Patents

Literature

90results about How to "Continuous work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting cannabidiol

InactiveCN109053388AHigh yieldReduce in quantityOrganic chemistryOrganic compound preparationContinuous/uninterruptedSolvent

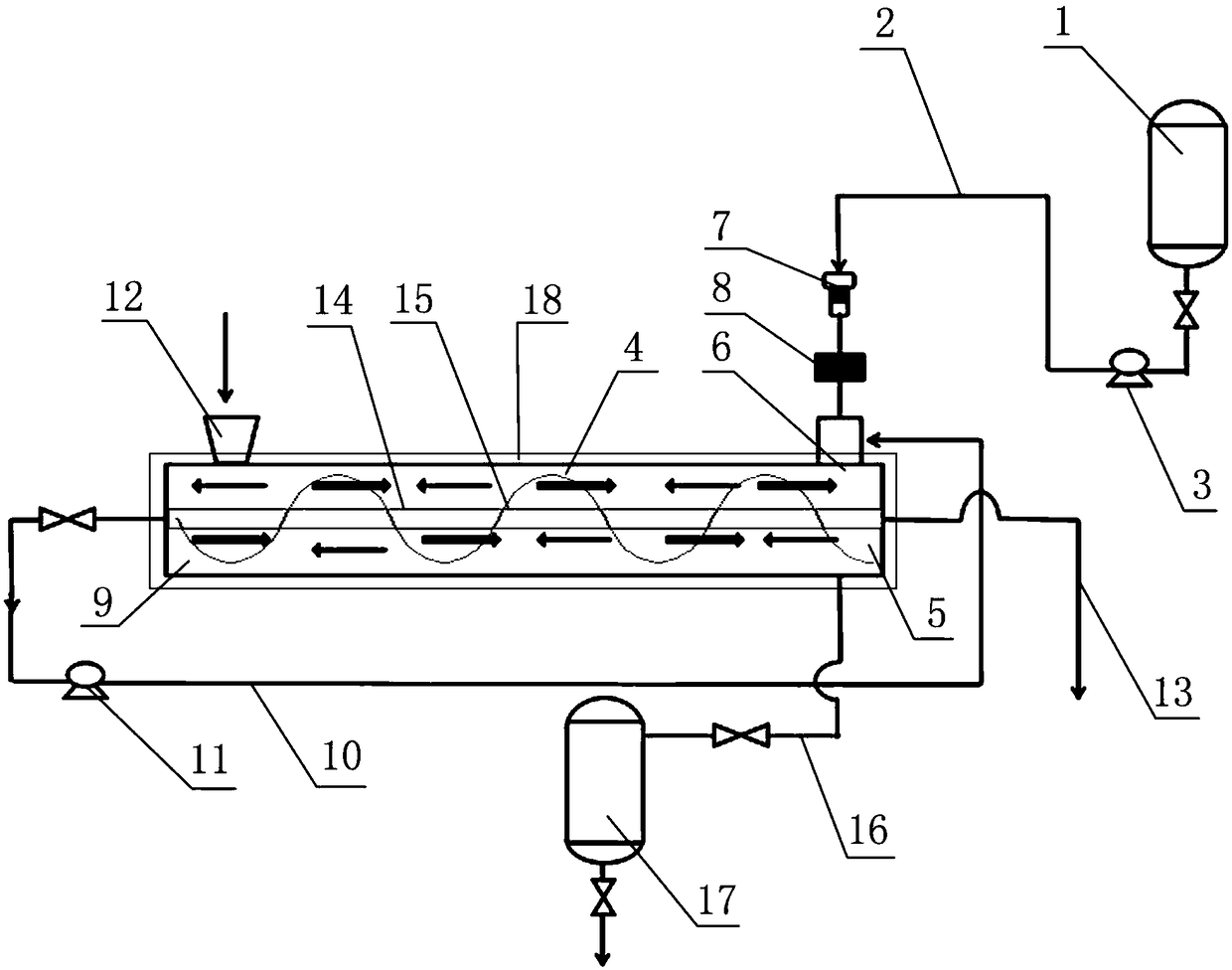

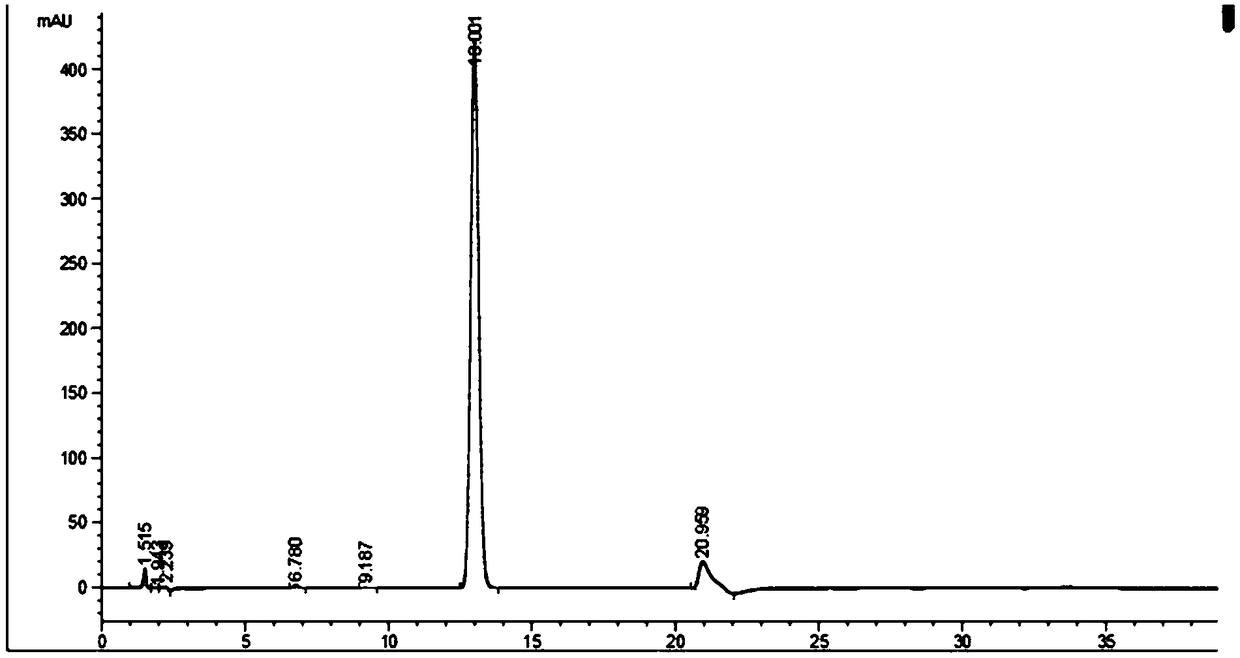

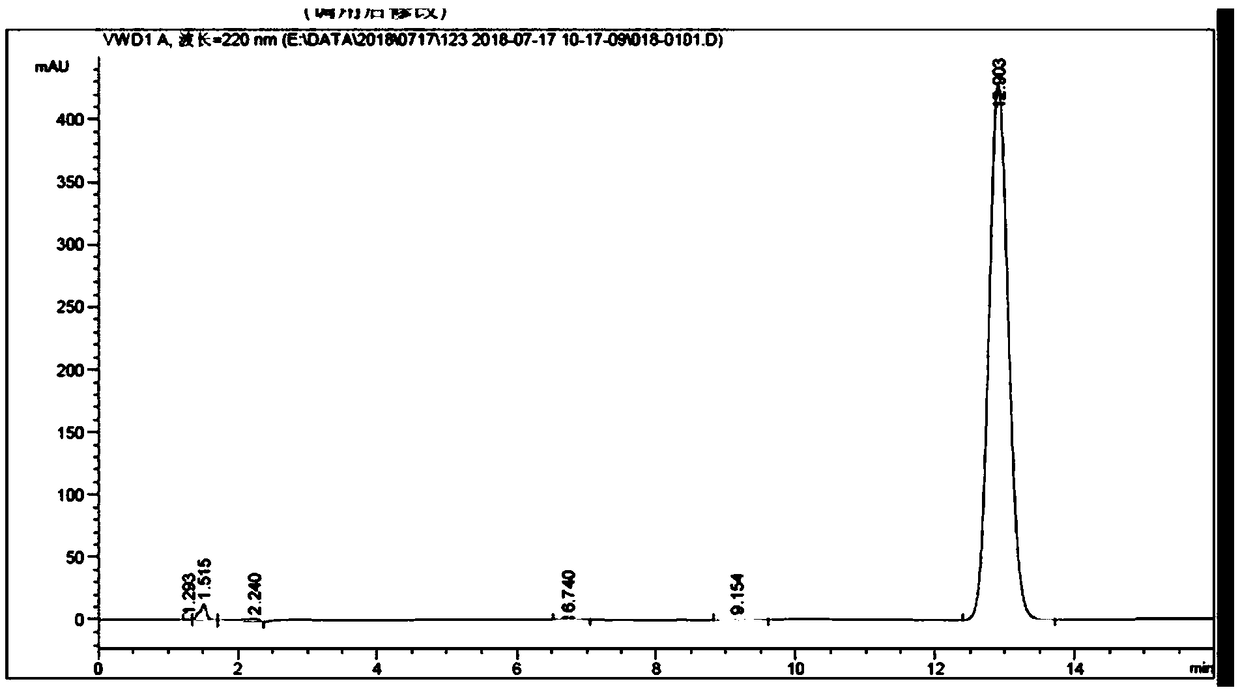

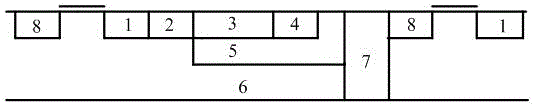

The present invention provides a method for extracting cannabidiol, and belongs to the technical field of industrial extraction. The method comprises the following operation steps of drying the flowers and leaves of a mariguana plant, grinding and crushing, performing reverse extracting on the crushed coarse powder and a solvent in a reverse extracting device along the opposite directions, and enabling the solvent to extract the effective components of the coarse powder out of an extracting solution; performing pressure-relief heating on the extracting solution, and volatilizing the excessiveethanol in the extracting solution, so as to obtain a concentrated solution of cannabidiol; adding purified water into the concentrated solution of cannabidiol, diluting, eluting by a chromatography column in a gradient way, and collecting a target eluting solution; combining the target eluting solution, and performing pressure-relief concentrating at the temperature of 50 to 70 DEG C, so as to obtain a secondary concentrated solution of cannabidiol; adding 90%w / w ethanol over-saturated solution into the secondary concentrated solution of cannabidiol, obtaining a crystallized product, washingby the purified water, and drying, so as to obtain a cannabidiol product. The method has the advantages that the method can be applied to large-scale continuous production; the working is continuous without interruption; the output is high; the energy source is saved; the safety and reliability are realized.

Owner:上海昶健生物科技有限公司

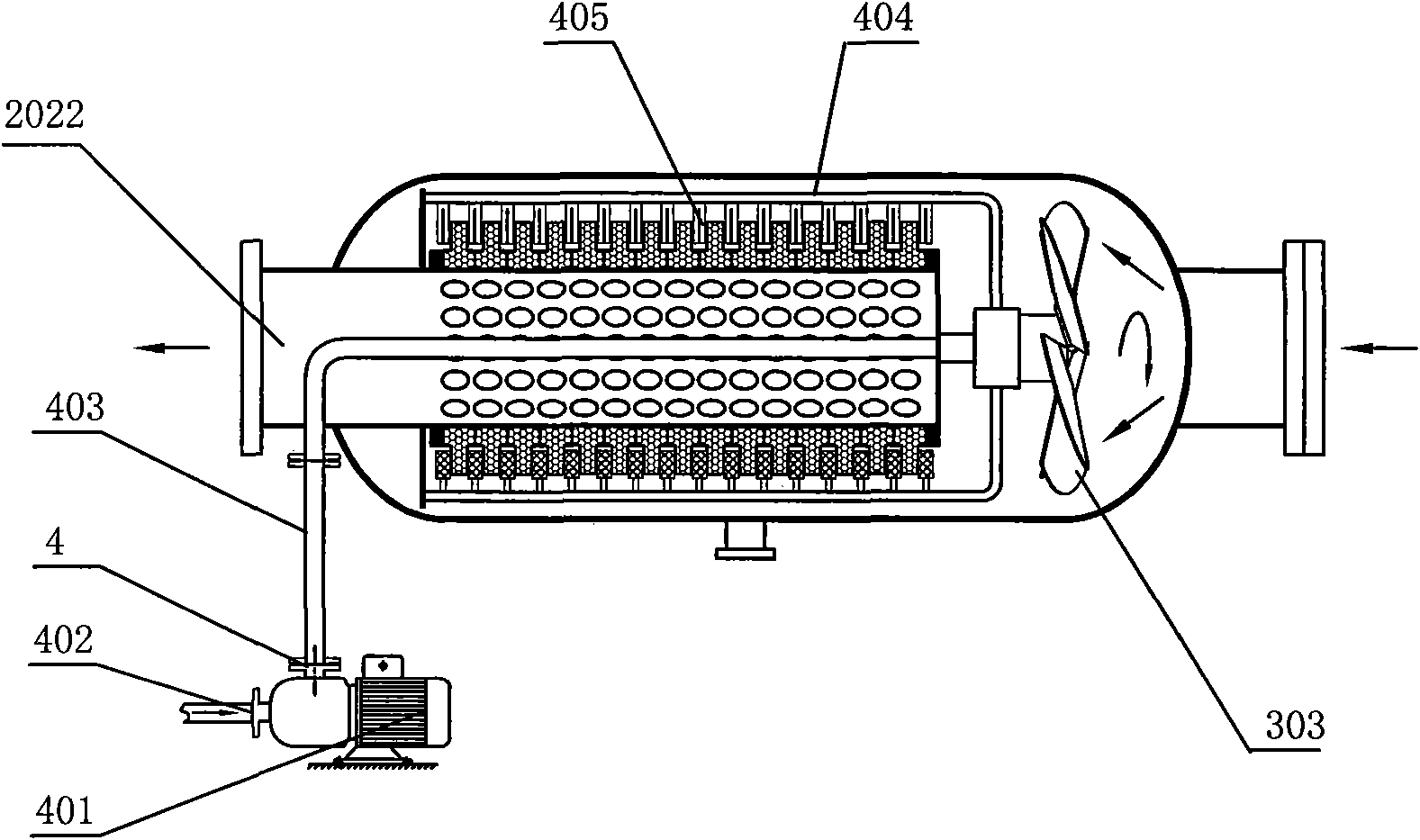

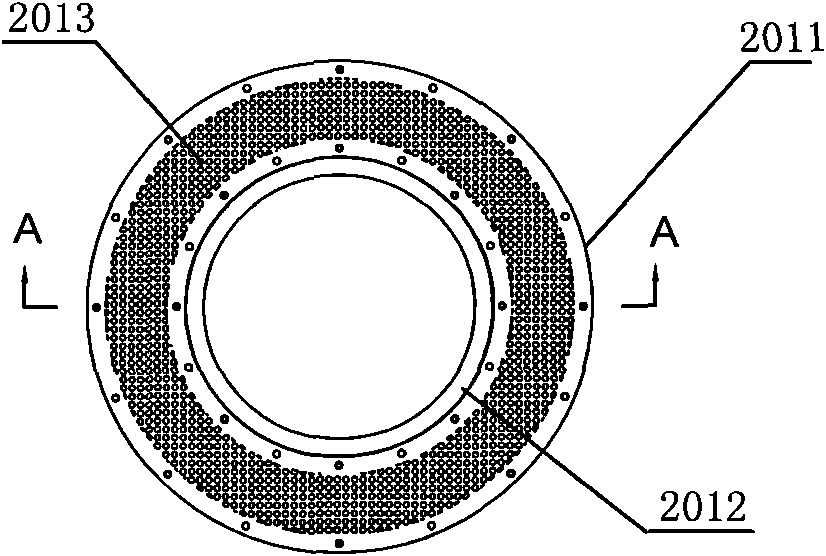

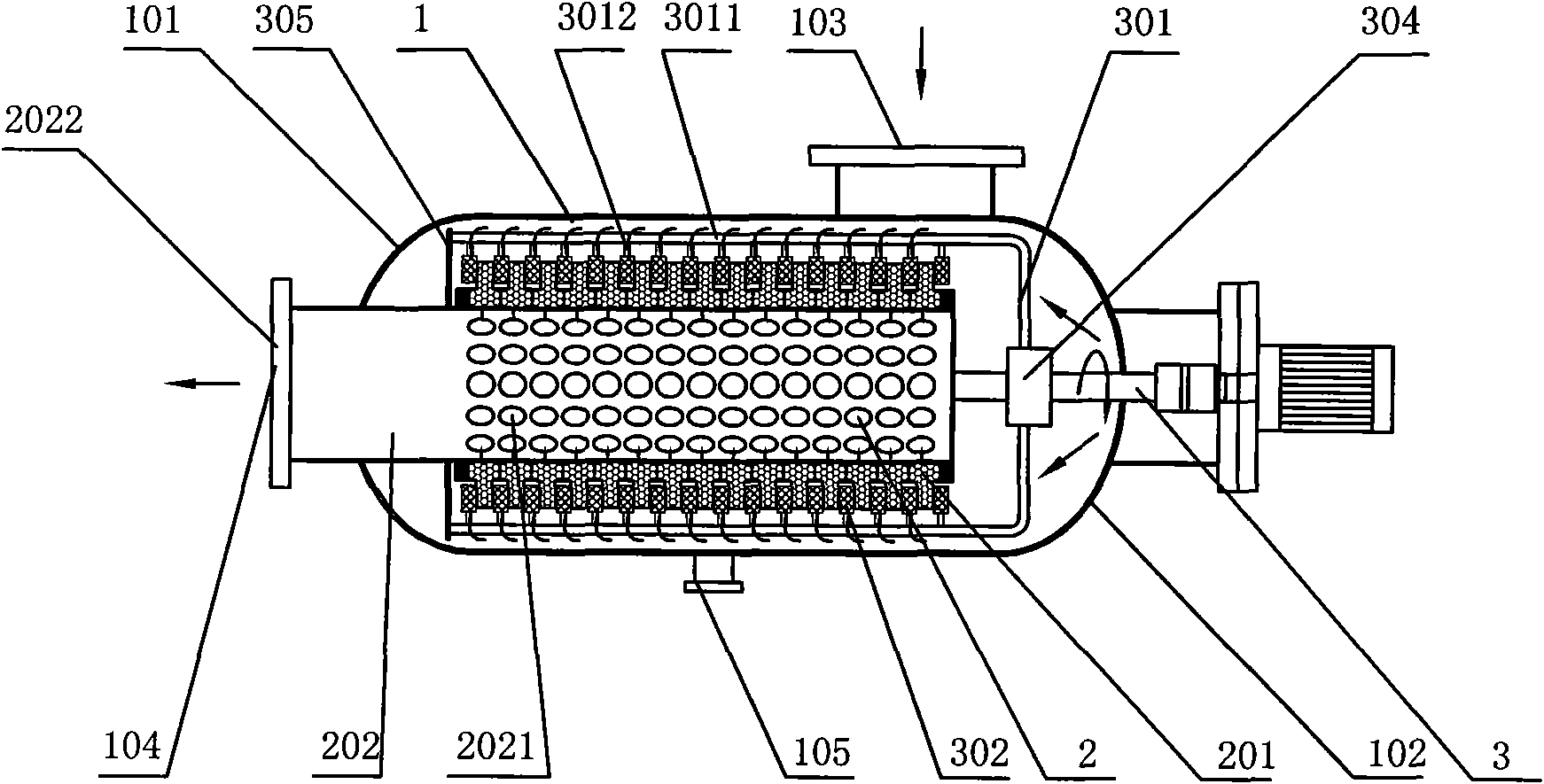

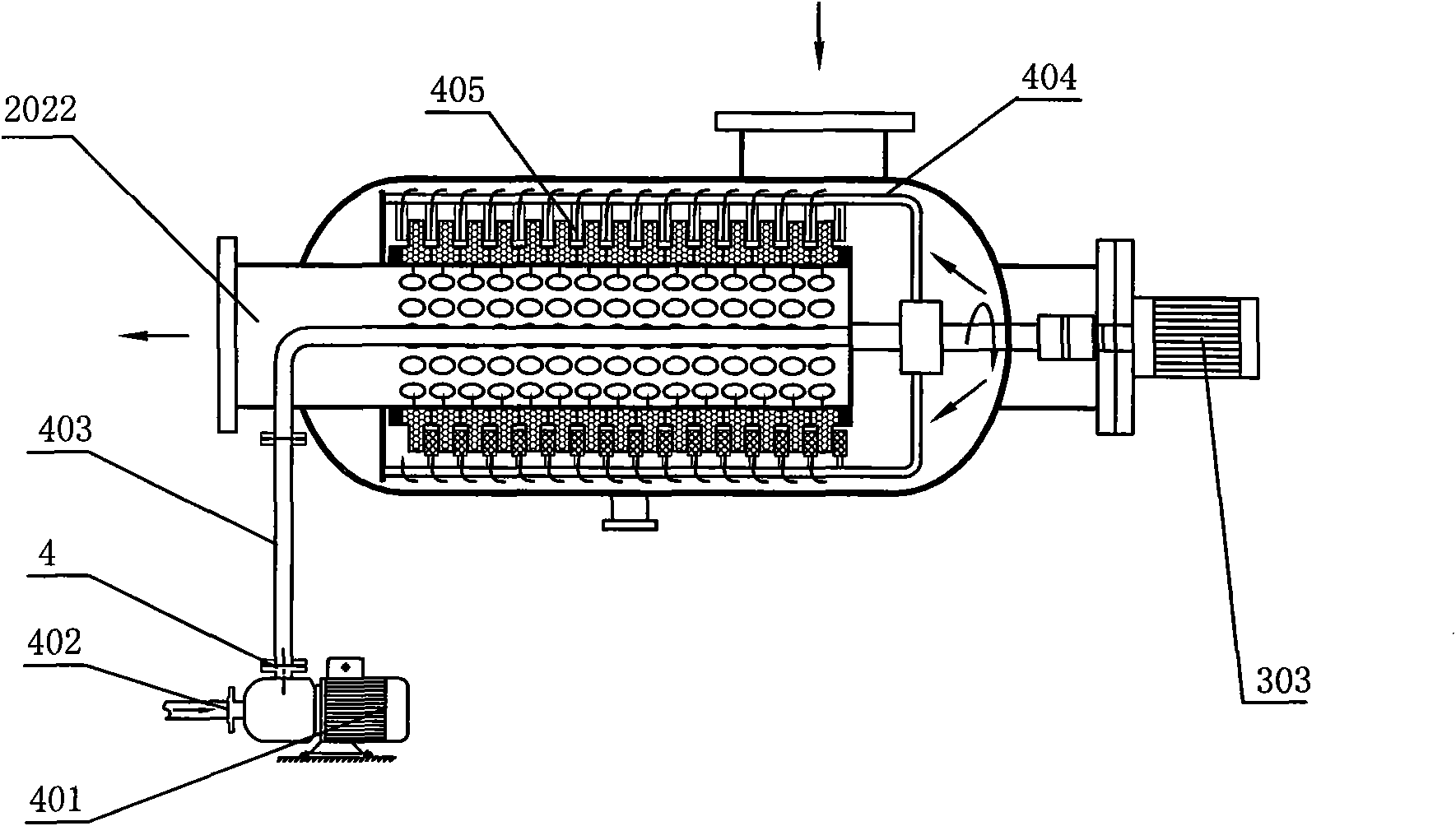

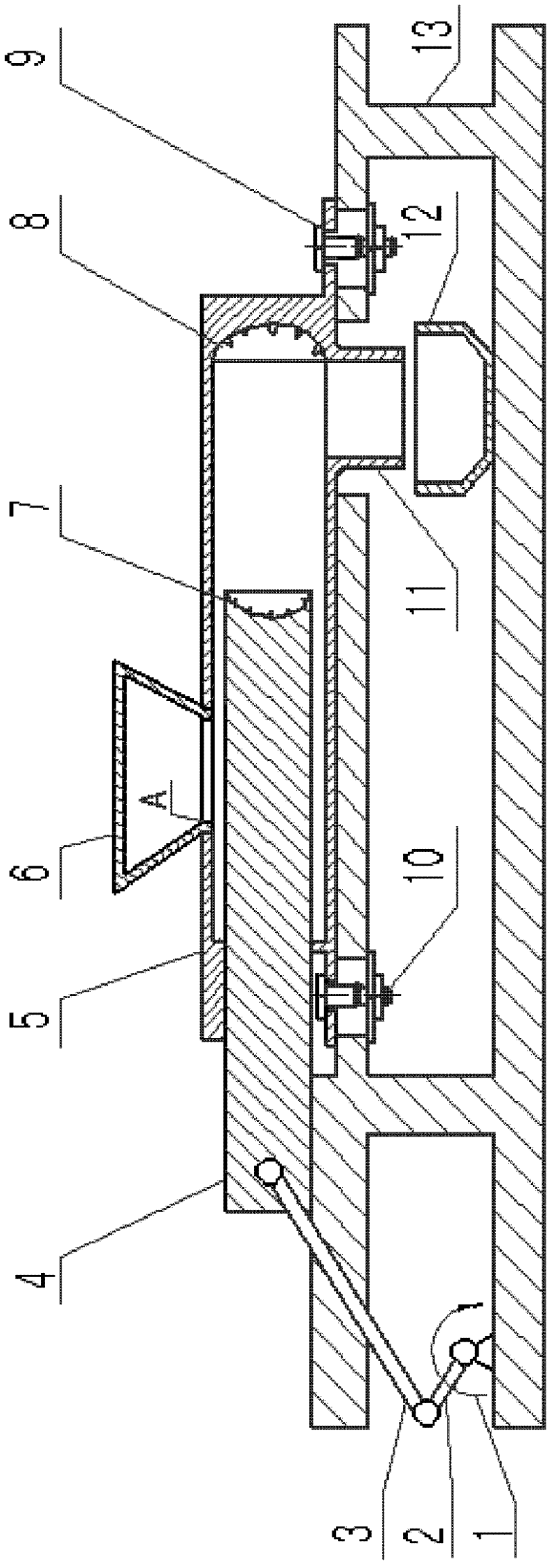

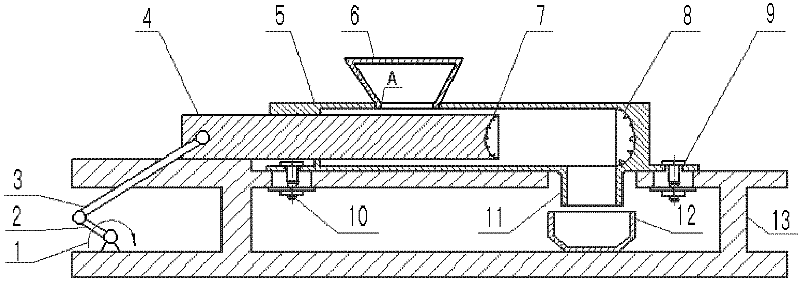

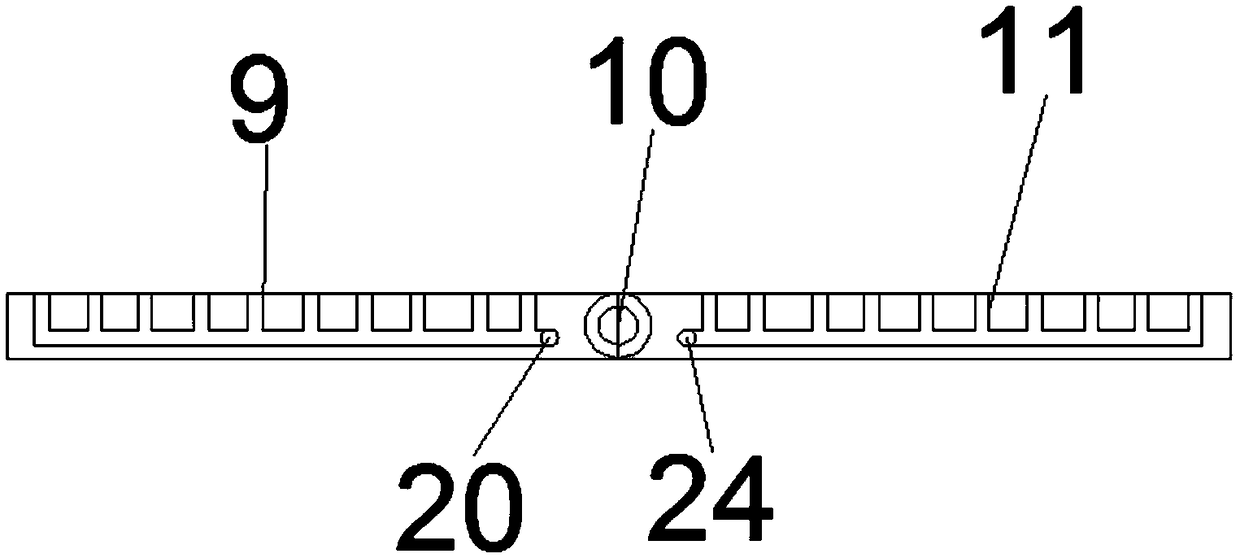

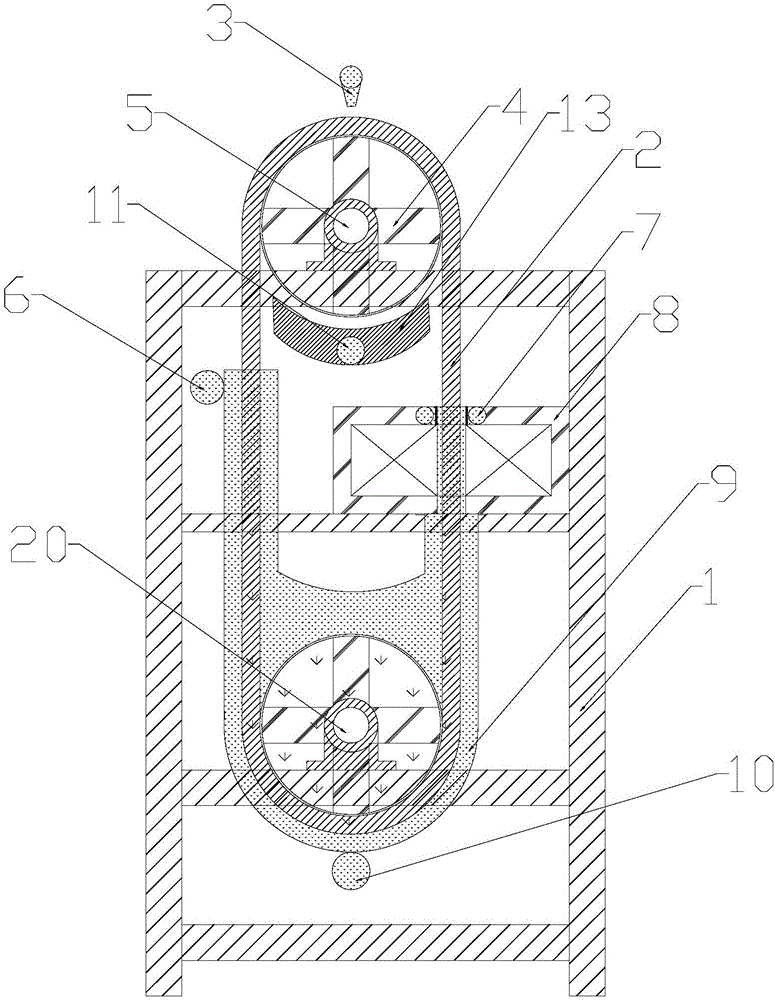

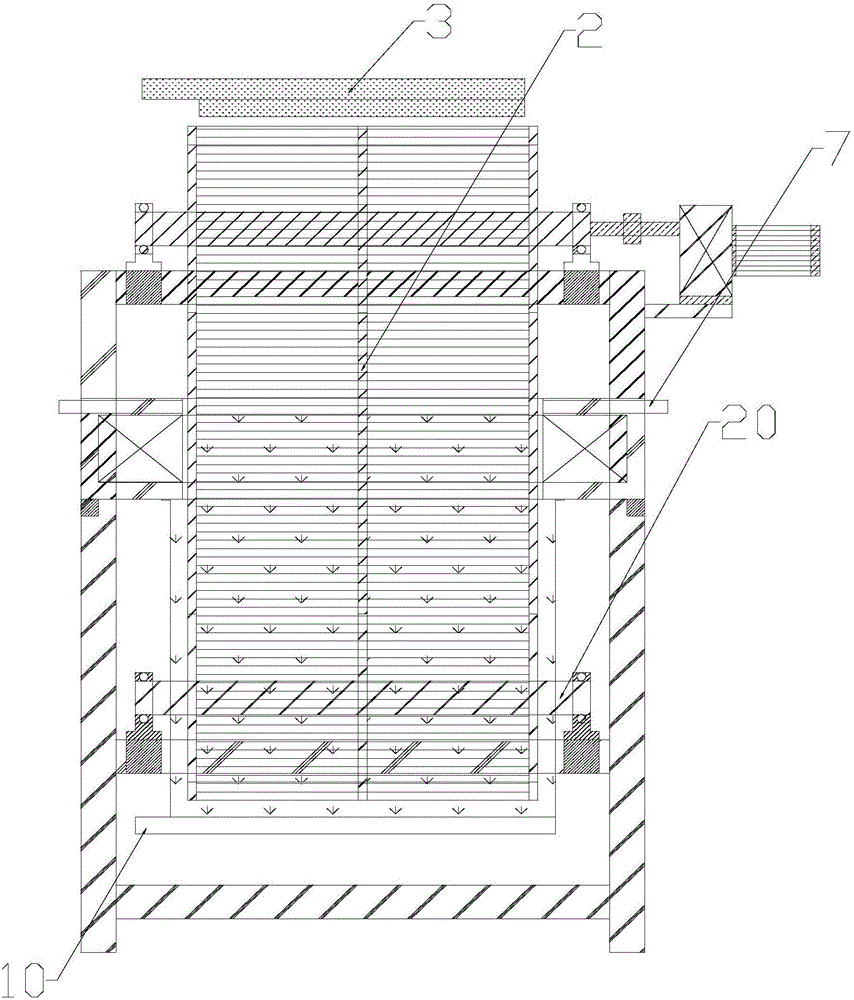

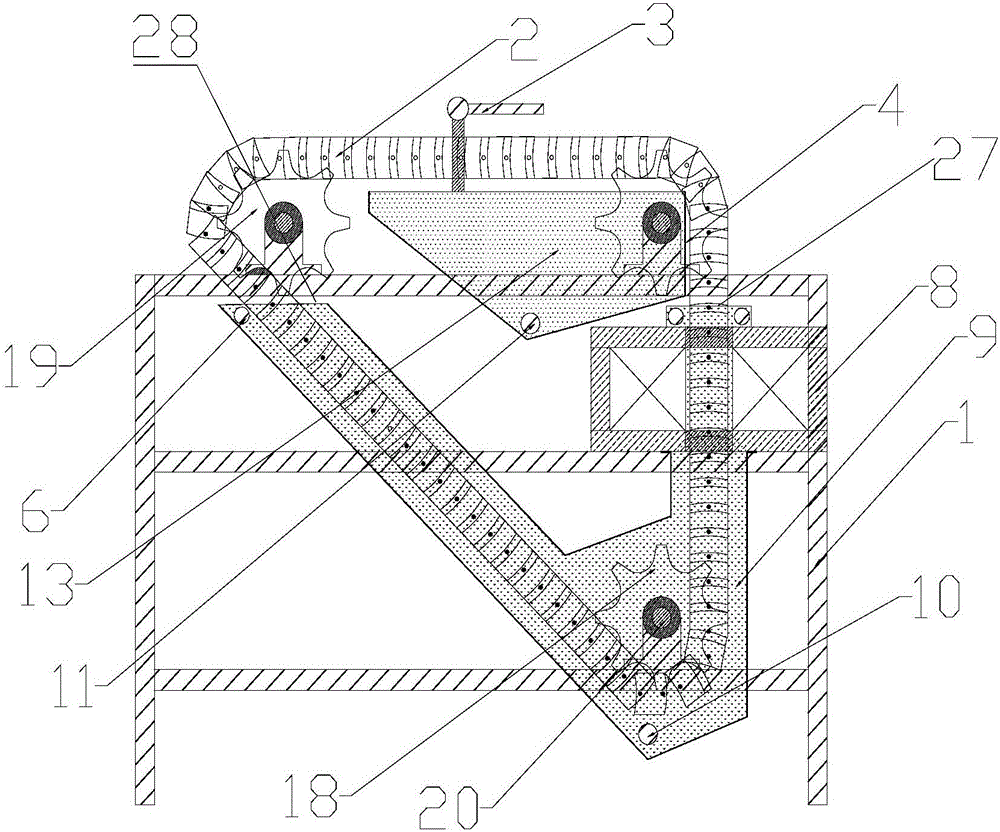

Unpowered automatic cleaning laminated filter

InactiveCN101961572AAchieve cleaningDriving realization of cleaning deviceMembrane filtersStationary filtering element filtersBallastFilter element

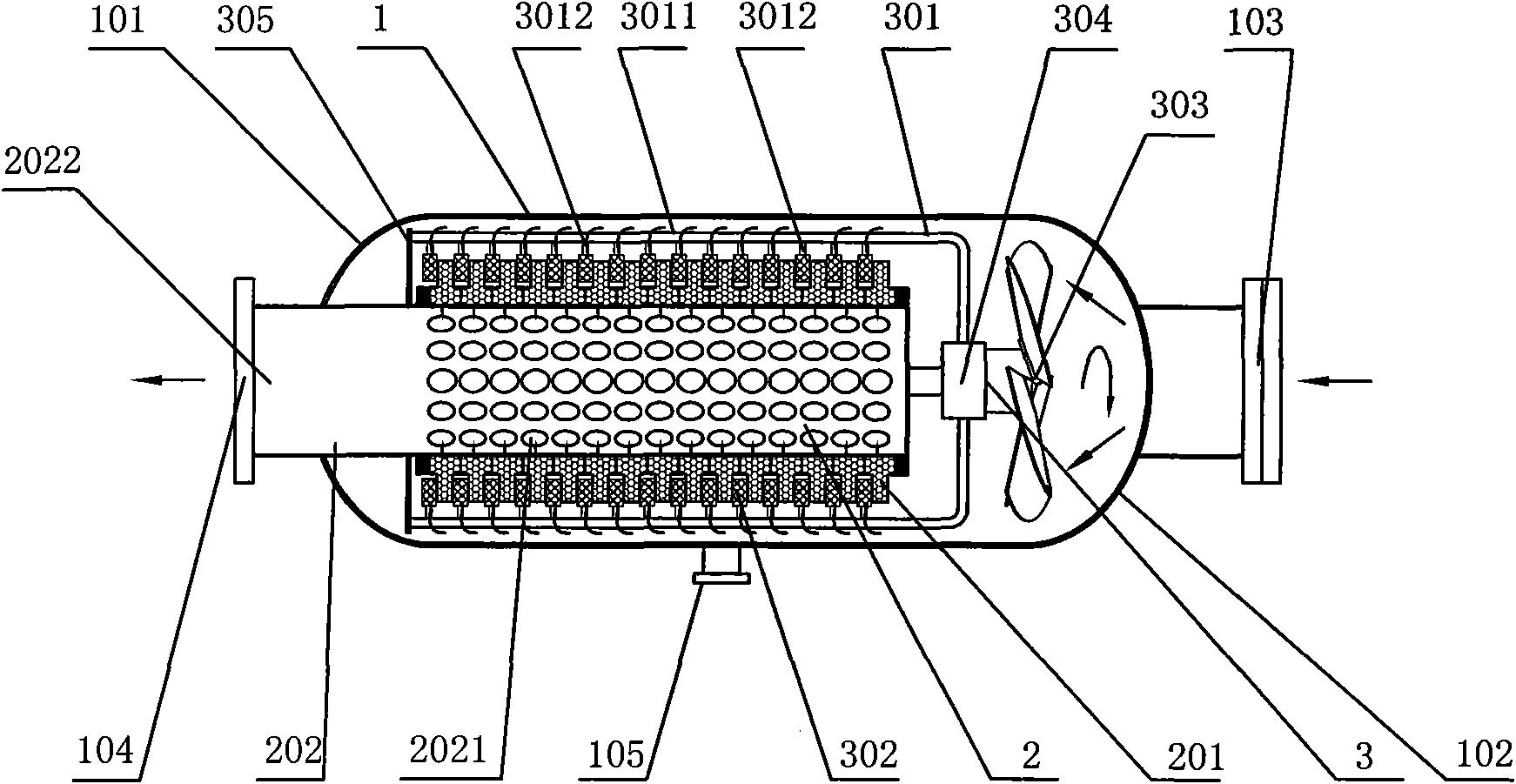

The invention provides an unpowered automatic cleaning laminated filter, which comprises a shell and a filter element, wherein the shell is a cylinder with end covers at two ends; a water inlet and a water outlet are arranged on the two end covers or at positions close to the end parts of the cylinder; the filter element consists of a group of hollow filter discs and a water outlet core pipe; the hollow filter discs are sleeved on the water outlet core pipe; a distance is kept between each two adjacent hollow filter discs; the effluent of the hollow filter discs flows into the water outlet core pipe; and one end of the water outlet pipe is closed, while the other end is provided with a water outlet, which is connected with the water outlet of the filter or directly serves as the water outlet of the filter. The filter also has a washing device which comprises a cleaning brush holder, a cleaning brush, a driving device and a mounting frame, wherein the mounting frame is connected with the driving device; the cleaning brush is fixed on the mounting frame; the head of the cleaning brush is positioned on the surface of the annular filter discs; and the cleaning device is driven by the driving device to rotate to realize the cleaning of the filter discs. The filter can be used for filtering ship ballast water, cooling water and the like.

Owner:FUJIAN NEWLAND ENTECH CO LTD

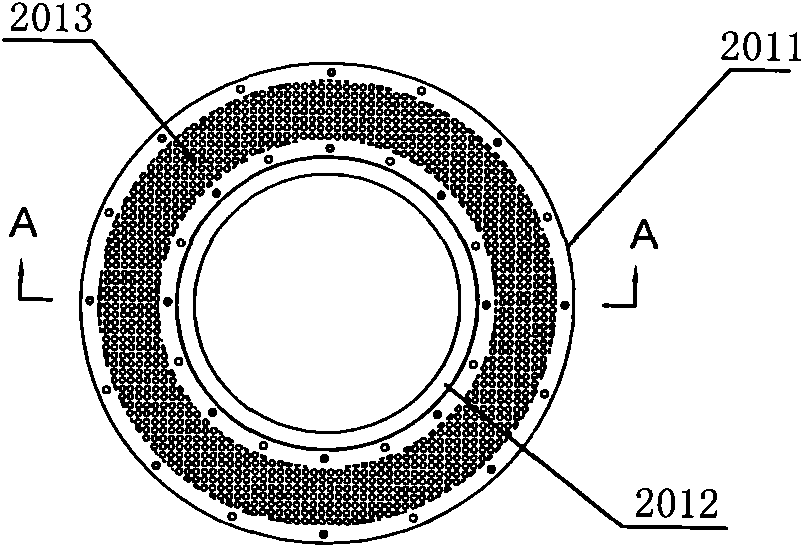

Laminated filter with automatic cleaning device

InactiveCN101954215AMaintain Filtration EfficiencyReduce labor costsStationary filtering element filtersFilter elementBallast

The invention provides a laminated filter with an automatic cleaning device. The laminated filter comprises a shell and a filter element, wherein the shell is a cylinder of which the two ends are provided with end covers; a water inlet and a water outlet are formed on the two end covers or close to the ends of the cylinder respectively; the filter element consists of a group of hollow filtering disks and a water outlet core tube; the hollow filtering disks are sleeved on the water outlet core tube; space is reserved between two adjacent hollow filtering disks; water from the hollow filtering disks flows into the water outlet core tube; one end of the water outlet core tube is closed, while the other end is provided with a water outlet which is connected with the water outlet of the filter or directly used as the water outlet of the filter; the laminated filter is also provided with a cleaning device which comprises a cleaning brush frame, a cleaning brush, a driving device and a mounting frame; the mounting frame is connected with the driving device; the cleaning brush frame is fixed on the mounting frame; the head of the cleaning brush is positioned on the surface of the annular filtering disk; and the cleaning device is driven to rotate by the driving device so as to clean the filtering disks. The laminated filter can be used for filtering the ballast water, cooling water and the like of ships.

Owner:FUJIAN NEWLAND ENTECH CO LTD

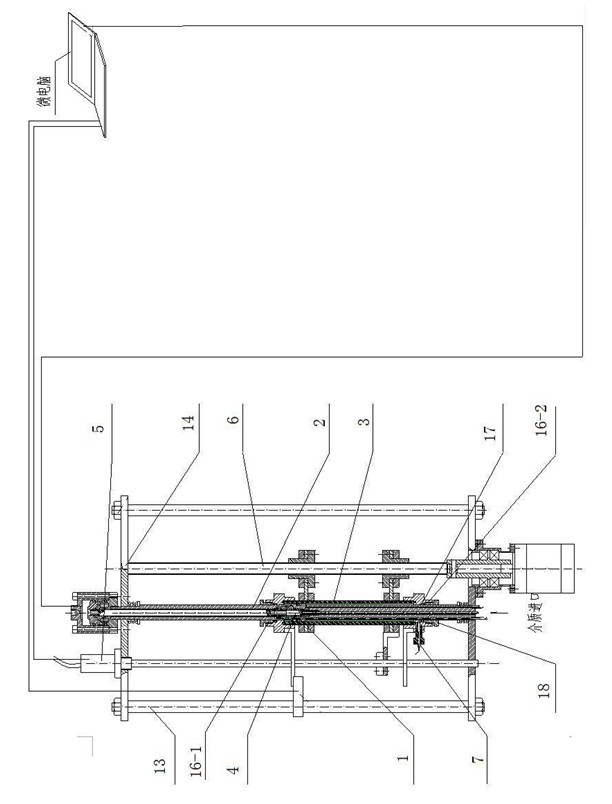

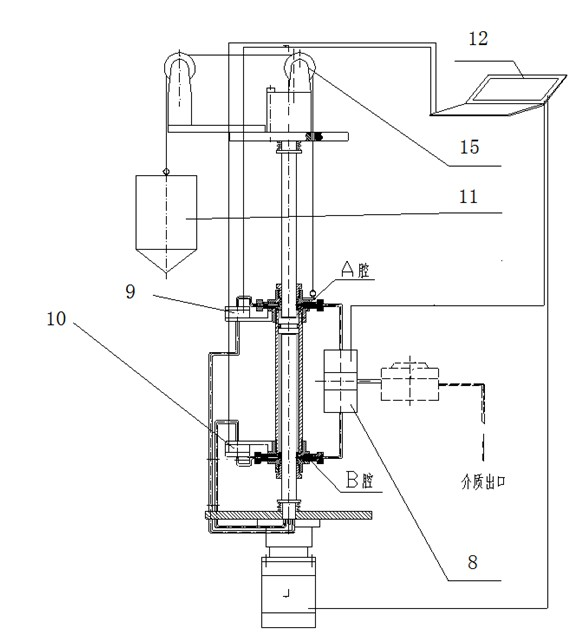

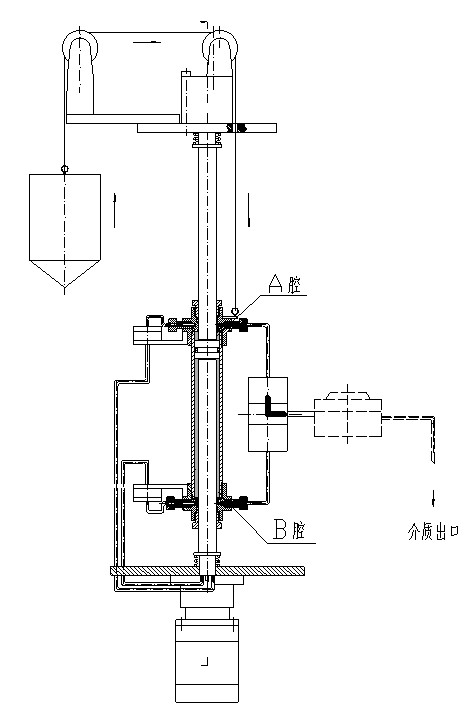

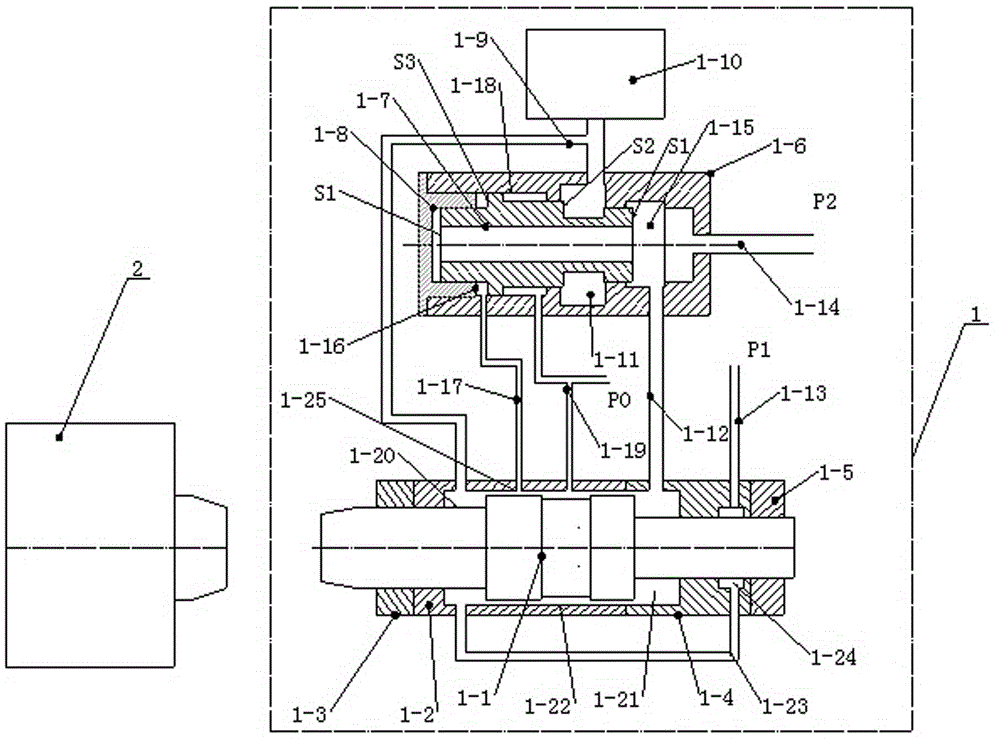

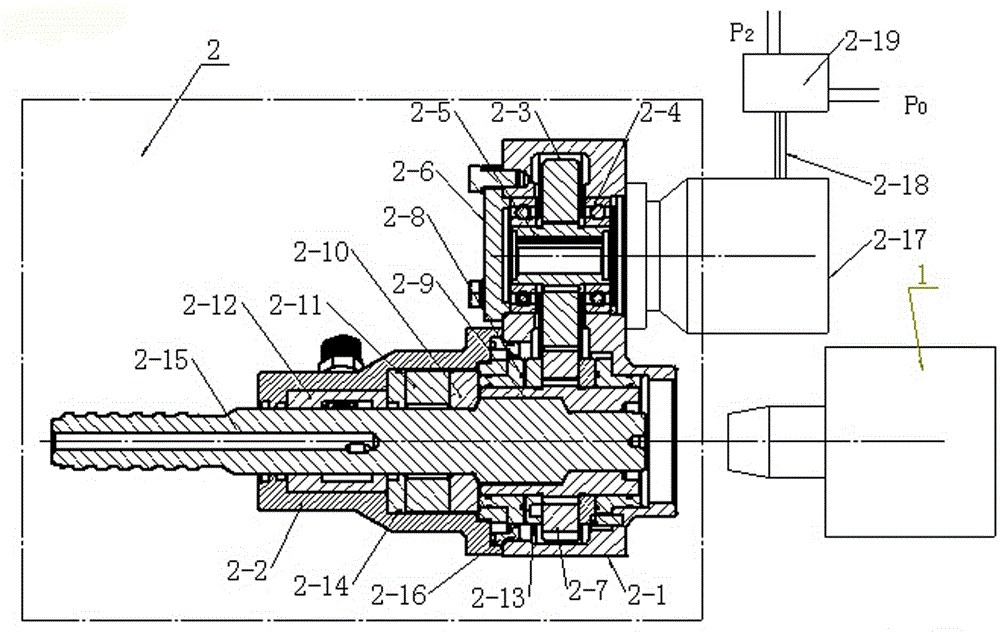

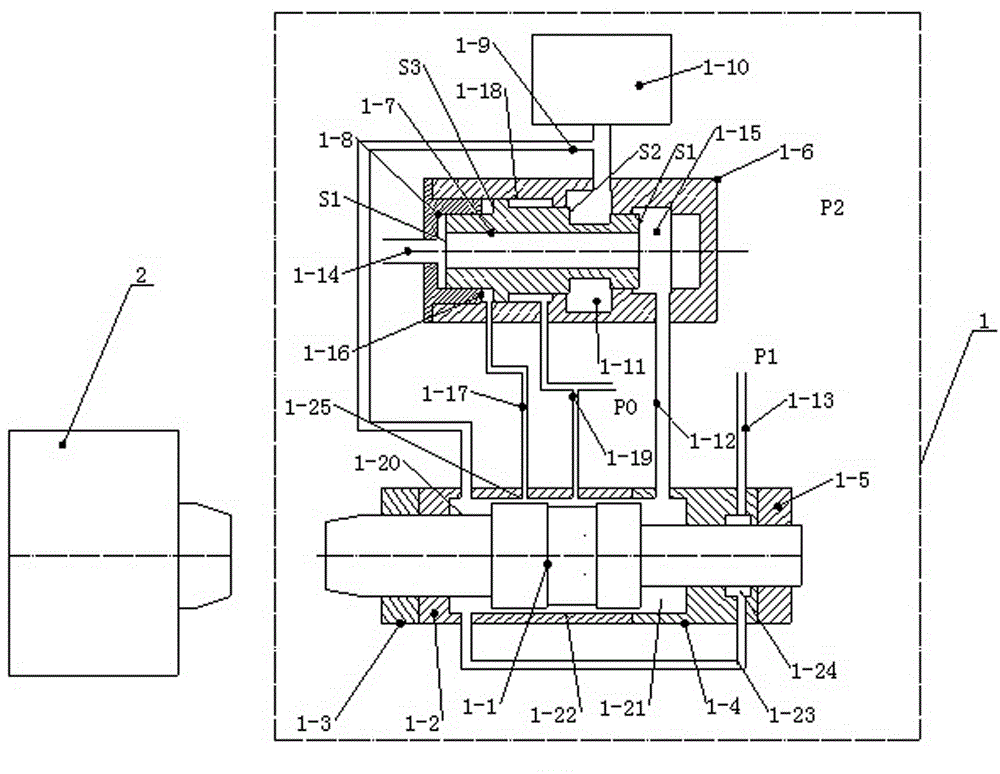

Oil-water tow-phase flowmeter

ActiveCN102243086AAccurately reflectReduced void volumeVolume/mass flow by differential pressureMeasurement deviceDifferential pressure

The invention provides an oil-water two-phase flowmeter. The flowmeter comprises a piston, piston rods, a cylinder, an inlet three-way reversing valve, an outlet three-way reversing valve, a linear displacement sensor, a seal resistance removal device, cavities A and B, differential pressure transducers for the cavities A and B, a temperature sensor, a balance weight and a micro-computer, wherein the piston rods are arranged at upper and lower ends of the piston; the cylinder is sleeved outside the piston; the inlet three-way reversing valve is positioned inside the piston; and the linear displacement sensor and the seal resistance removal device are parallel to the piston rods. The oil-water two-phase flowmeter has the advantages that: 1, total instant flow and accumulated flow of a two-phase mixture can be measured online, and the respective instant flow and accumulated flow of oil and water can be simultaneously measured; 2, the flowmeter can be connected in series between an experimental model and a back pressure valve, the blank volume of pipelines between the experimental model and the measurement device can be minimized, so that the measurement device can truly and instantly reflect the dynamic situation of two phases in the experimental model; and 3, the flow meter can endure high pressure.

Owner:海安华达石油仪器有限公司

Continuous walnut shell breaking machine

The invention discloses a continuous walnut shell breaking machine. A steel cylinder is fixed on a machine base by virtue of bolts, one end of the steel cylinder is closed and the other end of the steel cylinder is opened; the steel cylinder is internally provided with a slide block, the slide block, a crank and a rocker jointly form an offset crank slide block mechanism, a power device transfers power and force onto the slide block by virtue of the crank and the rocker, the slide block is driven to reciprocate in the steel cylinder, a plane extending out 5-8cm from the opening of the steel cylinder is contacted with the slide block, a charging bin communicated with the steel cylinder is arranged above a position, which is 5-8cm away from the opening, in the steel cylinder, a discharge hole is arranged below a closed end face in the steel cylinder, and a charging bucket is arranged under the discharge hole. The continuous walnut shell breaking machine disclosed by the invention has enough pressure and certain breakage stroke, different walnut shells can be appropriately broken, the continuous walnut shell breaking machine is automatic and fast, works reliably, has a good effect and a simple structure, is small and practical and is simple and convenient to operate.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

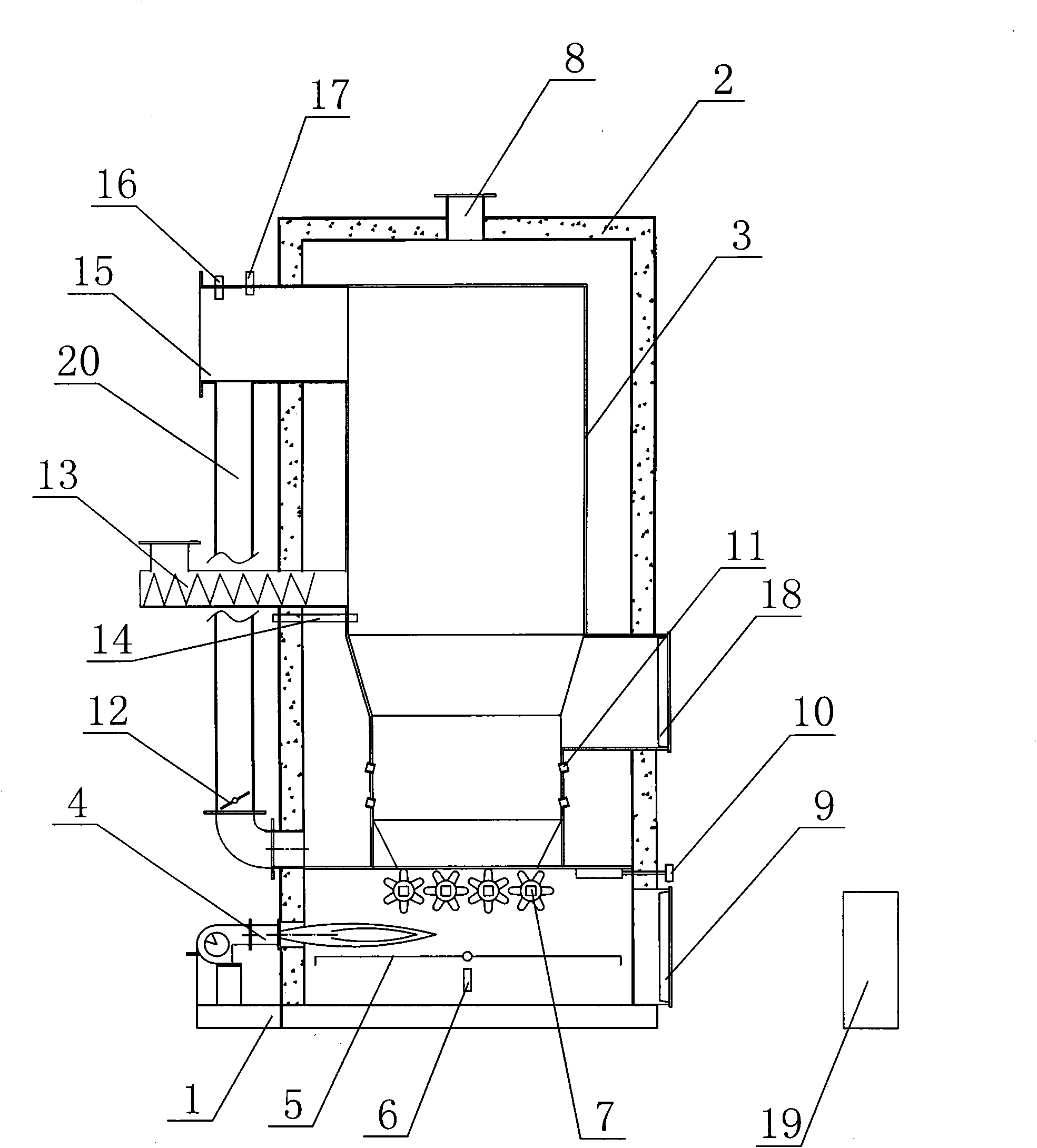

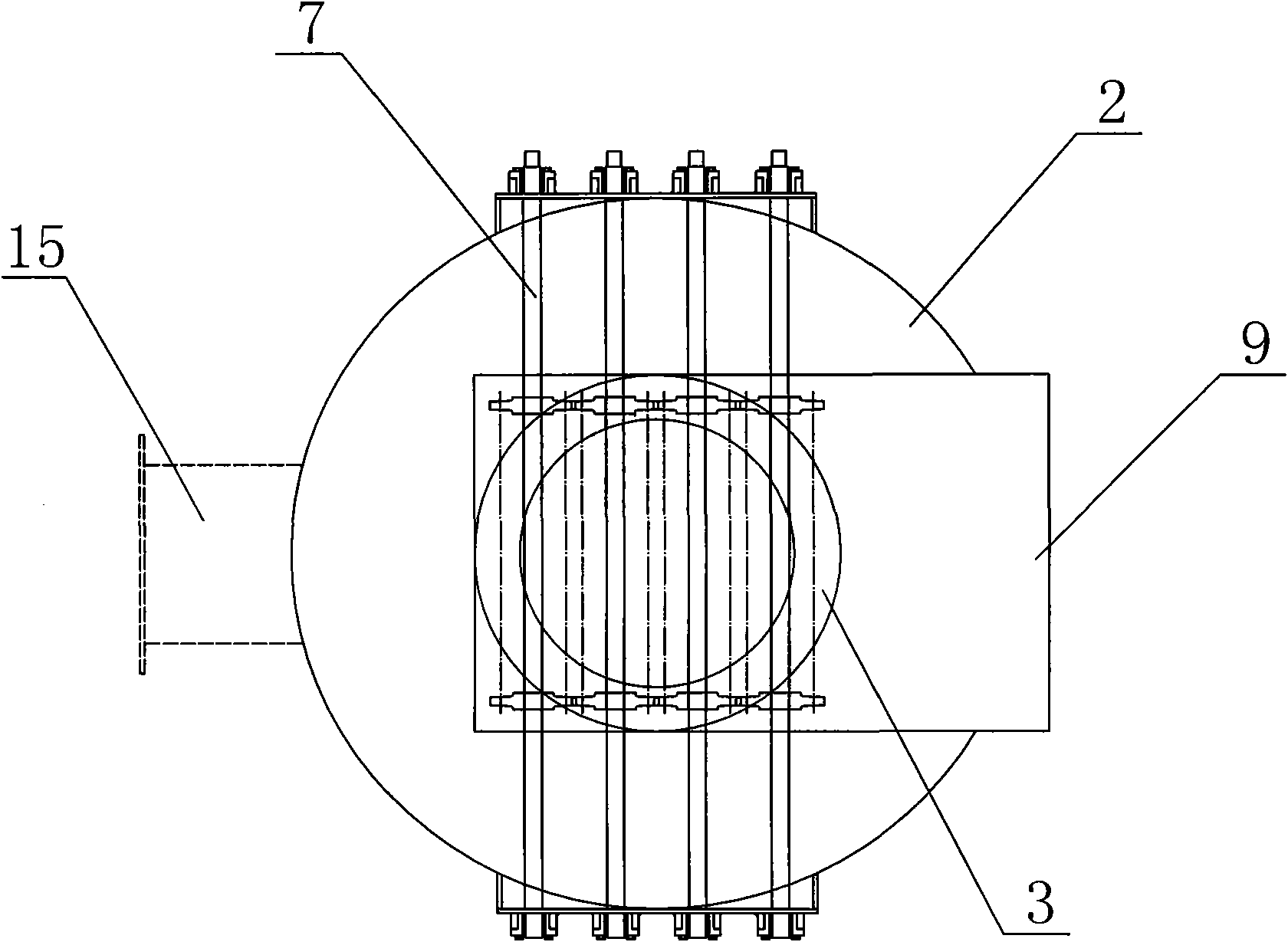

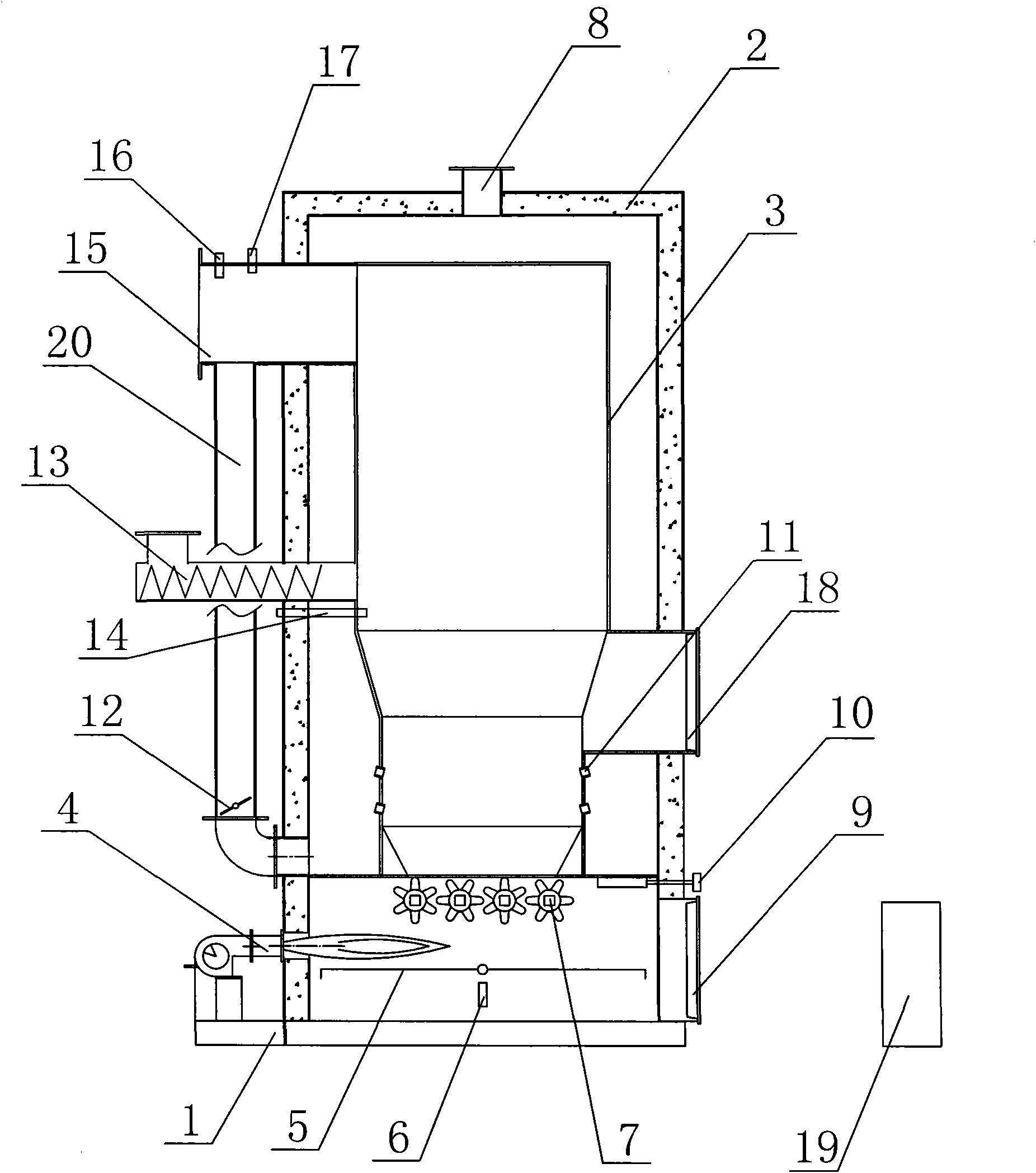

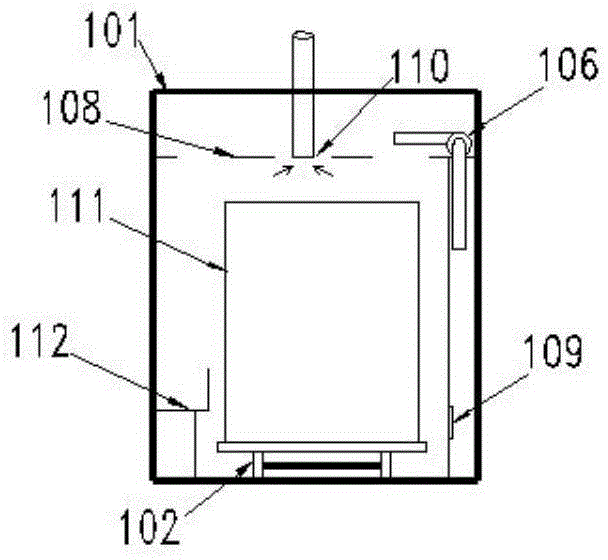

Intelligent sludge incinerator

InactiveCN101956987AIncineration stableHarmless treatmentIncinerator apparatusAutomatic controlCombustion

The invention discloses an intelligent sludge incinerator. The sludge incinerator comprises an outer furnace body, an inner furnace body, a base, an electrically driven automatic slag discharge grate, a screw feeder, an automatic slag discharge device, a diesel oil burner, a primary air inlet system, a secondary air inlet system and a controller, wherein the controller is used for controlling one or more temperature sensors arranged at a hearth, a smoke outlet and a primary inlet, an oxygen quantity sensor arranged at the smoke outlet and a weight sensor for automatic slag discharge. The intelligent sludge incinerator can realize reduction and harmlessness of sludge by adopting a bubbling suspension combustion method, and meanwhile realizes low discharge of pollutants; the combustion is stable by automatic control of parameters of primary and secondary air inlet, and the temperature in the incinerator is controlled at 850 to 950 DEG C all the time for combustion; and the sludge incinerator has high automation degree, saves labor, relieves labor intensity, realizes stable incineration of the sludge, obviously reduces the fault rate, and has low maintenance expense and humanized operation.

Owner:WUXI AMDI ENVIRONMENTAL PROTECTION TECH CO LTD

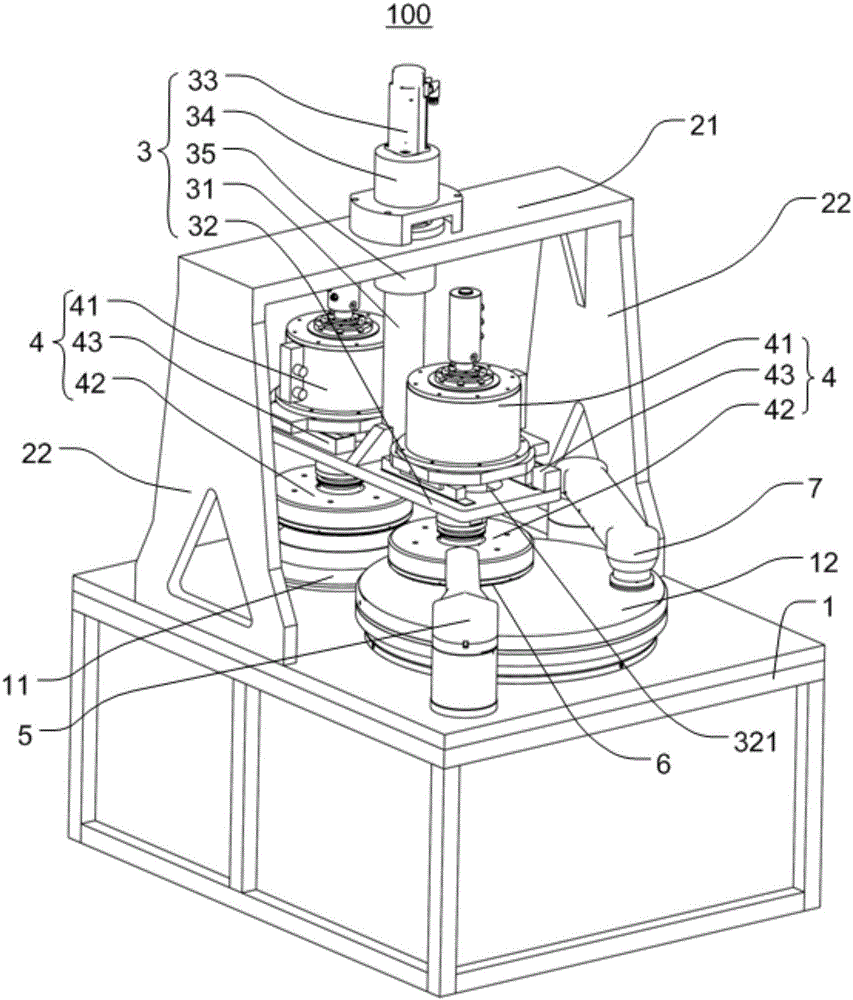

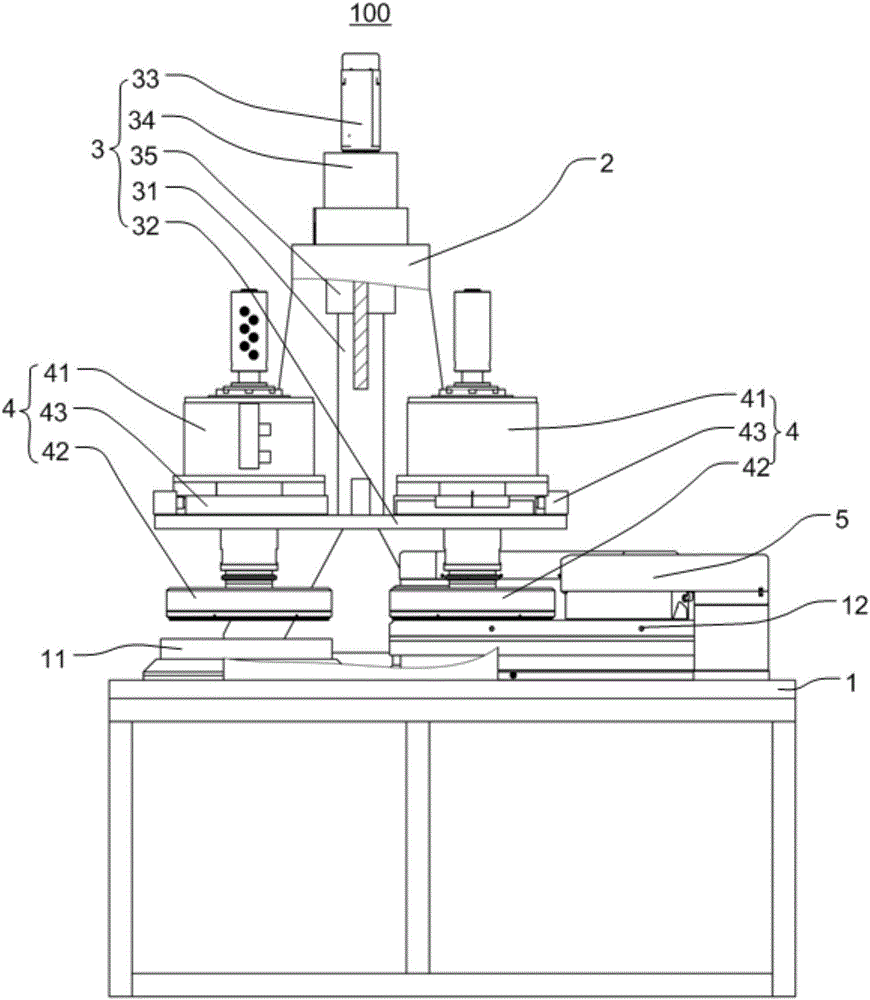

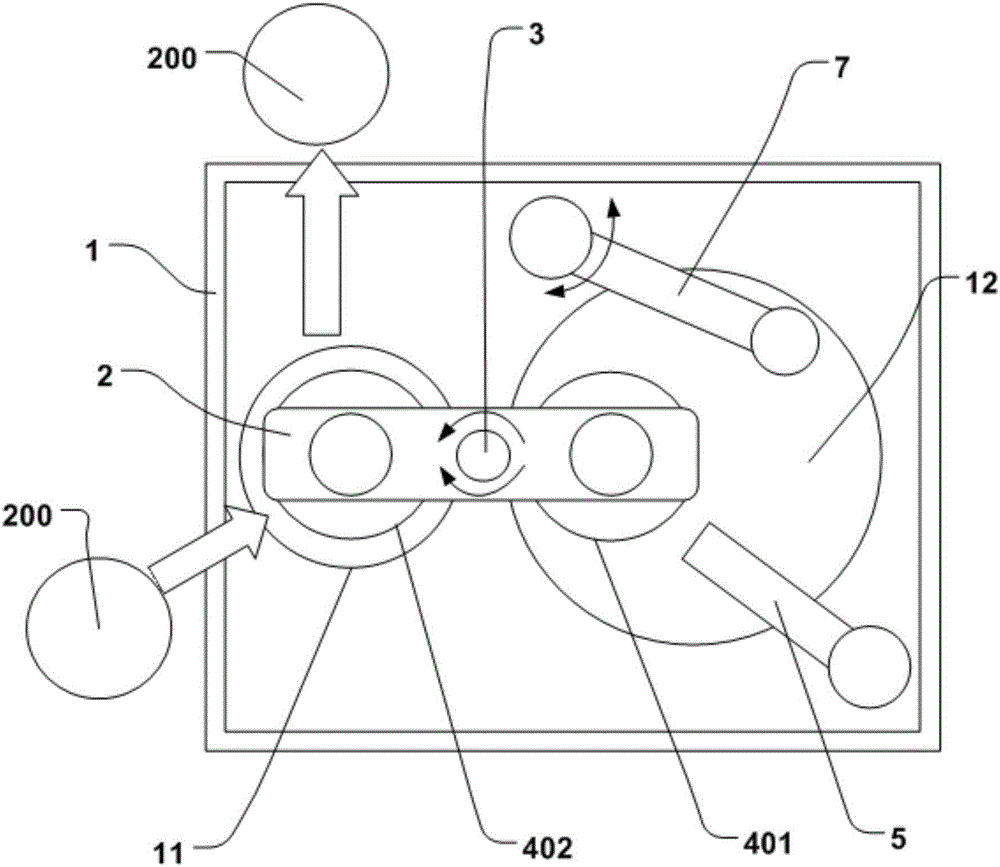

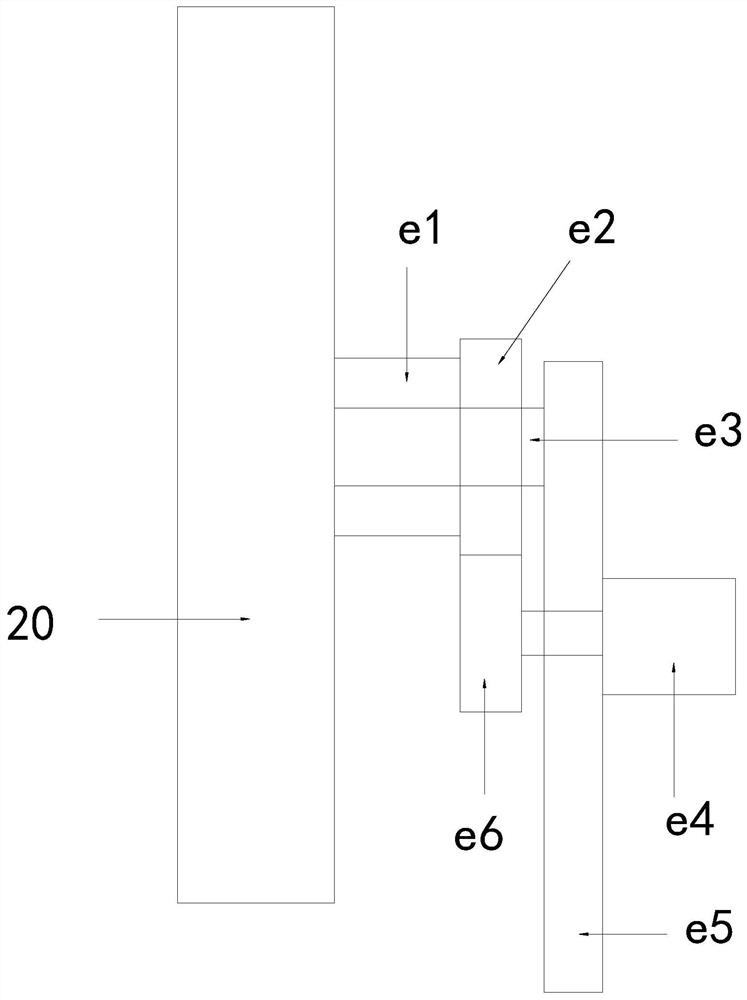

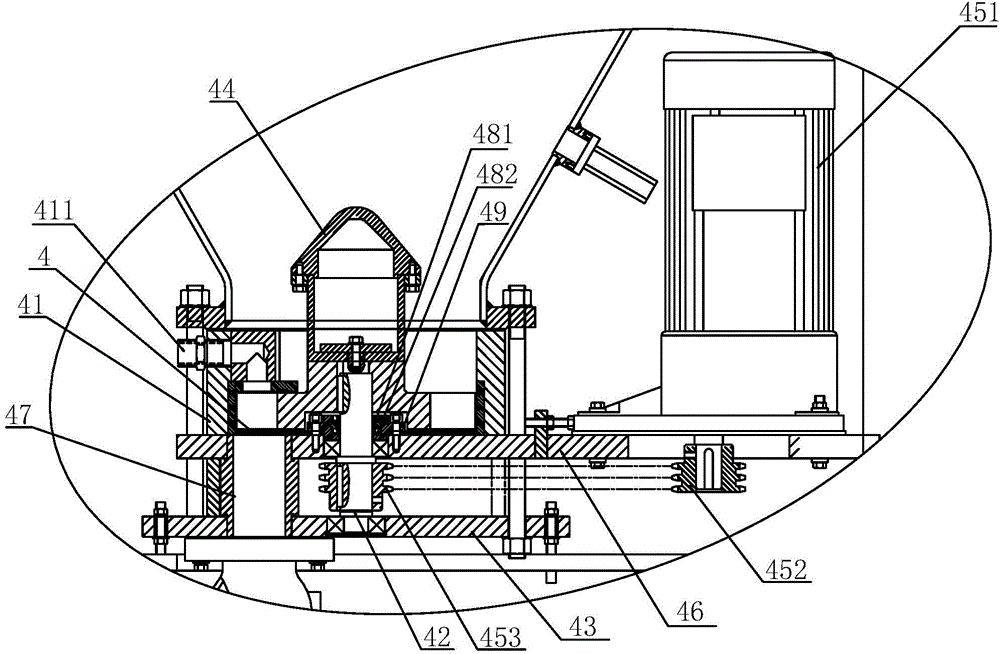

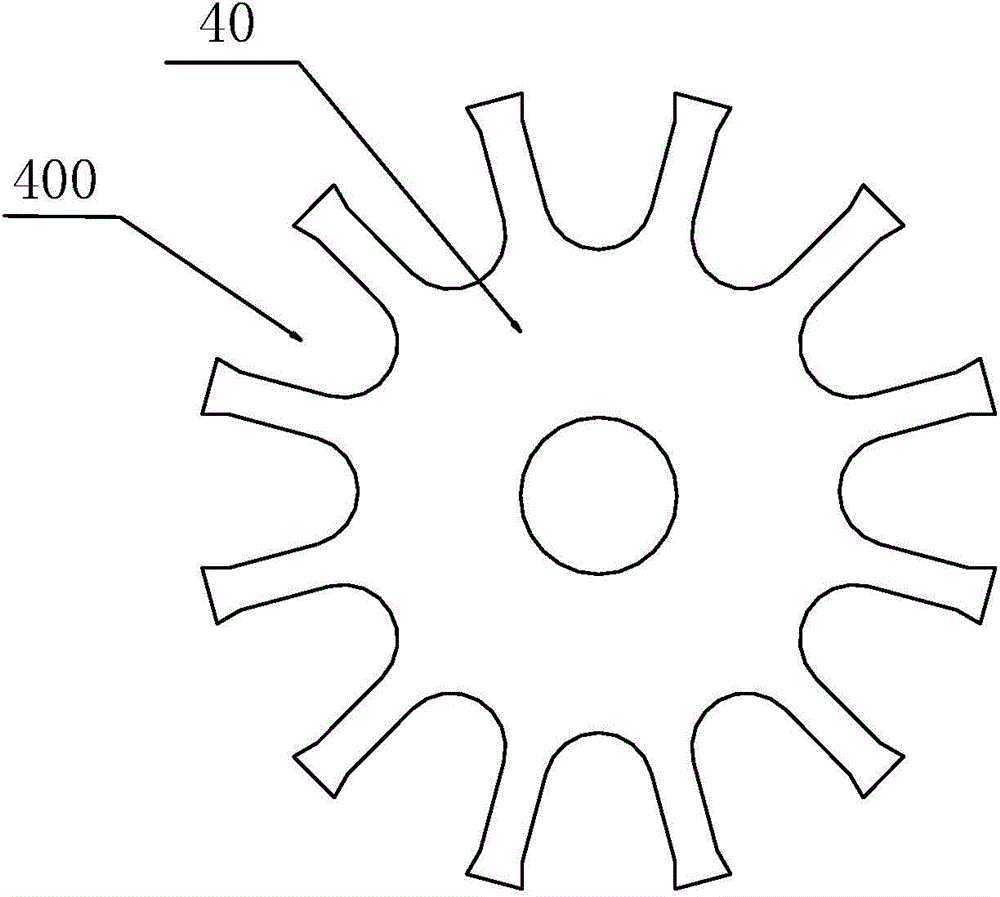

Chemical-mechanical polishing machine and polishing assembly for chemical-mechanical polishing machine

InactiveCN106737055AContinuous workImprove work efficiencyLapping machinesGrinding machinesEngineeringTower

The invention discloses a chemical-mechanical polishing machine and a polishing assembly for the chemical-mechanical polishing machine. The polishing assembly comprises a lower support, an upper support, a driving rotating tower and two polishing head assemblies. A worktable and a polishing disc are arranged on the lower support; the upper support is erected on the lower support; the driving rotating tower is suspended on the upper support, and at least one part of the driving rotating tower can rotate in a pivoted mode relative to the lower support; and the two polishing head assemblies are installed on the driving rotating tower and can move between a loading and unloading position corresponding to the worktable position and a polishing position corresponding to the polishing disc position under pivot rotation of the driving rotating tower, wherein when one polishing head assembly is located at the loading and unloading position, the other polishing head assembly is located at the polishing position. According to the polishing assembly for the chemical-mechanical polishing machine, while one polishing head assembly polishes, the other polishing head assembly can load and unload wafers, and the two polishing head assemblies can polish alternately so that continuous working can be conducted, and accordingly working efficiency can be improved.

Owner:HWATSING TECH +1

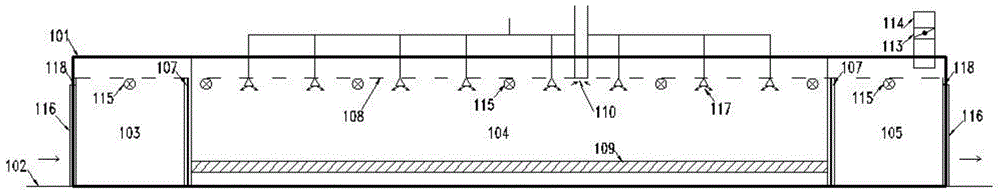

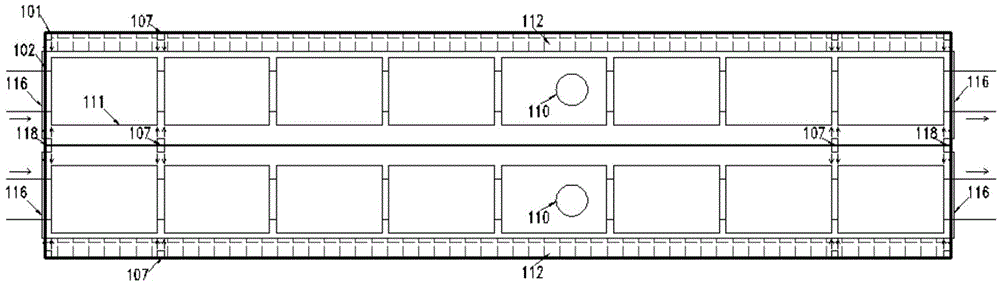

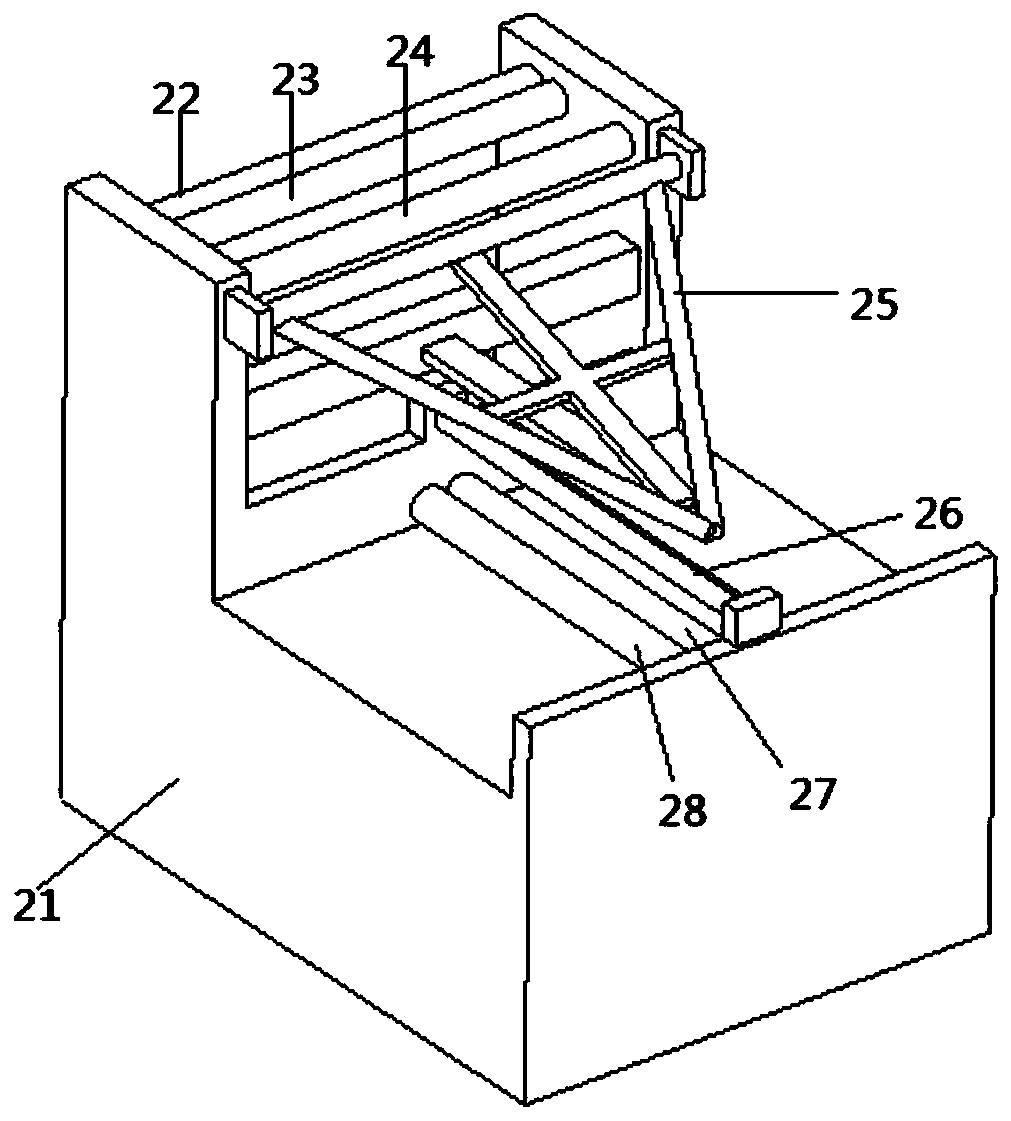

Wood fumigation quarantine and disinfection system

ActiveCN104552513AEnvironmentally friendlyEfficient quarantine fumigation workWood treatment detailsPressure impregnationActivated carbon filtrationDesorption

The invention discloses a wood fumigation quarantine and disinfection system, which comprises a fumigation chamber and a wood transfer system, wherein the fumigation chamber is a tunnel type building, and comprises a preheating section, a fumigation section and a desorption section; horizontal counter-blowing air curtains are arranged between every two sections and at inlets and outlets of tunnels; an air circulation system and an exhaust system are arranged in the fumigation section; an air outlet of the exhaust system is positioned in the top of the fumigation section, and is connected with an exhaust absorption and rectification system; the exhaust absorption and rectification system comprises an absorption tower and a rectification tower; an air inlet with an airtight valve and an activated carbon filtering device is formed in the outer wall of the desorption section; the wood transfer system comprises a rail arranged on the ground in and outside the fumigation chamber and a rail trolley on the rail. The wood fumigation quarantine and disinfection system can be used for performing automatic assembly line fumigation treatment on imported logs in a large scale, so that the quarantine and disinfection working efficiency is improved; in addition, the quarantine and disinfection requirements are met, and meanwhile, a treatment process is more efficient, energy-saving and environment-friendly and safer.

Owner:TIANJIN UNIV

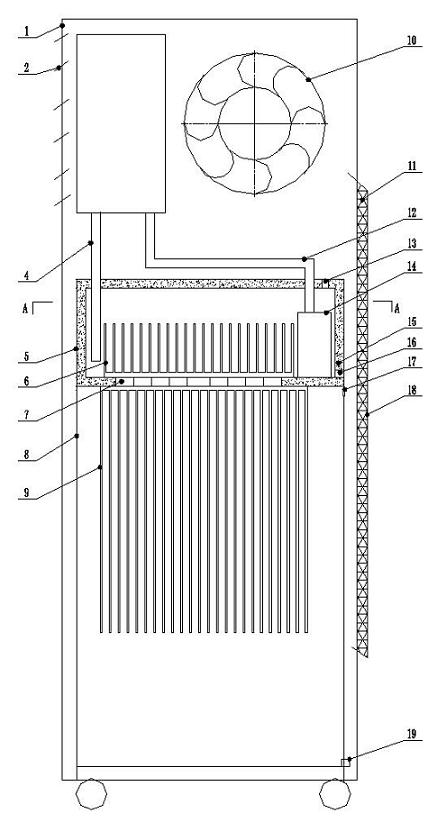

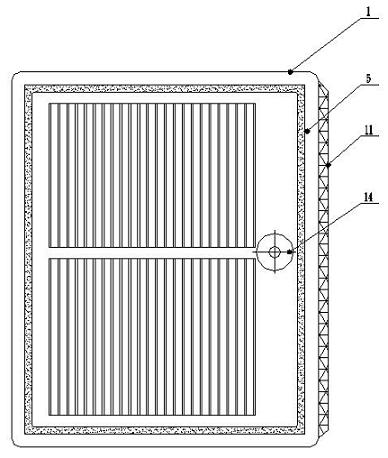

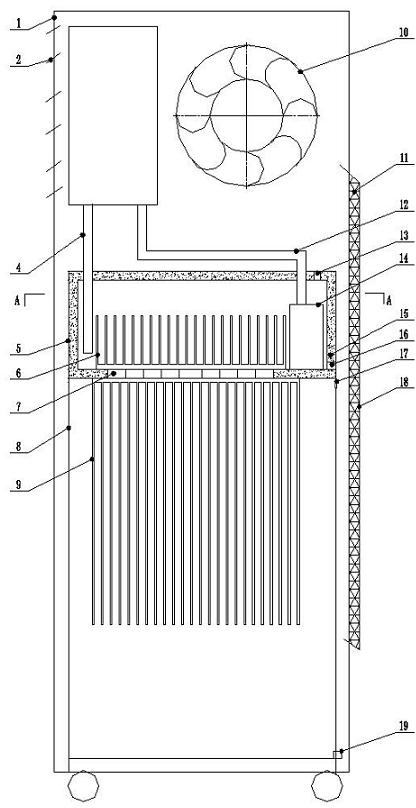

Semiconductor water temperature air conditioner

InactiveCN102401441ANo vibrationExtend your lifeLighting and heating apparatusAir conditioning systemsWater tanksSemiconductor

The invention discloses a semiconductor water temperature air conditioner, which comprises a shell 1, an air outlet 2, a radiator 3, a water return hose 4, a cold / hot water tank 5, a water tank 8, lower cooling radiating fins 9, a fan 10, an air filter screen 11, a water inlet hose 12, water injection holes 13 and 17, drainage holes 16 and 19, an air inlet 18 and a cold / hot water generating device. The air conditioner is characterized in that: the cold / hot water generating device comprises the cold / hot water tank 5, a micro water pump 14, a semiconductor 7 and upper cooling radiating fins 6, wherein the micro water pump 14 is arranged in the cold / hot water tank 5, a semiconductor 7 is hermetically arranged in a bottom hole of the cold / hot water tank 5, the upper cooling radiating fins 6 are tightly attached to the upper end face of the semiconductor 7, and the lower cooling radiating fins 9 are arranged on the lower end face of the semiconductor 7 and placed into the water tank 8. The semiconductor water temperature air conditioner has the advantages of low energy consumption, no pollution, simple structure, economical efficiency and practicability.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

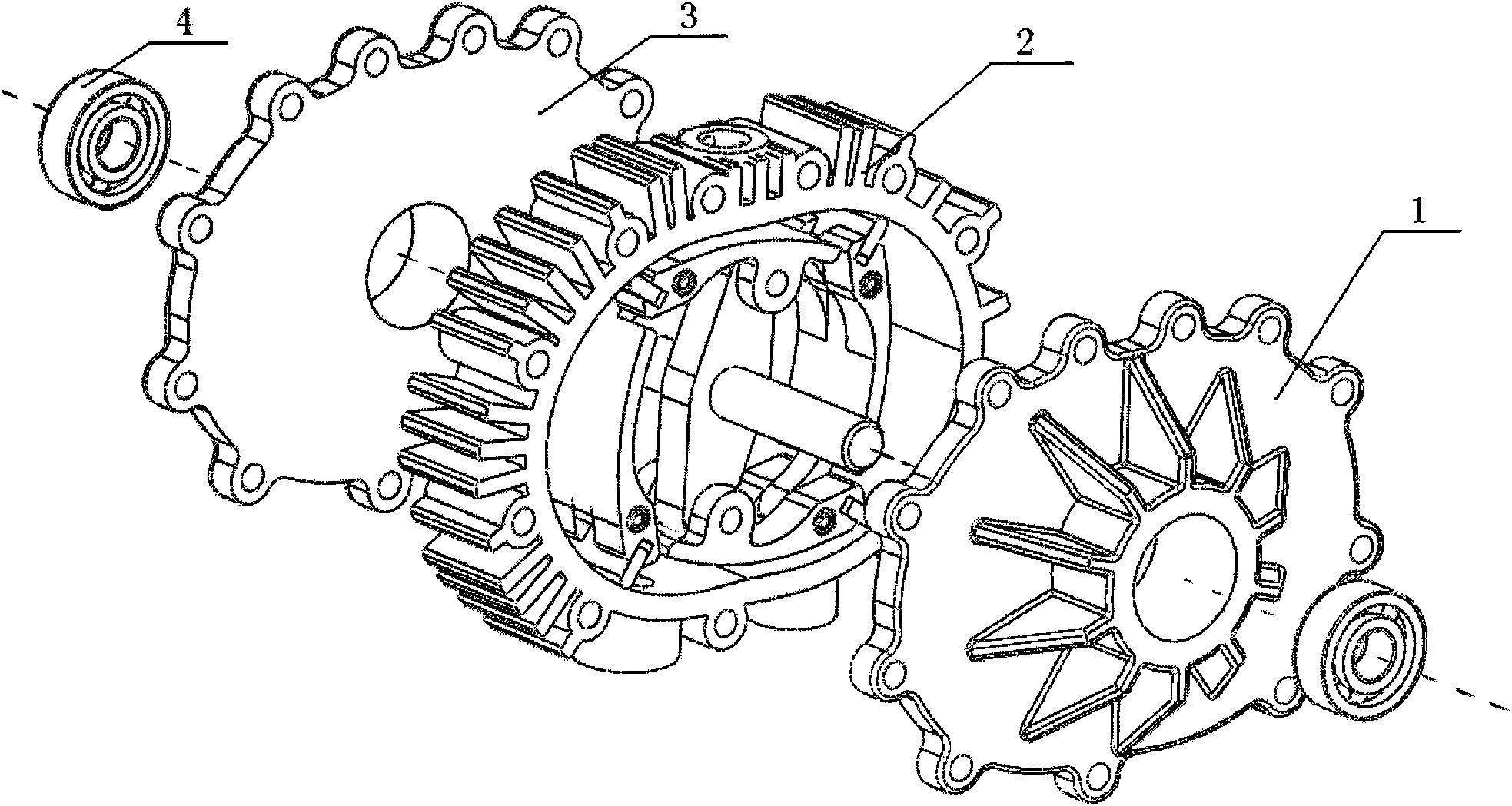

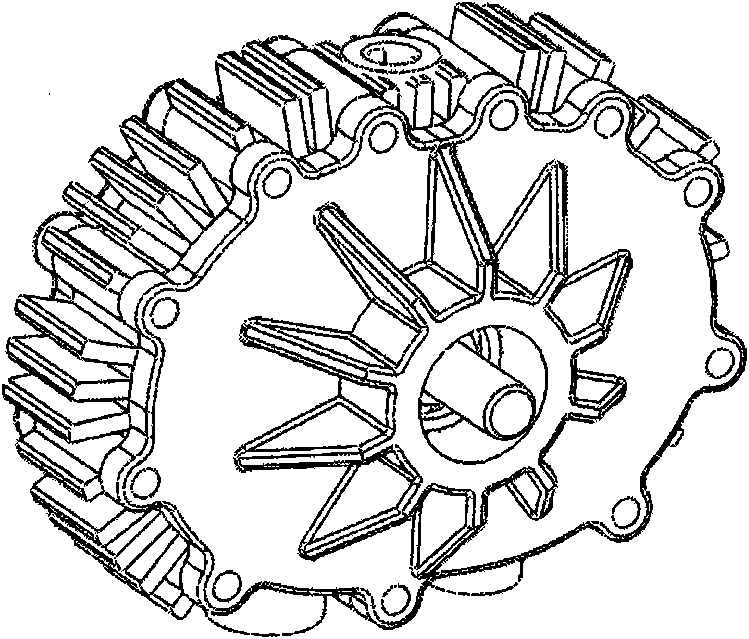

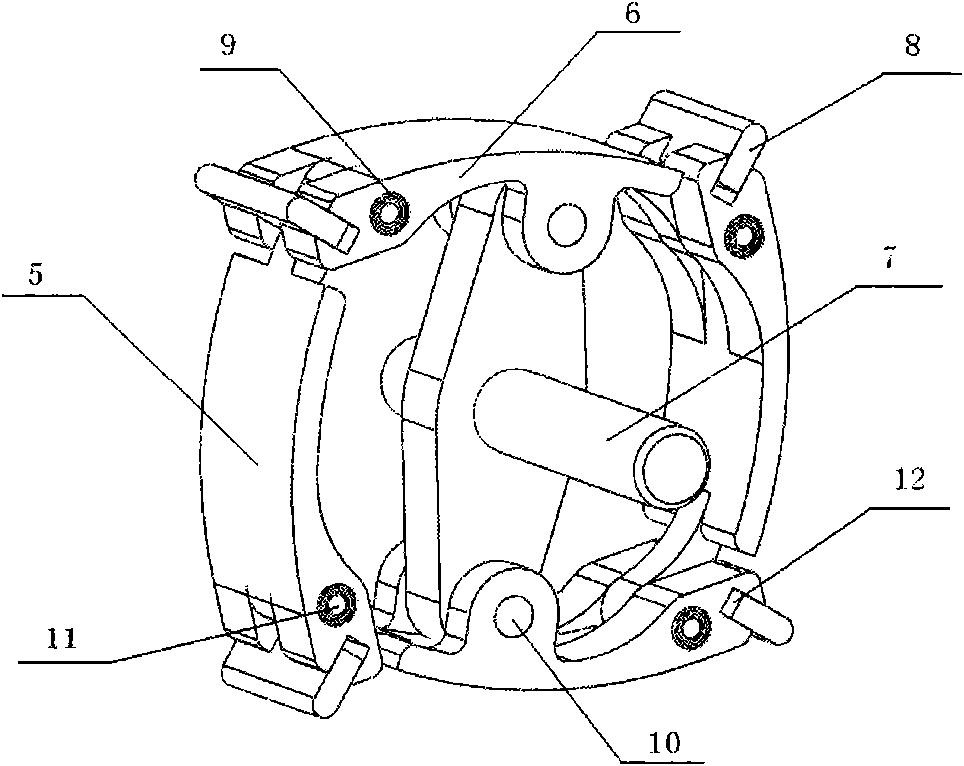

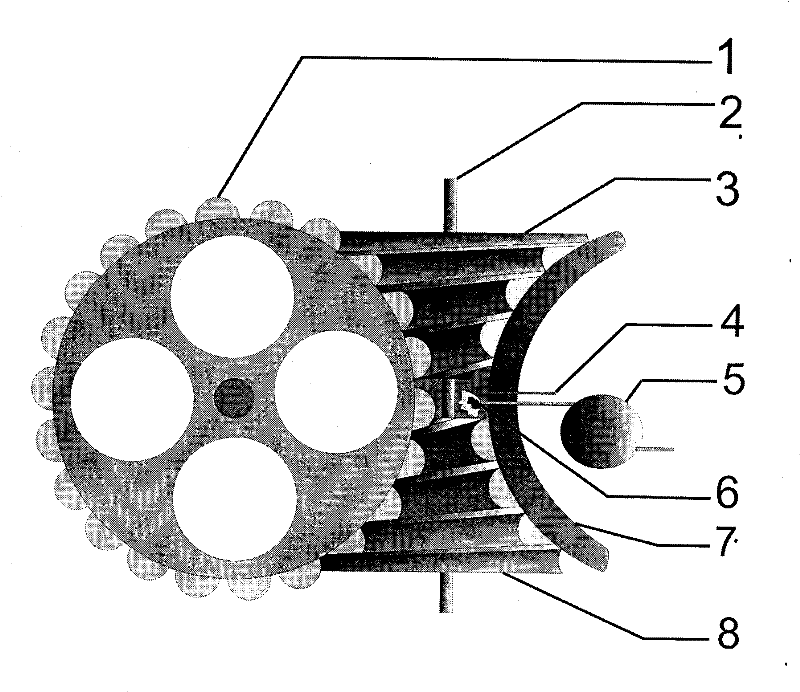

Four-corner rotating piston engine

InactiveCN101818685ASmooth runningNo vibrationInternal combustion piston enginesFree-piston enginePiston ring

The invention relates to a four-corner rotating piston engine. The four-corner rotating piston engine consists of a front cylinder cover, a cylinder, a rear cylinder cover, bearings, pistons, driving pistons, a main shaft, sealing elements, small bearings, driving pins, piston pins and spring pieces, wherein the position connection relation is that: the small bearings are arranged in the internal holes of the pistons and the driving pistons; a pair of pistons and a pair of driving pistons in which the small bearings are arranged are formed into a similar square part; the piston pins pass through the internal holes of the small bearings; the driving pistons are connected with the main shaft through the driving pins; the spring pieces are arranged in rectangular grooves of the pistons and the driving pistons respectively; the sealing elements are arranged on the spring pieces; the bearings are arranged in the internal holes of the front cylinder cover and the rear cylinder cover; the connected pistons, driving pistons, main shaft, sealing elements, small bearings, driving pins, piston pins and spring pieces form a rotor assembly to be placed in the cylinder; the front cylinder cover and the rear cylinder cover are sleeved at the front end and the rear end of the main shaft respectively; and the front cylinder cover and the rear cylinder cover are tightly connected with the cylinder by screws and nuts. The four-corner rotating piston engine has simple structure and scientific design and is a novel multi-purpose engine.

Owner:BEIHANG UNIV

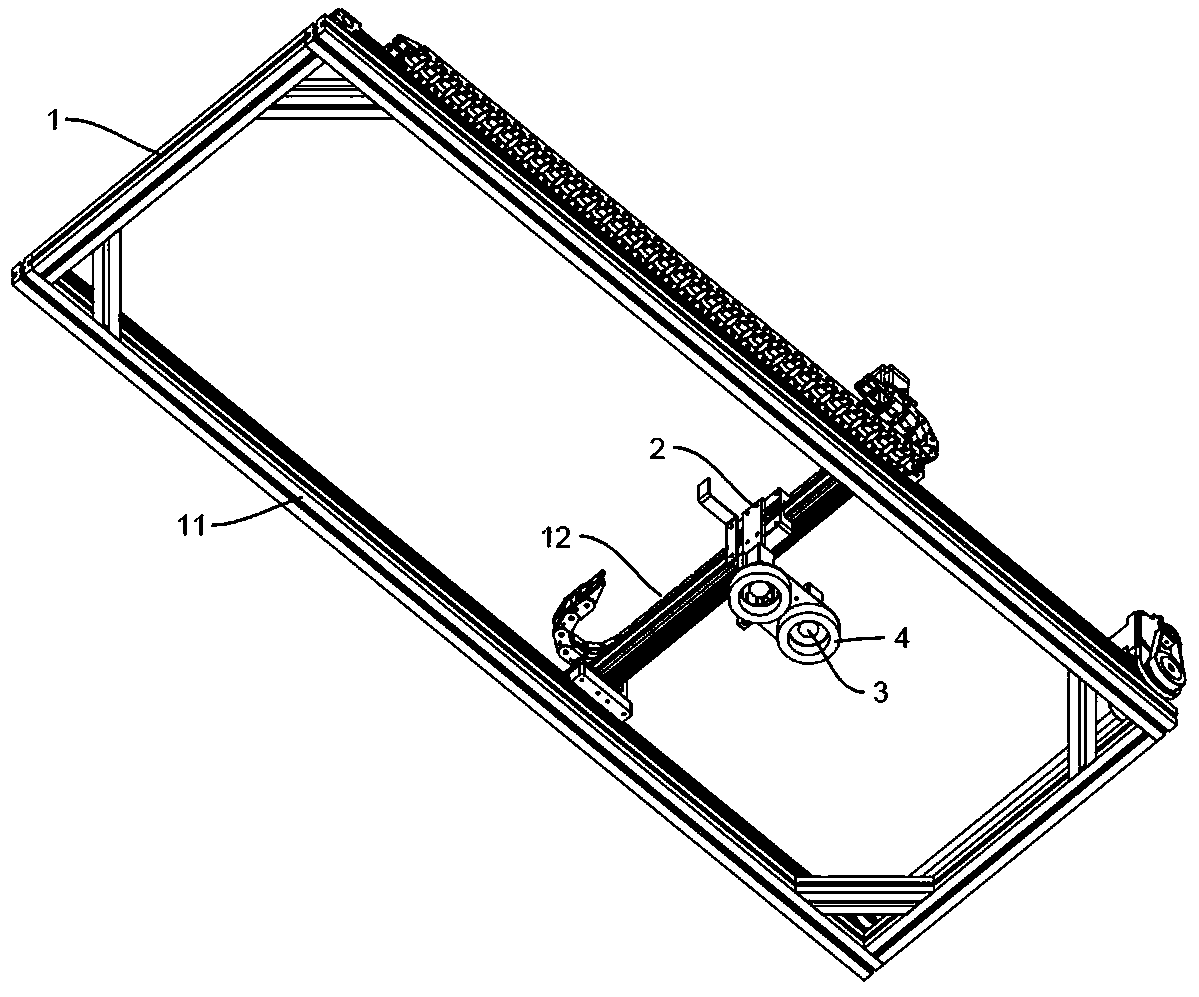

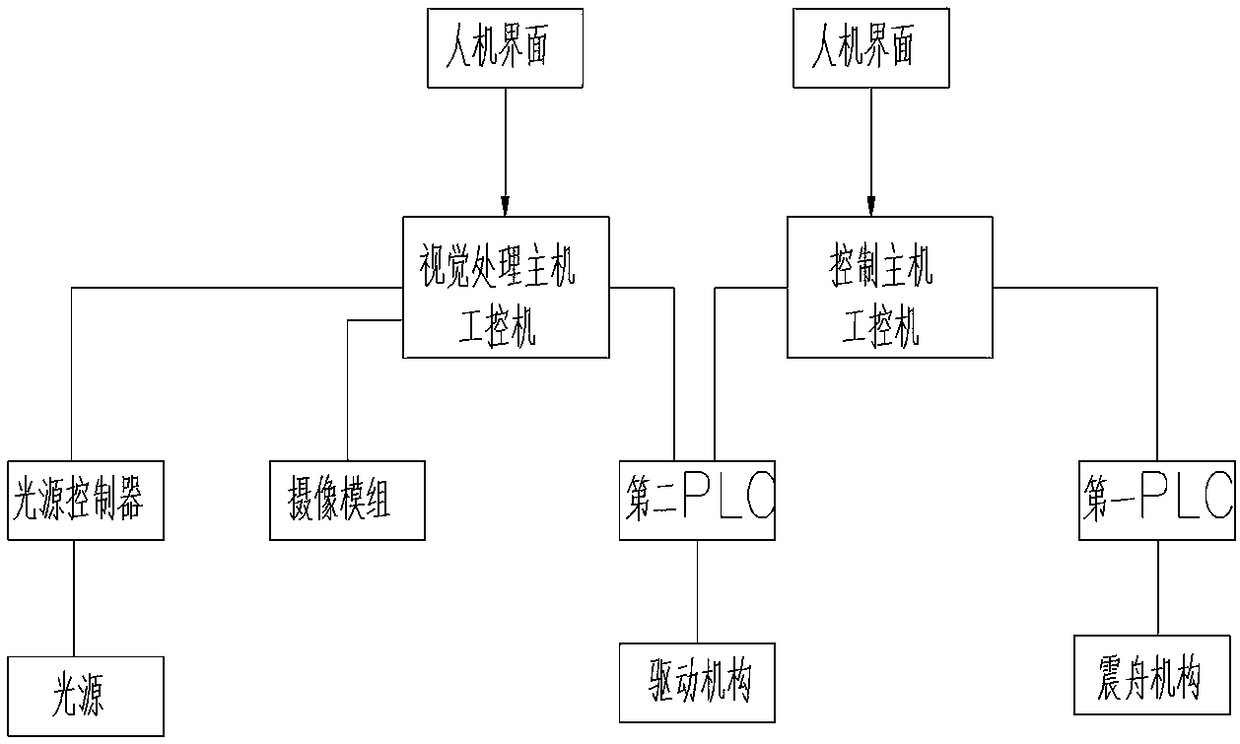

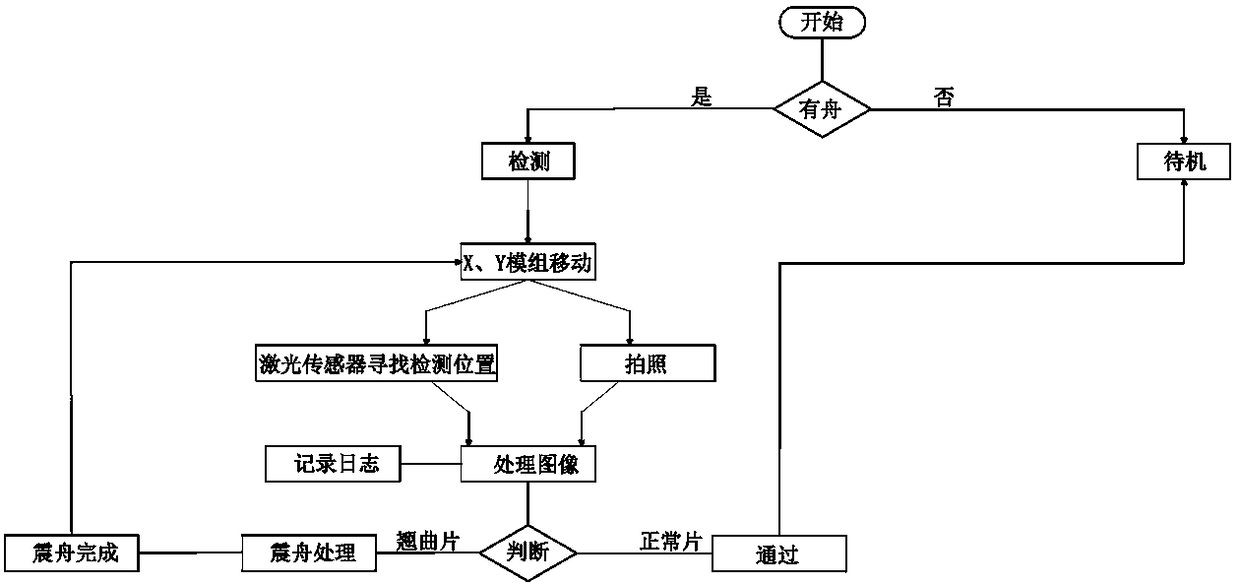

Detection device for detecting silicon wafer positions, silicon wafer processing system and detection method

PendingCN108878329AImprove detection accuracyAvoid visual fatigueSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingPhysicsLight source

The invention discloses a detection device for detecting silicon wafer positions, a silicon wafer processing system and a detection method. The detection device comprises a camera shooting module, a light source adaptive with the camera shooting module and a driving mechanism for driving the camera shooting module and the light source to move along two orthogonal directions, wherein the driving mechanism is used for moving the camera shooting module to each detection point; and the camera shooting module is used for collecting the images of each detection point and carrying out processing analysis on the images to determine whether wafers are leaked or whether the silicon wafer positions are normal. The detection precision is high, and a great deal of manpower and energy can be saved.

Owner:S C NEW ENERGY TECH CORP

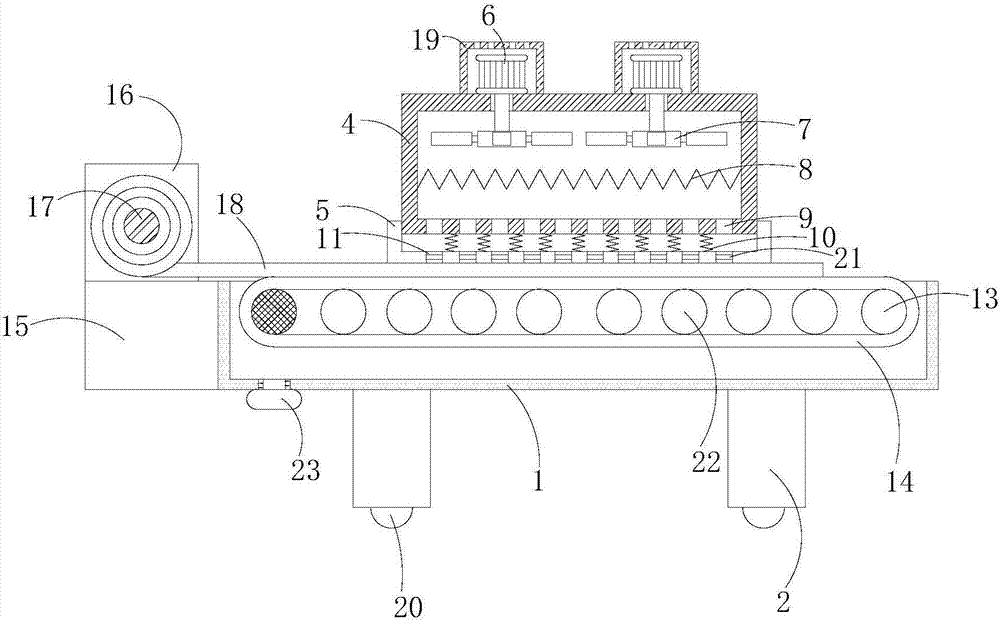

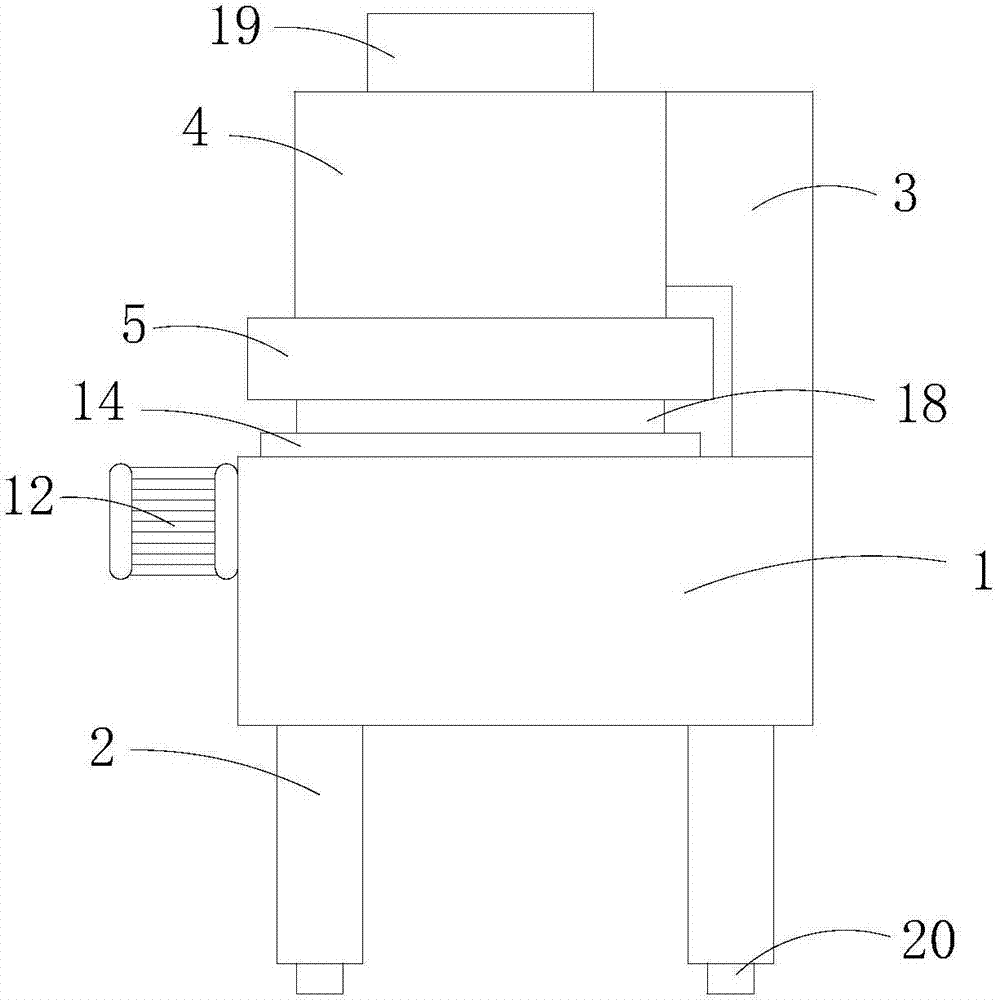

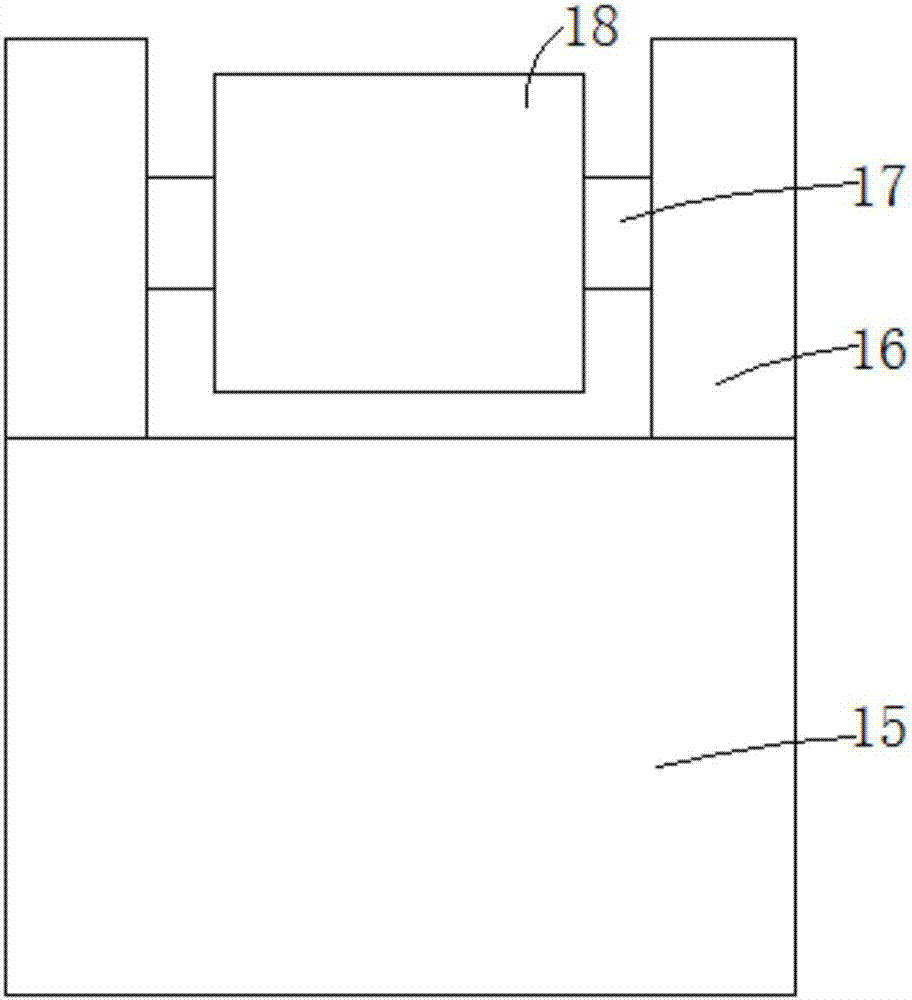

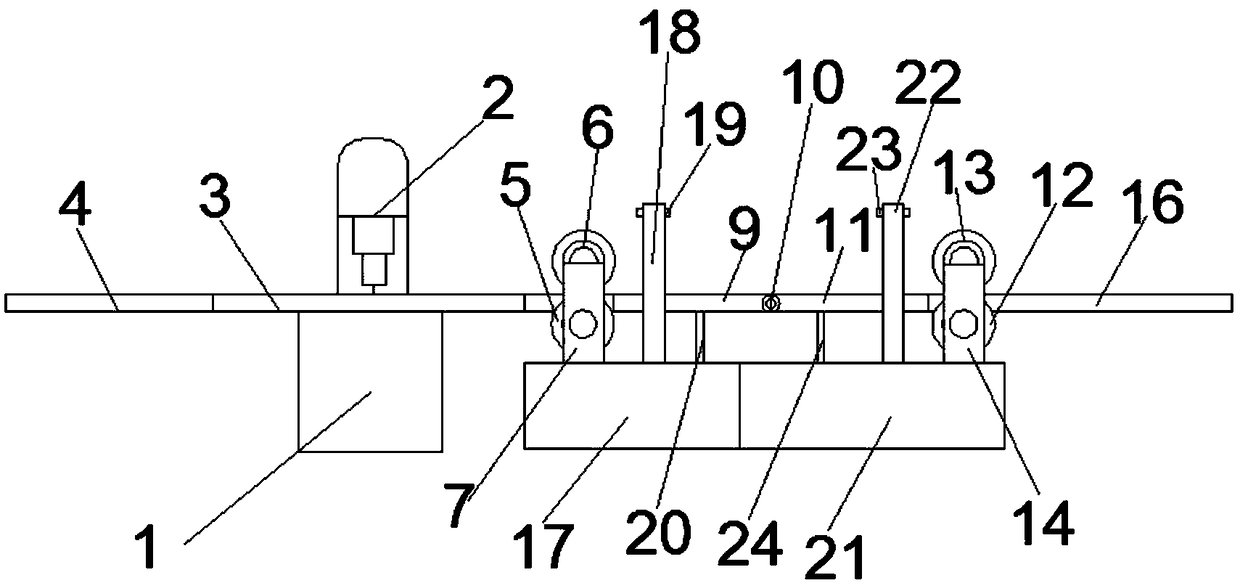

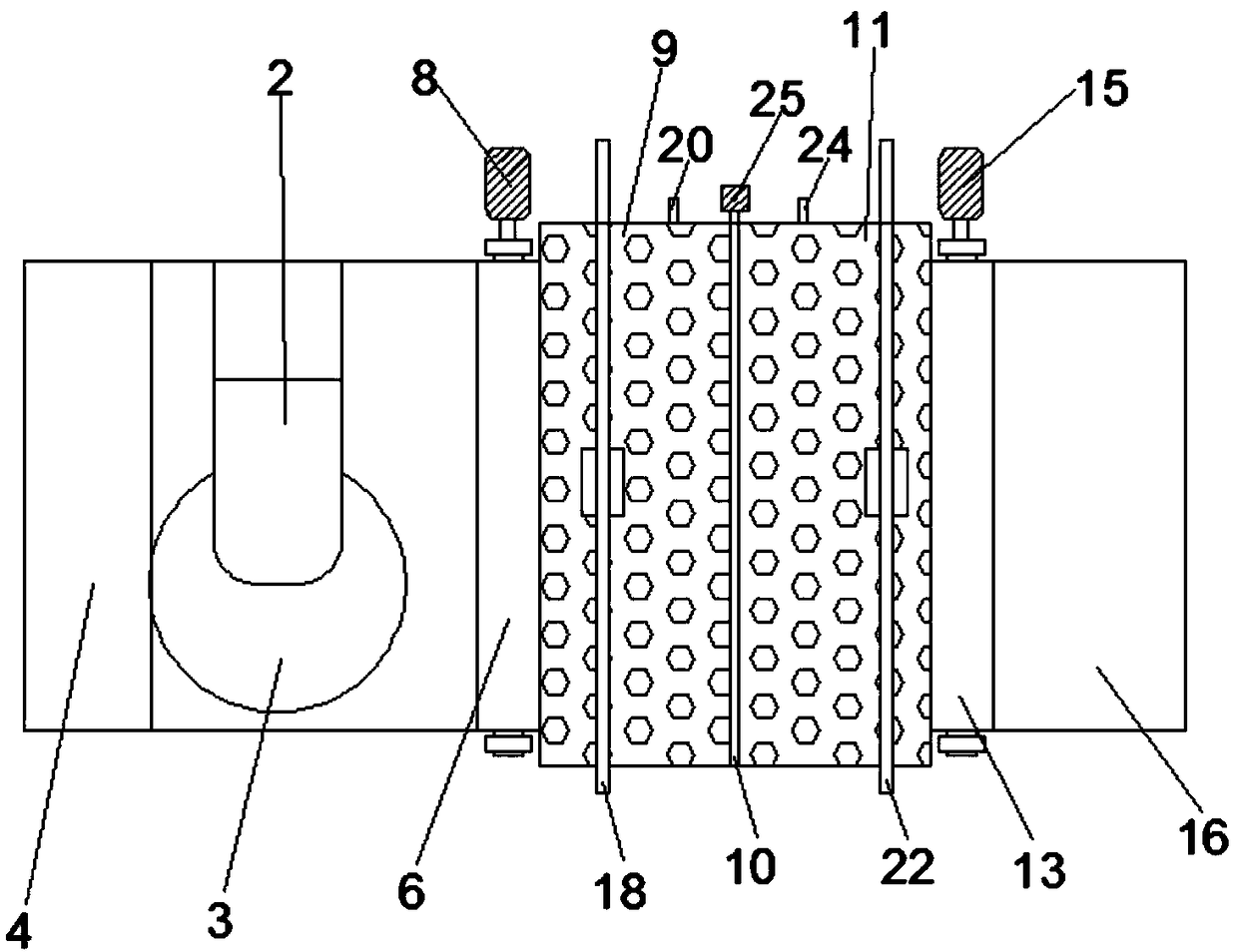

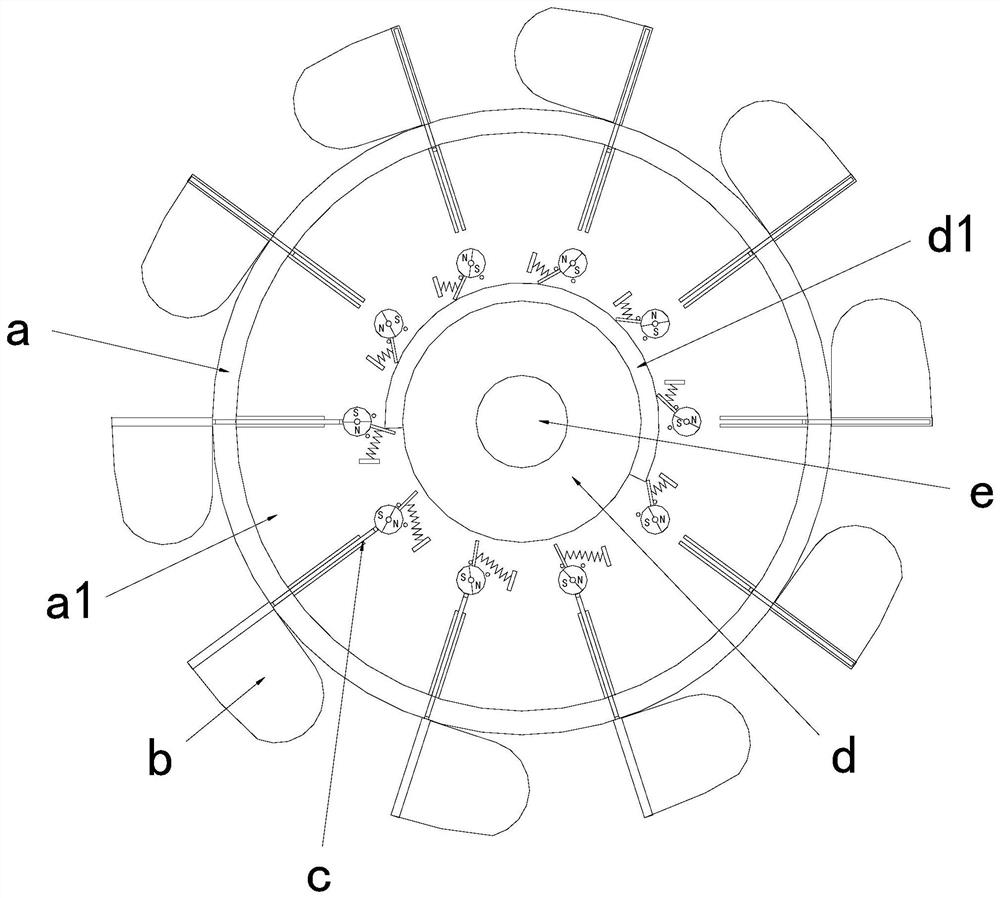

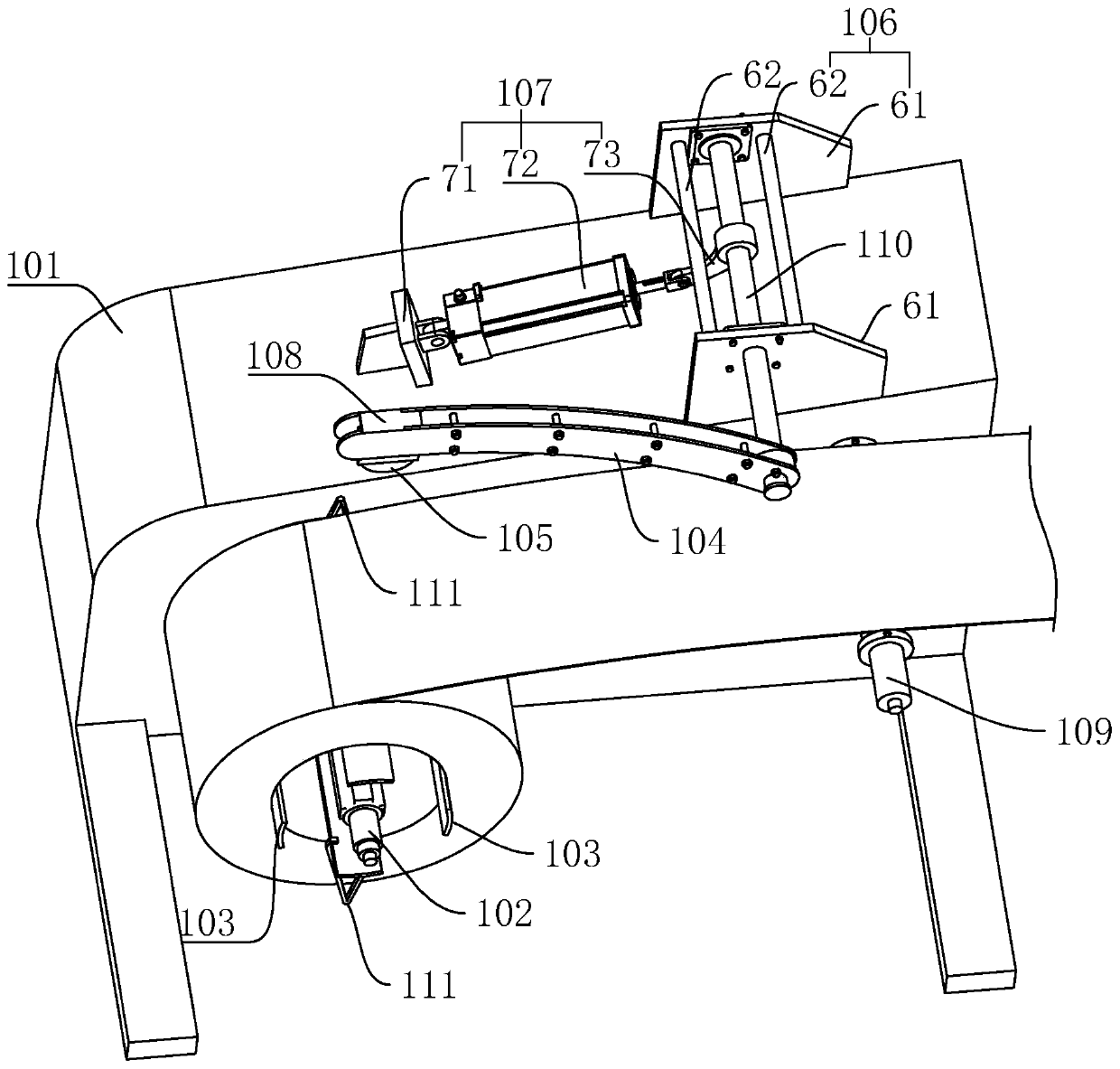

Automatic bagging, feeding and discharging all-in-one machine for edible mushrooms

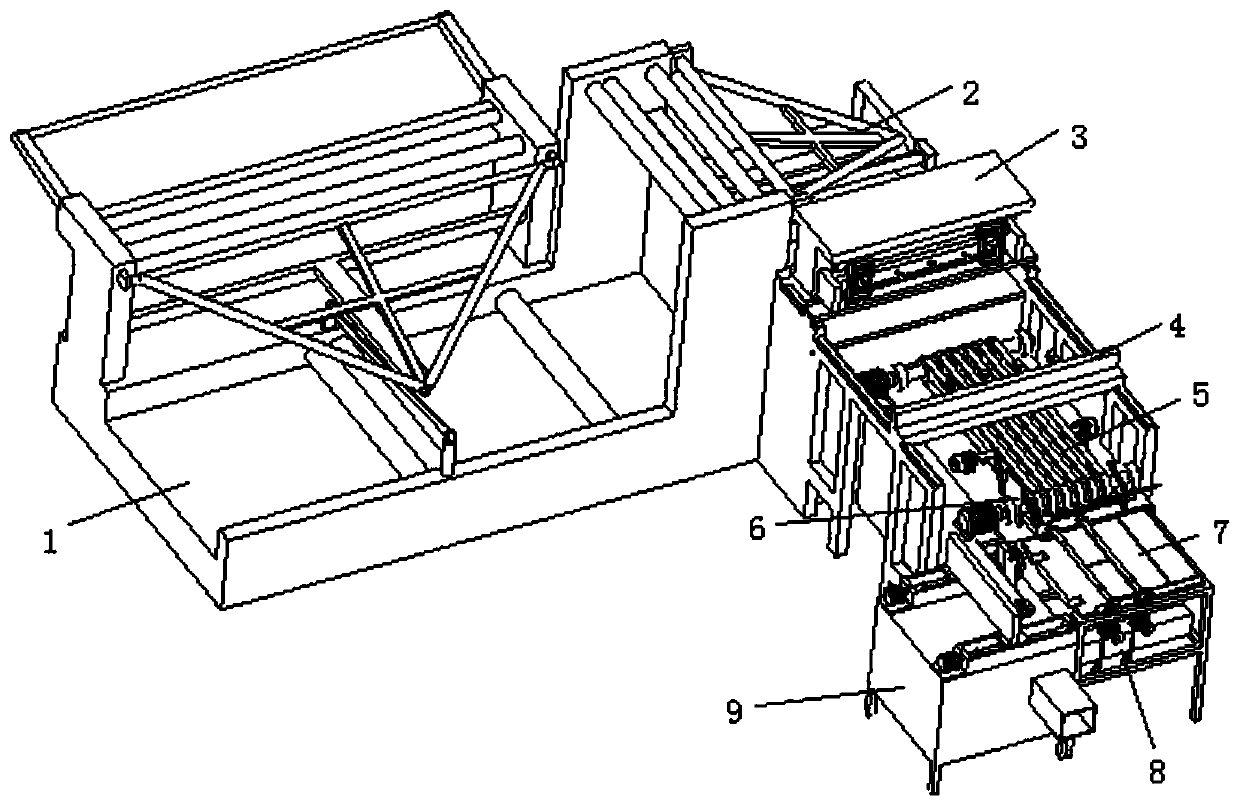

ActiveCN106613315AGuaranteed uptimeContinuous workCultivating equipmentsMushroom cultivationEngineeringEdible mushroom

The invention relates to the field of agricultural machinery, in particular to an automatic bagging, feeding and discharging all-in-one machine for edible mushrooms. The machine includes a machine body, a mushroom strain feeding hopper and a push cylinder, and further includes a rotating device, a bag feeding device and a bagging device. The rotating device includes a supporting frame, a rotating motor, a rotating disk and a rotating shaft; the bag feeding device includes a bag feeding cylinder, a cylinder feeding device, a bag taking device, a bag pulling device, a bag opening device and a bag feeding air storage tank; the bagging device includes a pair of bagging air cylinders, a bagging supporting frame, a bagging cylinder, a bagging rotating base, a feeding plate, a feeding air cylinder, a rotating cylinder air cylinder and a chute. The all-in-one machine can achieve automatic bag taking, automatic bagging and automatic unloading, can continuously and uninterruptedly work without manual operation, and is simple in structure and high in practicability.

Owner:山东惠民齐发果蔬有限责任公司

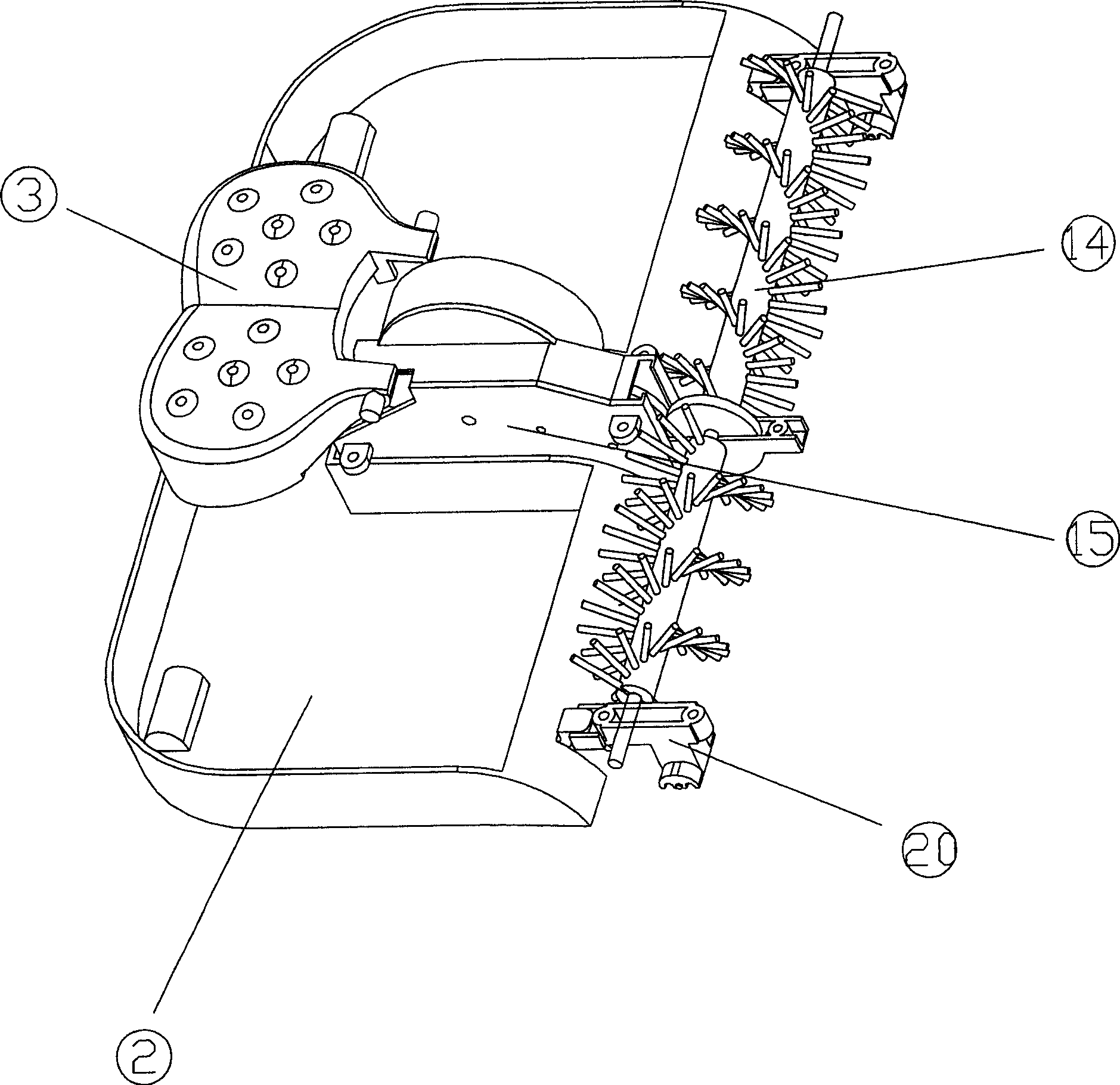

Edible fungus bagging robot

ActiveCN106240924AAvoid Loose SituationsContinuous workPackagingAgricultural engineeringContinuous operation

The invention relates to the field of agricultural machinery, in particular to an edible fungus bagging robot. The edible fungus bagging robot comprises a body, a fungus strain feeding hopper, a pushing barrel, a rotating device, a bag delivery device and a sleeving device. The rotating device comprises a supporting frame, a rotating motor, a rotating plate and a rotating shaft. The bag delivery device comprises a bag delivery barrel, a delivery barrel device, a bag taking device, a bag pulling device, a bag opening device and a bag delivery air storage tank. The sleeving device comprises a pair of sleeving air cylinders, a sleeving support, a sleeving barrel, a sleeving rotary seat, a discharging plate, a discharging air cylinder, a rotary air cylinder and a chute. The edible fungus bagging robot has advantages that automatic bag taking, automatic sleeving, automatic bagging and automatic discharging can be realized, and uninterrupted continuous operations are realized without manual operations; in addition, loosing of sleeved fungus strain bags in a return process of a bag discharging device is avoided, so that better bagging effects are achieved; further, structural simplicity and high practicality are realized.

Owner:ANHUI ACQUISITIVE INTERNET OF THINGS CO LTD

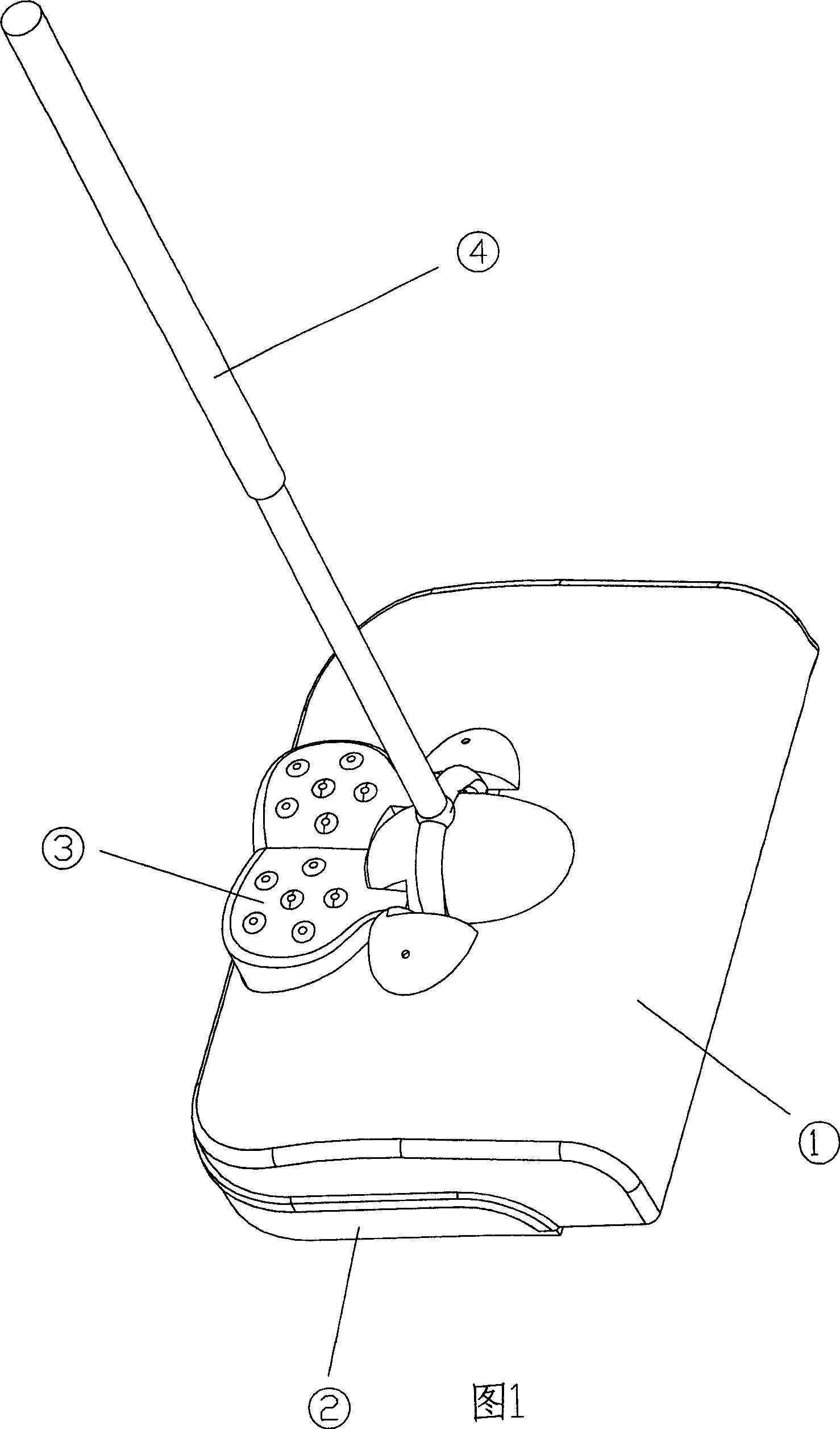

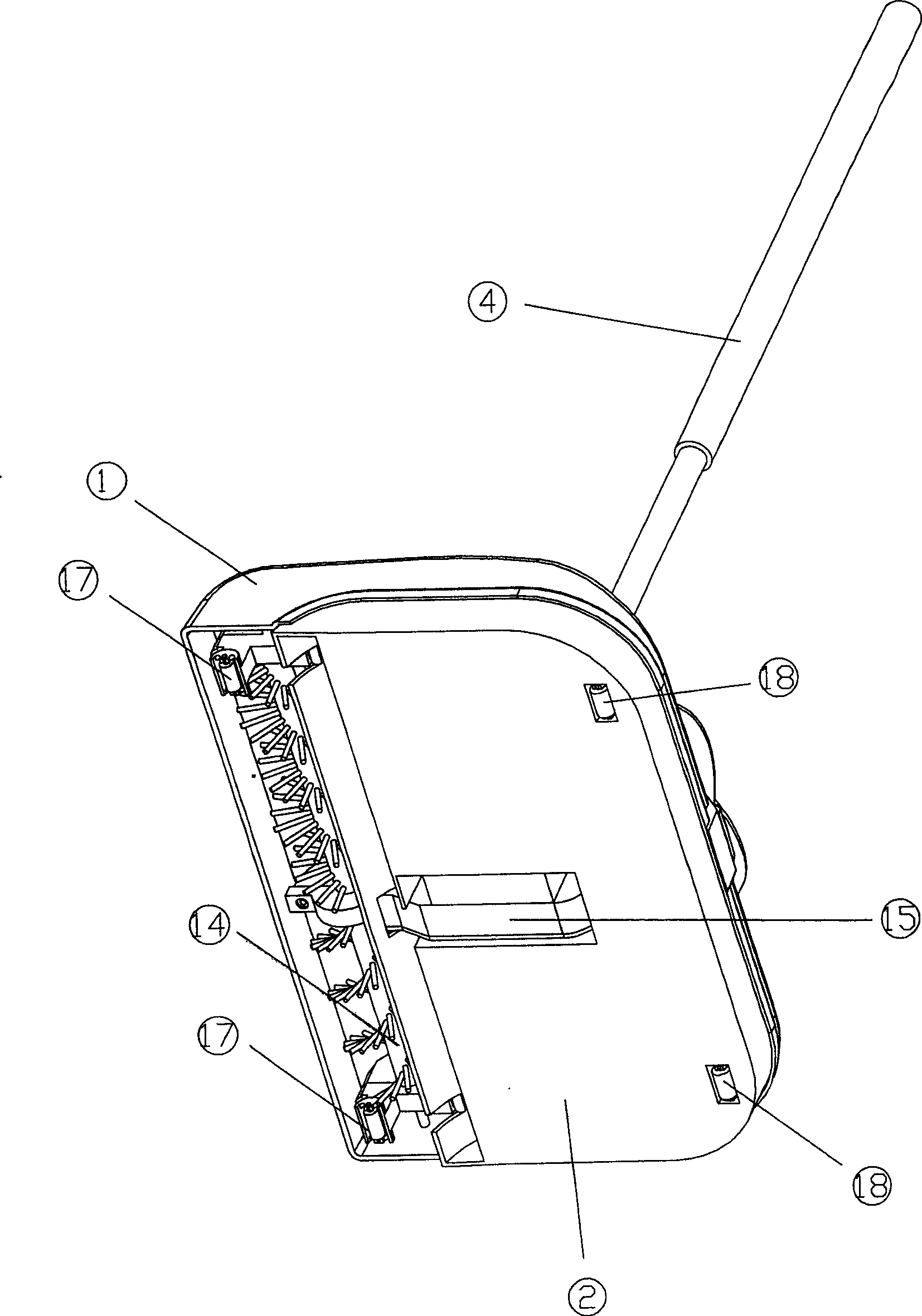

Floor sweeping machine

Owner:伍尚强

Efficient hydraulic rock drill

InactiveCN104154050AImprove efficiencyReduce energy consumptionMechanical apparatusConstructionsPistonEngineering

The invention discloses an efficient hydraulic rock drill. An energy accumulator is arranged upon a valve body in a piston impacter and communicated with an oil inlet chamber of the valve body and an oil chamber of a front cylinder sleeve respectively through a first oil channel. The oil chamber of the front cylinder sleeve is communicated with a support oil chamber of a back cylinder sleeve through a fifth oil channel. The support oil chamber is communicated with an oil inlet. An oil controlling chamber of a valve core is communicated with an oil controlling opening of the front cylinder sleeve through a third oil channel. An oil returning chamber of the valve body is communicated with an oil chamber of the back cylinder sleeve through a second oil channel and communicated with an oil returning channel which is connected with a reversing valve of a rotary portion. The other oil controlling opening of the front cylinder sleeve is communicated with a valve core oil chamber through a forth channel which enters an oil tank. A hydraulic motor and the reversing valve are arranged in a shank rotator. One end of the reversing valve is communicated with the oil returning channel of the piston impacter, and the other end of the reversing valve is communicated with the hydraulic motor. According to the arrangement, the abrasion problem of an impacting piston and a support is solved to decrease abrasion of the piston; energy consumption of an impacting portion is converted into power of the rotary portion, so that energy consumption is greatly reduced, and working efficiency is improved.

Owner:李田生

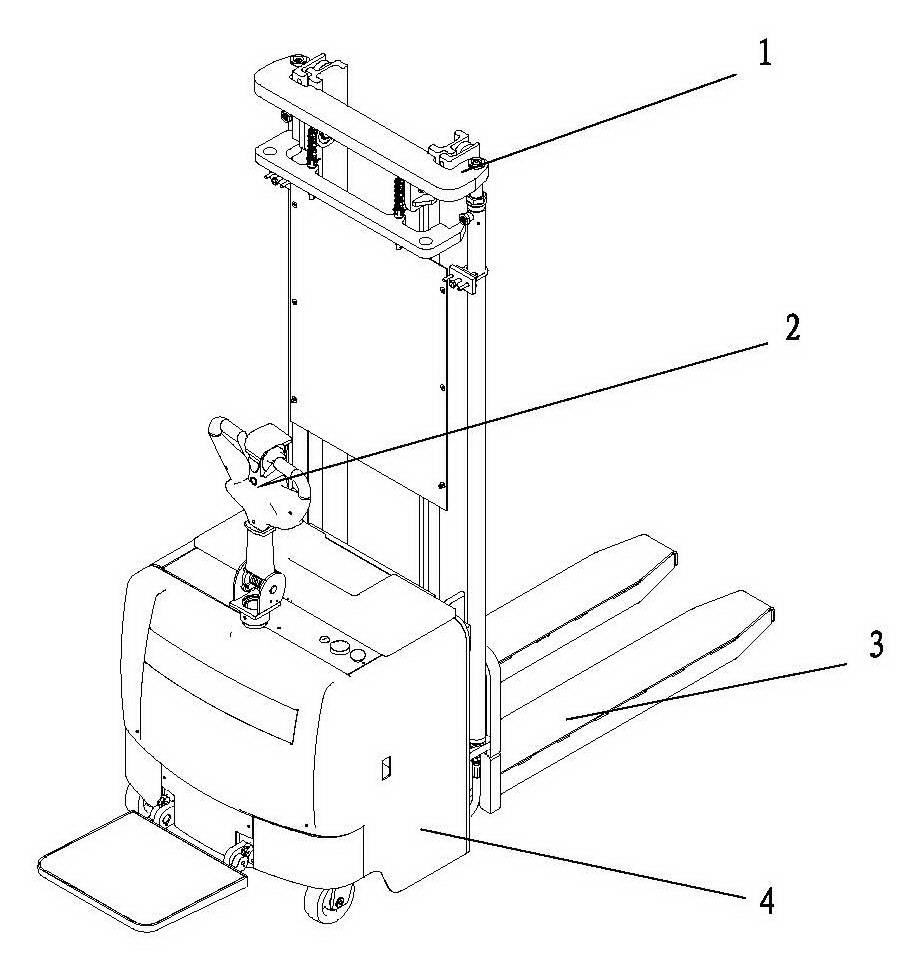

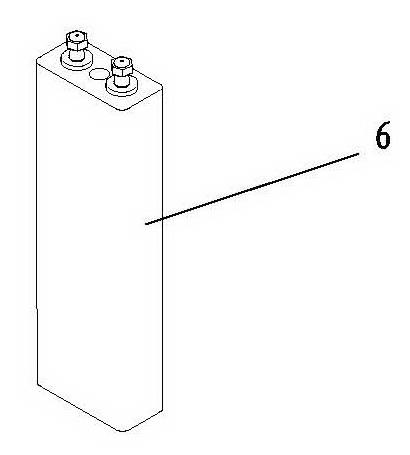

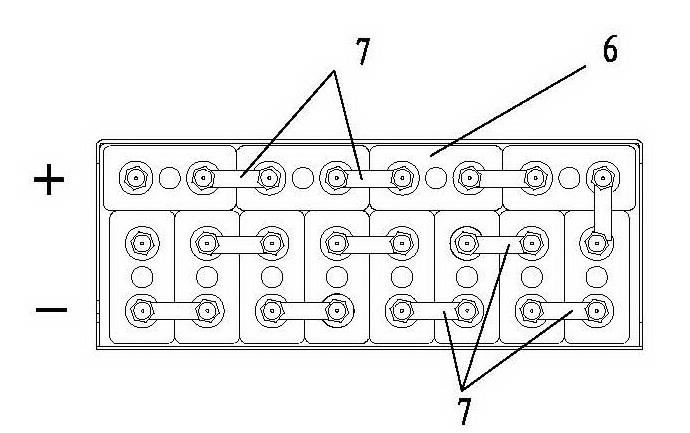

Integral hoisting battery box stacking vehicle

InactiveCN102381664AIncrease productivityImprove safety and reliabilityLifting devicesElectrical batteryBody system

The invention relates to an integral hoisting battery box stacking vehicle, a battery cavity is arranged in a vehicle body system, the battery cavity is a cuboid cavity, a battery box is matched and arranged in the battery cavity, an opening is arranged on the upper surface of the battery box, a hoisting hole is further arranged on the box wall in the position of the opening, a battery pack constituted by a plurality of batteries is matched and embedded in the battery box, electrodes of the batteries face towards the opening of the battery box respectively, positive and negative poles of the adjacent two batteries are respectively connected through conducting wires for connecting the batteries in series, and the positive output end and the negative output end are further remained. The shape of the battery cavity of a vehicle body of the stacking vehicle is subtly modified, the batteries are subtly arranged, connected and merged for forming the battery pack, and the battery pack can be placed into the battery box which can be hoisted integrally, thereby not only obviously improving the production efficiency, but also enhancing the safety and the reliability of a product.

Owner:上海梯佑国际贸易有限公司

Wrinkle-removal finishing device of multi-functional military textile fabric

InactiveCN107190452AEasy to useImprove drying efficiencyTextiles drying apparatusTransmission beltAgricultural engineering

The invention discloses a wrinkle-removing and finishing device for military multifunctional textile fabrics, which comprises a support plate, the four corners of the bottom of the support plate are fixedly connected with support legs, the top of the support plate is fixedly connected with a connecting block, and the connecting block The front of the drying box is fixedly connected with a drying box, the bottom of the drying box is sleeved with a pressing block, both sides of the top of the drying box are fixedly connected with a first motor, and the bottom end of the first motor shaft runs through the drying box. The dry box extends to the interior of the drying box and is fixedly connected with fan blades. The present invention makes the drying and wrinkle removing device easy to use by setting a drying box, a briquetting block, a first motor, a fan blade, a heating wire, an air outlet, a spring, a hot air hole, a second motor and a transmission belt, and the drying and wrinkle removing device The drying efficiency is higher, the temperature in the drying and wrinkle removing device is more uniform, and continuous drying can be performed, which can meet the needs of many textile manufacturers and is beneficial to people's use.

Owner:浙江盛伦科技有限公司

Shirt cuff processing complete device

InactiveCN108796847AThe operation of the equipment is simple and convenientReduce material costWork-feeding meansTextile shapingEngineeringButt joint

The invention relates to the technical field of garment processing, in particular to a shirt cuff processing complete device. The shirt cuff processing complete device includes a sewing main control box, a sewing machine assembly is welded to one end of the top face of the main control box, a disc is arranged between the sewing machine assembly and the main control box, one end of the disk is in butt joint with a discharging plate, and the end, away from the discharging plate, of the disc is in butt joint with a first drive rolling shaft; the upper end of the first drive rolling shaft is in butt joint with a first driven rolling shaft, the two ends of the first driven rolling shaft are in sleeved connected with support rods, and the ends, away from first driven rolling shaft, of the support rods are in sleeved connected with the first drive rolling shaft, the first drive rolling shaft and the first driven rolling shaft are parallel in a support rod plane, one end of the first drive rolling shaft is welded to the output end of a first motor, the first drive rolling shaft is in butt joint with a folded ironing plate, and a rolling shaft hinge is welded to the end, away from the firstdrive rolling shaft, of the folded ironing plate; a folded air blowing and suction plate is welded to the end, away from the folded ironing plate, of the rolling shaft hinge. The shirt cuff processing complete device runs efficiently through a series of control programming.

Owner:池州市达宏信息技术有限公司

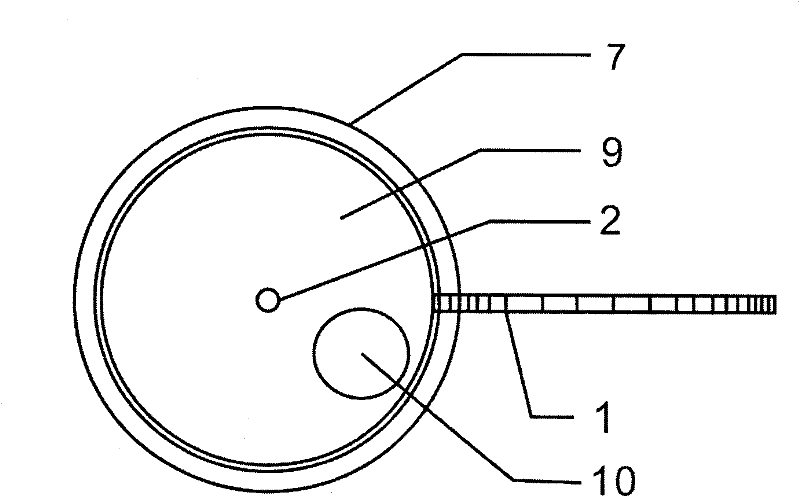

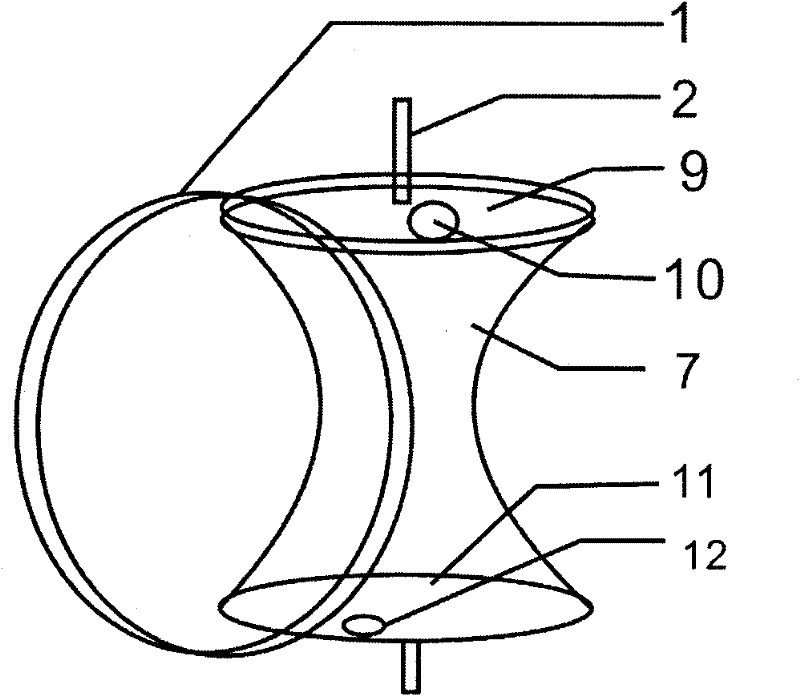

Novel screw rotor engine

InactiveCN102345506ASmooth runningContinuous workInternal combustion piston enginesCombustion chamberWhole body

The invention discloses a novel screw rotor engine, which is characterized in that: two special trumpet-shaped screw rods are arranged in a dumbbell-shaped shell; the small ends of the special trumpet-shaped screw rods are opposite to each other; the special trumpet-shaped screw rods are respectively pivoted into a whole body with a main shaft, and the whole body is meshed with a gear on a side face to play a role in guiding flow; the periphery of the whole body is sealed with a cylinder body; and a space opposite to a middle screw rod of the cylinder body serves as a combustion chamber in which a spark plug and an oil spray nozzle are arranged. In the running process, air is compressed by an air inlet screw rod to enter the combustion chamber, and oil burns continuously and is used for driving an acting screw rod to run.

Owner:任涛

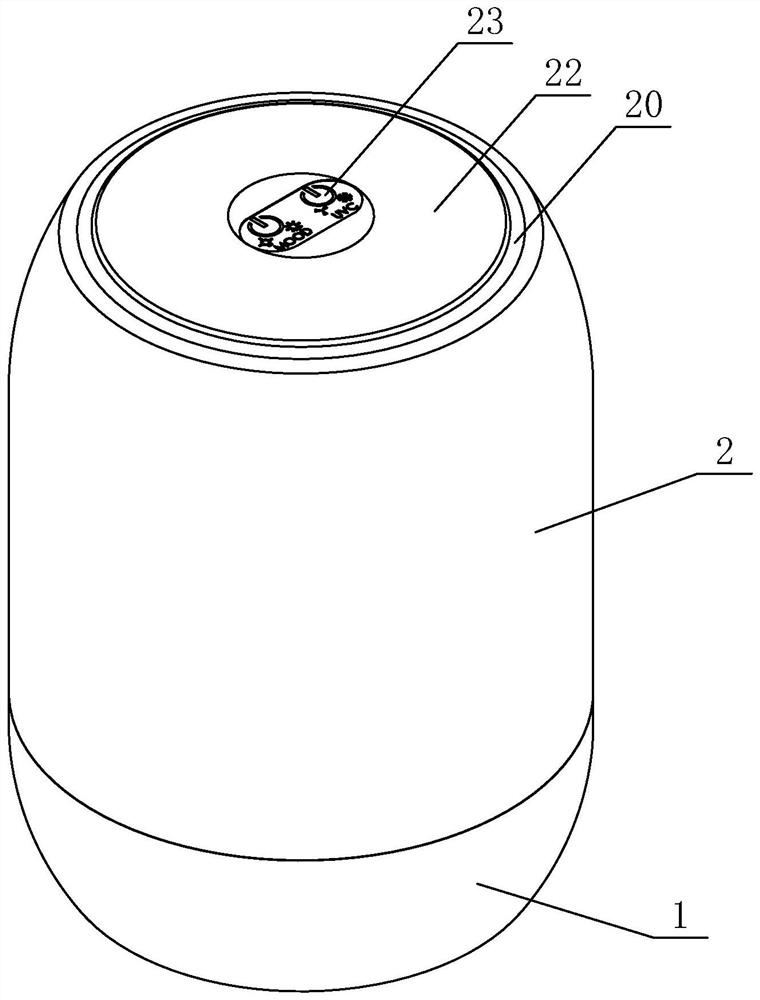

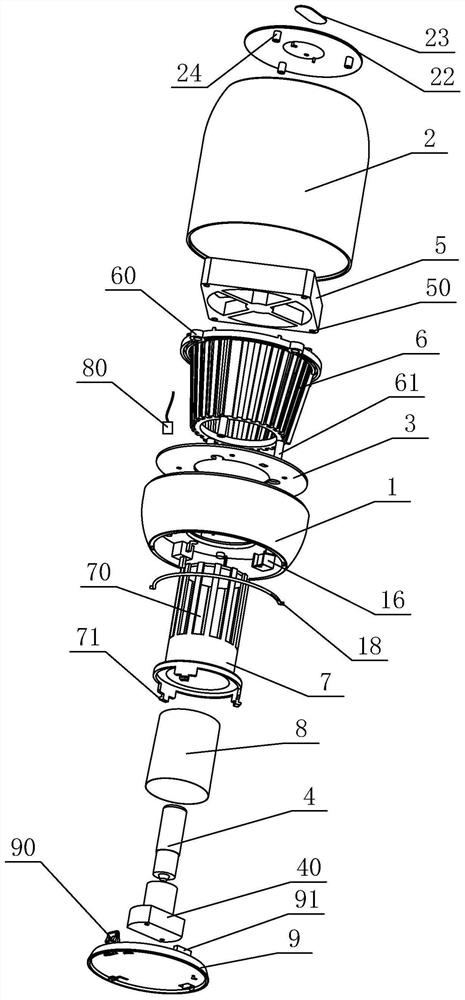

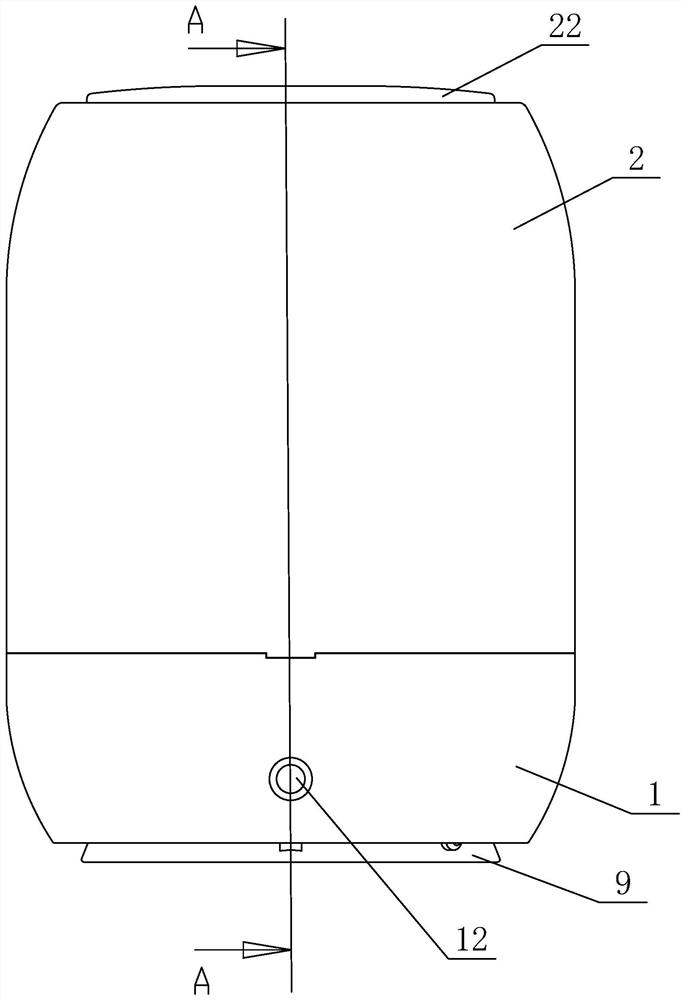

Enhanced sterilization disinfection lamp

PendingCN111821500AImprove filtration efficiencyImprove adsorption capacityDispersed particle filtrationDeodrantsAir filtrationBacterial virus

The invention discloses an enhanced sterilization disinfection lamp. The enhanced sterilization disinfection lamp comprises a lamp body assembly, wherein an air inlet hole and an air outlet hole are formed in the bottom and the top of the lamp body assembly respectively; a circuit board assembly, an ultraviolet light-emitting device, a fan, a filter screen support and a negative-ion generator arearranged in the lamp body assembly; the ultraviolet light-emitting device is covered with the filter screen support, and an air filtering device is wrapped with the filter screen support. The fan sucks external air into an inner cavity of the filter screen support from the air inlet hole, the external air is filtered by the air filtering device and then discharged from the air outlet hole, when the external air flows through the air filtering device, virus, bacteria and tiny particles are filtered and intercepted by the air filtering device, and the sterilization disinfection is irradiated bythe ultraviolet light-emitting device; a negative-ion generator is used for purifying air, killing bacteria and virus; the air filtering device comprises a metal filter screen; and the negative-ion generator is located beside the air filtering device and used for enabling the metal filter screen to generate static electricity, virus, bacteria and tiny particles in the air are adsorbed through thestatic electricity, and the filtering efficiency of the air filtering device is enhanced.

Owner:CE LIGHTING

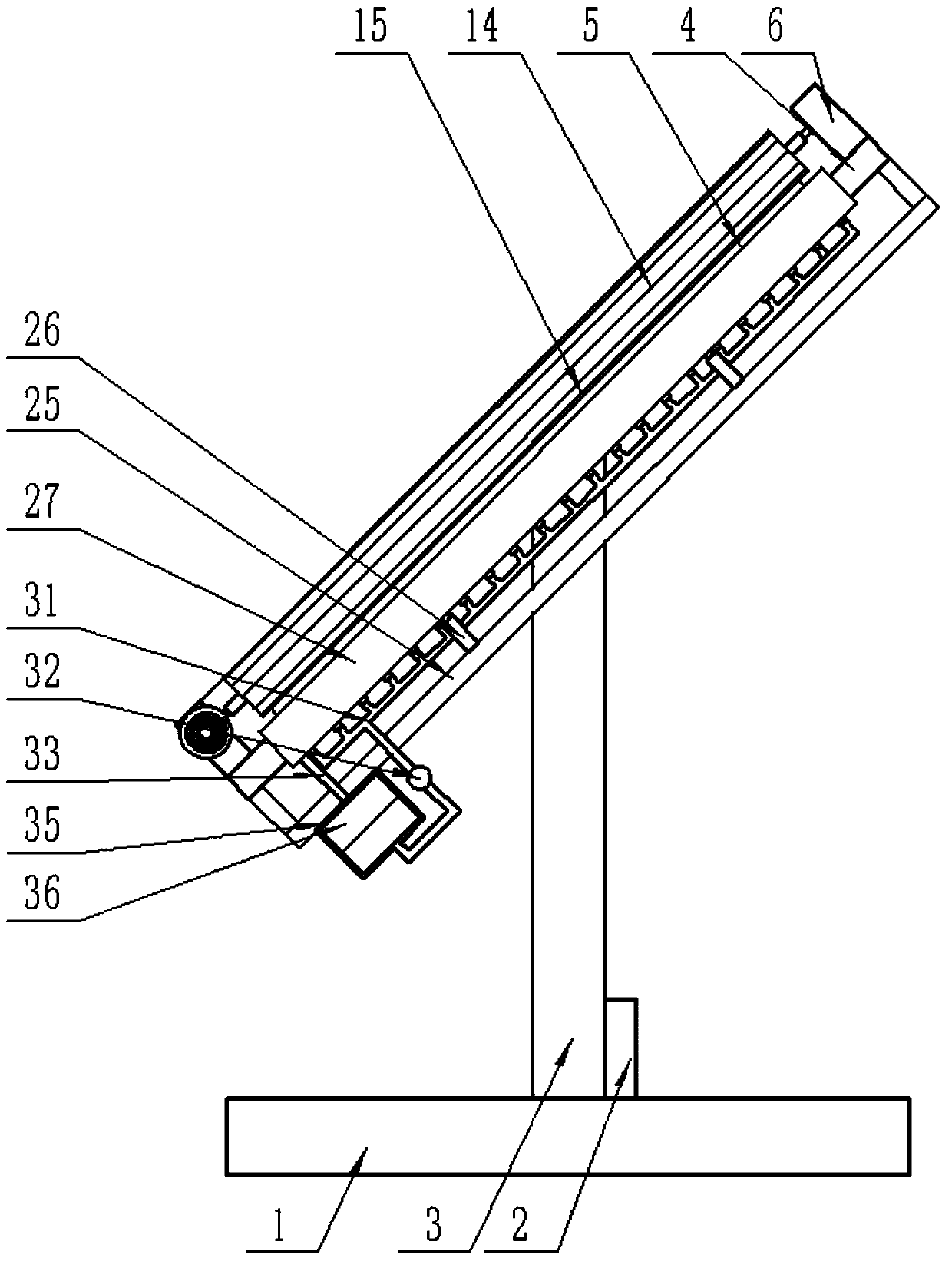

Efficient solar energy cleaning device

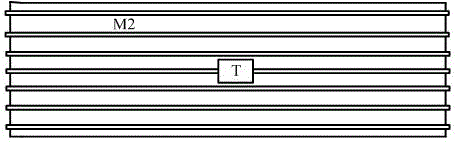

ActiveCN109848098AEasy to cleanReduce wearPhotovoltaicsCleaning using toolsWaste managementSolar energy

The invention discloses an efficient solar energy cleaning device. The efficient solar energy cleaning device comprises a base, a solar energy bracket device is arranged at the upper portion of the base, a rotating-type solar energy cleaning device is mounted in the solar energy bracket device, a washing cylinder cleaning device is arranged on one side of the solar energy bracket, and the solar energy bracket device is connected with the rotating-type solar energy cleaning device; and through the connection of a screw rod and a sliding seat, the sliding seat is connected with a cleaning cylinder for reciprocating washing, the washing cylinder cleaning device is arranged below one side of the rotating-type solar energy cleaning device, through the connection of a telescopic rod and a washing frame, a brush and a nozzle are arranged in the washing frame for washing the cleaning cylinder, and a control device is arranged on the base. The efficient solar energy cleaning device has the beneficial effects of being simple in structure and high in practicability.

Owner:HANGZHOU YAOYAO PHOTOVOLTAIC TECH CO LTD

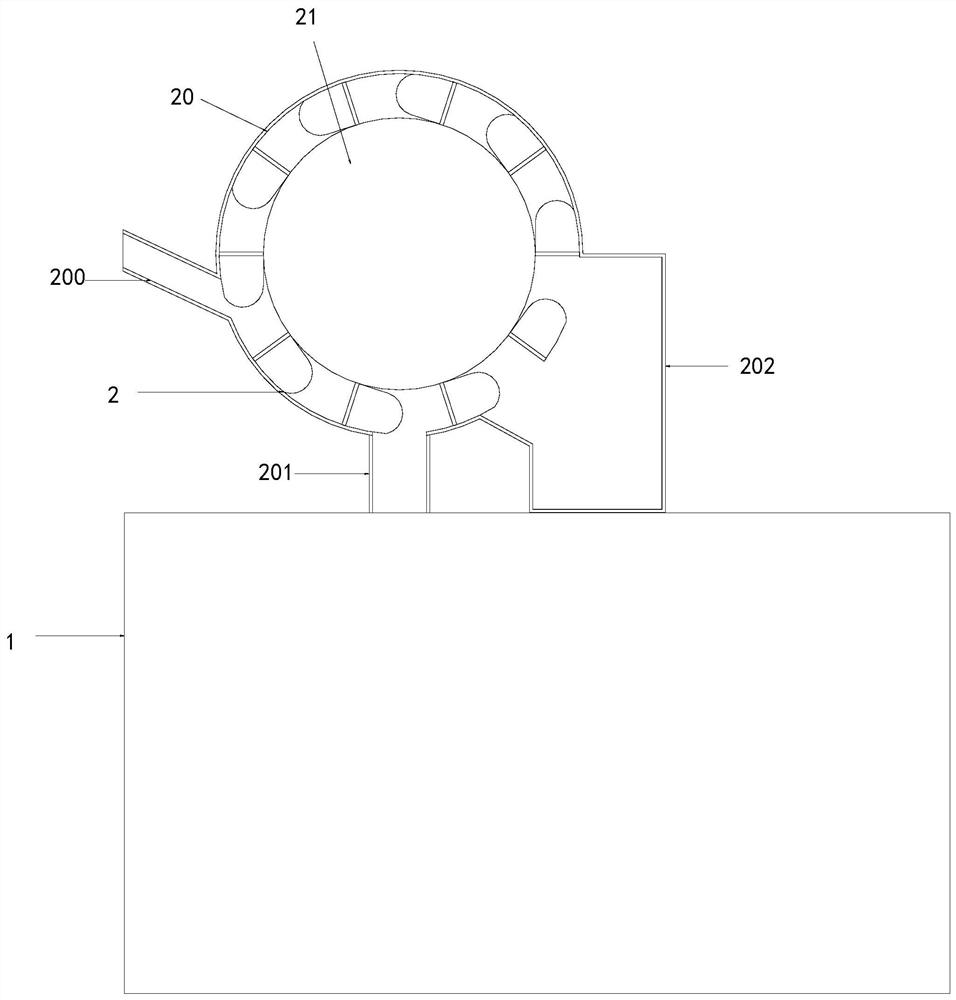

Industrial sewage collecting tank

InactiveCN112076527AOpen in timeClose in timeFatty/oily/floating substances removal devicesSewerage structuresEngineeringSewage

The invention discloses an industrial sewage collecting tank which structurally comprises a collecting tank and a fishing structure, the fishing structure is arranged above the collecting tank, the fishing structure comprises a shell and a rotary fisher, the rotary fisher is arranged in the shell, a water inlet is formed in the side face of the shell, a water outlet is formed in the bottom of theshell, and a collecting tank is connected to the side, opposite to the side provided with the water inlet, of the shell; The rotary fisher comprises a rotary disc, a fishing net, an upper cover structure, a fixed disc and a power structure, the evenly-distributed fishing net is connected to the side face of the rotary disc, a cavity is formed in the rotary disc, and the fixed disc is arranged in the middle of the cavity. The invention has the beneficial effects that impurities in industrial sewage can be continuously fished through the continuously rotating fishing net, so that the tank can continuously work, and the feeding of waste water does not need to be stopped; therefore, the sewage treatment efficiency is improved, the fishing net can be opened and closed in time through the uppercover structure, and sundries are prevented from being attached to the back face of the next fishing net in a disordered mode.

Owner:彭川

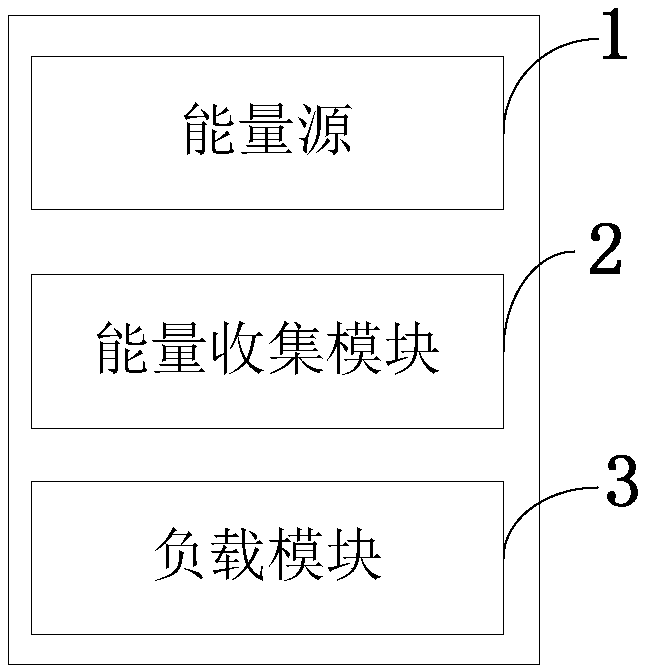

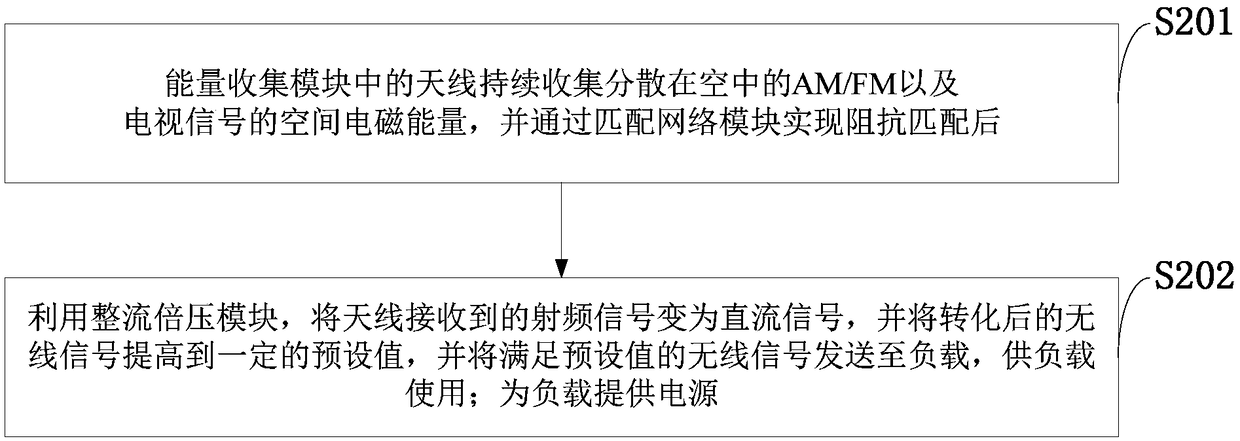

Space electromagnetic energy collection system and method based on AM/FM and TV signal

The invention belongs to the system technical field of storing electric energy, and discloses a space electromagnetic energy collection system and a method based on AM / FM and TV signals, which are composed of an energy source, namely AM / FM dispersed in space, a space electromagnetic energy of TV signals, an energy collection module and a load. The energy collection module collects the space electromagnetic energy of AM / FM and TV signal, and through a certain circuit conversion, to achieve the energy storage, and provides the corresponding interface, connected with the load, to power the load.The invention can realize the system energy self-sufficiency, ensure the continuous and uninterrupted work of the system, and is not influenced by the insufficient energy. At the same time, it realizes the recycling of energy and saves resources. Collect and utilize the electromagnetic energy of AM / FM and TV signal which widely exist in the space to realize the recycling utilization of energy andsave resources; So that the equipment is not limited to the lack of power, easy to miniaturization of equipment, integrated development.

Owner:CHENGDU YUEYANG TECH CO LTD

Magnetic separation device

Owner:李保红

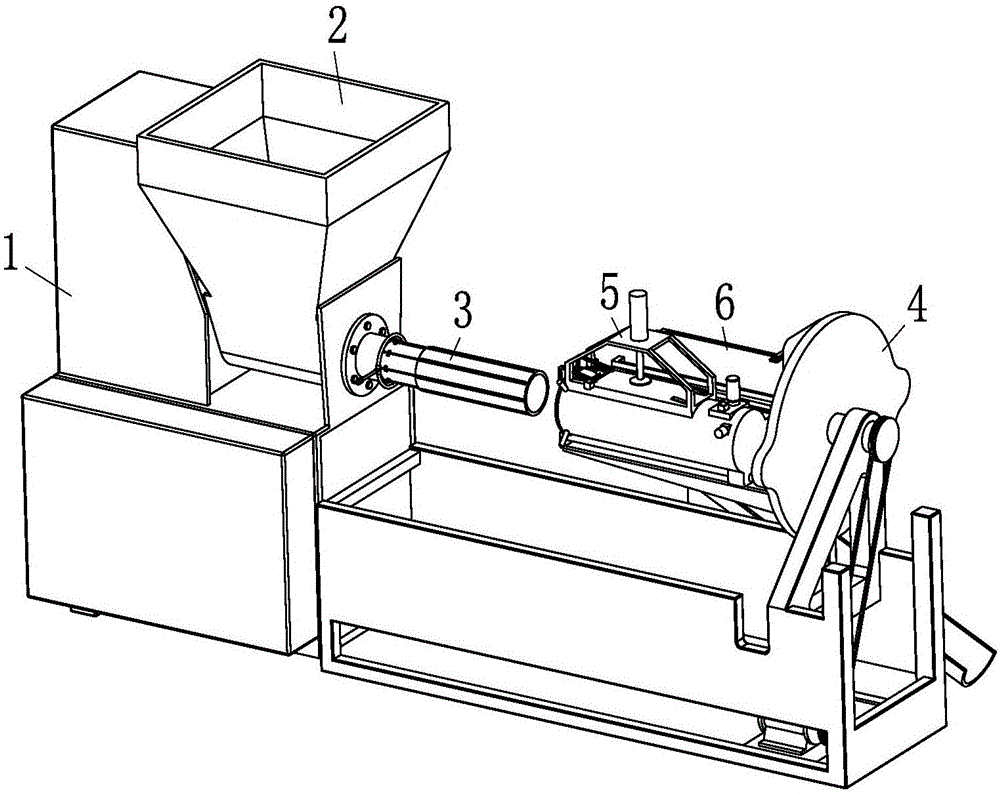

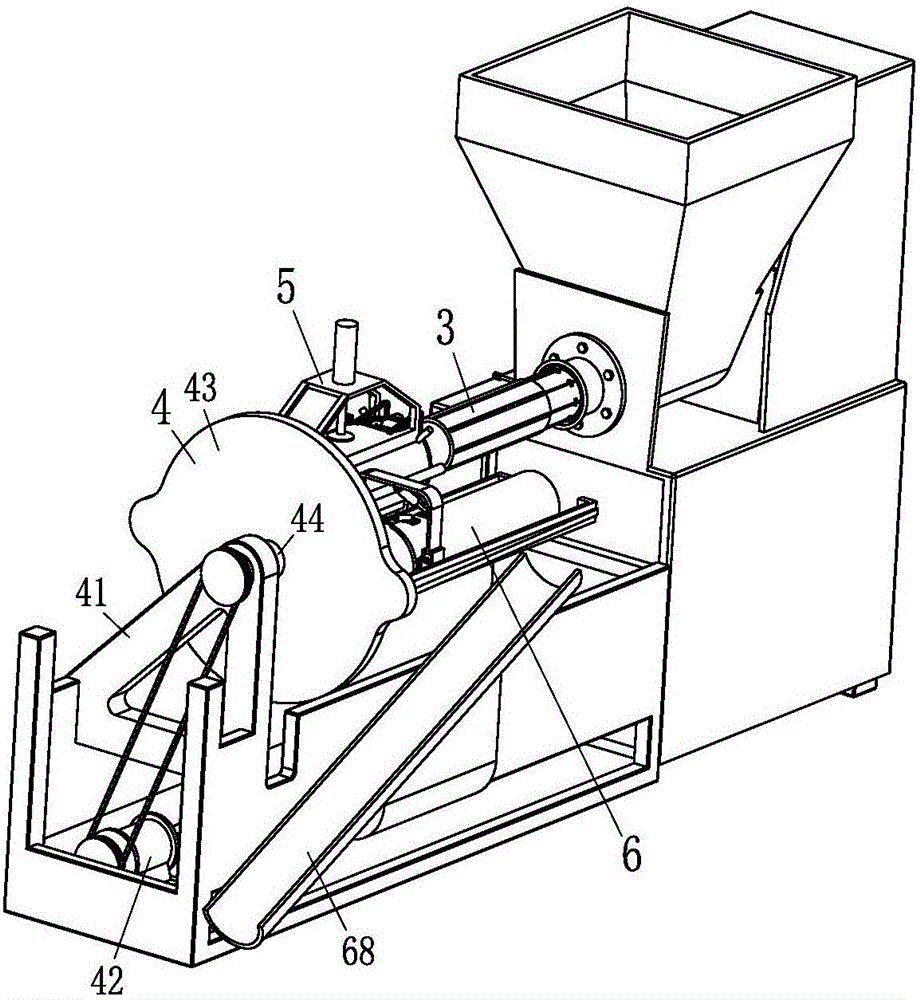

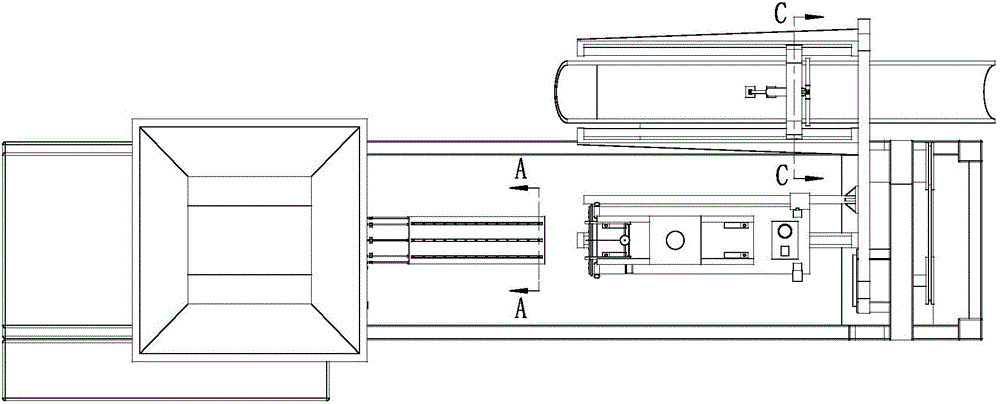

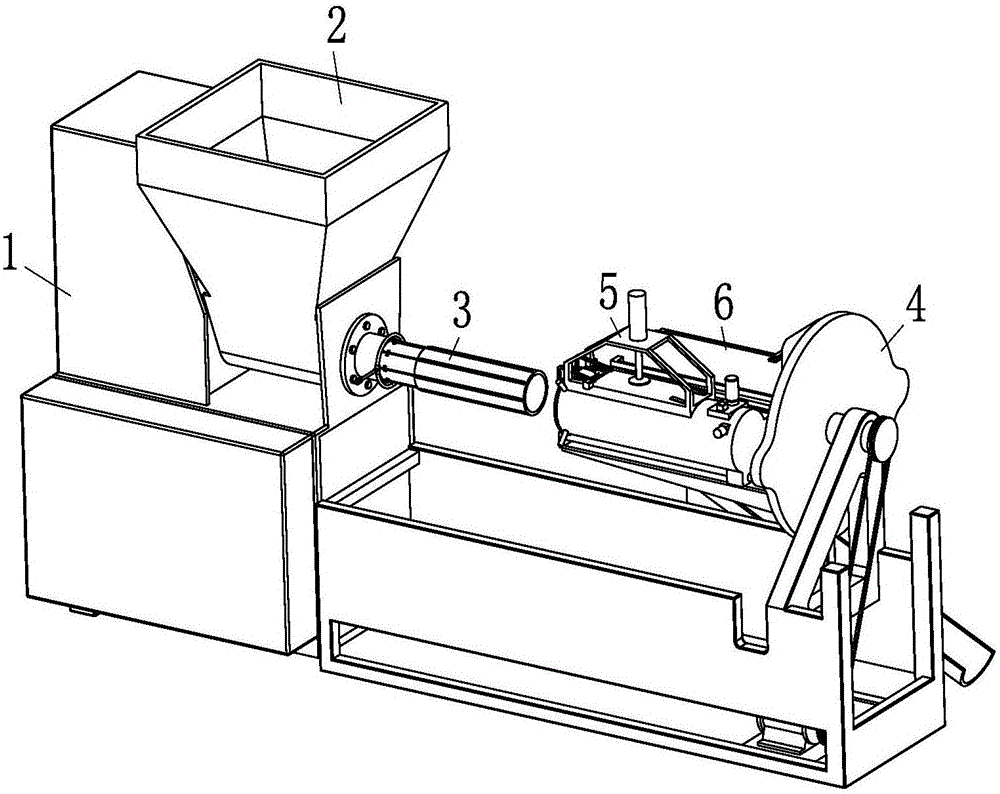

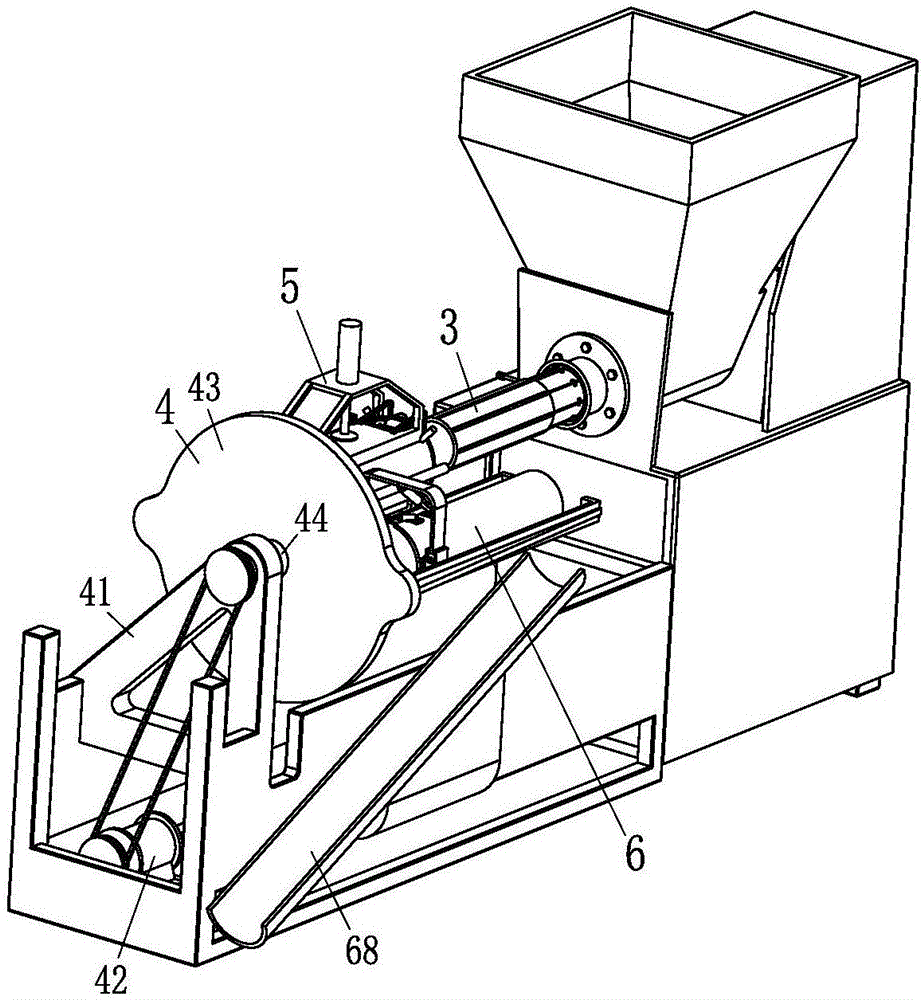

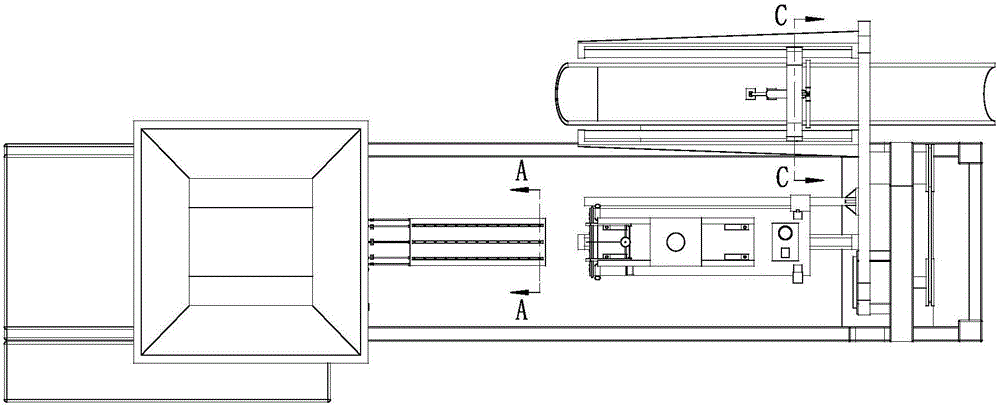

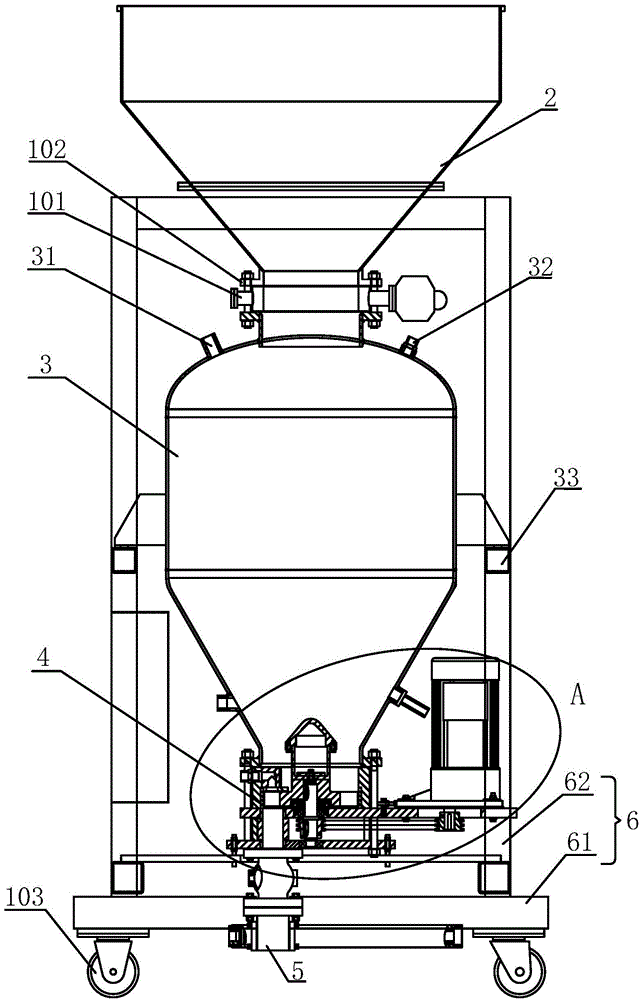

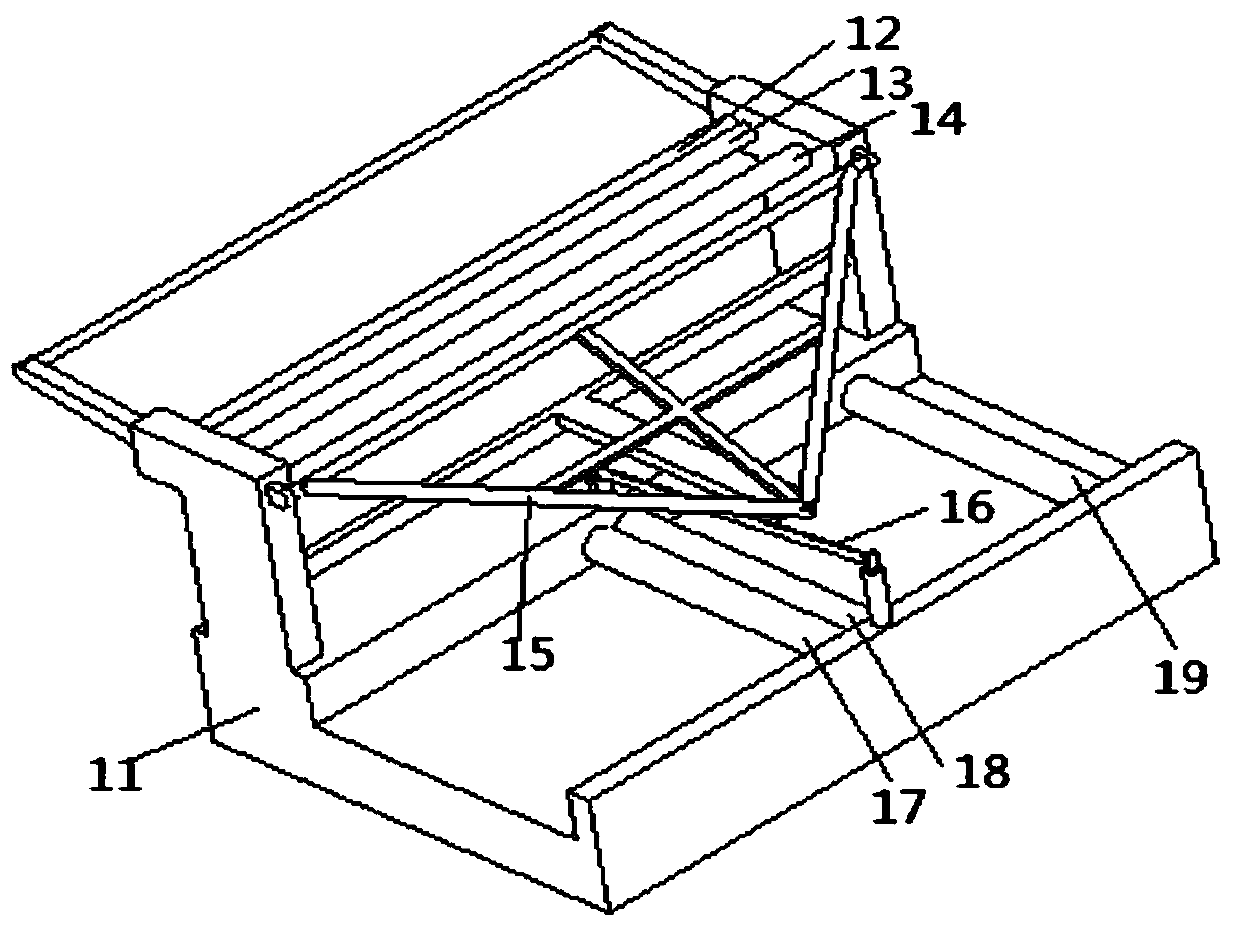

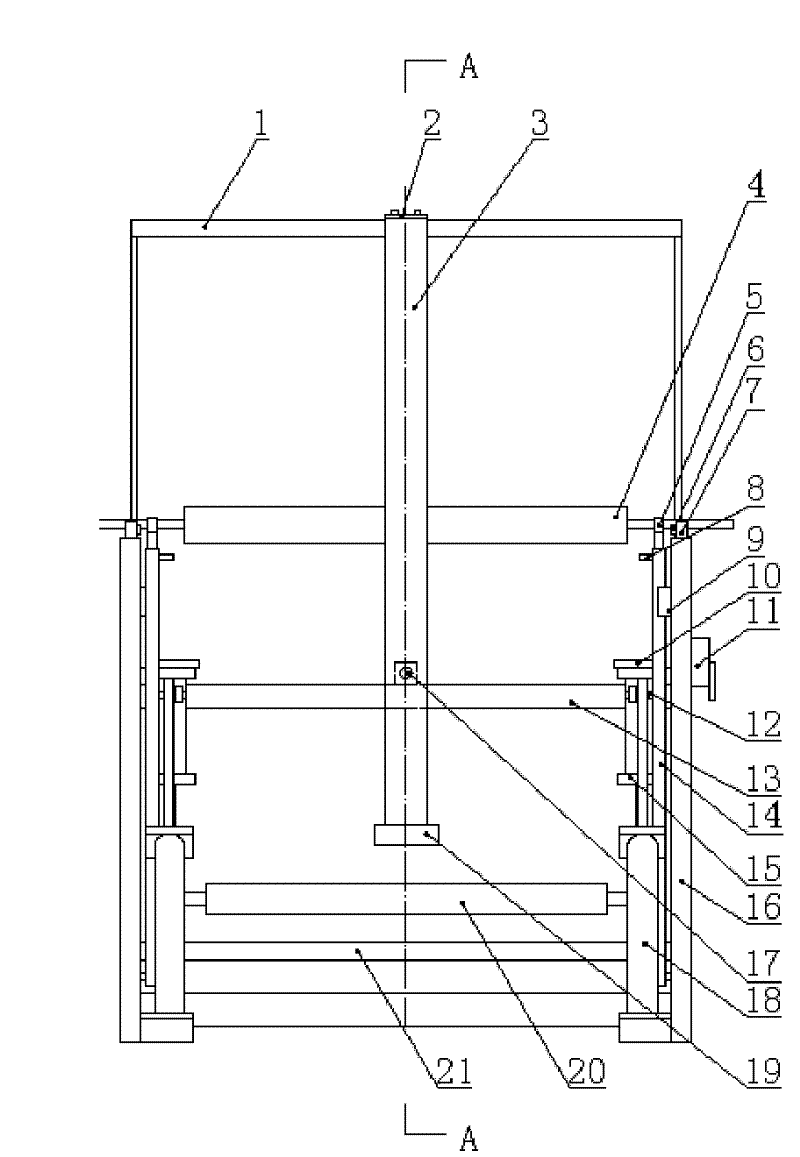

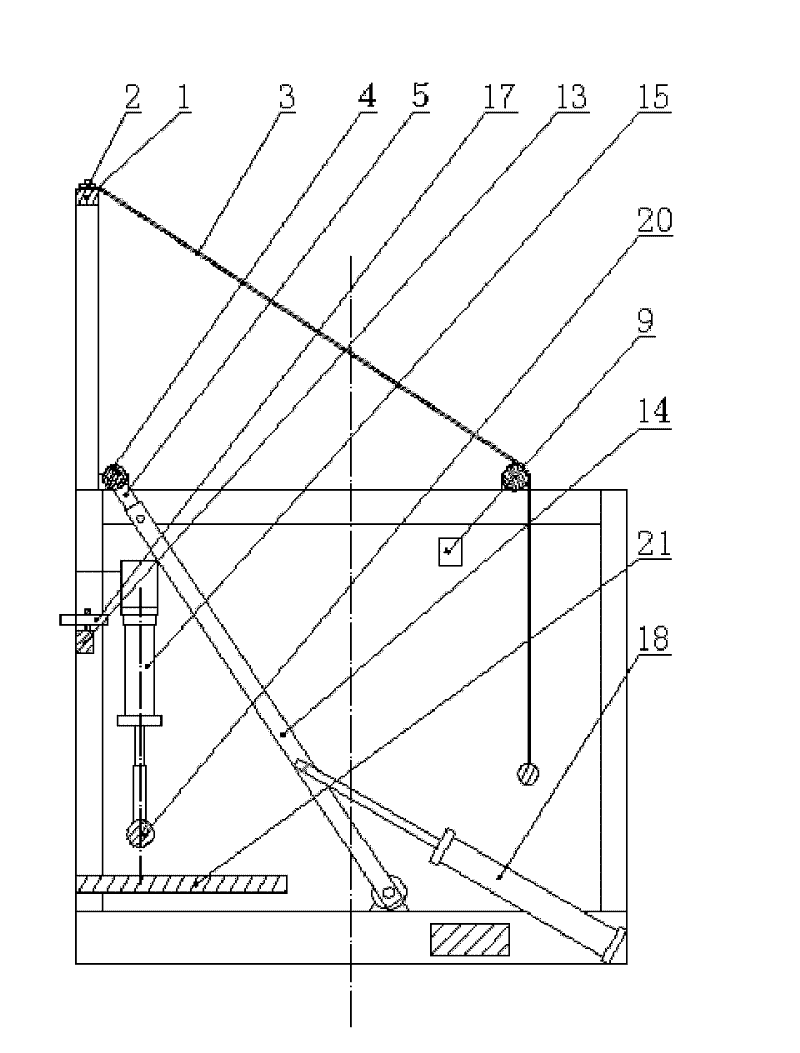

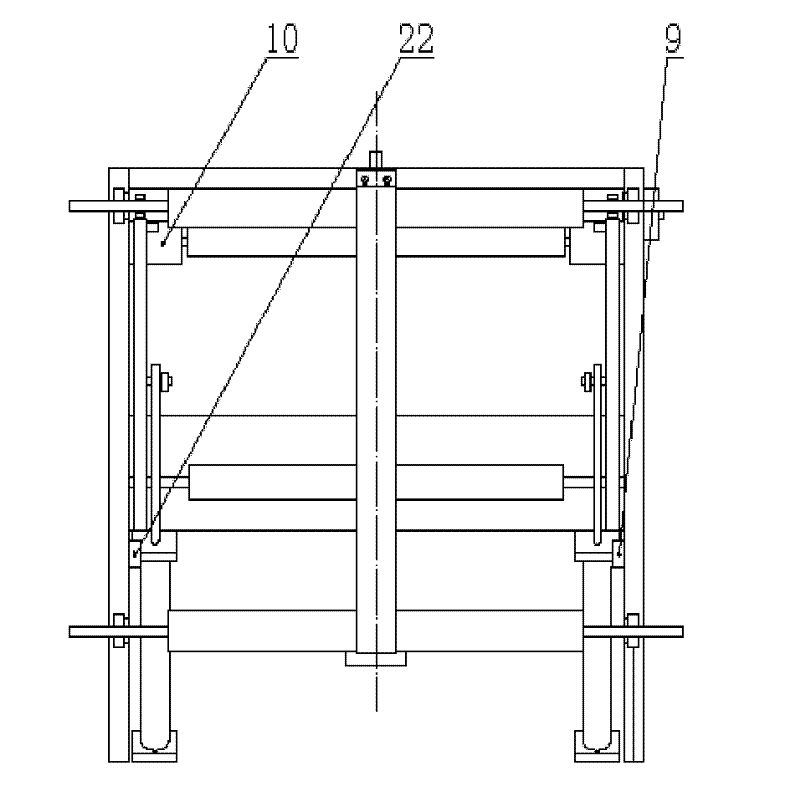

Automatic feeding and gunning machine for furnace refractory maintenance

The invention provides an automatic feeding and gunning machine for furnace refractory maintenance. The automatic feeding and gunning machine comprises a feeding machine, a material receiving hopper, a pressure tank, a material distribution disc, an ejector and a main machine frame. The feeding port of the material receiving hopper is located under the discharge port of the feeding machine. The discharge port of the material receiving hopper is connected with the upper opening of the pressure tank. The material distribution disc is located between the lower opening of the pressure tank and the ejector. The material distribution disc is a grid disc which is arranged in a shell with openings in the upper portion and the lower portion. The upper opening of the shell is connected with the lower opening of the pressure tank. A rotating shaft is arranged in the grid disc in a penetrating manner. The upper end of the rotating shaft is connected with a stirrer. The lower end of the rotating shaft is connected with a transmission device. A discharge pipe is arranged at the lower end of the grid disc and connected with the inlet of the injector. The automatic feeding and gunning machine for furnace refractory maintenance is uniform in discharge, low in maintenance cost, high in work efficiency and gunning quality and capable of automatically feeding refractories to a high place from a low place, and secondary raised dust is reduced; and the number of operators is decreased, the work strength of the operators is reduced, and potential safety hazards are reduced.

Owner:MCC BAOSTEEL TECH SERVICE

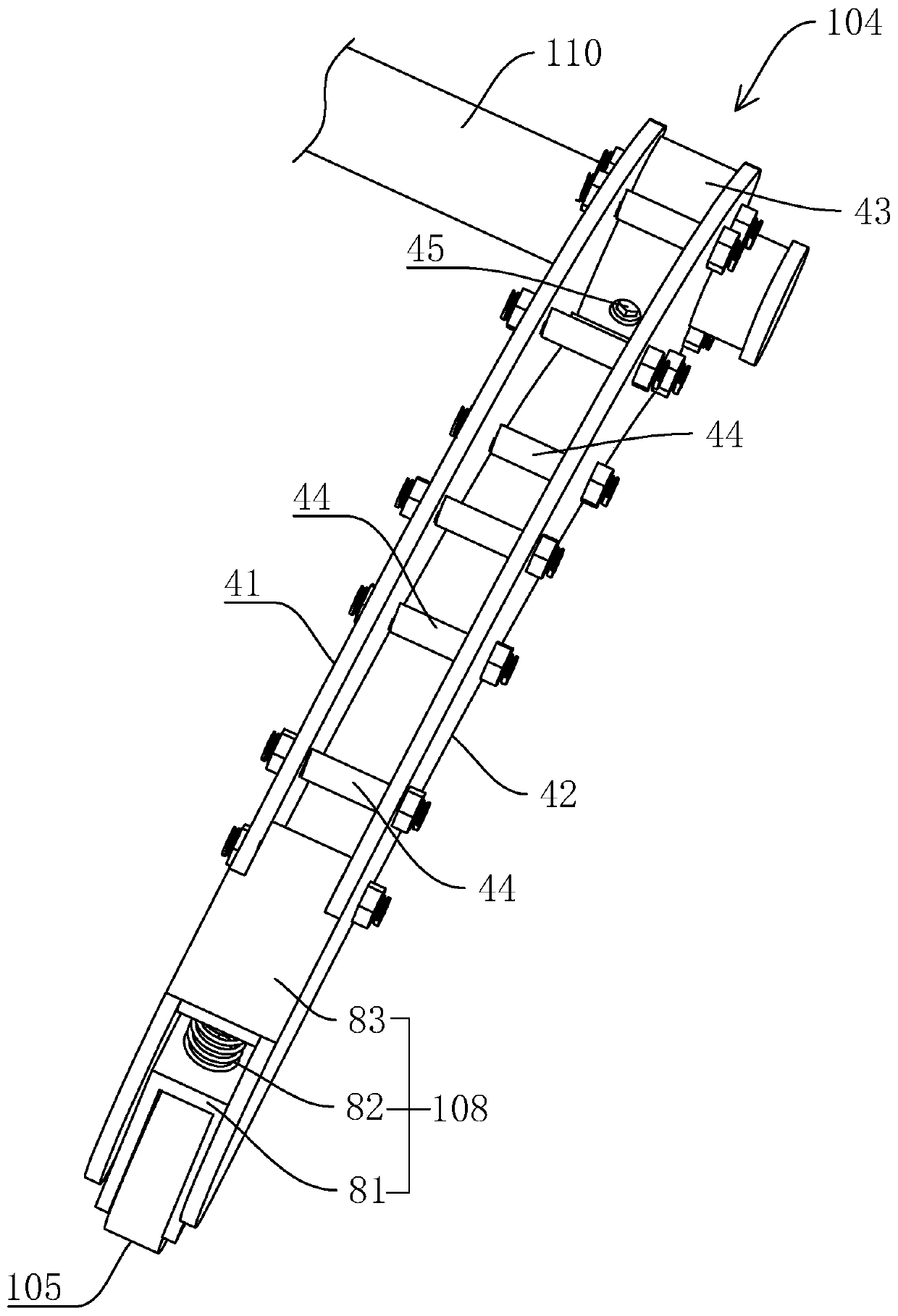

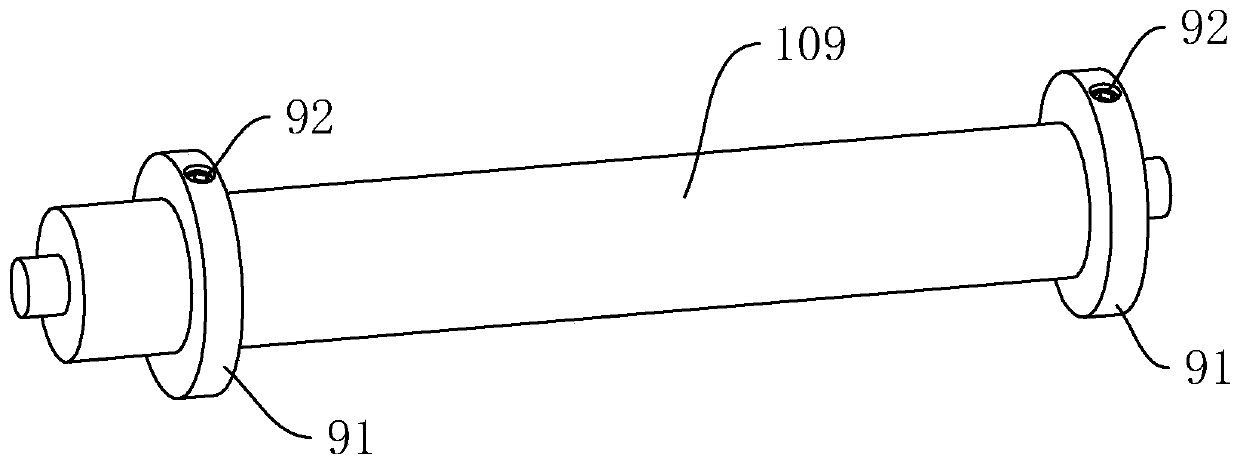

Strip steel uncoiling mechanism

The invention relates to a strip steel uncoiling mechanism, and relates to the technical field of production of metal stamping parts. The strip steel uncoiling mechanism comprises a machine case, a power motor, an uncoiling spindle and an expansion tile, and further includes a guide roller, a rotating shaft, an arc arm, a pressure wheel, a mounting frame, a driving part and an elastic component; the mounting frame is installed on the top surface of the machine case, the guide roller is arranged on the side face of the machine case and is located obliquely above the uncoiling spindle, the rotating shaft is rotatably arranged on the mounting frame and located above the guide roller, and the uncoiling spindle, the guide roller and the rotating shaft are arranged horizontally and are arrangedin parallel; the driving part is arranged between the machine case and the rotating shaft, the driving part is used for driving the rotating shaft to rotate forwards and backwards, one end of the arcarm is connected to the rotating shaft, and the other end of the arc arm is provided with the elastic component; and the pressure wheel is rotatably arranged on the elastic component, the rotation axis of the pressure wheel is parallel to the uncoiling spindle, and the elastic component is used for driving the pressure wheel to press the upper surface of strip steel. The strip steel uncoiling mechanism has the effects of being stable and firm in structure and being capable of pressing the rolled strip steel on the expansion tile to prevent the rolled strip steel from loosening.

Owner:武汉宏升鑫汽车部件有限公司

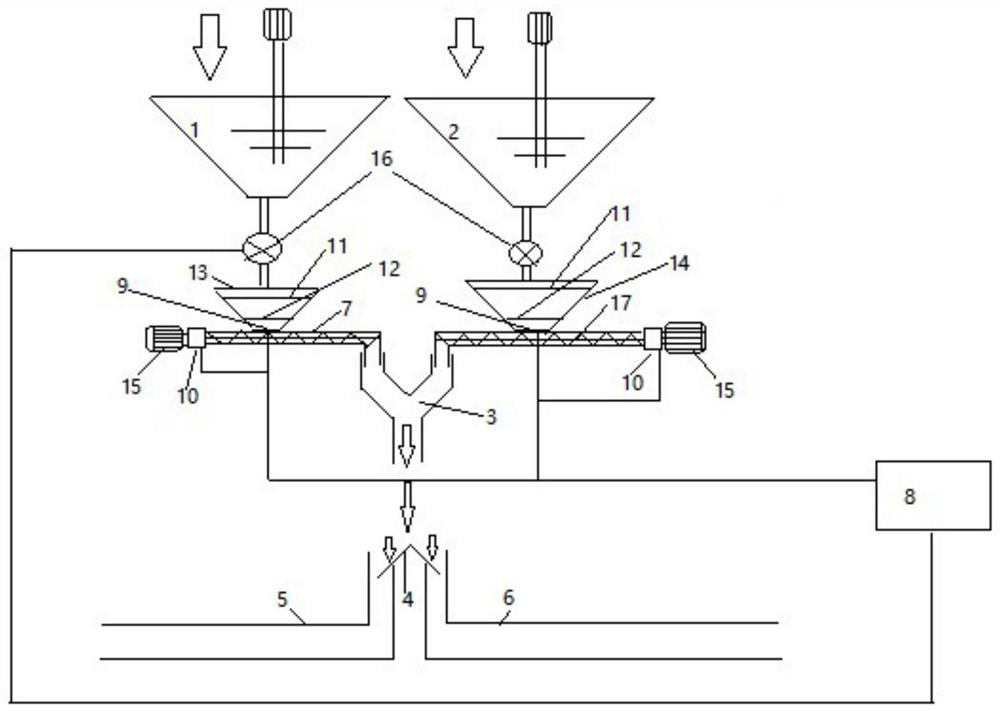

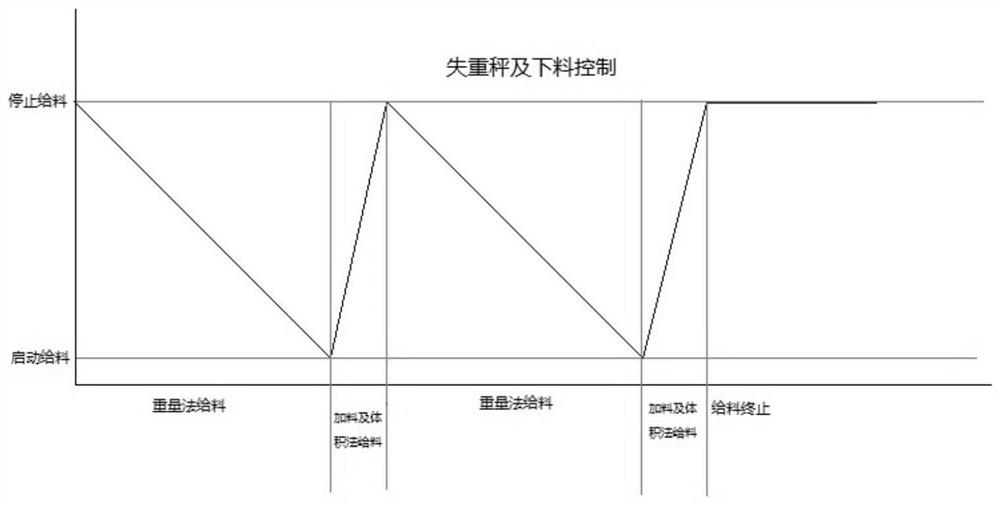

High-precision and stable discharging device in lithium battery industry and control method thereof

InactiveCN113247595AContinuous and stable feedingImprove work efficiencyControl devices for conveyorsPackagingLoop controlEngineering

The invention discloses a high-precision and stable discharging device in the lithium battery industry and a control method thereof. The high-precision and stable discharging device in the lithium battery industry comprises at least two temporary storage bins, a discharging opening of each temporary storage bin is connected with a feeding bin through a material conveying pipeline, a feeding valve is mounted on each material conveying pipeline, a weightlessness scale is mounted in the bottom of each feeding bin, a weightlessness scale sensor is arranged in the weightlessness scale, a speed-adjustable discharging mechanism is arranged below a discharging port of the feeding bin, the speed of the speed-adjustable discharging mechanism is adjusted through a controller, and the controller is connected with the feeding valve and the weightlessness scale sensor at the same time. According to the control method, closed-loop control is achieved through a control program, so that continuous, stable and uninterrupted discharging of the discharging device is achieved, and meanwhile, the batch feeding metering precision is improved, and interference of external factors is avoided. The high-precision and stable discharging device in the lithium battery industry and the control method thereof are suitable for online simultaneous stable discharging of two or more than two ultra-high molecular weight polyethylene, and guarantee can be provided for preparation of high-stability and high-consistency diaphragm products.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

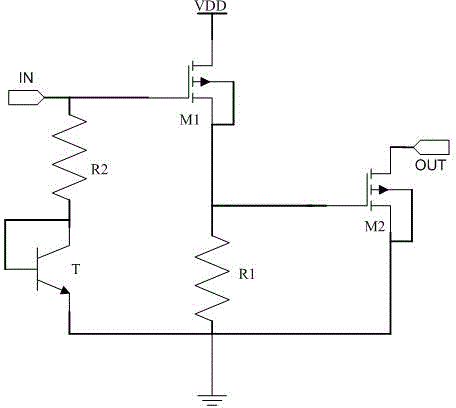

Temperature self-adaptive adjustment power tube

ActiveCN104407640AAvoid shutdown lossesContinuous workTemperature control using electric meansSelf adaptiveVoltage

Provided is a temperature self-adaptive adjustment power tube which comprises a signal input end, a power tube and a gate electrode thereof. The temperature self-adaptive adjustment power tube is characterized by further comprising a gate electrode control circuit which is composed of a pull-down resistor, a voltage dropping resistor, a temperature induction device, a first signal input tube and a second signal input tube. The first signal input tube is connected between a power supply and the pull-down resistor which is grounded. The common end of the pull-down resistor and the first signal input tube is connected with the gate electrode of the power tube. The signal input end is connected with the control end of the second signal input tube. The voltage dropping resistor and the temperature induction device are connected in series between the drain electrode of the second signal input tube and the ground. The second signal input tube is a PMOS, the source electrode of the second signal input tube is connected with the power supply and the drain electrode is connected with the control end of the first signal input tube. Output voltage of the temperature induction device is a negative temperature coefficient. Adjustment of the heat value of the power tube can be realized only via additional arrangement of a small amount of devices so that the power tube is enabled to work continuously and uninterruptedly and unnecessary shutdown loss can be avoided.

Owner:四川广义微电子股份有限公司

Automatic gathering and feeding device for wide-width polymer net laying

The invention relates to an Automatic gathering and feeding device for wide-width polymer net laying. The automatic gathering and feeding device comprises a folding device I, a folding device II, a cutting device, four clamping devices I, a conveying device, an overturning device, a symmetric folding device I, a symmetric folding device II and a feeding device. The folding device I is fixedly installed on the ground, the rear side of the folding device II is mounted on the right side of the folding device I in a seamless manner, and the rear side of the cutting device is installed on the rightside of the folding device II; the four identical clamping devices I are installed on the front side of a baffle of a sliding guide rail of the lower step of the cutting device, and the conveying device is installed in the middle of two supporting frames of the cutting device; the overturning device is mounted on a square plate extending from an upper top surface of a fixing bracket of the conveying device, and a rack D of the symmetric folding device I is mounted on the right side of the conveying device; and the symmetric folding device II is mounted at the quarter of the top surface of therack D of the symmetric folding device I, and the feeding device is installed on the left side of the folding device I. The quick folding vertical feeding of wide polymer net materials is realized byadopting a mechanical control mode.

Owner:QINGDAO UNIV OF SCI & TECH

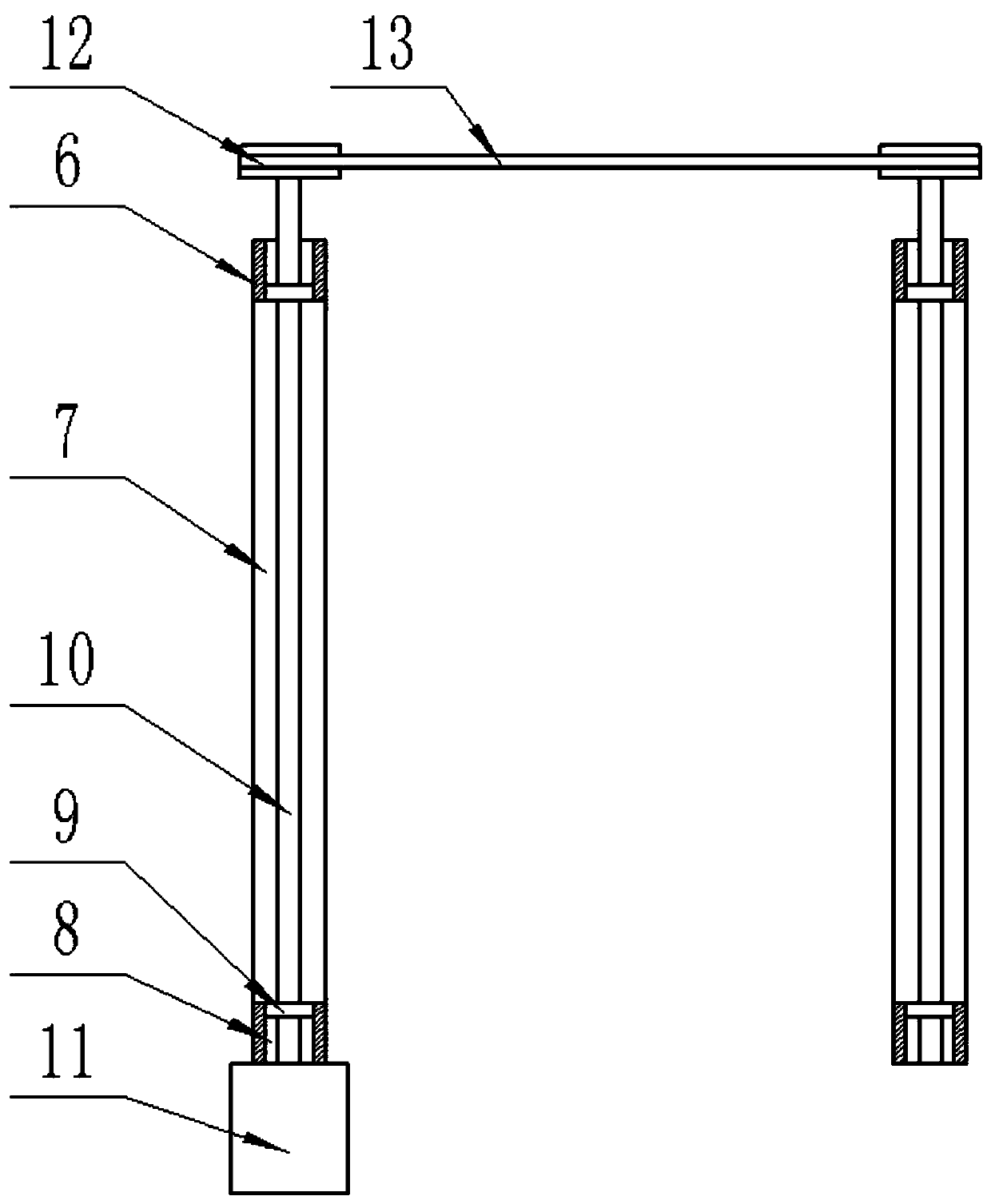

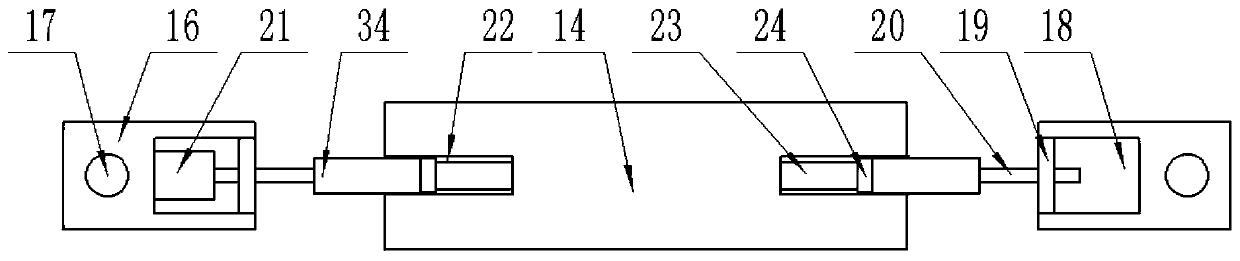

Automatic feeder for woven bag making machine

InactiveCN102241340AIncrease productivityContinuous workWebs handlingContinuous/uninterruptedFailure rate

The invention relates to an automatic feeder for woven bag making machine. The automatic feeder comprises a door-shaped frame, a bracket and a middle shaft, wherein the bracket is fixedly mounted on the upper end surfaces of the two side walls of the door-shaped frame; and the middle shaft is mounted at the lower part of the door-shaped frame and is close to a feed port of the woven bag making machine. The automatic feeder also comprises a detection mechanism, a carrying mechanism and a crimping mechanism. By the adoption of the automatic feeder for a woven bag making machine, the continuous work of the woven bag making machine can be realized, thereby effectively improving the production efficiency, increasing the economic benefits of enterprises; the start / stop frequency of the woven bag making machine is reduced, thereby effectively reducing the failure rate of equipment and guaranteeing safe production and further improving the economic benefits of enterprises. The automatic feeder provided by the invention is scientific and reasonable in design, simple in structure and easy to implement.

Owner:TIANJIN DEMEI PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com