Gas-stove, gas-stove panel, and pot racks

A gas stove and panel technology, which is applied in the field of kitchen utensils, can solve the problems of insufficient air volume in the Venturi mixing tube, deviation of the pot frame from the burner, and insufficient combustion of gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

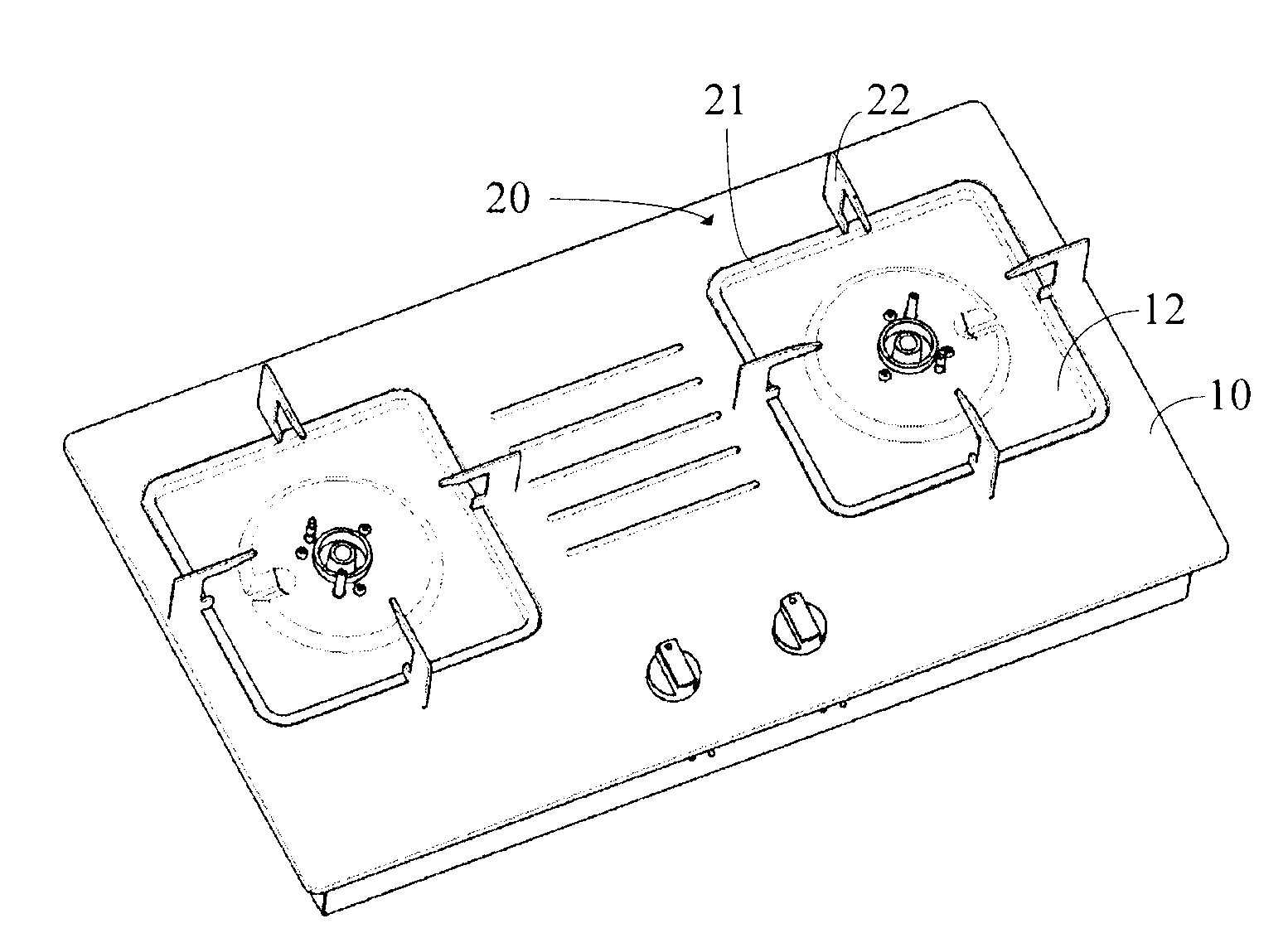

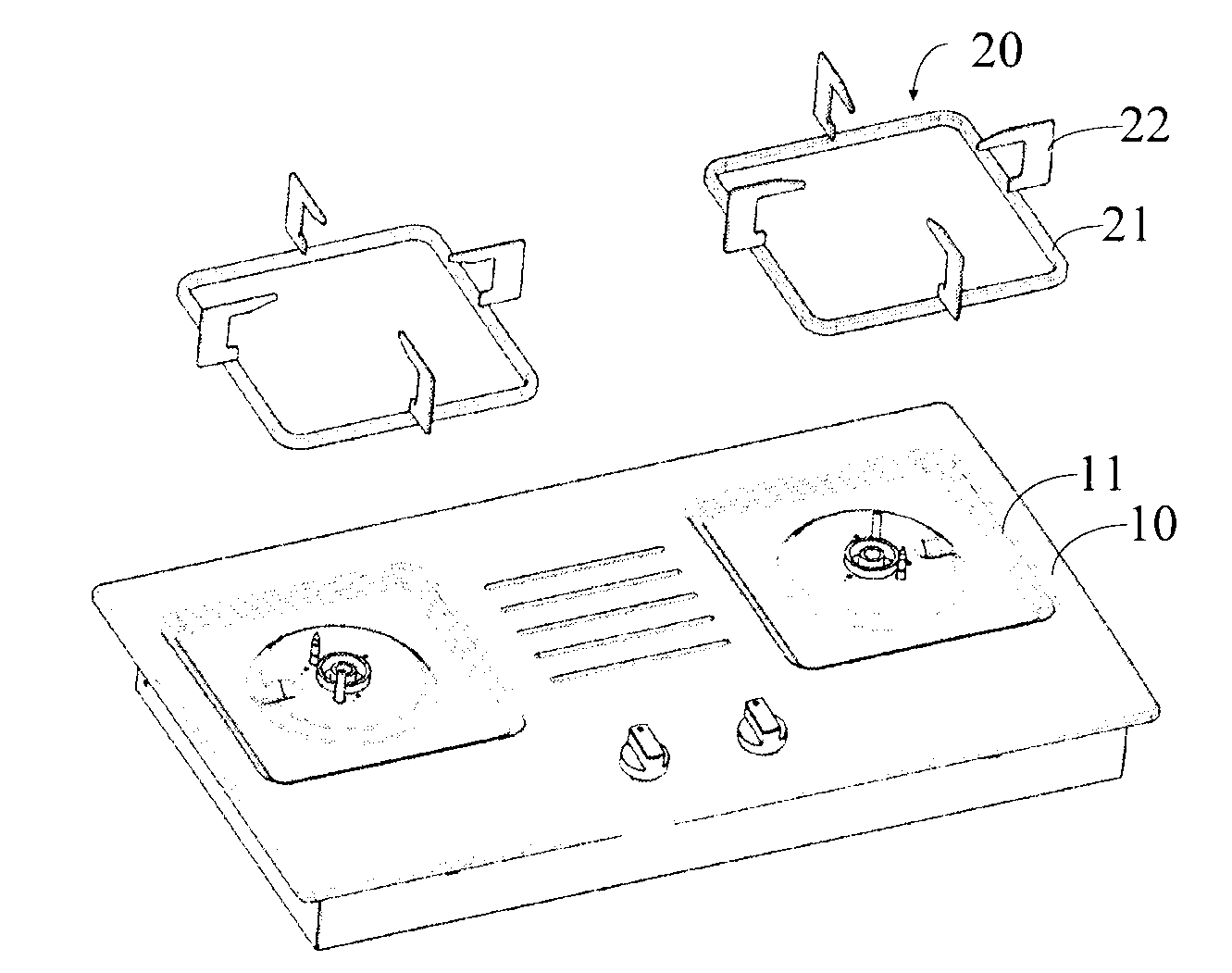

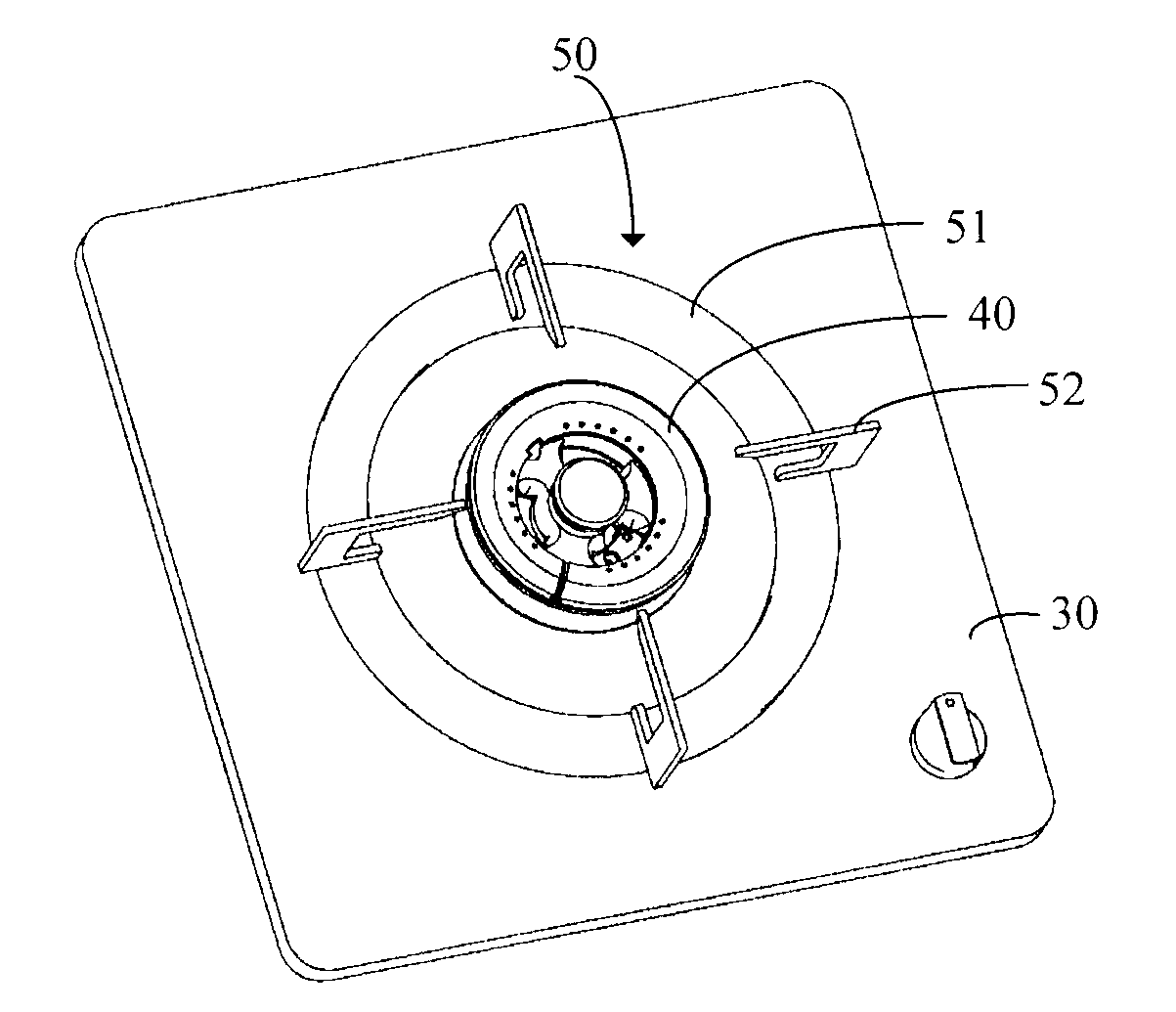

[0052] refer to image 3 , the gas cooker of the present invention includes: a panel 30, a burner 40, a Venturi mixing tube (not shown) and a pan support 50; the Venturi mixing tube communicates with the burner 40 for mixing The gas after the air is supplied to the burner 40; the pot support 50 includes a support frame 51 and a support member 52, the support member 52 is arranged on the support frame 51, and the pot (not shown) is placed on the support member 52, the support 52 is used to support the pot. Figure 4 is a perspective view of the panel of the first specific embodiment of the present invention, Figure 5 It is a top view of the panel of the first specific embodiment of the present invention, Figure 6 for Figure 5 The schematic diagram of the cross-sectional structure of the panel along the A-A direction, combined with reference Figure 4 , Figure 5 , Figure 6 , the panel 30 has a boss 31 adapted to the shape of the support frame 51, and the boss 31 has a...

no. 2 Embodiment

[0066] Compared with the first specific embodiment, in the second specific embodiment, the outer ring blocking part is in contact with the panel to play the role of supporting the pan support, and there is a through hole on the outer ring blocking part, and the outer ring blocking part has a Through holes, outside air flows into the Venturi mixer through the through holes, the gaps, and the through holes of the boss in sequence on the outer ring blocking portion.

[0067] The structures of other components are the same as those in the first specific embodiment, and will not be repeated here.

no. 3 Embodiment

[0069] In the third specific embodiment, the support frame is ring-shaped, including a ring-shaped body and an outer ring stopper and an inner ring stopper provided on the body; the outer ring stopper is located outside the boss, and the shield boss The outer side of the platform, the bottom end of which is in contact with the panel to support the pot support, and the outer ring blocking part has a through hole, and the outside air passes through the through hole, the gap, and the through hole of the boss in turn on the outer ring blocking part Then flow into the Venturi mixing tube; the inner ring blocking part is located on the inside of the boss, and there is a gap between the bottom end of the inner ring blocking part and the panel, and the inner ring blocking part and the boss Medial contact. Since the inner ring blocking part is in contact with the inner side of the boss, the air in the gap can also be confined in the space of the gap, and will not flow out through the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com