Roller rotating and driving slag removal hearth

A technology of drum rotation and slag discharge furnace, which is applied in the direction of non-flammable liquid/gas transportation, combustion method, solid fuel combustion, etc. It can solve the problems of difficult discharge of coke-like slag, too large furnace, insufficient combustion, etc., to achieve Facilitate local repair and maintenance, improve combustion efficiency, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

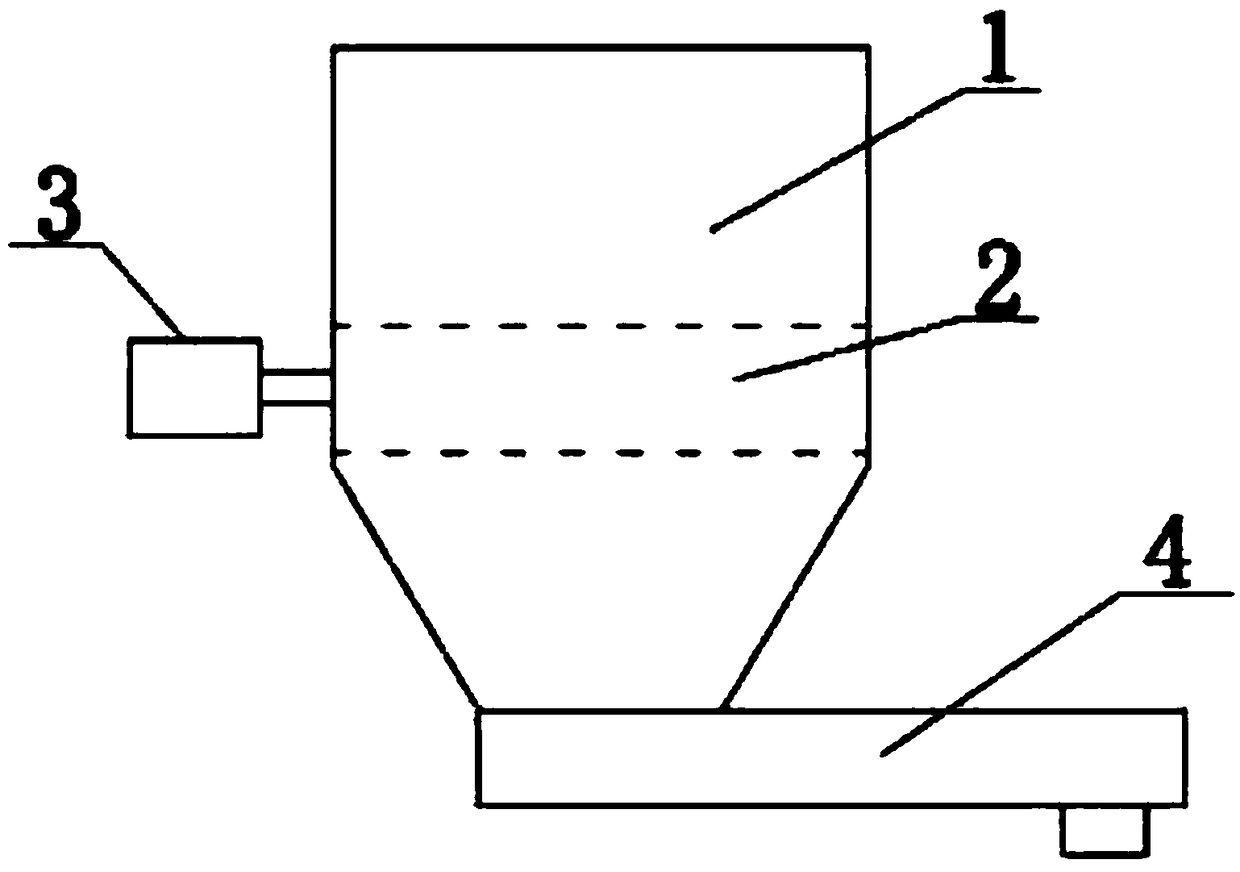

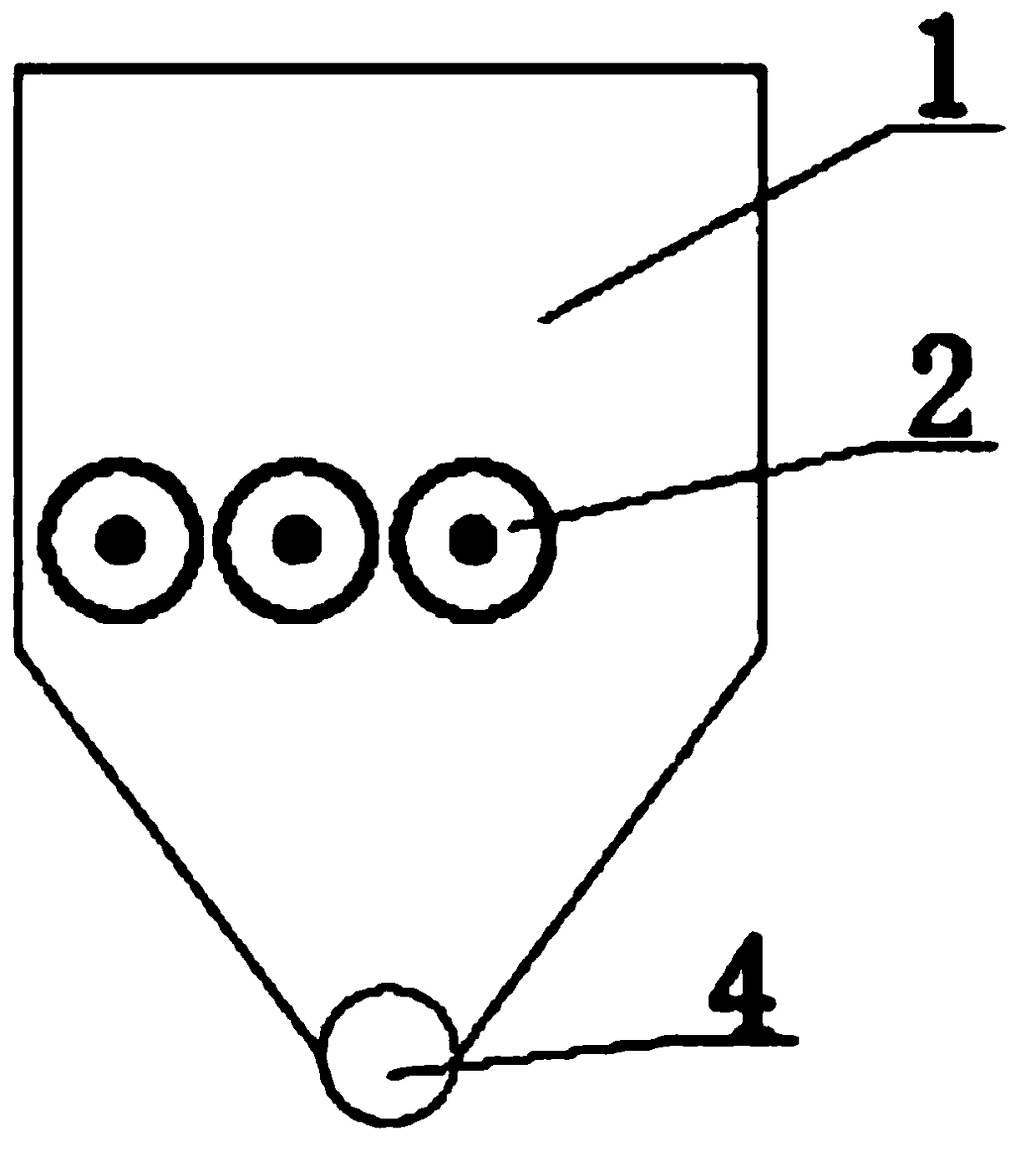

[0009] exist figure 1 Among them, there are 3 drums (2) at the bottom of the furnace square box (1), and the 3 drums are driven by the motor (3) to rotate in the same direction to drive the granular fuel and the slag produced by the combustion forward, and the burnt slag Roll down to the slag remover (4) at the bottom of the furnace, and then be automatically transported to the outside of the boiler.

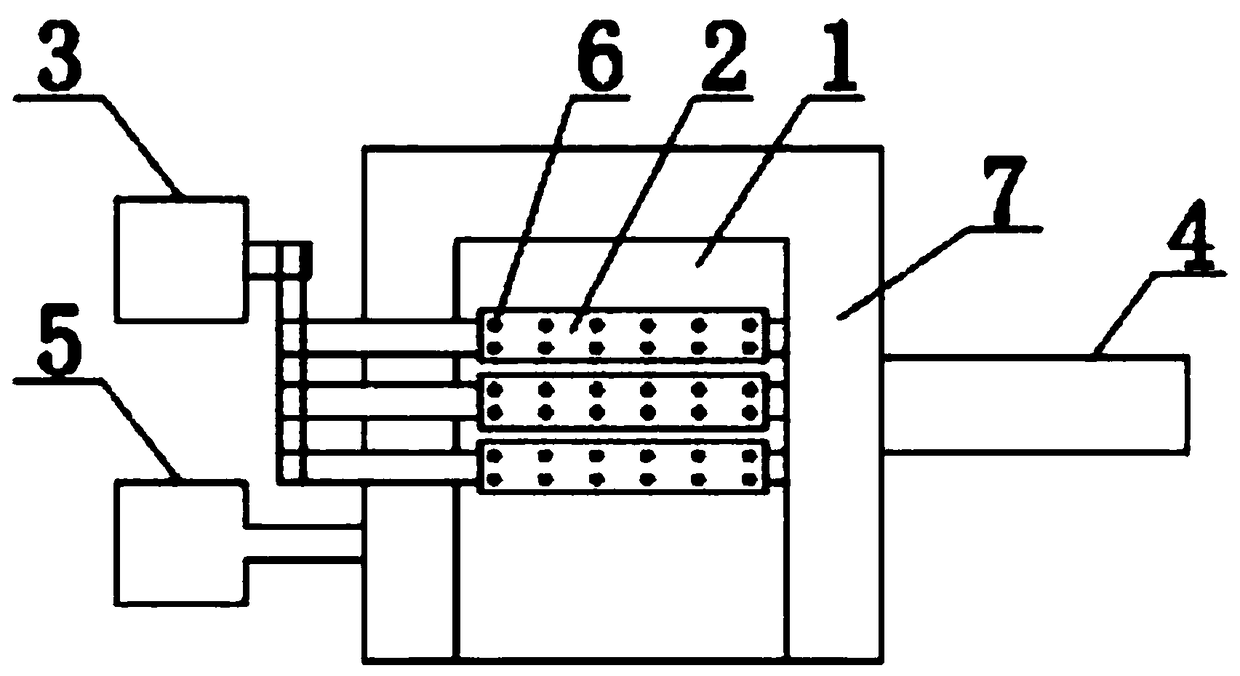

[0010] exist figure 2 In the example shown, the three drums (2) are installed in parallel at the bottom of the furnace and rotate in the same direction driven by the motor (3). The drums (2) are provided with air ducts (6), which enter the bottom of the drums through the fan (5). In the bellows, the wind in the bellows at the bottom of the drum passes through the air channel (6) on the drum to distribute air to the fuel on the drum at one time, and the three sides of the furnace are equipped with air channel boxes (7) to face the drum (2) from the left, right and rear The fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com