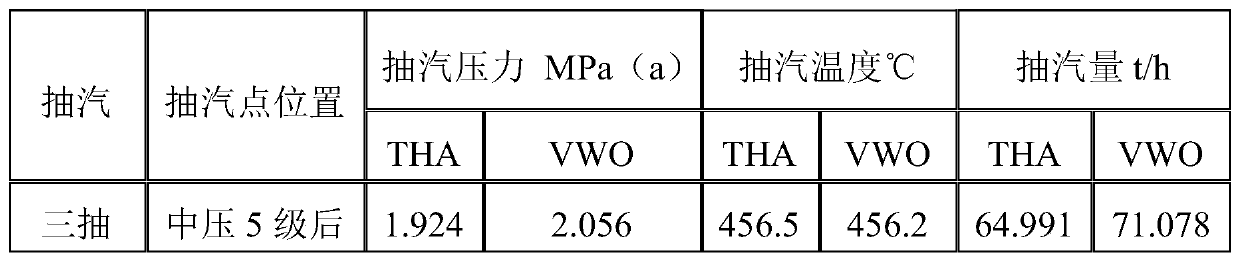

Full-load selective catalytic reduction (SCR) denitration system of coal-fired boiler

PendingCN110141961ARaise the temperature levelGuaranteed uptimeGas treatmentLighting and heating apparatusAir preheaterEngineering

The invention relates to a full-load selective catalytic reduction (SCR) denitration system of a coal-fired boiler. The system comprises a denitration reactor and an air preheater; the air preheater comprises a flue gas channel and an air channel; a flue outlet of the denitration reactor is connected with an electrostatic dust removal device through the flue gas channel of the air preheater; the input end of the air channel of the air preheater is connected with an air blower; the output end of the air channel is connected with a secondary air box; the system further comprises an air heater; the input end of the air heater is connected with an air suction port of a pressure cylinder close to a steam turbine of a generator set and is connected with the output end of the air channel of the air preheater; and the output end of the air heater is connected with a flue inlet of the denitration reactor. Compared with the prior art, the system has the advantages that full-load full-period stable operation of the coal-fired boiler can be ensured at lowest technology output, NOx emission in flue gas meets the emission requirements set by the country, and full-load denitration operation in the true sense after the grid connection can be realized.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

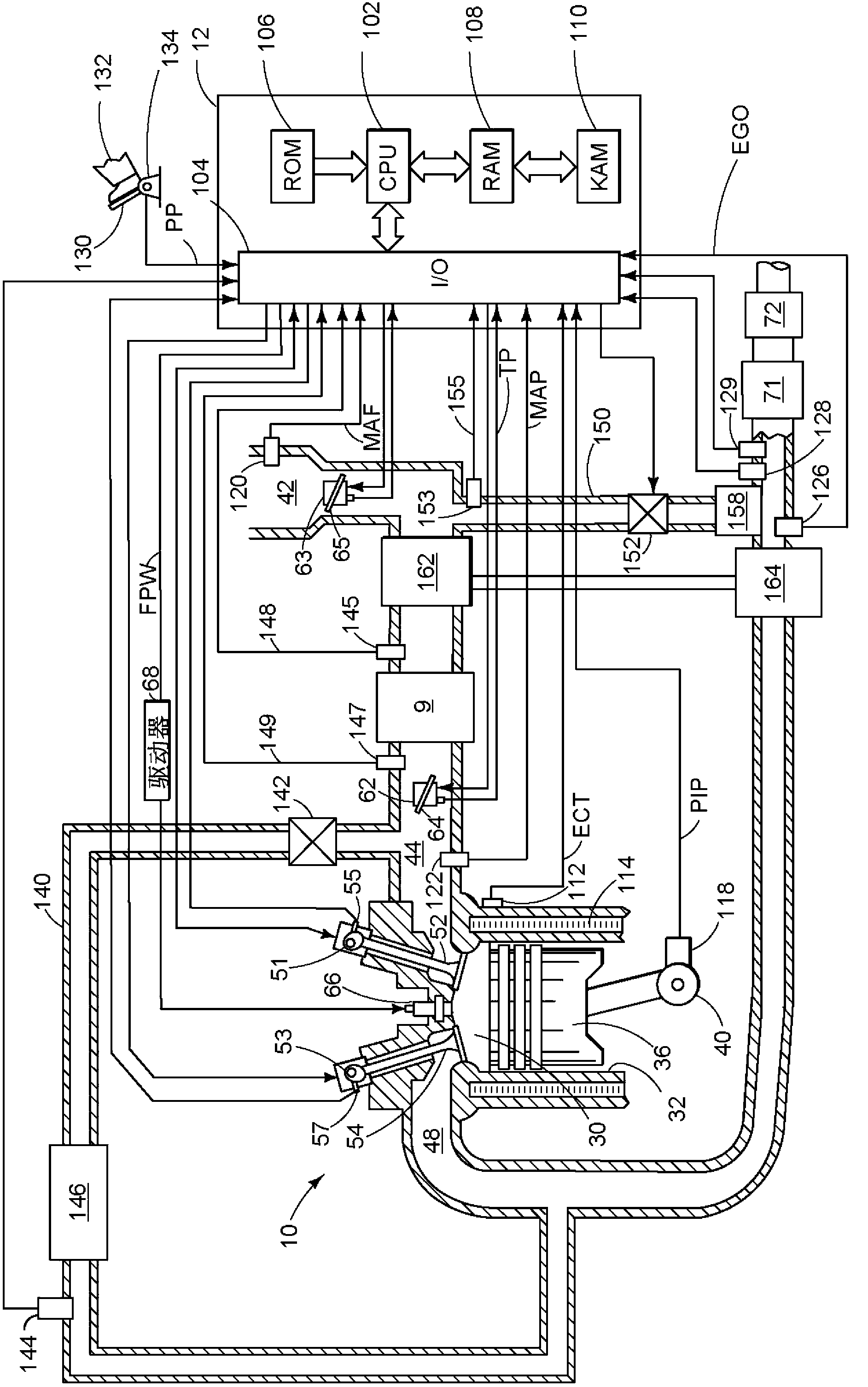

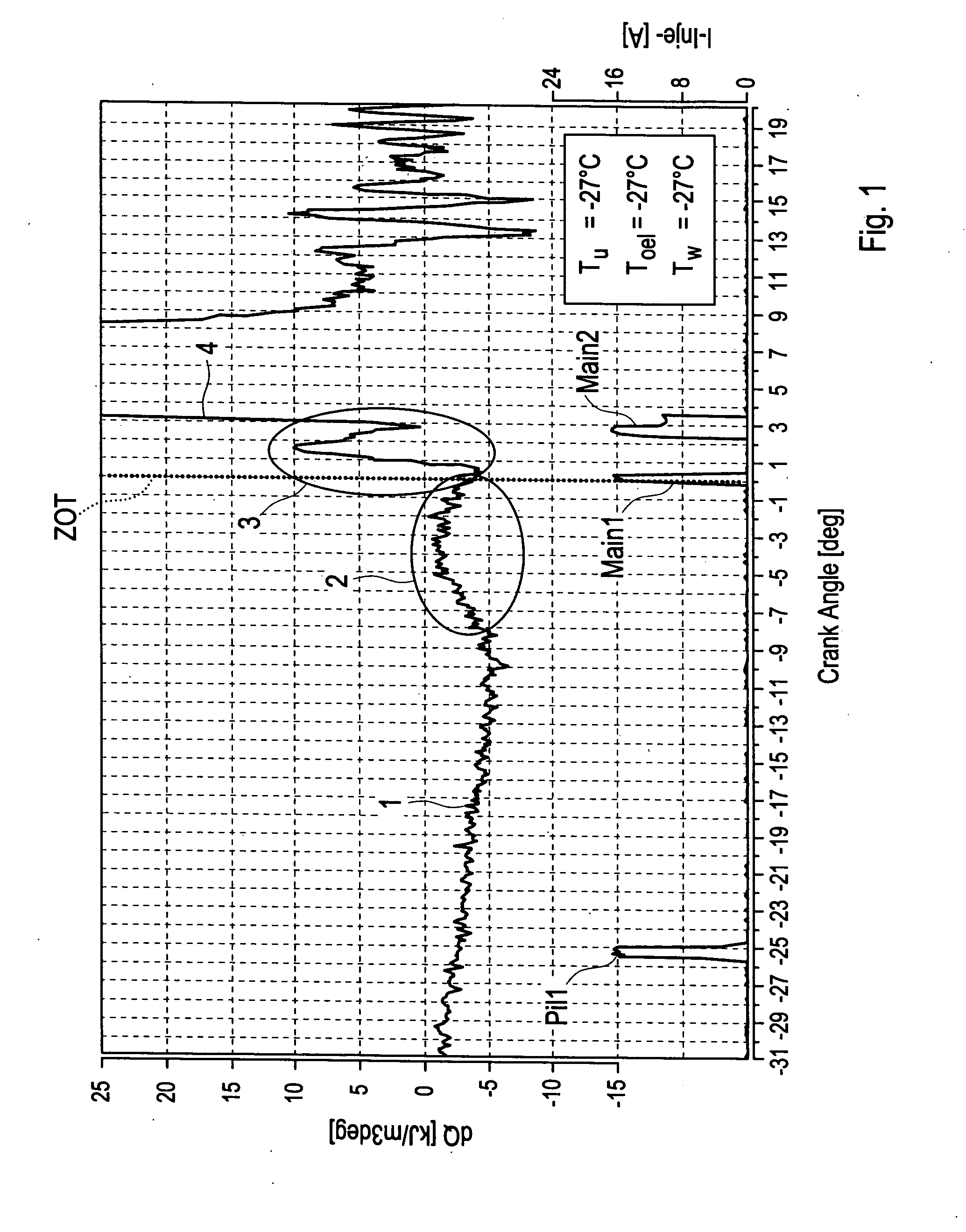

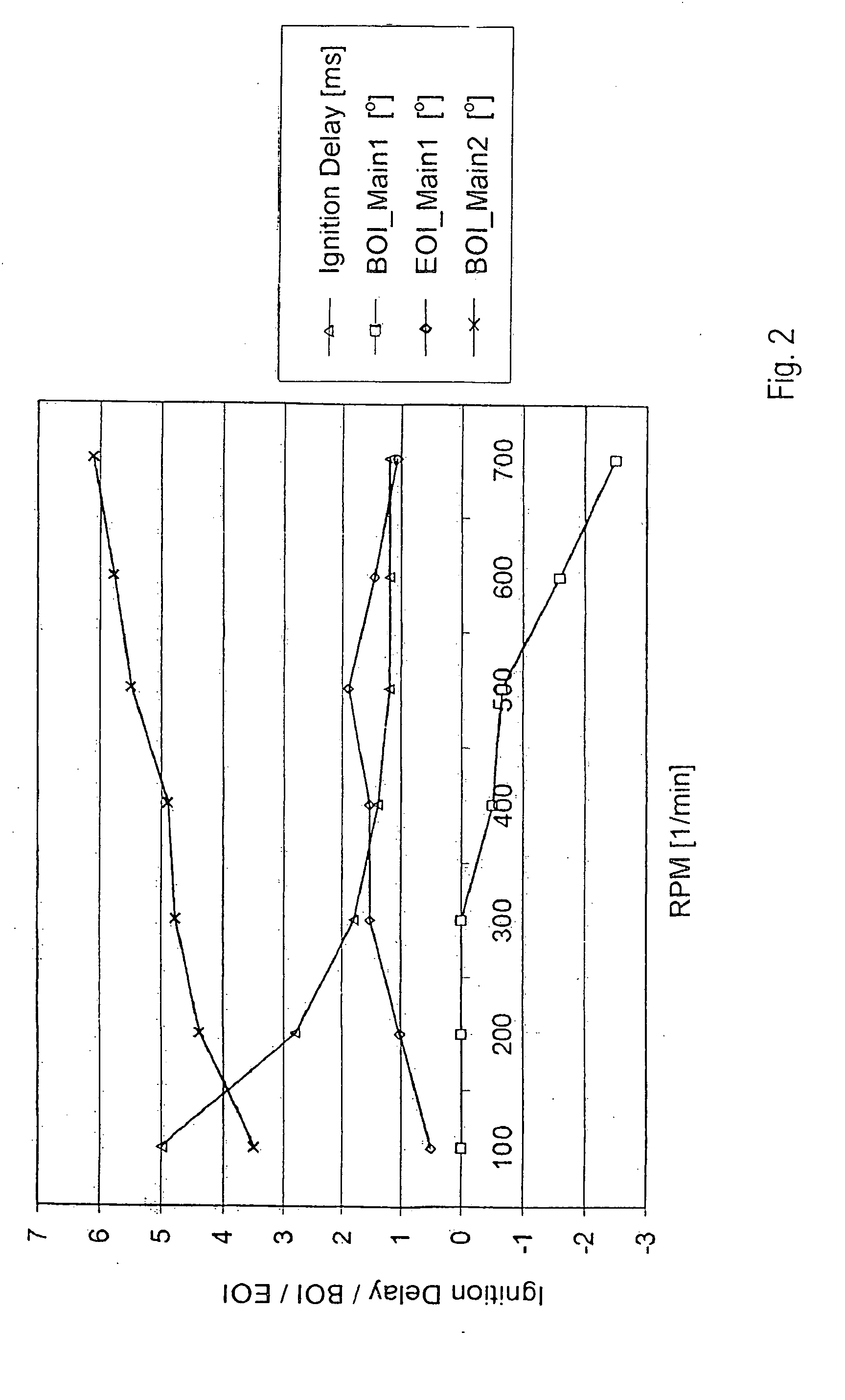

Method for starting a self-igniting internal combustion engine at low temperatures

InactiveUS20110073067A1Raise the temperature levelShort ignition delayElectrical controlInternal combustion piston enginesExternal combustion engineIgnition delay

In a method for starting a self-igniting internal combustion engine at low temperatures, a first fuel amount is injected into the combustion chamber during a compression stroke of the internal combustion engine by a fuel pre-injection, so as to form a partially homogenous pre-mixture in the combustion chamber; a main fuel amount is then injected into the combustion chamber during a main injection and the fuel / air mixture is combusted by self-ignition, the injection start of the pre-injection being selected such that the partially homogenous pre-mixture can be ignited after a very short ignition delay, and an injection start of the main injection is selected such that the main fuel amount is injected into the combustion chamber either during a combustion phase or directly after a combustion phase of the ignited pre-injection mixture

Owner:RITZINGER JOHANNES +1

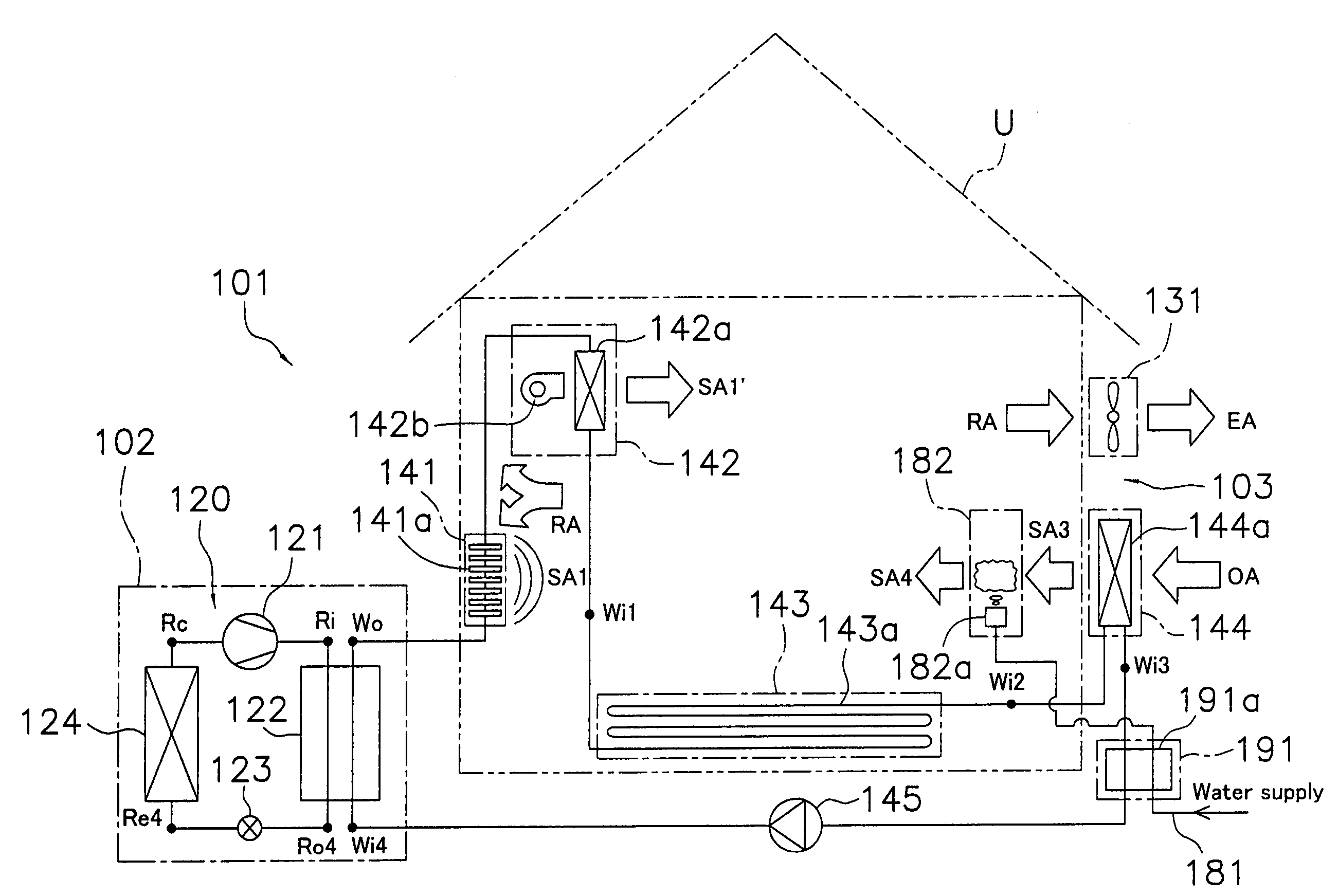

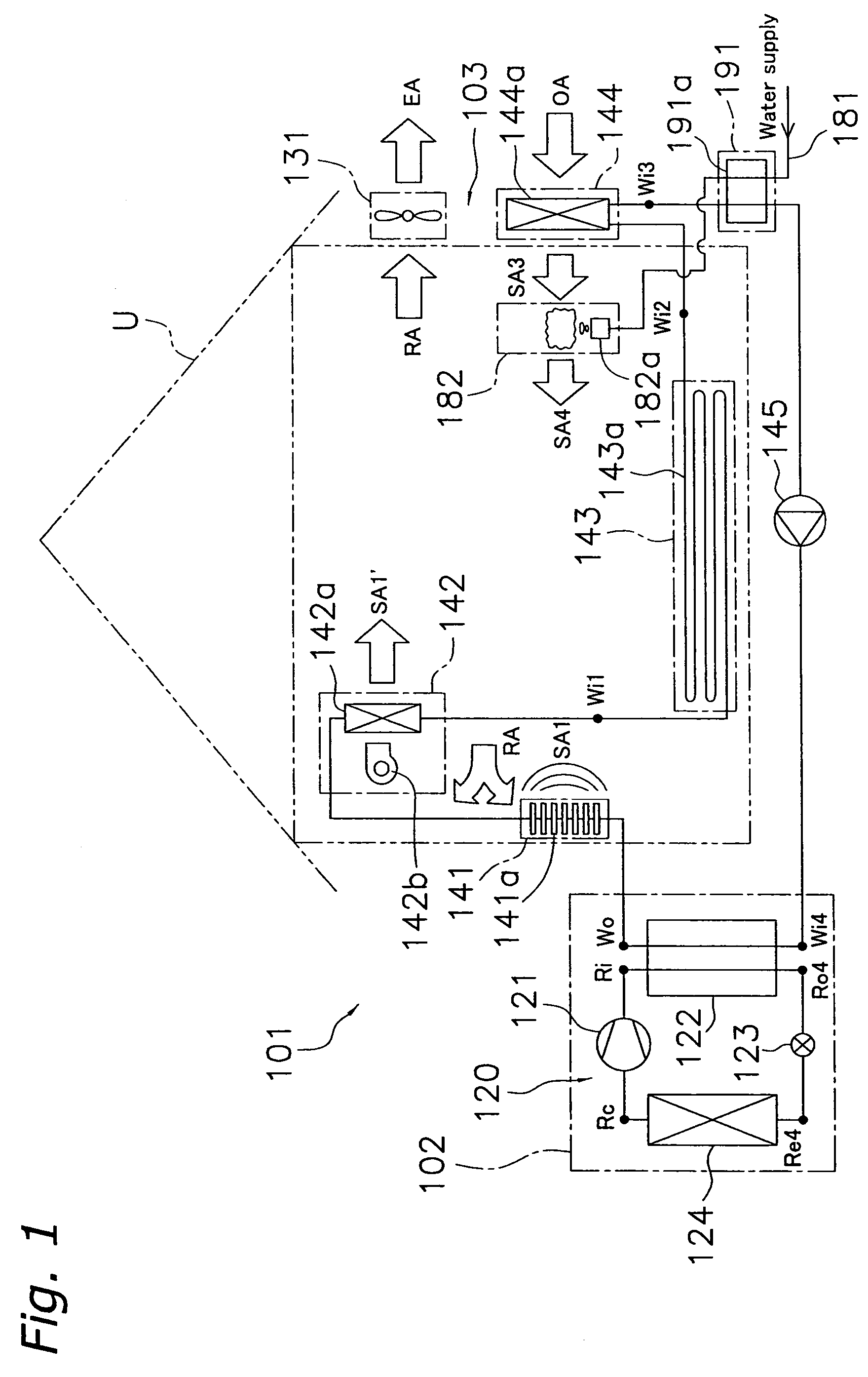

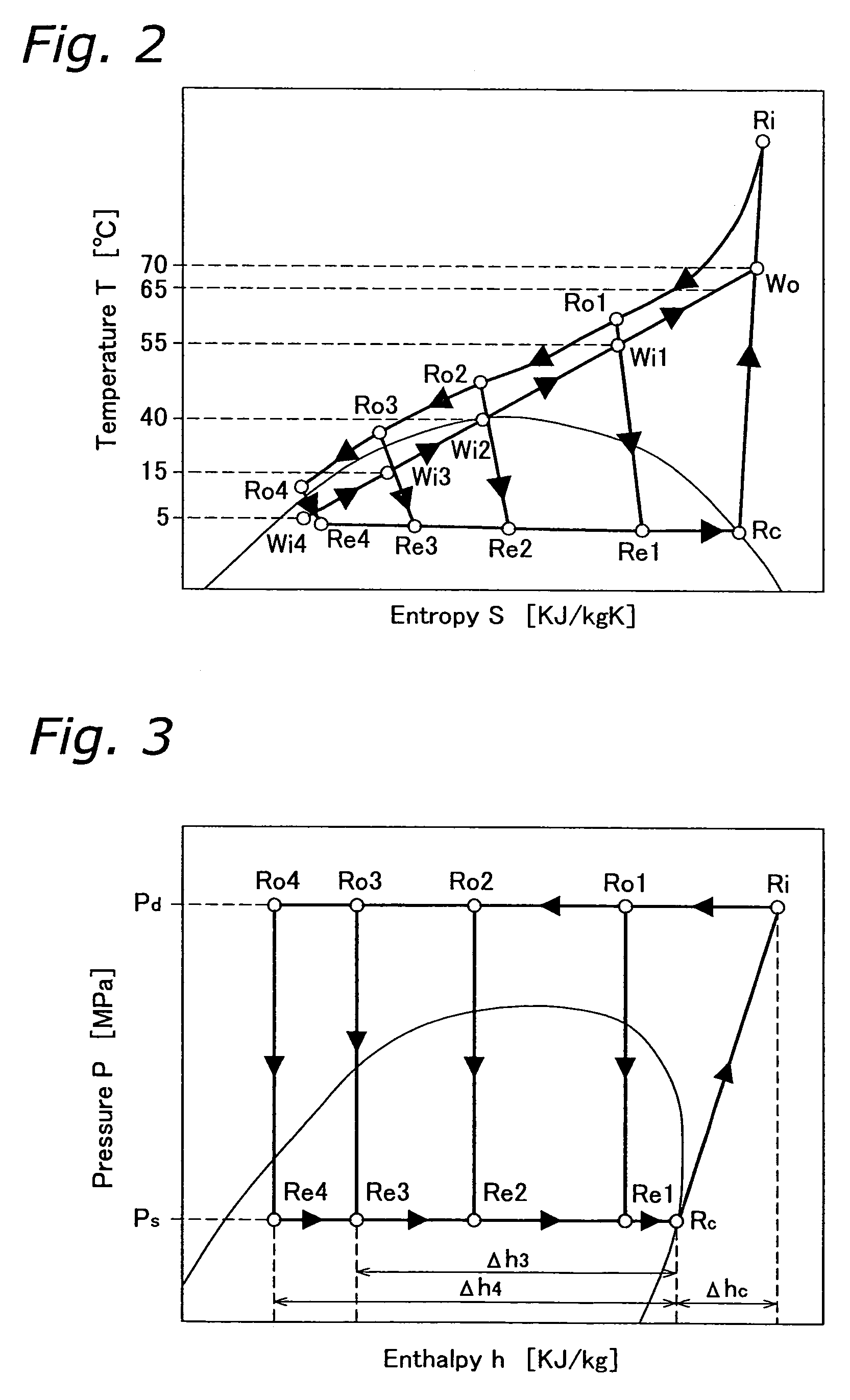

Air conditioning system

InactiveUS7685835B2Decrease in humidityRaise the temperature levelServomotor componentsFree-cooling systemsEngineeringAir conditioning

An air conditioning system includes a heat source unit, an air supply device that supplies the outside air to the room as the ventilation air, a water supply type humidifier for humidifying the ventilation air, a heating medium circuit, and a supply water heating device. The heat source unit heats a heating medium that is used for heating the room in a heating medium—refrigerant heat exchanger. The heating medium circuit includes at least one room heating device that releases the heat of the heating medium heated in the heating medium—refrigerant heat exchanger into the room, and circulates the heating medium between the room heating device and the heating medium—refrigerant heat exchanger. The supply water heating device uses the heat generated from the heat source unit in order to heat water to be used in the humidifier.

Owner:DAIKIN IND LTD

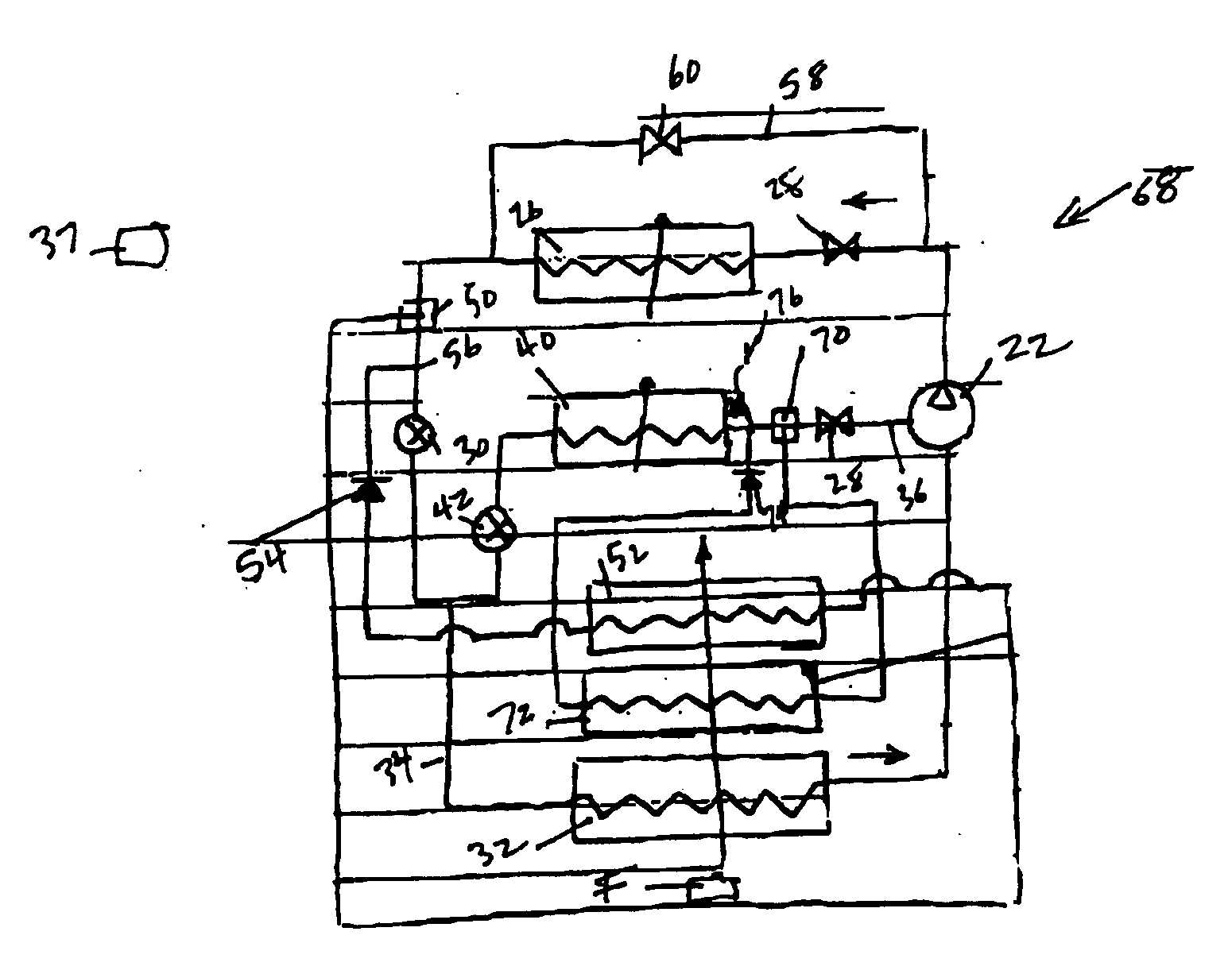

Dehumidification system with multiple condensers and compound compressor

InactiveUS20060090501A1Raise the temperature levelCompression machines with non-reversible cycleEvaporators/condensersHeat rejectionEngineering

A refrigerant cycle is provided with a multi-port compressor or compressor stages connected in series, and multiple condensers. A single evaporator communicates with the plurality of condensers. At least one of the plurality of condensers receives fully compressed refrigerant while the other condensers receive refrigerant at intermediate pressure. A control can optionally direct refrigerant to the condensers to achieve desired system heat rejection characteristics and operating conditions. One or multiple reheat coils may be associated with the evaporator and are arranged either in series or in parallel to provide a desired dehumidification function and reheat stages. One or several of the intermediate pressure condensers may be utilized for the reheat function as well.

Owner:CARRIER CORP

A circular flow energy-saving smokeless oven

ActiveCN106983387AReduce power consumptionRaise the temperature levelFood scienceElectric energyEngineering

The invention relates to a circular flow energy-saving smokeless oven and belongs to the technical field of barbecue devices for civil use. The oven comprises a double-circulation system, a main oven, a grill system, an auxiliary oven, a biological oil collector and a power supply device. The main oven communicates with the auxiliary oven via the double-circulation system; the grill system is arranged on the main oven and the auxiliary oven; collection stands at the bottoms of the main oven and the auxiliary oven are connected with the biological oil collector; the power supply device is installed on a side surface of the auxiliary oven for providing power; the temperature of the upper portion and the temperature of the middle portion of the main oven are higher than the temperature of the lower portion; the temperature of the upper portion and the middle portion of the auxiliary oven are lower than the temperature of the lower portion. The circular flow energy-saving smokeless oven has the advantages of high heat energy utilization rate, high efficiency, cleanness, convenient and low cost and is a device for civil cooking which can be used for continuous large-scale barbecue.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com