Patents

Literature

80results about How to "Resolve Insufficient Combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

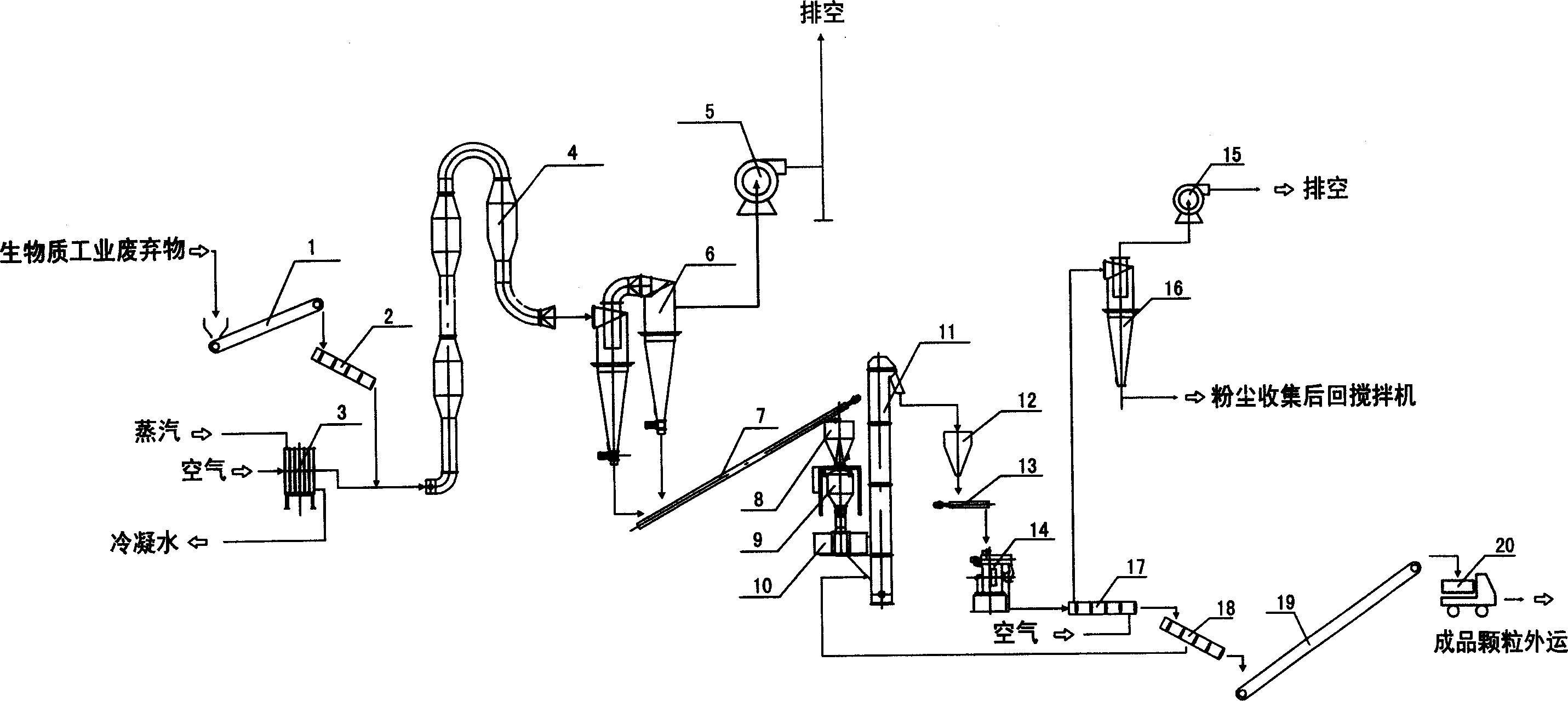

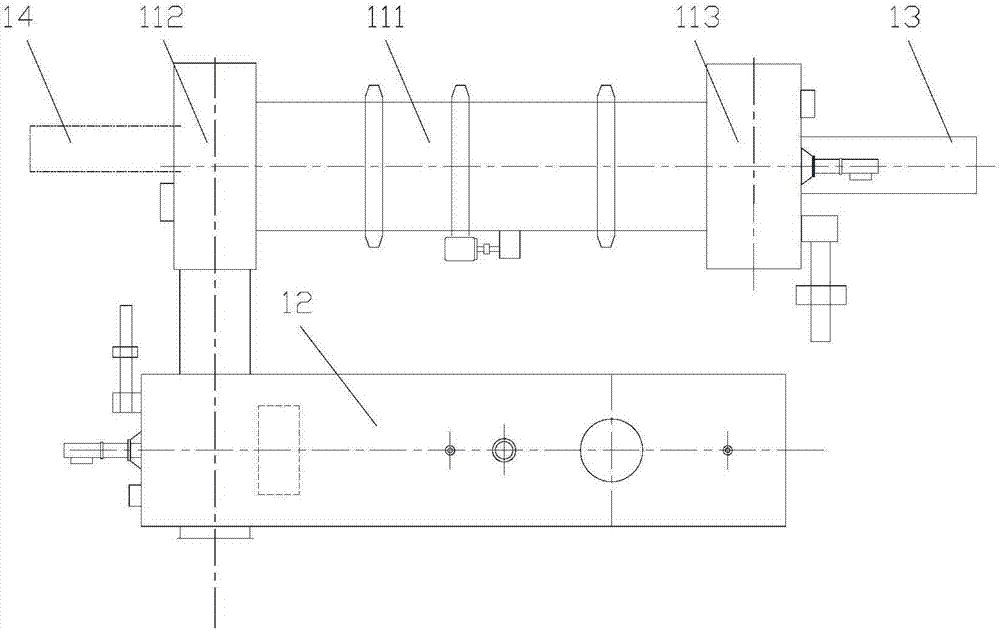

Method for producing granular fuel from biomass industrial produced wastes

InactiveCN1858166ASolve the problem of not being able to burnAvoid pollutionBiofuelsSolid fuelsPulp and paper industryPellet fuel

The method of producing granular fuel with industrial biomass waste belongs to the field of comprehensive utilization technology. Industrial biomass waste with water content of 30-35% is first extruded to form in a ring mold type pelletizing machine while softening material with the heat generated during extruding formation, and then cooled and sieved to obtain the product. The present invention utilizes industrial biomass waste effectively and is environment friendly, and the produced granular fuel may be used to replace charcoal for warming, barbecue, etc.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

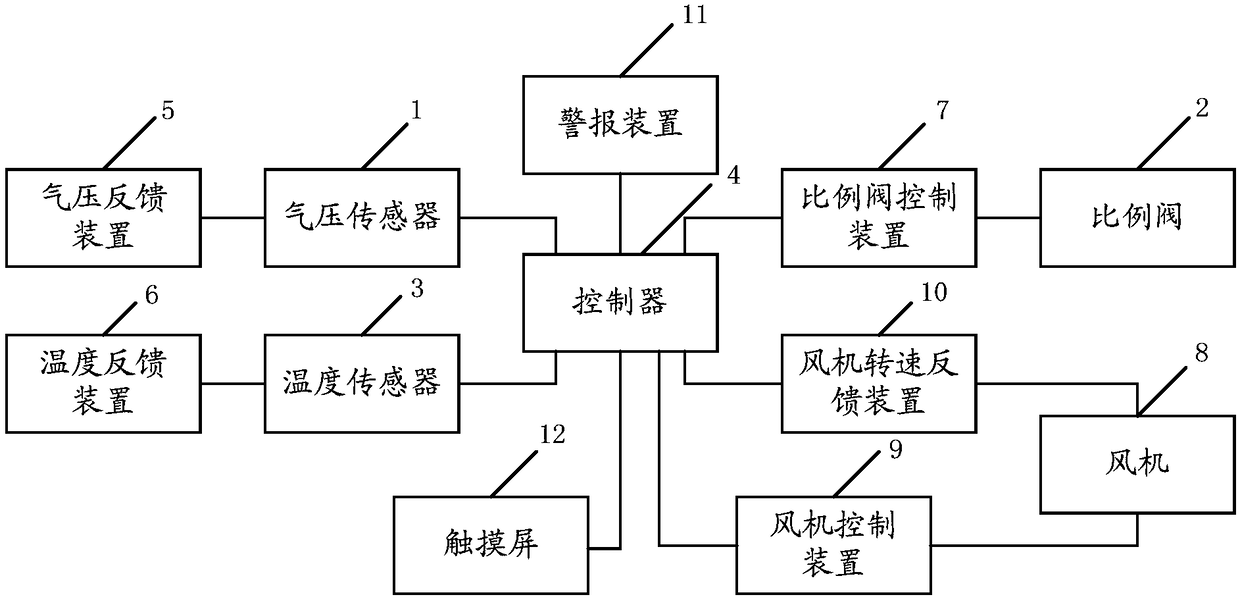

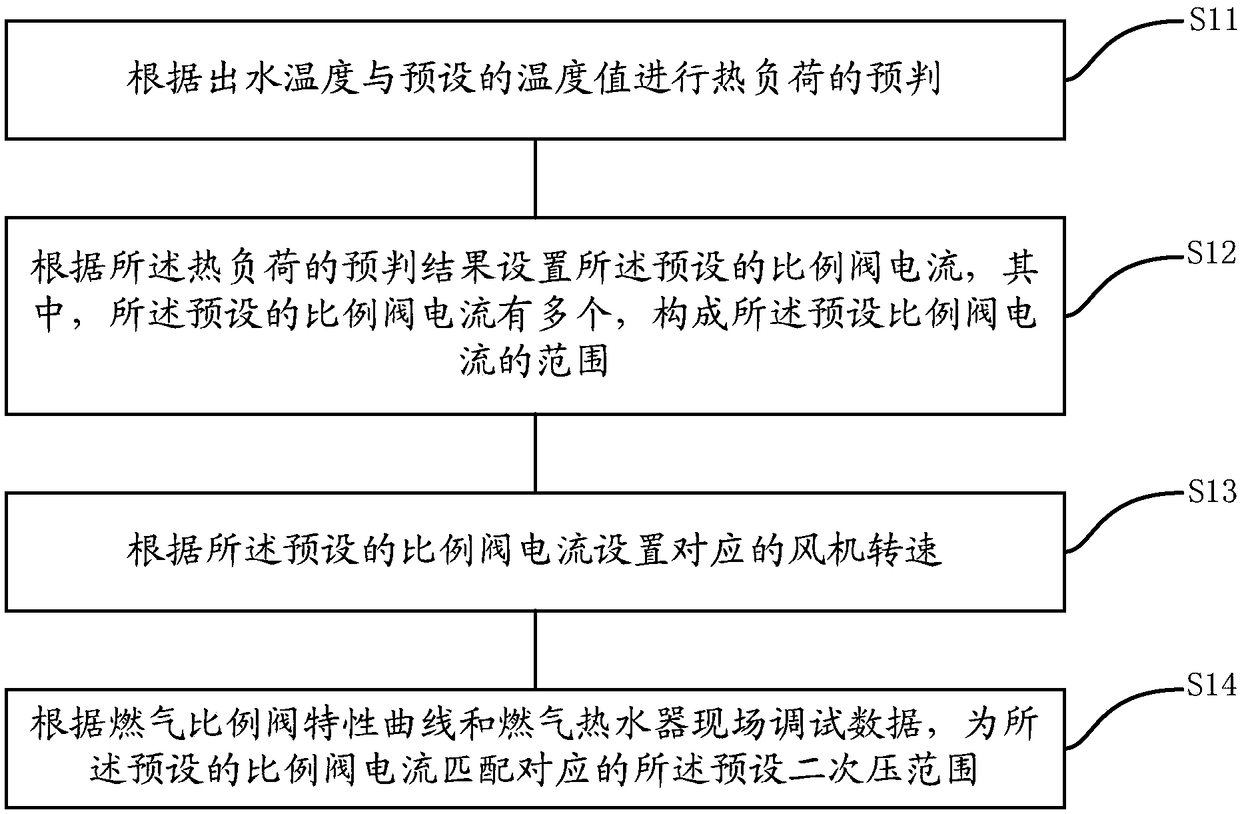

Method and system for adjusting secondary pressure of fuel gas

PendingCN108469120AHigh speed matchingResolve Insufficient CombustionFluid heatersDomestic stoves or rangesCurrent rangeAtmospheric pressure

The invention discloses a method for adjusting secondary pressure of fuel gas. The method comprises the following steps that when it is detected that the secondary pressure of the fuel gas deviates from a preset secondary pressure range, the rotating speed of a fan is adjusted according to the secondary pressure of the fuel gas; the following steps are carried out repeatedly until the water outlettemperature meets a preset temperature range or the proportional valve current reaches a preset proportional valve current limit value; when it is detected that the water outlet temperature does notmeet the preset temperature range, whether the proportional valve current is within a preset proportional valve current range or not is judged; when the proportional valve current is not in the presetproportional valve current range, the proportional valve current is adjusted according to the difference value between the water outlet temperature and the preset temperature range; and when it is detected that the current rotating speed of the fan is not matched with the current secondary pressure of the fuel gas, the current rotating speed of the fan is adjusted according to the current secondary pressure of the fuel gas. The invention further provides a system for adjusting the secondary pressure of the fuel gas. According to the method and system for adjusting the secondary pressure of the fuel gas, it is ensured that the secondary pressure of the fuel gas is always matched with the optimal rotating speed of the fan when a whole machine runs at whatever air pressure.

Owner:GUANGDONG WANHE THERMAL ENERGY TECH CO LTD

Biomass briquette and preparation method thereof

InactiveCN107033980AImprove adhesionHigh calorific valueBiofuelsSolid fuelsAluminum silicateBiomass briquettes

The invention discloses a biomass briquette. The biomass briquette is prepared from the following raw materials by weight: 30 to 45 parts of straw, 25 to 35 parts of wood chips, 15 to 25 parts of rice husks, 10 to 15 parts of corncob, 5 to 10 parts of anthracite, 1 to 3 parts of quicklime and 6 to 9 parts of magnesium aluminum silicate hydrate. The invention also discloses a preparation method for the biomass briquette. According to the invention, the biomass briquette and the preparation method thereof can effectively utilize biomass raw materials and have the advantages of simple processing technology, low cost, small density, high calorific value, low ash content, full combustion, etc.

Owner:湖南双晟科技信息咨询有限公司

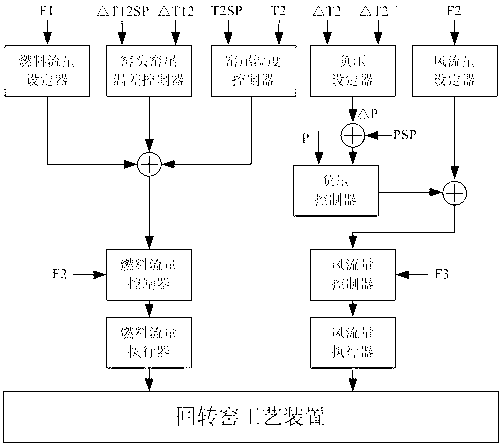

Optimization control method of temperature gradient inside rotary kiln

ActiveCN103217013AResolve Insufficient CombustionReduce consumptionRotary drum furnacesRotary kilnEngineering

The invention relates to an optimization control method of temperature gradient inside a rotary kiln. The closed-ring control of the negative pressure in the kiln is realized according to the change in temperature of a kiln tail and the temperature change rate, and the closed-ring control of the air flow is realized according to the negative pressure and the load. The optimization control method effectively solve the quality problems of products caused by unreasonable distribution of the temperature field in the rotary kiln, and the fuel insufficient combustion problems caused by unreasonable temperature gradient in the rotary kiln, so as to reduce the fuel consumption and stabilize the quality of the products.

Owner:北京和隆优化科技股份有限公司

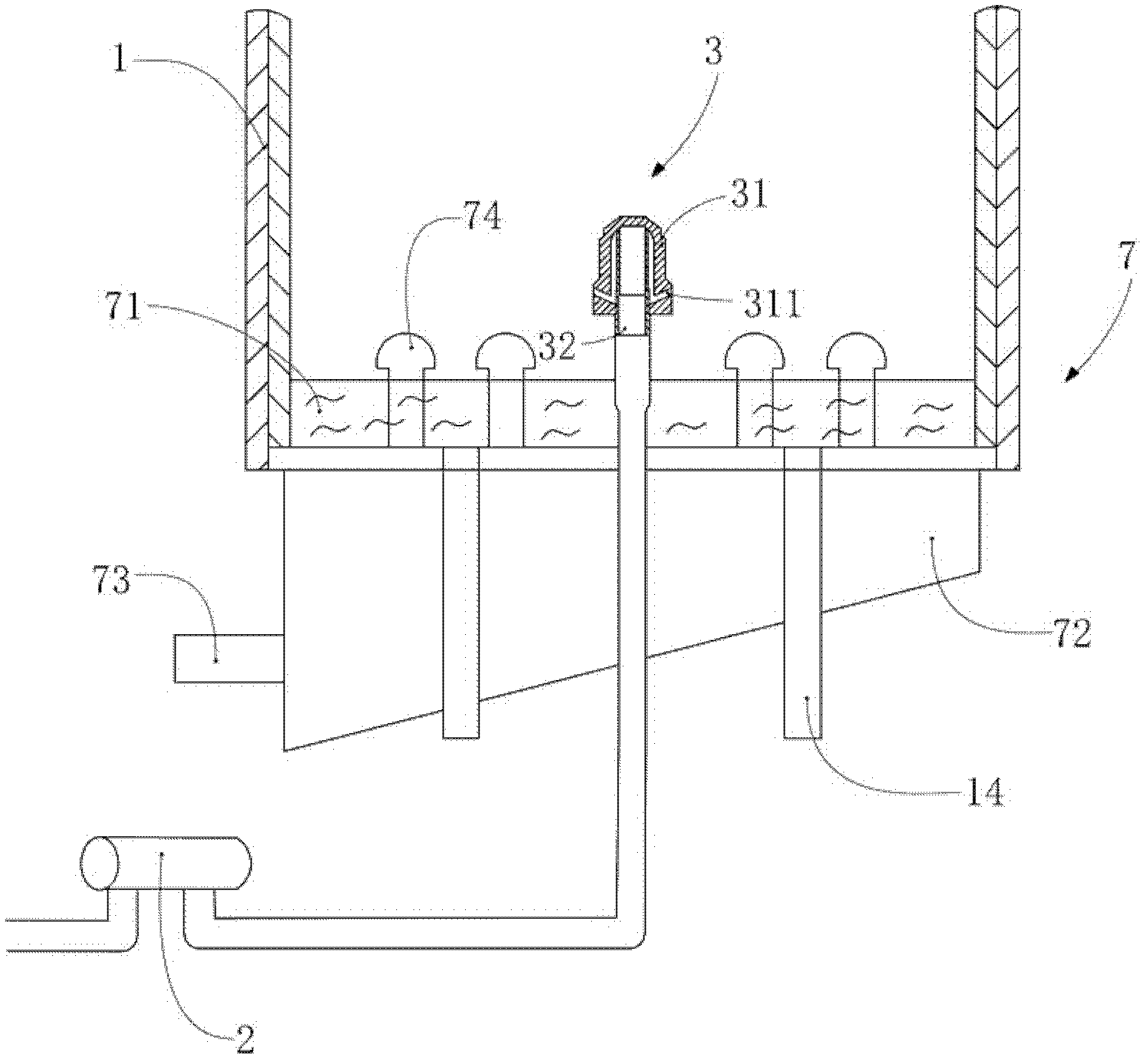

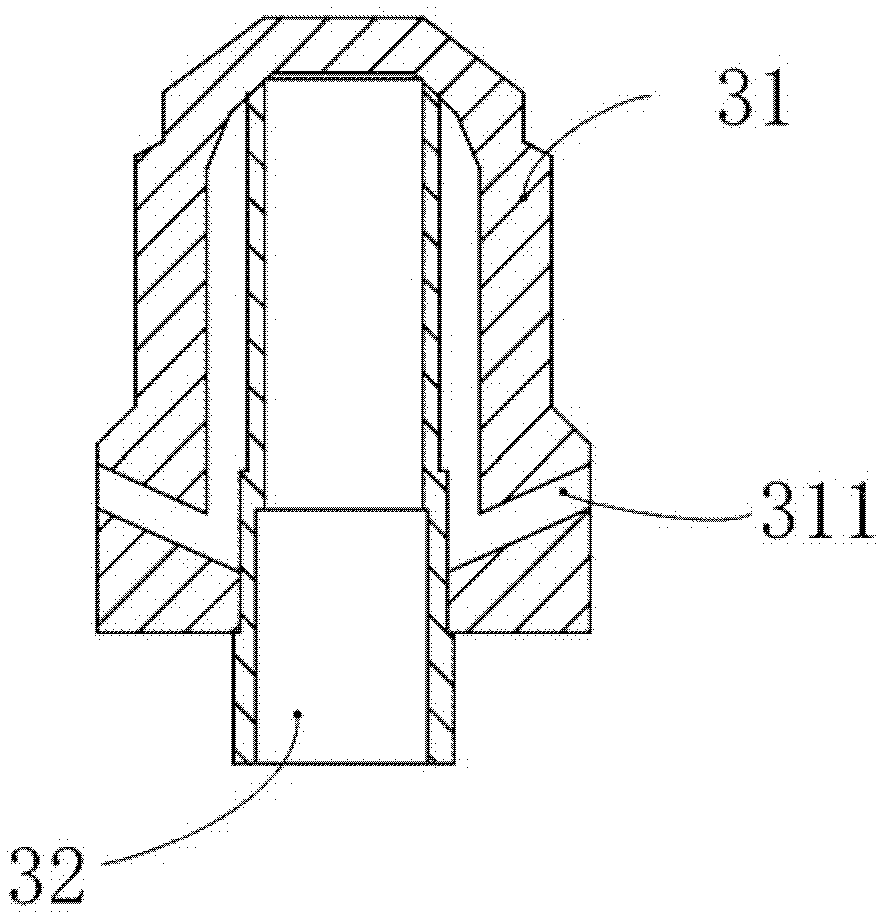

Gas combustion-supporting device of recirculating fluidized bed and combustion control device of recirculating fluidized bed

InactiveCN102353044AResolve Insufficient CombustionSolve the landfill problemFluidized bed combustionDirect carbon-dioxide mitigationCombustion systemCombustion chamber

The invention relates to the technical field of fluidized bed combustion, and in particular relates to a gas combustion-supporting device of a recirculating fluidized bed and a combustion control device of the recirculating fluidized bed. The combustion-supporting device comprises a fluidized bed combustion chamber and a gas compression device; the gas compression device is communicated with the fluidized bed combustion chamber through a pipeline, and gas is introduced into the fluidized bed combustion chamber; and the top end of the pipeline is provided with a gas compression ejector. Through the gas combustion-supporting device of the recirculating fluidized bed provided by the invention, the problem of insufficient combustion brought by the calorific value, less than 2500kcal / kg, of the recirculating fluidized bed of fuel material (mud) can be solved effectively, thus the combustion is fuller, and the desulfurization and deslagging operations are easier, and clean combustion is realized; simultaneously the emission of carbon dioxide is reduced effectively, and the tail gas treating cost is lowered; and in addition, the sufficient combustion of fuel materials in the fluidized bed enables the fuel material waste residue to be decreased greatly, the problem of land occupation by landfill of waste residue is solved effectively, the comprehensive benefit is good, and the device and the system accord with the principles of reduction, harmlessness and resource utilization of mud treatment.

Owner:北京君达能源投资有限公司

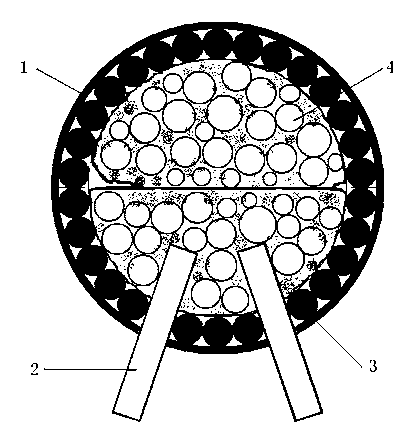

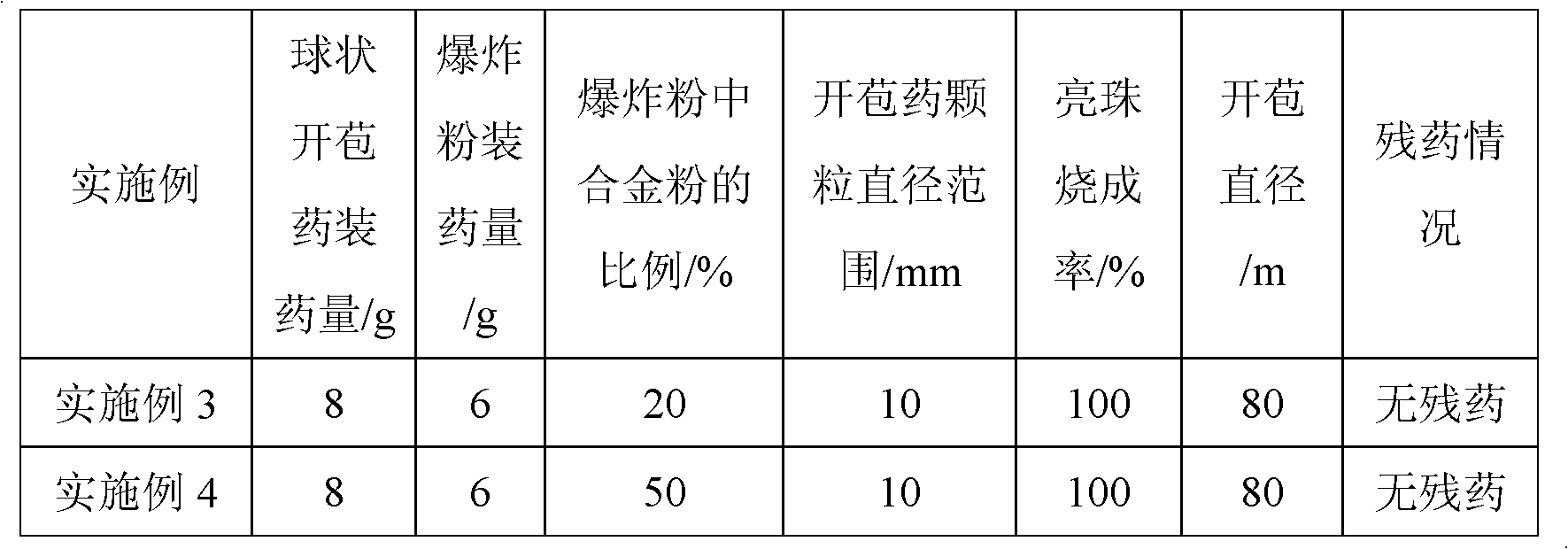

Display shell preparation method for increasing explosion diameter

The invention discloses a display shell preparation method with pellet-shaped smokeless firework explosive as the explosive. The method comprises the following steps that first bright beads are lined on the inner side of the spherical shell of the display shell, and then the pre-prepared pellet-shaped explosive and a small amount of explosive which contains magnesium-aluminum alloy powder are mixed together, wrapped by a piece of thin paper and charged to the semi-spherical shell; the other half shell of the display shell is filled in the same charging order; and finally the two halves of spherical body are buckled, and the paper is pasted on the surface of the shell and dried. According to the preparation method of the display shell, area ignition is facilitated, the problems that the burning is not full or medicine particles are left when granular microporous firework explosive serves as the explosive are thoroughly solved, the explosion diameter of the display shell is greatly increased, and the ornamental effect is effectively improved.

Owner:NANJING UNIV OF SCI & TECH

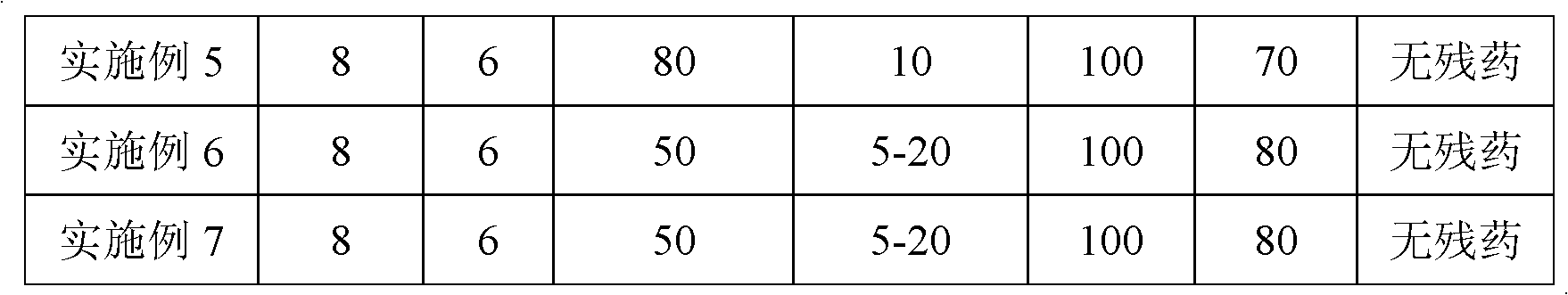

W-shaped flame boiler gap type OFA (over fire air) device arranged above arch wing wall

The invention discloses a W-shaped flame boiler gap type OFA (over fire air) device arranged above an arch wing wall and relates to a boiler OFA device. The device solves the problems of a W-shaped flame boiler that in the case that OFA is increased and the NOX discharge is reduced, the flying ash is caused and the content of combustible matter is high, not all burners at four corners can be put into operation and the wall surfaces of water-cooling walls at beside the a side wall and wing walls are over-temperature, and even the water cooling walls in the region are torn. Each wing wall is provided with a group of gap type wing wall OFA nozzles, each group of gap type wing wall after combustion air nozzles is correspondingly provided with a wing wall OFA box, and each group of gap type arch OFA nozzles is correspondingly provided with an arch OFA box; and an air outlet of a fan is communicated with one end of a secondary air pipe, the other end of the secondary air pipe sequentially passes through a main burner air box, and the side wall of the secondary air pipe is respectively communicated with the arch OFA boxes and wing wall OFA boxes through a plurality of guiding pipes. The W-shaped flame boiler gap type OFA device provided by the invention is used for a W-shaped flame boiler.

Owner:HARBIN INST OF TECH

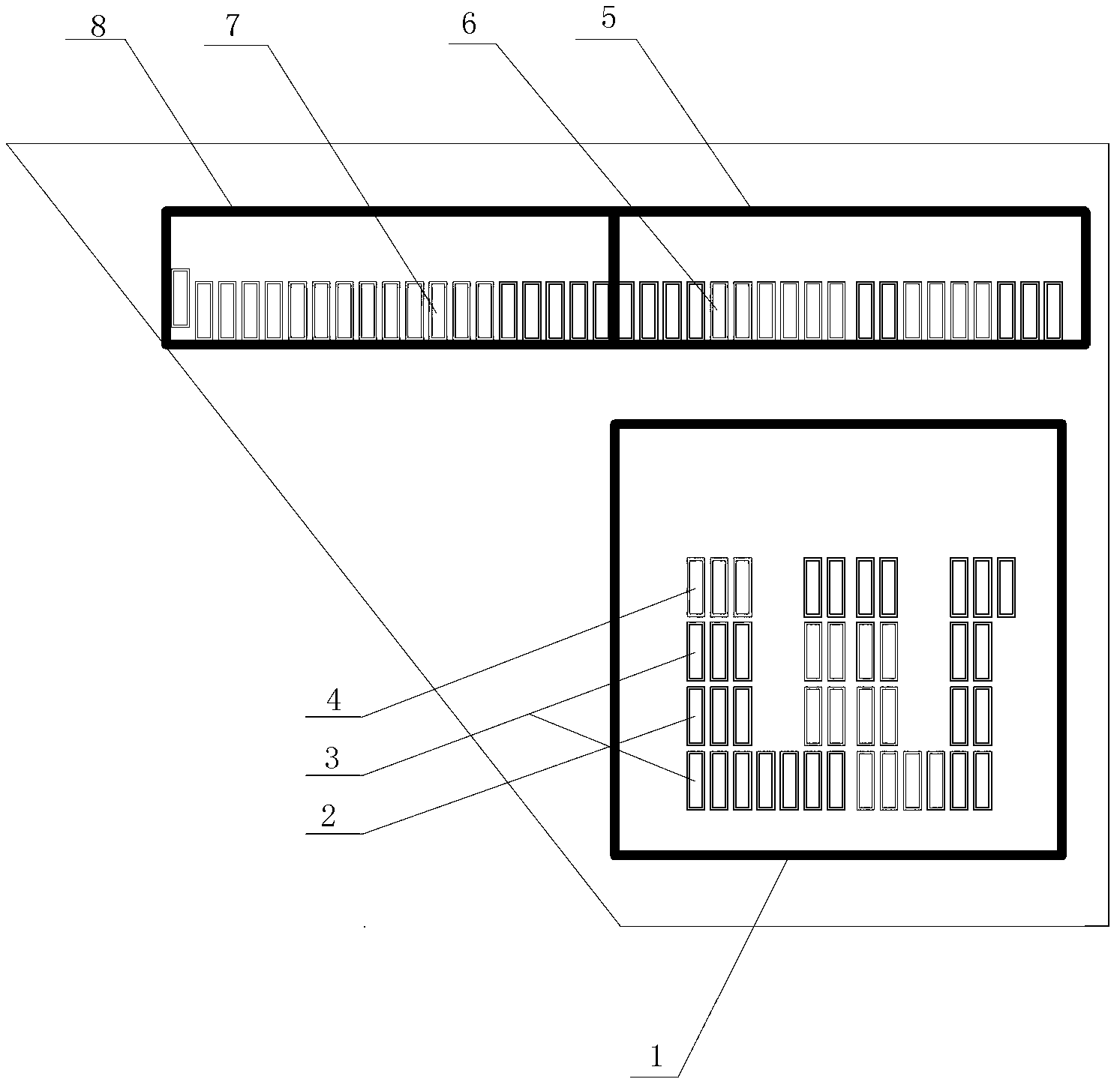

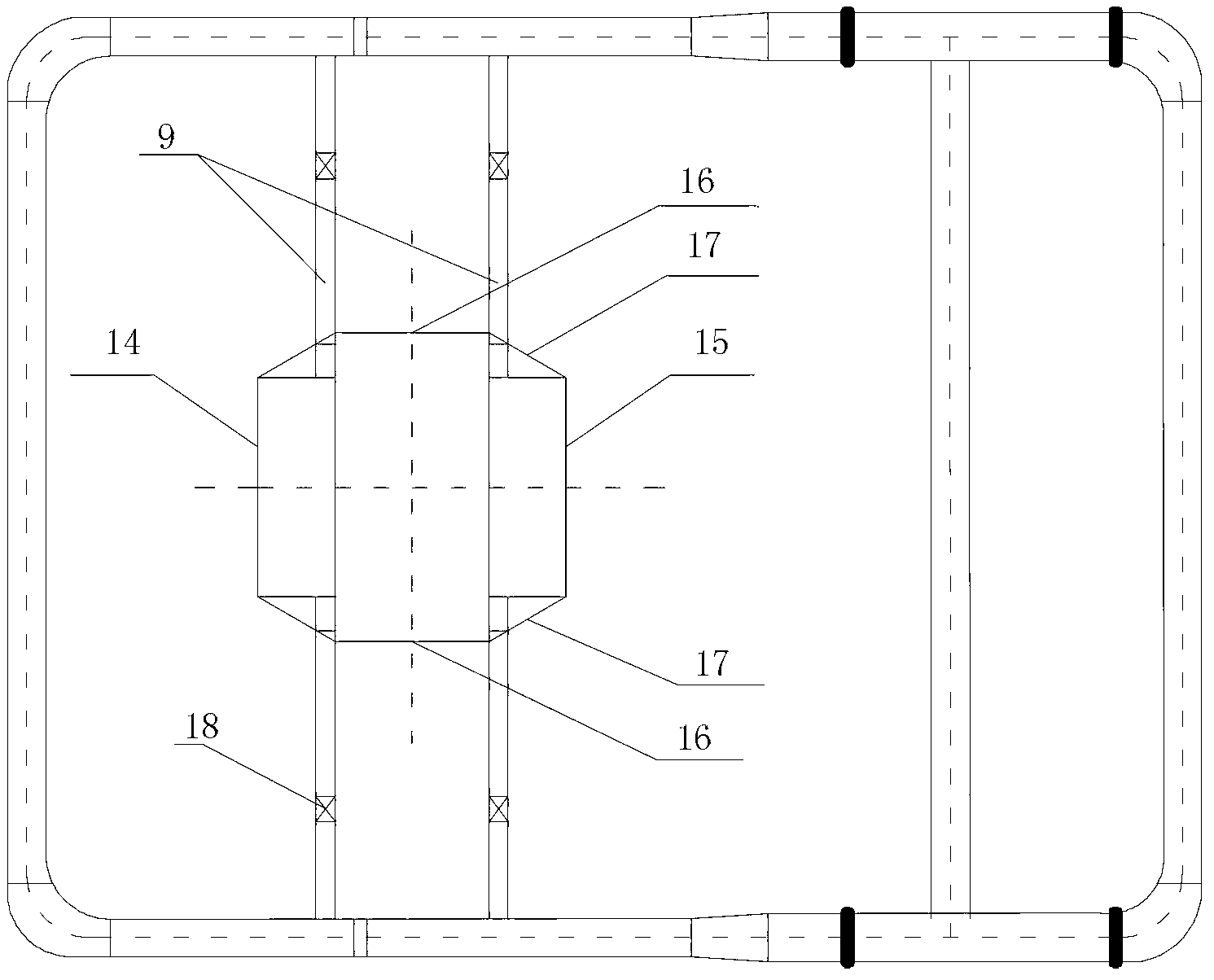

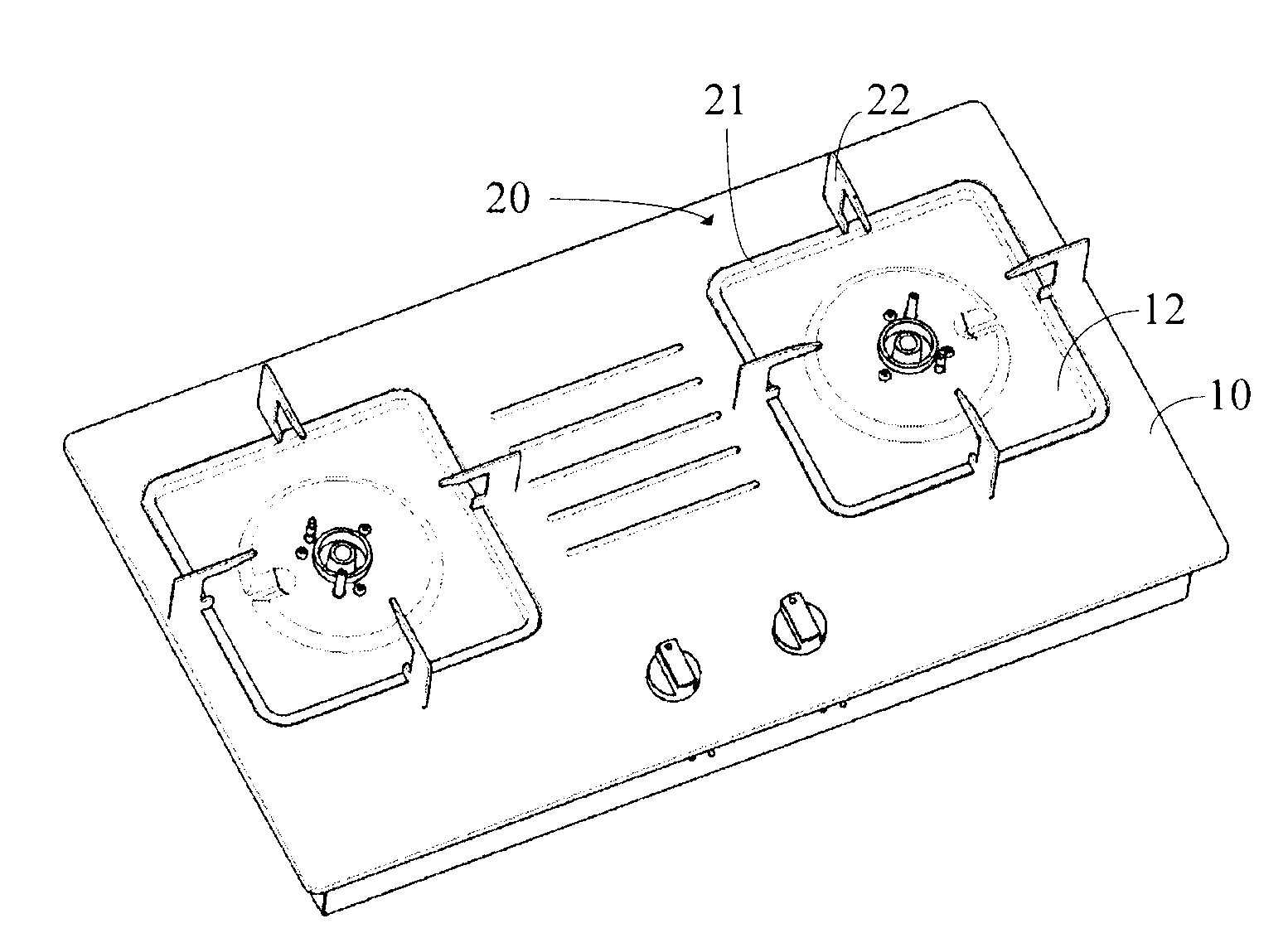

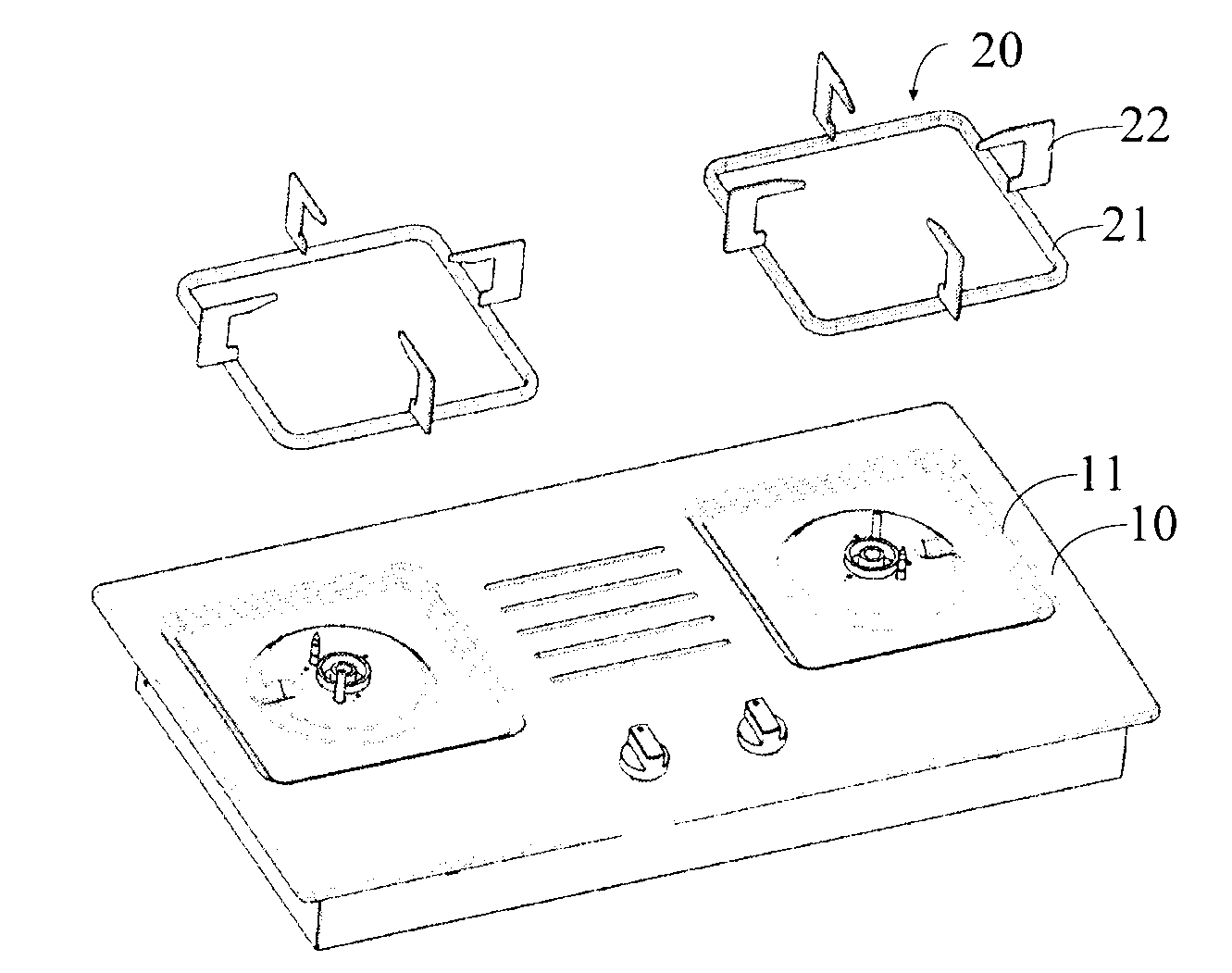

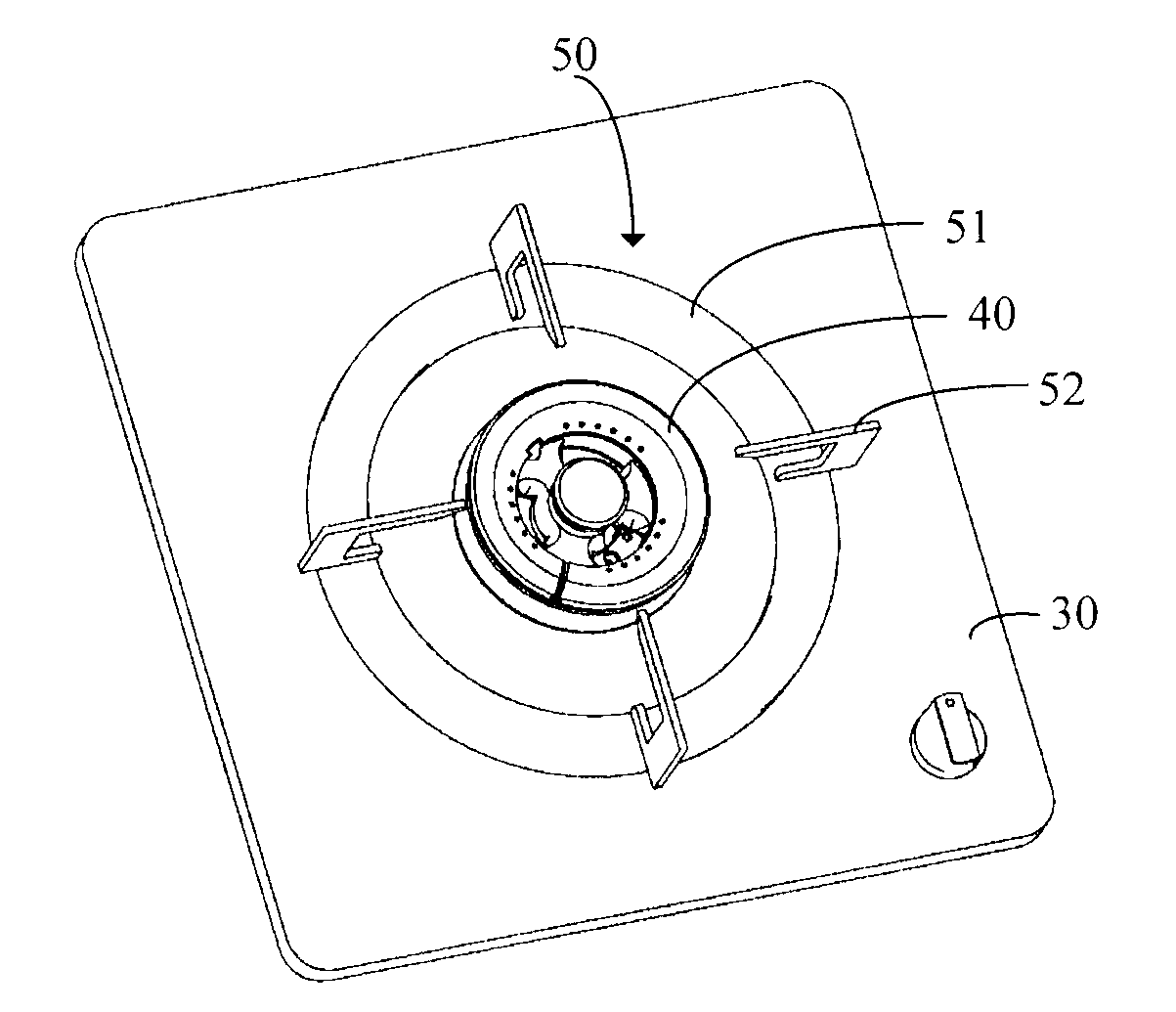

Gas-stove, gas-stove panel, and pot racks

ActiveCN102829493AResolve Insufficient CombustionPrevent moving back and forthDomestic stoves or rangesLighting and heating apparatusCombustorEngineering

The invention relates to a gas-stove, a gas-stove panel, and pot racks. The gas-stove comprises a panel (30), combustors (40), Venturi mixing tubes, and pot racks (50). The Venturi mixing tubes communicate with the combustors (40), and are used for providing a mixture of air and fuel gas to the combustors (40). The pot racks (50) comprise supporting racks (51) and supports (52). The supports (52) are arranged on the supporting racks (51), and are used for supporting pots. Bosses (31) with shapes matching those of the supporting racks (51) are arranged on the panel. Each boss comprises at least one through hole (32). The supporting racks (51) are positioned above the bosses (31). Spaces (60) are formed between the bosses (31) and the supporting racks (51). The spaces (60) communicate with the outside. Outside air sequentially passes through the spaces (60) and the through holes (32), and flows into the Venturi mixing tubes. The outside air can also enter the Venturi mixing tubes through the spaces and the holes on the bosses, such that a problem of insufficient fuel gas combustion caused by insufficient air in cupboards can be solved.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

Method for producing large-size disc-type cast iron parts by means of lost foam casting

InactiveCN107570664AImprove surface qualityResolve Insufficient CombustionFoundry mouldsFoundry coresProduction rateCombustion

The invention discloses a method for producing large-size disc-type cast iron parts by means of lost foam casting, and belongs to the technical field of lost foam casting. By implementing the technical scheme comprising the steps of bead selecting, prefoaming, drying and curing, model making, model drying, connecting and combining, staining and drying, combination splitting, dry sand compacting, negative-pressure sucking, negative-pressure pouring and taking out and cleaning, the problems that the cast part surface has gaps due to the fact that a lost foam model is improper in bead selection,insufficient in model strength and large in gas generation volume and deformation in the casting production process, and the size is unqualified due to deformation are solved, and the problems such asslag blowholes, shrinkage porosity and shrinkage cavities which are generated due to the fact that cast part model combustion is insufficient, iron liquid model filling is unstable, iron liquid solidification is unbalanced, and the pressure maintaining time is insufficient are solved. According to the method, conception is novel, layers are clear, operation is easy and convenient, and implementation is easy; in addition, the product parts produced through casting are high in stability and production rate and have the propagable practical value.

Owner:FIRST TRACTOR

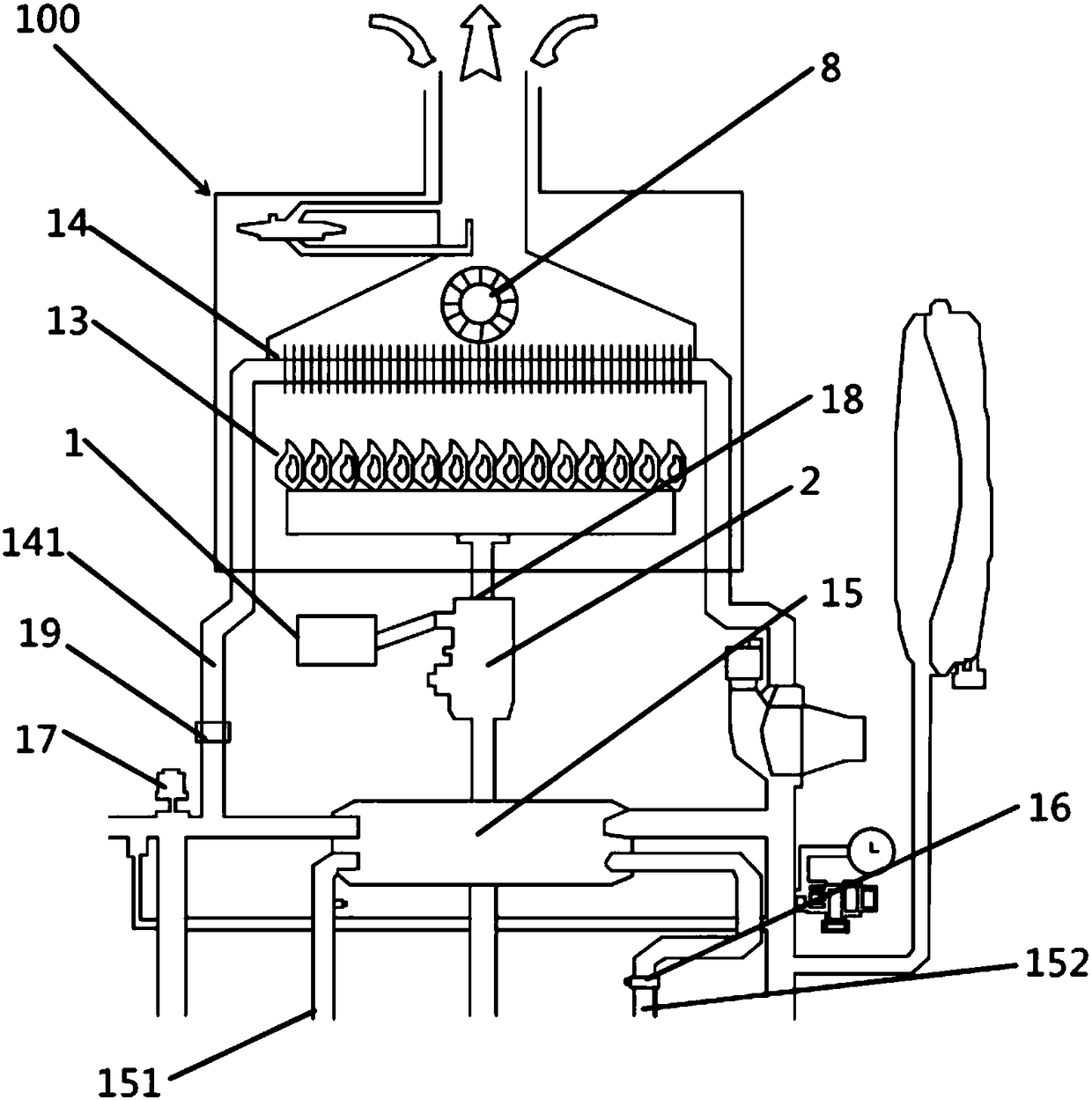

Gas water heater

ActiveCN105588323AGood energy saving effectReduce generationWater heatersCombustion chamberWater storage tank

The invention discloses a gas water heater which comprises an air heater, a heat exchanger and a smoke exhaust fan. The air heater comprises a combustion chamber and a combustor arranged in the combustion chamber. The combustion chamber is provided with a cold air inlet, a hot air outlet and a gas inlet. The combustor is configured to enable the concentration of nitrogen oxide in generated hot air to be smaller than or equal to 30 mg / m<3> and the concentration of carbon monoxide in the generated hot air to be smaller than or equal to 50 mg / m<3>. The heat exchanger comprises a water storage tank and a heat exchange part. The heat exchange part is provided with a water inlet, a water outlet, an air inlet and an air exhaust opening. The water outlet communicates with the water storage tank. The air inlet communicates with the hot air outlet. The heat exchange part is configured to enable water entering from the water inlet to exchange heat with air entering from the air inlet. The smoke exhaust fan is used for sucking hot air generated by the combustor into the heat exchange part. By means of the gas water heater, generation of harmful gas of CO, nitrogen oxide and the like can better reduced, clean exhausting can be achieved, and the heat exchange efficiency between hot air and water can be improved.

Owner:BEIJING ORIENT DELTA SCI & TECH CO LTD

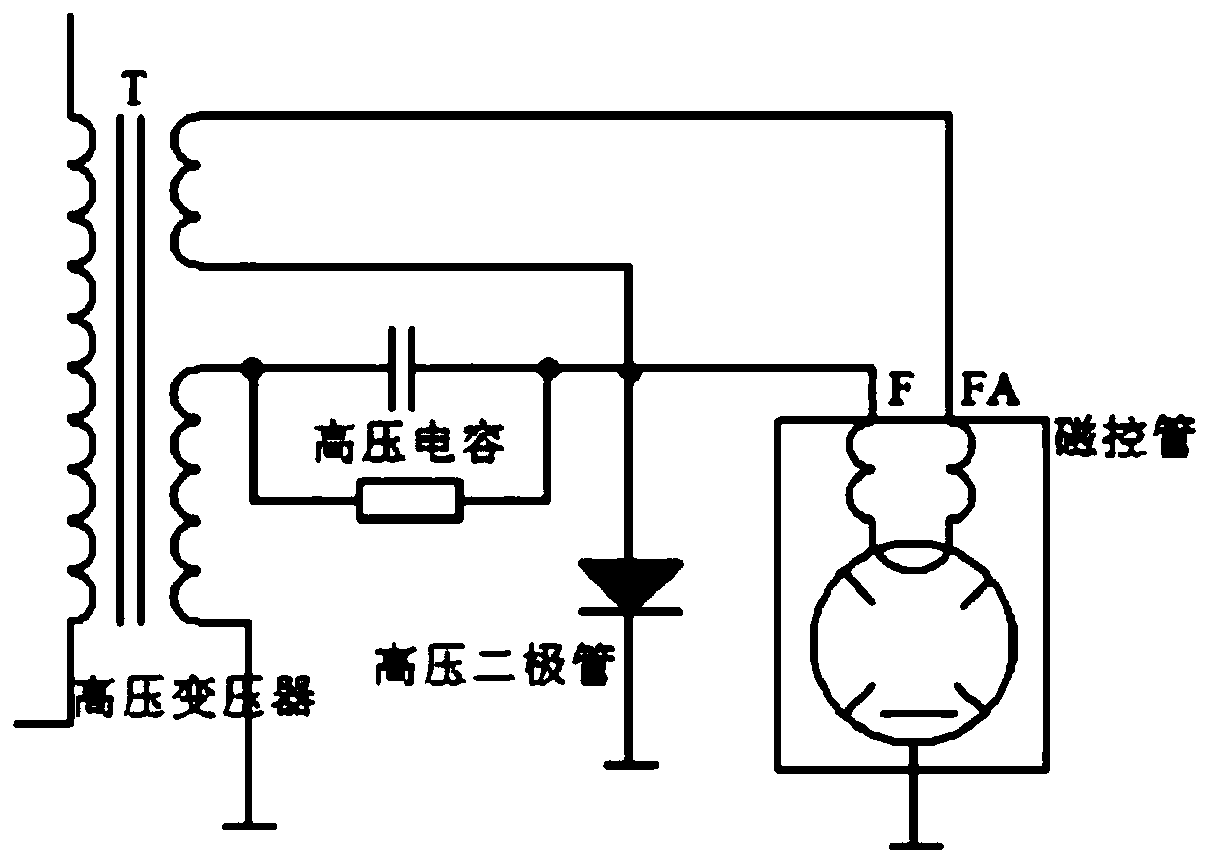

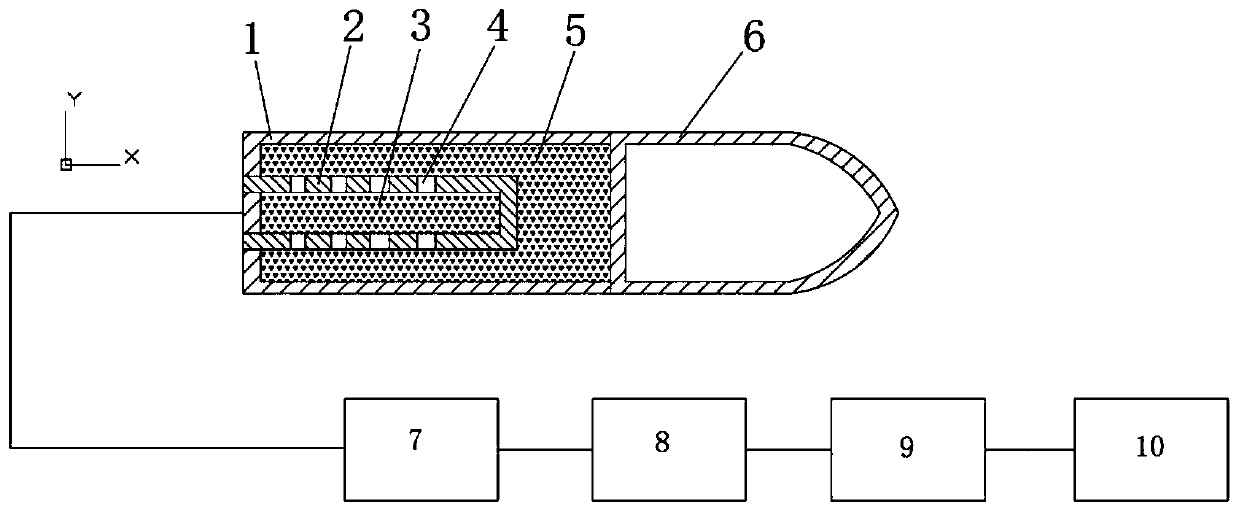

Ignition powder igniting device

ActiveCN110595304AImprove ignition efficiencyBurn fullyAmmunition fuzesPlasma techniqueResonant cavityMicrowave

The invention discloses an ignition powder igniting device. The ignition powder igniting device comprises a microwave source power supply, a magnetron, a resonant cavity, a waveguide pipe, a coaxial resonant cavity, a resonant cavity inner conductor, ignition powder and gunpowder, wherein the microwave source power supply provides a power supply for a built-in circuit of the magnetron, the resonant cavity is arranged outside the magnetron, one end of the waveguide pipe is connected with the resonant cavity, and the other end of the waveguide pipe is connected with the coaxial resonant cavity,the resonant cavity inner conductor is arranged in the coaxial resonant cavity, the resonant cavity inner conductor is filled with the ignition powder, a plurality of through holes are formed in the resonant cavity inner conductor, the arrangement of the through holes correspond to hollow points generated by microwave of the resonant cavity inner conductor, a cavity between the resonant cavity inner conductor and the coaxial resonant cavity is filled with the gunpowder, and the coaxial resonant cavity is provided with an open end for transmitting detonation waves. The ignition powder ignitingdevice can realize efficient, safe and pollution-free and reliable ignition.

Owner:NANJING UNIV OF SCI & TECH

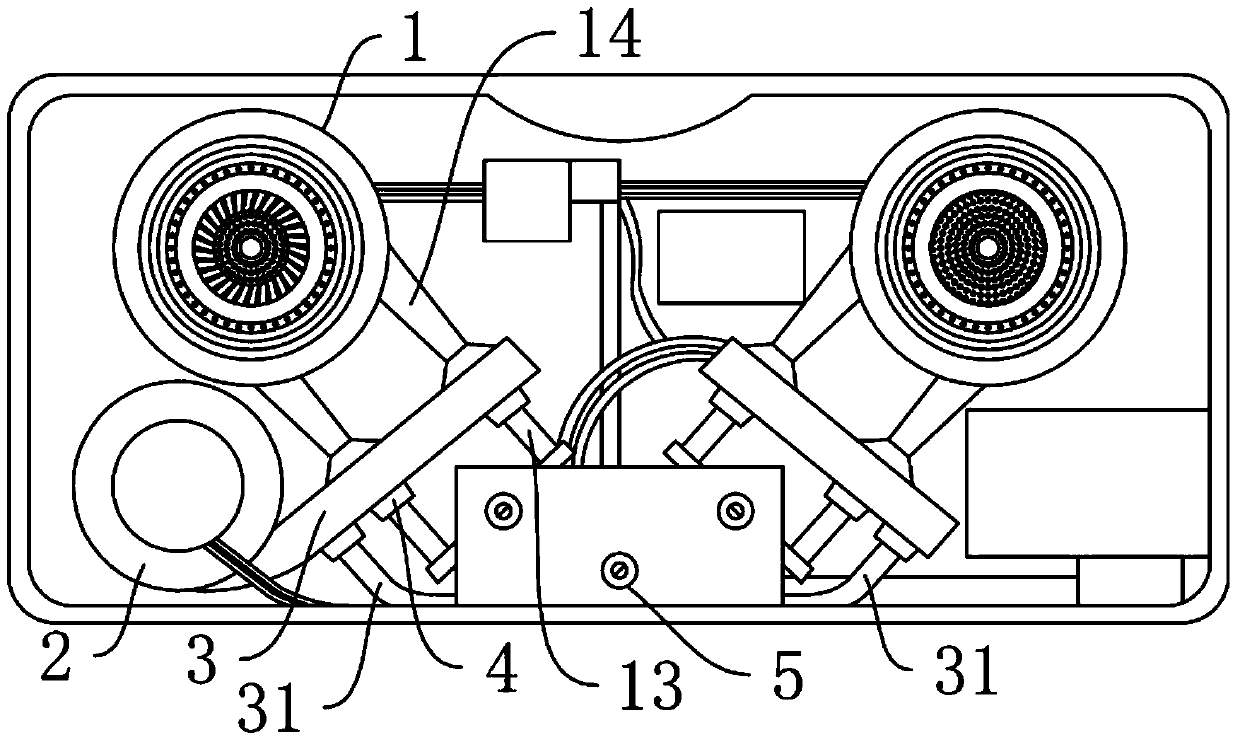

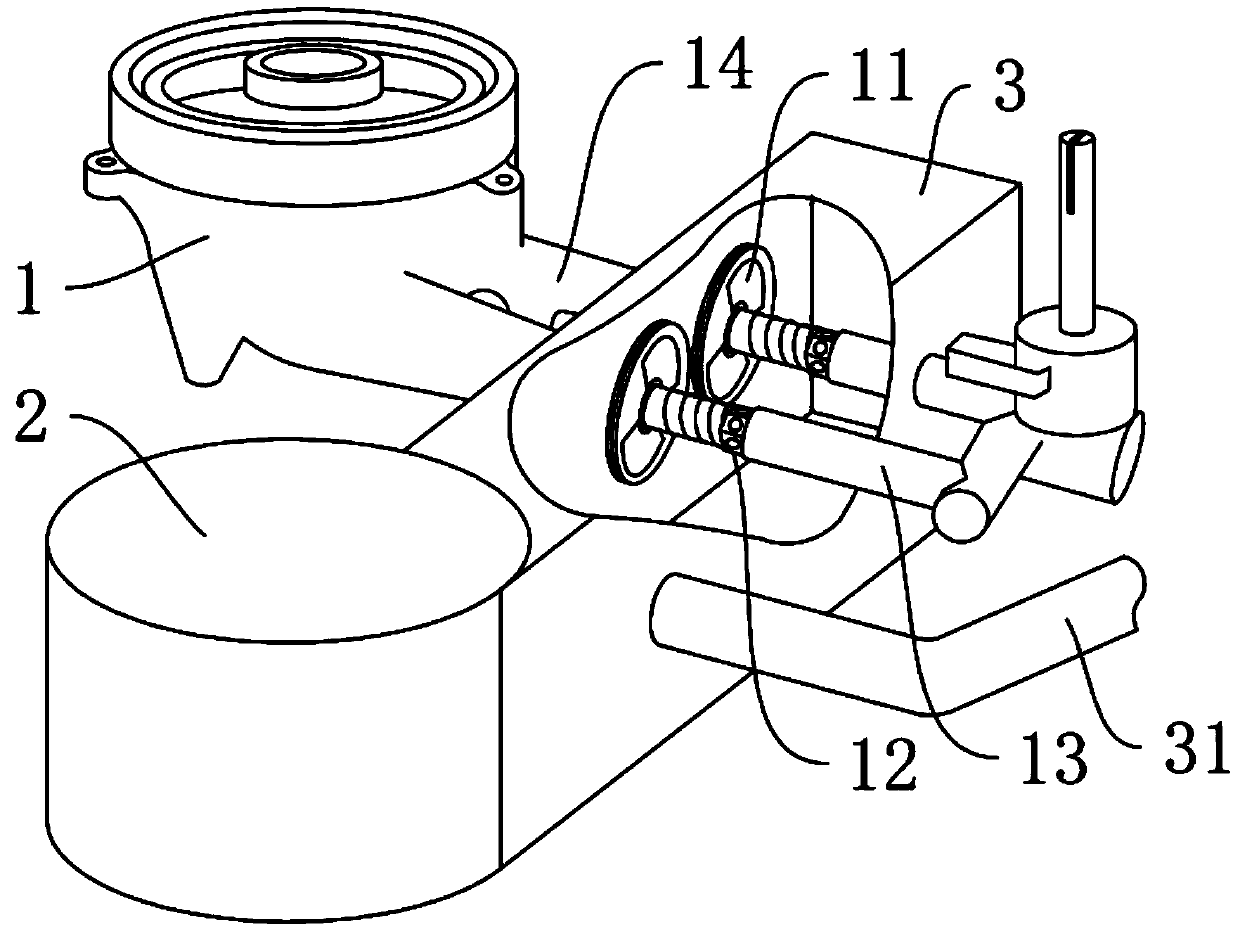

Gas stove with turbo-charging pre-mixer

InactiveCN103759304AAvoid inadequate mixingResolve Insufficient CombustionDomestic stoves or rangesGaseous fuel burnerTurbochargerProcess engineering

The invention discloses a gas stove with a turbo-charging pre-mixer. The gas stove comprises a burner and a turbocharger and is characterized by further comprising a pre-mixing cavity which is communicated with an air outlet of the turbocharger, and the pre-mixing cavity is also communicated with an air inlet and a valve nozzle of the burner.

Owner:许文广

Biomass coal briquette by use of anthracite coal and carbonized biomass fuel as base materials

InactiveCN105316057AHigh calorific valueResolve Insufficient CombustionSolid fuelsWaste based fuelCoal briquetteSorbent

The invention discloses a biomass coal briquette by use of anthracite coal and carbonized biomass fuel as base materials. The biomass coal briquette comprises the following raw materials in parts by weight: 49-59 parts of anthracite coal, 30-36 parts of carbonized biomass fuel powder, 0.5-12 parts of a combustion improver and 9-14 parts of a binding agent; the carbonized biomass fuel powder is obtained by carbonizing the following raw materials in parts by weight: 50-72 parts of eucalyptus bark, 15-20 parts of pine branches, 15-20 parts of straws, 5-8 parts of corncob, 15-20 parts of corn straws and 15-20 parts of soybean straws. The biomass coal briquette is prepared from anthracite coal and carbonized biomass fuel powder which are used in a combined manner, so that the content of volatile matters is low, the use of a sulfur fixation sorbent is eliminated, and energy conservation and environmental protection are realized.

Owner:GUANGXI KUONENGBA ENERGY TECH DEV CO LTD

Preparation method of biomass solid fuel

The invention discloses a preparation method of biomass solid fuel. The method includes the steps of adding cassava lees into a smashing machine to be smashed to be 40-60 mesh to obtain cassava lee powder, adding the cassava lee powder, magnesium oxide, acetylene sludge, attapulgite and pucherite into a stirring device, adding a proper amount of water to be stirred into paste, putting the paste into a muffle furnace to be sintered for 3-5 h at a temperature of 500-600 DEG C to obtain carbide, evenly mixing the carbide with polyurethane rubber and polyurethane asphalt, conveying the obtained mixed materials to a forming machine to be press-formed at a temperature of 120-140 DEG C and pressure of 60-80 MPa to obtain formed fuel, drying the formed fuel, cooling the fuel to the room temperature, and packaging the fuel to obtain the biomass solid fuel. The method has the advantages of being simple in preparation process, low in energy consumption, high in production efficiency, high in forming rate, low in cost and the like; the prepared biomass solid fuel is low in density, high in heat value, small in ash content, small in production internal gap, free of loosening, good in humidity resistance, capable of being stored for a long time and suitable for industrial production.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Gas water heater and method for removing noise of gas water heater

ActiveCN104819574AResolve Insufficient CombustionSolve the noiseFluid heatersFuel supply regulationFlameoutEngineering

The invention discloses a gas water heater and a method for removing noise of the gas water heater. In the ignition process, a rotary knob of an electronic ignition and gear adjusting gas valve is pressed down and twisted. Gas passes through an ion or pressure flameout protection gas valve, and then, the first path of gas passes through an ignition valve of the electronic ignition and gear adjusting gas valve, and is sprayed into an interlayer of double layers of honeycomb catalyst alloy meshes or foam alloy plates from an ignition nozzle so as to be ignited by an electronic pulse igniter; the second path of gas passes through a gear valve of the electronic ignition and gear adjusting gas valve, and is sprayed into a pre-mixing chamber from a gear adjusting gas nozzle; and the third path of gas passes through a water temperature adjusting gas valve, and is sprayed into the pre-mixing chamber from a water temperature adjusting gas nozzle. The gas penetrates the lower layer honeycomb catalyst alloy mesh or the lower foam alloy plate to be ignited by flames sprayed by the ignition nozzle. A semiconductor temperature difference power generation device is heated to generate voltage to drive an axial fan to rotate; and the first part of air blown by the axial fan enters the pre-mixing chamber, and the second part of air blown by the axial fan is blown to the interlayer of the double layers of honeycomb catalyst alloy meshes or foam alloy plates.

Owner:张英华

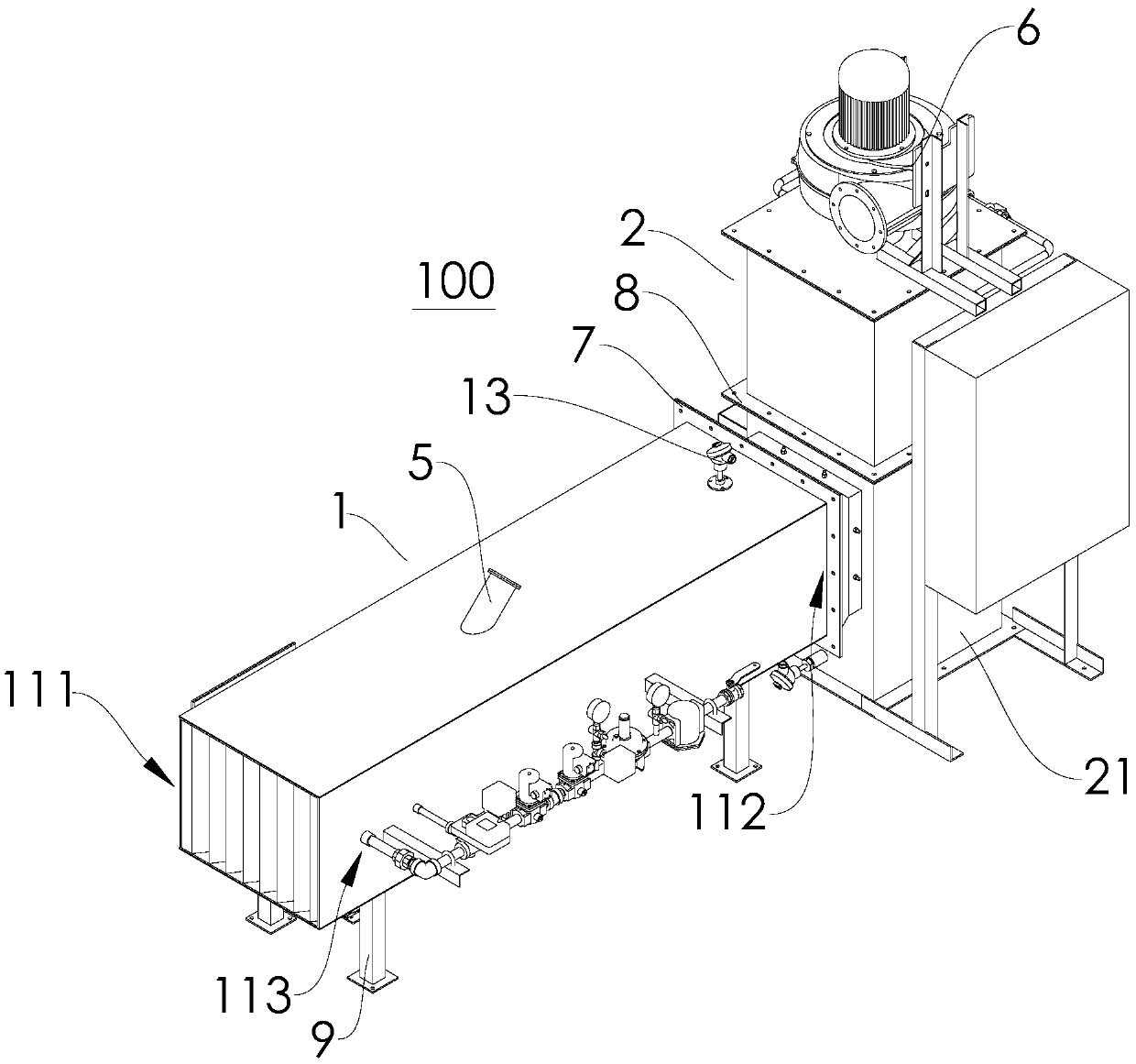

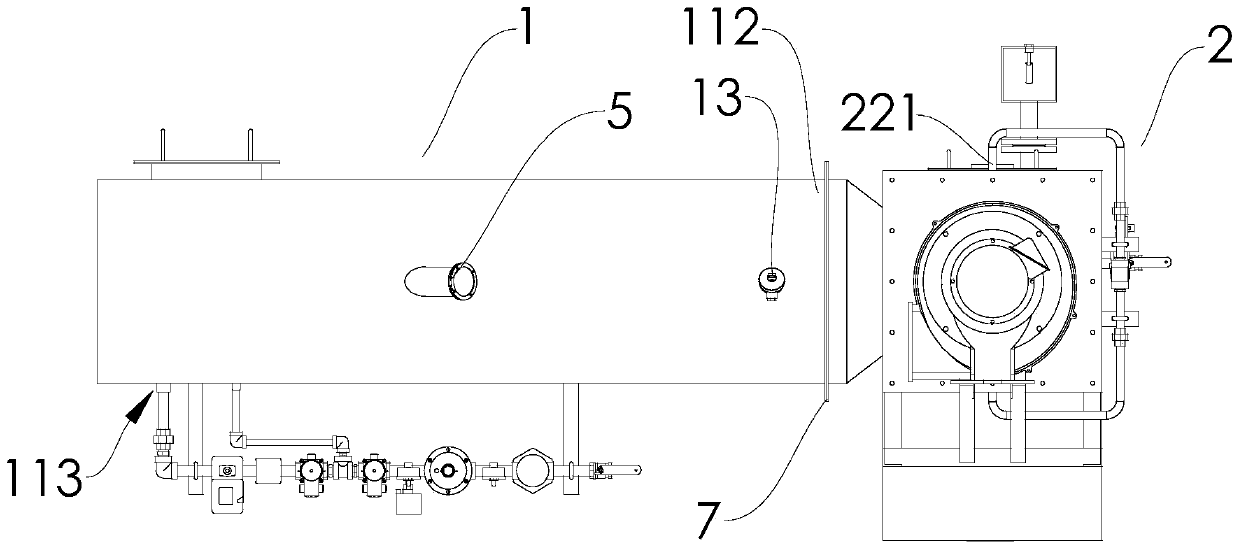

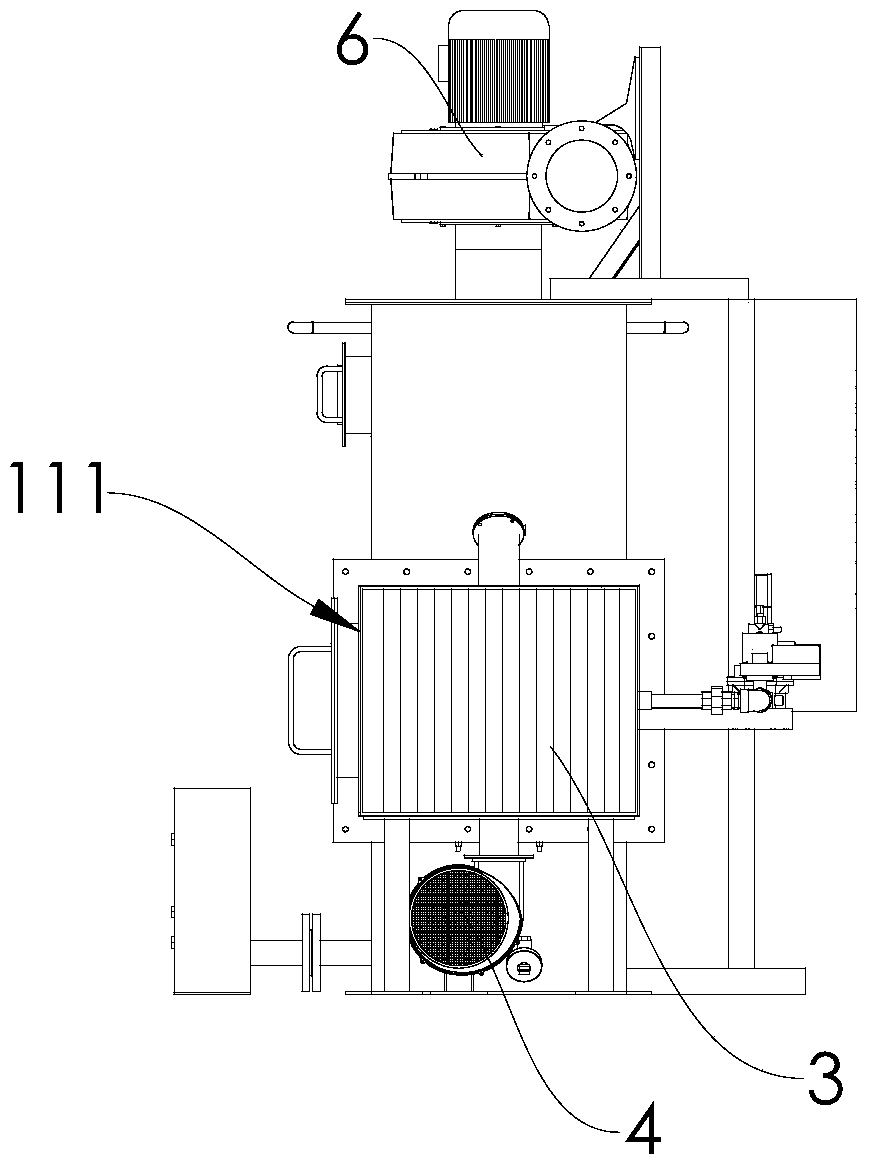

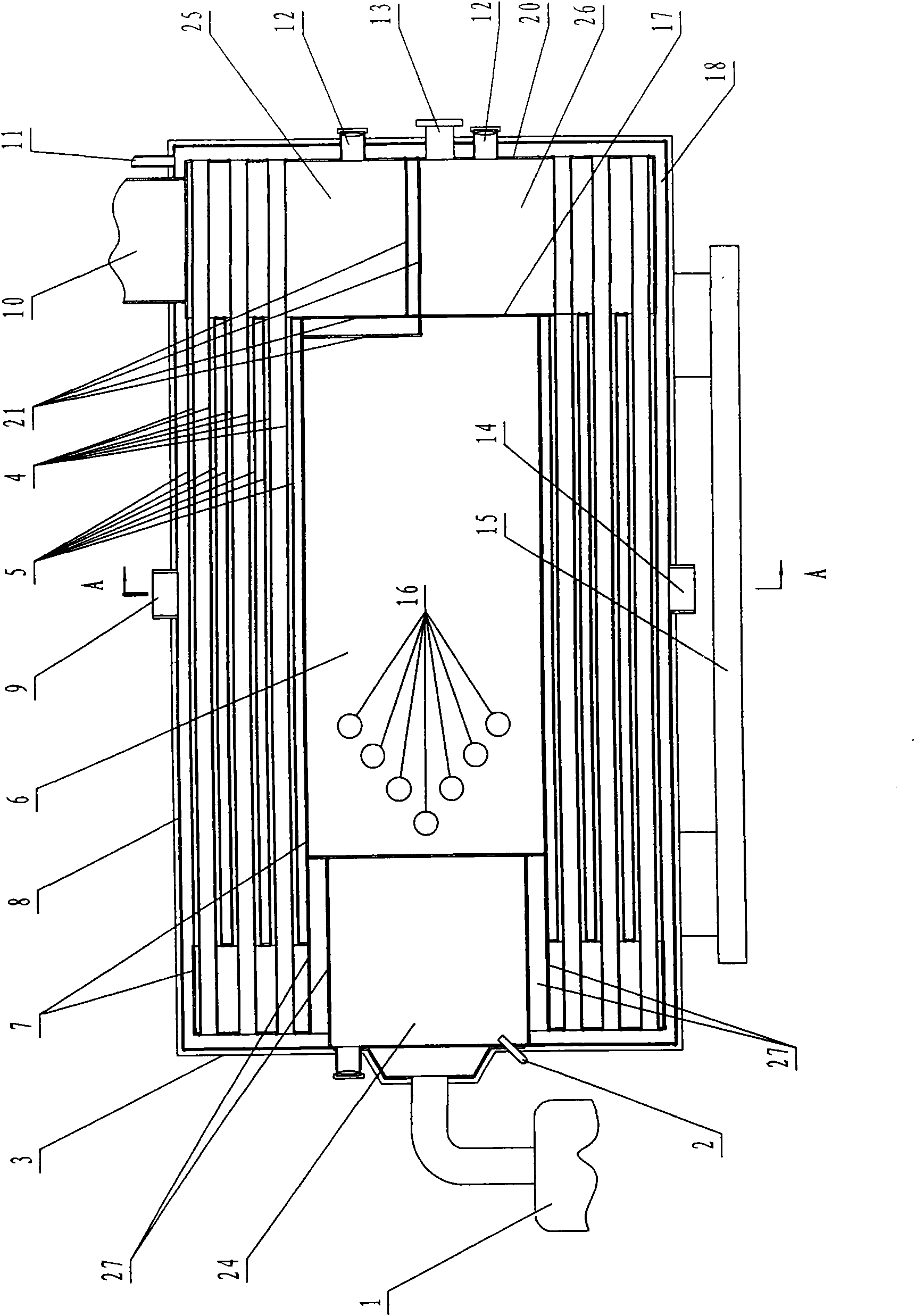

Incinerator device

PendingCN106989401ABurn fullyBurn completelyCombustion technology mitigationIncinerator apparatusCombustion chamberEngineering

The invention provides an incinerator device which comprises an incinerator unit and a smoke treatment unit. The incinerator unit comprises a rotary kiln and a secondary combustion chamber communicating with the rotary kiln. The amount of gas introduced into the rotary kiln is lower than a preset value. The amount of gas introduced into the secondary combustion chamber is higher than a preset value. The smoke treatment unit communicates with the incinerator unit to as to treat smoke in the incinerator unit. According to the technical scheme, the problem that in the prior art, hazardous waste cannot be decomposed thoroughly or combusted sufficiently is effectively solved.

Owner:CHINA ENFI ENGINEERING CORPORATION

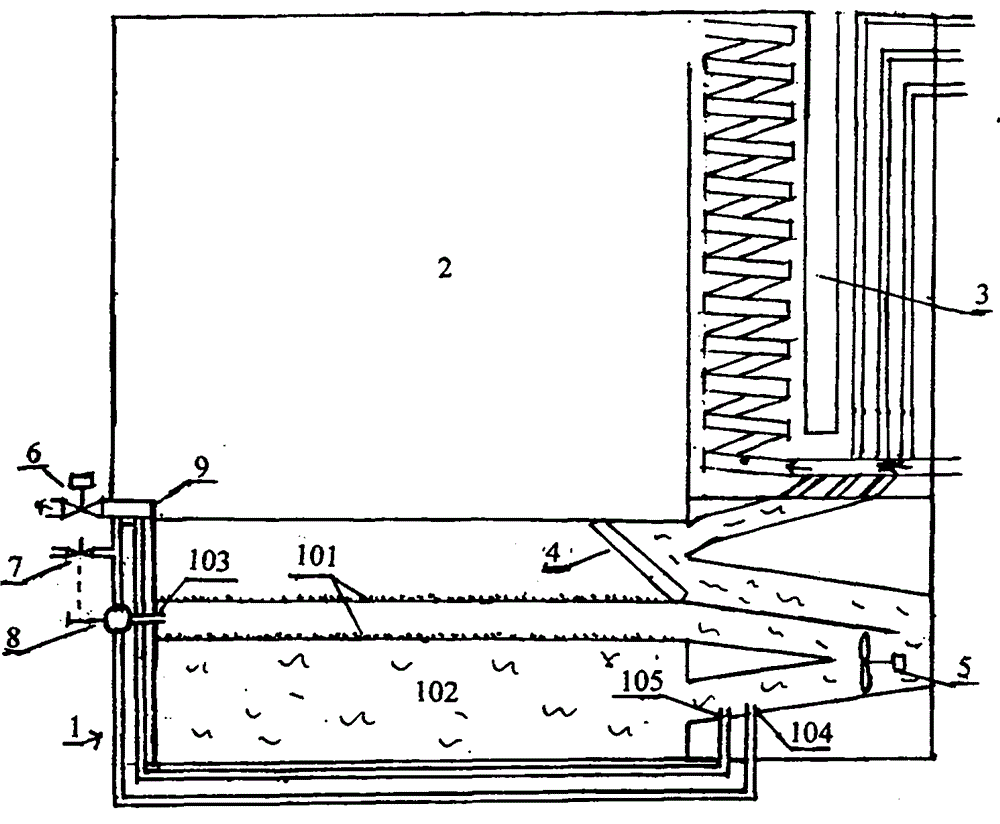

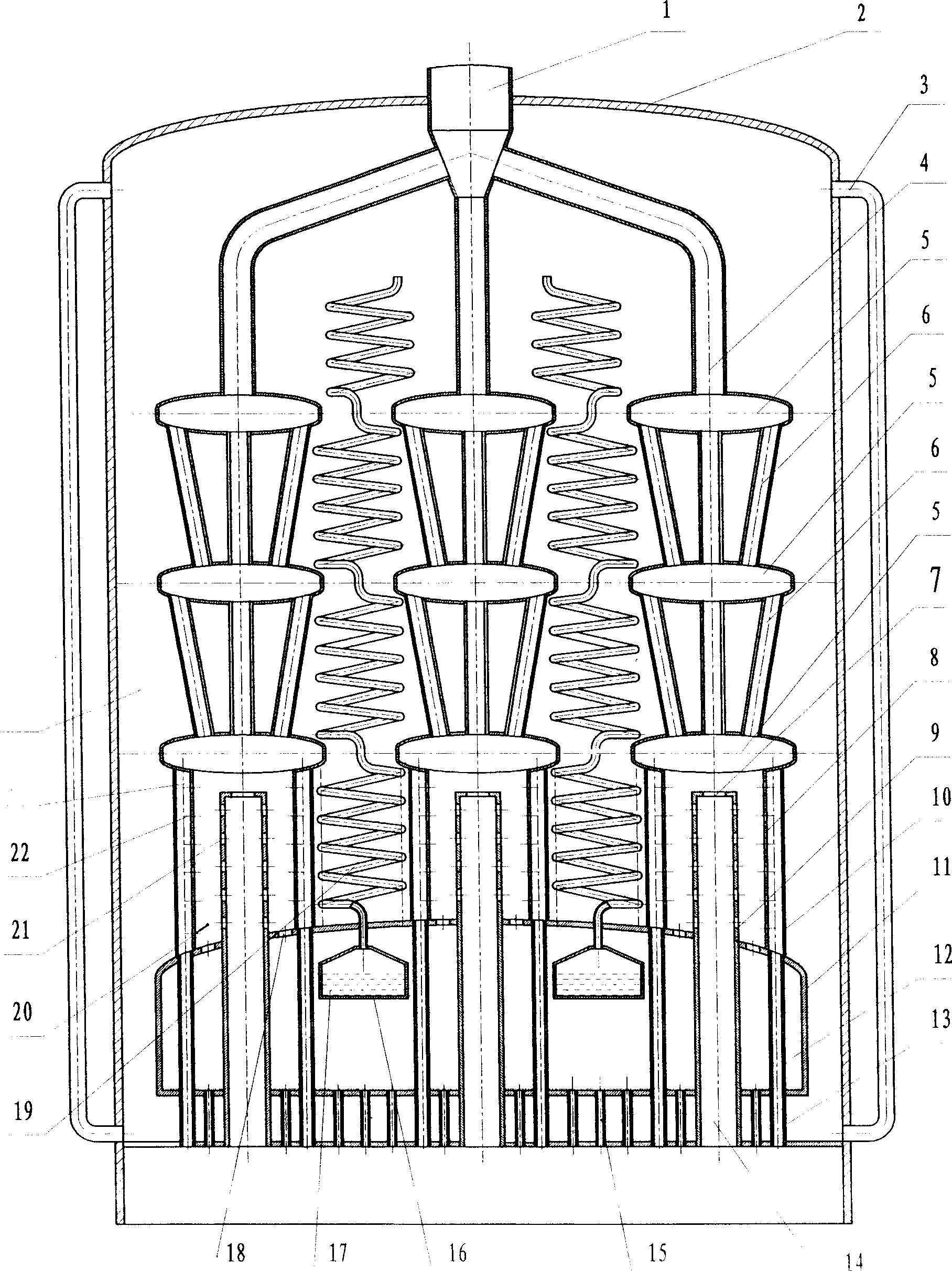

Energy-saving high-efficient gas normal-pressure boiler

InactiveCN101586874ASolve the large gas consumptionResolve Insufficient CombustionWater heatersThermal energyCombustion chamber

The present invention relates to a gas boiler, and particularly to an energy-saving high-efficient gas normal-pressure boiler. The energy-saving high-efficient gas normal-pressure boiler of the invention settles the problems of large gas consumption, insufficient burning, low thermal efficiency and inferior durability existing in the prior gas boiler. The energy-saving high-efficient gas normal-pressure boiler comprises the following components: a boiler housing, a fire tube, an inner container of a hearth, an outer container of the hearth, an inner face plate, the hearth surrounded by the inner container of the hearth, a water interlayer which is surrounded by the fire tube, the inner container of the hearth, the outer container of the hearth and the inner face plate, a first vortex combustion chamber and a second vortex combustion chamber that are respectively provided at the front end and the back end in the boiler housing. The fire tube is sleeved with a water tube with both ends communicated with the water interlayer. The two ends of the water tube are provided with the outer face plates which have edges fixed with the side wall of the inner container of the hearth and are used for supporting the water tube. The energy-saving high-efficient gas normal-pressure boiler of the invention reduces the gas consumption amount while increasing the usage factor of the heat energy of the fuel, and is a novel gas boiler which has the advantages of energy saving and environment protecting.

Owner:曲沃县秀水炉业有限公司

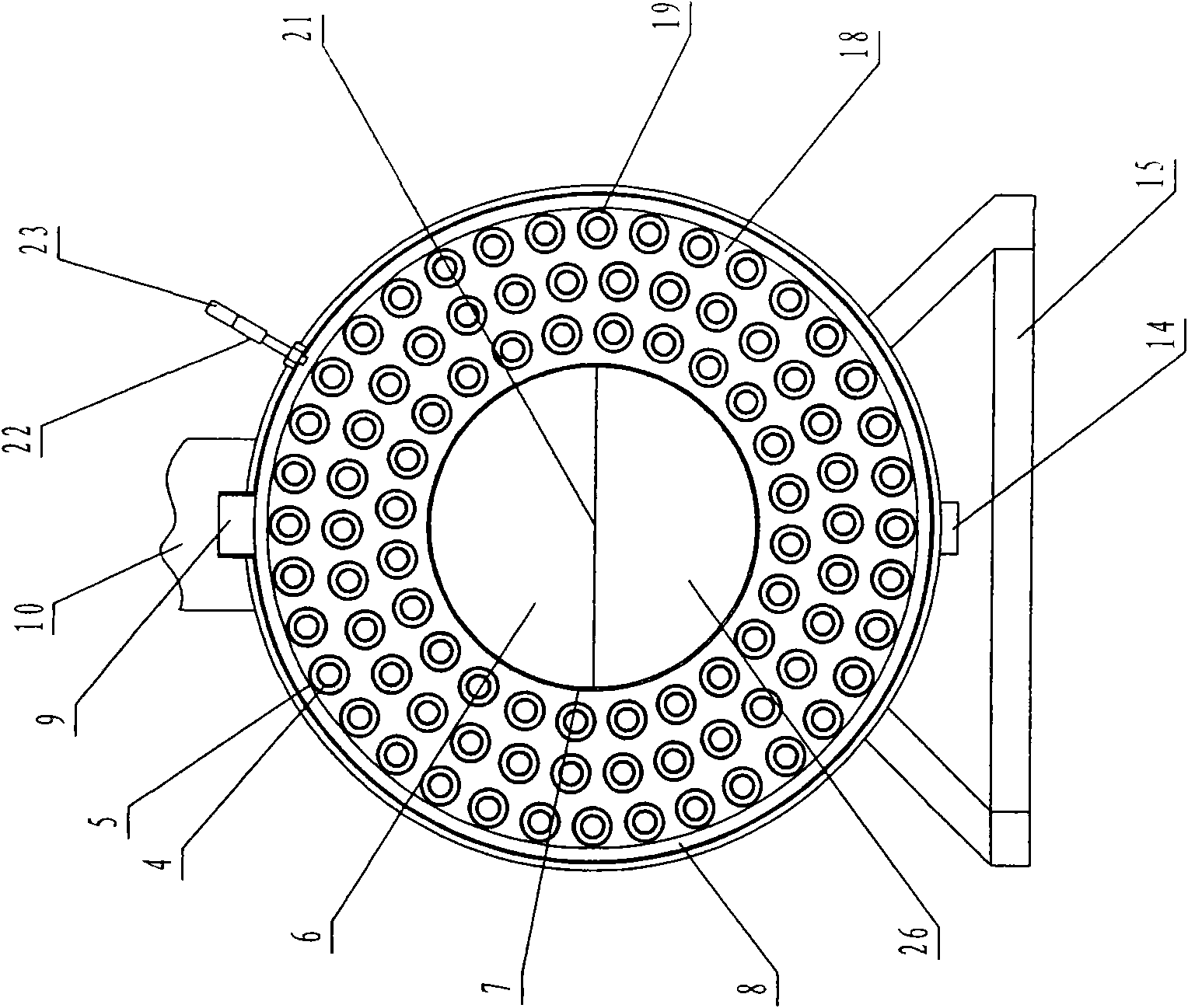

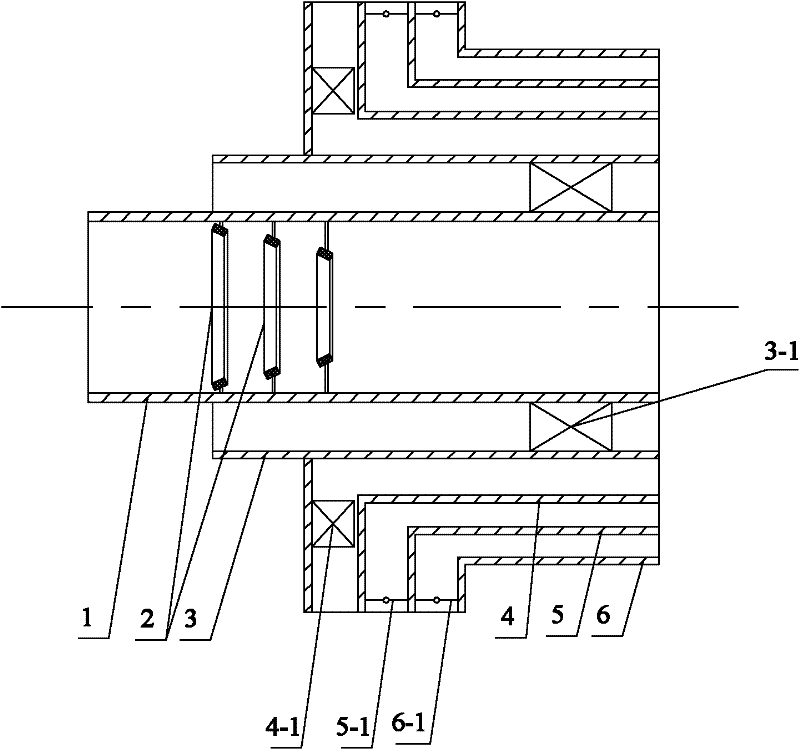

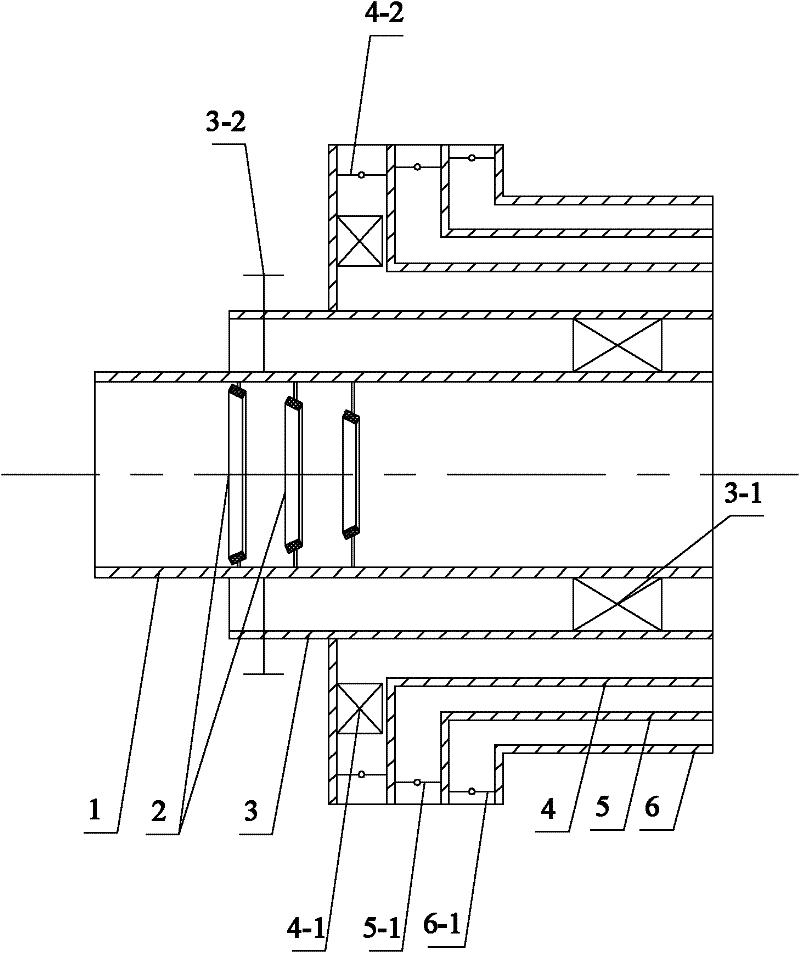

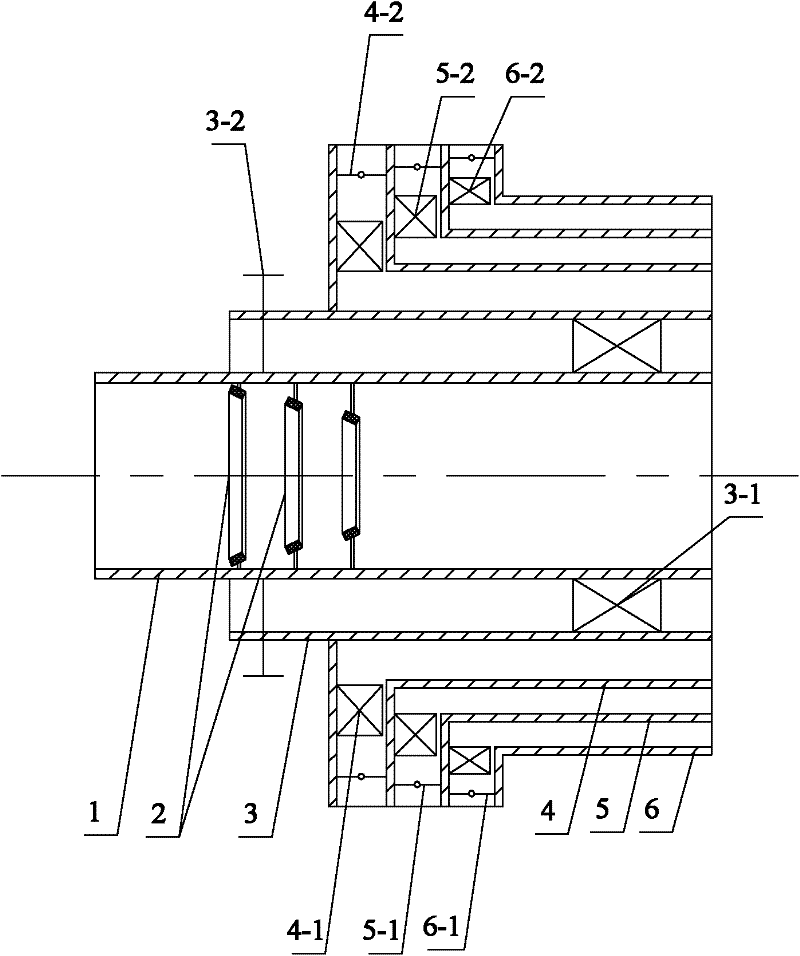

Multichannel rotational flow coal burner

InactiveCN102269404AReduce adverse effectsReduce the impactPulverulent fuel combustion burnersCombustionRotational flow

The invention discloses to a multichannel rotational flow coal burner and relates to a rotational flow coal burner, and the multichannel rotational flow coal burner is used for solving the problems that the coal dust flame of the existing rotational flow coal burner has bad stability, and the burning is insufficiency and the perfect diffusion airflow exists. The burner provided by the invention is characterized in that one end of a primary air pipeline is arranged in a secondary air first pipeline, and the secondary air first pipeline is arranged in a secondary air second pipeline; the secondary air second pipeline is arranged in a secondary air third pipeline, and the secondary air third pipeline is arranged in a secondary air regulating pipeline; a first swirler is arranged in the secondary air first pipeline, and a second swirler is arranged in the secondary air second pipeline; and the ventilation door of the secondary air third pipeline is arranged in the secondary air third pipeline, and the ventilation door of the secondary air regulating pipeline is arranged in the secondary air regulating pipeline. The rotational flow coal burner provided by the invention is used for boiler combustion.

Owner:HARBIN INST OF TECH

Device and method for smoking cigarettes

The invention relates to an electronic device and method for directly igniting and smoking common marketing cigarettes. The device comprises a combustion pipe, at least three arc generation components, a power component and a control component, the arc generation components are mutually and axially arranged on the combustion pipe at intervals, and the control component can successively drive the all arc generation components to ignite the cigarettes. The smoking method includes the steps: inserting a cigarette into the combustion pipe, driving the arc generation component at the most front endto ignite the cigarette, smoking first cigarette by matching with an aspiratory action, and immediately extinguishing the cigarette; when preset conditions are met, igniting the cigarette by an adjacent arc generation component by a control device; cycling the steps until the cigarette is completely smoked. According to the device and the method, the cigarette in the combustion pipe is relativelyand accurately ignited by a sectioning fixed ignition mode, the characteristic that an electric arc moves along the direction of air flow is skillfully used, and the overall cigarette is smoked by matching with aspiratory action of a smoker.

Owner:深圳维昔技术有限公司

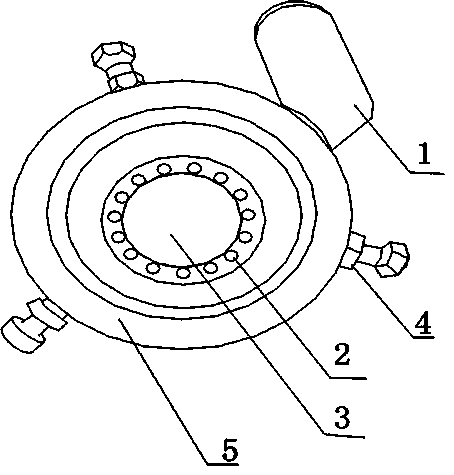

Array type gas inlet mixing valve

InactiveCN104179598AResolve Insufficient CombustionSolve the costInternal combustion piston enginesFuel supply apparatusCombustionCompressed natural gas

The invention discloses an array type gas inlet mixing valve, mainly comprising an air inlet, a CNG (Compressed Natural Gas) inlet pipe, CNG dispersing openings, a circular valve body and installation bolts, wherein the air inlet and the CNG inlet pipe are respectively arranged on the circular valve body; the CNG dispersing openings are in array type circular arrangement on the air inlet; the installation bolts are arranged on the external surface of the circular valve body. According to the array type gas inlet mixing valve, the circular valve body is fixedly arranged on an air inlet valve of an engine; natural gas of which the pressure is reduced enters the circular valve body through the CNG inlet pipe, is uniformly dispersed through the CNG dispersing openings in array type circular distribution in the air inlet, and is fully mixed with air passing through the air inlet; therefore an about 12:1 (standard state) mass ratio of the air to the natural gas is realized, i.e. a best combustion effect is realized; the problems of insufficient fuel combustion and not high reliability are solved; the mixing valve is simple in structure and easy to dismantle; the manufacturing cost of the mixing valve is lowered greatly.

Owner:CHENGDU DUJIA ELECTRICAL

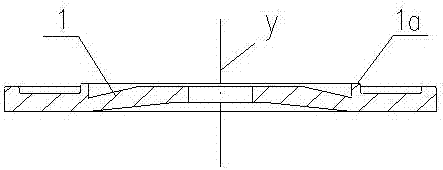

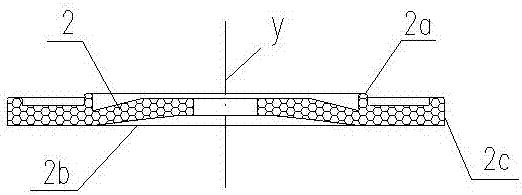

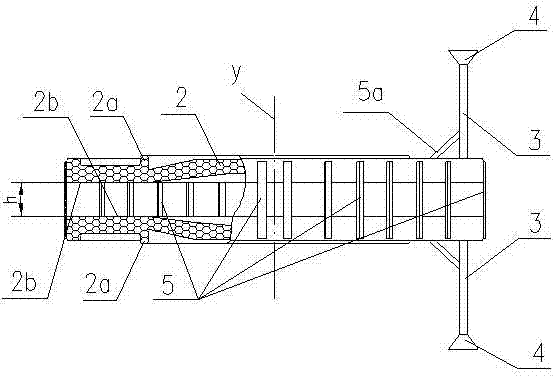

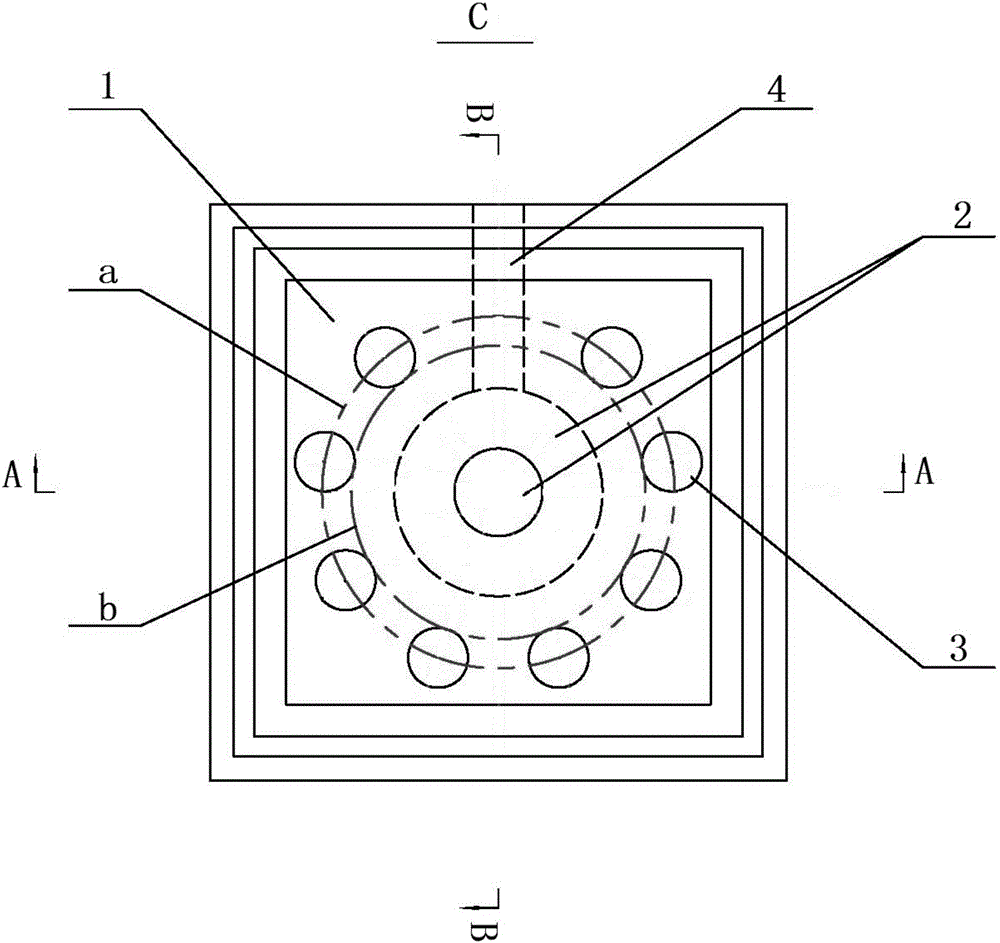

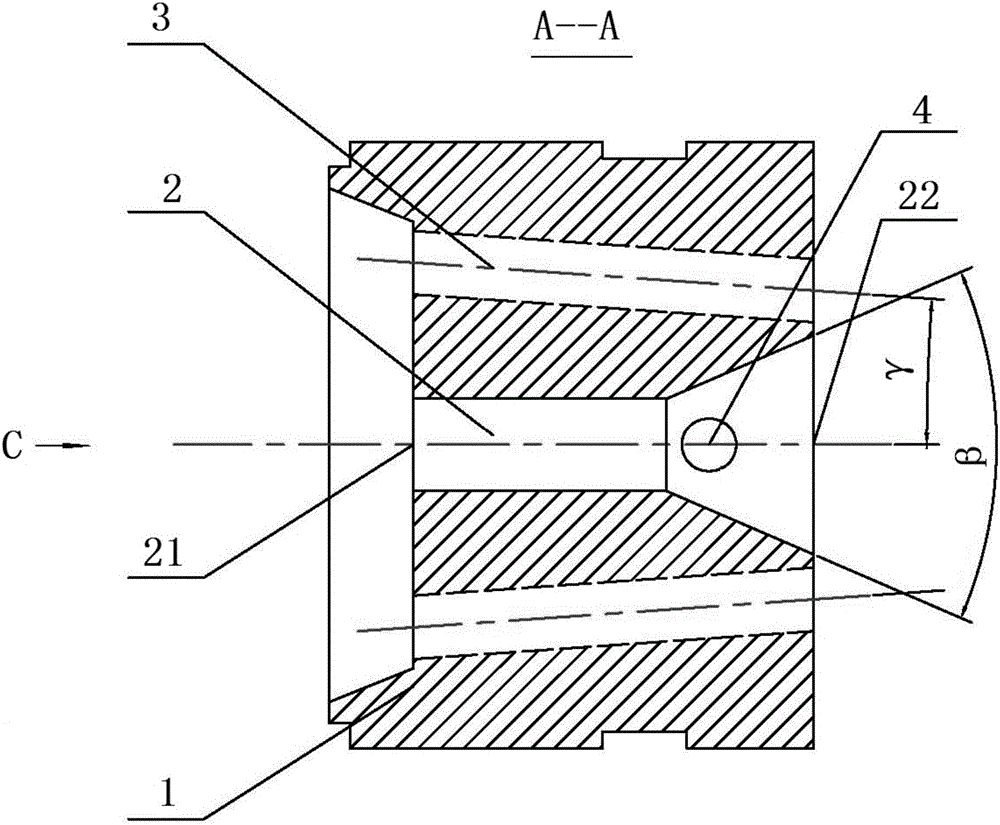

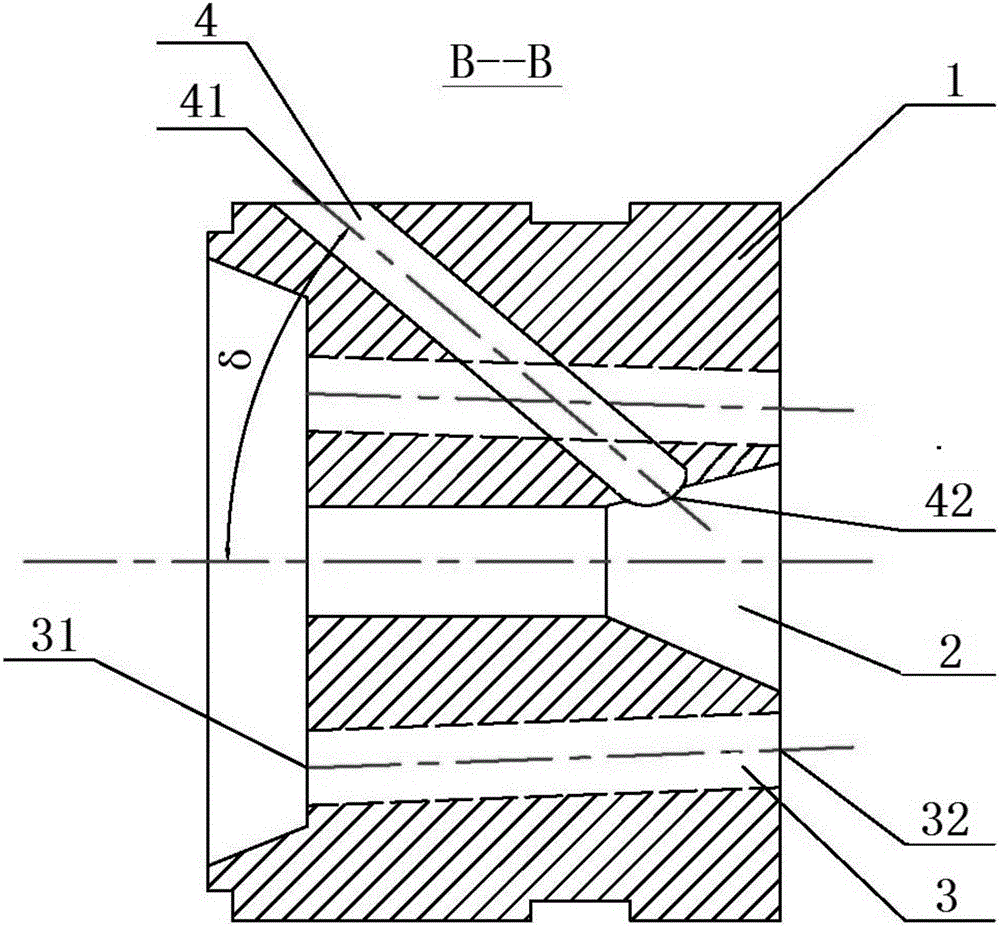

Nozzle and manufacturing method thereof

ActiveCN105889930AIncrease contact areaResolve Insufficient CombustionIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringGas burner

The invention discloses a nozzle and a manufacturing method thereof and belongs to the technical field of premixed gas burners. The nozzle comprises a primary air channel, secondary air channels and a natural gas channel which are located inside a nozzle body, the primary air channel comprises a uniform-section channel section and a gradually-wide channel section in sequence from a primary air inlet to a primary air outlet, three or more secondary air channels are distributed around the primary air channel, and a natural gas outlet of the natural gas channel is communicated with the gradually-wide channel section; the included angle delta between the natural gas channel and the central axis of the uniform-section channel section is greater than or equal to 30 degrees and less than or equal to 50 degrees; the included angle beta between two side edges on the axial cross section of the gradually-wide channel section is greater than or equal to 34 degrees and less than or equal to 60 degrees; the included angle gamma between each secondary air channel and the central axis of the uniform-section channel section is greater than or equal to 0 degree and less than or equal to 10 degrees. The nozzle is good in comprehensive combustion performance and used for gas combustion.

Owner:MAANSHAN TIANZHOU ENERGY SAVING ENG TECH

After-combustion type low consumption high efficiency smokeless green boiler

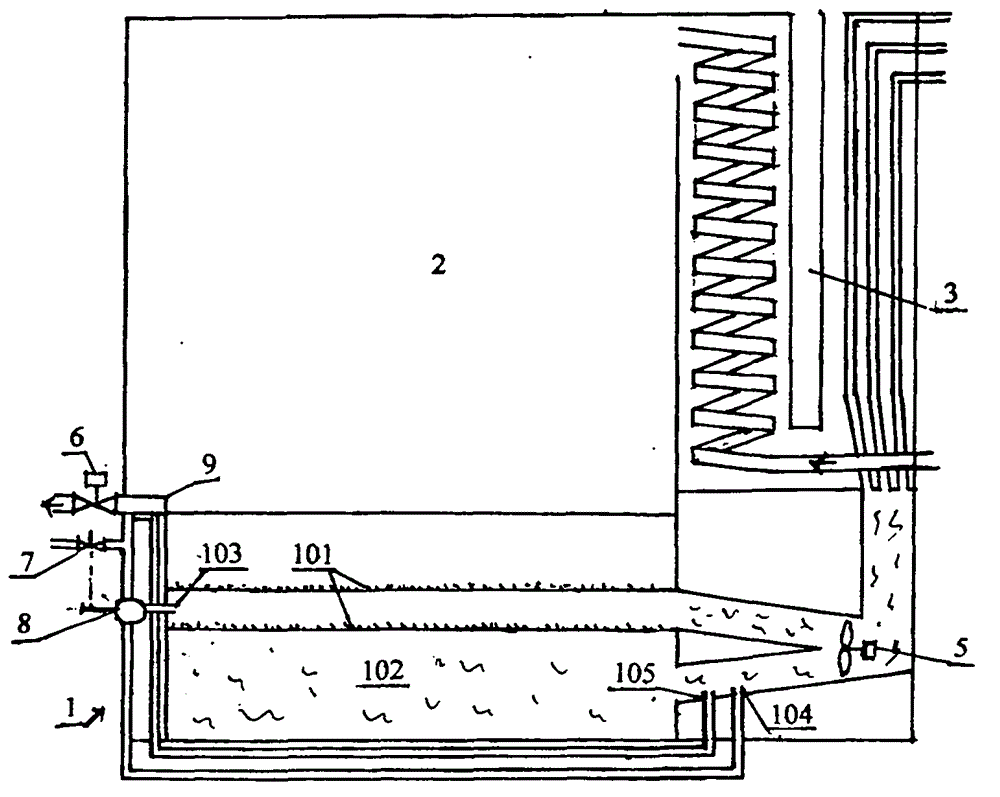

InactiveCN1409072AResolve Insufficient CombustionSolve air pollutionStorage heatersCombustion chamberEngineering

In the after-combustion type boiler with low power consumption, high efficiency and no smoke, the combustion chamber has air pipe connected to atmosphere in the bottom to "suspend" it in the boiler barrel, burning port in the top communicated to a re-combustion chamber and at least one heat conducting medium box; and the re-combustion chamber has one heated device on the upper part. The present invention has simple structure and high heat efficiency, and its re-combustion chamber produces secondary combustion to make the boiler possess complete combustion, no smoke, no environmental pollutionand no need of chimney.

Owner:牟玉昌 +1

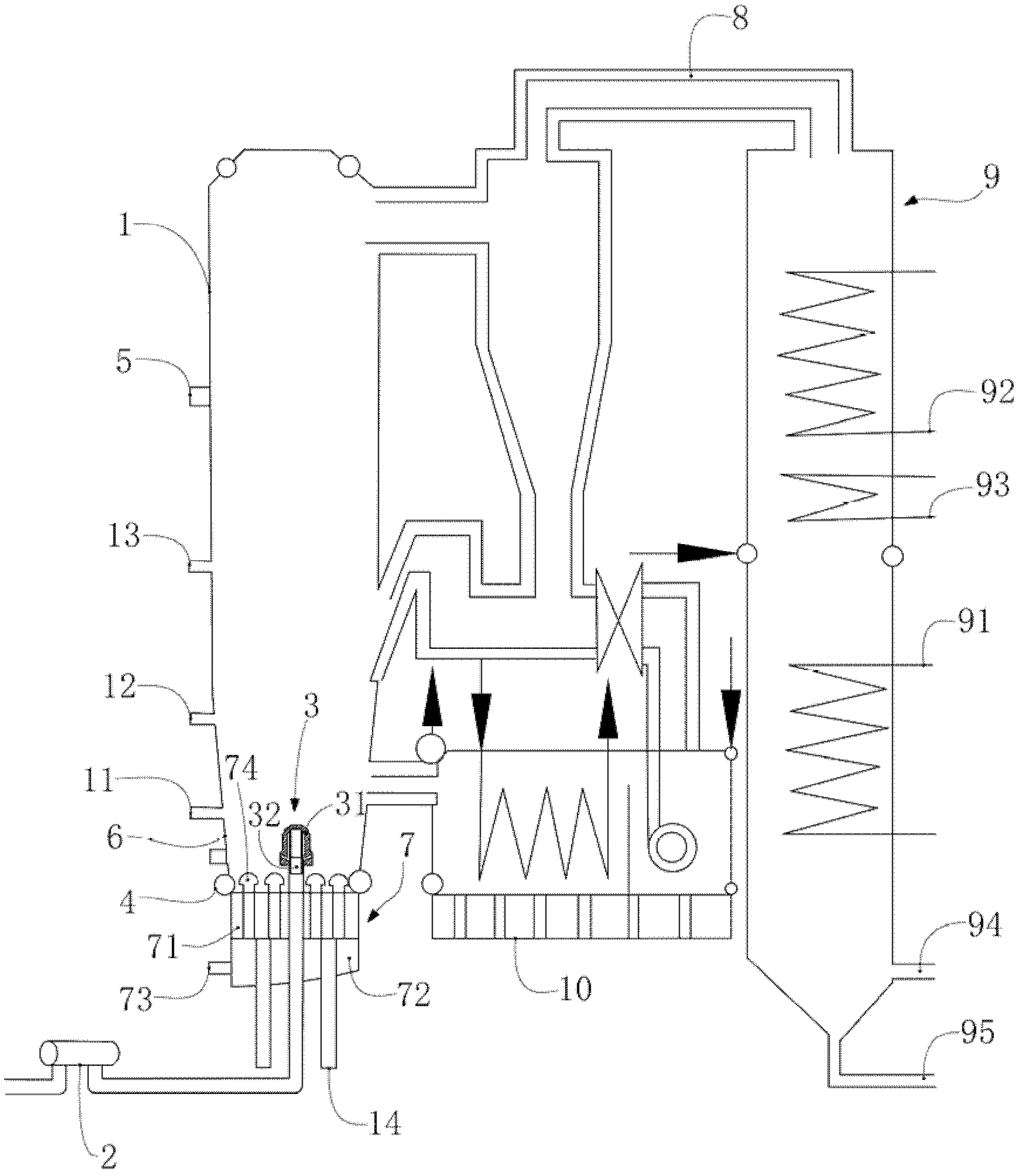

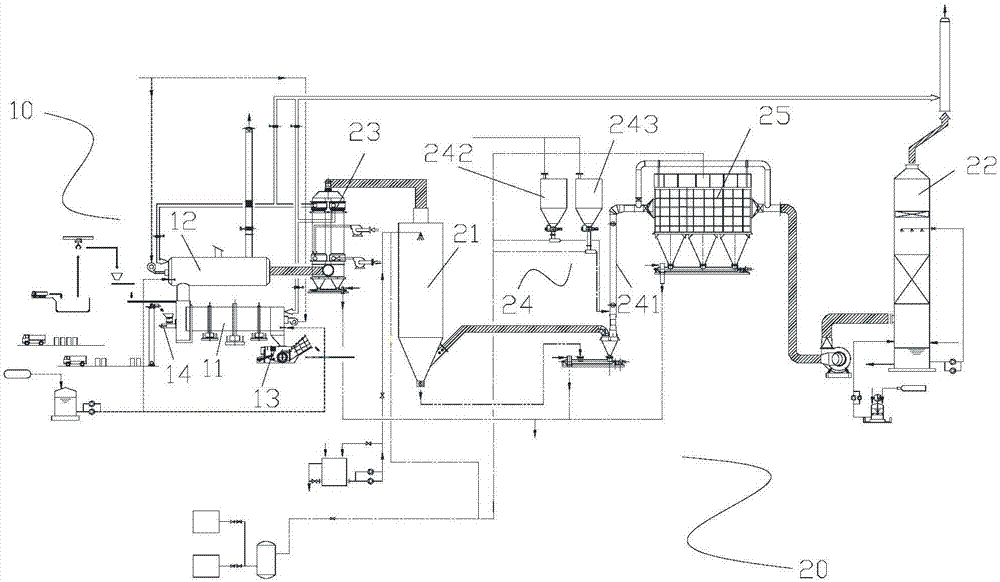

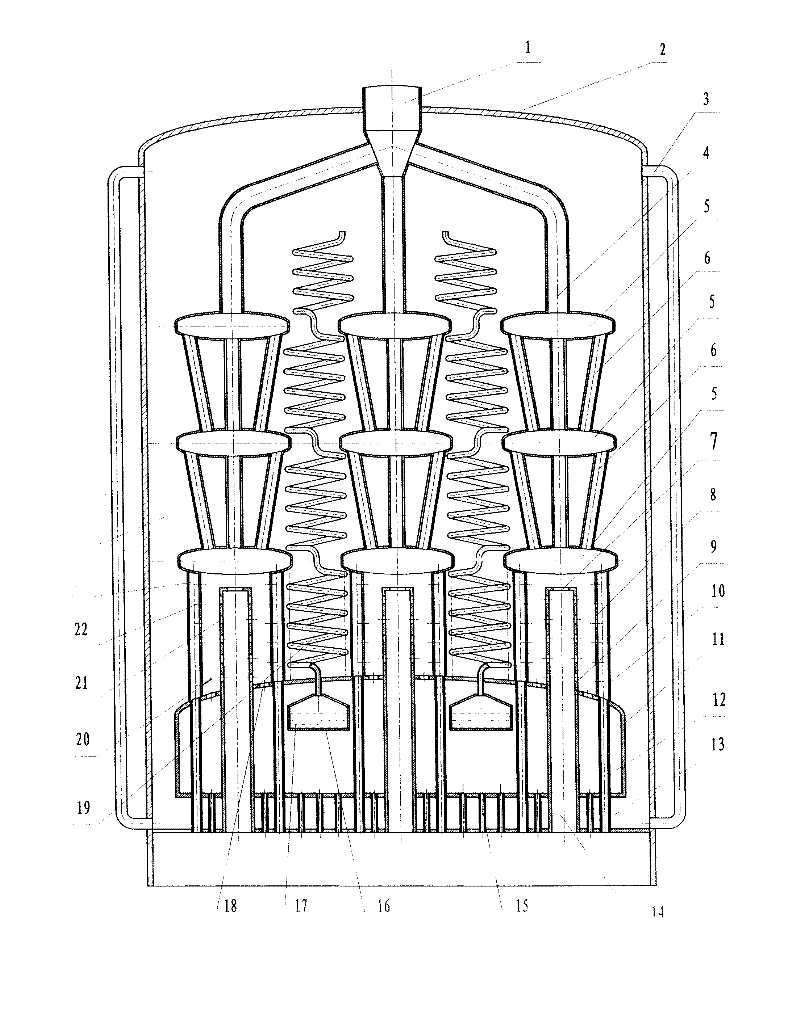

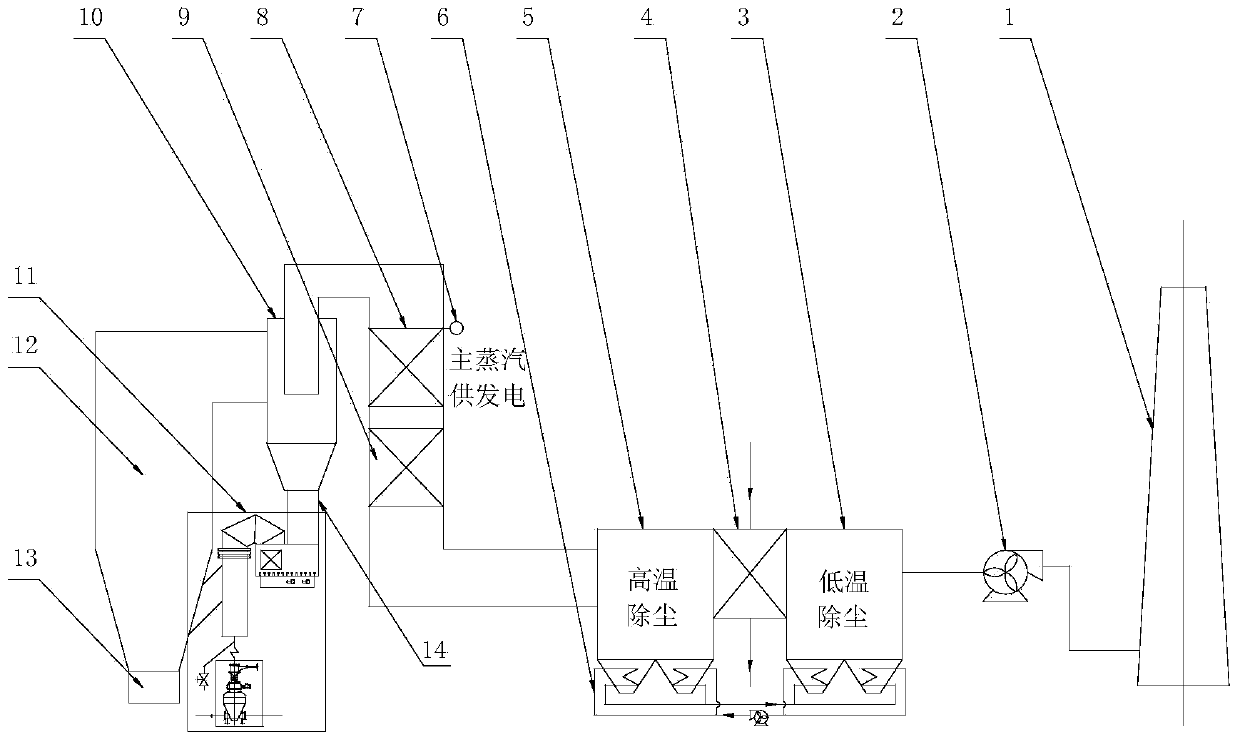

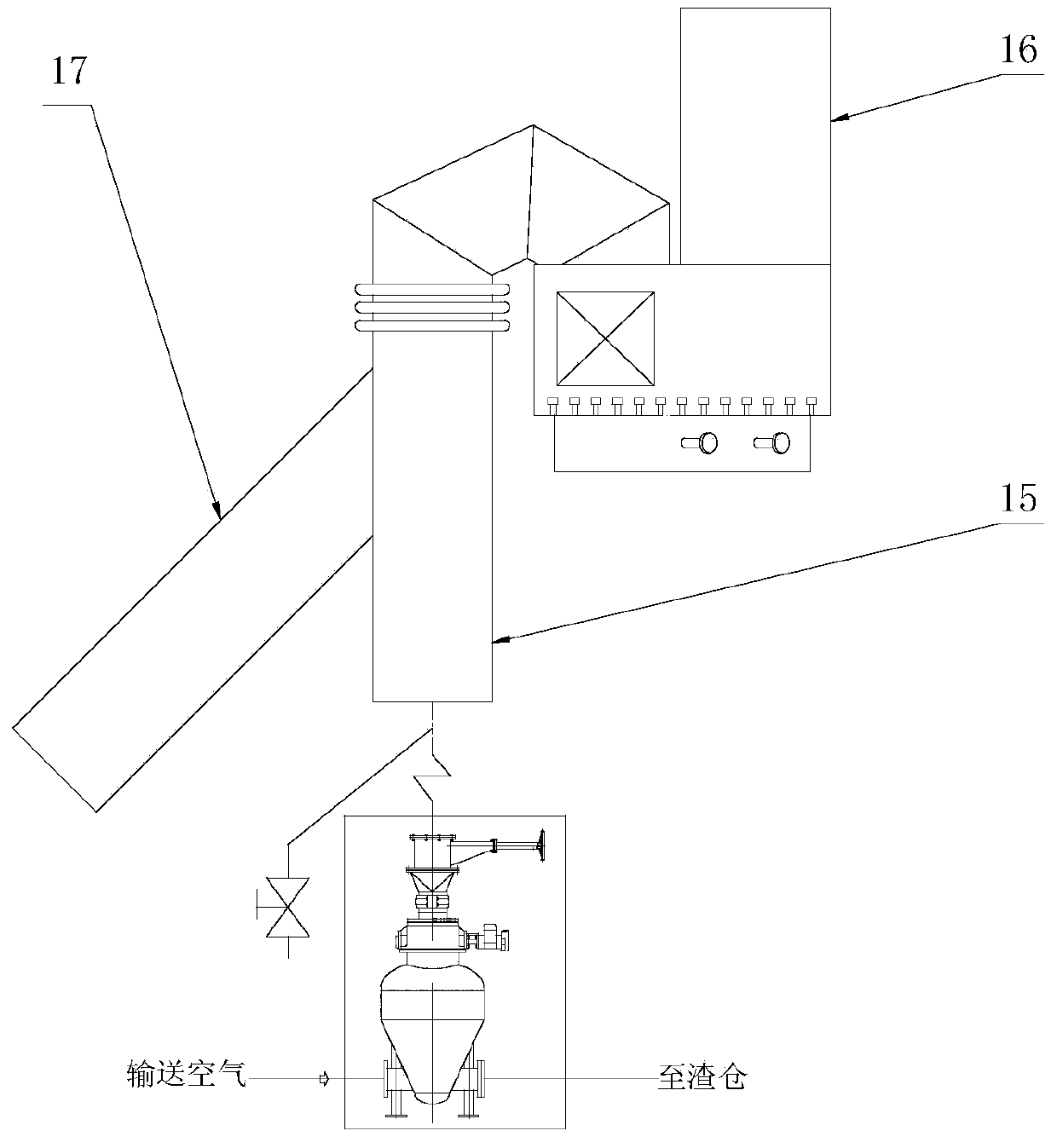

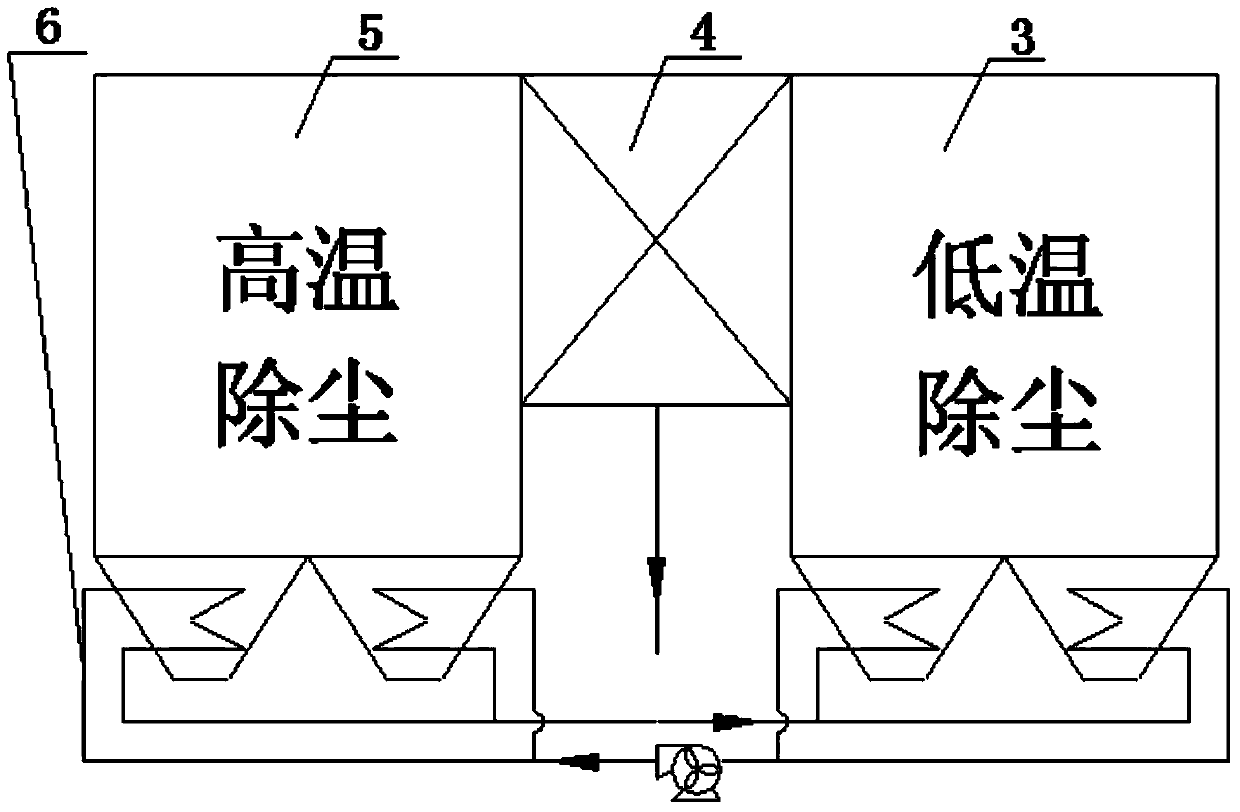

Stone coal power generation selenium extraction comprehensive utilization system and method

InactiveCN104214770ASolve the problem of low bed temperatureResolve Insufficient CombustionFluidized bed combustionSteam boilersFlueSuperheater

Disclosed are a stone coal power generation selenium extraction comprehensive utilization system and method. The system comprises a fluidized bed boiler, a superheater, an economizer, high-temperature dust removing equipment and low-temperature dust removing equipment. The superheater and the economizer are sequentially arranged in a tail flue of the fluidized bed boiler, the high-temperature dust removing equipment and the low-temperature dust removing equipment are sequentially arranged on different temperature area segments of an outlet of the tail flue of the boiler, and the fluidized bed boiler comprises a combustion chamber, a separator communicated with the top of the combustion chamber and a circulating dust discharging controller communicated with the separator and the combustion chamber. A controller dust inlet pipe on the top of the circulating dust discharging controller and a material returning device stand pipe at the bottom of the separator are used in common, or one branch is led out of the material returning device stand pipe. A material returning inclined pipe and a low-temperature dust discharging pipe are arranged on an outlet of the circulating dust discharging controller, the material returning inclined pipe is communicated with a combustion chamber dense-phase area, an outlet of the low-temperature dust discharging pipe is divided into two paths, one path is connected with a circulating dust conveying system, and the other path performs direct discharging. The stone coal power generation selenium extraction comprehensive utilization method of the system is provided. The method and system have the advantages of being low in energy consumption, high in selenium extraction efficiency, simple in system, small in selenium extraction investment scale, low in selenium escape rate, low in equipment investment and the like.

Owner:HUANENG CLEAN ENERGY RES INST

Multistage hydraulic jet engine for military use

InactiveCN102877983AHigh power compression forceSolve supply problemsJet type power plantsGas turbine plantsCombustion chamberJet engine

The invention discloses a multistage hydraulic jet engine for military use. A boosting tank is installed at an air inlet of an engine; through a compression tank, air can be compressed automatically by high pressure and a force arm during the high-speed flying in order to store air and obtain multiple air inlet volumes within a short time; a compression air expansion chamber is added in front of an engine combustion chamber and used as an expansion cabin of the compression air; the temperature of the engine is reduced by using the gas expansion and heat-absorption; meanwhile, secondary expansion is performed on the air; and finally, the high-speed expanded and exposed air is introduced to the combustion chamber in order to obtain more air in the space within a unit time for burning and exploding more fuels. With the adoption of the method, a certain flying speed is increased when a warplane achieves the highest speed in order to fight and avoid the incoming missiles; and an outer-hanging hydraulic air tank can be used as an assistant flying tool to help the warplane to realize the lifting and landing abilities at a short distance.

Owner:郑有志

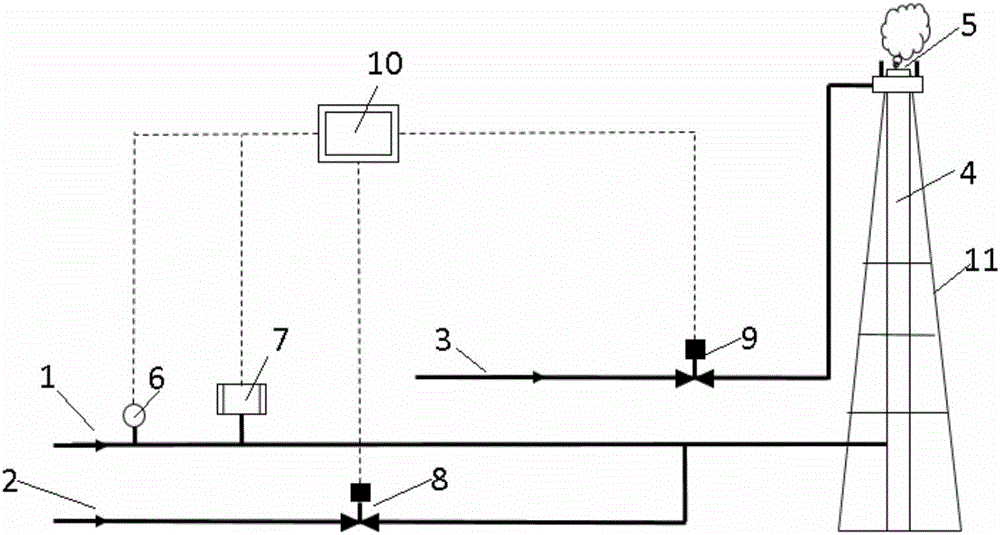

Torch burning efficiency control device

InactiveCN105841187AAccurate control of combustion efficiencyImprove combustion efficiencyFuel supply regulationIncinerator apparatusCombustorControl system

The invention relates to a torch burning efficiency control device. The torch burning efficiency control device comprises a torch discharging pipeline, wherein the torch discharging pipeline is connected with a flow meter, a gas component analyzing device and a torch cylinder separately; the flow meter and the gas component analyzing device are connected with a control system; the control system is connected with a steam pipeline via a steam pipeline control valve; the steam pipeline is connected with a torch burner; a fuel gas supplementing pipeline is connected with the control system and the torch discharging pipeline separately via a fuel gas supplementing pipeline control valve; the torch burner is arranged on the torch cylinder. The torch burning efficiency control device is capable of accurately controlling the torch gas burning efficiency, improving the torch burning efficiency and ensuring that the torch gas is burned safely, and is of important significance to the safe and environment-friendly operation of refinery plants.

Owner:CHINA PETROLEUM & CHEM CORP +1

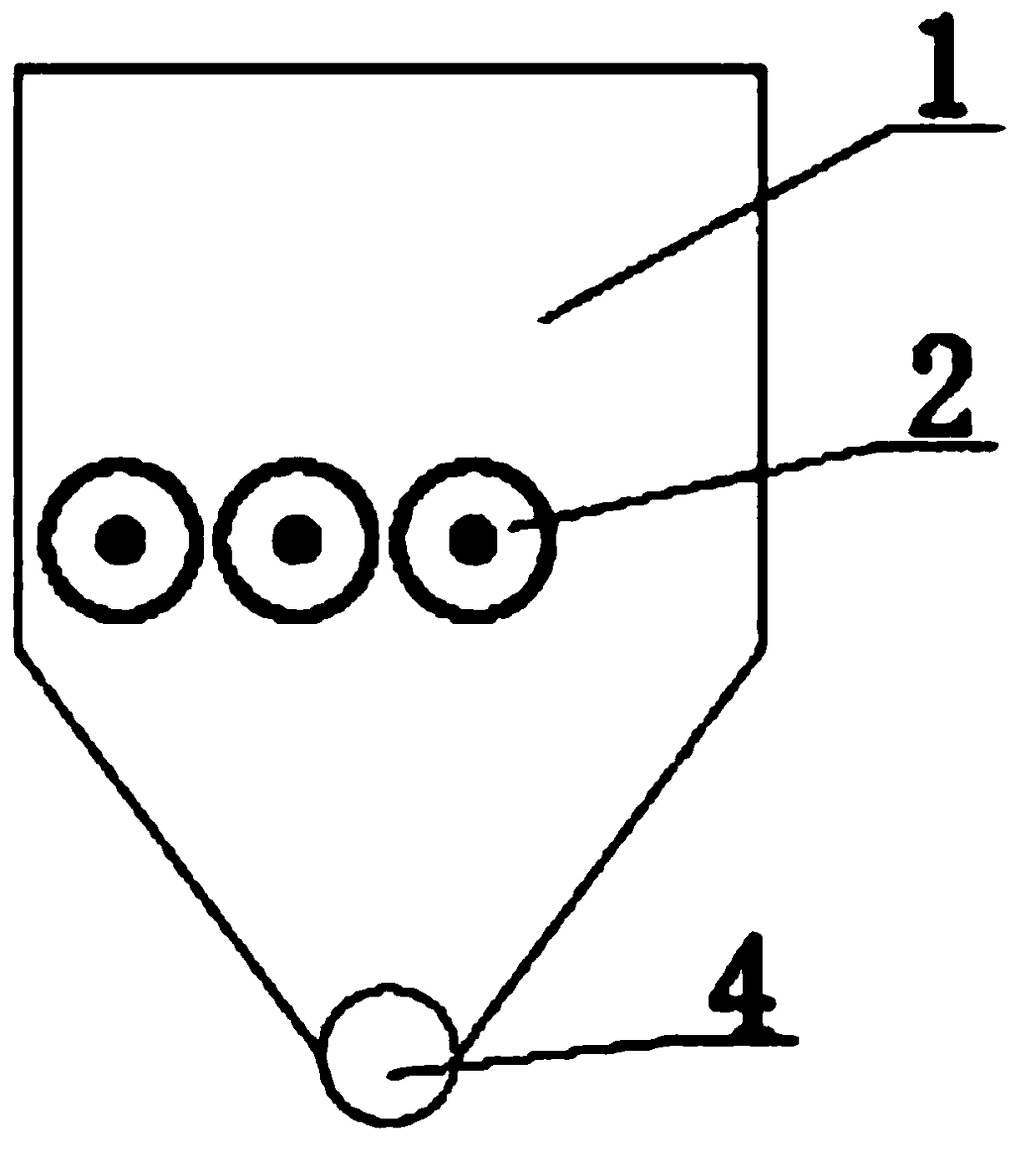

Roller rotating and driving slag removal hearth

PendingCN108870376ASolve the problem that the hearth is too largeImprove combustion efficiencySolid fuel combustionNon-combustible gases/liquids supplySlagBiomass boiler

The invention relates to a roller rotating and driving slag removal hearth, which can be used for fully automatically discharging slag generated when a biomass boiler burns out of the boiler. According to the roller rotating and driving slag removal hearth, one or multiple circular rollers are arranged in a square box body of the hearth, and the circular rollers are driven to rotate by a motor, sothat slag generated when biomass fuel burns can be automatically discharged out of the hearth and then can be discharged out of the boiler by virtue of an automatic slag extractor at the bottom of the hearth, and the full-automatic discharge of the slag is realized. Air channels are formed in three directions including the left side, the right side and the back side of the square box body of thehearth so as to perform secondary air distribution on the fuel in the hearth, air channel holes are formed in the rotary rollers, bellows are arranged on the lower ends of the air channel holes, air in the bellows is upward so as to perform primary air distribution on the biomass fuel during burning, and additionally, residual ash in the air channel holes in the rollers can be blown off.

Owner:正圆合(长春)生物质科技有限公司

High-efficiency biomass solid pellet fuel

The invention discloses a high-efficiency biomass solid pellet fuel. The high-efficiency biomass solid pellet fuel is prepared from corncobs, magnesium oxide, calcium carbide slag, starch, lanthanum oxide, petroleum resin and polyurethane asphalt according to a weight ratio of 100:5-10:5-8:6-10:3-5:5-8:4-6 through crushing, molding and drying processes. The calorific value of the prepared biomass solid pellet fuel product is 24-28MJ / kg, the ash content of the product is 2.5-4.0%, the water absorption rate of the product is 8-10%, and all performances of the product are better than those of current commercial products. A preparation method of the biomass solid pellet fuel has the advantages of simple process, low energy consumption, low production efficiency, high molding rate and low cost.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

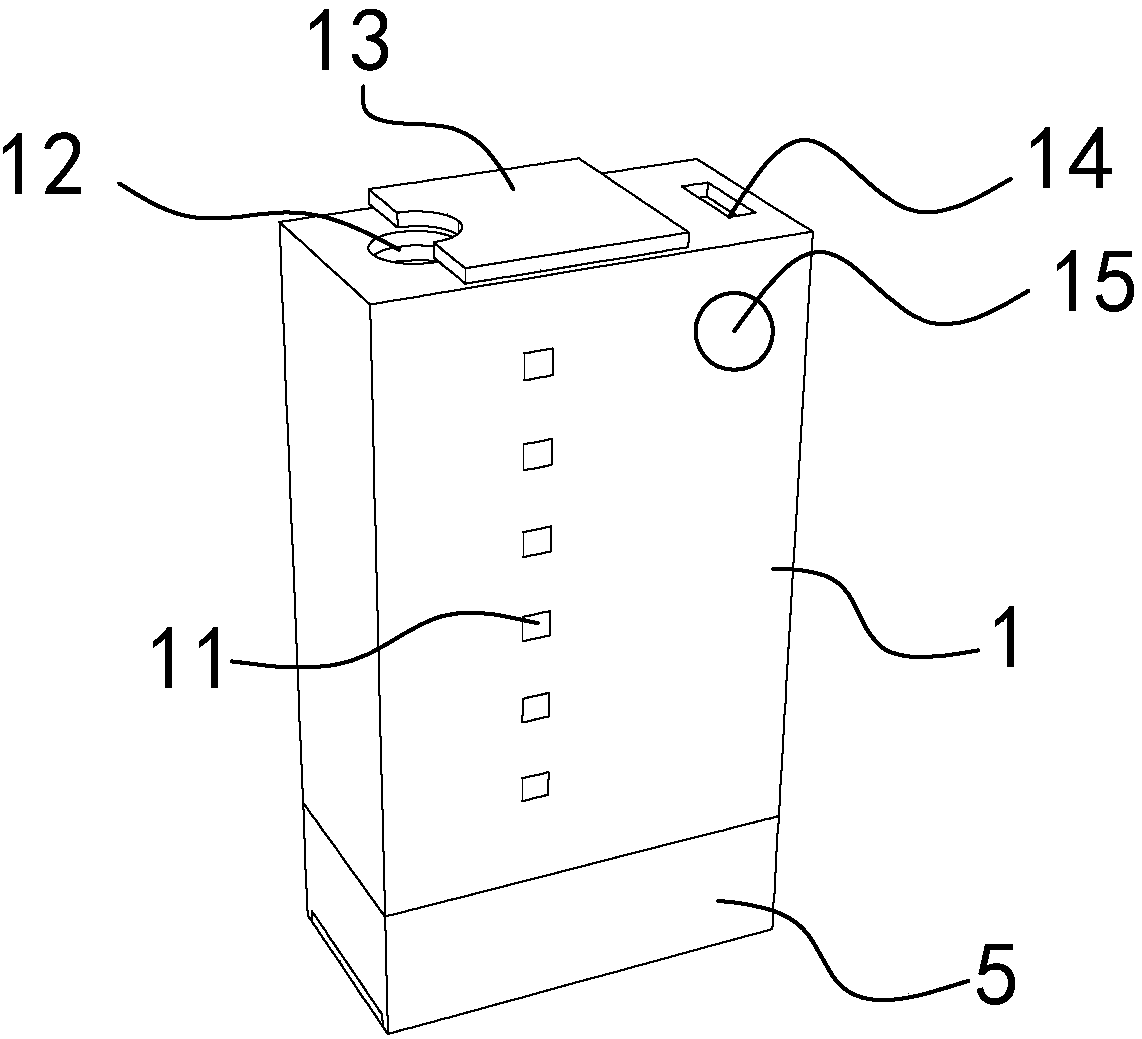

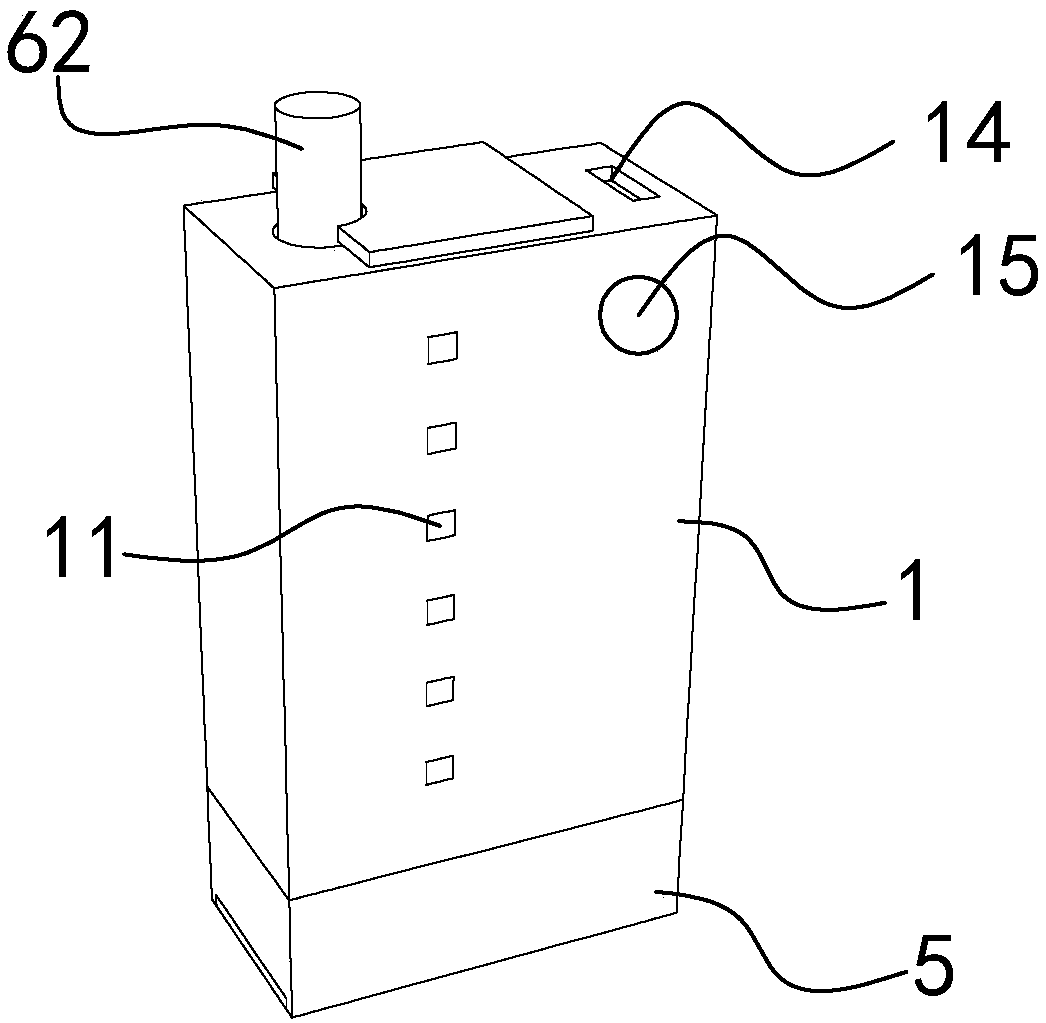

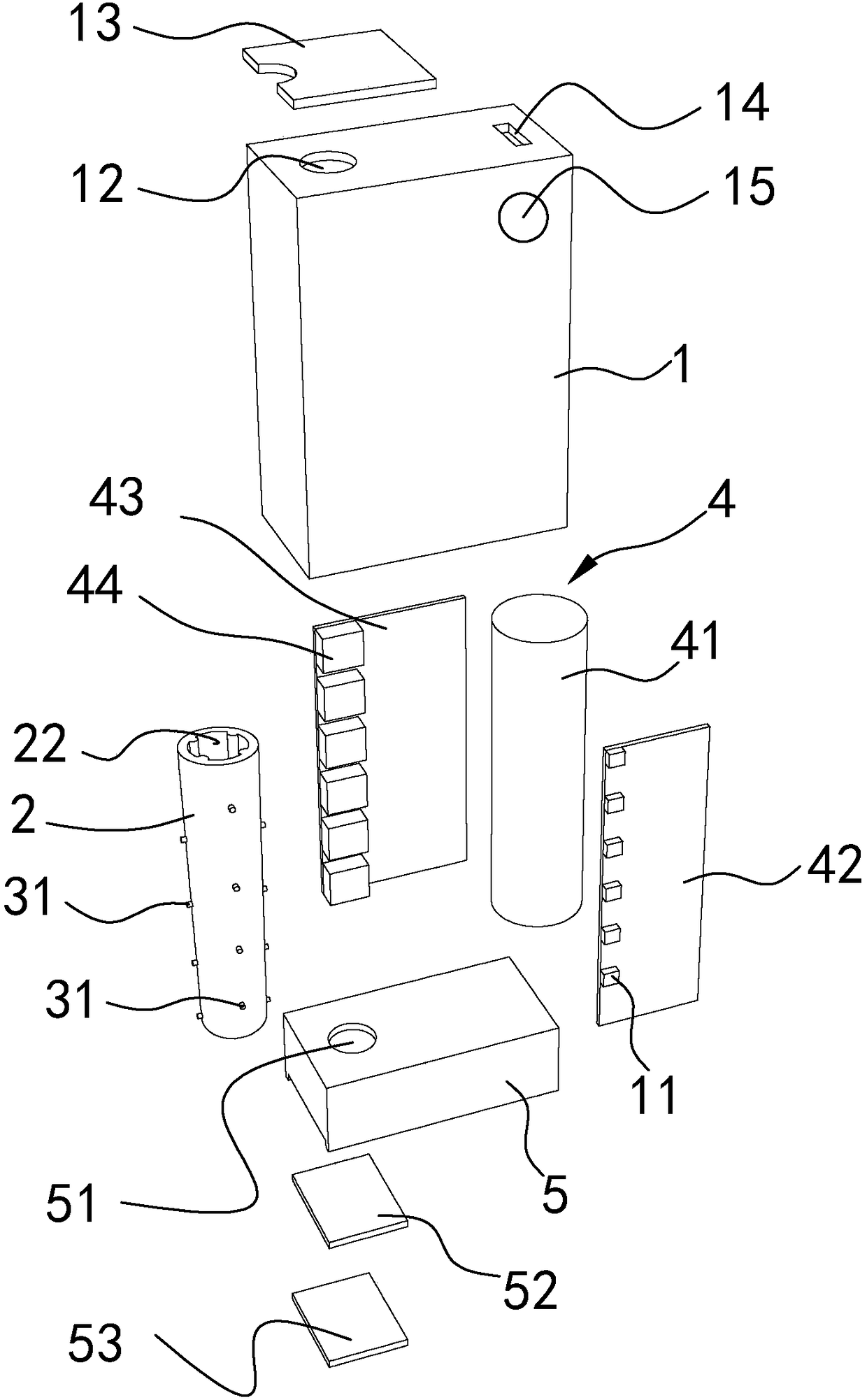

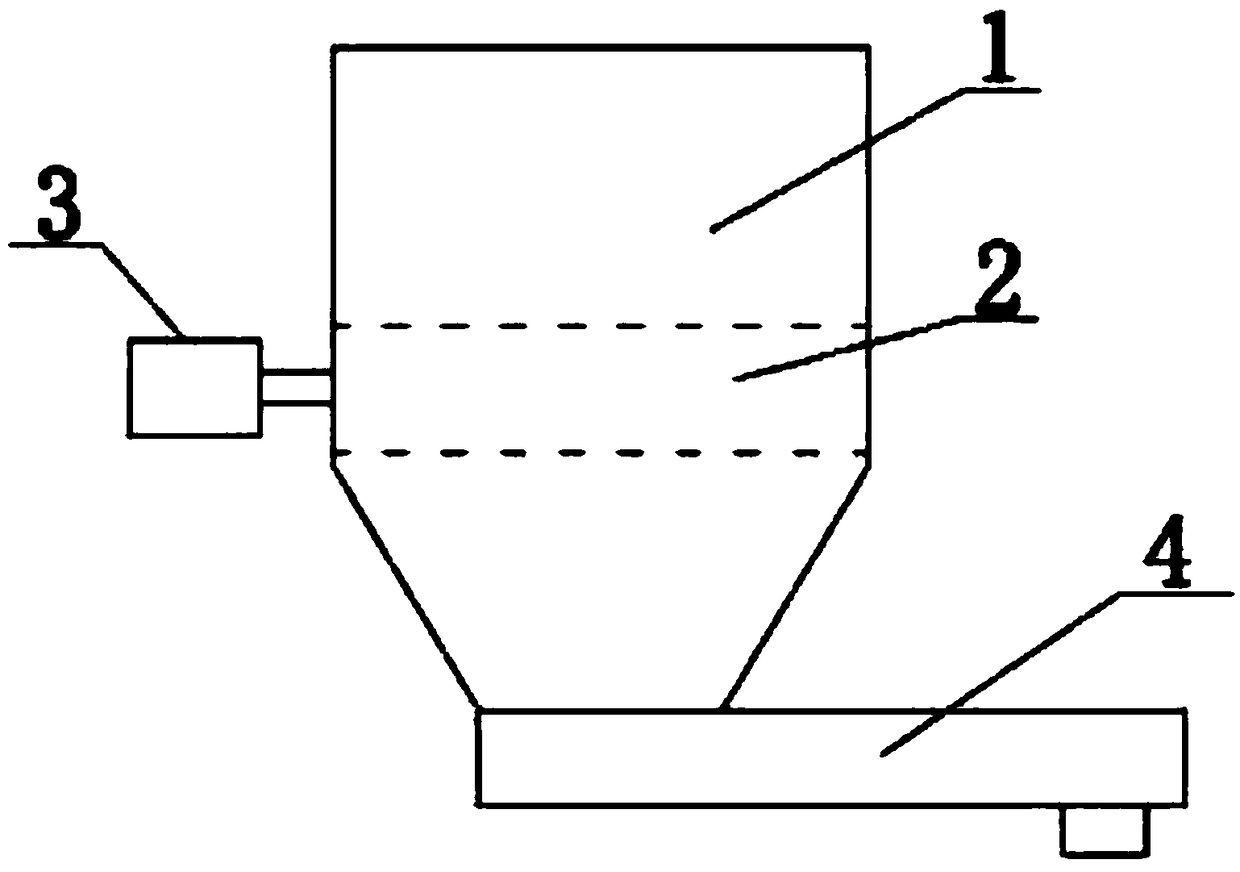

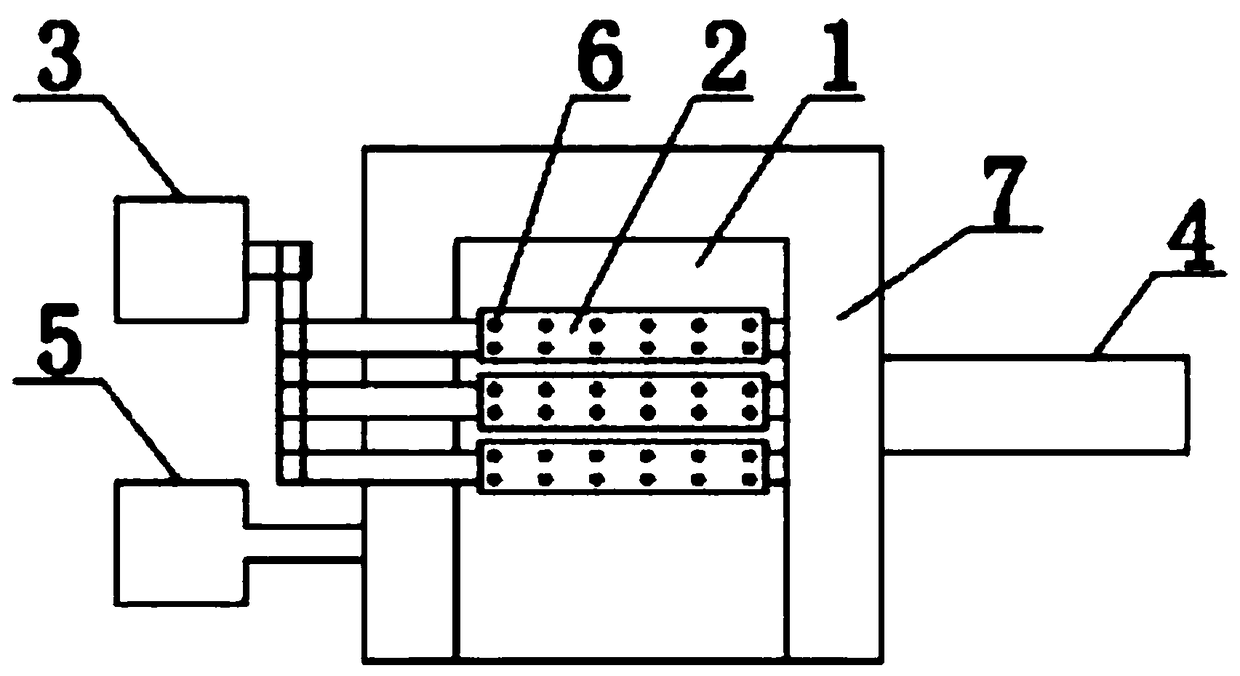

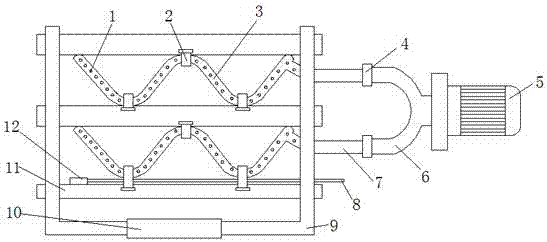

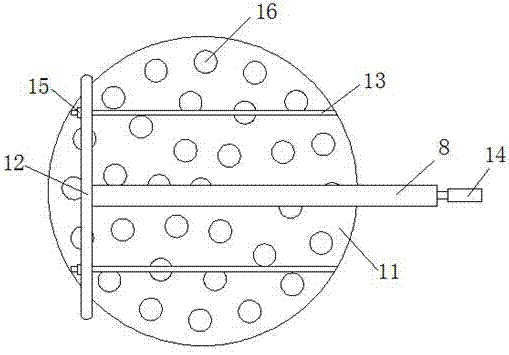

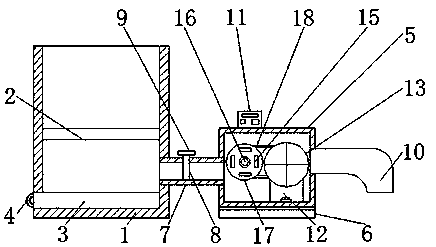

Coal-fired boiler auxiliary combustion device

PendingCN107166372AResolve Insufficient CombustionSolve the problem of wasted fuelSolid fuel combustionCombustion apparatusCoal briquetteCombustion

The invention relates to the technical field of boilers, in particular to a coal-fired boiler auxiliary combustion device. The coal-fired boiler auxiliary combustion device comprises an installation seat. An installation hole is formed in the installation seat, L-shaped supporting rods are welded to the four corners of the side edges of the installation seat, and three layers of bearing steel plates are arranged above the installation seat in the mode that the bearing steel plates are in parallel with the installation seat; the upper ends of the L-shaped supporting rods are welded to the four corners of the outer sides of the bearing steel plates, a plurality of through holes are evenly formed in each bearing steel plate at equal intervals, and the top face of the lowest bearing steel plate is slidably connected with a baffle; a connecting rod is connected to the middle of the baffle and is arranged to be perpendicular to the baffle, a bent-type steel pipe is arranged between every two bearing steel plates, and the bent-type steel pipes are fixed to the bearing steel plates through fixing rings; and a plurality of air scattering ports are evenly formed in each bent-type steel pipe at equal intervals, one side of each bent-type steel pipe is connected with a straight-type steel pipe, and each straight-type steel pipe is connected with a U-shaped air pipe which is connected with an air blower. According to the coal-fired boiler auxiliary combustion device, the problem that coal briquettes in an existing coal-fired boiler are insufficiently combusted is solved.

Combustion apparatus capable of fully burning coal

InactiveCN109114543AReduce dosageLow costDamper arrangementSolid fuel combustionCinderIndustrial furnace

The invention discloses a combustion apparatus capable of fully burning coal. The combustion apparatus includes a furnace body. A filter screen is fixedly connected to the inner cavity of the furnacebody; a cinder box is disposed at the bottom of the inner cavity of the furnace body; the left side of the cinder box communicates with an outer wall of the furnace body; a handle is fixedly connectedto the left side of the cinder box; the right side of the furnace body is provided with an operation box; the bottom of the operation box is provided with a loading plate; the left side of the operation box is fixedly connected with an air inlet pipe; and the right end of the air inlet pipe is connected with the inner wall of the operation box. Through mutual cooperation of the filter screen, thecinder box, the handle, the operation box, the loading plate, the air inlet pipe, a baffle plate, a lifting handle, an air suction pipe, a controller, a base, a motor, a rotating wheel, a belt, a cylinder, a wheel disc, the belt and fan blades, the combustion apparatus capable of fully burning the coal solves the problem that conventional industrial furnaces cause incomplete coal combustion, thesituation that the coal cannot be fully utilized is avoided, coal consumption is saved, and the production cost is reduced.

Owner:王永琴

Method for preparing efficient biomass briquettes

The invention discloses a method for preparing efficient biomass briquettes. The method comprises the steps of adding peanut shells into a pulverizer to obtain 40-60-mesh peanut shell powder through pulverizing; adding the peanut shell powder, magnesium oxide, red mud and cobalt carbonate into a stirrer, then adding a proper amount of water, and conducting stirring to obtain paste; placing the paste in a muffle furnace for roasting lasting 3-4 h at 600-800 DEG C, so that a carbide is obtained; evenly mixing the carbide with sodium carboxymethylcellulose mucilage and epoxy asphalt to obtain a mixture, and conveying the mixture to a forming machine for extrusion forming at 110-130 DEG C under the pressure of 60-80 Mpa, so that briquette fuel is obtained; drying the briquette fuel, reducing temperature to room temperature, and conducting packaging to obtain the biomass briquettes. The biomass briquettes have a calorific value of 25-30 MJ / kg, ash content of 2.5-4.0% and water absorption of 8-10%, and various performances are all higher than those of products currently available in the market.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com