Industrial sewage collecting tank

A technology for industrial sewage and collection pools, applied in water/sewage treatment, water/sludge/sewage treatment, water supply equipment, etc., can solve the problems of prolonging the time of sewage discharge and low efficiency, and prevent debris from running around, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

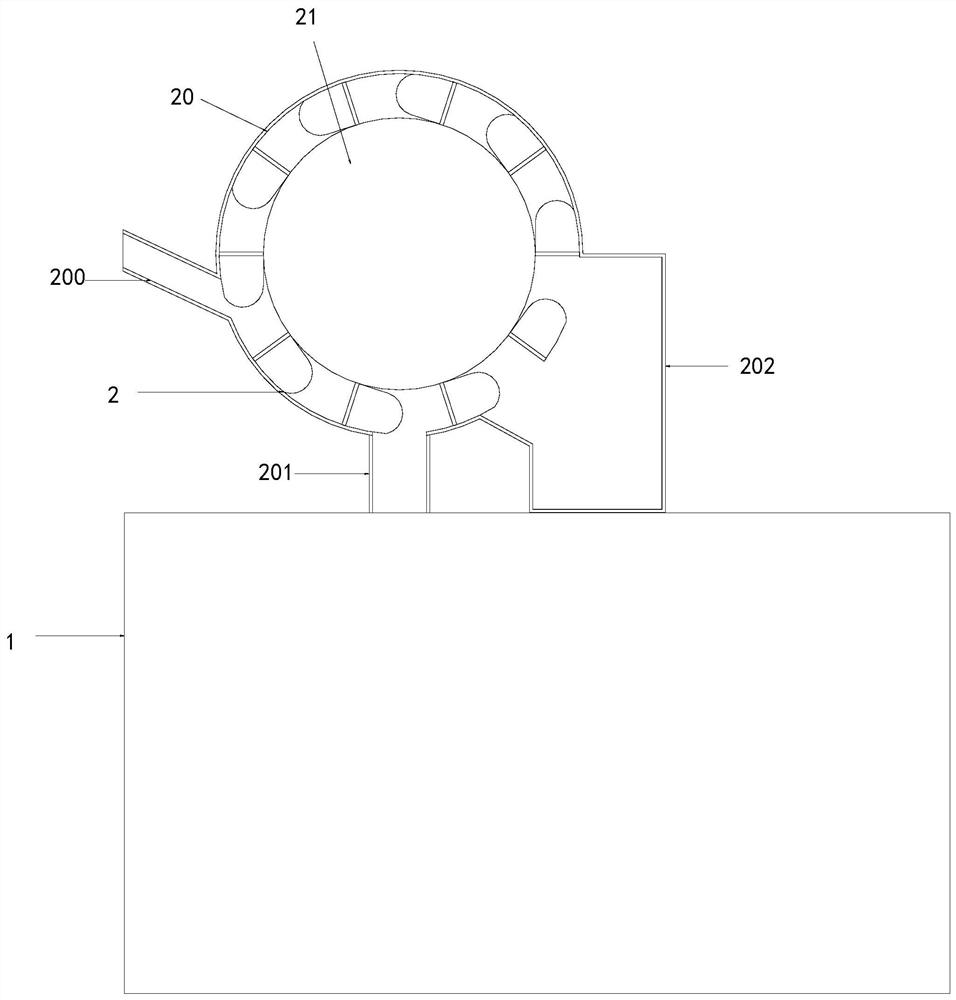

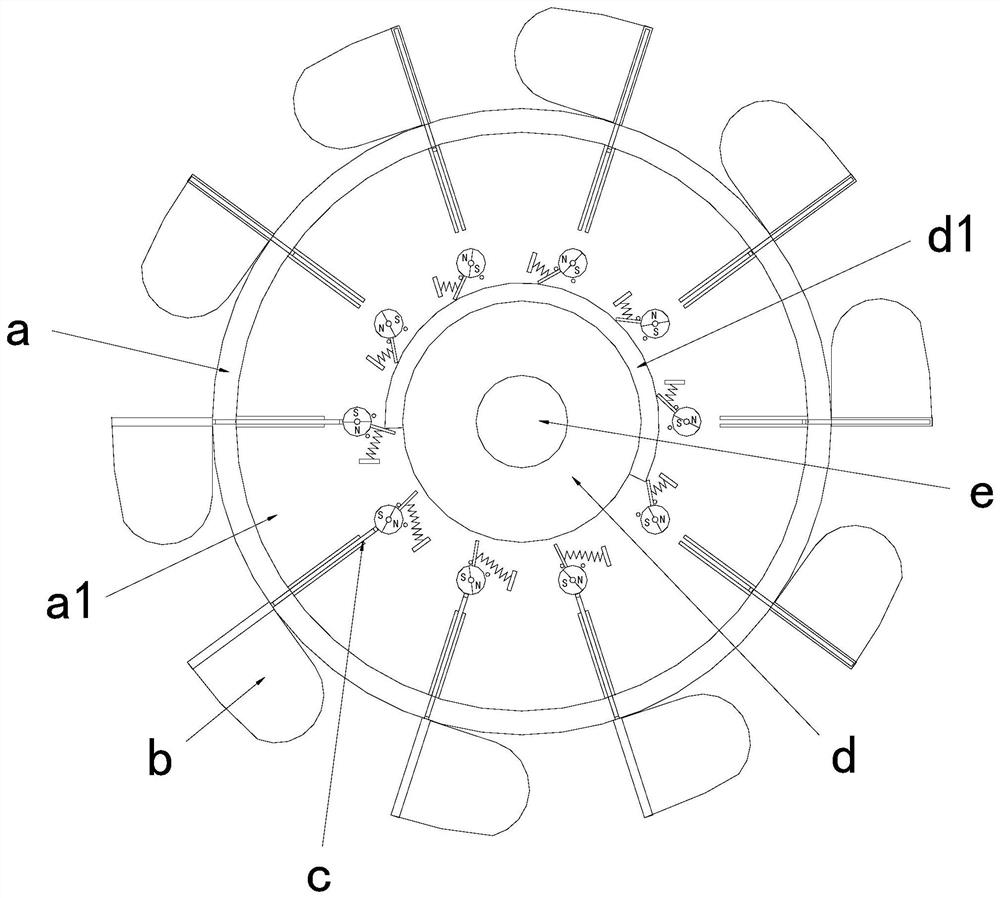

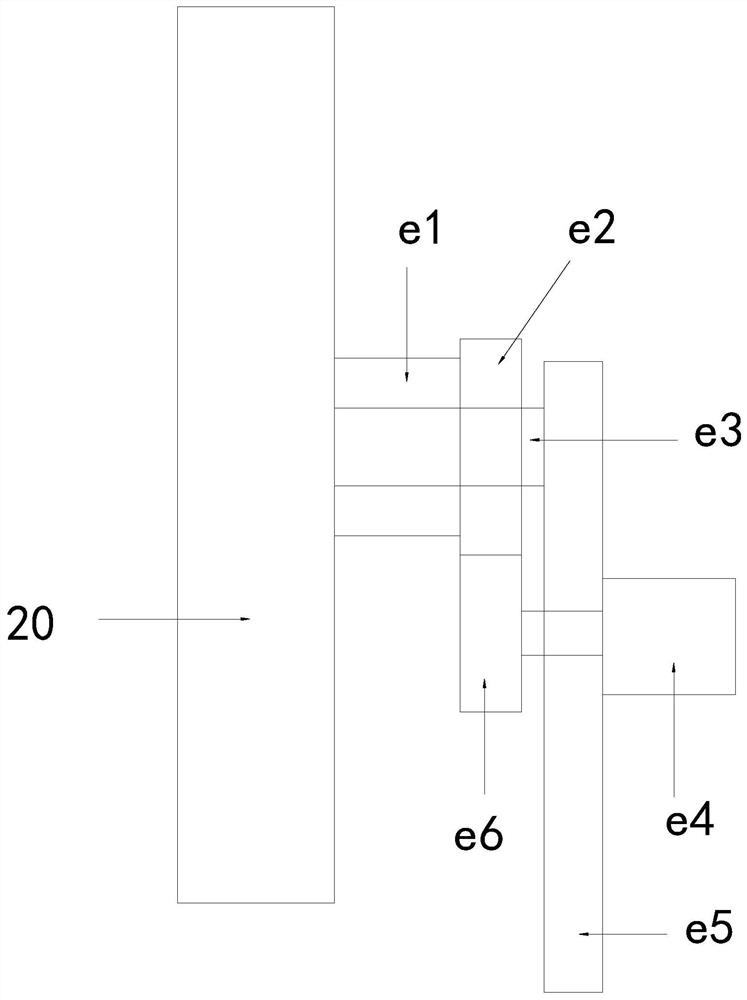

[0026] see Figure 1-2 , the present invention provides a technical solution for industrial sewage collection ponds: its structure includes a collection pond 1 and a salvage structure 2, a salvage structure 2 is arranged above the collection pond 1, and the salvage structure 2 includes a shell 20, a rotary fisher 21 , the housing 20 is provided with a rotary fisher 21, the side of the housing 20 is provided with a water inlet 200, the bottom of the housing 20 is provided with a water outlet 201, and the housing 20 is provided with the opposite of the water inlet 200 The side is connected with a collection tank 202, and the rotary fisher 21 includes a turntable a, a fishing net b, an upper cover structure c, a fixed disk d, and a power structure e, and the side of the turntable a is connected with evenly distributed fishing nets b. A cavity a1 is provided inside the turntable a, and a fixed disk d is arranged in the middle of the cavity a1. The upper cover structure c is evenly...

Embodiment 2

[0029] see Figure 1-4 , the present invention provides a technical solution for industrial sewage collection ponds: its structure includes a collection pond 1 and a salvage structure 2, a salvage structure 2 is arranged above the collection pond 1, and the salvage structure 2 includes a shell 20, a rotary fisher 21 , the housing 20 is provided with a rotary fisher 21, the side of the housing 20 is provided with a water inlet 200, the bottom of the housing 20 is provided with a water outlet 201, and the housing 20 is provided with the opposite of the water inlet 200 The side is connected with a collection tank 202, and the rotary fisher 21 includes a turntable a, a fishing net b, an upper cover structure c, a fixed disk d, and a power structure e, and the side of the turntable a is connected with evenly distributed fishing nets b. There is a cavity a1 inside the turntable a, and a fixed disk d is arranged in the middle of the cavity a1. The upper cover structure c is evenly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com