Patents

Literature

37results about How to "Realize automatic slag discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

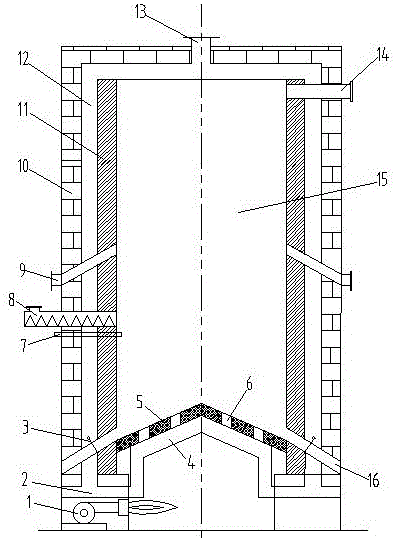

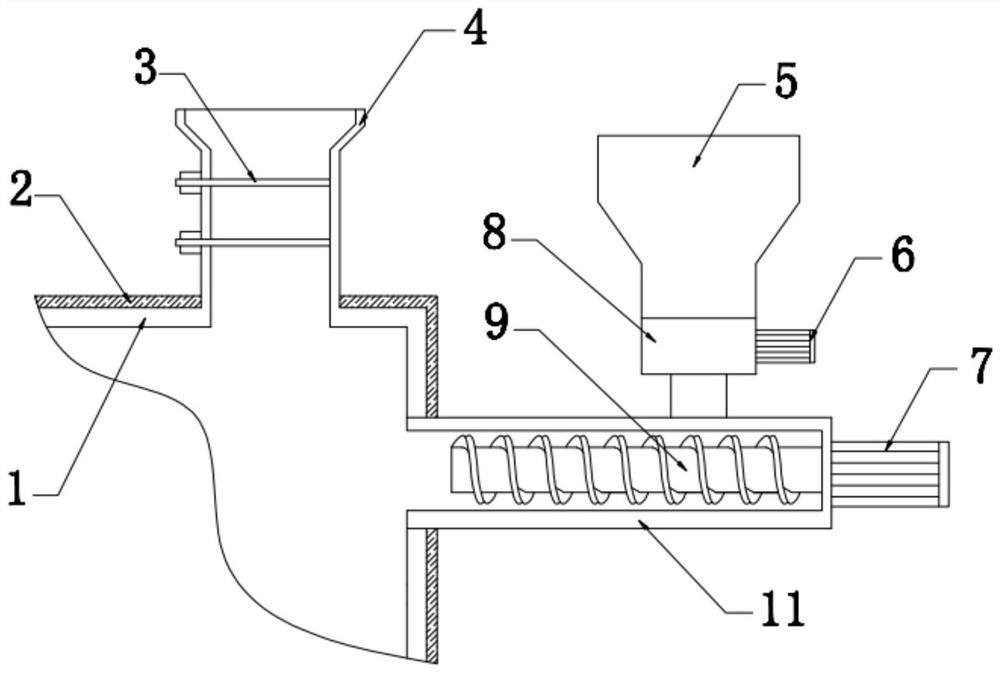

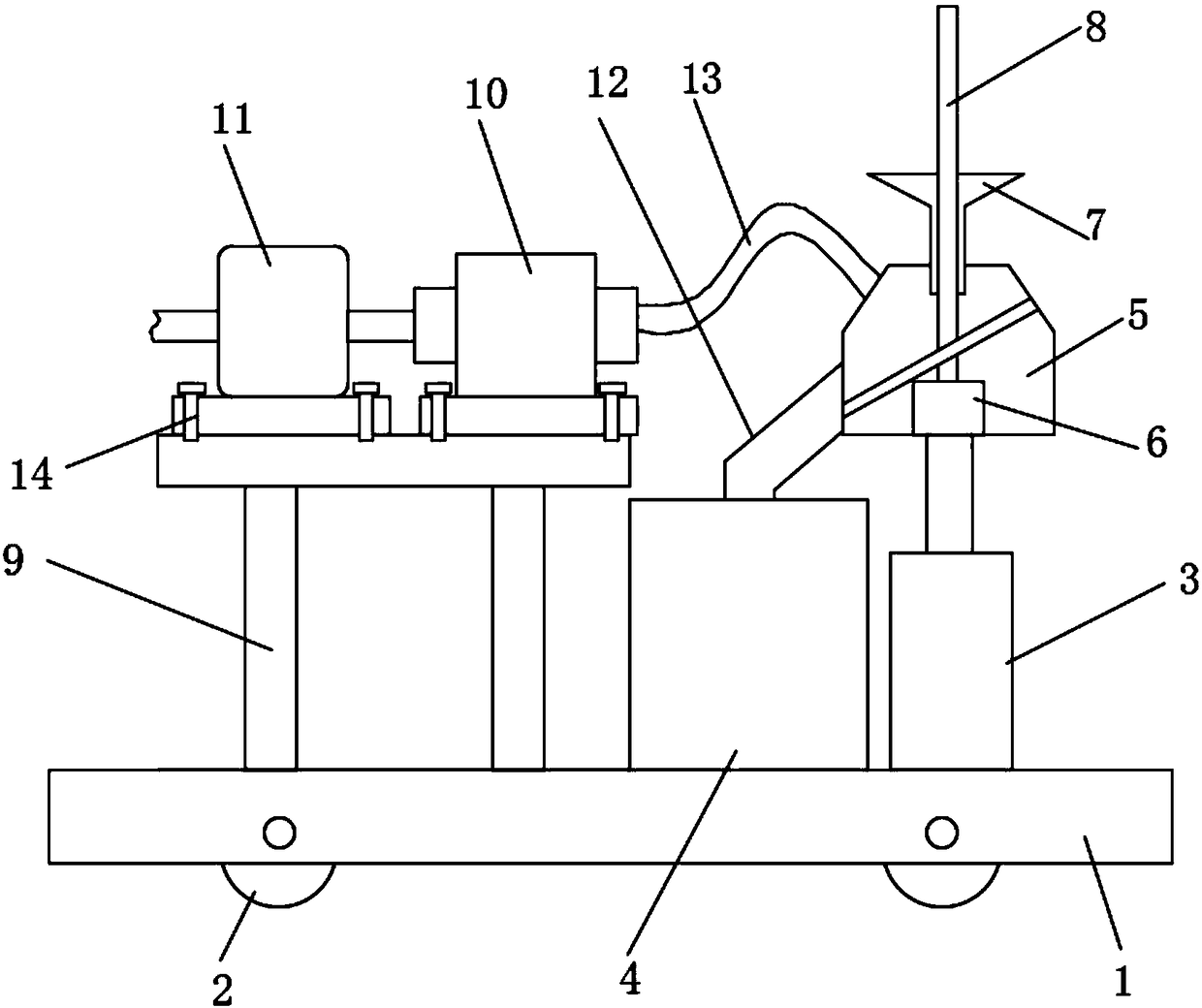

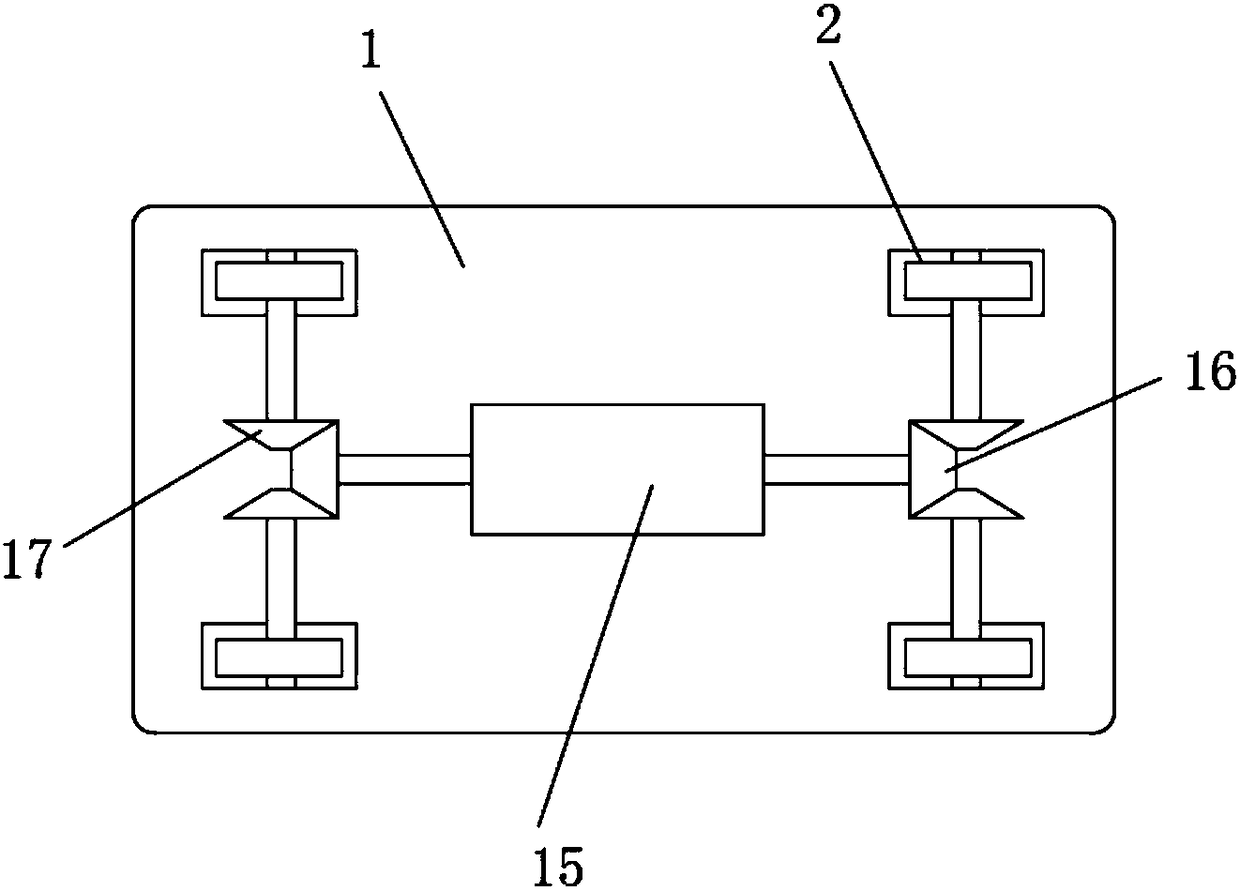

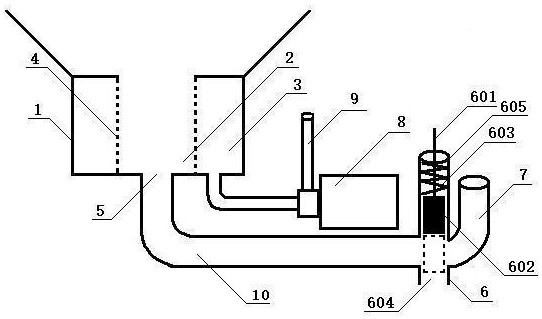

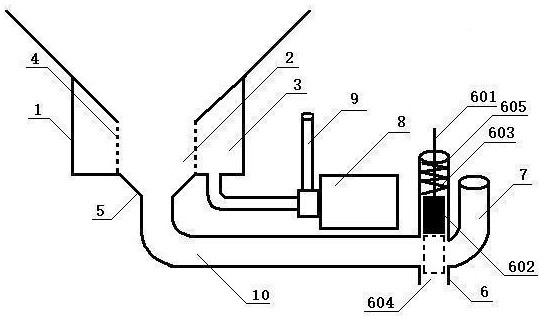

Efficient oil sludge incinerator

ActiveCN103939919AReduce the temperatureHigh thermal efficiencyIncinerator apparatusInlet channelDiesel combustion

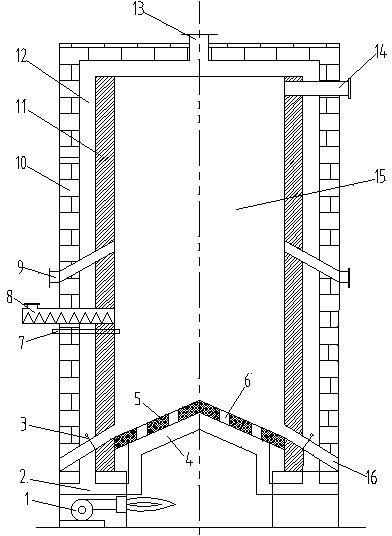

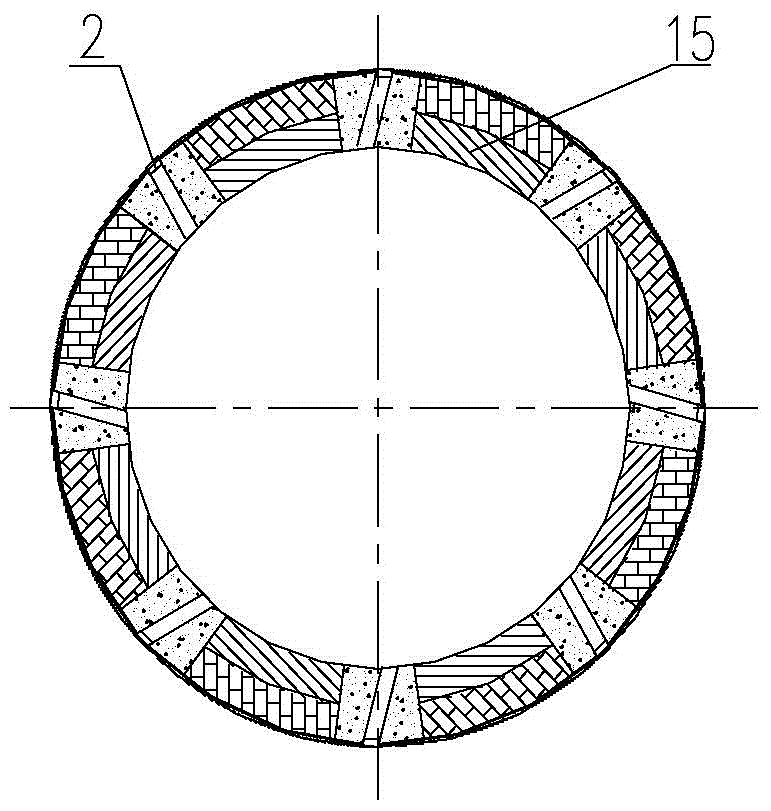

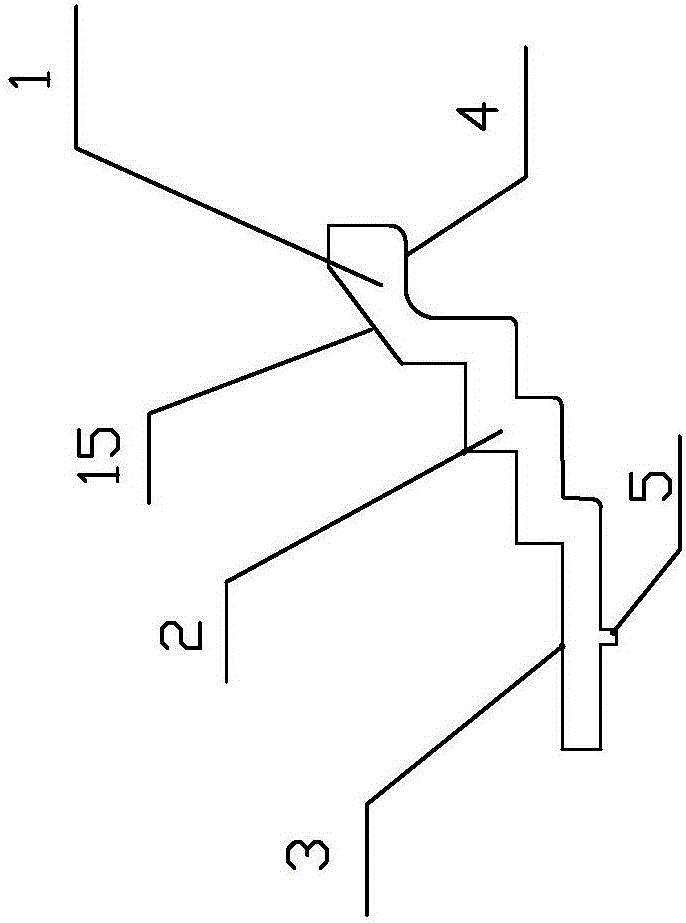

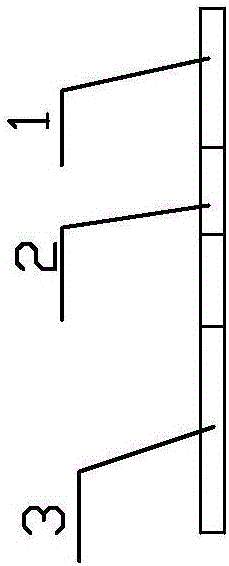

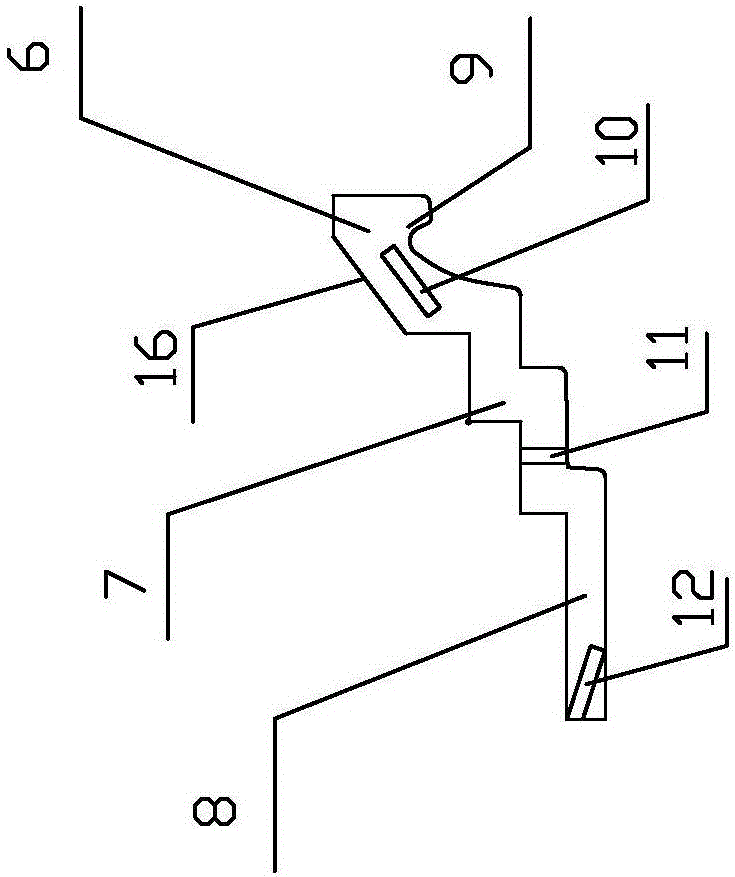

An efficient oil sludge incinerator comprises an incinerator body formed by an inner incinerator wall (11) and an outer incinerator wall (10). The efficient oil sludge incinerator is characterized in that an air interlayer (12) is formed between the inner incinerator wall and the outer incinerator wall, a primary air inlet (13) is formed in the outer incinerator wall, an incinerator bottom (5) is arranged on the lower portion of an incinerator chamber (15), an incinerator bottom air outlet (6) communicated with an air outlet of an air distribution plate (4) placed on the outer portion of an incinerator bottom (5) is formed in the incinerator bottom, an air inlet of the air distribution plate (4) is communicated with the air interlayer, a secondary air inlet channel (9) is arranged in the middle of the incinerator body, a screw feeder (8) which conveys oil sludge into the incinerator chamber is arranged on the middle-lower portion of the incinerator body, a diesel combustion-supporting device (1) is arranged on the lower portion of the incinerator body, a smoke outlet channel (14) is arranged on the upper portion of the incinerator body, and a controllable deslagging channel (16) is arranged on the lower portion of the incinerator body. The efficient oil sludge incinerator has the advantages of being high in burning efficiency, stable in incineration and low in mechanical fault rate, and ideal equipment is provided for oil sludge efficient cleaning processing.

Owner:JIANGSU JINDING BOILER

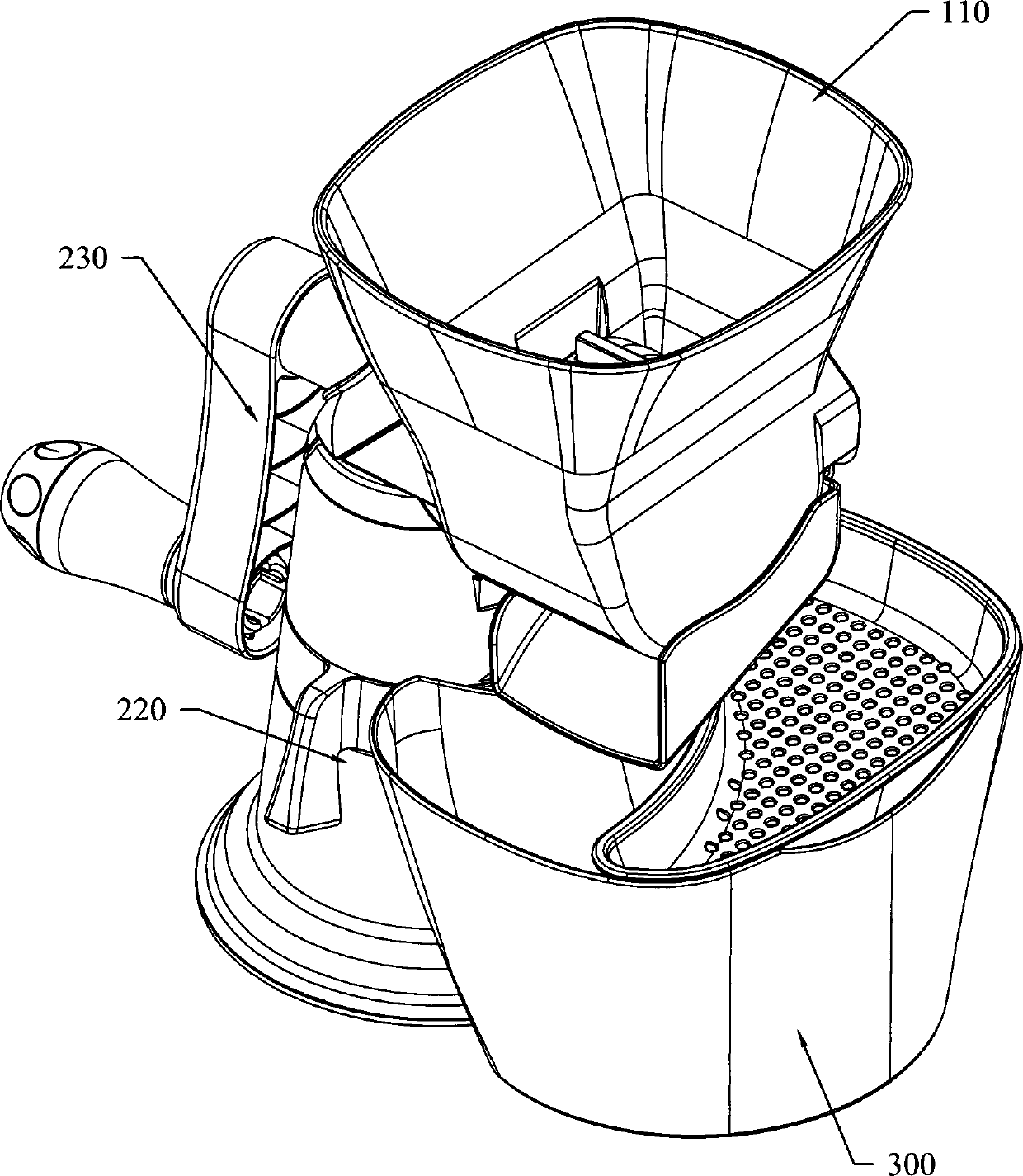

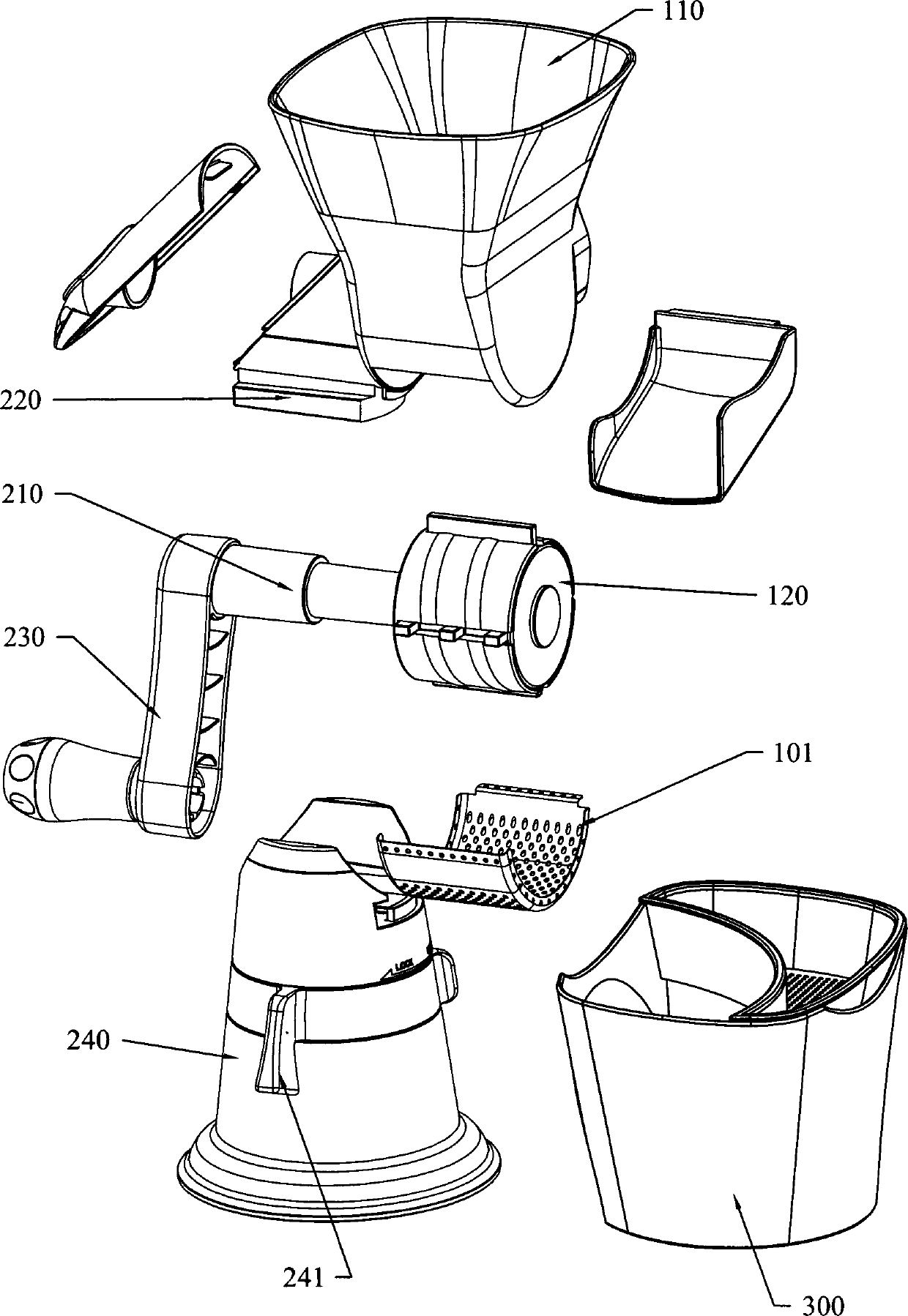

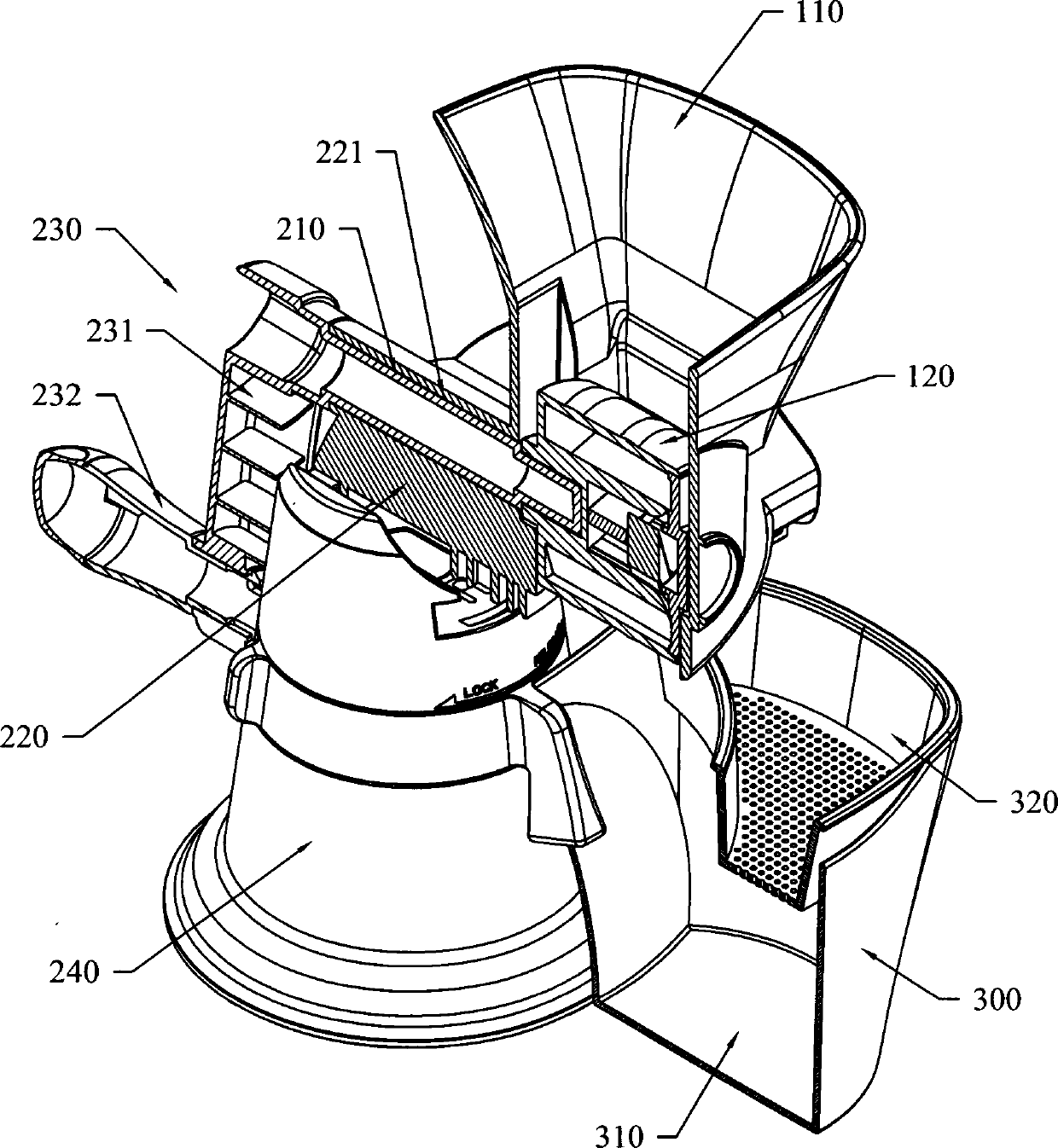

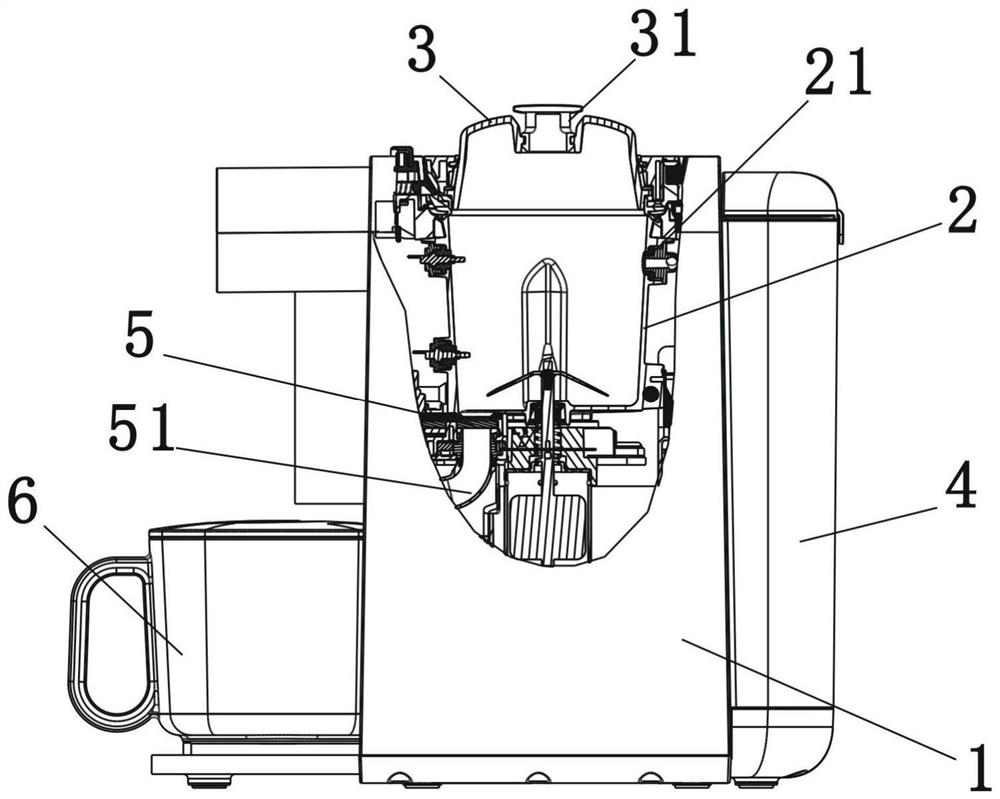

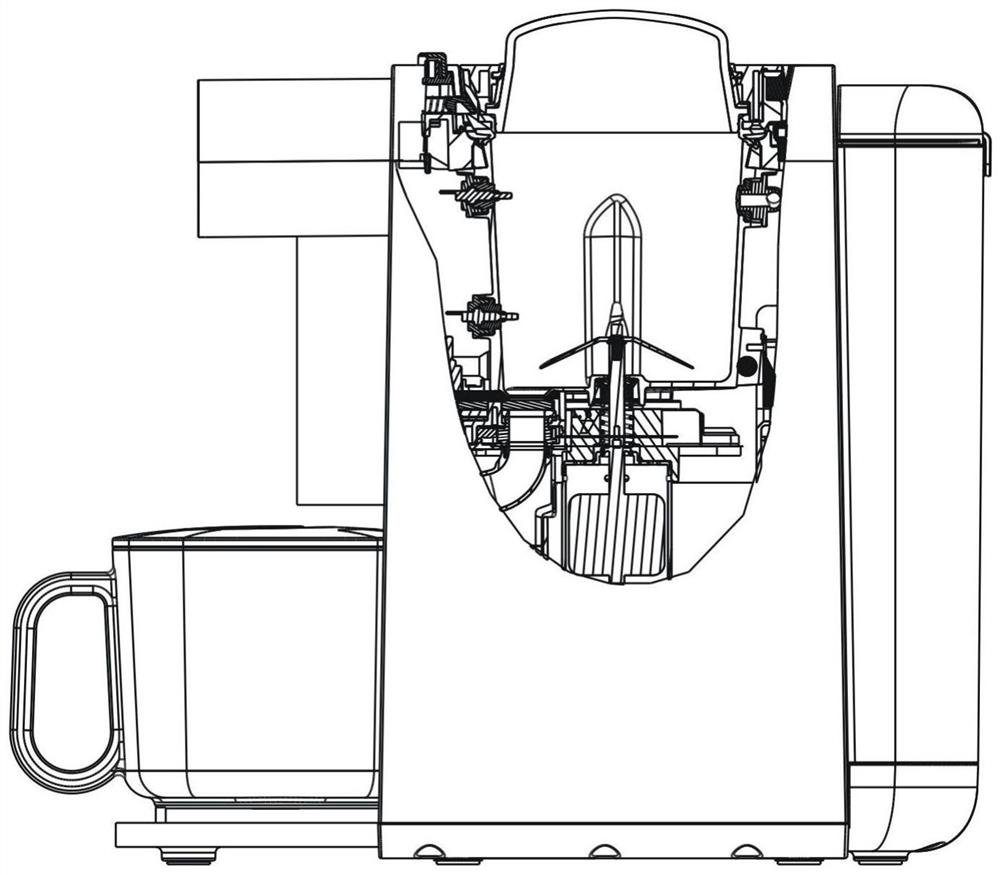

Juicer

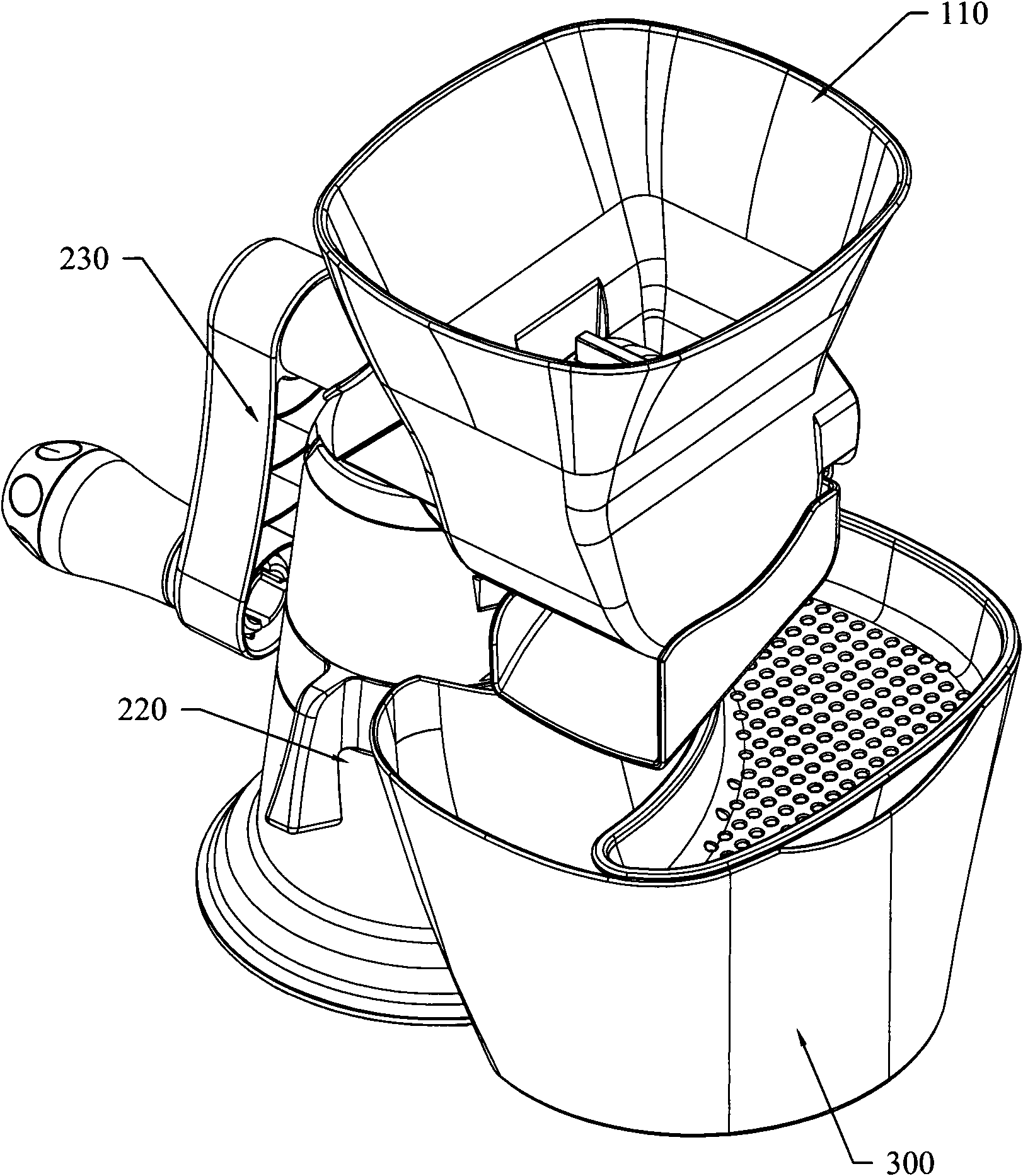

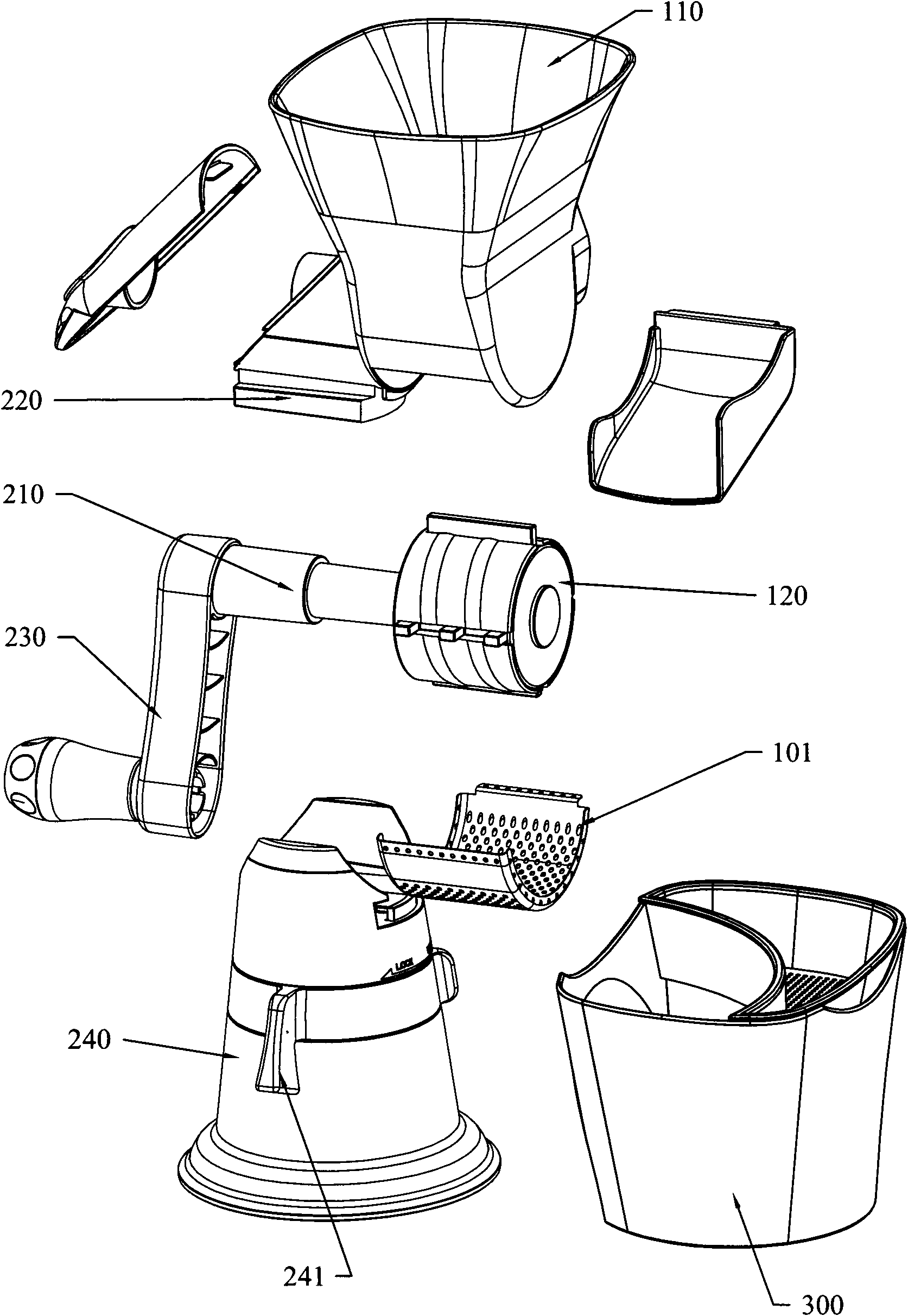

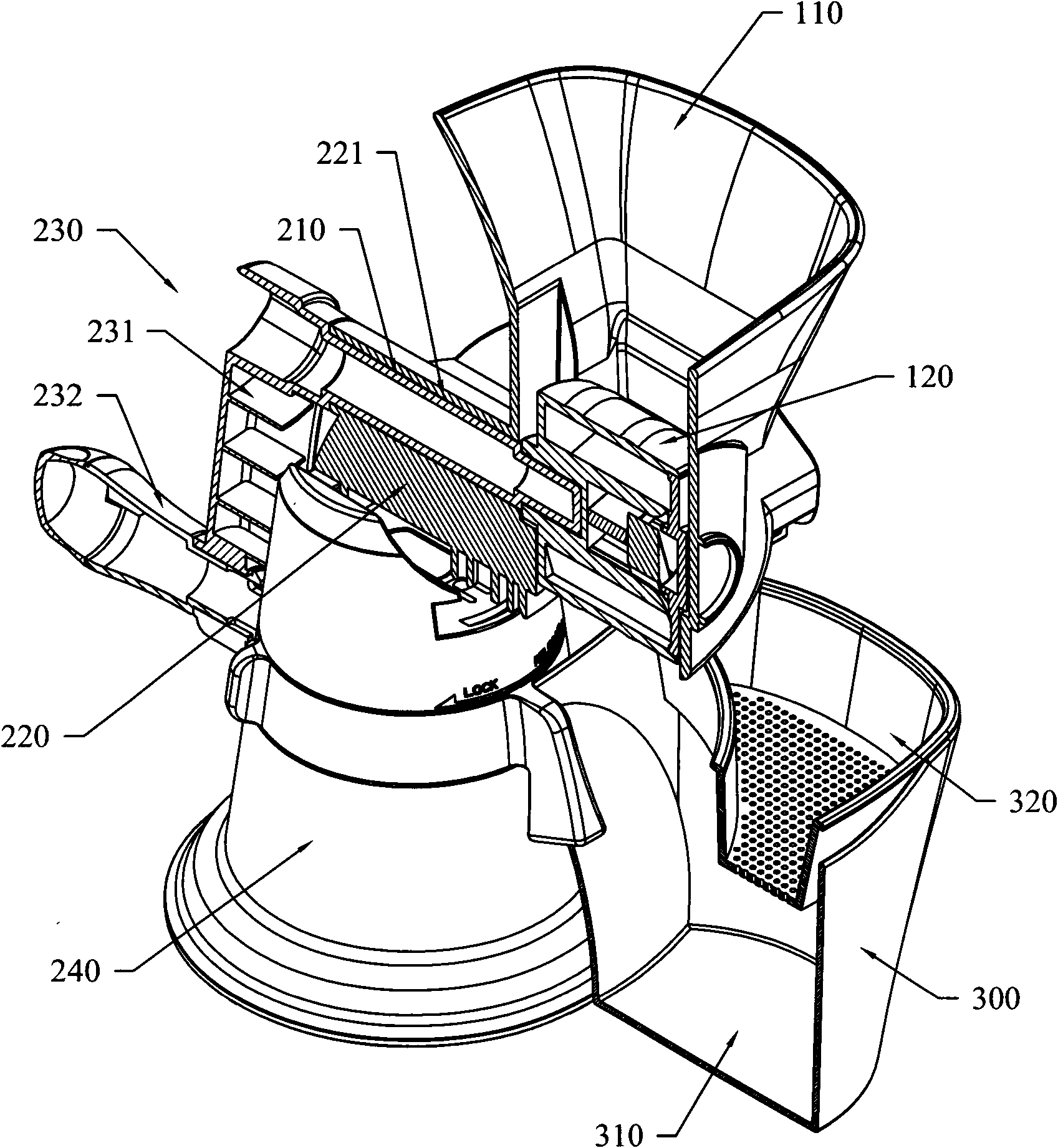

The invention relates to a juicer, which comprises a juicing mechanism and a driving mechanism for driving the juicing mechanism to run, wherein the juicing mechanism comprises a container and a rotary drum rotationally arranged in the container and driven by the driving mechanism; the rotary drum is provided with a scraping plate protruding the rolling surface of the rotary drum; and the wall of the container is provided with a juice outlet and a residue outlet. When fruits or vegetables enter the juicer from a fruit and vegetable passage, the rotary drum and the container wall squeeze the fruits or the vegetables, and sacs of the fruits or the vegetables are broken by squeezing, so that fruit juice or vegetable juice in the fruits or the vegetables flows out and is discharged from the juice outlet, the fruit residue or the vegetable residue is discharged by the scraping plate from the wall of the container to the residue outlet, separation of the juice and the residue is realized, the residue is automatically discharged, the operation is more convenient, and the problems of un-cleanliness, inconvenience and time waste caused by manual residue discharge are avoided.

Owner:汪恩光

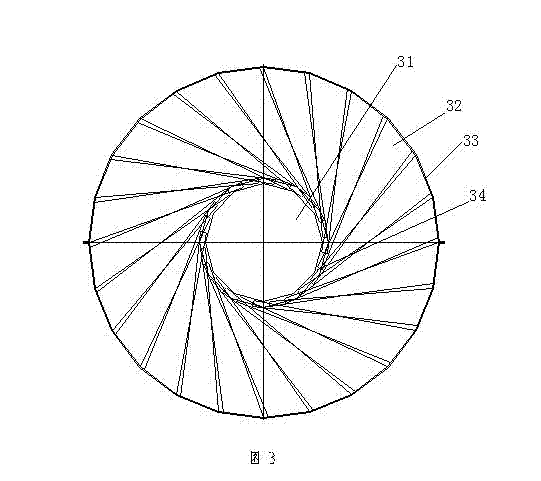

Fire coal smoke cyclone dedusting desulfurizer

InactiveCN102389696ARealize double loopLow running costCombination devicesWater bathsActivated carbon

The invention discloses a fire coal smoke cyclone dedusting desulfurizer, which adopts liquid as adsorbent, and is used for the smoke purification treatment of a coal burning boiler. The fire coal smoke cyclone dedusting desulfurizer comprises a body, two cyclone plates, a first dustchamber, a second dustchamber, a water bath dustchamber, a desulfuration chamber, a purification chamber, an alkali liquor spraying device, a water spraying device, an activated carbon desulfurization ring, a solution mixing pump, a solenoid valve, a circulation alkali tank, a stirrer, a solution transfer pump, a filter tank, a slag scraping machine, a transfer trolley and the like. Two-stage cyclone dedusting, solid-gas separation in the water bath, alkali liquor spraying, liquid adsorption desulfuration and wet-type purification are adopted by aiming at the smoke of an oil burning boiler, not only does the emission reach the environmental-friendly standard, but also both the clear water and the alkali liquor are recycled, so the double circulation of lye and alkali liquor and the automatic slag discharge are realized.

Owner:张步芳

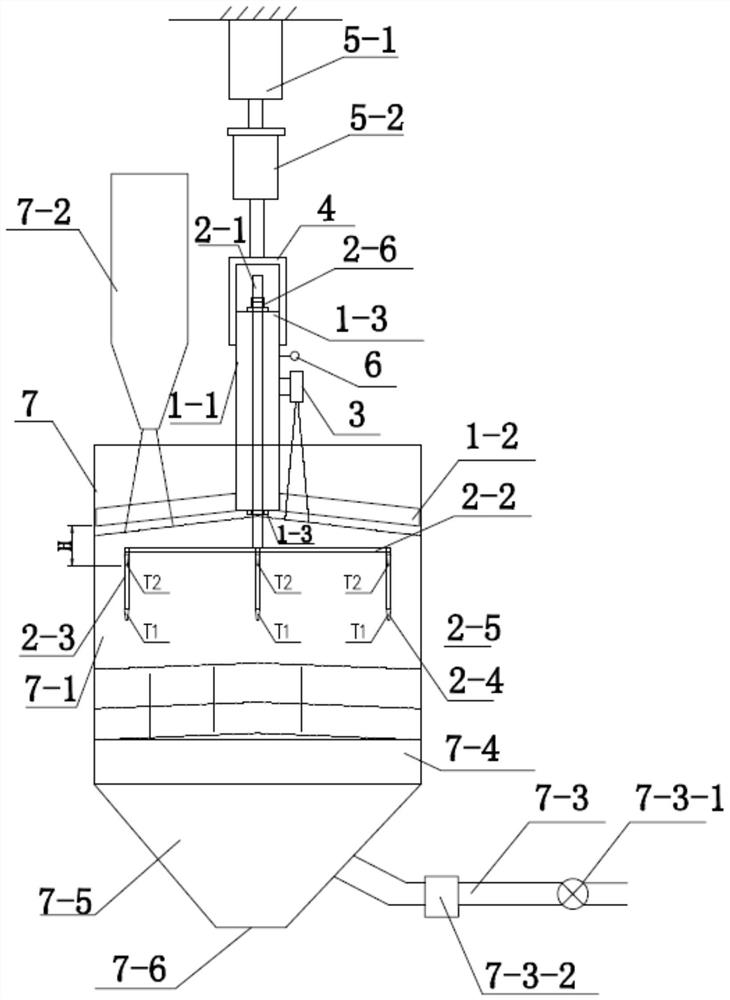

Internal rotary gasifier and domestic waste treatment technology

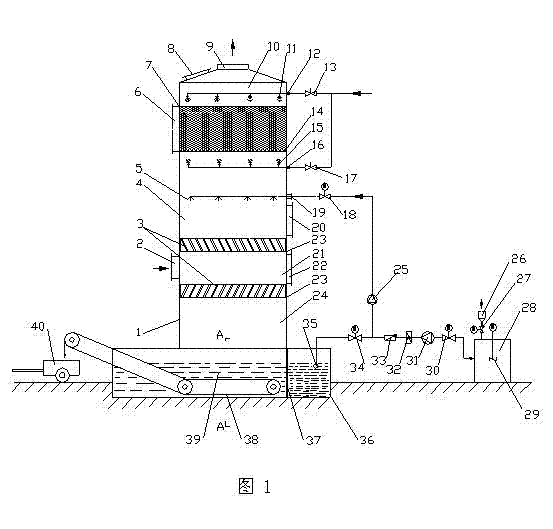

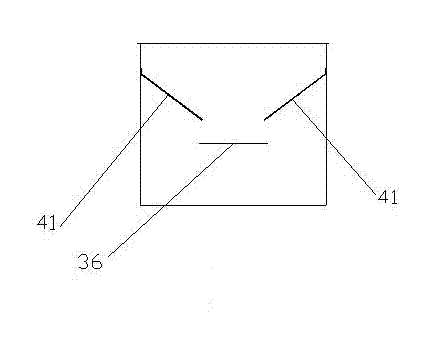

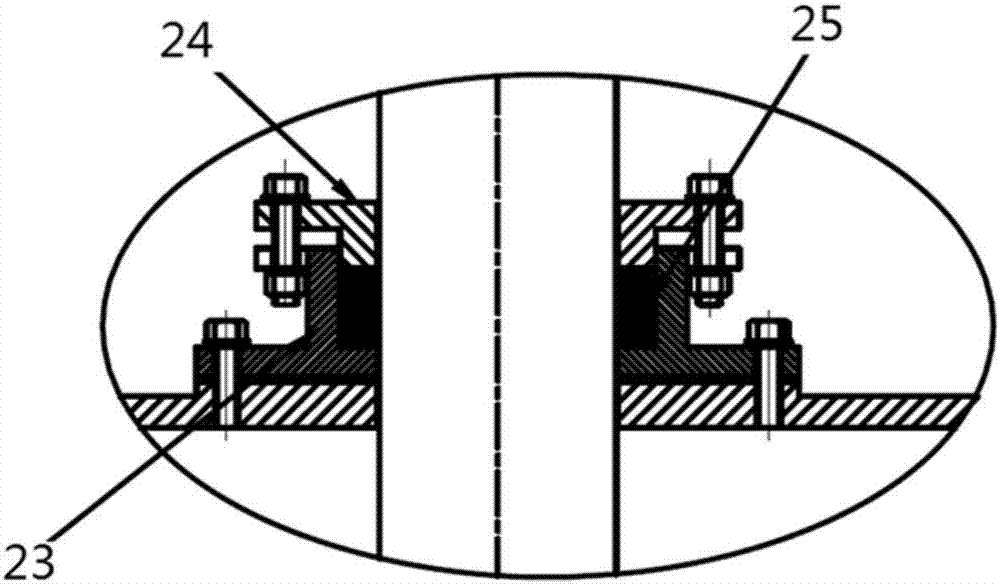

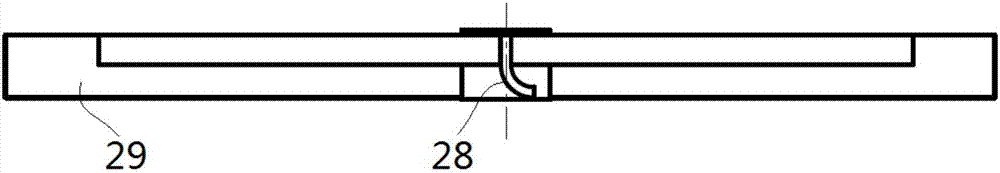

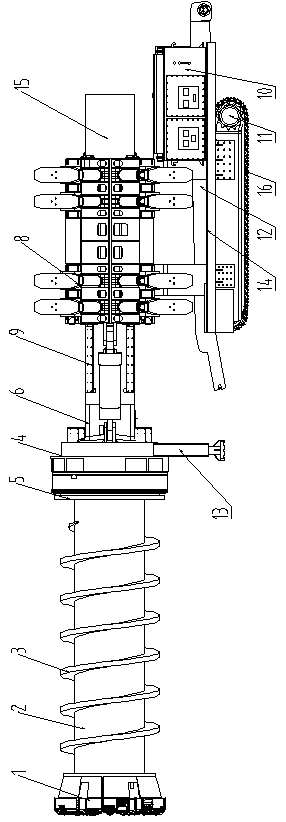

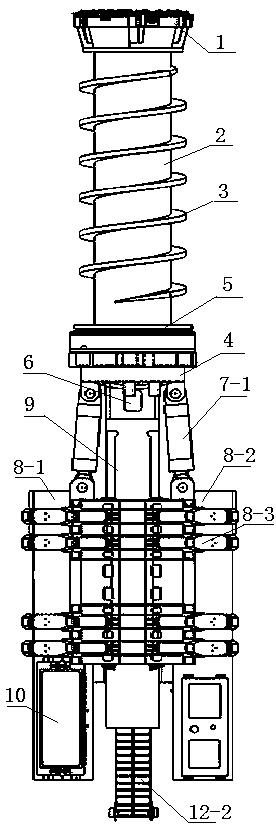

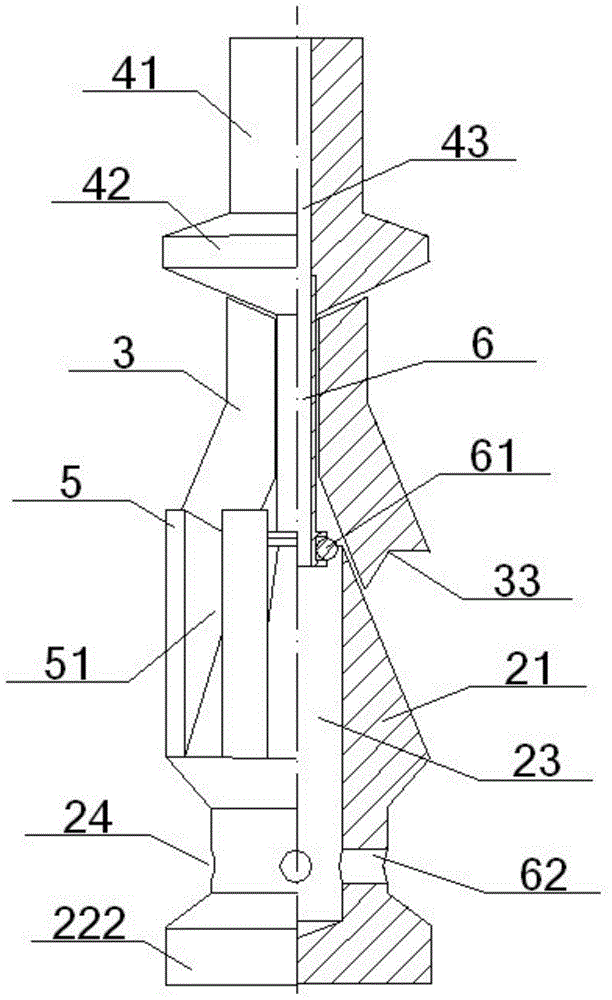

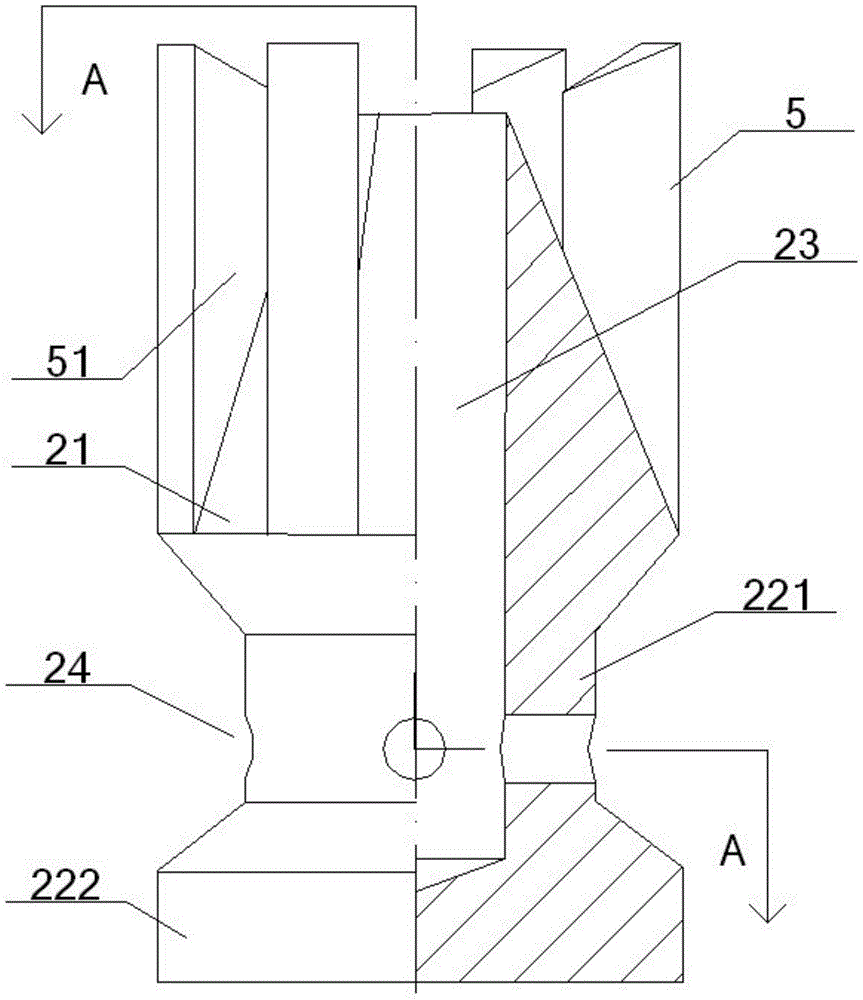

InactiveCN107011945ASolve harmless disposalRealize automatic slag dischargeGasifier feeding meansCombustible gas productionMaterial balancePhysical health

The invention discloses an internal rotary gasifier and a domestic waste treatment technology. The internal rotary gasifier comprises a gasifier body and a material balancing and pressing structure, wherein a feeding hole is formed in the top of the gasifier body and an ash outlet is formed in the bottom of the gasifier body; an air outlet is formed in the upper part or the top part of the gasifier body; the material balancing and pressing structure is arranged in the gasifier body and is used for uniformly dispersing a material from the feeding hole into a gasifier cavity and pressing the material which is uniformly dispersed into the gasifier cavity; the material balancing and pressing structure is fixedly connected with the bottom end of a rotating shaft which partially extends outside relative to the top of the gasifier body; and a lifting device for driving the rotating shaft to move up and down along the axial direction and a rotating device for driving the rotating shaft to horizontally rotate are arranged at the top end of the rotating shaft. The problem of increasing municipal domestic wastes can be solved, the environment is not polluted, meanwhile, the problem of pollution of dioxin to land and air is also solved, and the physical health of people is greatly protected.

Owner:HUNAN YUANYANG COAL MACHINE MFG

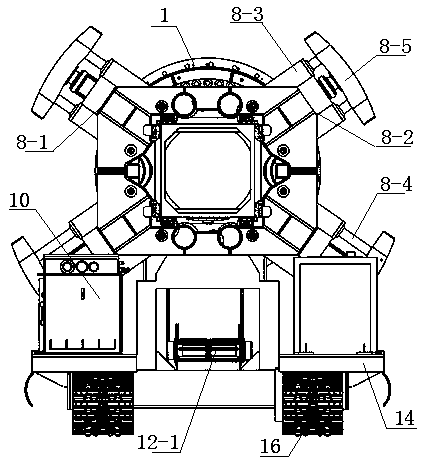

Borehole-blasting method tunnel weak large deformation and rock burst pretreatment TBM (Full Face Rock Tunnel Boring Machine)

The invention discloses a borehole-blasting method tunnel weak large deformation and rock burst pretreatment TBM (Full Face Rock Tunnel Boring Machine) and aims at solving the problems of low construction efficiency and low safety coefficient of a borehole-blasting method tunnel weak large deformation and rock burst pretreatment process in the prior art. The borehole-blasting method tunnel weak large deformation and rock burst pretreatment TBM disclosed by the invention comprises a movable car body, wherein a slag discharging system, an X-shaped supporting jack system and a telescopic mechanism are arranged on the movable car body; the front end of the telescopic mechanism is connected with a hollow shaft through a main driver, an outer spiral is arranged on the outer periphery of the hollow shaft, a cutter disk is arranged at the front end of the hollow shaft, and the main driver is connected with the movable car body through a propelling mechanism. According to the borehole-blastingmethod tunnel weak large deformation and rock burst pretreatment TBM disclosed by the invention, the movable car body has self power, can move flexibly and can achieve advanced excavation; when a borehole-blasting method meets large deformation, the borehole-blasting method weak large deformation and rock burst pretreatment TBM is used; thus, the construction efficiency is improved, and the construction risk is reduced. The TBM construction method is matched with the flexibility characteristic of a mining method, major risk of construction under the special geological conditions is avoided, and the construction safety coefficient is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

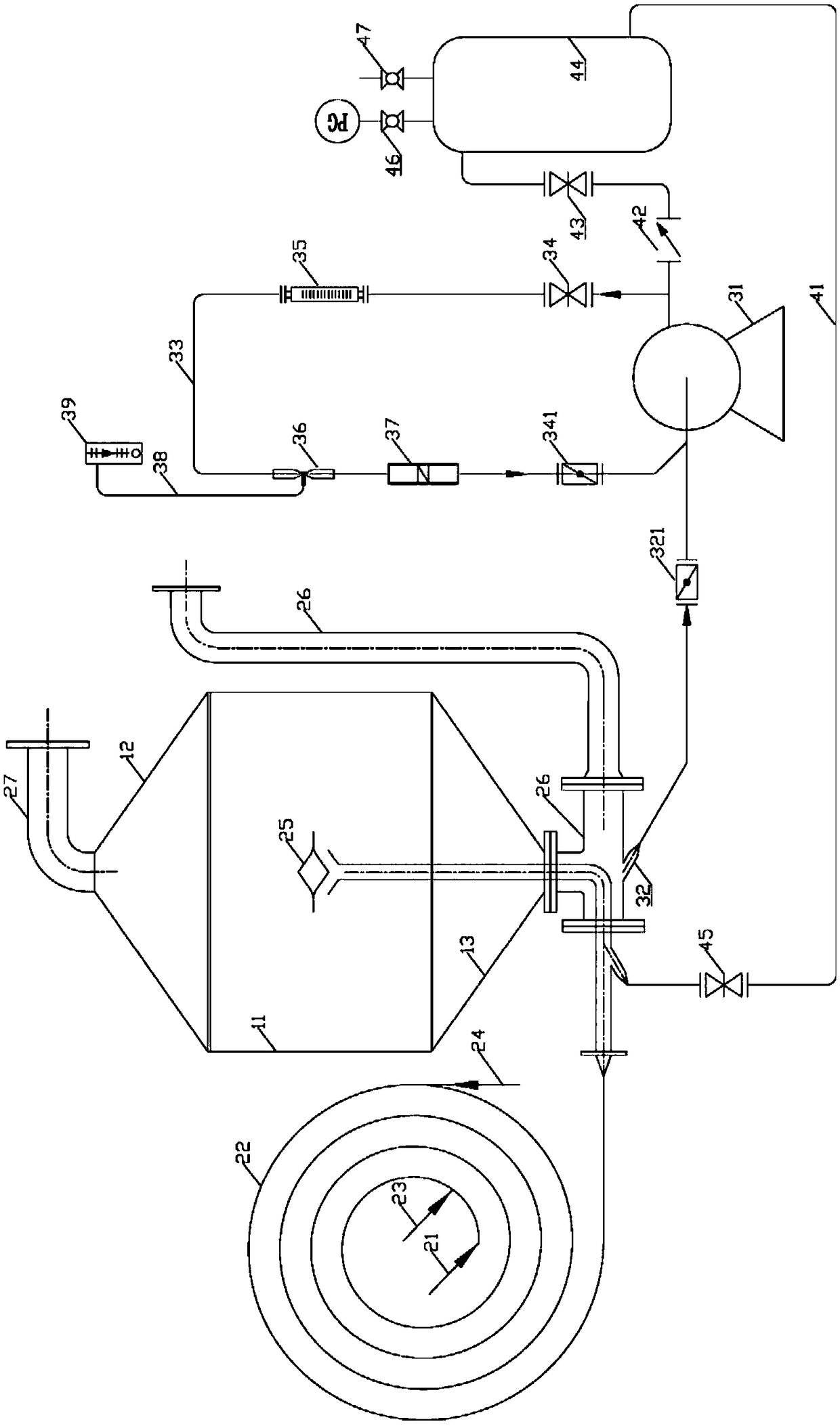

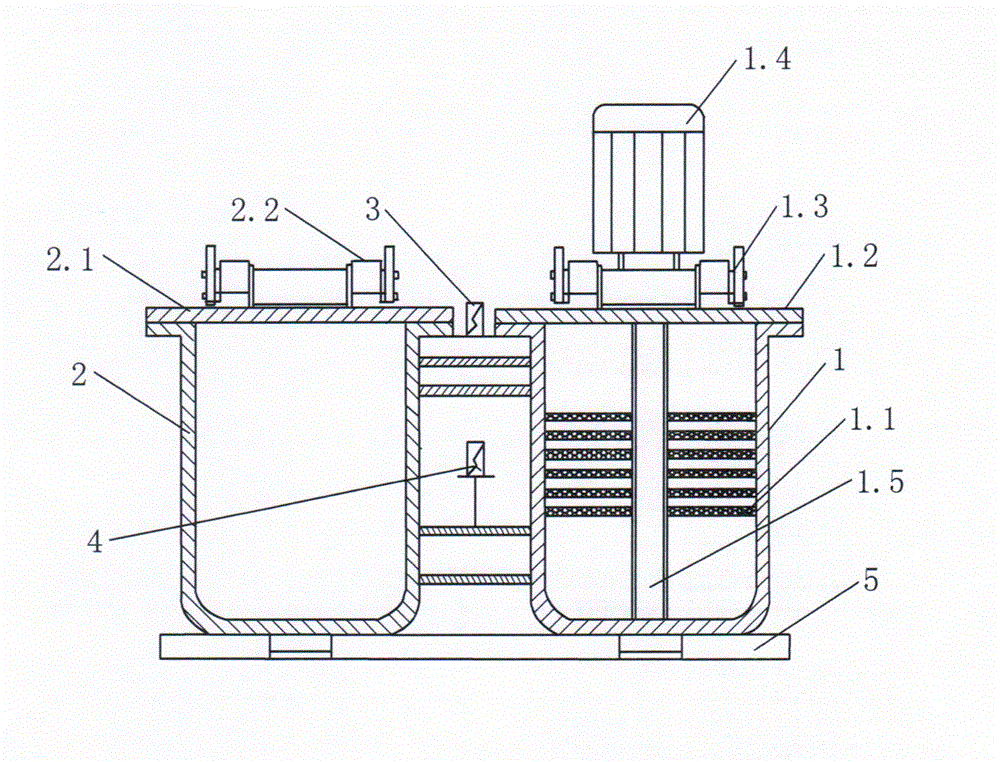

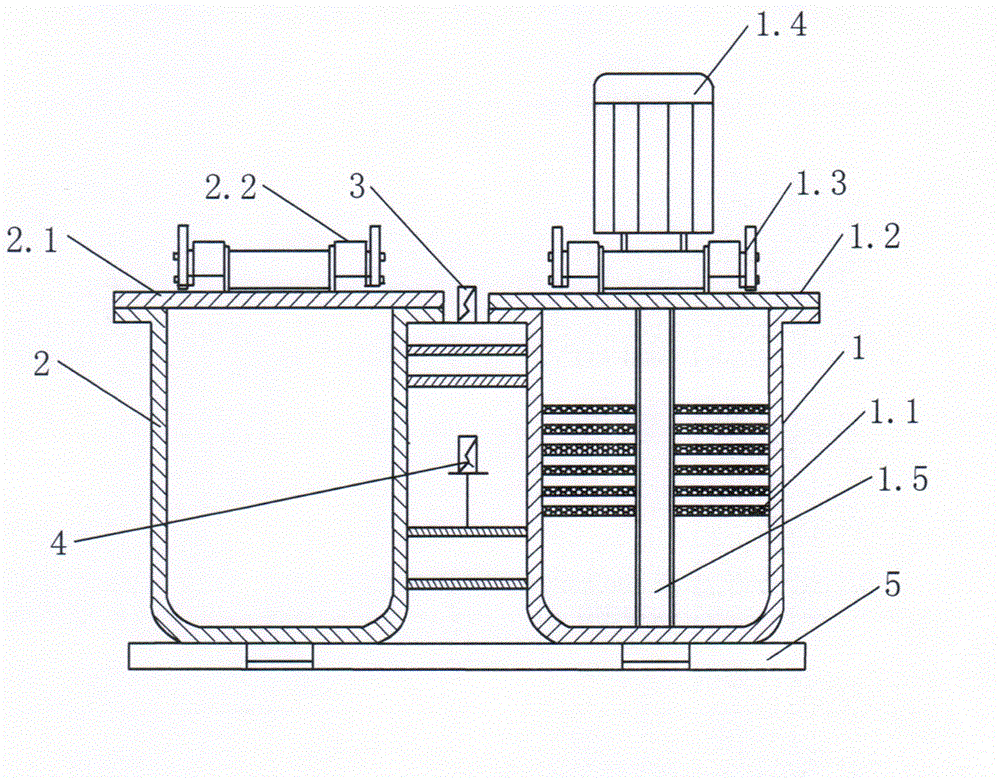

Non-mechanical-stirring sludge treatment anaerobic reactor and method for material circulation in reactor

PendingCN107434343ARealize no mechanical circulation stirringFully fermentedWater treatment parameter controlWater treatment flow arrangementsThermodynamicsProcess engineering

The invention brings forward a non-mechanical-stirring sludge treatment anaerobic reactor, which comprises a fermentation tank body and a feeding and discharging system. The feeding and discharging system comprises a main feed pipe and a discharge pipe which is communicated with the bottom of the tank body. The top of the tank body is provided with a feed inlet. A discharge end of the main feed pipe is communicated with the feed inlet. The feeding and discharging system also comprises a first feeding pump, which is used for pumping external materials into the tank body through the main feed pipe. A material circulation system comprises a material absorption header-pipe arranged at the lower middle part inside the tank body, and an auxiliary feed pipe which is arranged outside the tank body and is communicated with the main feed pipe. A discharge end of the material absorption header-pipe is communicated with the auxiliary feed pipe through a second feeding pump. The domestic sludge treatment technology is based on the non-mechanical-stirring anaerobic reactor. According to the technology, the anaerobic reactor adopts the mode of feeding at upper part and circulating at middle part to form an internal circulating fluid system of the material. Thus, problems such as nonuniform distribution, crusting at top of the tank, etc. are solved. The invention also brings forward a method for material circulation in the anaerobic reactor. According to the invention, anaerobic fermentation treatment of domestic sludge is mainly solved.

Owner:青岛中环能生物科技有限公司

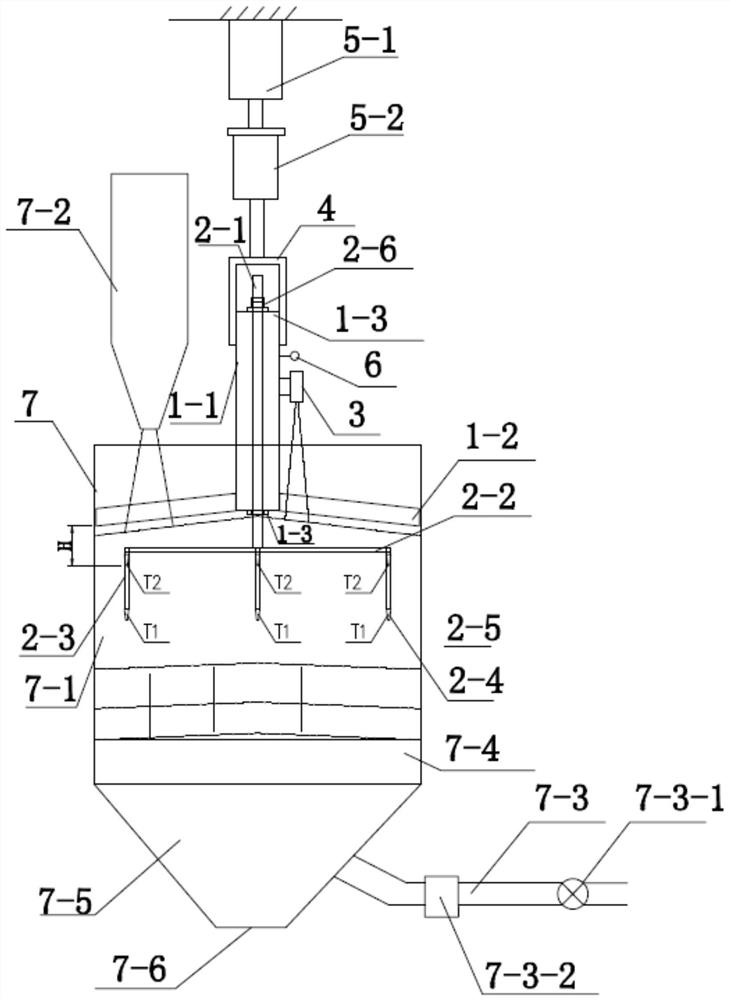

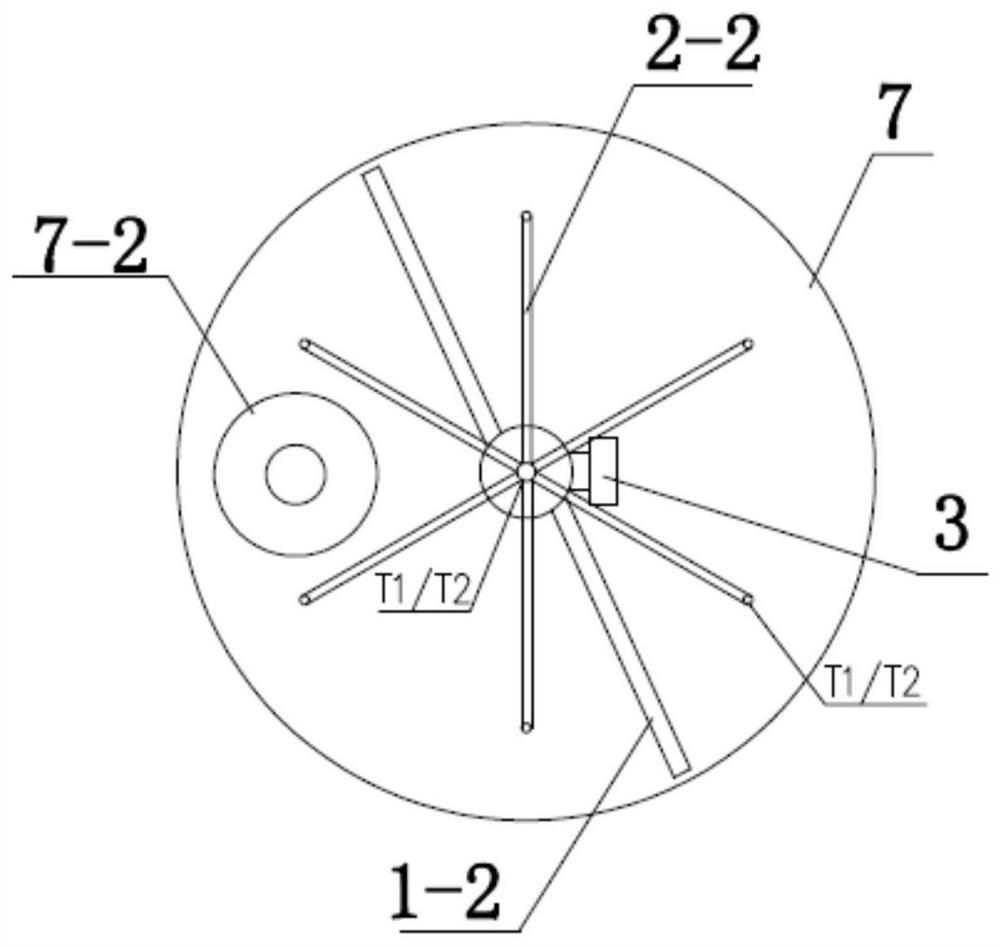

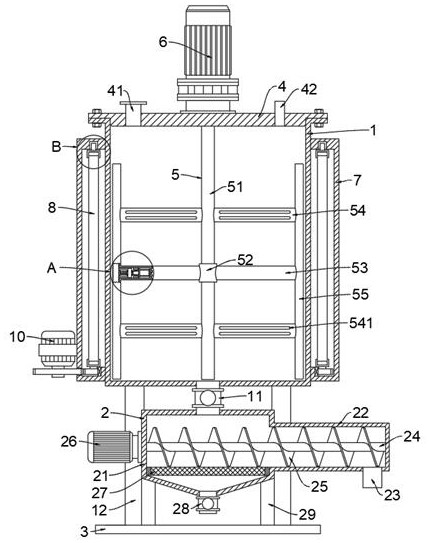

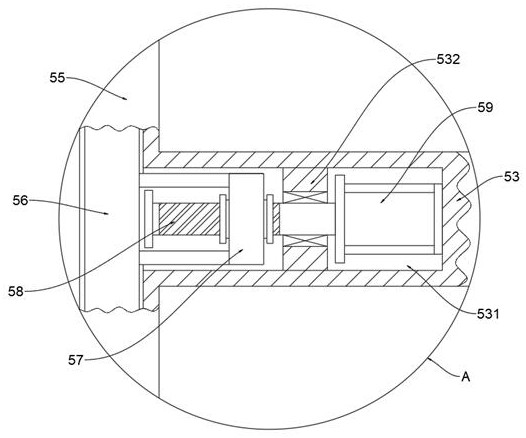

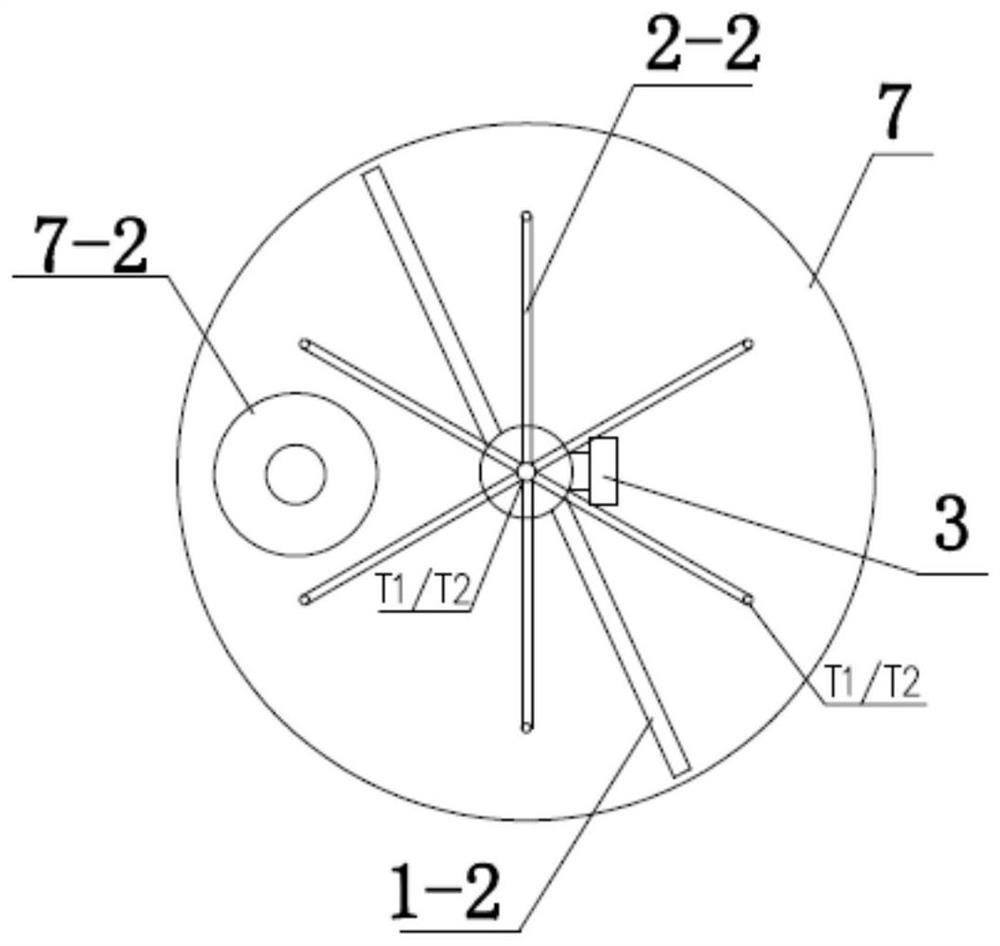

Biomass gasification fixed bed with anti-burnthrough function

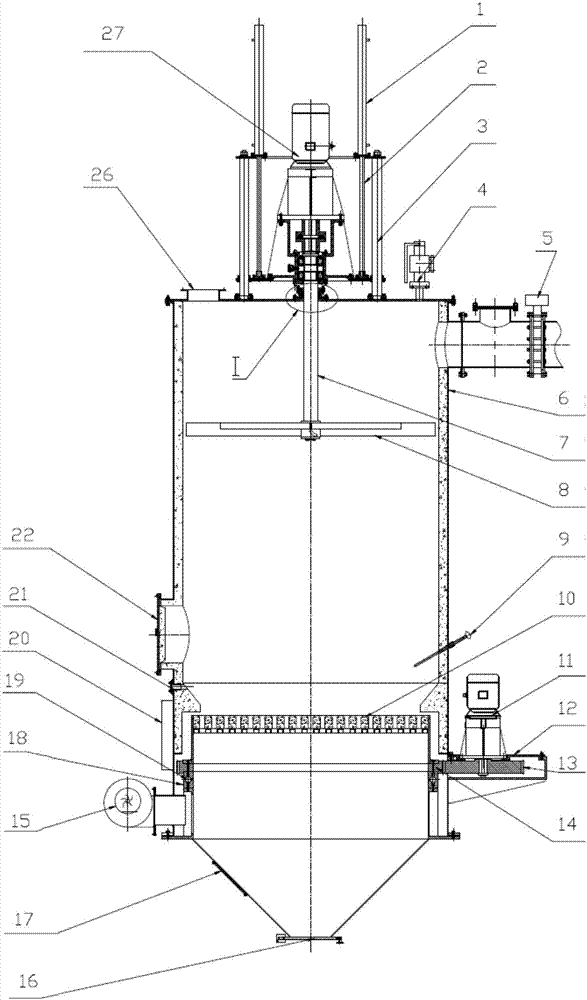

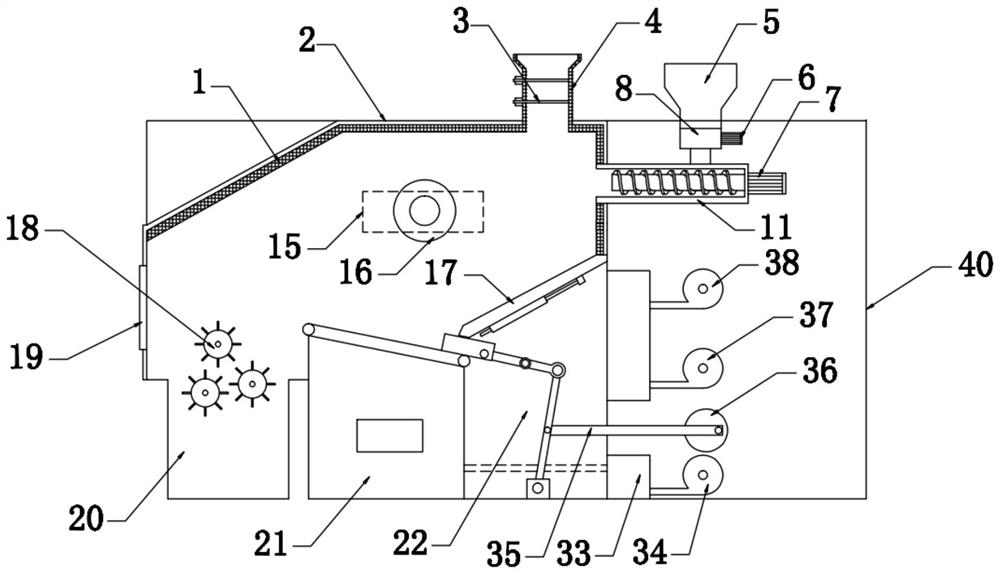

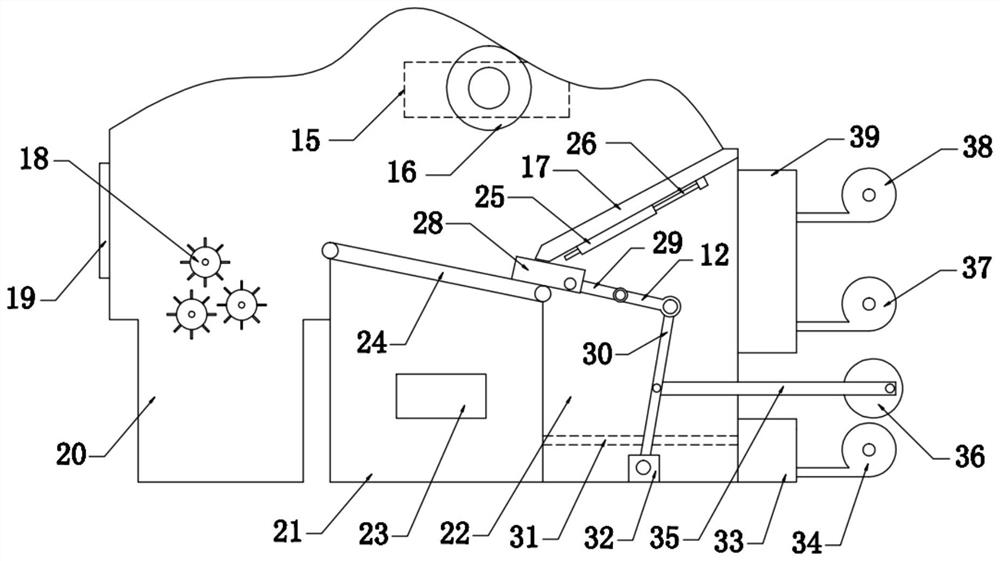

ActiveCN111944561ASolve the problem of easy burn throughFully automatedGasification processes detailsCombustible gas productionThermodynamicsCombustion

The invention discloses a biomass gasification fixed bed with an anti-burnthrough function, belonging to the technical field of biomass energy utilization equipment. The biomass gasification fixed bedcomprises a furnace body, a spreading device and a multi-point temperature detection device, wherein the furnace body comprises an upper cavity and a lower cavity, and the upper cavity and the lowercavity are separated through a fire grate; the spreading device and the multi-point temperature detecting device are both located in the upper cavity; the multi-point temperature detecting device is located below the spreading device; the spreading device and the multi-point temperature detecting device are connected with a transmission device; the fire grate comprises an upper fire grate body anda lower fire grate body which are arranged in a staggered mode; the upper fire grate body and the lower fire grate body are both rotationally connected with the furnace body; and a moving component is used for driving the upper fire grate body and the lower fire grate body to rotate. According to the invention, the defects of a traditional mode that personnel are on duty on site or a remote videomonitor isinstalled are overcome, combustion conditions in a furnace is predicted in advance, and the risks of deviated combustion and burnthrough are predicted and prevented in advance.

Owner:江苏嘉林新能源科技有限公司

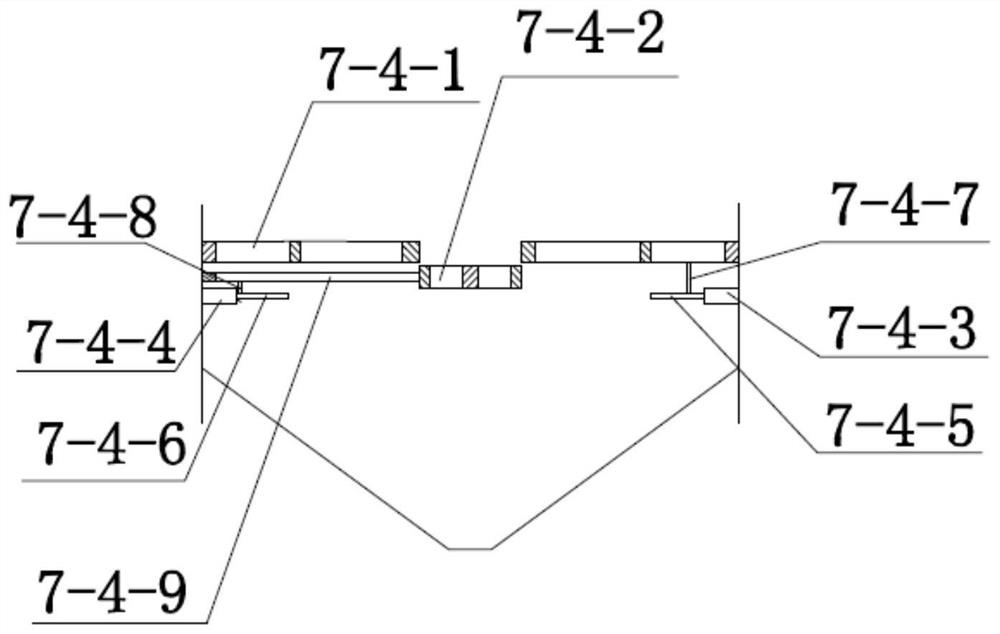

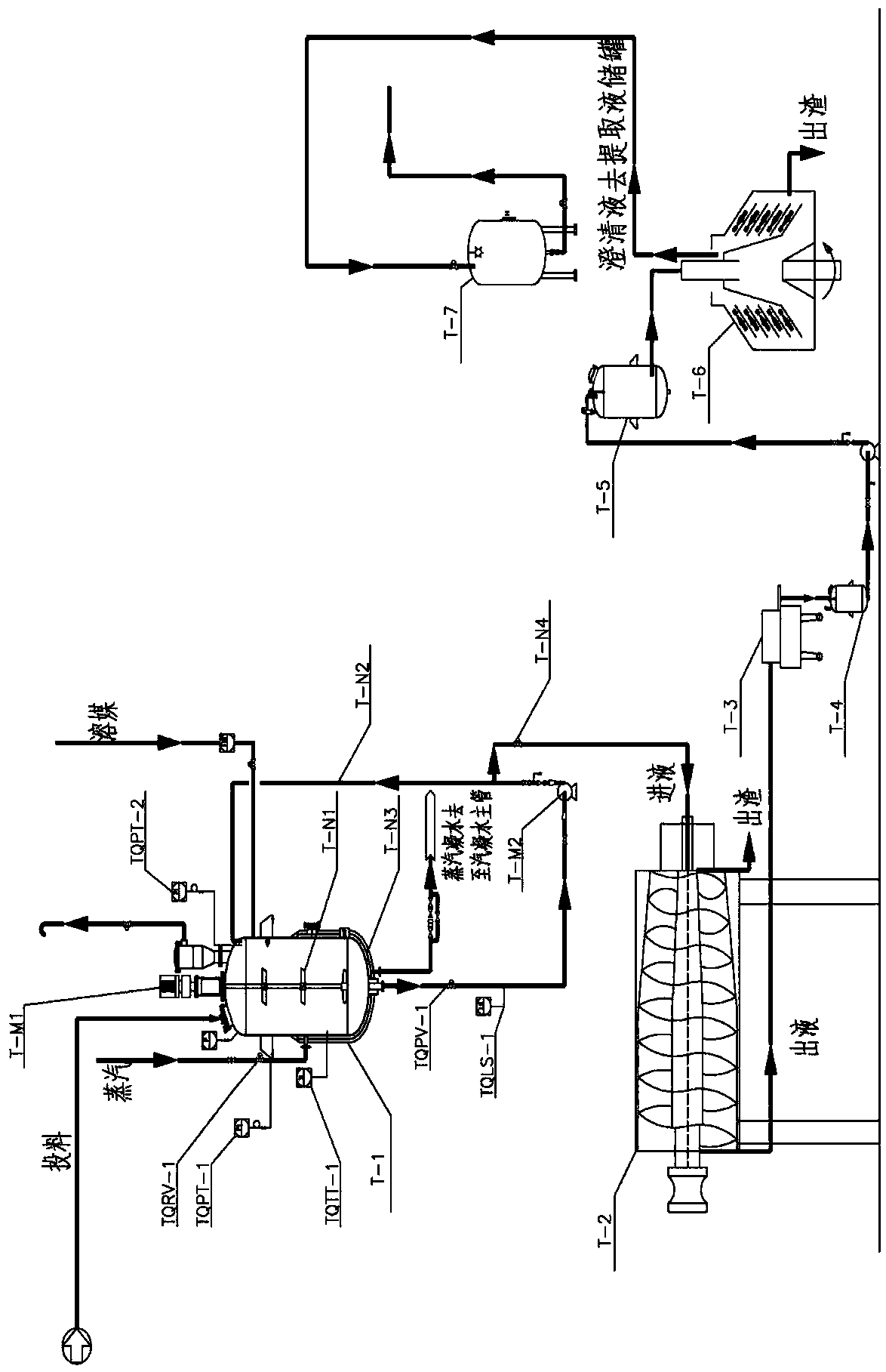

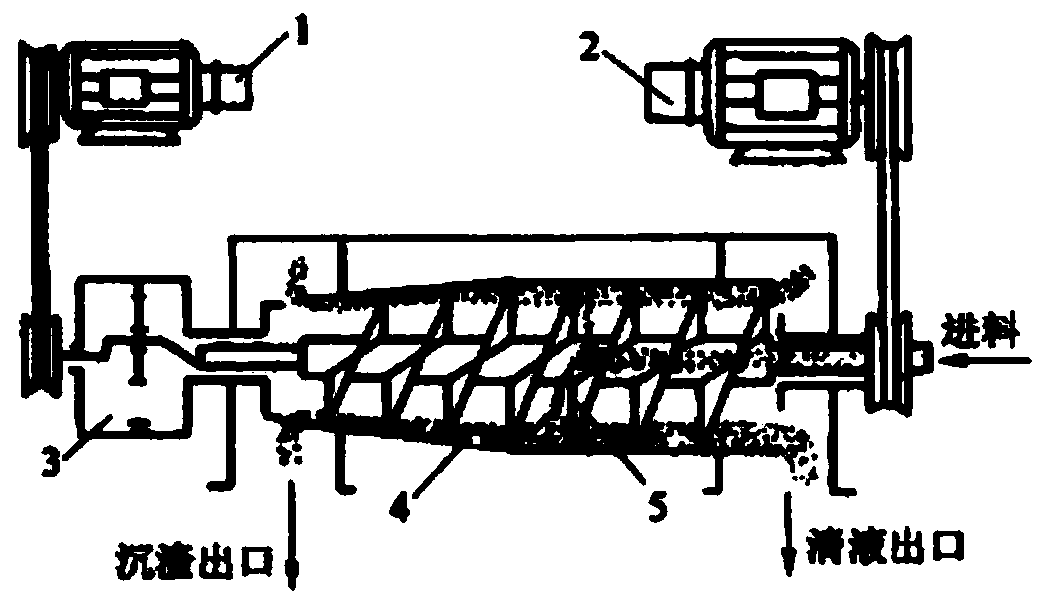

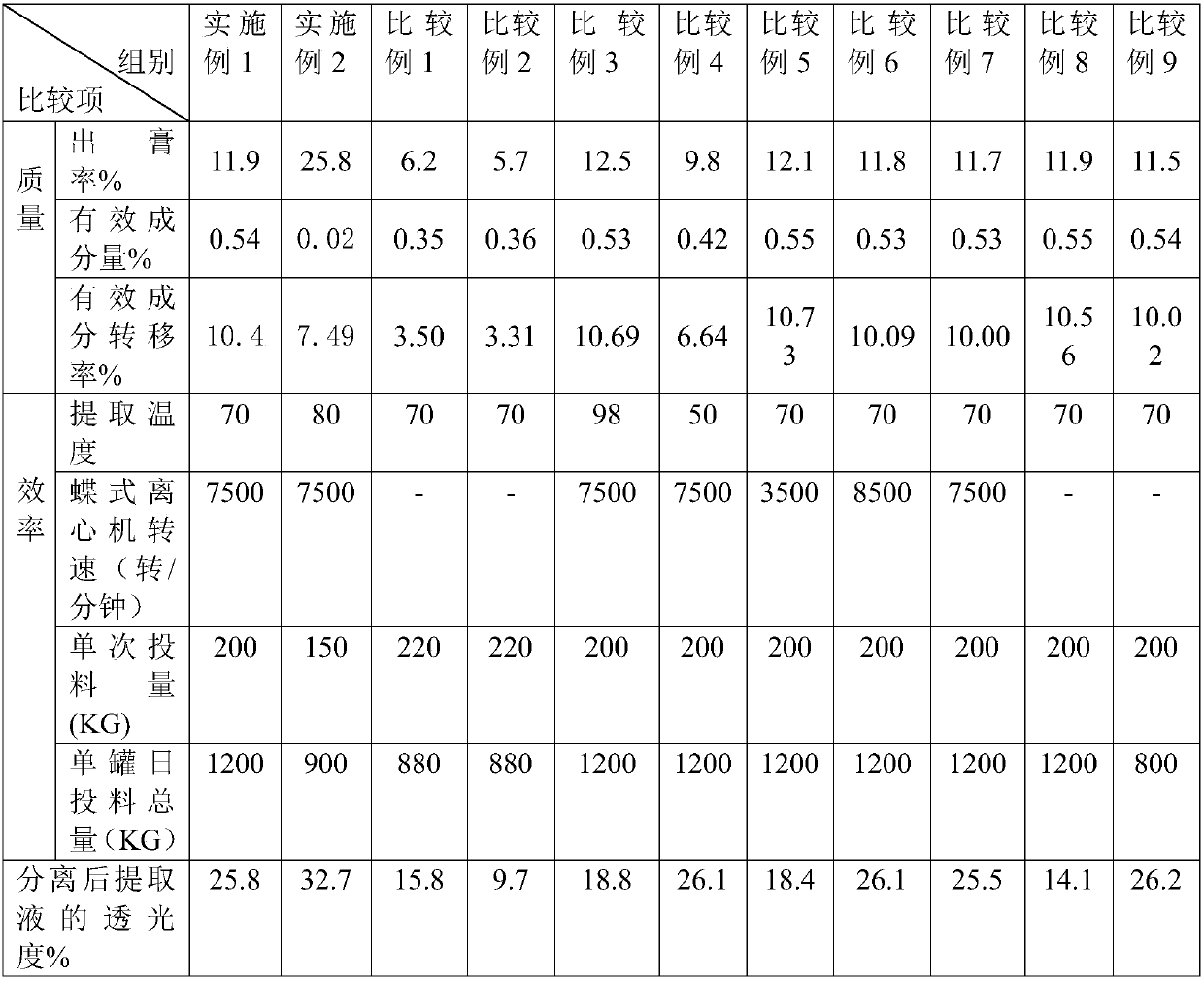

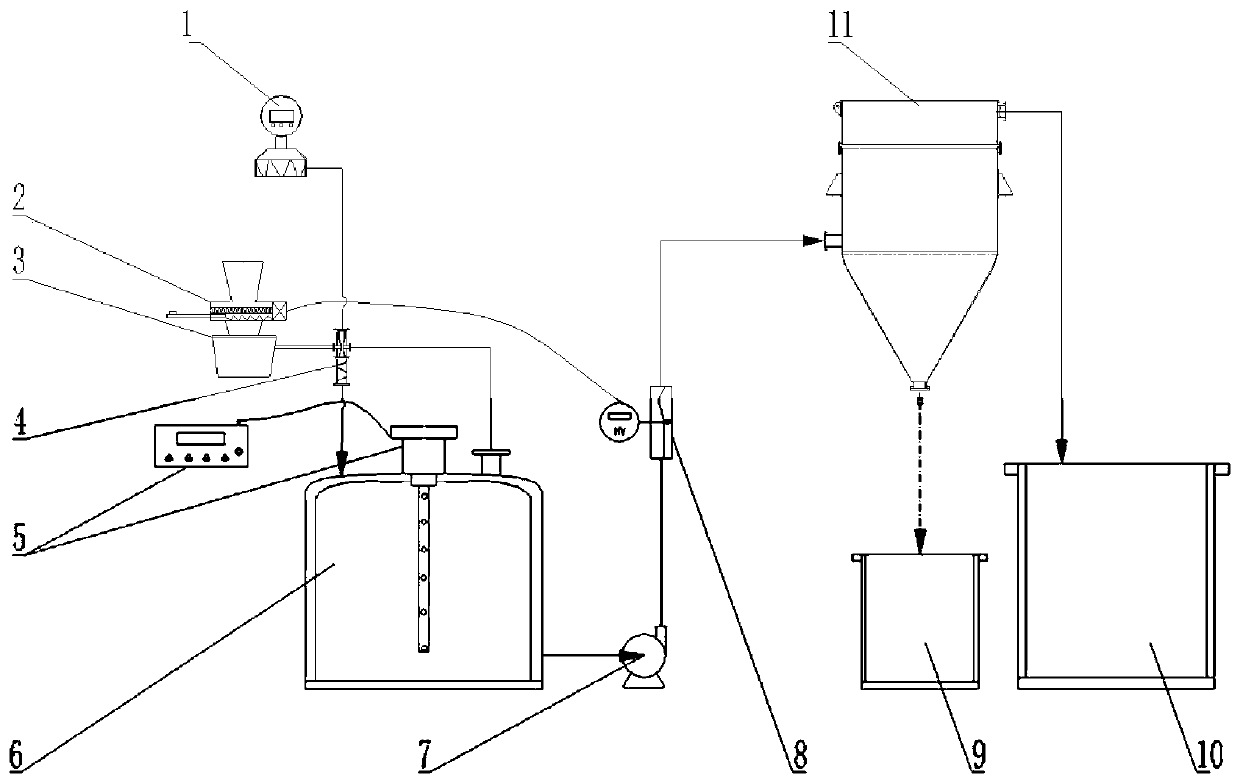

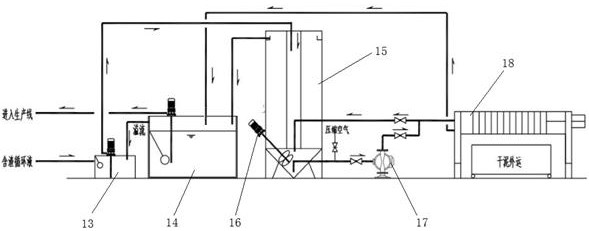

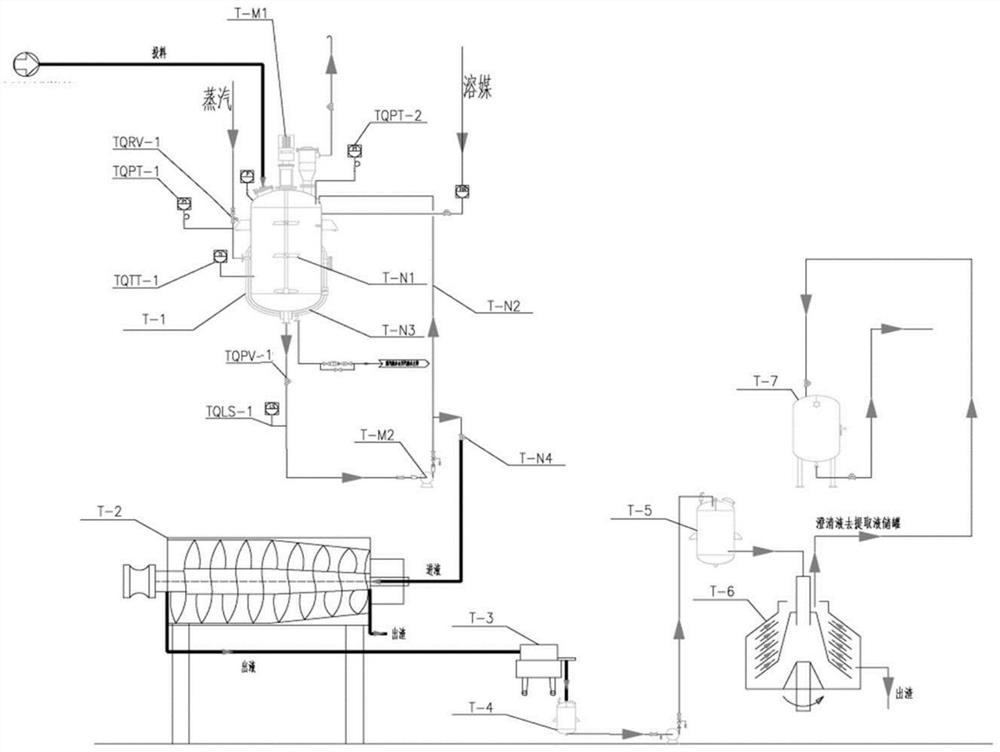

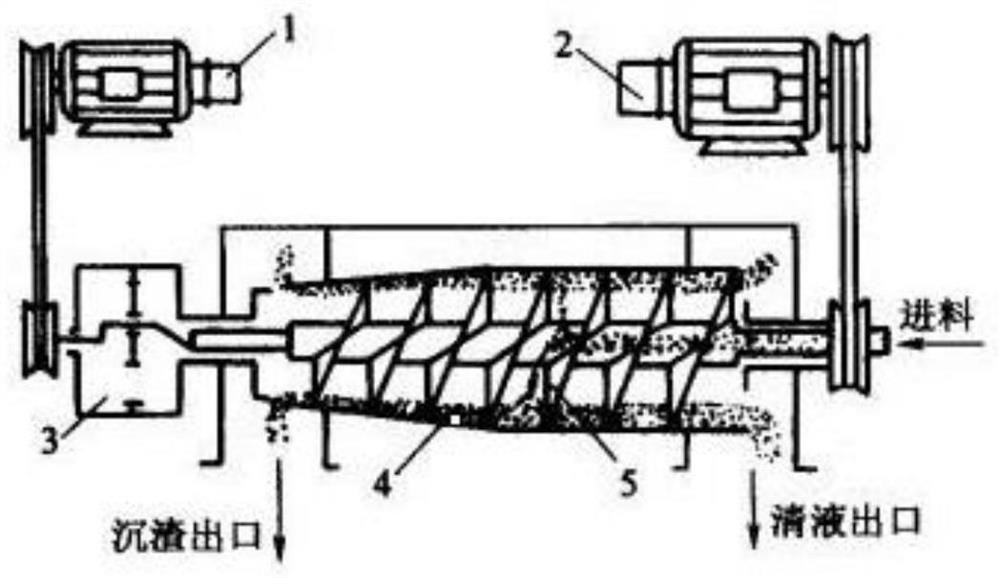

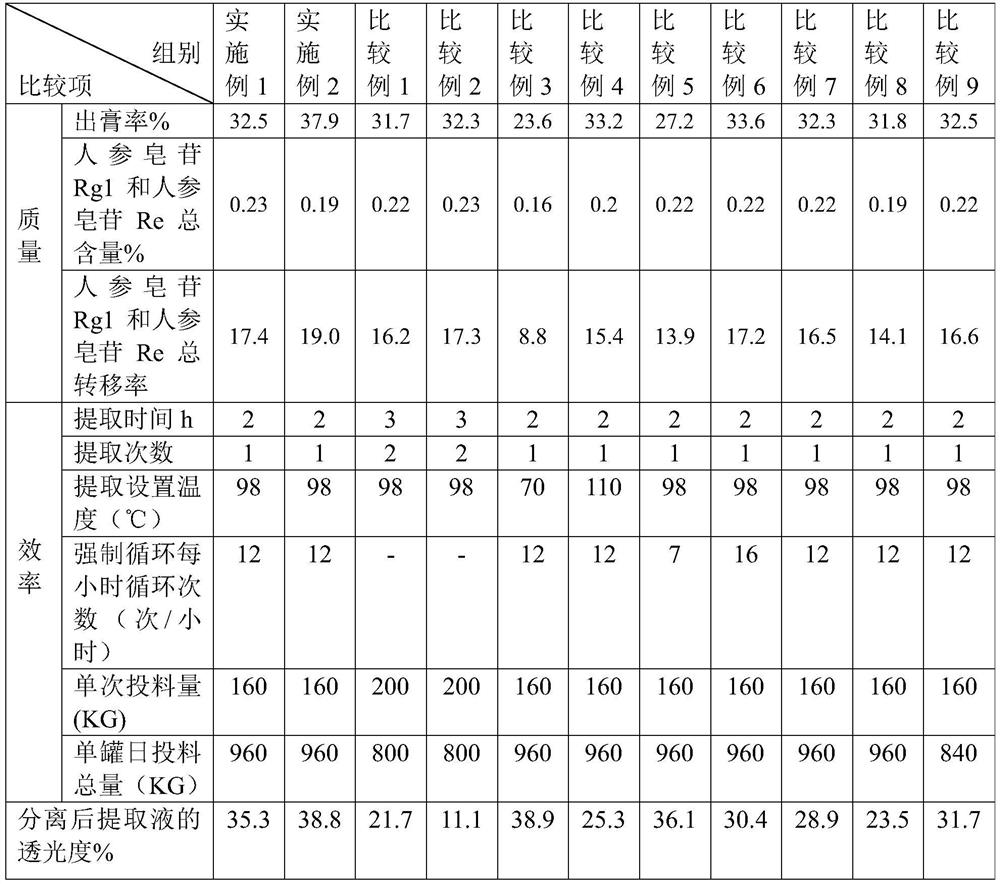

Automatic extraction and separation method for starch traditional Chinese medicines

PendingCN109569019AImprove extraction productivityImprove efficiencySolid solvent extractionFiltration circuitsSlagTransmittance

The invention relates to an automatic extraction and separation method for starch traditional Chinese medicines. The method includes a solid-liquid separation step for an extracting solution obtainedby dynamic extraction, wherein the separation step sequentially utilizes a primary centrifuge or a slag remover, a filtering solid-liquid separator and a secondary centrifuge to preform combined solid-liquid separation on the extracting solution and medicine slags flowing out of a dynamic extraction tank. Three-stage solid-liquid separation equipment is adopted to preform continuous operation, filtering bottleneck and blockage cannot be generated, continuous production can be realized, the production efficiency is high, the cost is low, and the separated product has high light transmittance and less precipitation.

Owner:JIANGYIN TIANJIANG PHARMA

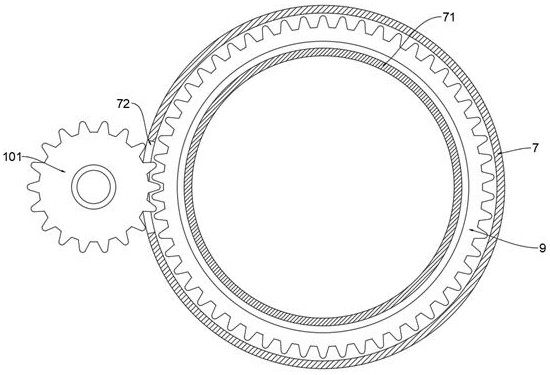

Roller rotating and driving slag removal hearth

PendingCN108870376ASolve the problem that the hearth is too largeImprove combustion efficiencySolid fuel combustionNon-combustible gases/liquids supplySlagBiomass boiler

The invention relates to a roller rotating and driving slag removal hearth, which can be used for fully automatically discharging slag generated when a biomass boiler burns out of the boiler. According to the roller rotating and driving slag removal hearth, one or multiple circular rollers are arranged in a square box body of the hearth, and the circular rollers are driven to rotate by a motor, sothat slag generated when biomass fuel burns can be automatically discharged out of the hearth and then can be discharged out of the boiler by virtue of an automatic slag extractor at the bottom of the hearth, and the full-automatic discharge of the slag is realized. Air channels are formed in three directions including the left side, the right side and the back side of the square box body of thehearth so as to perform secondary air distribution on the fuel in the hearth, air channel holes are formed in the rotary rollers, bellows are arranged on the lower ends of the air channel holes, air in the bellows is upward so as to perform primary air distribution on the biomass fuel during burning, and additionally, residual ash in the air channel holes in the rollers can be blown off.

Owner:正圆合(长春)生物质科技有限公司

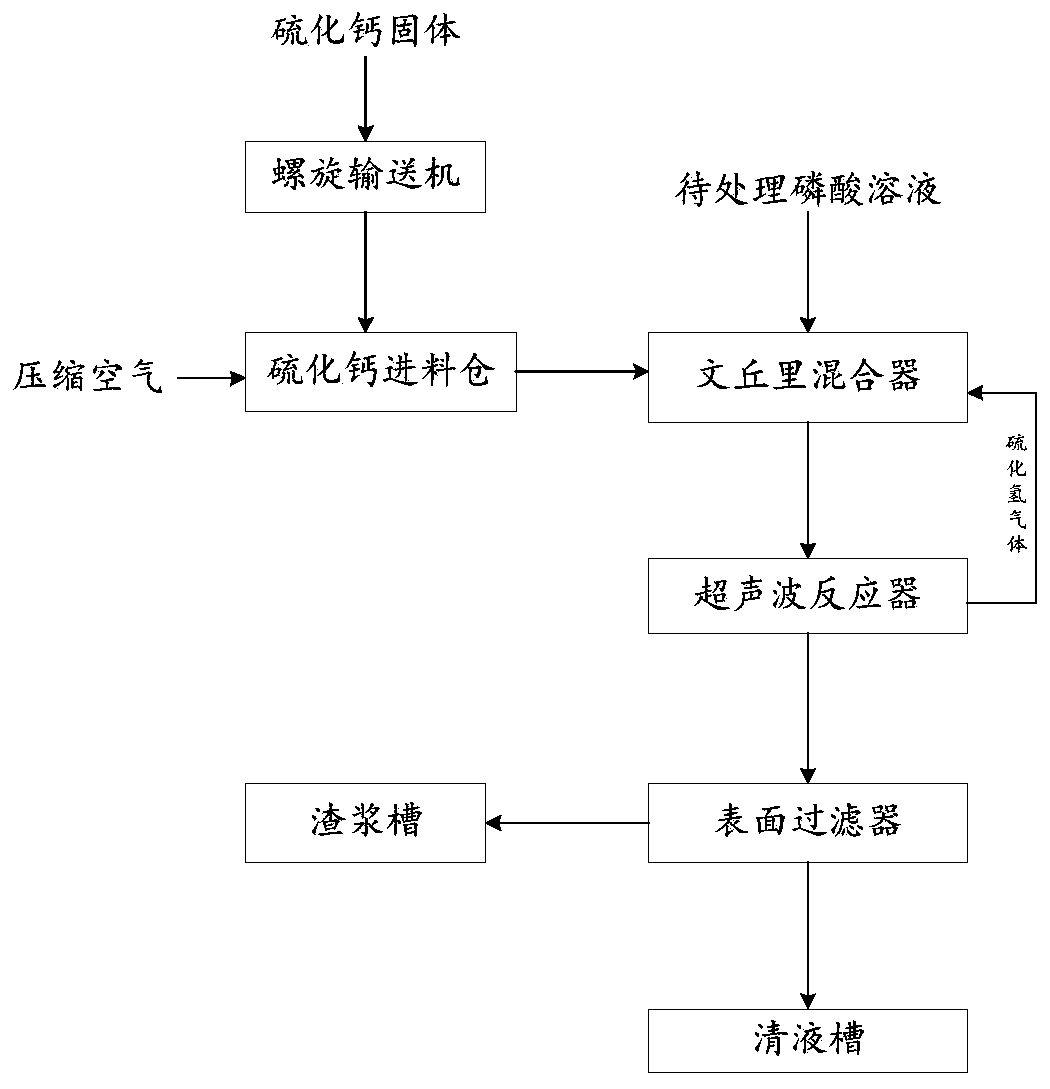

Arsenic removal apparatus and method for purifying wet-process phosphoric acid by vulcanization

The invention discloses an arsenic removal apparatus and method for purifying wet-process phosphoric acid by vulcanization. The apparatus herein comprises a screw conveyer, a vulcanizer chamber, a venturi mixer, a reaction tank and a solid-liquid separator. A vulcanizer is fed into the vulcanizer chamber through the screw conveyer; an outlet of the vulcanizer chamber is connected with a vulcanizerinlet of the venturi mixer; an outlet of the venturi mixer is connected with an inlet of the reaction tank; an outlet of the reaction tank is connected with the solid-liquid separator; the venturi mixer is also provided with a phosphoric acid solution inlet; the vulcanizer chamber is provided with a compressed air inlet; the reaction tank is an airtight device. Traditional stirring is replaced with the venturi mixer, so that materials are mixed well in the venturi mixer; the apparatus requires small floor area and has no power consumption, so that energy is saved, and the cost is reduced. Inaddition, the reaction tank is the airtight device, the vulcanizer has no need for being independently configured into a solution, overflow of hydrogen sulfide gas generated by the reaction is effectively prevented, field operation safety is improved, and the environment is protected.

Owner:陕西金禹科技发展有限公司

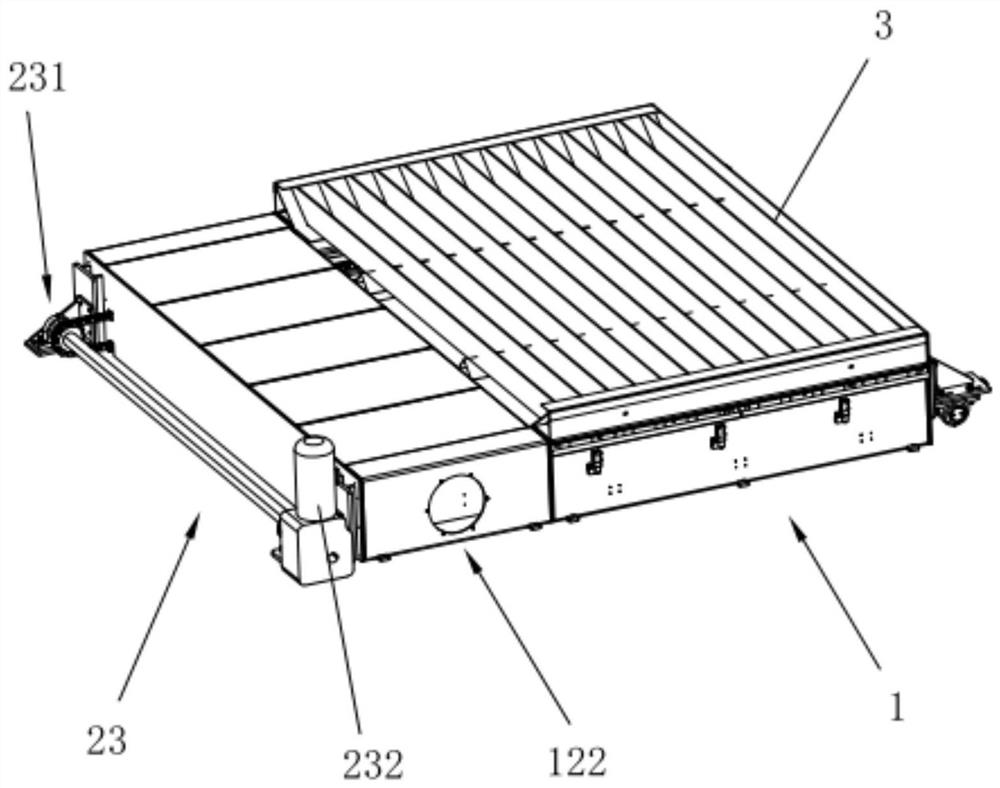

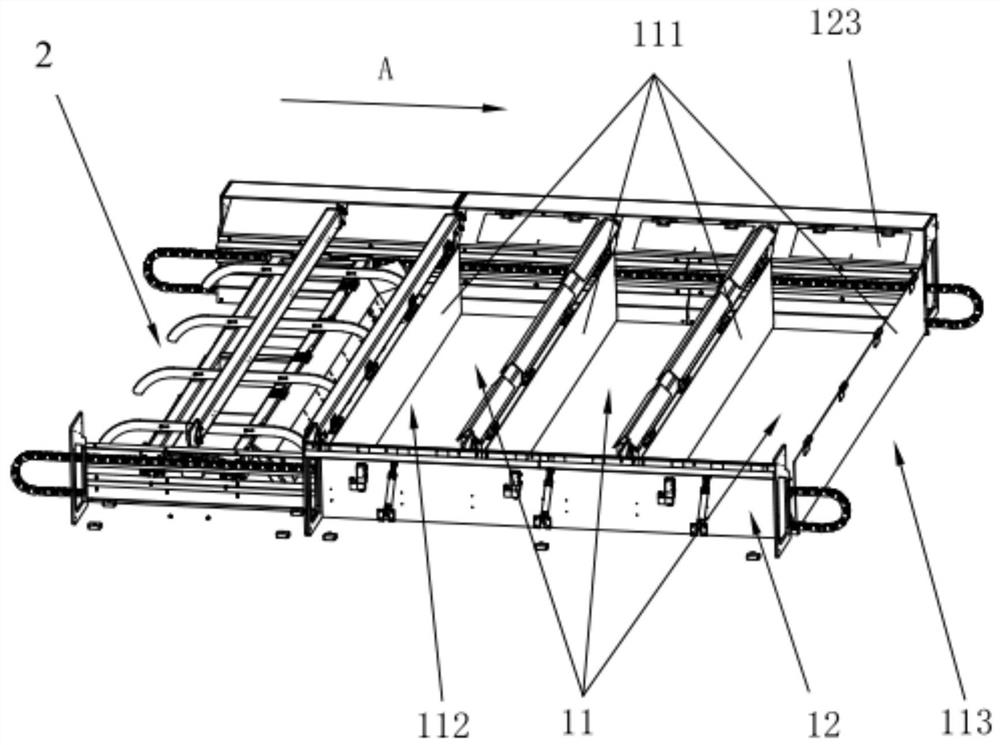

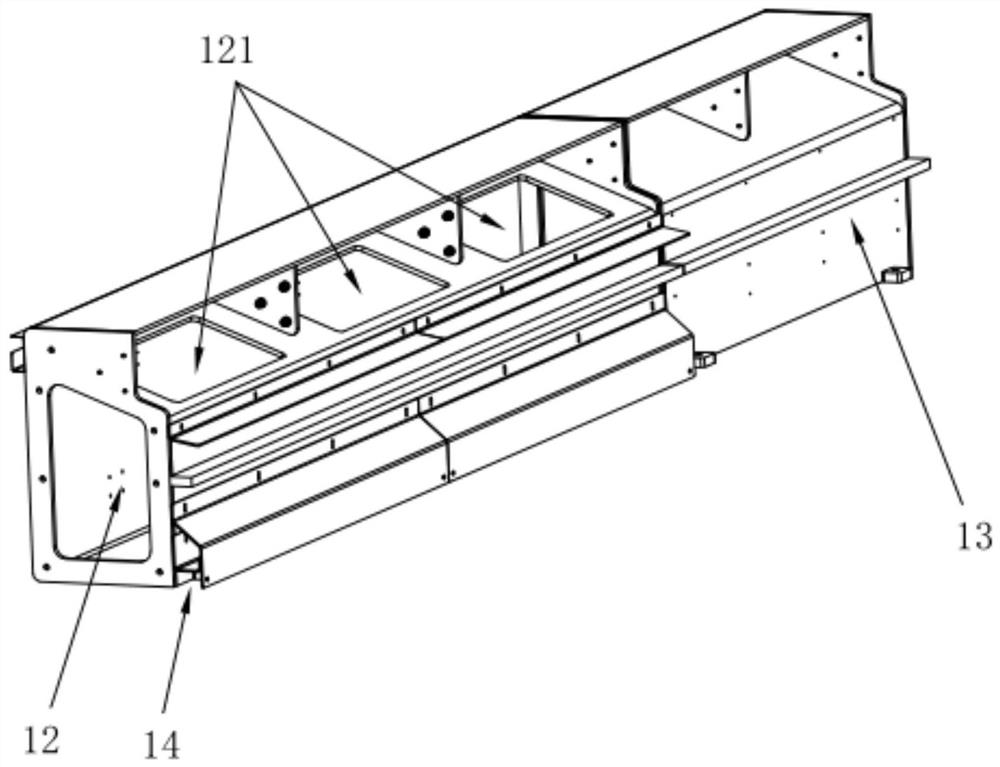

Cutting workbench

PendingCN112122948AShorten the timeRealize automatic slag dischargeLarge fixed membersMaintainance and safety accessoriesSlagDust control

The invention belongs to the technical field of machining equipment, and discloses a cutting workbench which comprises a workbench main body and a slag removal device. A part to be cut is supported through the workbench main body, and a slag storage chamber used for collecting waste slag generated by cutting the part to be cut is arranged in the workbench main body; a dust removal duct is arrangedon the side wall of the slag storage chamber; The interior of the slag storage chamber is divided into a plurality of chambers in the first direction, and each chamber is provided with an air inlet communicating with the dust removal duct; the air inlets communicate with the chambers through air doors selectively; and when the air doors are opened and the air inlets communicate with the chambers,smoke dust generated in the cutting process can be removed through the air inlets and the dust removal duct. The slag removal device can enter each chamber in the first direction so that the waste slag in the chambers can be discharged. According to the workbench, automatic slag removal can be achieved through the slag removal device, the time that a machine is shut down for removing the waste slag is reduced, and the slag removal efficiency is improved.

Owner:上海气焊机厂有限公司

Sewage treatment structure for sewage treatment equipment

InactiveCN112456712AReduce labor intensityImprove mixing effectSpecific water treatment objectivesRotary stirring mixersElectric machinerySewage treatment

The invention discloses a sewage treatment structure for sewage treatment equipment, relates to the technical field of sewage treatment, and aims to solve the problems that a large number of precipitated impurities are accumulated on a filtering plate when the existing sewage treatment equipment is used for treating sewage, and filtering holes of the filtering plate are easy to block after long-time use. A water discharging pipe is arranged at the bottom end of the tank body, a slag discharging mechanism is installed at the lower end of the water discharging pipe, the slag discharging mechanism comprises a collecting box, a slag discharging pipeline, a slag discharging opening, a rotating shaft, a spiral conveying piece, a first driving motor, a filtering plate, a water outlet pipe and a second supporting foot, and the slag discharging pipeline is arranged on one side of the collecting box; and the rotating shaft is arranged in the middle of the slag discharging pipeline, the spiral conveying piece is arranged outside the rotating shaft, the first driving motor is arranged on the other side of the collecting box, the filtering plate is arranged in the collecting box, and the wateroutlet pipe is arranged at the bottom end of the collecting box.

Owner:刘贤龙

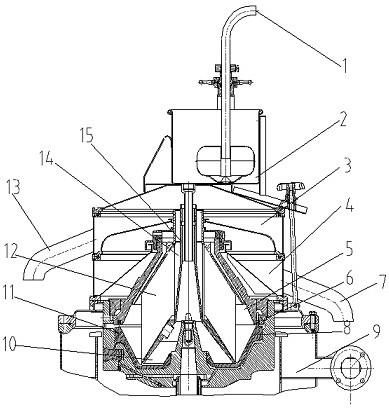

Automatic deslagging latex separator

The invention relates to an automatic deslagging latex separator. The automatic deslagging latex separator is characterized in that a feeding barrel is arranged at the top of a separator shell, and a pipeline of the feeding barrel is inserted into the center of a distributor in a rotary drum; a feeding pipe is arranged in the feeding barrel, and the end, extending out of the barrel, of the feeding pipe is connected with a natural fresh latex inlet; a disc is connected to the distributor of the rotary drum in a sleeving mode, a heavy liquid channel is formed outside the circumference of the disc, and a clear liquid channel is arranged outside the circumference of the distributor; an upper cover and a lower cover are arranged in the separator shell, the upper cover is connected with a concentrated latex outlet through a pipeline, and the lower cover is connected with a skim latex outlet through a pipeline; light concentrated natural latex enters the light liquid channel, is thrown out of the rotary drum through centrifugal force, enters the upper cover and flows out through the concentrated latex outlet; heavy skim latex is thrown out of the rotary drum through centrifugal force, enters the lower cover and flows out through the skim latex outlet; heavies solid impurities are attached to the outermost side in the rotary drum and in a horn mouth through centrifugal force; and a solid impurity outlet is formed in the bottom of the separator shell. The separator can effectively prolong the separation service time, does not need to be frequently disassembled, assembled and cleaned, and improves the production efficiency.

Owner:CSSC NANJING LUZHOU MACHINE

Juicer

The invention relates to a juicer, which comprises a juicing mechanism and a driving mechanism for driving the juicing mechanism to run, wherein the juicing mechanism comprises a container and a rotary drum rotationally arranged in the container and driven by the driving mechanism; the rotary drum is provided with a scraping plate protruding the rolling surface of the rotary drum; and the wall of the container is provided with a juice outlet and a residue outlet. When fruits or vegetables enter the juicer from a fruit and vegetable passage, the rotary drum and the container wall squeeze the fruits or the vegetables, and sacs of the fruits or the vegetables are broken by squeezing, so that fruit juice or vegetable juice in the fruits or the vegetables flows out and is discharged from the juice outlet, the fruit residue or the vegetable residue is discharged by the scraping plate from the wall of the container to the residue outlet, separation of the juice and the residue is realized, the residue is automatically discharged, the operation is more convenient, and the problems of un-cleanliness, inconvenience and time waste caused by manual residue discharge are avoided.

Owner:汪恩光

Automatic residue discharging method of food processor

PendingCN113455938ARealize automatic slag dischargeRealize automatic cleaningKitchen equipmentProcess engineeringSteam generation

The invention relates to a control method of kitchen household appliances, in particular to an automatic residue discharging method of a food processor, the food processor comprises a pulping chamber, a liquid discharging assembly for controlling the pulping chamber to be opened and closed, and a steam generating device for introducing steam into the pulping chamber, the automatic residue discharging method of the food processor is characterized by comprising the steps that after slurry discharging is finished, when the liquid discharging assembly is in an open state, the steam generating device introduces steam into the pulping chamber, and the steam drives slurry residues to be discharged out of the pulping chamber through the liquid discharging assembly. According to the food processor adopting the residue discharging method, the purpose that the pulp residues in the pulping chamber can be discharged through steam without cleaning water or with little cleaning water can be achieved, in addition, the method can achieve automatic residue discharging of the food processor, and automatic cleaning without hand washing can also be achieved.

Owner:JOYOUNG CO LTD

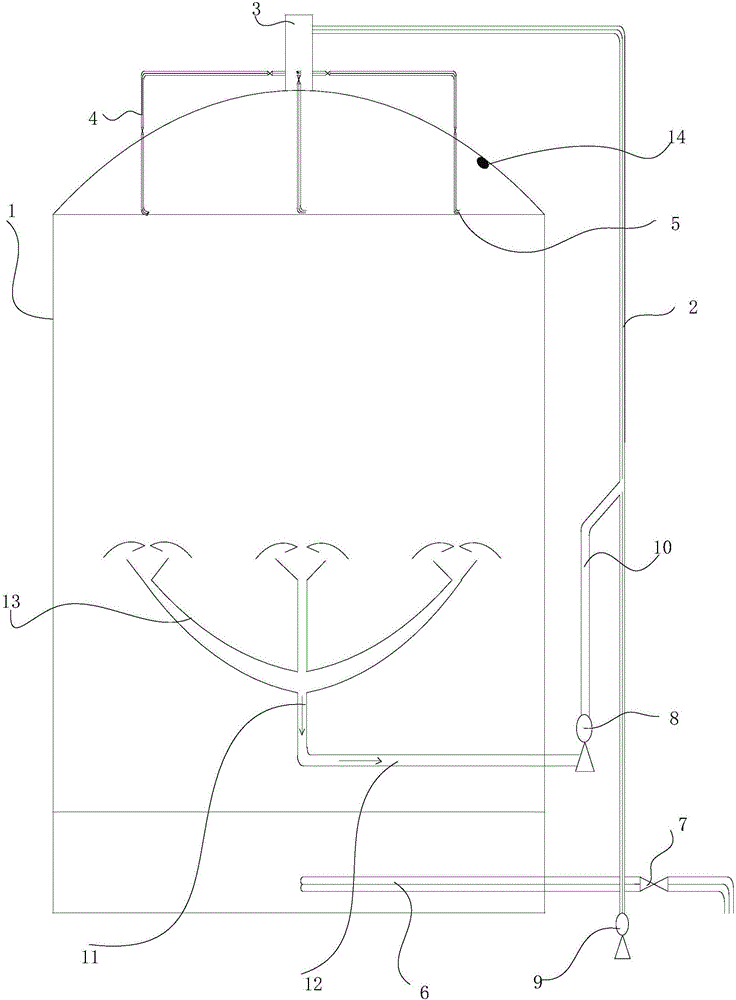

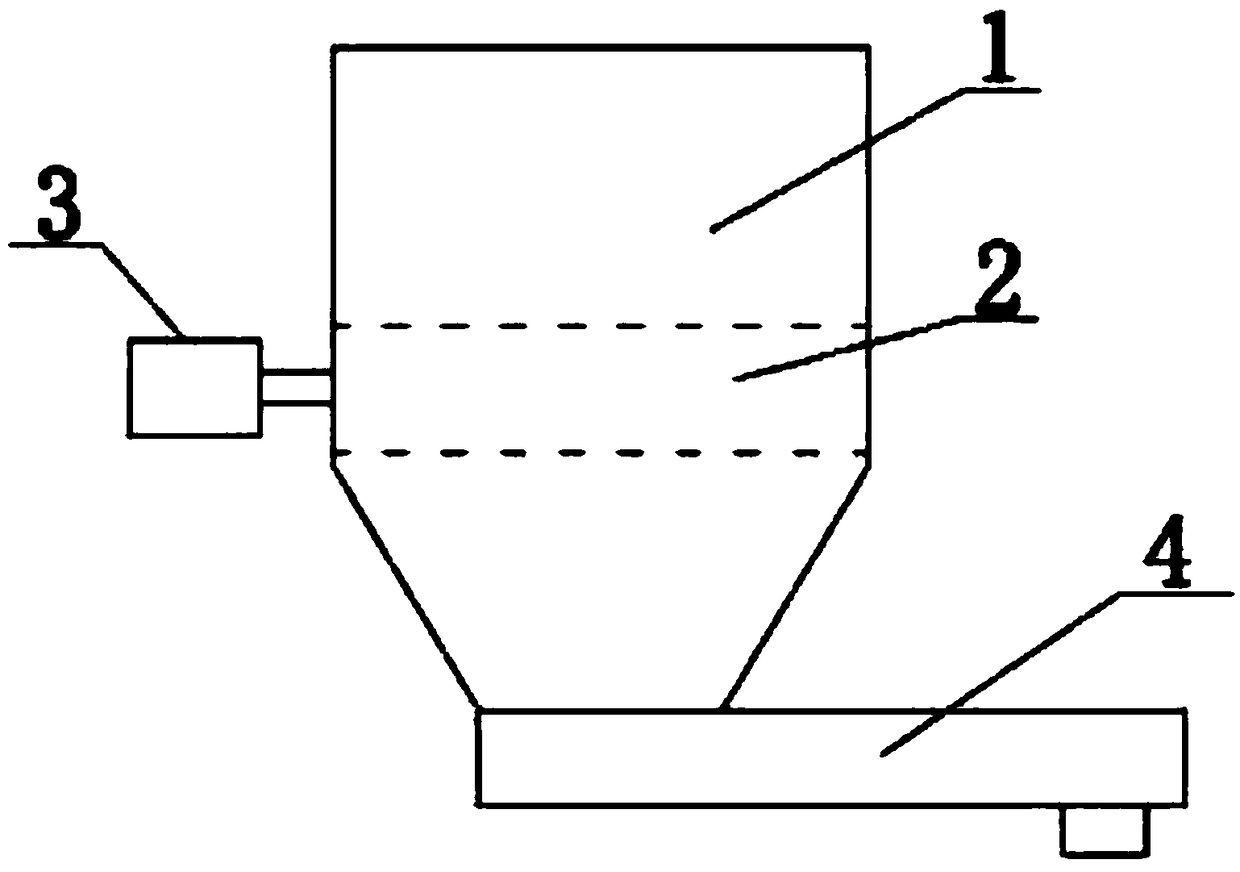

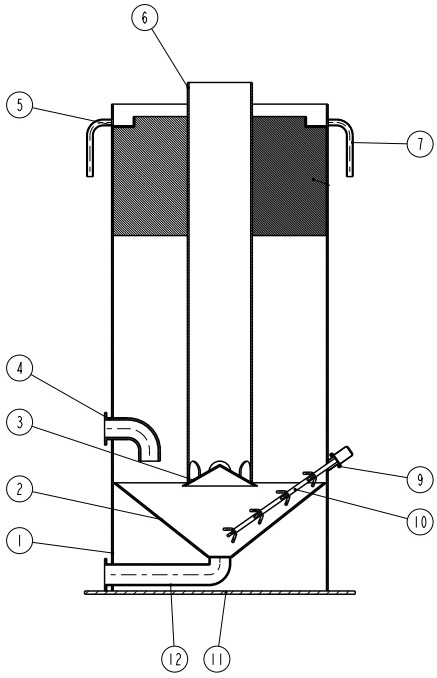

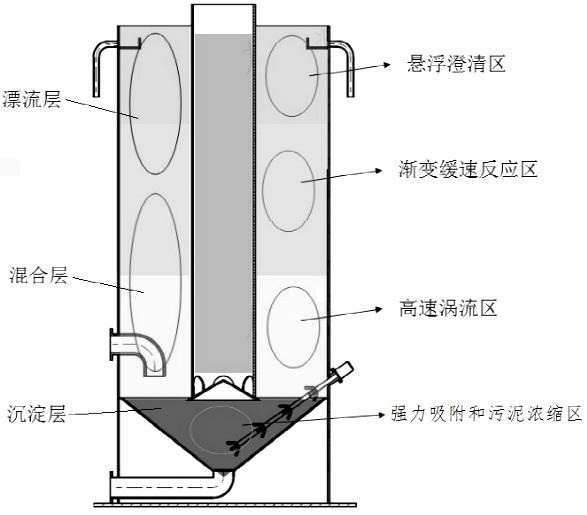

Extremely simple high efficiency gas floatation machine, and gas floatation method

PendingCN108622972ANo overflowRealize automatic slag dischargeWater/sewage treatment apparatusWater/sewage treatment by flotationRefluxProcess engineering

The invention discloses an extremely simple high efficiency gas floatation machine. The extremely simple high efficiency gas floatation machine comprises a gas floatation pool main body, a spiral water inlet pipeline, a reflux pump, a gas inflation pipeline, and a gas dissolving pipeline; the upper end and the lower end of the gas floatation pool main body are designed to shape like a cone; the top end and the bottom end of the gas flotation pool main body are provided with a residue discharging pipeline and a water outlet pipe with adjustable height respectively; an agent adding port a and anagent adding port b are arranged on the spiral water inlet pipeline. In applications, agents and sewage are subjected to high speed eddy flow in an eddy flow water inlet pipeline, so that rapid stirring mixing full reaction is realized; the residue discharging pipeline is arranged on the top part of the upper cone-shaped end of the gas floatation pool main body, and is combined with the water outlet pipe with adjustable height, so that automatic residue discharging is realized; an outlet of the reflux pump is provided with the gas inflation pipeline and the gas dissolving pipeline, on the gasinflation pipeline, a venturi tube is used for gas suction, and gas is introduced into an inlet of the reflux pump, so that automatic gas inflation is realized. The extremely simple high efficiency gas floatation machine is capable of solving technical problems in the prior art that the amount of gas floatation machine mechanical equipment is too large, water consumption of per ton is high, and mud is easily accumulated at pool bottoms.

Owner:NINGBO SHANGFUYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

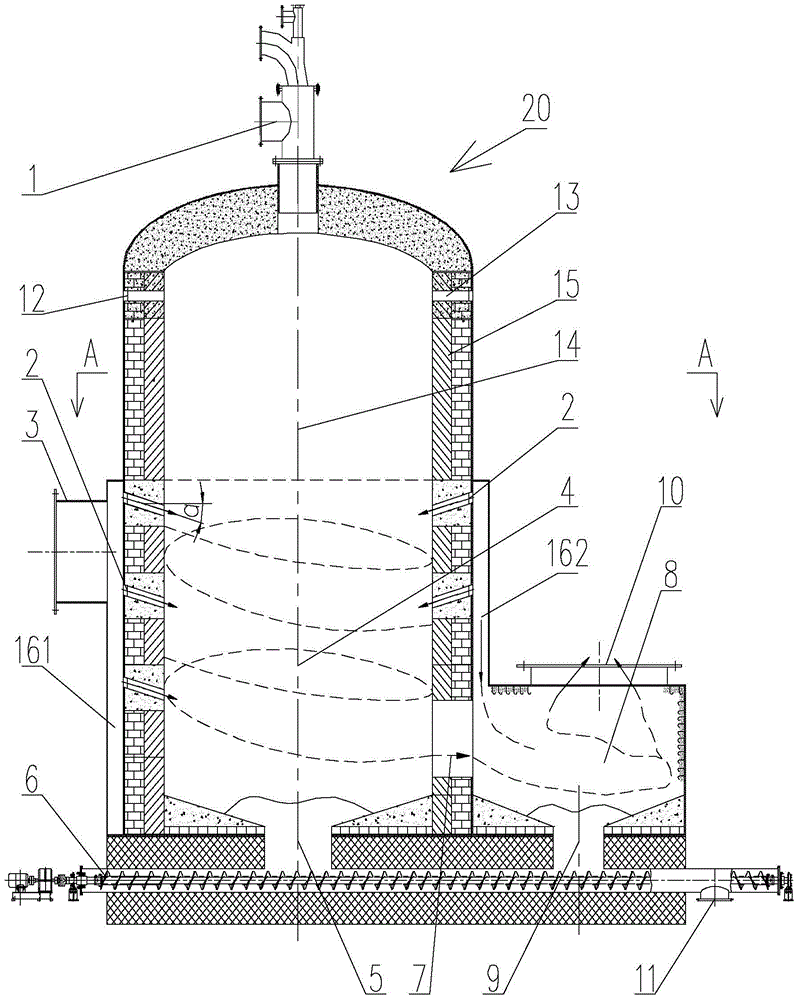

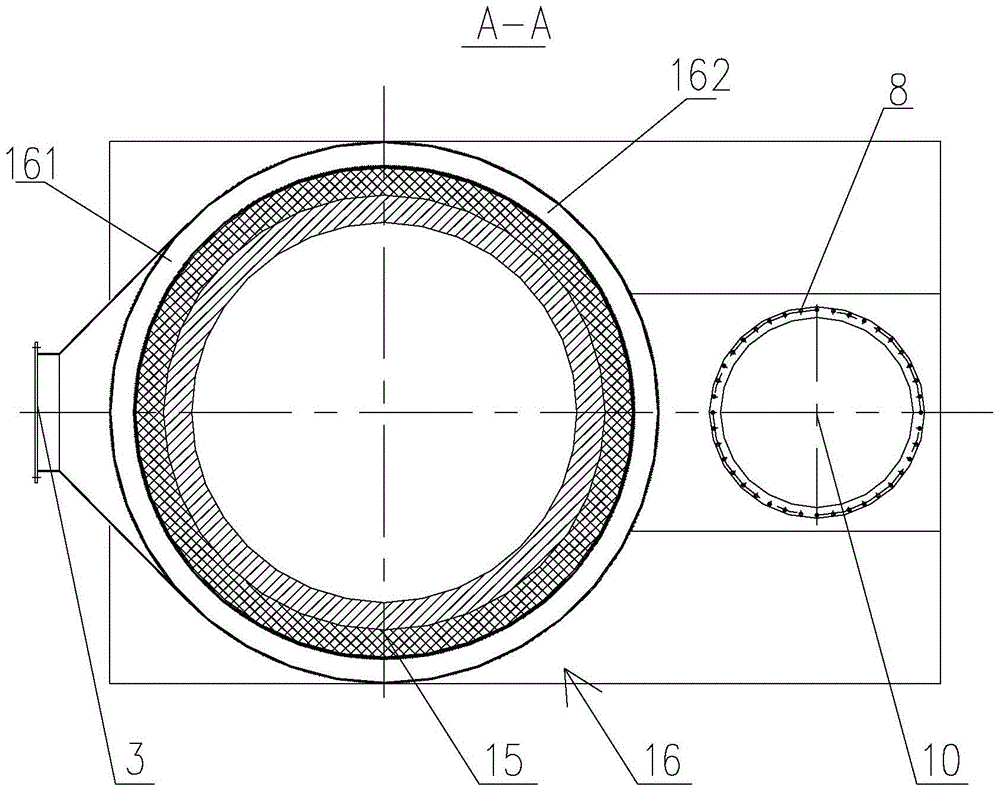

High efficiency oil sludge incinerator

ActiveCN103939919BReduce the temperatureHigh thermal efficiencyIncinerator apparatusInlet channelDiesel combustion

An efficient oil sludge incinerator comprises an incinerator body formed by an inner incinerator wall (11) and an outer incinerator wall (10). The efficient oil sludge incinerator is characterized in that an air interlayer (12) is formed between the inner incinerator wall and the outer incinerator wall, a primary air inlet (13) is formed in the outer incinerator wall, an incinerator bottom (5) is arranged on the lower portion of an incinerator chamber (15), an incinerator bottom air outlet (6) communicated with an air outlet of an air distribution plate (4) placed on the outer portion of an incinerator bottom (5) is formed in the incinerator bottom, an air inlet of the air distribution plate (4) is communicated with the air interlayer, a secondary air inlet channel (9) is arranged in the middle of the incinerator body, a screw feeder (8) which conveys oil sludge into the incinerator chamber is arranged on the middle-lower portion of the incinerator body, a diesel combustion-supporting device (1) is arranged on the lower portion of the incinerator body, a smoke outlet channel (14) is arranged on the upper portion of the incinerator body, and a controllable deslagging channel (16) is arranged on the lower portion of the incinerator body. The efficient oil sludge incinerator has the advantages of being high in burning efficiency, stable in incineration and low in mechanical fault rate, and ideal equipment is provided for oil sludge efficient cleaning processing.

Owner:JIANGSU JINDING BOILER

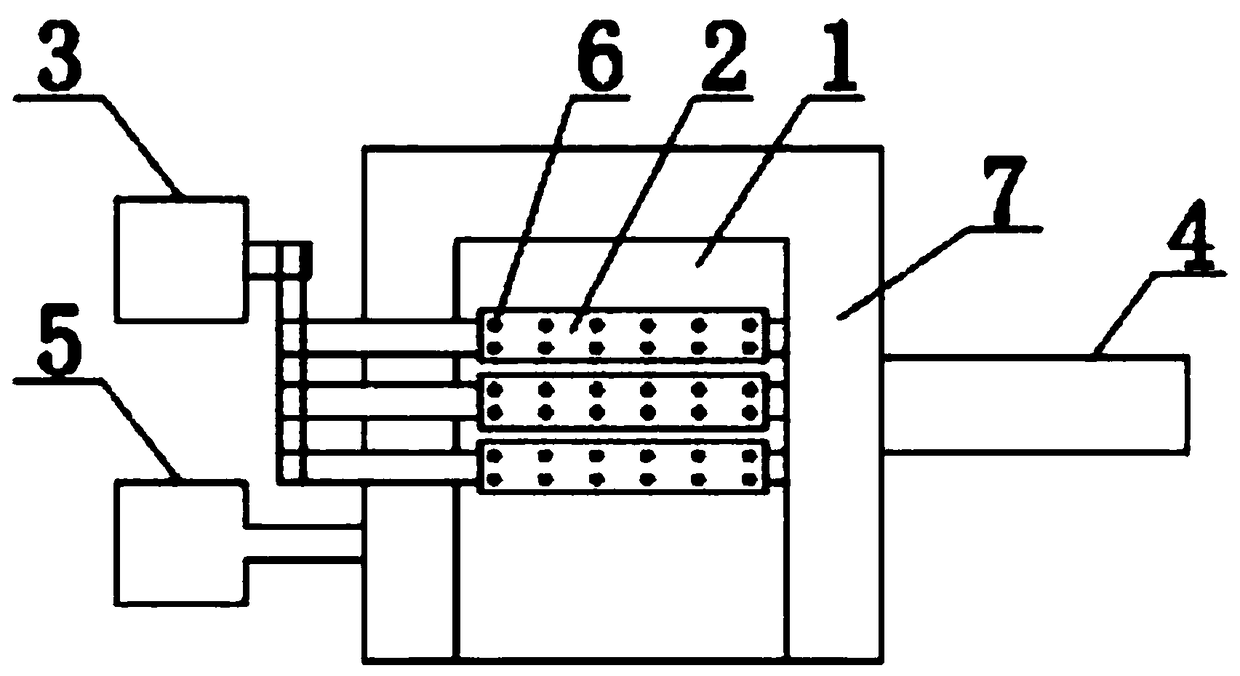

Grinding fluid automatic circulation and physicochemical precipitation filter press purification device for centerless grinder

ActiveCN111890146BStable working conditionLow moisture content in slagRevolution surface grinding machinesGrinding/polishing safety devicesThermodynamicsSlag

The invention discloses a grinding fluid automatic circulation and physicochemical precipitation pressure filtration purification device for a centerless grinder. Including slag-containing wastewater collection tank, clean circulating fluid collection tank, agitated four-partition integrated precipitator, submersible mixer, mortar pump and centrifugal filter press; the waste water submerged pump in the slag-containing wastewater collection tank pumps slag-containing circulating fluid pumped into the agitated four-division integrated precipitator; the cleaning circulating fluid in the upper floating layer of the agitated four-divided integrated precipitator overflows to the clean circulating fluid collection tank through the overflow pipe; the mortar pump transfers the agitated four-divided The slag-containing circulating fluid in the mixed layer in the middle of the integrated precipitator is pumped into the centrifugal filter press. The invention satisfies the technical requirements of large amount of grinding debris and high cleanliness of the grinding fluid during the grinding process of the centerless grinding equipment, prolongs the service life of the grinding fluid, reduces the frequency of replacement, reduces the amount of addition, and improves the grinding quality of the workpiece. Significantly improve the overall efficiency of the equipment.

Owner:XCMG HYDRAULICS CO LTD

Pulverized coal combustion heating furnace

ActiveCN104197320BBurn fullyImprove the mixing effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFlue gas

The invention provides a pulverized coal combustion and warming furnace. The pulverized coal combustion and warming furnace comprises a main furnace shell, a pulverized coal combustor, a combustion region, a primary mixing region, a secondary mixing region, a waste flue gas inlet and a dried flue gas outlet, wherein the main furnace shell is provided with an inner cavity; the pulverized coal combustor is arranged on the main furnace shell; the combustion region is arranged in the inner cavity of the main furnace shell and is connected with the pulverized coal combustor; the primary mixing region is arranged in the inner cavity of the main furnace shell and is connected with the combustion region; the combustion region is arranged between the pulverized coal combustor and the primary mixing region; the secondary mixing region is arranged outside the main furnace shell and is communicated with the primary mixing region; the waste flue gas inlet is formed in the main furnace shell and is connected with the primary mixing region; and the dried flue gas outlet is formed outside the main furnace shell and is communicated with the secondary mixing region. The pulverized coal combustion and warming furnace has the technical advantages that pulverized coal is sufficiently combusted, flue gas is uniformly mixed in the furnace, the content of oxygen of the flue gas at the outlet is low, slag can be automatically discharged, the heat efficiency of a furnace body is high, the heat loss is relatively small and the like.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Fire grate suitable for large particle solid fuels

InactiveCN106122987ARealize automatic blankingRealize automatic focus breakingTravelling grateSlagSolid fuel

The invention discloses a fire grate suitable for large-grain solid fuels, and provides a fire grate capable of automatically breaking coke and having the function of automatic cleaning. It is composed of a stepped fixed furnace bar and a stepped movable furnace bar. The furnace bar base of the stepped fixed furnace bar is composed of the upper first fuel sliding area, the middle first fuel main combustion area and the lower first slag discharge area; The first fuel main combustion area is stepped; the grate body of the stepped active grate is composed of the upper second fuel sliding area, the middle second fuel main burning area and the lower second slagging area, the second fuel sliding There is a rocking support groove matched with the rocker below the zone; the second fuel main combustion zone is stepped. The stepped solid grate and the stepped movable grate are arranged side by side; the first fuel main combustion zone in the stepped fixed grate and the second fuel main combustion zone in the stepped movable grate have the same stepped structure and form a stove Fuel main combustion zone. Automatic feeding is realized, avoiding coking in a large area.

Owner:TIANJIN JUNENG BOILER MFG CO LTD

Marine serial-wash filter

InactiveCN104524859AExtended service lifeEasy to observeFiltration circuitsFilter paperFilter element

The invention provides a marine serial-wash filter. A heating base plate is provided with a serial-wash filter and a filtering paper filter, wherein the upper part of the serial-wash filter is provided with a serial-wash filter upper cover which is provided with serial-wash filter pressure difference displays; the upper part of the serial-wash filter is provided with a motor; a rotation shaft connected with the motor penetrates through the middle of a filter element; the upper part of the filtering paper filter is provided with a filtering paper filter upper cover which is provided with a filtering paper filter pressure difference display; the filtering paper filter is internally provided with filtering paper; an automatic pressure difference switching control valve and an automatic temperature switching control valve are installed between the serial-wash filter and the filtering paper filter. The marine serial-wash filter is long in service life, can be used for observing the serial wash effect conveniently, can improve the serial wash efficiency and achieve automatic residue discharging, and is suitable for being used as a device for marine pipeline serial wash.

Owner:BOHAI SHIP HEAVY IND CO LTD

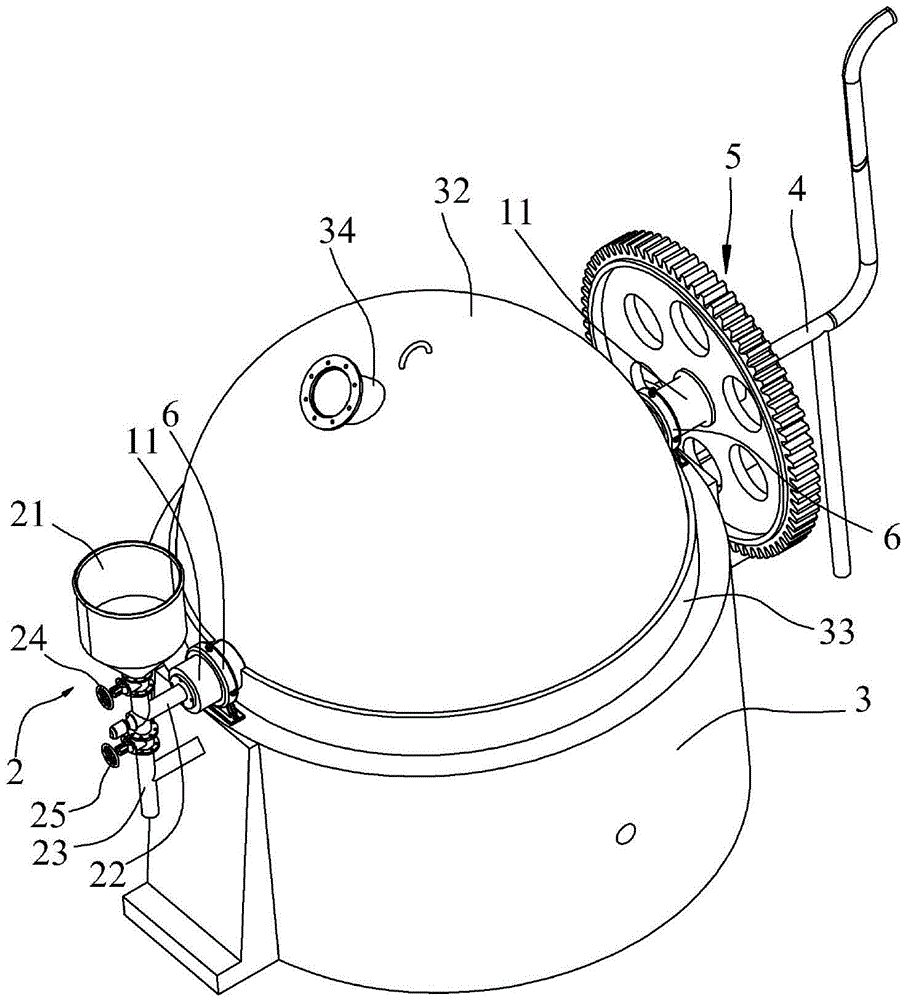

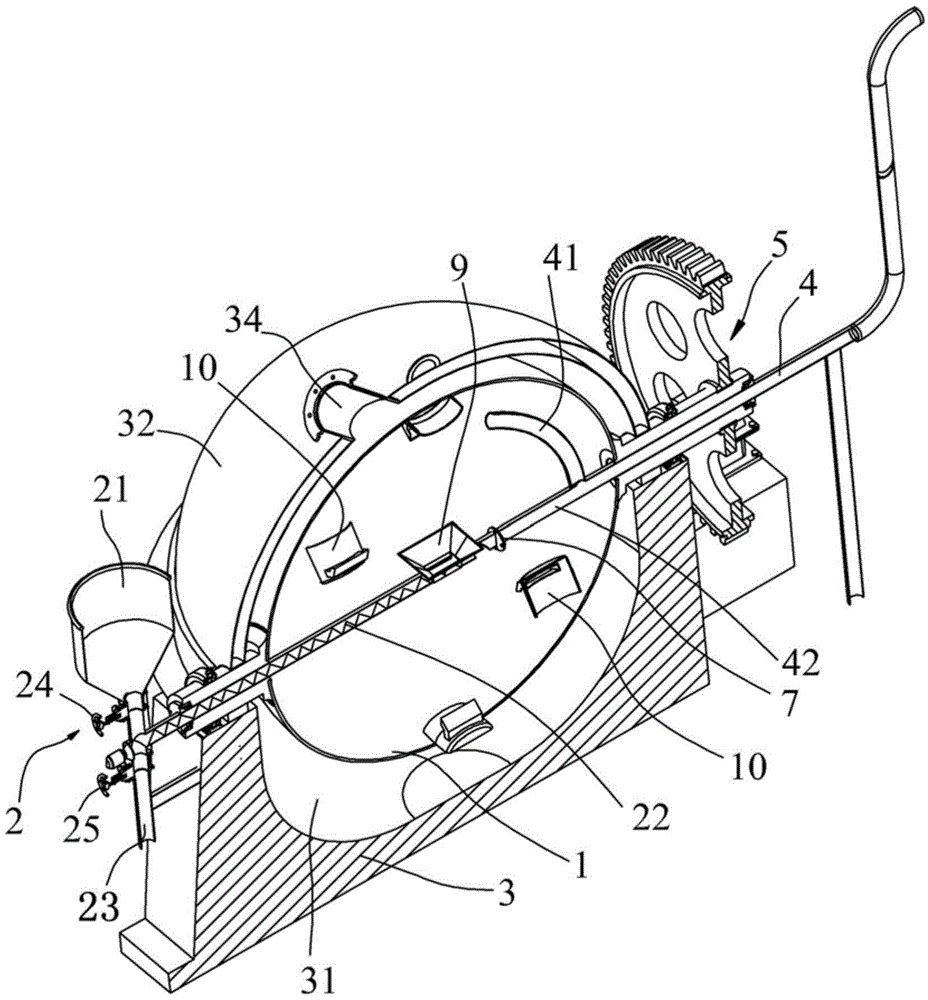

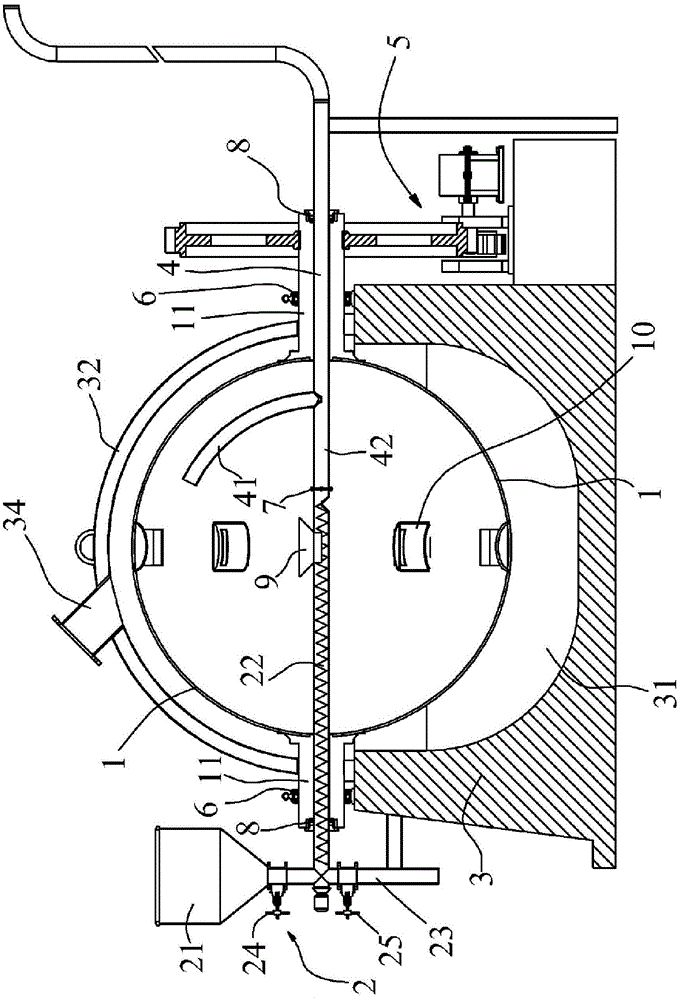

Catalytic cracking device for biodiesel preparation

InactiveCN103275810BIncrease profitFully lysedFatty acid chemical modificationBiofuelsGas collecting tubeProcess engineering

The invention discloses a catalytic cracking device for biodiesel preparation, which comprises a reaction kettle, a feeding / discharging device, a heating furnace, a gas collecting tube and a rotary driving device, wherein the reaction kettle is used for accommodating used cooking oil; the feeding / discharging device is used for feeding a catalyst in the reaction kettle or outputting residues from the reaction kettle to the outside; the heating furnace is used for heating the reaction kettle; the gas collecting tube is used for collecting and leading out biodiesel gas in the reaction kettle; the rotary driving device is used for driving the reaction kettle to rotate; the reaction kettle is a hollow spherical shell, axle tubes are respectively fixed on the symmetrical two side shells of the reaction kettle, and are braced above the heating furnace through a first bearing; the output end of the rotary driving device is connected with the axle tubes, and drives the reaction kettle to rotate around the axial centers of the axle tubes; and a inlet / outlet of the feeding / discharging device is communicated with the reaction kettle, one end of the gas collecting tube is inserted into the reaction kettle, and the other end of the gas collecting tube extends out of the reaction kettle. According to the catalytic cracking device, used cooking oil is in full contact with an oil catalyst, and after the complete cracking of the used cooking oil is implemented, biodiesel gas is obtained.

Owner:李红艳 +1

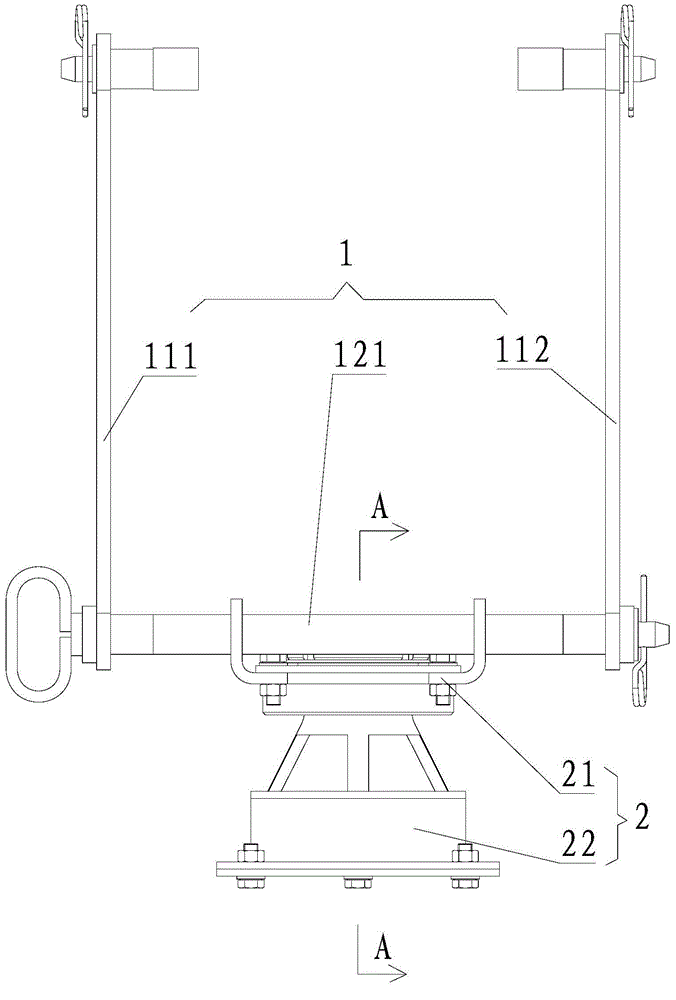

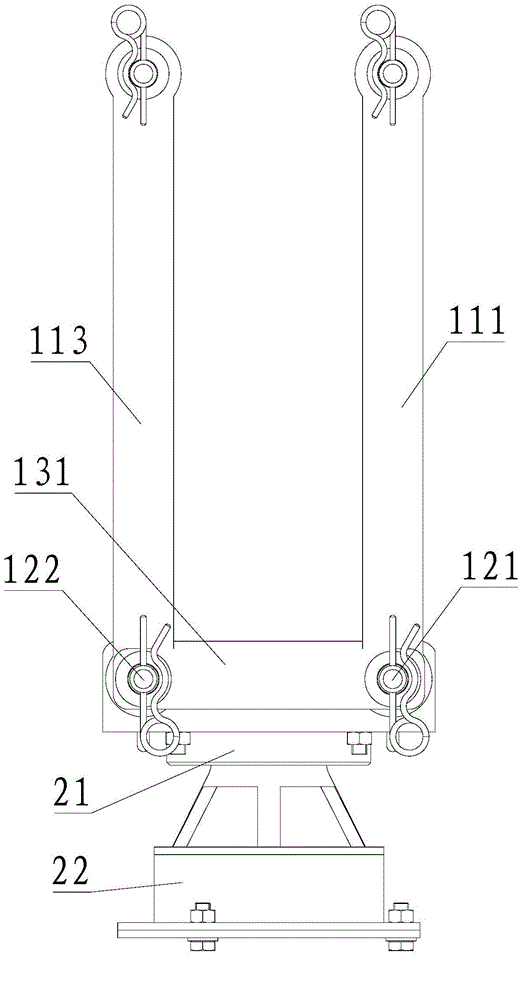

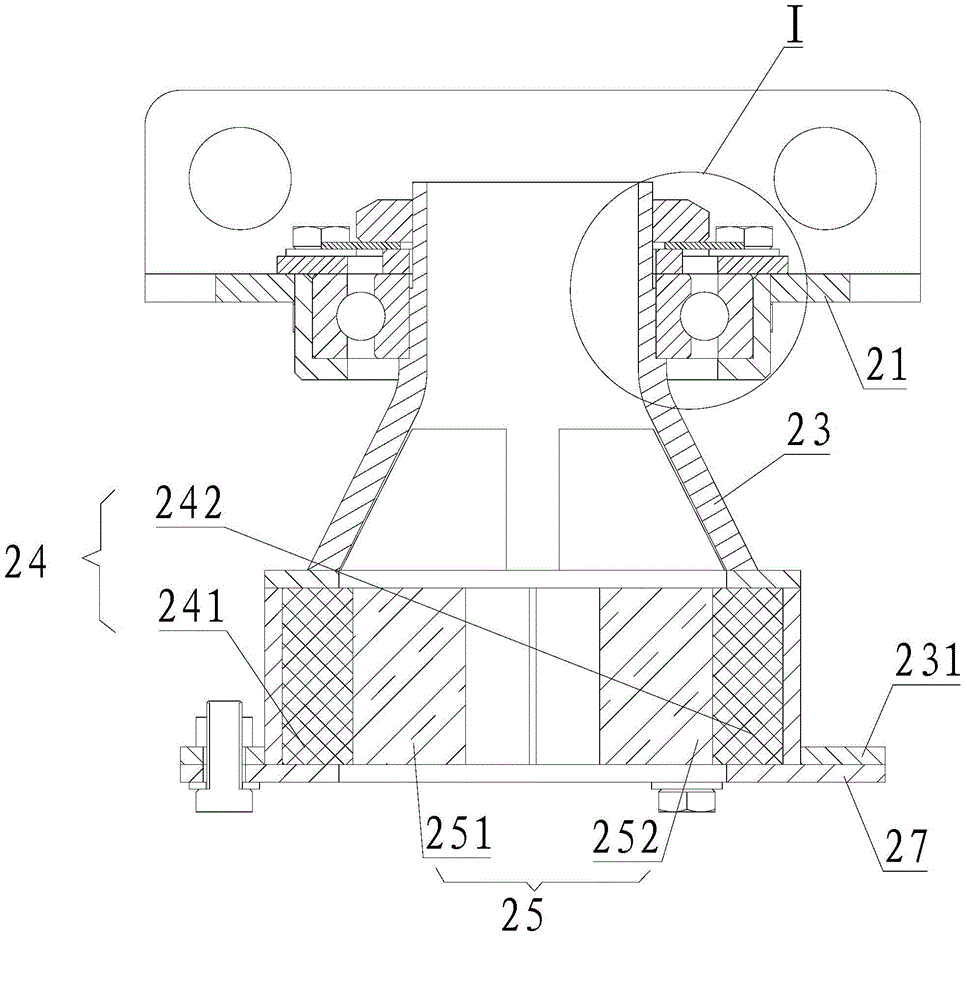

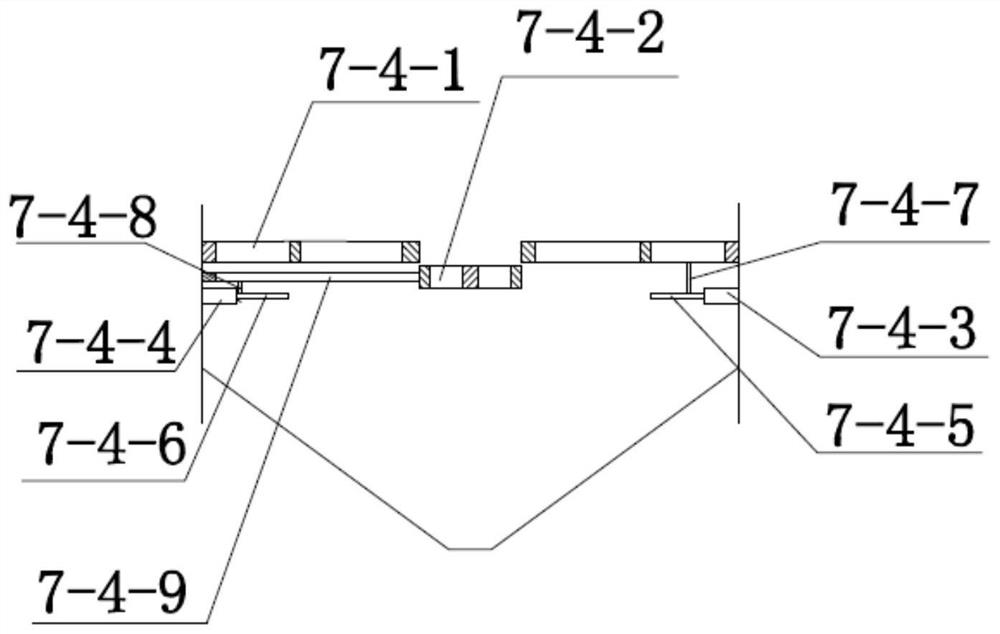

Steel wire rope protection device and rotary drilling rig

ActiveCN104477805APlay a protective effectExtended service lifeWinding mechanismsForeign matterSurface cleaning

The invention discloses a steel wire rope protection device and a rotary drilling rig. The steel wire rope protection device comprises a support mechanism and a rotary mechanism, wherein the rotary mechanism comprises a supporting portion and a rotary portion. The supporting portion is installed on the support mechanism. The rotary portion is rotatably installed on the supporting portion and provided with a rope through hole for a steel wire rope to penetrate through, and a brush is arranged on the inner wall of the rope through hole. When the steel wire rope protection device is used, the steel wire rope penetrates through the rope through hole of the rotary portion and is in contact with the brush in the rotary portion. The steel wire rope performs axial motion, the rotary portion performs peripheral rotation, the steel wire rope and the brush produce relative motions, the brush brushes off silt and other foreign matter on the surface of the steel wire rope to achieve the steel wire rope surface cleaning effect, a protection role is played on the steel wire rope, and the service life of the steel wire rope is prolonged.

Owner:BEIJING SANY HEAVY MASCH CO LTD

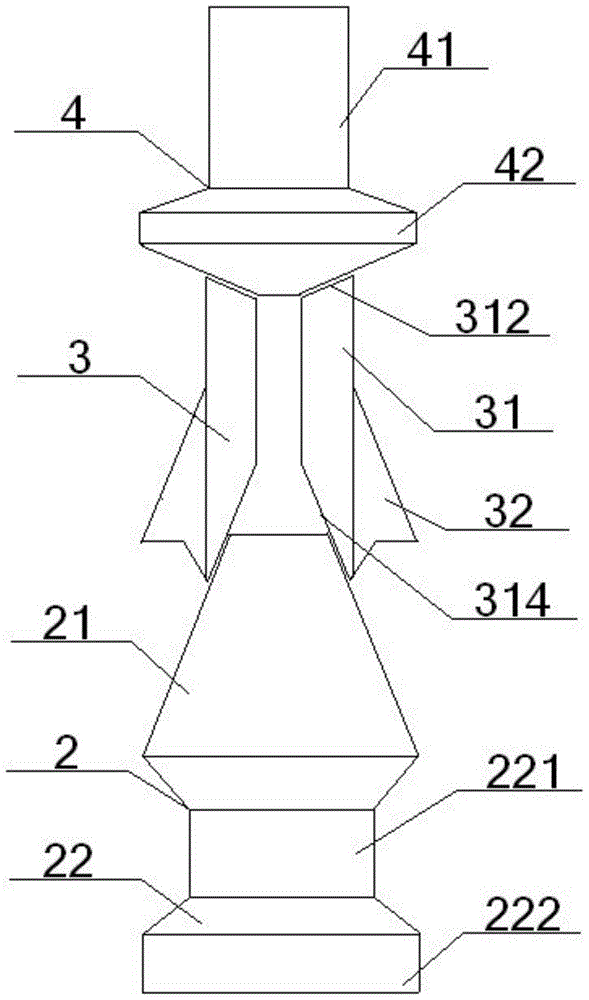

An inner anchor head for down-the-hole impact bottom expansion and its use method

ActiveCN105401578BShorten the pathLower quality requirementsBulkheads/pilesAnchoring boltsEnergy transferEngineering

An inner anchor head for down-the-hole impact expansion, including a connecting cap, a cutter head and a base arranged in sequence from top to bottom. The surface is slidingly matched with the side of the base head of the frustum of cone structure, and a socket is opened in the base to connect the anchor rod body; Temporary connection, then connect the down-the-hole drilling air pressure impactor and connecting rod, and then put them into the straight hole, and the impactor directly impacts the inner anchor head to expand the bottom. After completion, pull out the drill pipe, impactor, and connecting cap, and then Insert the anchor rod body into the socket for connection, and finally inject grout. When expanding the bottom, the debris chiseled by the cutter head can be blown away immediately through the air guide tube. This design is not only suitable for the self-expanding bottom of longer bolts, but also has high energy transfer efficiency and good hole reaming effect, and has low environmental requirements, automatic slag discharge, and high excavation efficiency.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Full-automatic efficient biomass gasification burner

PendingCN114811573AEmission reductionBurn fullySolid fuel combustionBlast-producing apparatusWood wasteCombustion chamber

The full-automatic efficient biomass gasification burner comprises a cuboid furnace body and a refractory cement pouring wall located in the cuboid furnace body, the bottom of the refractory cement pouring wall is sequentially provided with a slag discharging tank, a first air chamber and a second air chamber which are communicated with a combustion chamber, and the top of the slag discharging tank is provided with a slag crushing roller; a water-cooling fire grate is arranged at the top of the first air chamber; a slag pushing block slides on the water-cooling fire grate, the upper portion and the lower portion of the side edge of the first air bellow are connected with a secondary oxygen distribution fan and a tail gas circulating fan correspondingly, and the lower portion of the side edge of the second air bellow is connected with a gasification oxygen distribution fan. Combustion is more sufficient, heat efficiency is higher, and energy is saved; biomass with low ash content and melting point, such as straw and other wastes and old furniture and other wood wastes, can be used, so that renewable resources can be utilized more effectively; and automatic operation is achieved, automatic deslagging is achieved, and continuous operation is achieved.

Owner:罗小华

A kind of automatic extraction method of noble and thin traditional Chinese medicine

ActiveCN109350993BDissolves quicklyImprove extraction productivitySolid solvent extractionProcess engineeringIndustrial engineering

The invention relates to an automatic extraction method for precious and fine traditional Chinese medicine. The extraction method adopted in the invention can improve the extraction efficiency and the transfer rate of effective components. The invention also adopts three-stage solid-liquid separation equipment, which can carry out continuous operation and does not A filtration bottleneck is generated, no blockage occurs, continuous production can be realized, the production efficiency is high, the cost is low, and the separated product has good solubility, high clarity and less sedimentation.

Owner:JIANGYIN TIANJIANG PHARMA

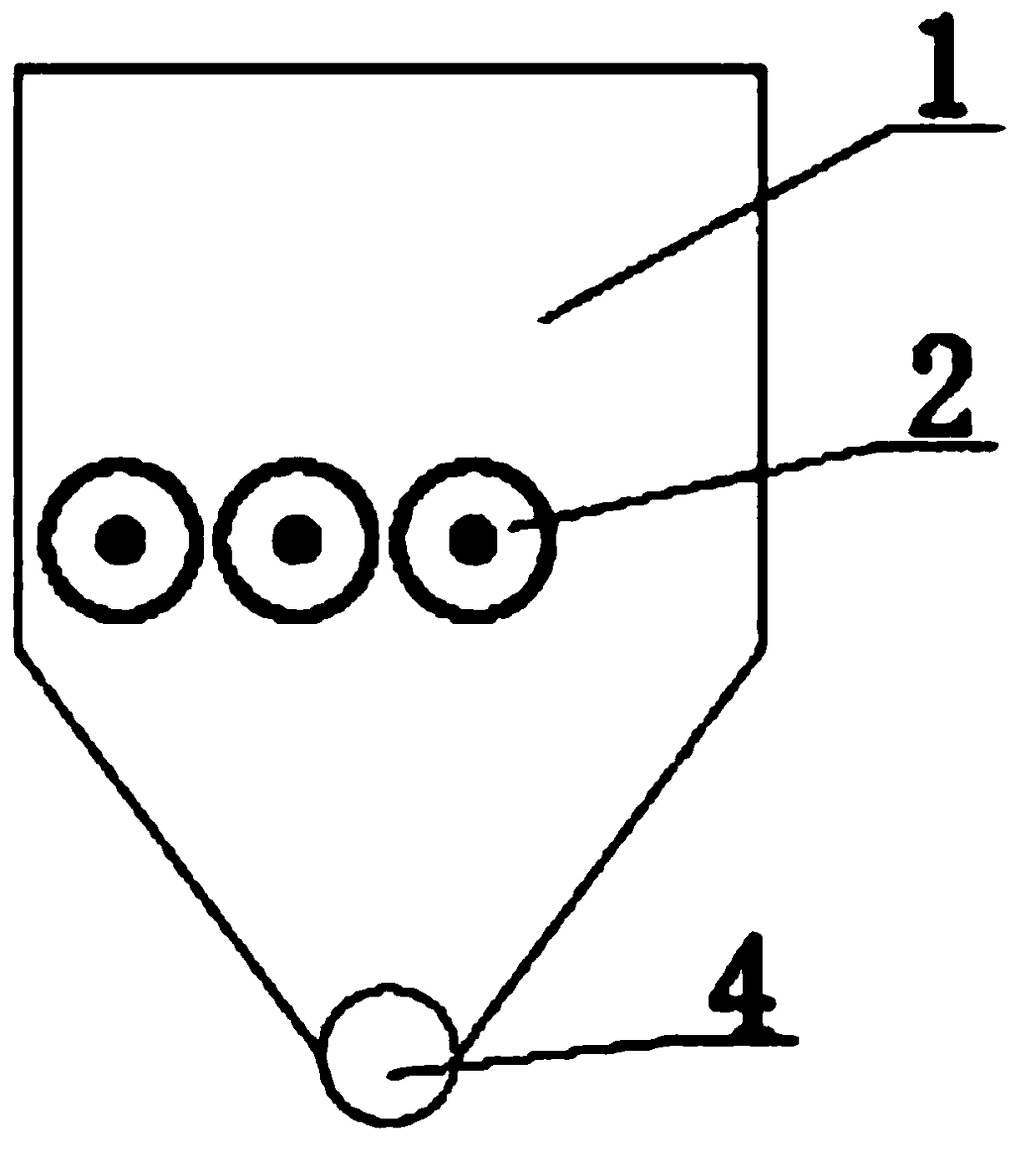

Lower slag jacking machine used for vacuum-smelting reduction device

ActiveCN108106448ARealize automatic slag dischargeSave human effortIncrustation removal devicesSlagFlue gas

The invention discloses a lower slag jacking machine used for a vacuum-smelting reduction device. The lower slag jacking machine comprises a bottom plate, wherein the lower side wall of the bottom plate is equipped with four rollers; the upper side wall of the bottom plate is equipped with a servo oil cylinder; the drive end of the servo oil cylinder is connected with a receiving slot; a funnel isinserted into the upper end of the receiving slot; the funnel communicates with the inner part of the receiving slot; an inclined plate is arranged inside the receiving slot; the inner bottom of thereceiving slot is equipped with a rotary motor; the drive end of the rotary motor is connected with a rotary rod; the upper end of the rotary rod penetrates through the inclined plate and extends to the outer part of the funnel; two supporting plates and a storage box are further arranged on the upper side wall of the bottom plate; and the upper ends of the two supporting plates are equipped witha fixed plate. The lower slag jacking machine realizes automatic slag discharge work of magnesium slag, saves labor power, improves working efficiency, performs adsorption treatment on flue gas and dust in the magnesium slag, protects the environment, is simple in structure, and is convenient to popularize.

Owner:巢湖云海镁业有限公司

Biomass gasification fixed bed with anti-burn-through function

ActiveCN111944561BSolve the problem of easy burn throughFully automatedGasification processes detailsCombustible gas productionVideo monitoringThermodynamics

The invention discloses a biomass gasification fixed bed with the function of preventing burn-through, which belongs to the technical field of biomass energy utilization equipment and includes a furnace body, a material laying device and a multi-point temperature detection device; the furnace body includes an upper cavity and the lower cavity, the upper cavity and the lower cavity are separated by a fire grate; the material spreading device and the multi-point temperature detection device are all located inside the upper cavity, and the multi-point temperature detection device Located below the material spreading device, the material spreading device and the multi-point temperature detection device are respectively connected to the transmission device; The lower grate is rotatably connected with the furnace body, and is used to drive the upper grate and the lower grate to rotate through moving parts. The invention overcomes the traditional mode of on-site duty or installation of remote video monitoring, predicts the combustion conditions in the furnace in advance, predicts the risks of partial burning and burn-through, and prevents problems before they happen.

Owner:江苏嘉林新能源科技有限公司

Water filtering and residue discharging structure and dish-washing machine with same

PendingCN112642193AAutomatic slag dischargeRealize automatic slag dischargeStationary filtering element filtersProcess engineeringWater storage

The invention discloses a water filtering and residue discharging structure which comprises a water storage part, a filter screen and a residue discharging opening. The filter screen is arranged in the water storage part, a water filtering part is formed in the filter screen, a water purifying part is formed between the filter screen and the water storage part, and the residue discharging opening is formed in an opening in the bottom of the water filtering part. The problem that an existing filter screen is installed at the bottom or the top for filtering, residues can only be cleaned manually, and / or automatic residue discharging cannot be achieved is mainly solved. Compared with the prior art, the invention discloses a dish rack of a dish washing machine, which has the following beneficial effects that 1, an existing filter screen is mounted at the bottom or the top for filtering, residues can only be cleaned manually, and automatic residue discharging cannot be achieved, however, the filter screen of the invention carries out filtering from the periphery, and residues are discharged from the bottom; 2, automatic residue discharging can be realized; and 3, the filter screen does not need to be cleaned.

Owner:湖南美佳电器有限公司

A kind of marine string washing filter

InactiveCN104524859BExtended service lifeEasy to observeFiltration circuitsDifferential pressurePulp and paper industry

Owner:BOHAI SHIP HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com