Novel screw rotor engine

A rotary engine and screw technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as vibration, high energy efficiency, and loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

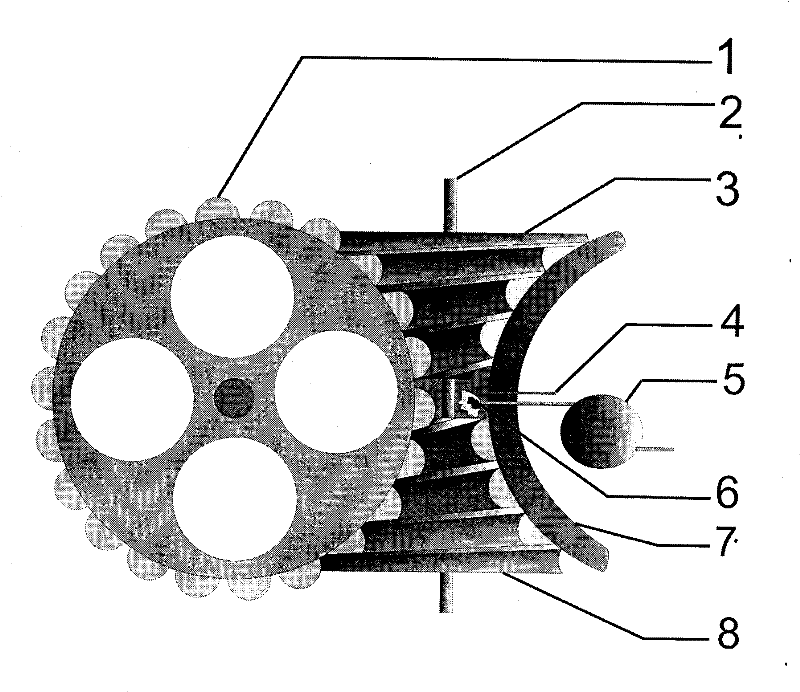

[0014] exist figure 1 Among them, the intake screw (8) and the work screw (3) are anchored on the main shaft (2) to form a rotor, the rotor is tightly connected to the casing (7) and meshed with the guide gear (1), the guide gear and the rotor can be freely Rotate, the cavity that forms between two screw rods is combustion chamber, and combustion chamber has spark plug (4) and fuel injection nozzle (6).

[0015] When running, the rotor rotates from left to right, the guide gear rotates counterclockwise, the air is compressed from the intake screw and enters the combustion chamber, and the oil pump (5) pumps the oil into the combustion chamber to mix with the air, and burns under the ignition of the spark plug, pushing The work screw does work to make the engine run.

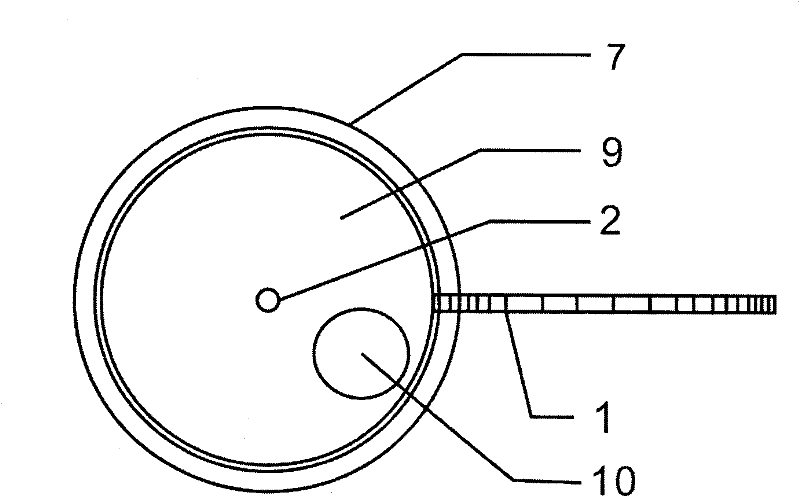

[0016] exist figure 2 , shows the combination of guide gear (1) and cylinder (7)

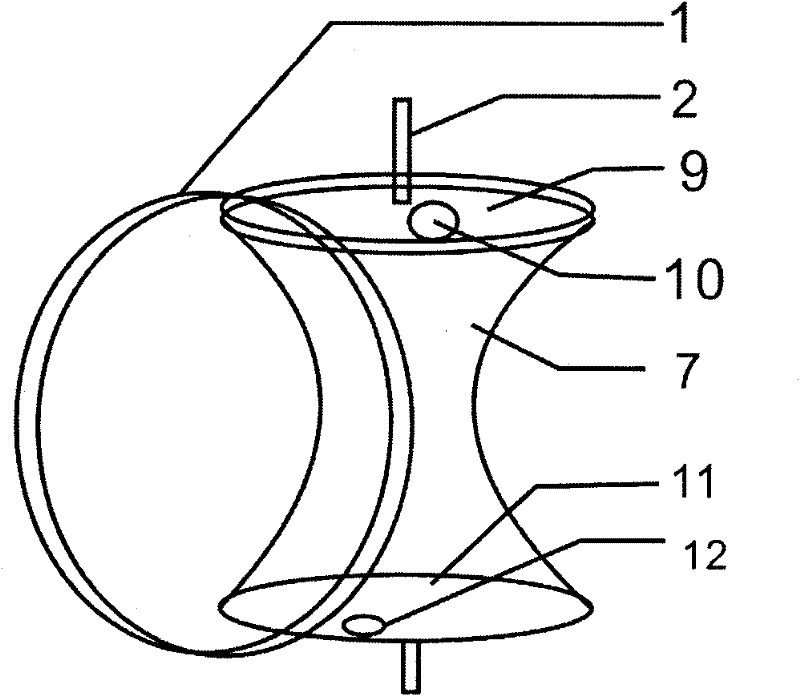

[0017] exist image 3 Among them, the air intake hole (12), the exhaust hole (10), the position of the top cover (9) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com