Laminated filter with automatic cleaning device

A lamination filter, automatic cleaning technology, applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of inability to meet the filtration requirements, the system cannot run continuously, and the dirt is washed clean. Save labor and labor costs, maintain filtration efficiency, and improve the effect of filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

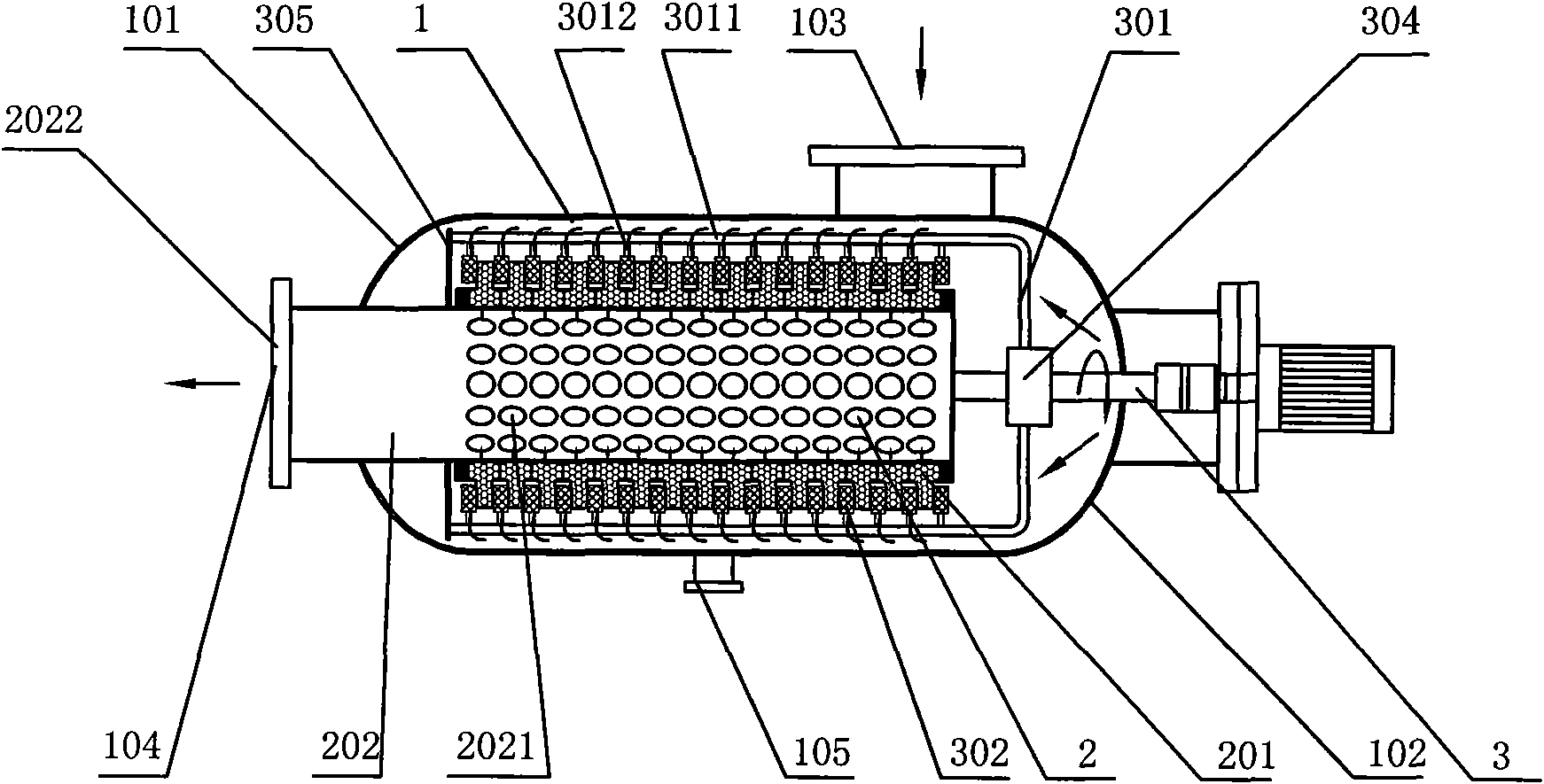

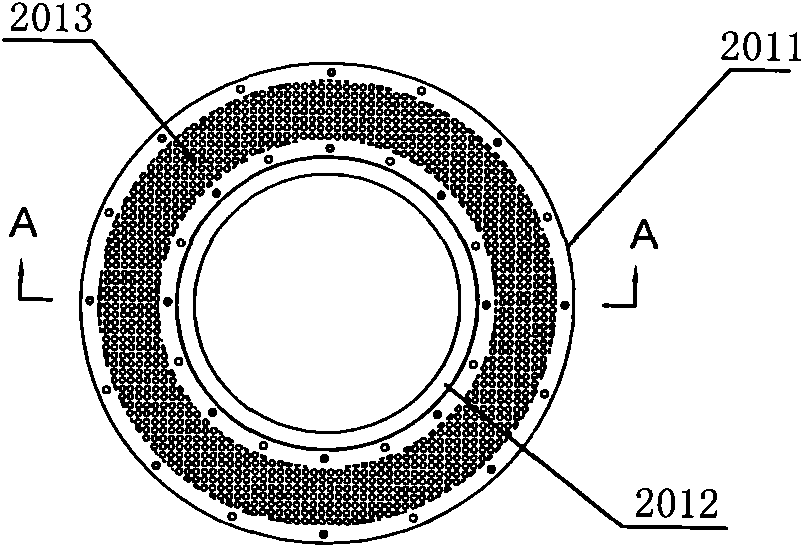

[0025] Such as Figure 1a As shown in , a laminated filter with an automatic cleaning device described in the technical solution of the present invention includes a casing and a filter element. The casing is a cylinder 1 with end caps at both ends, and the water inlet of the filter is set on the cylinder The position near the end of the body, the water outlet is set on the end cover 101, and also includes an automatic cleaning device 3, the filter element 2 is composed of a set of hollow filter discs 201 and a water outlet core pipe 202, and the hollow filter disc 201 is sleeved On the water outlet core pipe 202, there is a distance between two adjacent hollow filter discs 201. The inner side of the hollow filter disc 201 has several water outlet holes 2014, and several water inlet holes 2014 are provided on the side of the water outlet core pipe 202. hole 2021, the outlet water of the hollow filter disc 201 flows into the water outlet core tube 202 from the water inlet hole 20...

Embodiment 2

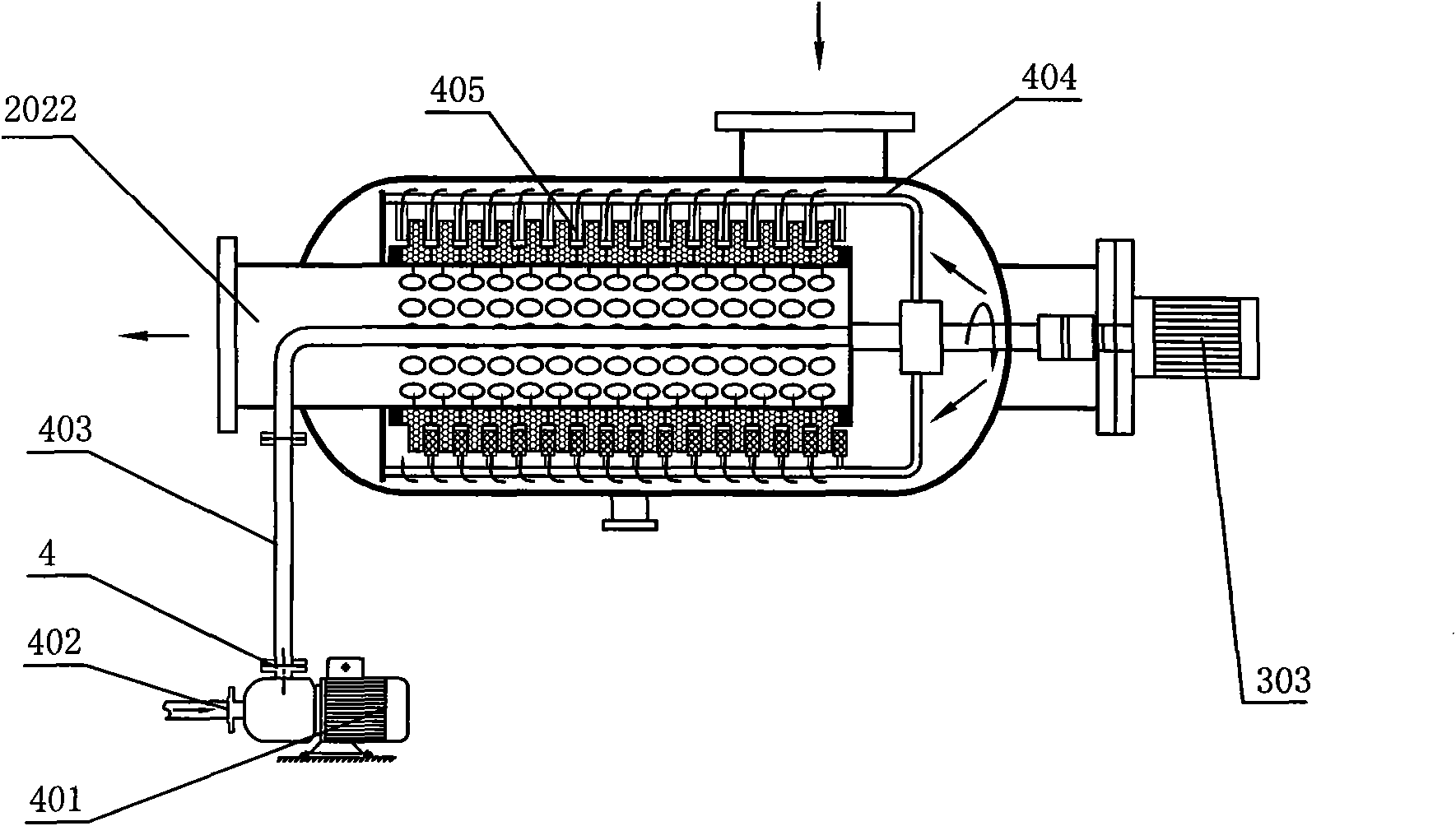

[0027] Such as Figure 1b As shown in , in order to better clean the dirt on the disk surface, the cleaning device in this embodiment also includes a high-pressure flushing device 4, which is composed of a high-pressure pump 401, a high-pressure pump The water inlet pipe 402 of 401, the water delivery pipe 403 of the pressure pump 401, the water delivery branch pipe 404 and the high-pressure water injection pipe 405 form. One end of the water delivery pipe 403 is connected to the water outlet of the high-pressure pump 401, the other end of the water delivery pipe 403 is fixed on the mounting frame 304, and is branched into a plurality of water delivery branch pipes 404 at the installation frame 304, and the other end of the water delivery branch pipe 404 Fixed on the spacer 305, the water delivery branch pipe 404 is on the outside of the hollow filter disc 201, and each water delivery branch pipe 404 is provided with a plurality of injection pipes 405, and the injection pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com