Sewage treatment structure for sewage treatment equipment

A kind of sewage treatment equipment and sewage treatment technology, applied in the direction of water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of filter hole blockage of the filter plate, and achieve improved activity and improved treatment Efficiency, the effect of speeding up the response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

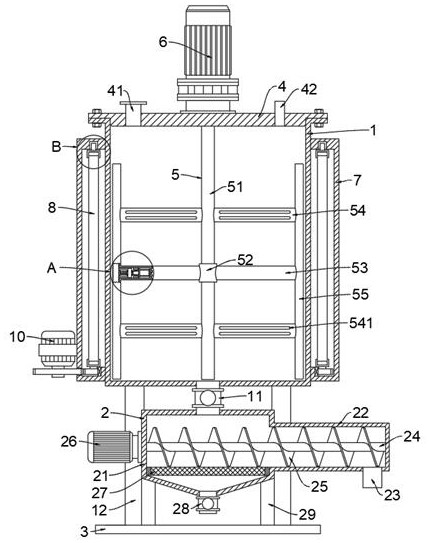

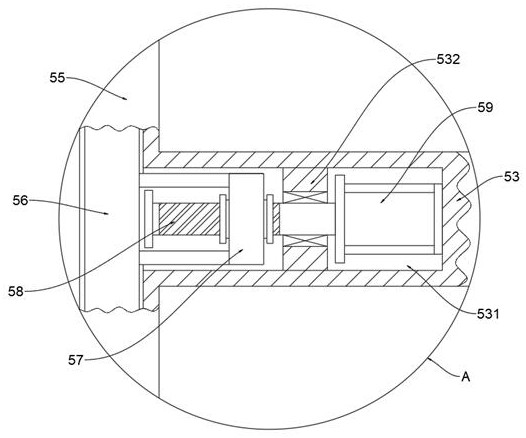

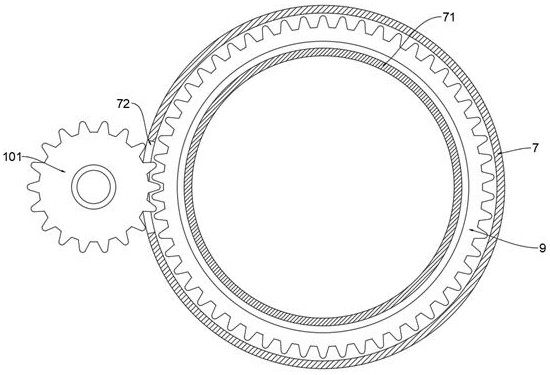

[0025] see Figure 1-5 , an embodiment provided by the present invention: a sewage treatment structure for sewage treatment equipment, comprising a tank body 1, a drain pipe 11 is provided at the bottom end of the tank body 1, and a slag discharge mechanism 2 is installed at the bottom end of the drain pipe 11 to discharge The slag mechanism 2 includes a collection box 21, a slag discharge pipe 22, a slag discharge port 23, a rotating shaft 24, a screw conveyor 25, a first drive motor 26, a filter plate 27, an outlet pipe 28 and a second leg 29, and the slag discharge pipe 22 is set On one side of the collection box 21, and welded to the collection box 21, the slag d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com