Water filtering and residue discharging structure and dish-washing machine with same

A technology for water filtering and slag discharge, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc. It can solve the problems of incapable of automatic slag discharge and can only manually clean the residue, etc., and achieve the effect of automatic slag discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

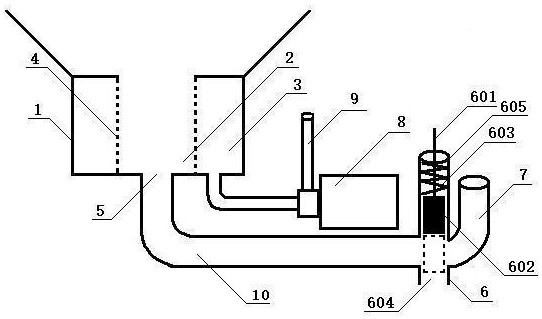

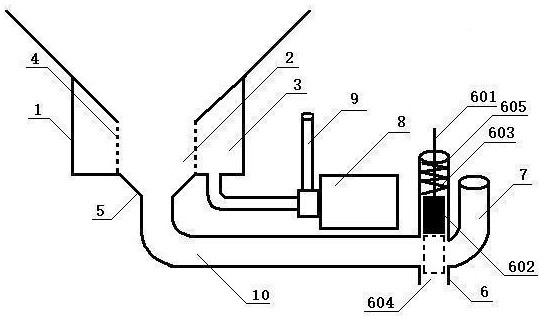

[0031] A water filtration and slag discharge structure, comprising a water storage part 1, a filter screen 4 and a slag discharge port 5, the water storage part 1 is provided with a filter screen 4, the filter screen 4 forms a water filter part 2, the filter screen 4 and the water storage A water purification part 3 is formed between the parts 1, and a slag outlet 5 is provided at the bottom opening of the water filtering part 2; the filter screen 4 is in a cylindrical structure or a square structure, and the filter screen 4 is arranged in the middle of the water storage part 1, The filter screen 4 forms the water purification part around.

Embodiment 2

[0033] The water filtration and slag discharge structure as described in Embodiment 1 also includes a sewage discharge pipe 10, a sewage discharge valve 6 and an exhaust pipe 7 in the machine. In-machine exhaust pipe 7; the filter screen 4 is in a cylindrical structure or a square structure, and the filter screen 4 is arranged in the middle of the water storage part 1, and the water purification part is formed around the filter screen 4.

Embodiment 3

[0035] As in the water filtration and slag discharge structure described in Embodiment 1 or 2, the sewage valve 6 is composed of a gate valve pull rod 601, a water blocking rubber plug 602, a spring 603 and a sewage outlet 604. The front end of the gate valve pull rod 601 is covered with a spring 603, and the gate valve pull rod 601 The rear end is provided with a water blocking rubber plug 602, and the gate valve pull rod 601, spring 603 and water blocking rubber plug 602 move in the sewage valve body 605; the filter screen 4 is in a cylindrical or square structure, and the filter screen 4 is arranged on In the middle of the water storage part 1, the water purification part is formed around the filter screen 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com