Continuous walnut shell breaking machine

A shell crusher, continuous technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of unavoidable failure to crush or excessive crushing, difficulty in batch shelling processing, and different impact strength, etc. Conducive to the promotion of production and use, the device is simple and compact, and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

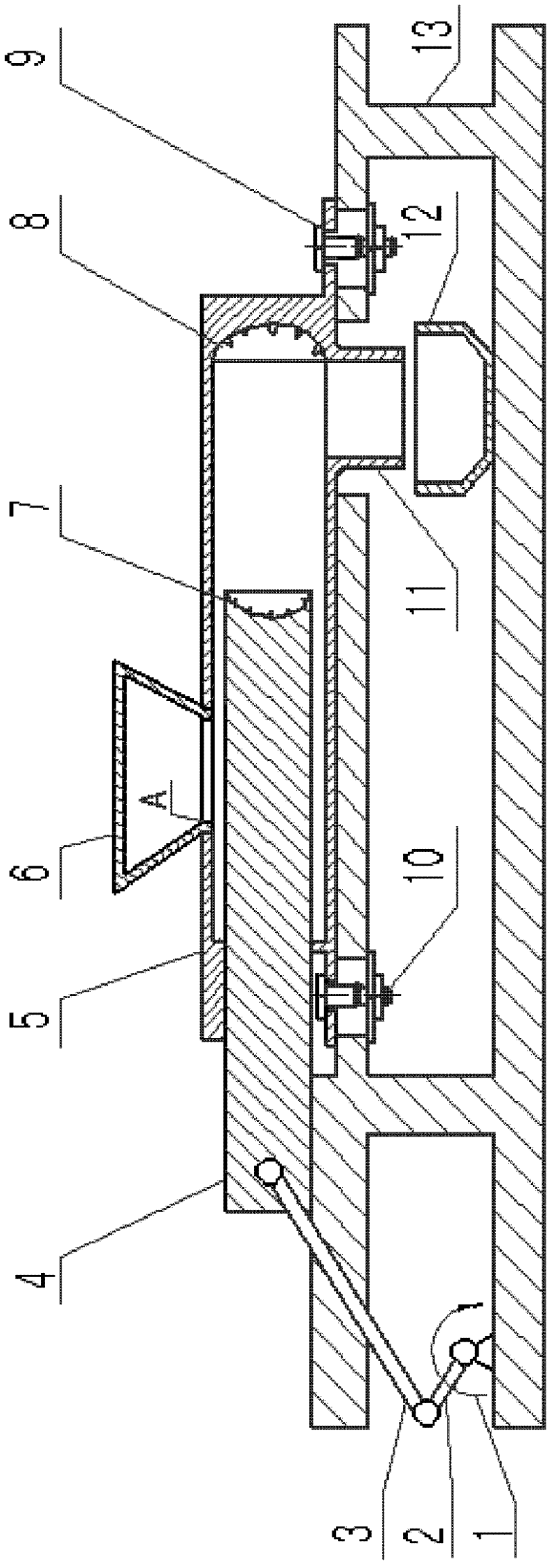

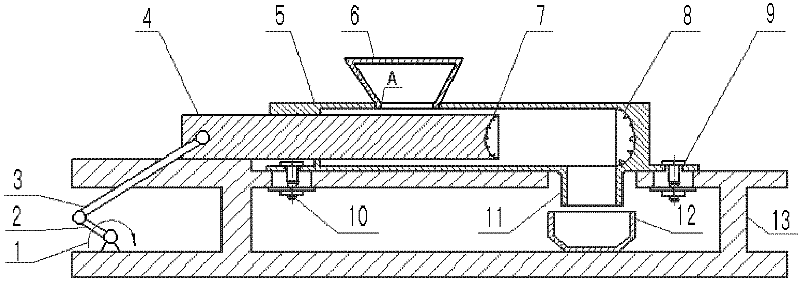

[0013] Such as figure 1 Shown, it is the sectional view of the present invention. The walnut shell cracker includes a power unit 1, a crank 2, a rocker 3, a slider 4, a steel cylinder 5, a feed bin 6, a convex point 7, a groove 8, a bolt 9, a bolt 10, and a discharge port 11 , charging bucket 12, machine base 13.

[0014] The steel cylinder 5 is fixed on the machine base 13 by bolts, one end is closed and the other end is open. There is a slider 4 inside the steel cylinder 5. The slider 4 is purchased together with the crank 2 and the rocker 3 to form an offset crank slider mechanism. The steel cylinder 5 A 5-8cm long plane protruding from the upper side of the opening is in contact with the slider 4, so that the stability of the processing process can be ensured when the slider 4 punches the crushed shell; A feed bin 6 connected to the steel cylinder is provided, a discharge port 11 is provided below the closed end surface of the steel cylinder 5 , and a charging barrel 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com