Biomass gasification fixed bed with anti-burn-through function

A technology of biomass and fixed bed, applied in gasification process, manufacture of combustible gas, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

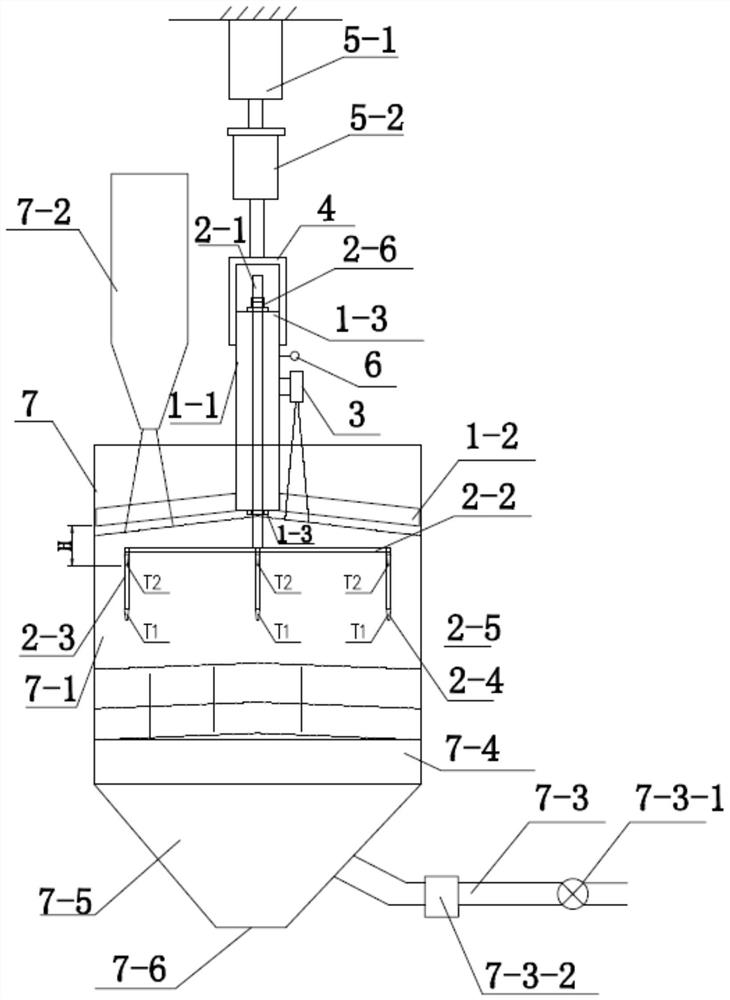

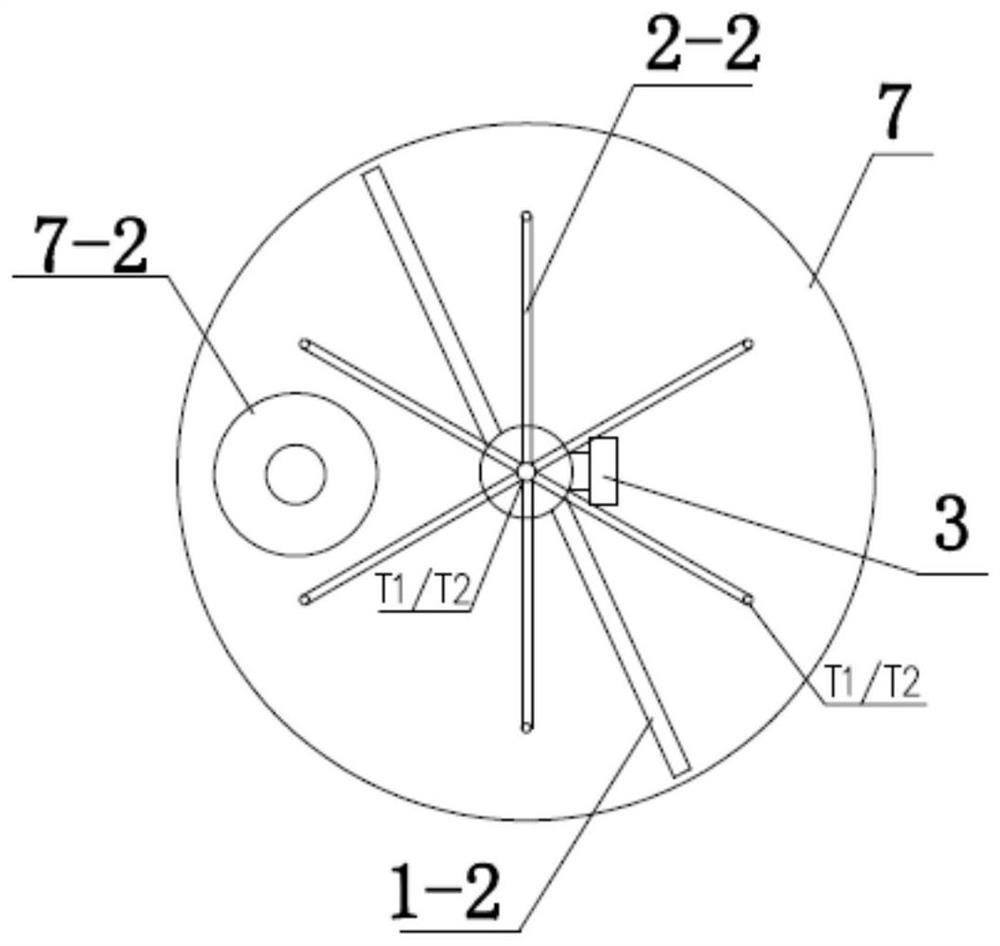

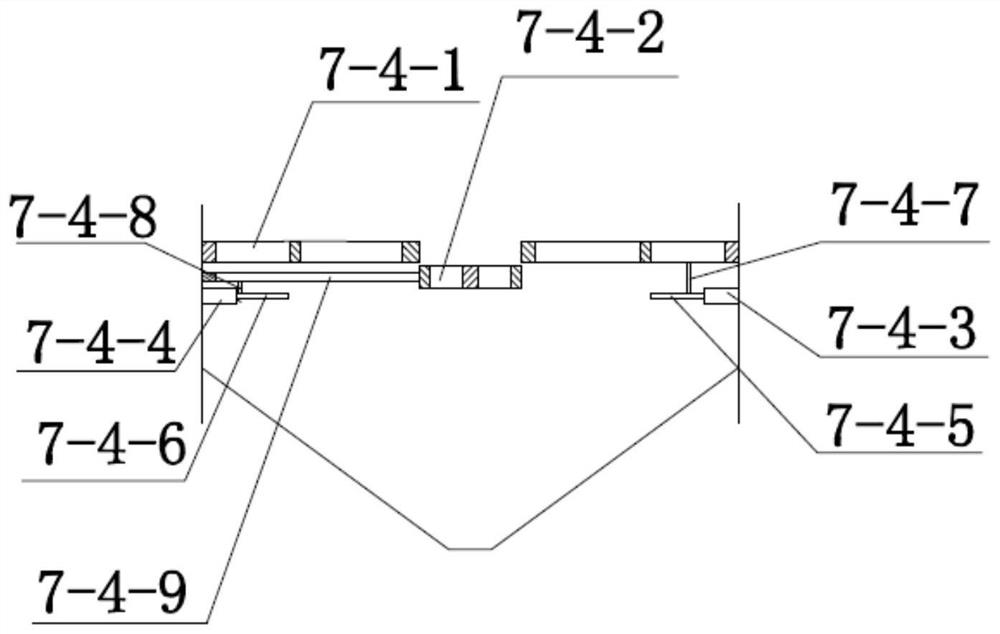

[0052] like figure 1 , figure 2 As shown, a biomass gasification fixed bed with anti-burn-through function is characterized in that it includes a furnace body 7, a material spreading device and a multi-point temperature detection device; the furnace body 7 includes an upper cavity 7-1 and The lower cavity 7-5, the upper cavity 7-1 and the lower cavity 7-5 are separated by a fire grate 7-4.

[0053] Both the material spreading device and the multi-point temperature detecting device are located inside the upper cavity 7-1, the multi-point temperature detecting device is located below the material spreading device, the material spreading device and the The multi-point temperature detection devices are respectively connected with the transmission device.

[0054] The transmission device includes a vertical suspension column 1-1, the outer wall of the upper section of the suspension column 1-1 is fixedly connected with the connecting piece 4, and the connecting piece 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com