Reciprocation type rotational extrusion filter

A kind of filter, reciprocating technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of incomplete separation, high filter plate material requirements, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

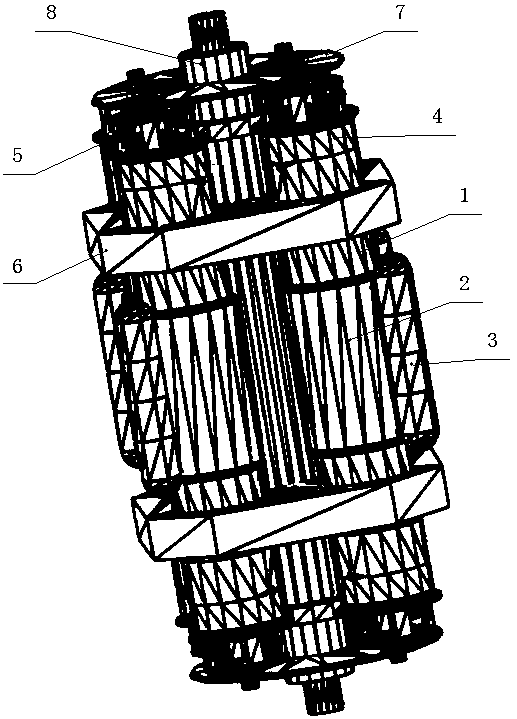

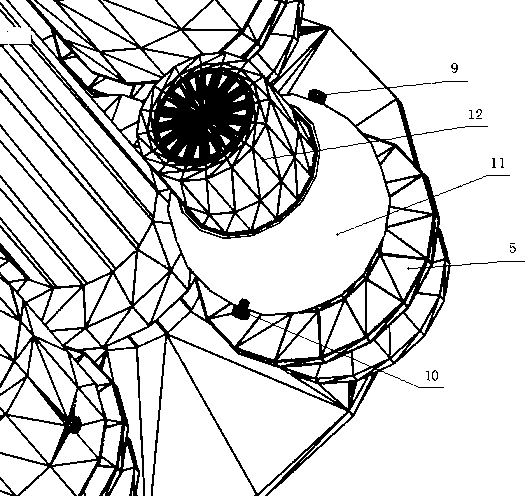

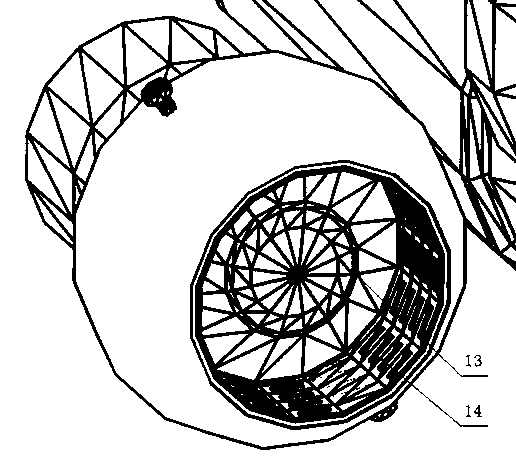

[0022] Such as figure 1 , figure 2 As shown, a reciprocating rotary extrusion filter mainly consists of at least one set of piston barrel 1, piston 12, connecting shaft, hollow body 4, circular sphere 11, and extrusion plate. The piston 12 is transferred to In the piston cylinder 1, and the size is suitable, the connecting shaft is connected to the piston 12, and drives the piston 12 to move, the end of the piston cylinder 1 is connected to the hollow body 4, and the hollow body 4 Corresponding to the two ends of the piston 12 in the linear direction, two ports are respectively opened, and the port at one end is adapted to the size of the piston barrel 1, and is sealed and connected. The circular sphere 11 is transferred to the center of the hollow body 4, and the circular The sphere 11 matches the size of the interior of the hollow body 4, and makes the circular sphere 11 have at least one rotation axis to rotate around the interior of the hollow body 4. The two ends of the...

Embodiment 2

[0025] Such as figure 1 , figure 2As shown, a reciprocating rotary extrusion filter mainly consists of at least one set of piston barrel 1, piston 12, connecting shaft, hollow body 4, circular sphere 11, and extrusion plate. The piston 12 is transferred to In the piston cylinder 1, and the size is suitable, the connecting shaft is connected to the piston 12, and drives the piston 12 to move, the end of the piston cylinder 1 is connected to the hollow body 4, and the hollow body 4 Corresponding to the two ends of the piston 12 in the linear direction, two ports are respectively opened, and the port at one end is adapted to the size of the piston barrel 1, and is sealed and connected. The circular sphere 11 is transferred to the center of the hollow body 4, and the circular The sphere 11 matches the size of the interior of the hollow body 4, and makes the circular sphere 11 have at least one rotation axis to rotate around the interior of the hollow body 4. The two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com