Patents

Literature

62results about "Textiles drying apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

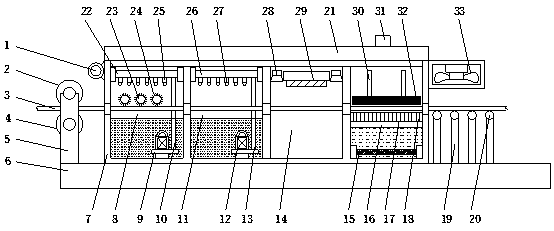

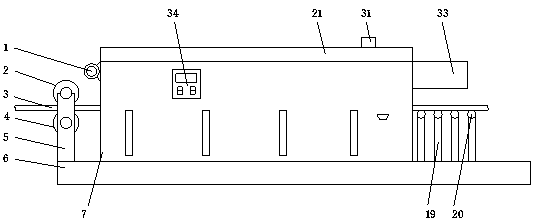

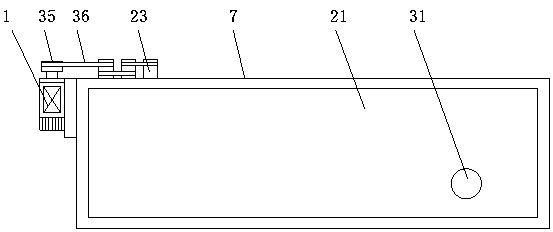

Special automatic dust collecting cloth rolling machine for cloth processing

ActiveCN107938239AEfficient removalEasy to operateCombination devicesMechanical cleaningEngineeringElectric heating

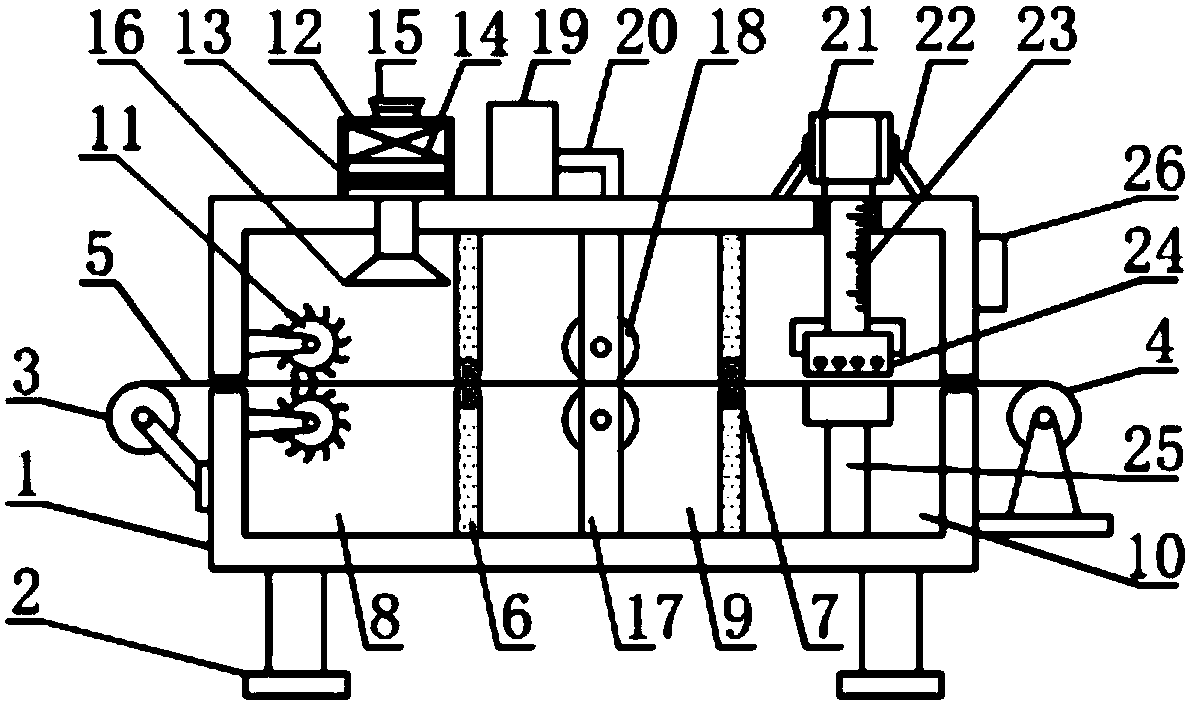

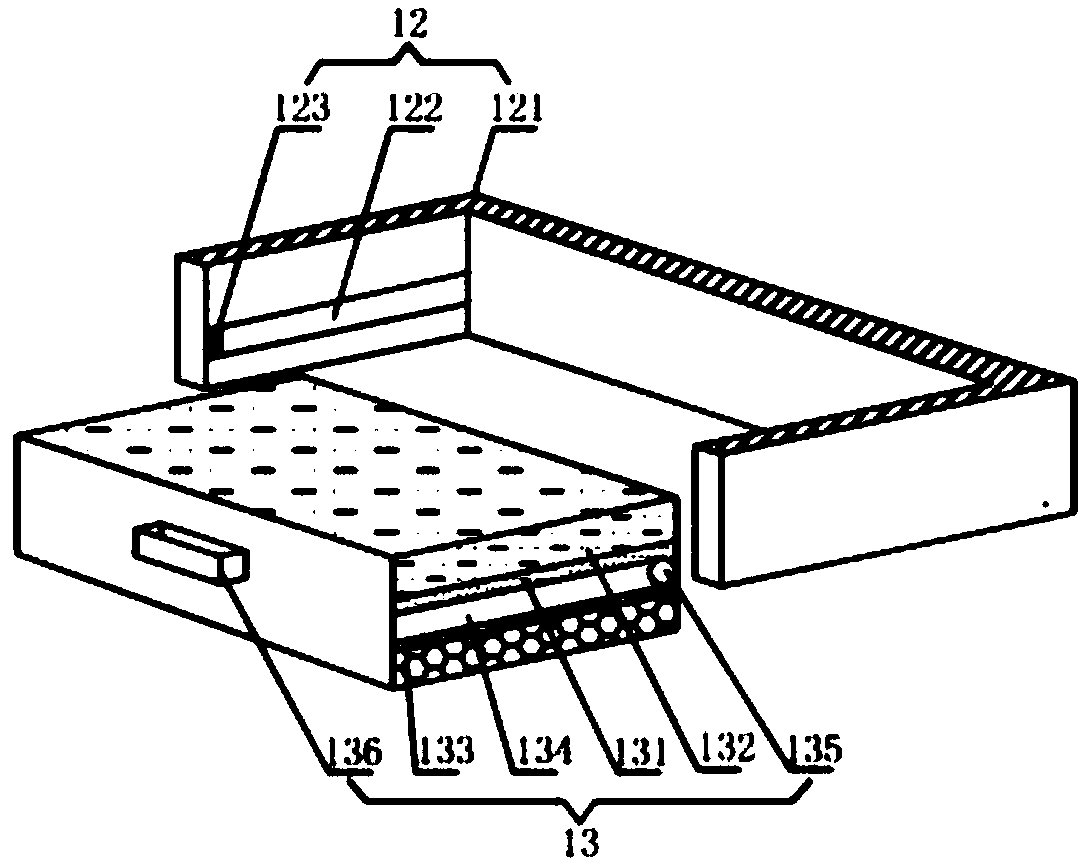

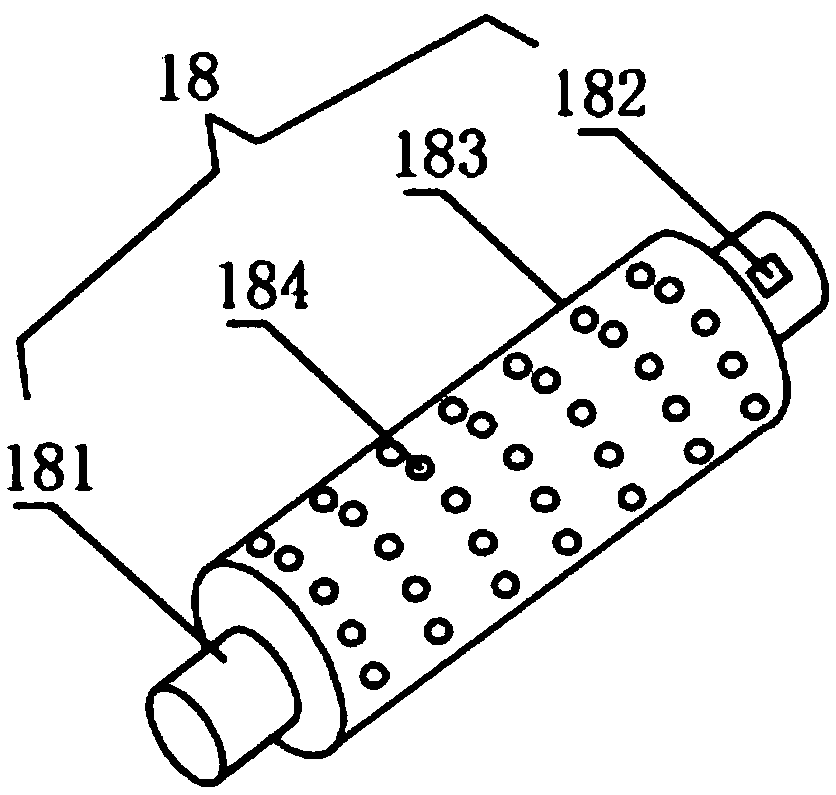

The invention discloses a special automatic dust collecting cloth rolling machine for cloth processing. The special automatic dust collecting cloth rolling machine for cloth processing comprises a rack, wherein an unreeling roller and a reeling roller are separately mounted on the left and right outer walls of the rack; two partition plates successively partition the inner cavity of the rack intoa dust collecting chamber, a steam drying chamber and a wrinkle-removing chamber; a dust collecting box is mounted on the top of the dust collecting chamber; and a steam drier is arranged on the steamdrying chamber. The special automatic dust collecting cloth rolling machine for cloth processing provided by the invention is simple to operate. Arc-shaped rubber brushing hairs are arranged on the outer walls of two dust collecting wheels, and the rotating directions of the two dust collecting wheels are opposite to the cloth forwarding direction, so that dust and cloth chips on the outer wall of the cloth can be eliminated effectively. Steam drying holes are formed in the surface of the steam drying roller, so that the cloth is dried, deodorized, enhanced in aroma, dry-washed and sterilizedconveniently, the storage period of the cloth without dust is improved effectively, the steam dried cloth is ironed by means of an electric heating plate, wrinkles on the surface of the cloth are eliminated conveniently, and the levelness of the cloth is improved effectively.

Owner:RUIAN BOAN STAB RESISTANT MATERIAL TECH

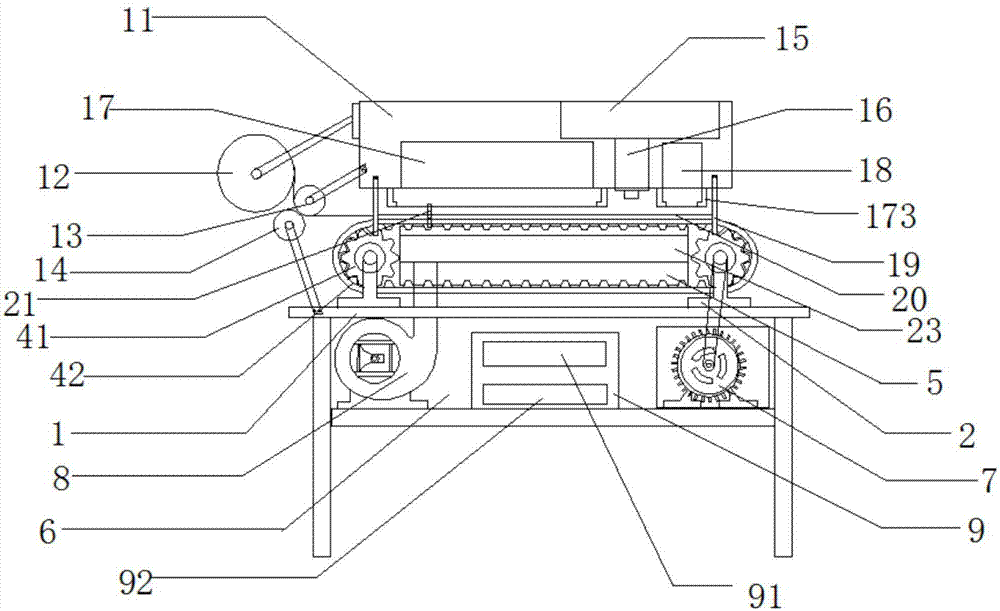

Textile fabric ironing and drying apparatus

InactiveCN107401018AAchieve the purpose of pavingAchieve the purpose of moving the ironing machineFabric finishing guides/expandersTextiles drying apparatusEngineeringAir heater

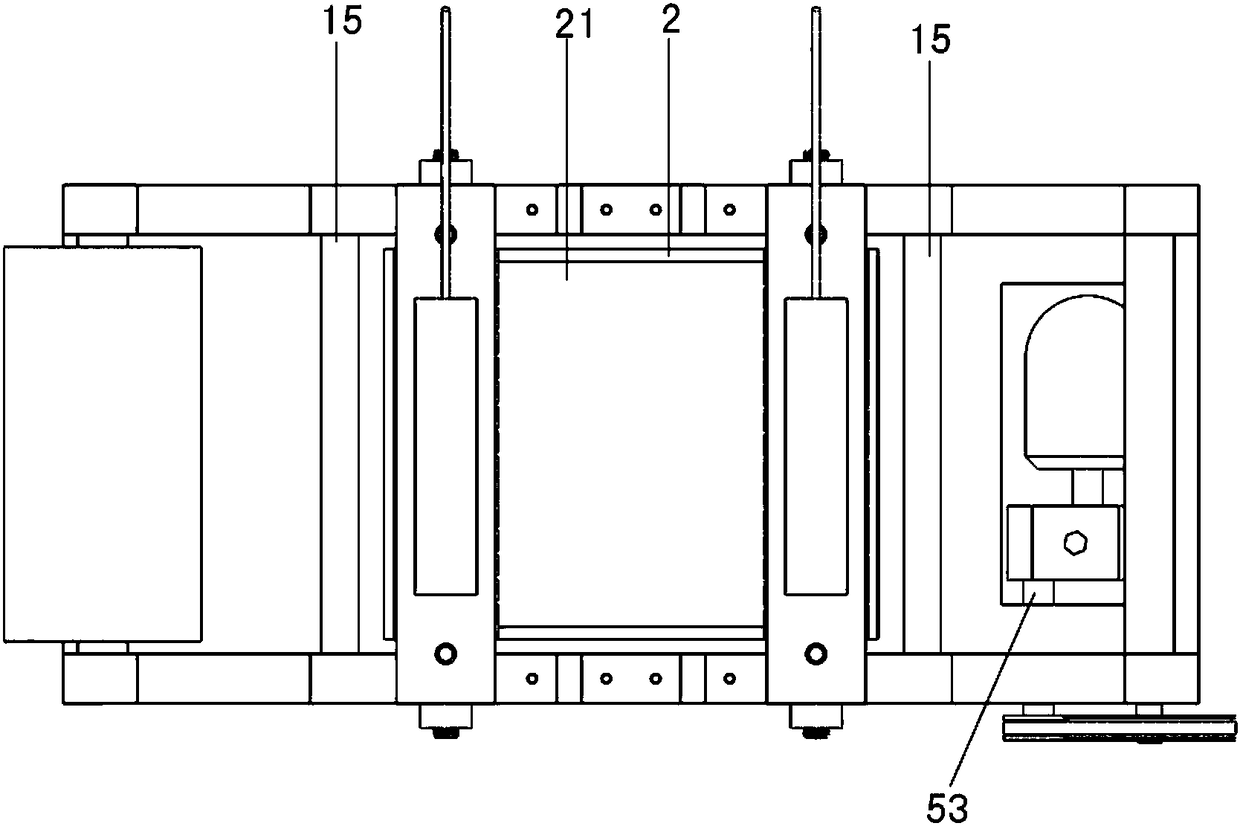

The invention discloses a textile fabric ironing and drying apparatus. The apparatus comprises an ironing chamber, the internal bottom end of the ironing chamber is fixedly connected with a lifting device, one end of a first pressure rod is fixedly connected with a first pressure roller, the first pressure roller is located at the top end of an ironing plate, a textile fabric compacting device is fixedly connected in a position, symmetrical to the first pressure roller, in the ironing chamber, the internal top end of the ironing chamber is fixedly connected with an ironing moving device, constant tension devices are fixedly connected to two sides of the ironing plate, an air heater is fixedly connected to the top end of a supporting plate and at the right side of a blower, and the right end of the air heater communicates with drying air outlet holes. The textile fabric ironing and drying apparatus relates to the technical field of textile device machines. The textile fabric ironing and drying apparatus solves the problems of no large-batch ironing and no automatic flattening during ironing of existing ironing devices needing manual operation, improves the ironing efficiency, and reduces the labor force.

Owner:HUZHOU BOREN TEXTILES

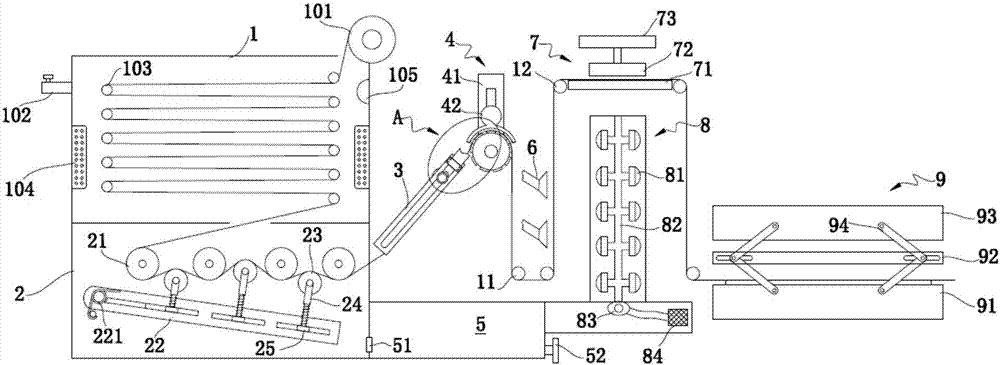

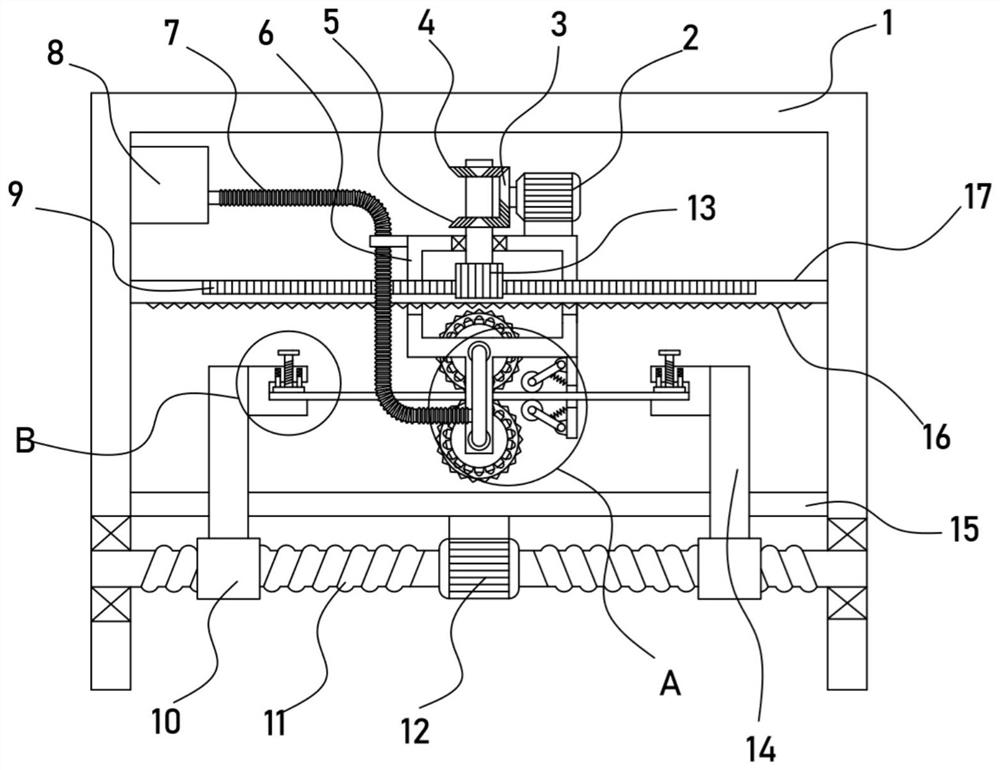

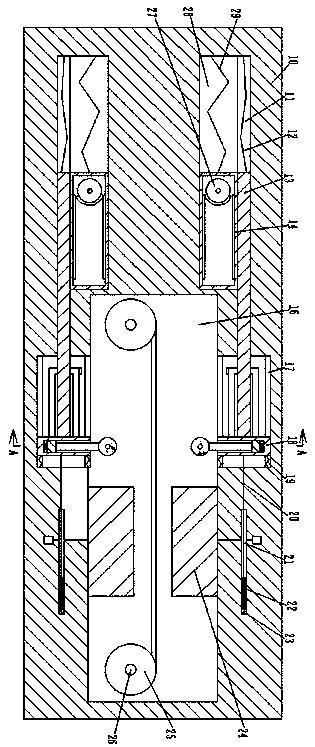

Printing and dyeing equipment

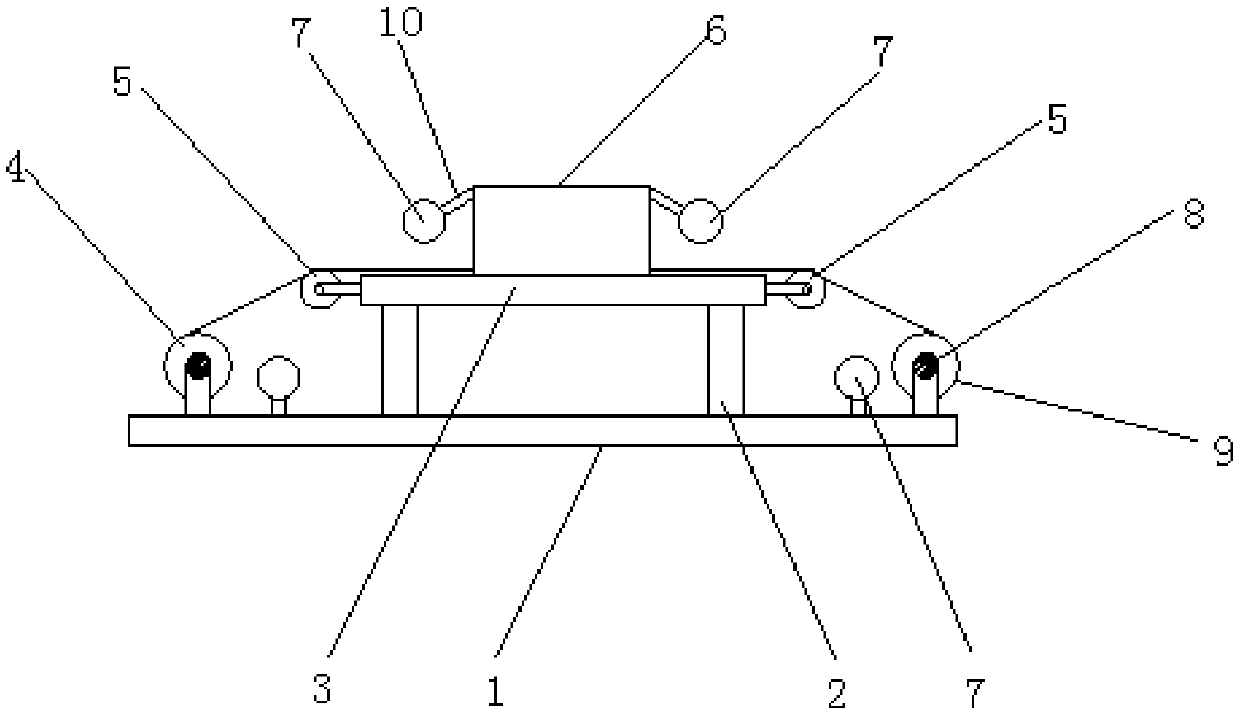

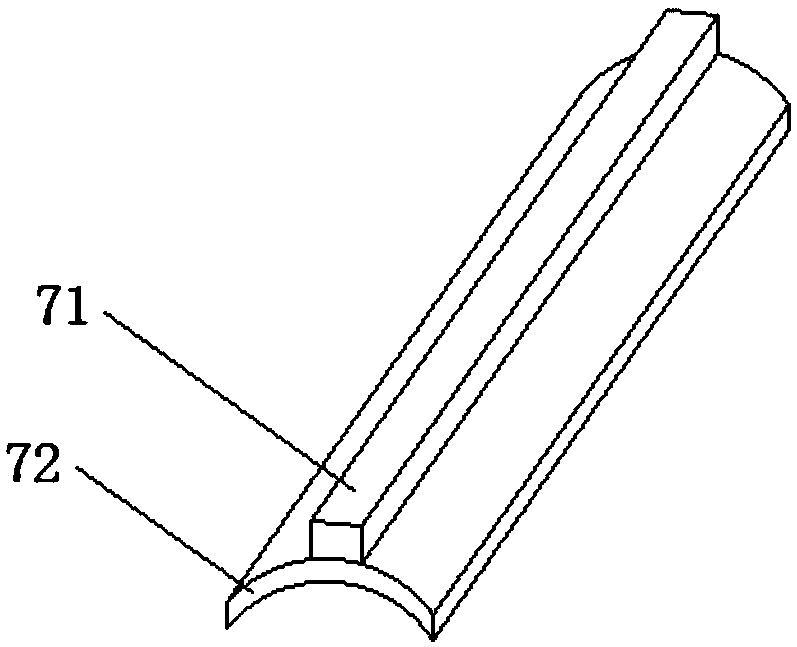

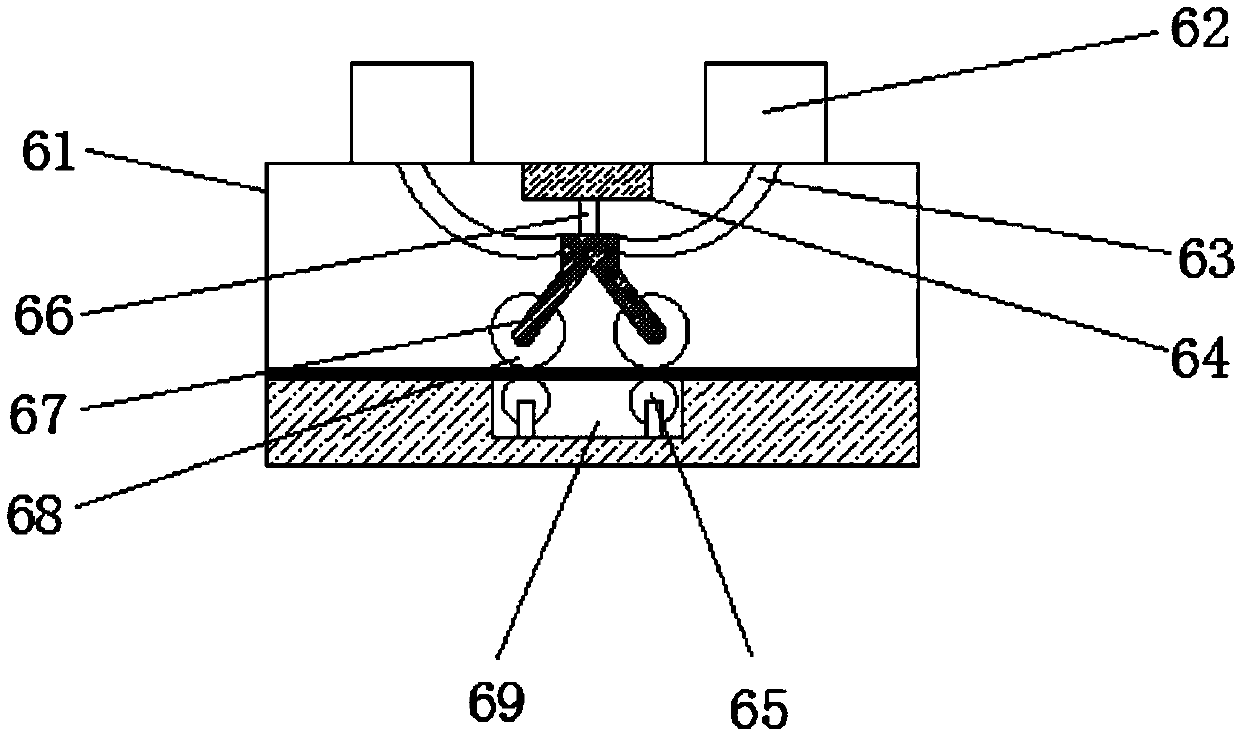

ActiveCN107974786AUniform dyeingAutomatically adjust the tensionLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersPulp and paper industryTextile dyeing

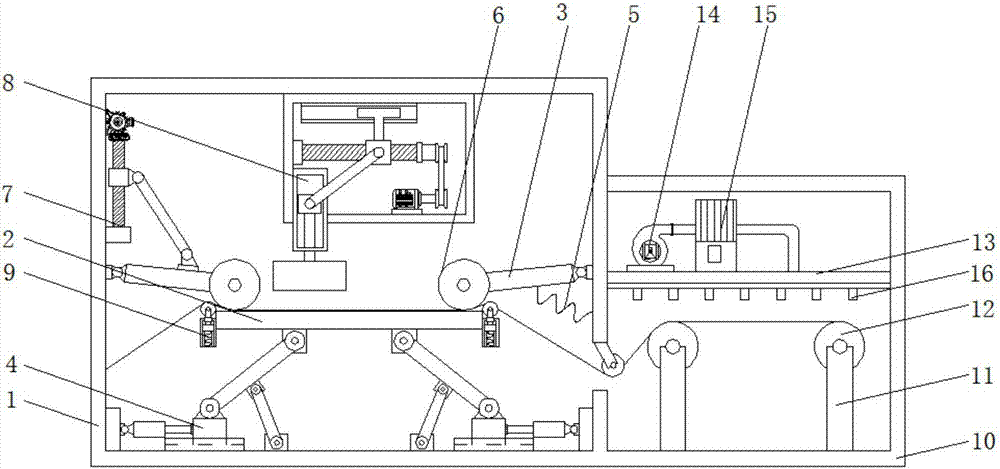

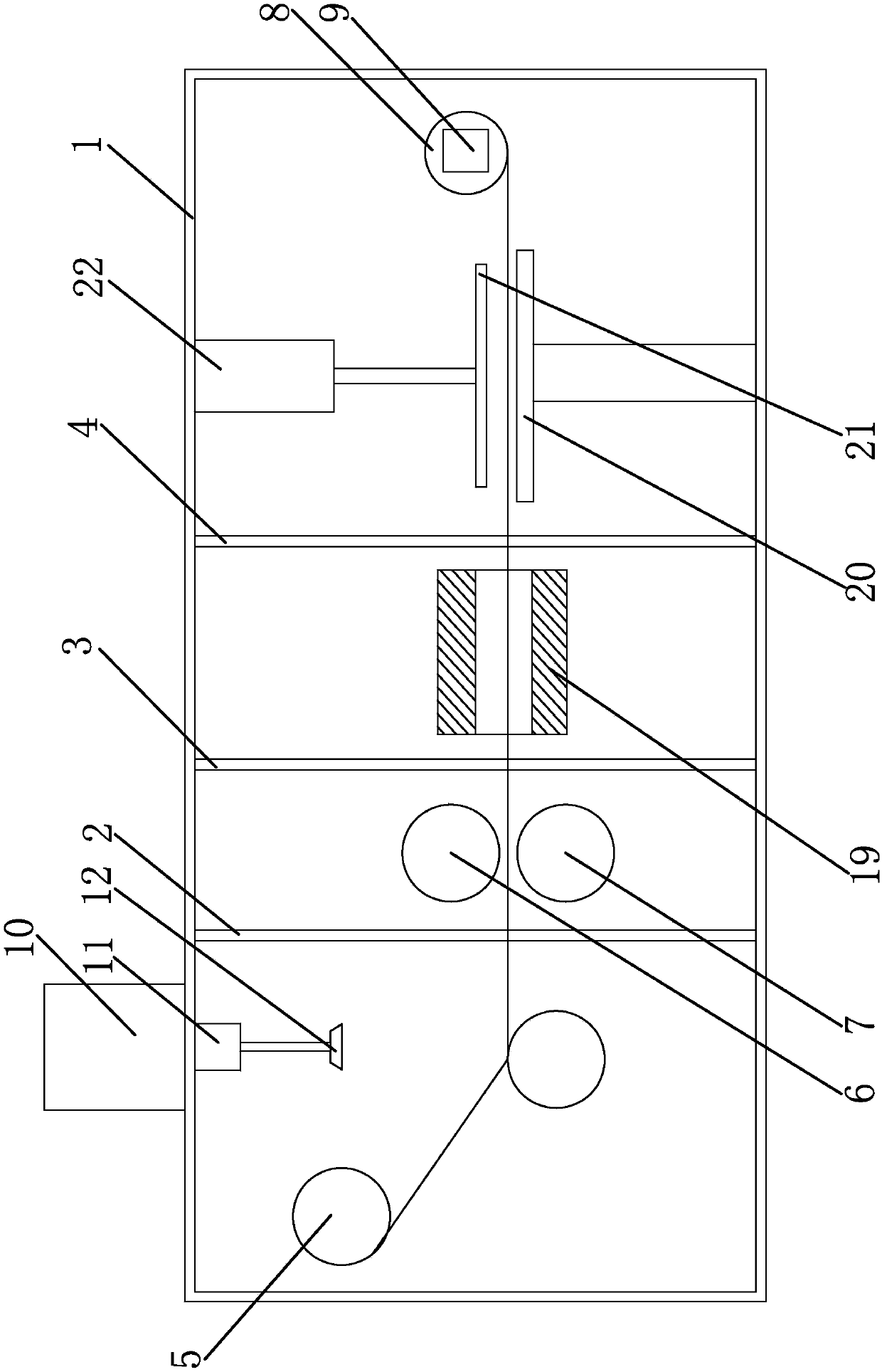

The invention provides printing and dyeing equipment. The printing and dyeing equipment comprises a dyeing box, a dewatering and drying mechanism and a printing machine which are arranged from left toright sequentially. The dewatering and drying mechanism comprises a dewatering mechanism, a water absorbing mechanism, an ironing mechanism and a drying machine which are arranged from left to rightsequentially. The dewatering mechanism comprises a guide rail frame. A water pressing roller is mounted in a groove of the guide rail frame movably through a wheel. An air cylinder is arranged on theright side of the guide rail frame. A piston rod of the air cylinder is connected with the water pressing roller. The water absorbing mechanism comprises a water pressing plate and a water absorbing roller. The printing and dyeing equipment has the advantages that centrifugal dewatering is not needed after textile dyeing through the dewatering and drying mechanism, so that flattening degree of textiles is guaranteed, and flattening on a scutcher is not needed; the dyeing equipment, the dewatering and drying equipment and the printing equipment are combined, so that equipment replacement time during working is reduced, dyeing and printing can be completed on one equipment, and working efficiency is improved.

Owner:TONGXIANG LONGXIANG PRINTING & DYEING CO LTD

Fabric shaping machine

ActiveCN107938233AImprove stylingWrinkles disappearHeating/cooling textile fabricsFabric finishing guides/expandersEngineeringMechanical engineering

The invention provides a fabric shaping machine, belongs to the technical field of shaping machine, and solves the problem of poor shaping effect in the prior art. The fabric shaping machine includesa machine box; the machine box is vertically fixedly provided with a first partition board, a second partition board and a third partition board; the interior of the machine box is divided into a first cavity, a second cavity, a third cavity and a fourth cavity by the first partition board, the second partition board and the third partition board successively; the first cavity is provided with anunreeling roller, the unreeling roller is arranged on the inner wall of the machine box by a circumferential rotation and axial fixing way, and the first cavity is provided with a humidification mechanism for humidifying a fabric; the second cavity is provided with a first heating roller and a second heating roller, and the first heating roller is located right above the second heating roller; themachine box is provided with an adjusting structure for adjusting the distance between the first heating roller and the second heating roller; the third cavity is provided with a drying mechanism which can be used for drying the fabric; the fourth cavity is provided with a cooling shaping mechanism which can be used for cooling and shaping the fabric. The fabric shaping machine has the advantageof good shaping effect.

Owner:浙江得伟科技股份有限公司

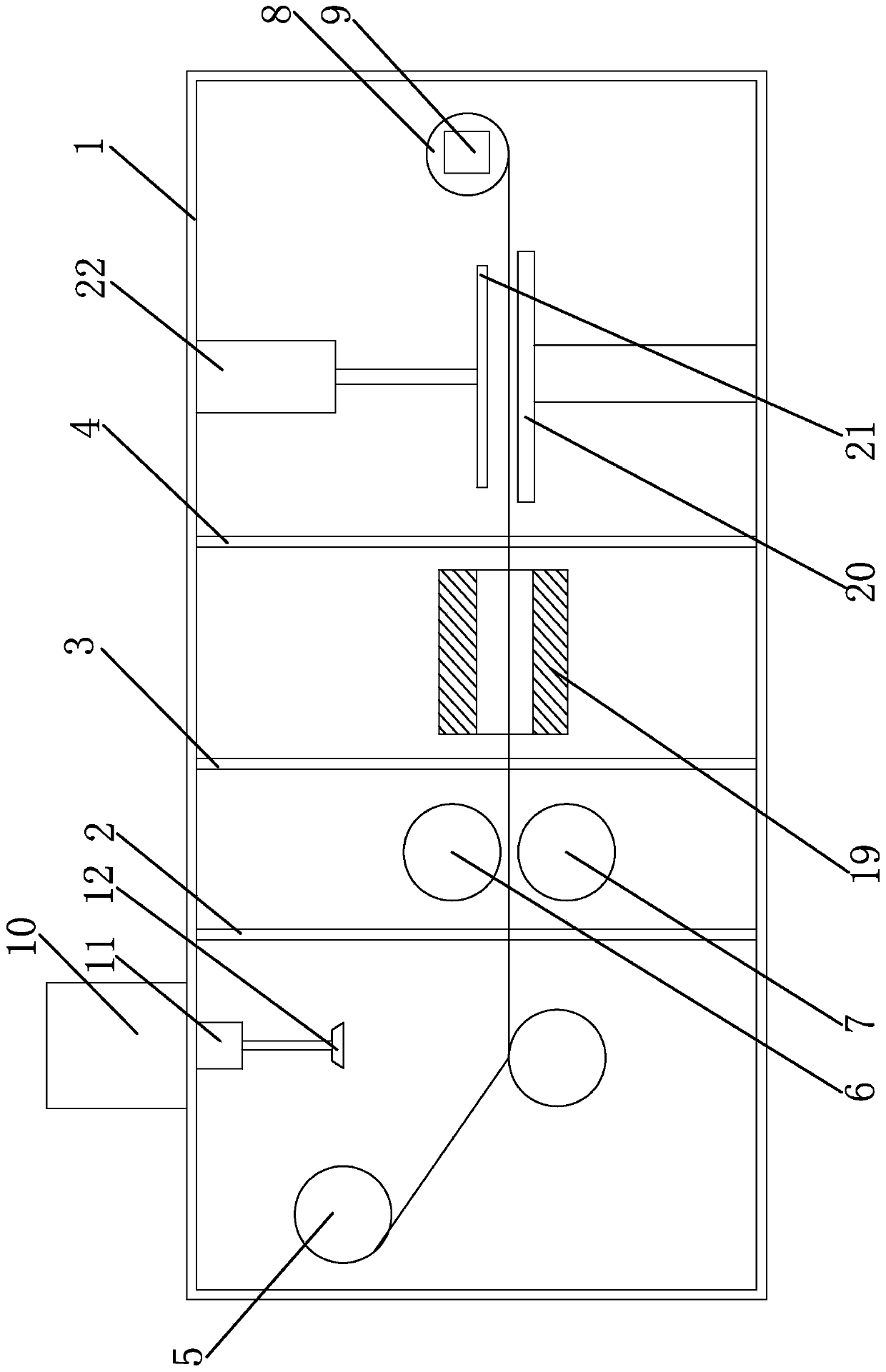

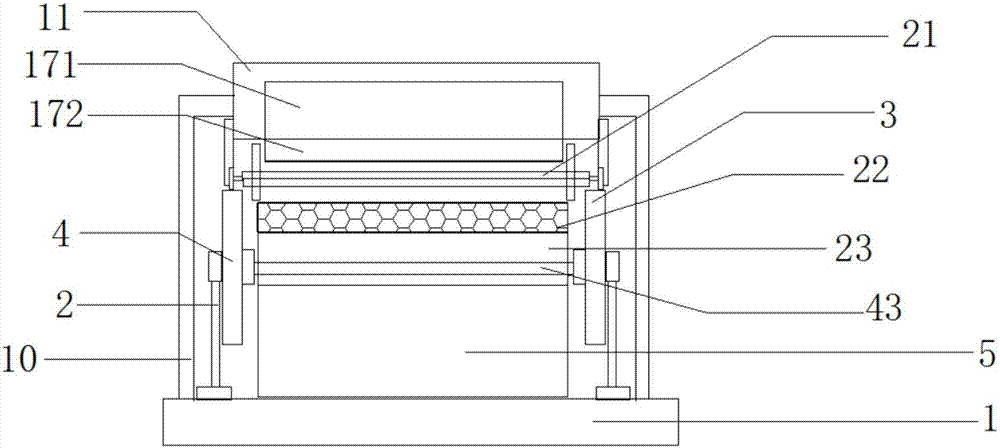

Anti-fold textile-fabric spraying drying system

InactiveCN106988061AGood effectUniform spray holeSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersBiochemical engineeringSpray drying

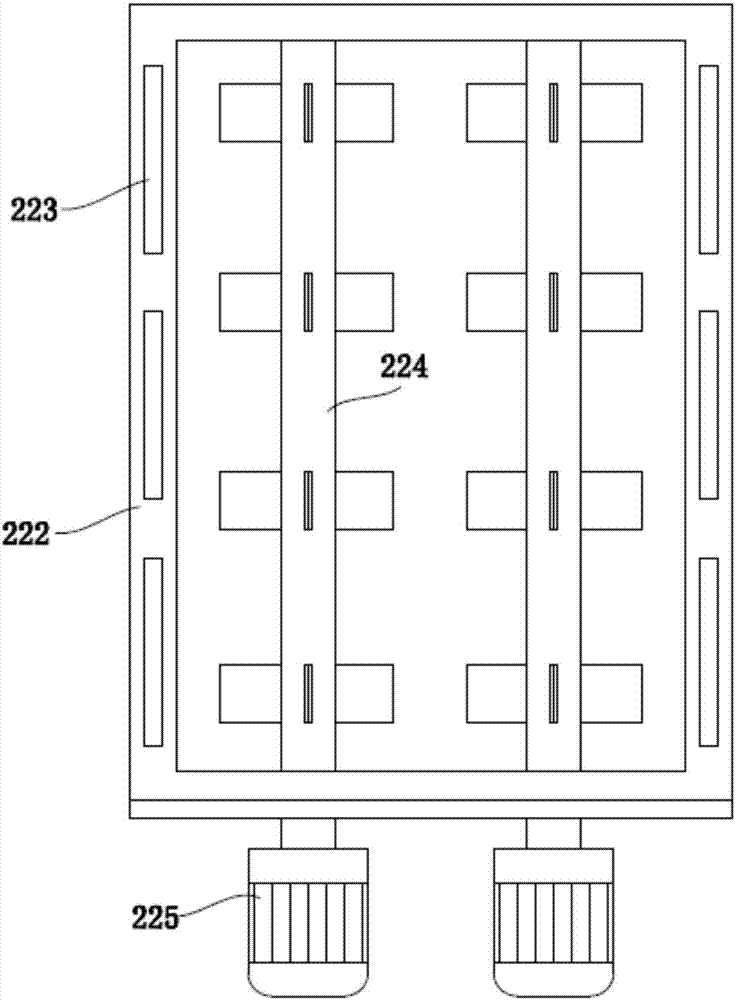

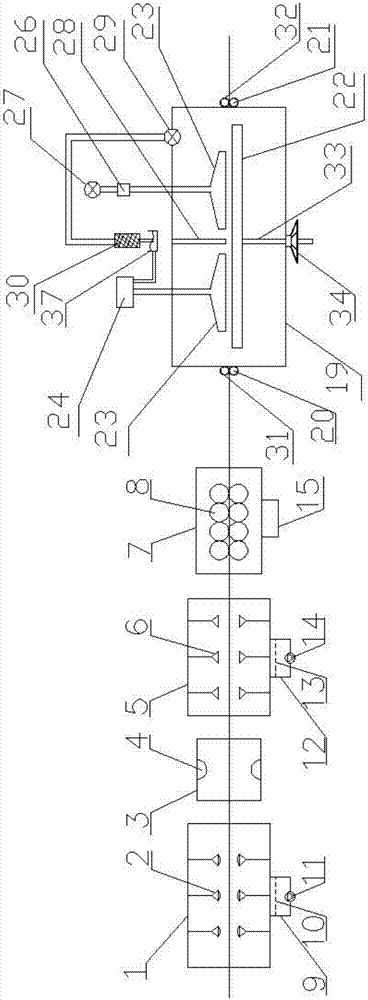

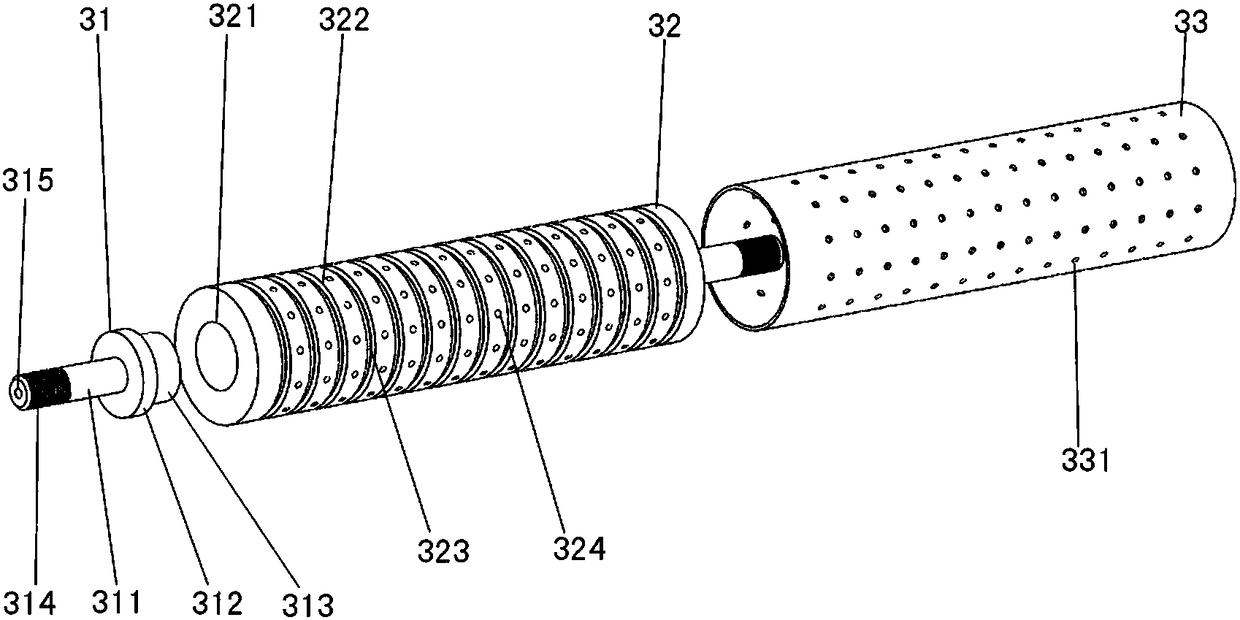

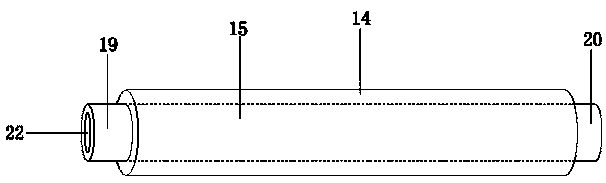

The invention discloses a spraying and drying system for anti-creasing textile fabrics, which comprises a dye box (1), the dye box (1) is provided with a plurality of dye nozzles (2); one end of the dye box (1) is provided with a heating box ( 3); the other end of the heating box (3) is provided with a rinsing box (5); the bottom of the dye box (1) is connected with a dye filter (9); the other end of the rinsing box (5) corresponding to the heating box (3) is provided with Dehydration box (7); the other end of the dehydration box (7) corresponding to the rinse box (5) is provided with a drying box (19); the inside of the drying box (19) is provided with a placement plate (22), and the top of the placement plate (22) One end is provided with a steam board (23); the other end above the placement board (22) is provided with a hot air board (25). The invention not only has uniform dyeing, reduces cost, improves dyestuff utilization rate, protects the environment, has good cloth drying effect and eliminates cloth deformation, but also has the advantages of ensuring cloth quality and high drying efficiency.

Owner:湖州南浔凯普纺织有限公司

Cloth drying equipment with leveling function used for textile processing

InactiveCN109137334AHeating fastReduce absorptionTextile treatment machine arrangementsFabric finishing guides/expandersEngineeringMechanical engineering

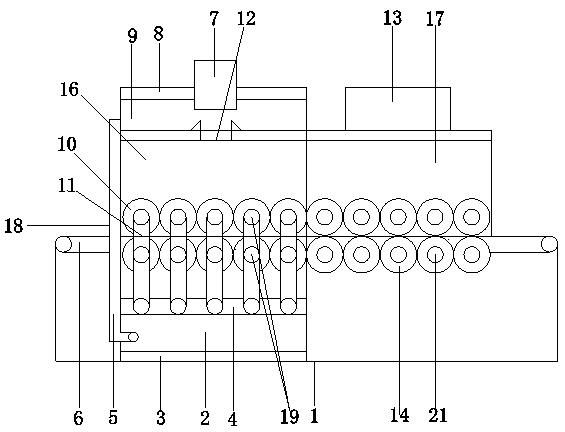

The invention discloses cloth drying equipment with a leveling function used for textile processing. The equipment comprises a box body, a separation plate, a feed inlet, a discharge port, conveyor roller groups, material guide roller groups and a rolling roller. The outer side of the discharge port is correspondingly provided with the rolling roller with driving clicking. Two conveyor roller groups are installed in a drying chamber. A vertical and adjustable scrape plate is arranged between the two conveyor roller groups. The two sides of a drying box are provided with the material guide roller groups. Clothes are sent to the drying box through the material guide roller groups. The right side of the drying box is provided with a leveling device. In the invention, the water of the sent clothes can be scraped under the effect of the scrape plate in the drying chamber, the scrape plate can adjust pressure according to the different materials of the clothes and the like, the water in theclothes can be scraped safely, the water absorbed in the clothes is reduced and a drying effect is increased. A contact roller in the drying box is fully contacted with the clothes, and high temperature air blown into from a lower portion can directly heat the contact roller so that the clothes can be heated rapidly.

Owner:陈璐

Singeing equipment with dust removing and drying effects

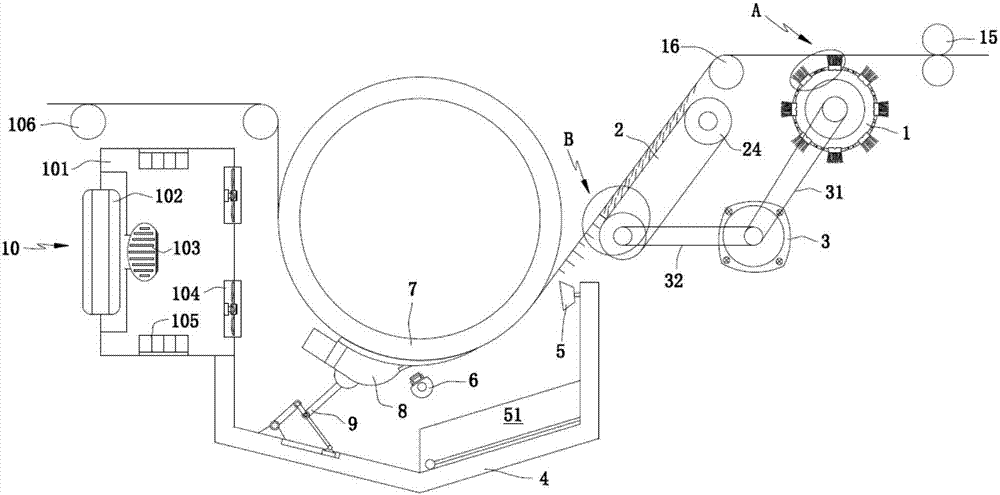

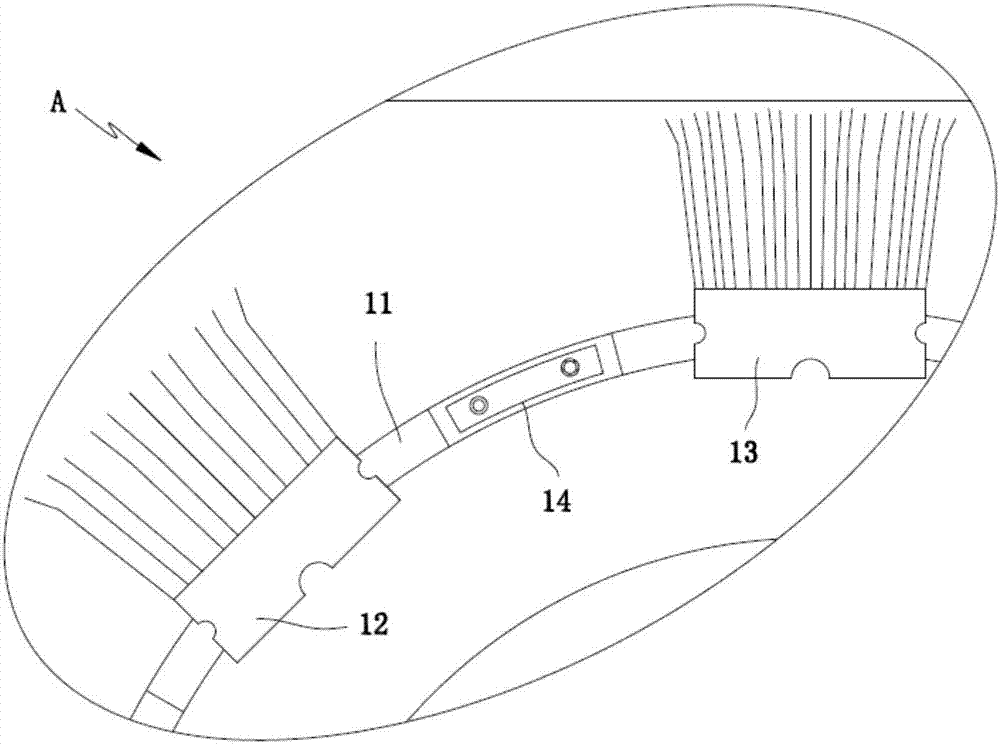

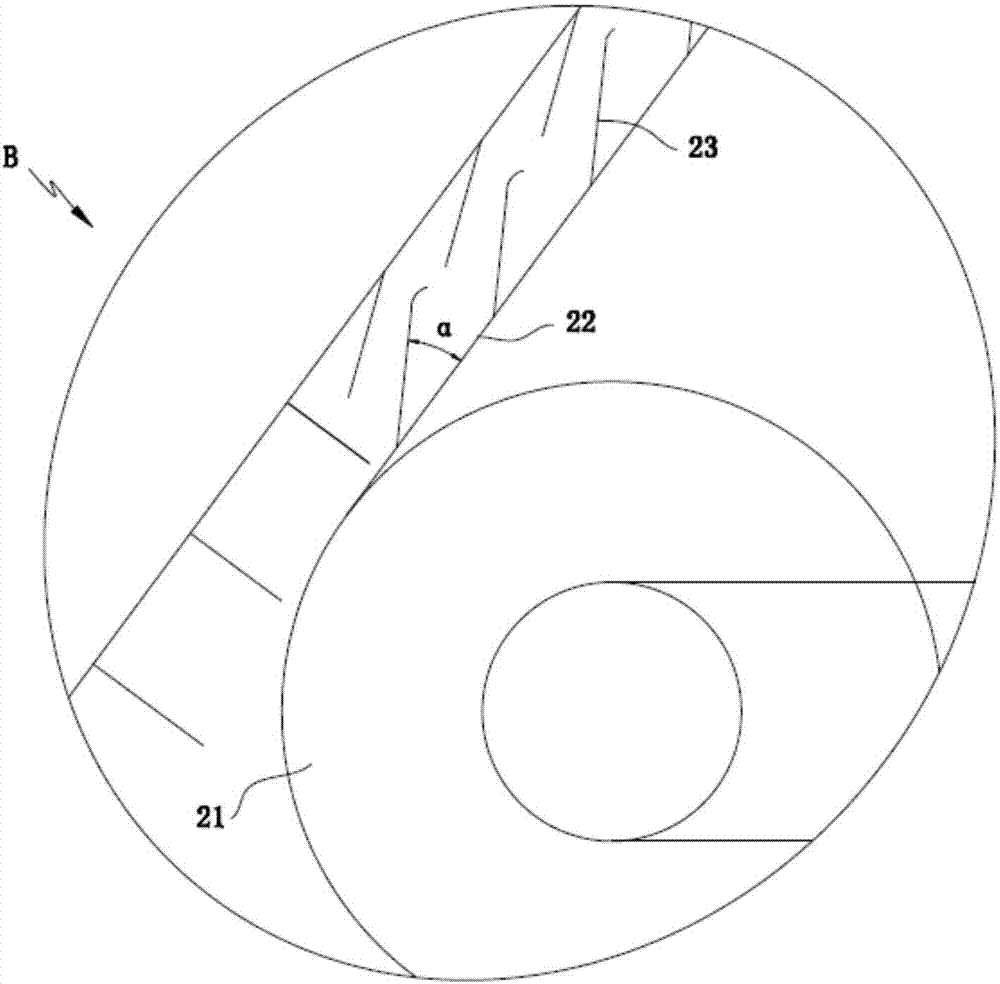

ActiveCN107956082AStraighten out fullyGood for singeingMechanical cleaningPressure cleaningEngineeringRight-to-left

The invention discloses singeing equipment with dust removing and drying effects. The singeing equipment with the dust removing and drying effects comprises a dust removing brush roller, a carding device, a singeing device and a drying device, wherein the dust removing brush roller, the carding device, the singeing device and the drying device are sequentially arranged from right to left; electrostatic adsorption plates are arranged between dust removing brushes of the dust removing brush roller; the carding device comprises a driving wheel, a carding belt and a driven wheel, and a plurality of carding needles are evenly arranged on the carding belt; the singeing device comprises a singeing table and an installing frame which are arranged up and down, a spraying head, a water storage pool,a singeing machine, a separating claw and a separating claw adjusting mechanism are arranged in the installing frame, the spraying head is installed at an inlet of the installing frame and connectedwith the water storage pool, the separating claw comprises a claw body and a dust storage cavity which are connected up and down, and the separating claw adjusting mechanism is installed at the lowerend of the separating claw. According to the singeing equipment with the dust removing and drying effects, through the dust removing brush roller and the carding device, fur on a textile fabric can befully smoothened, villus on the textile fabric is singed through the singeing device, the singeing effect is guaranteed, and damage to the textile fabric can be avoided.

Owner:浙江腾马纺织有限公司

Textile cloth washing equipment with drying mechanism

InactiveCN109680430ASmooth and tidy entryEnter cleanLiquid/gas/vapor removalTextiles drying apparatusEngineeringElectric heating

The invention discloses textile cloth washing equipment with a drying mechanism. The textile cloth washing equipment comprises a base, washing rolls and an infrared heating tube, wherein a tank body is mounted on the base, and a washing cavity is formed in the tank body; the washing rolls are mounted in the washing cavity, hairbrushes are mounted on the surfaces of the washing rolls, a first spraypipe is mounted in the washing cavity above the washing rolls, a cleaning cavity is formed in the tank body on one side of the washing cavity, a drying room is formed in the tank body on one side ofthe cleaning cavity, the infrared heating tube is arranged on the inner wall of the drying room, and ultraviolet lamps are mounted on the inner walls of two sides of the drying room; and an ironing room is formed in the tank body on one side of the drying room. By arranging the washing rolls, the first spray pipe, a second spray pipe, the hairbrushes, the infrared heating tube, the ultraviolet lamps, an electric heating pipe, a metal plate, a pressure plate and a draught fan structure, the problems that an existing equipment is not provided with a drying structure, and the rapid ironing and flatting cannot be realized are solved.

Owner:上海有洗洗涤设备有限公司

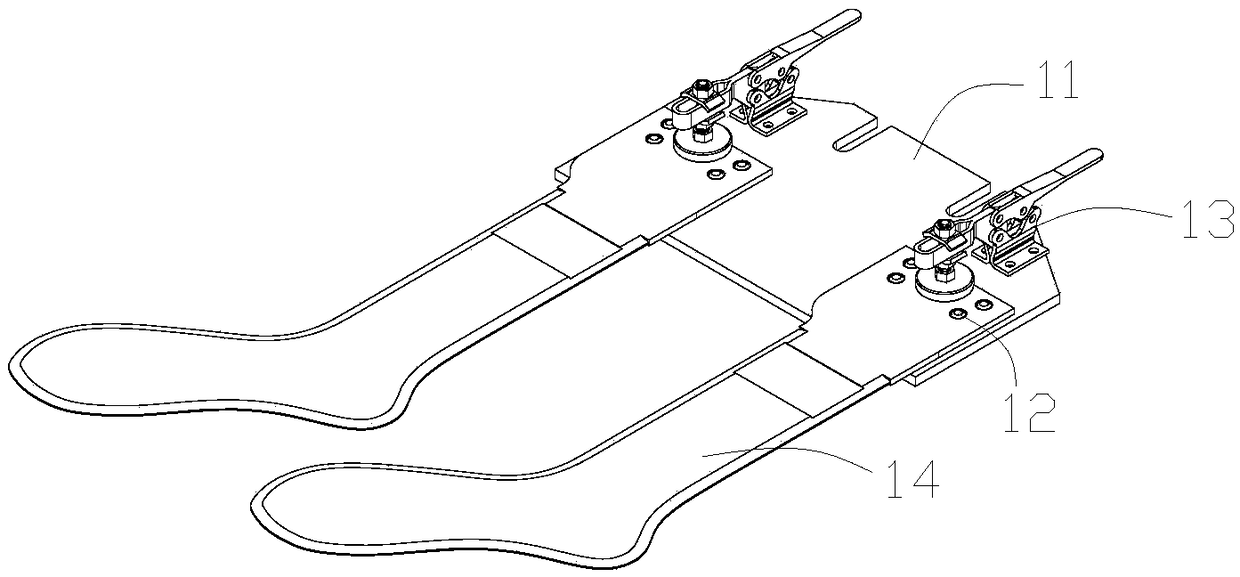

Cloth drying device for cotton sock processing

InactiveCN112050563ASpeed up the flowRealize the blast drying effectDrying solid materials without heatDrying gas arrangementsReciprocating motionElectric machinery

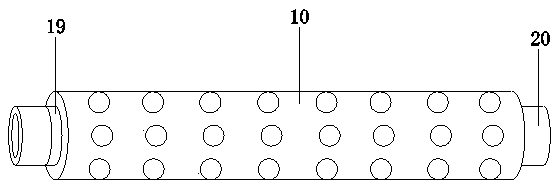

The invention discloses a cloth drying device for cotton sock processing, and relates to the technical field of cotton sock production. The cloth drying device comprises a supporting frame, a double-shaft motor and an air heater are fixed to the supporting frame, a drying mechanism used for drying cloth is rotationally installed on a movable frame, a reciprocating mechanism used for driving the movable frame to do transverse reciprocating motion is arranged on the movable frame, and a rolling mechanism for flattening the cloth is arranged at the bottom of the movable frame. Hot air generated by the air heater is blown through spray heads in the drying mechanism, the air blowing drying effect on the cloth is achieved, the reciprocating mechanism can drive the movable frame to do transversereciprocating motion, the drying mechanism can do transverse reciprocating motion, sufficient drying treatment on different positions of the cloth is achieved, meanwhile, in the moving process, hollowrotating rollers can achieve a rotating effect, air flowing around the cloth is effectively promoted, the sufficient drying effect on the cloth is guaranteed, and the drying efficiency and the dryingsufficiency are remarkably improved.

Owner:诸暨市佳叶袜业有限公司

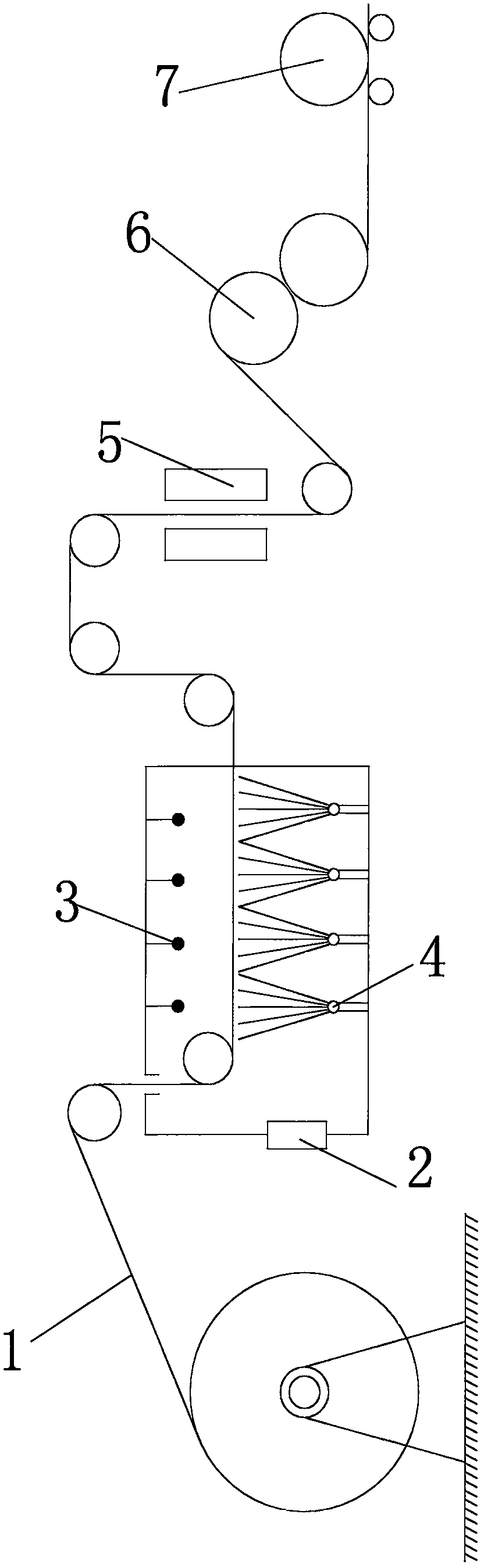

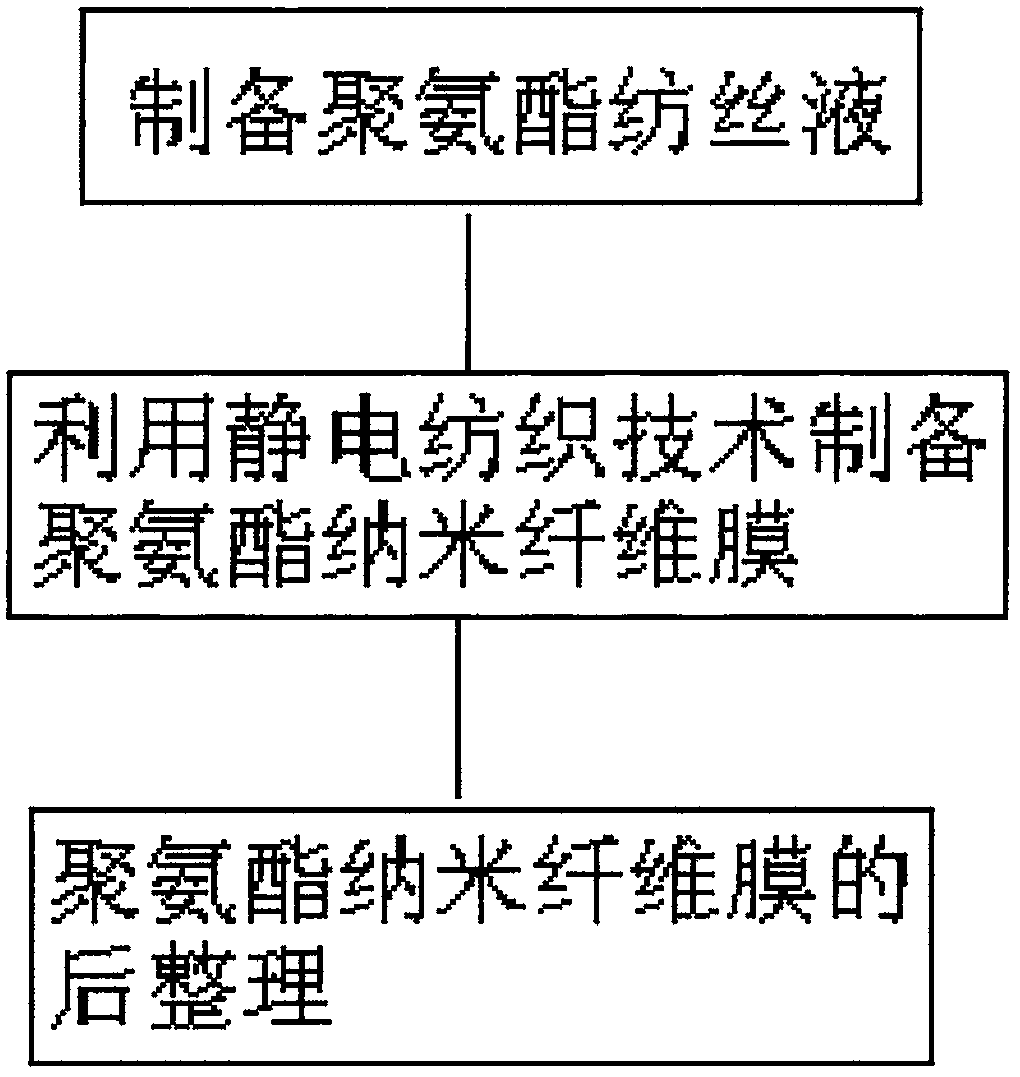

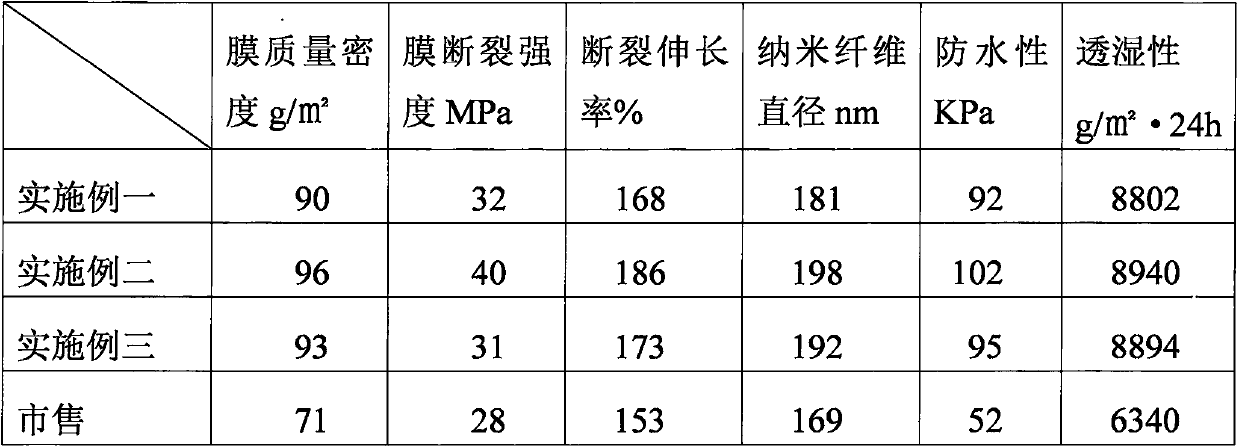

Preparation method of thermoplastic polyurethane nanofiber membrane

InactiveCN108049026AImprove the deposition effectAchieve serializationFilament/thread formingHeating/cooling textile fabricsNeedle freePorosity

The invention provides a preparation method of a thermoplastic polyurethane nanofiber membrane and solves the technical problem that the thermoplastic polyurethane membrane of the prior art cannot block liquid and has no high moisture permeation. The preparation method of the thermoplastic polyurethane nanofiber membrane is characterized by comprising the steps of 1) preparing a polyurethane spinning liquid; 2) depositing the polyurethane spinning liquid on a nanofiber membrane by means of a needle-free electrostatic spinning technique to obtain a web-like fiber membrane; 3) post-finishing thepolyurethane spinning liquid. An electrostatic field constructed with two needle-free electrode wires allows thermoplastic polyurethane electrostatic spinning to be performed to obtain a membrane that has morphology of a spiker web, fiber threads are about 200 nm in diameter, and the membrane has high porosity and large specific surface area.

Owner:QINGDAO UNIV

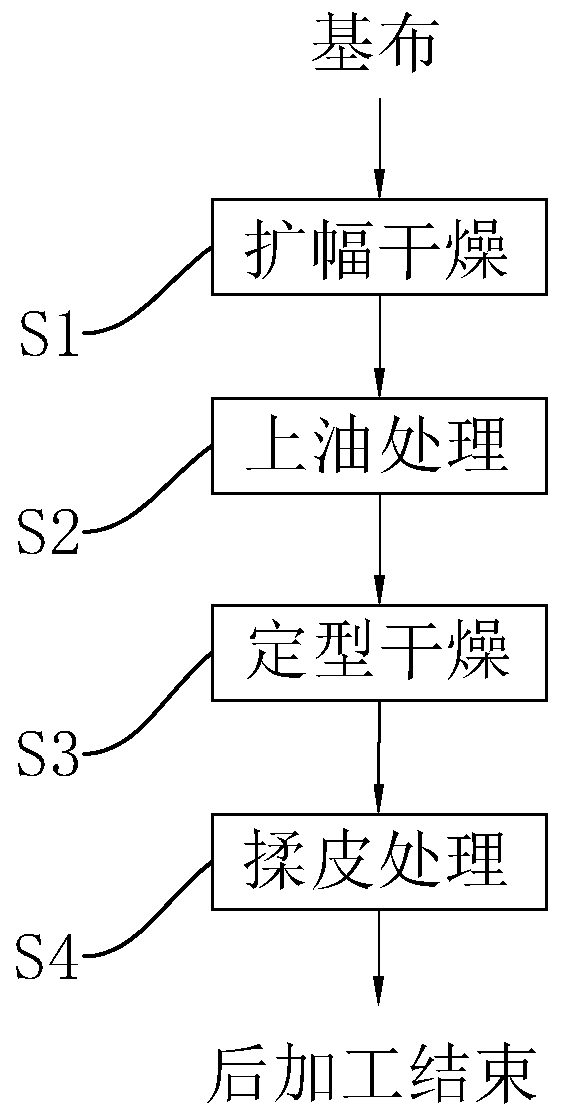

Base fabric post-processing technology for superfine fiber synthetic leather

ActiveCN110306315AHigh tear strengthAvoid wrinklesFabric breaking/softeningGrip property fibresKojic acidFiber

The invention relates to the technical field of preparation methods of superfine fiber synthetic leather, and discloses a base fabric post-processing technology of superfine fiber synthetic leather. Adecreased base fabric is treated by the technology comprising the following steps: S1, expanding and drying; S2, oiling, wherein the base fabric which is expanded and dried in step S1 is repeatedly soaked in an oiling agent. The oiling agent comprises the following chemical components in parts by weight: 40-60 parts of amino silicone oil, 30-50 parts of aminopropanol kojic acid phosphate, 6-9 parts of diatomite, 3-7 parts of talcum powder and 10-14 parts of a surfactant; S3, shaping and drying; and S4, carrying out puffing treatment. By using the oiling agent mentioned above, the tearing strength of the base fabric is improved.

Owner:浙江永祥合成材料有限公司

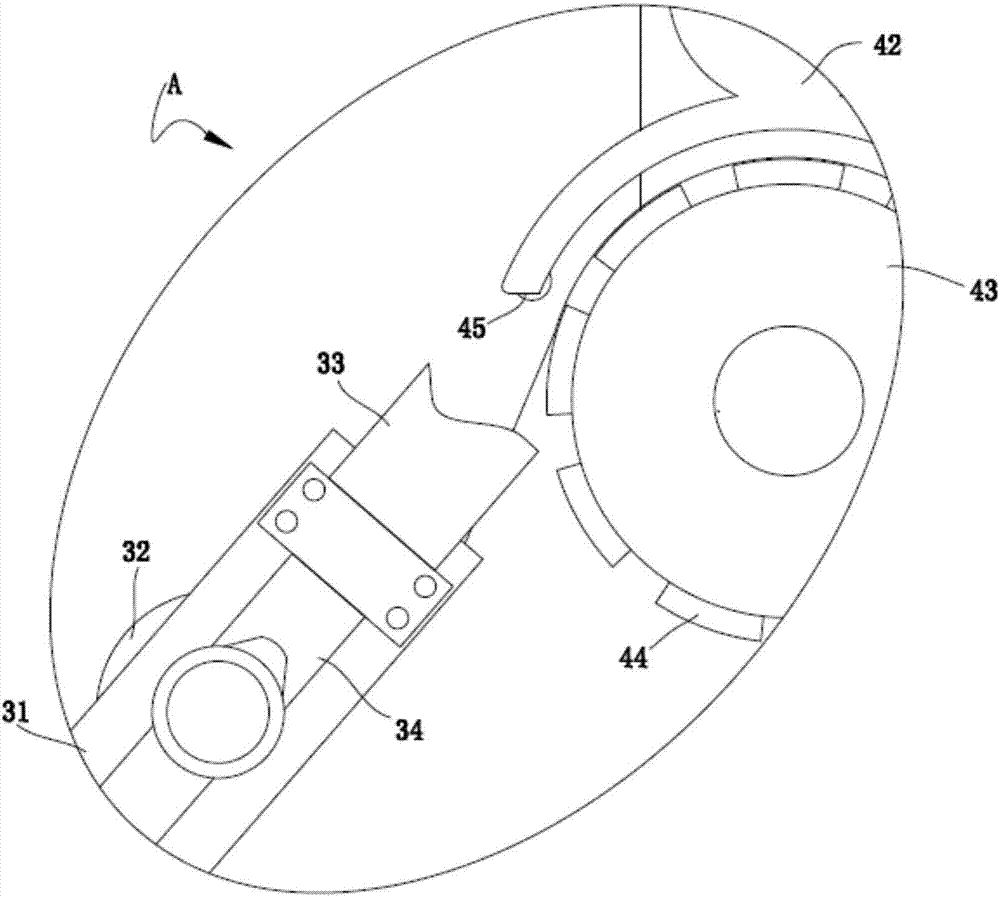

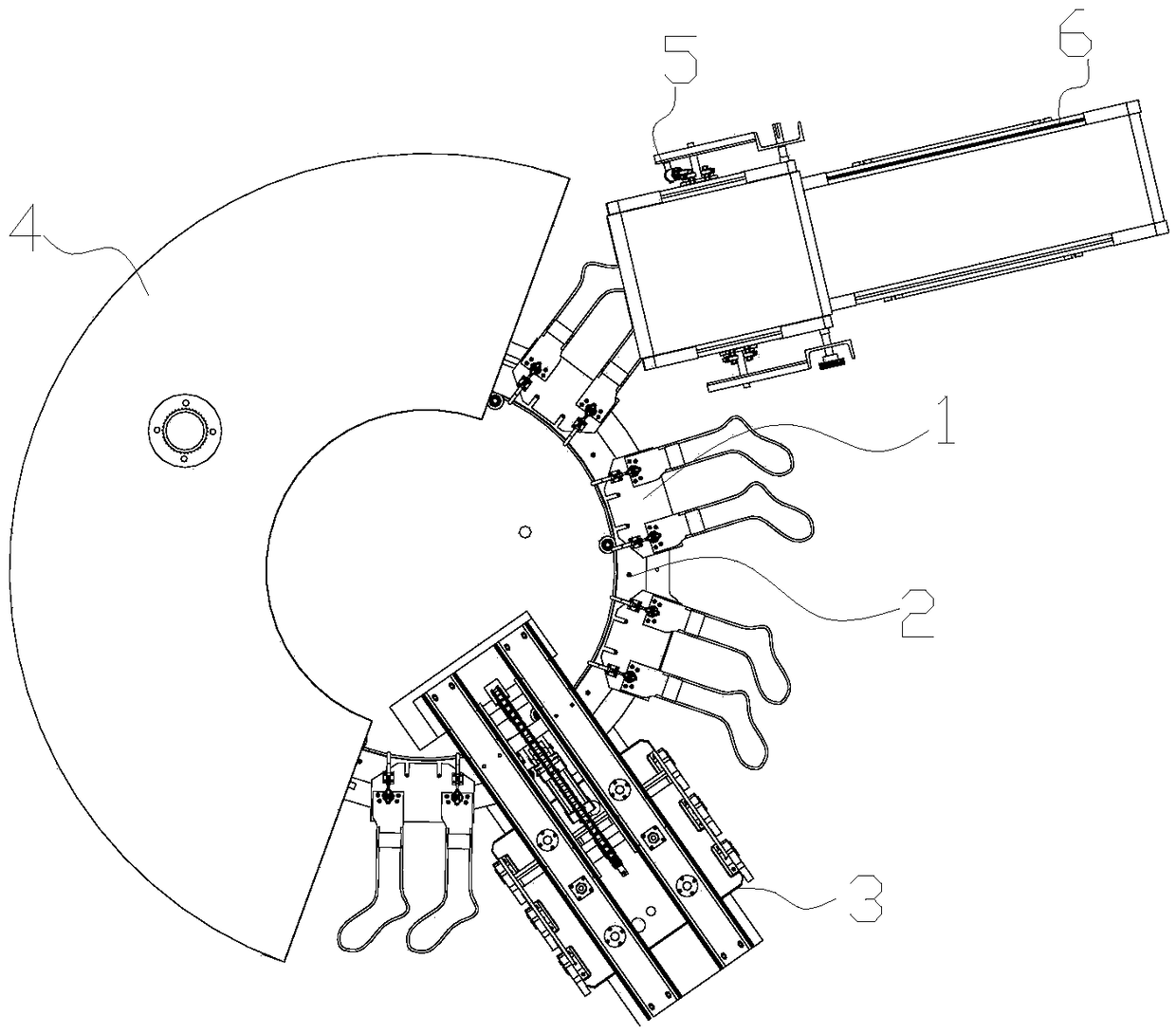

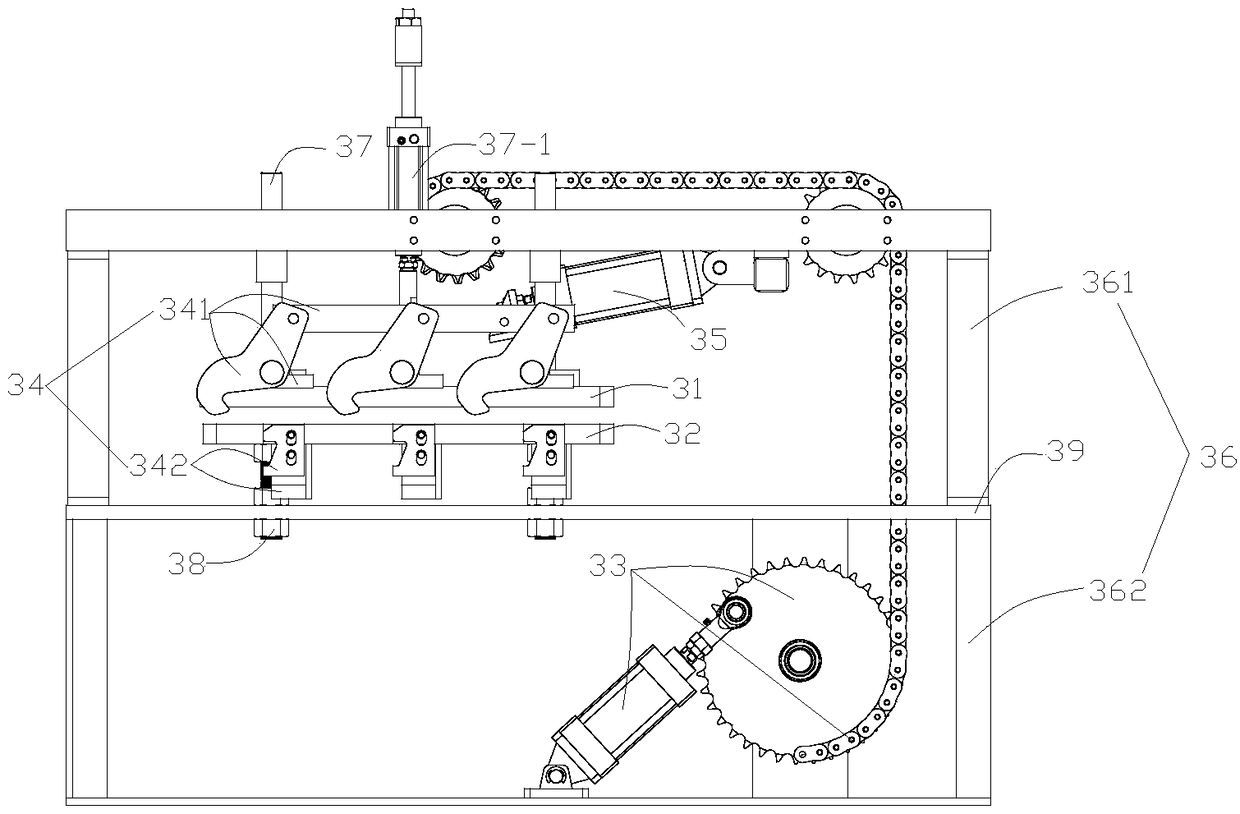

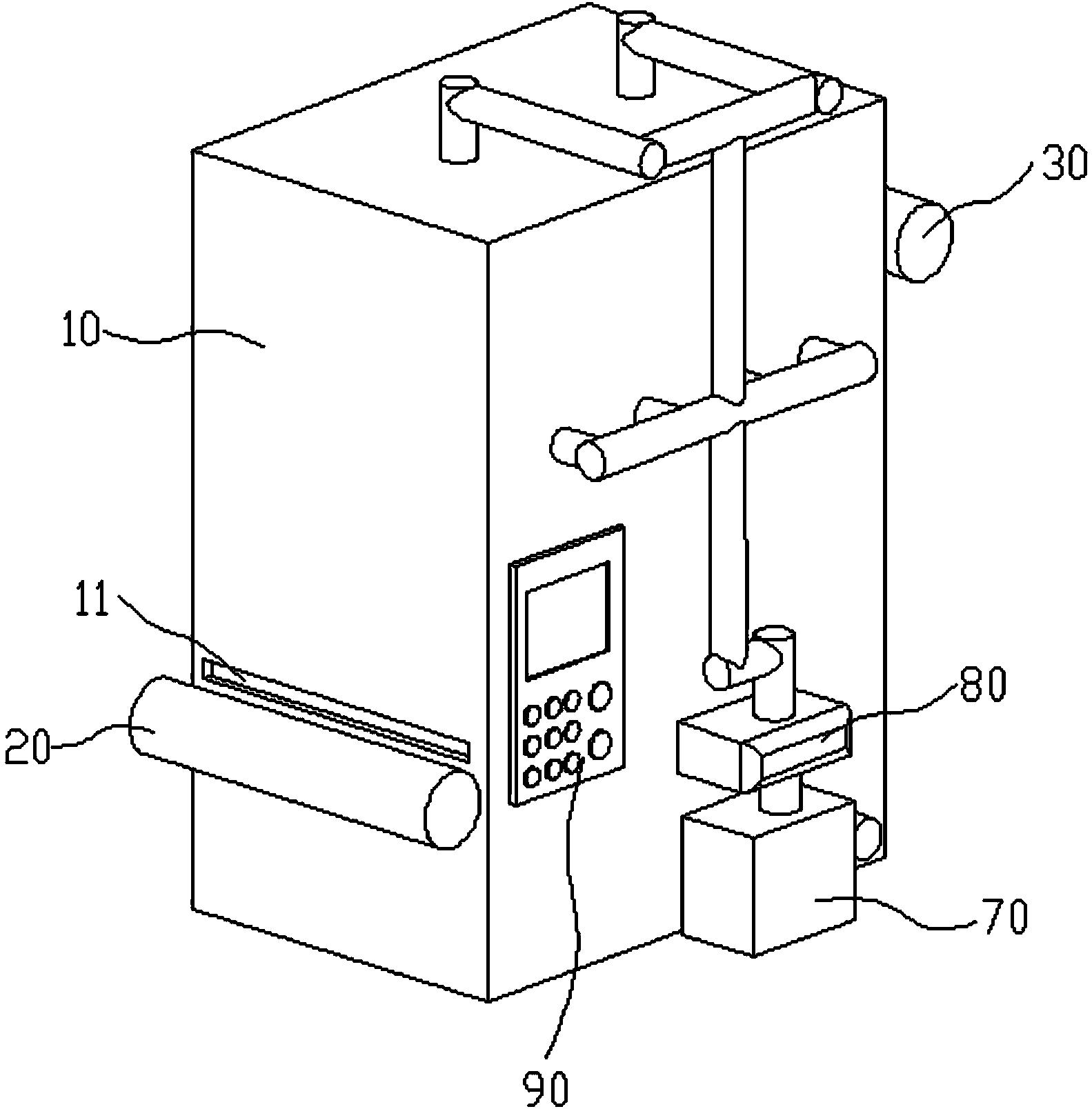

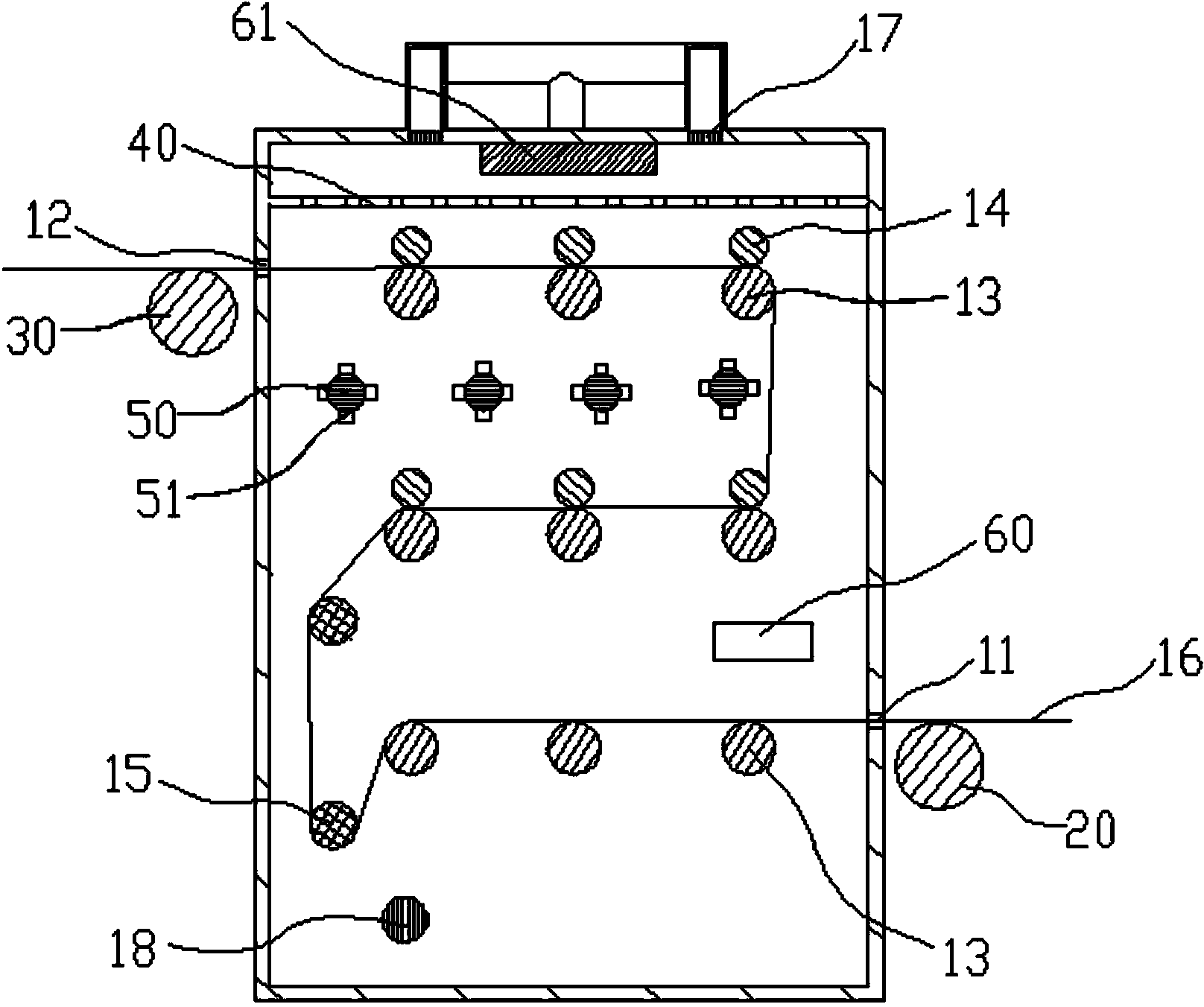

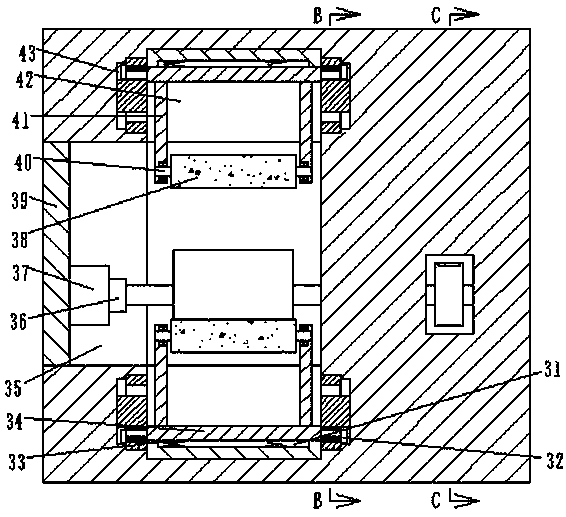

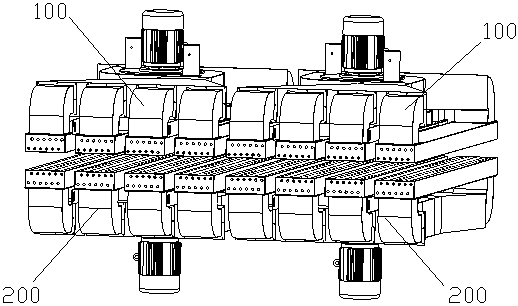

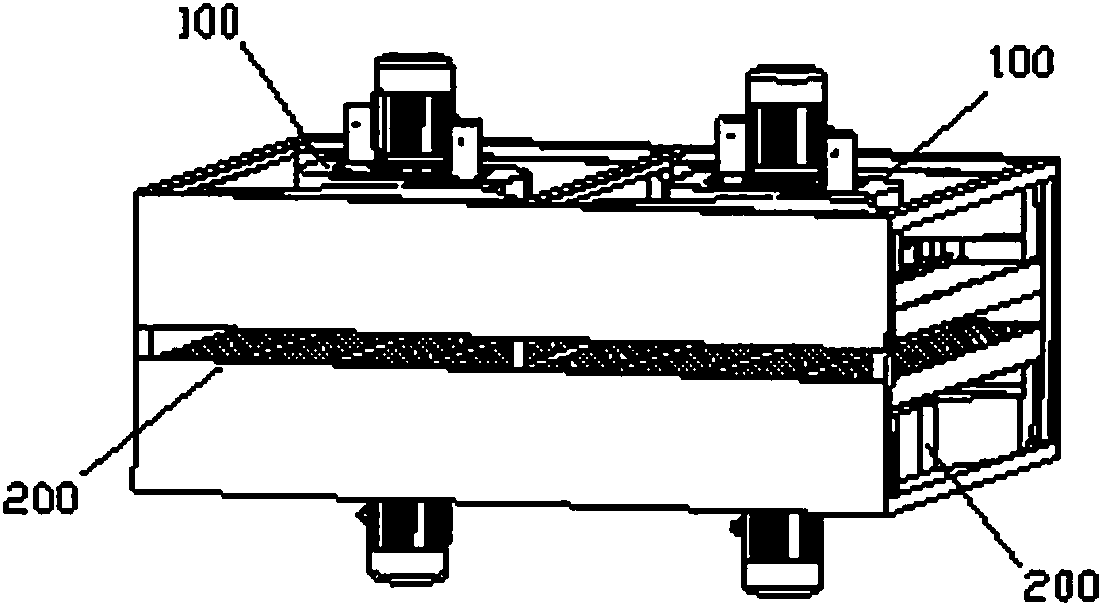

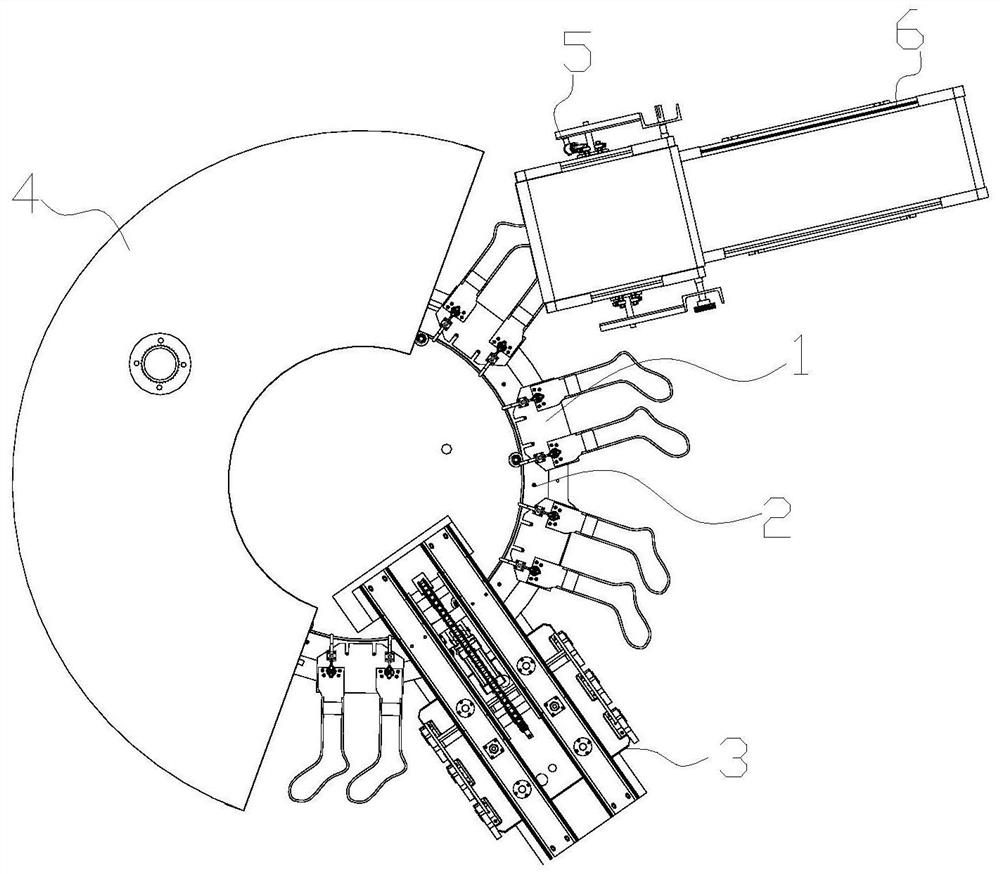

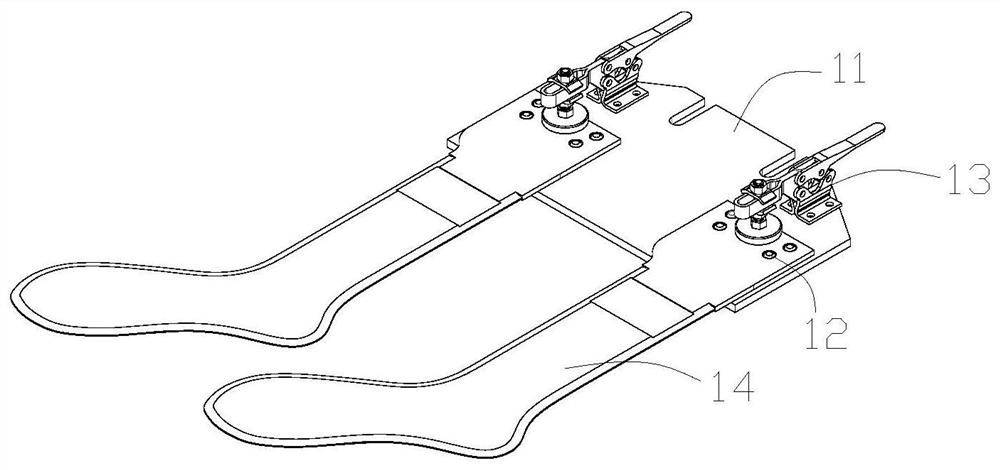

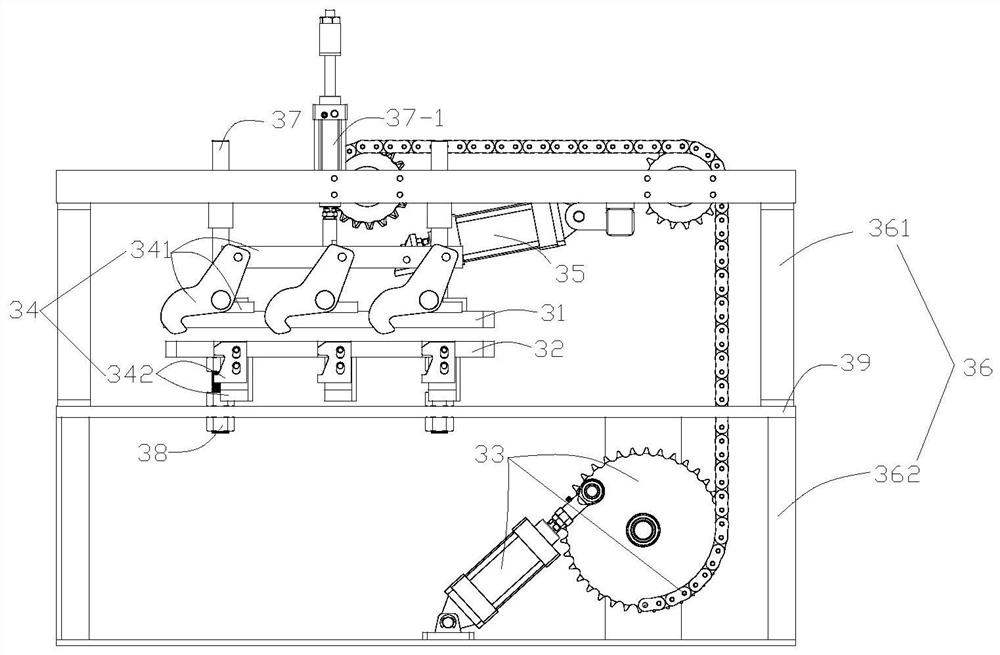

Plane shaping machine

ActiveCN108691131ATextiles drying apparatusShaping/stretching tubular fabricsEngineeringMechanical engineering

The invention relates to a plane shaping machine. The plane shaping machine comprises a rotary disc, a drying device, a stock discharge conveying device, and a stock steam shaping device. The plane shaping machine is characterized by also comprising a sock discharge device and a plurality of shaking installation bases, wherein the shaping installation bases are distributed on the rotary disc in acircumference array way; the stock discharge device is butted with the stock discharge conveying device; the stock steam shaping device, the drying device and the stock discharge device are sequentially arranged at the outer side of the rotary disc. The plane shaping machine has the advantages that the stock height is low, and the servicing and maintenance are convenient; an operator can sit on achair to charge the stock, so that the working difficulty is decreased; the occupation space of the whole machine is small, the manufacturing cost is low, the drying efficiency is quick, and the stockdischarge speed is quick.

Owner:DONGGUAN KEMEI MACHINERY

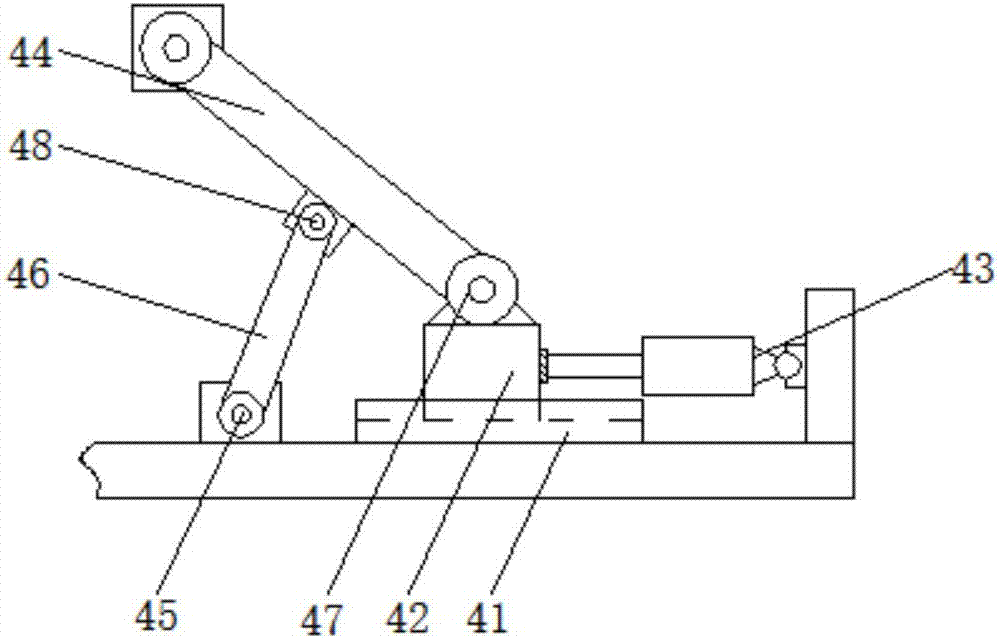

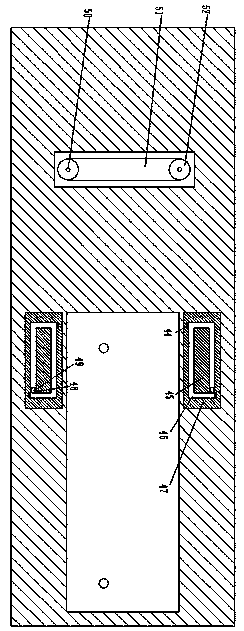

Unhairing equipment for waste textile fabric

InactiveCN109695120AStable deliveryAchieve anti-wrinkle levelingMechanical cleaningPressure cleaningWrinkle skinMechanical equipment

The invention discloses unhairing equipment for a waste textile fabric and belongs to the field of textile mechanical equipment. The unhairing equipment comprises a supporting table, an emptying device, a lower unhairing device, an upper unhairing device, a wrinkle-removing device, a spraying device, a drying device and a rolling device. The emptying device, the wrinkle-removing device, the dryingdevice and the rolling device are arranged on the supporting table along a straight line, an unhairing window is formed in the supporting table, the unhairing window is located between the emptying device and the wrinkle-removing device, the lower unhairing device and the upper unhairing device are separately located right below and right above the unhairing window, the spraying device is mountedon the wrinkle-removing device, positioning devices are arranged on two sides of the unhairing window, mounting seats are arranged between the drying device and the rolling device on the supporting table, and two transitional rollers are rotatably mounted on the mounting seats. The unhairing equipment unhairs the upper and lower surfaces of the waste textile fabric automatically and can remove wrinkles and level the waste textile fabric, so that the quality of the upper and lower surfaces of the waste textile fabric is improved.

Owner:曹钧恩

Wrinkle-removal finishing device of multi-functional military textile fabric

InactiveCN107190452AEasy to useImprove drying efficiencyTextiles drying apparatusTransmission beltAgricultural engineering

The invention discloses a wrinkle-removing and finishing device for military multifunctional textile fabrics, which comprises a support plate, the four corners of the bottom of the support plate are fixedly connected with support legs, the top of the support plate is fixedly connected with a connecting block, and the connecting block The front of the drying box is fixedly connected with a drying box, the bottom of the drying box is sleeved with a pressing block, both sides of the top of the drying box are fixedly connected with a first motor, and the bottom end of the first motor shaft runs through the drying box. The dry box extends to the interior of the drying box and is fixedly connected with fan blades. The present invention makes the drying and wrinkle removing device easy to use by setting a drying box, a briquetting block, a first motor, a fan blade, a heating wire, an air outlet, a spring, a hot air hole, a second motor and a transmission belt, and the drying and wrinkle removing device The drying efficiency is higher, the temperature in the drying and wrinkle removing device is more uniform, and continuous drying can be performed, which can meet the needs of many textile manufacturers and is beneficial to people's use.

Owner:浙江盛伦科技有限公司

Printing, dyeing and drying equipment with dedusting function for spinning

InactiveCN108505253AEasy to replaceImprove drying efficiencyTextile treatment machine partsLiquid/gas/vapor removalEngineeringLeft wall

The invention provides printing, dyeing and drying equipment with a dedusting function for spinning. The equipment includes a drying box body, the left wall of an inner cavity of the drying box body is fixedly connected with a clapboard, the right side of the clapboard is fixedly connected to the right wall of the inner cavity of the drying box body, a motor is fixedly installed on the left side of the top of the clapboard, a first gear is fixedly connected to an output end of the motor, a rotating shaft is movably connected to the top of the clapboard, the top of the rotating shaft is movablyconnected to the top wall of the inner cavity of the drying box body, and a second gear is fixedly installed on the surface of the rotating shaft. According to the printing, dyeing and drying equipment with the dedusting function for spinning, through arrangement of the motor, the first gear, the rotating shaft, the second gear and a bearing net framework, a box door is opened, the motor is switched on, the first gear is driven to rotate by the rotating output end of the motor and then drives the second gear to rotate, correspondingly the rotating shaft is driven to rotate by the second gear,and therefore the bearing net framework is driven by the rotating shaft to rotate, so that the effect of providing convenience for replacing printing and dyeing cloths on the top of a net base is achieved.

Owner:刘州豪

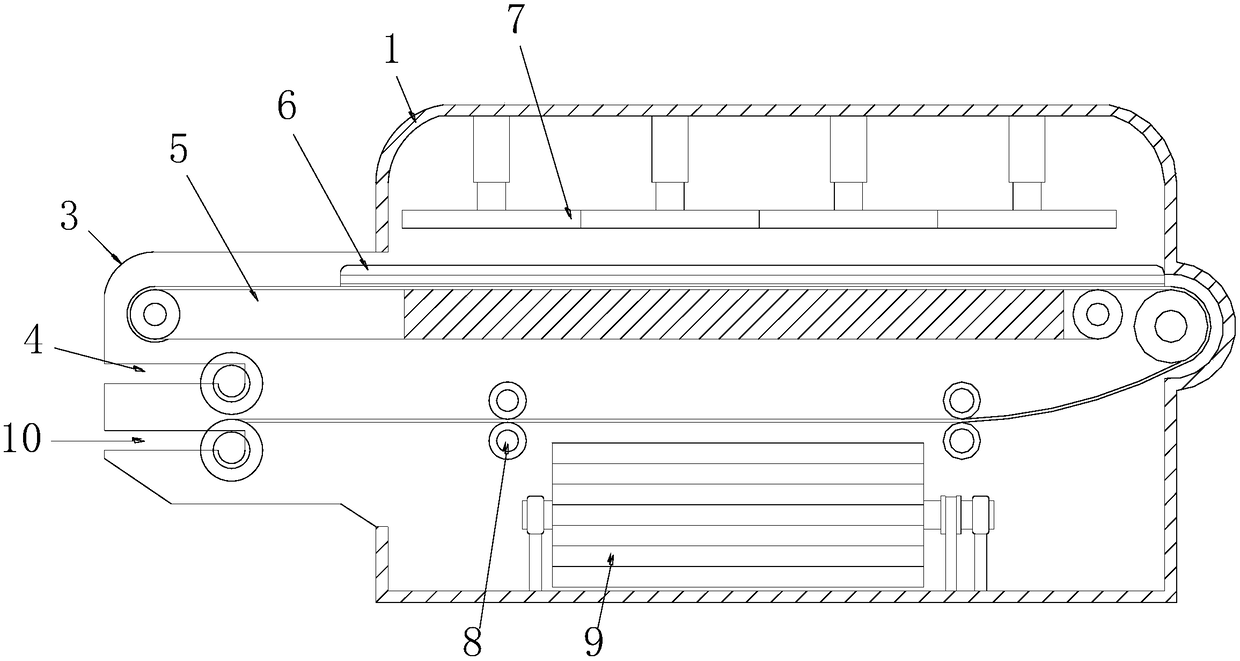

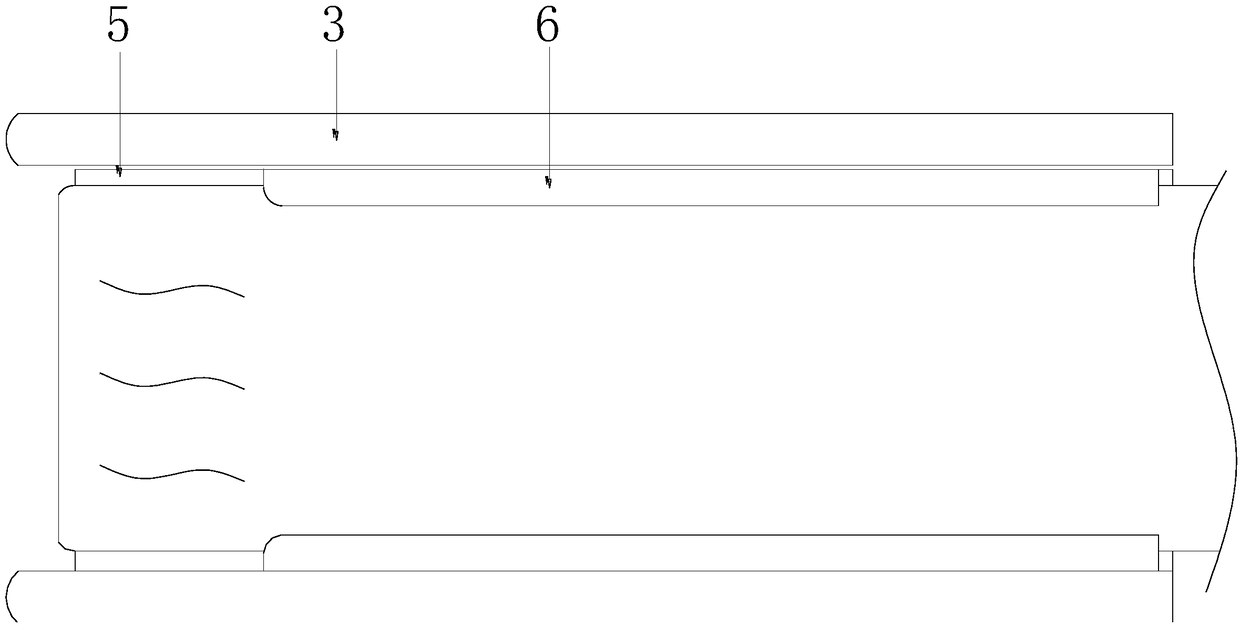

Automatically-rolling fabric drying and dust-removing device

InactiveCN108149431AEasy to dryRemovableMechanical cleaningPressure cleaningEngineeringFront and back ends

The invention discloses an automatically-rolling fabric drying and dust-removing device. The device comprises a base in an elongated concave shape, notches are formed in the middles of the two side walls of the base, a roller and rolled fabric are hinged between the two side walls of the front and back ends of the base respectively, the roller is connected to a drive device installed in an installation groove formed in the upper surface inside the base, multiple drying devices are arranged between the two side walls of the base, first adsorption devices are arranged on the upper surfaces of the two side walls of the base and opposite to the drying devices, and a second adsorption device is arranged on the upper surface inside the base. The automatically-rolling fabric drying and dust-removing device has the advantages that the device can dry the fabric quickly and iron the wrinkled surface of the fabric in the drying process, and has the effect of removing dust and nap; meanwhile, thedevice can automatically roll the dried fabric, which is very convenient.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

Thin clothes ironing and drying integrated machine

InactiveCN109137353AFast ironing and dryingImprove ironing effectFabric finishing guides/expandersTextiles drying apparatusProcess engineeringWater collection

The invention discloses a thin clothes ironing and drying integrated machine. The thin clothes ironing and drying integrated machine comprises an ironing equipment body, a steam ironing roller and a heating ironing roller; a water tank, a heating pipe, a joint bracket, a backflow pipe, a conveying belt, an exhaust fan, a condenser pipe, a liquefied water collection tank, the steam ironing roller,a steam conveying pipe, a steam outlet, a fan, the heating ironing roller, a heating pipe, a steam ironing box, a dry ironing box, a material inlet, an electromagnetic valve, a joint, a driving motorand a wire through hole are arranged on the ironing equipment body; as the steam ironing box and the dry ironing box are combined on the ironing equipment body, thin clothes are steam-ironed by usingthe steam ironing box first, and then are fed into the dry ironing box to be secondarily ironed; and meanwhile, the steam in the first ironing is removed. The thin clothes ironing and drying integrated machine disclosed by the invention has the advantages of reasonable design, high ironing and drying speed and good ironing effect.

Owner:NANTONG HECHENG TEXTILE CO LTD

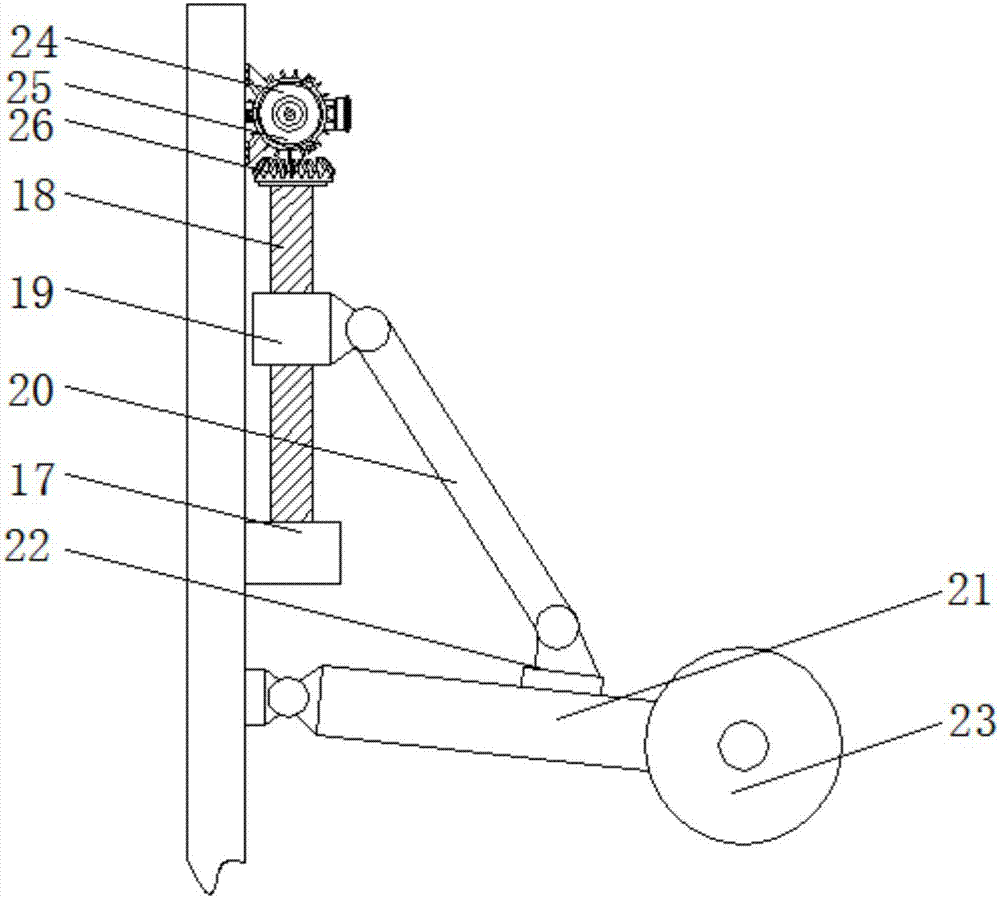

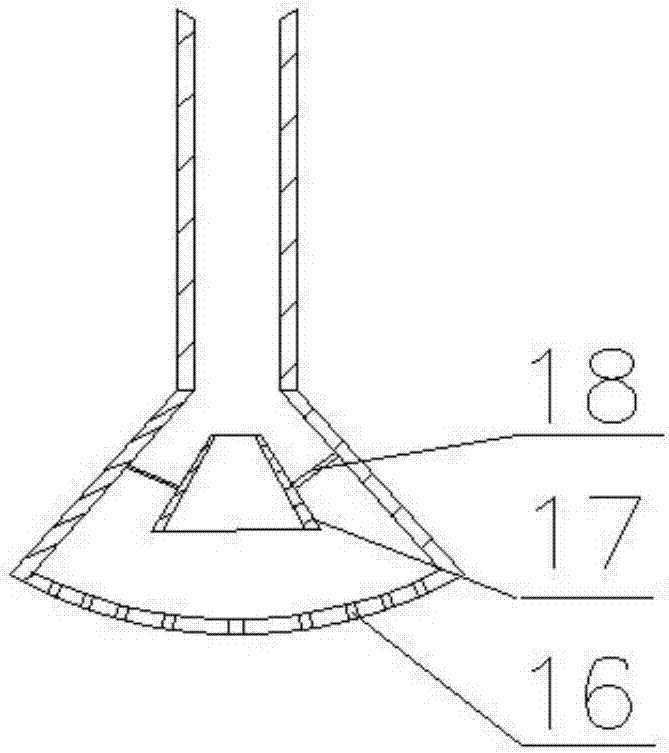

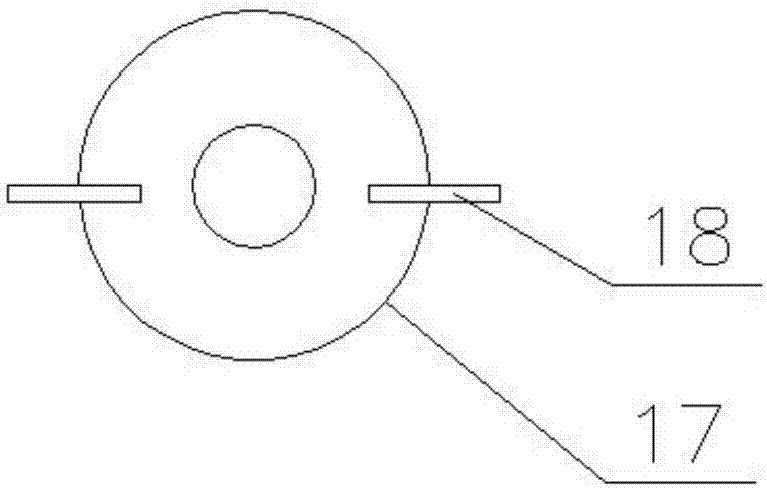

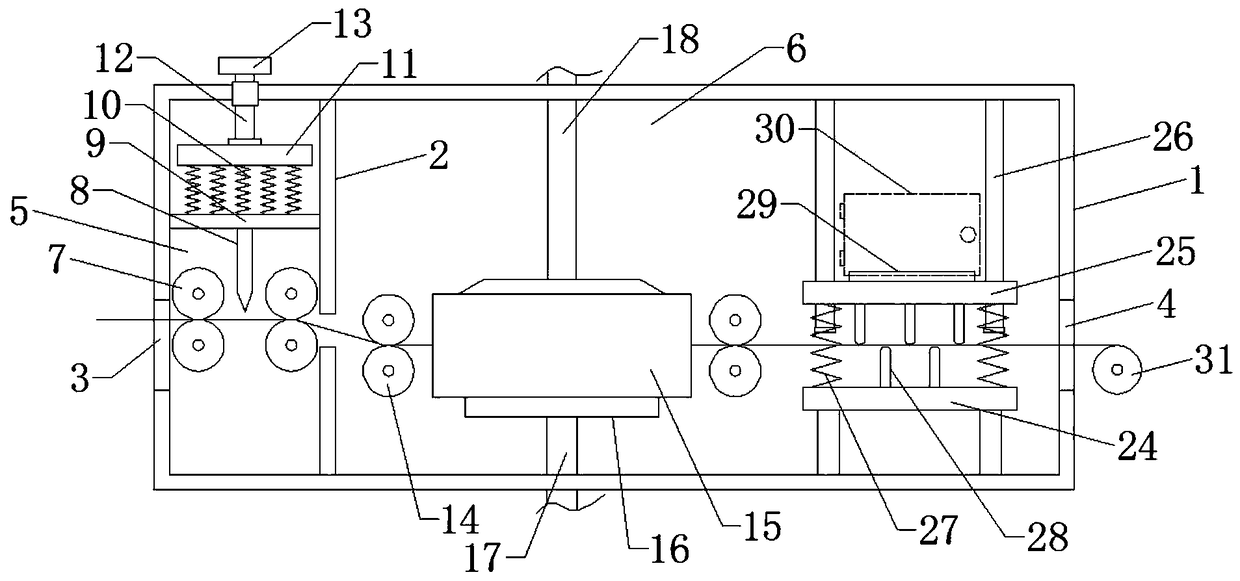

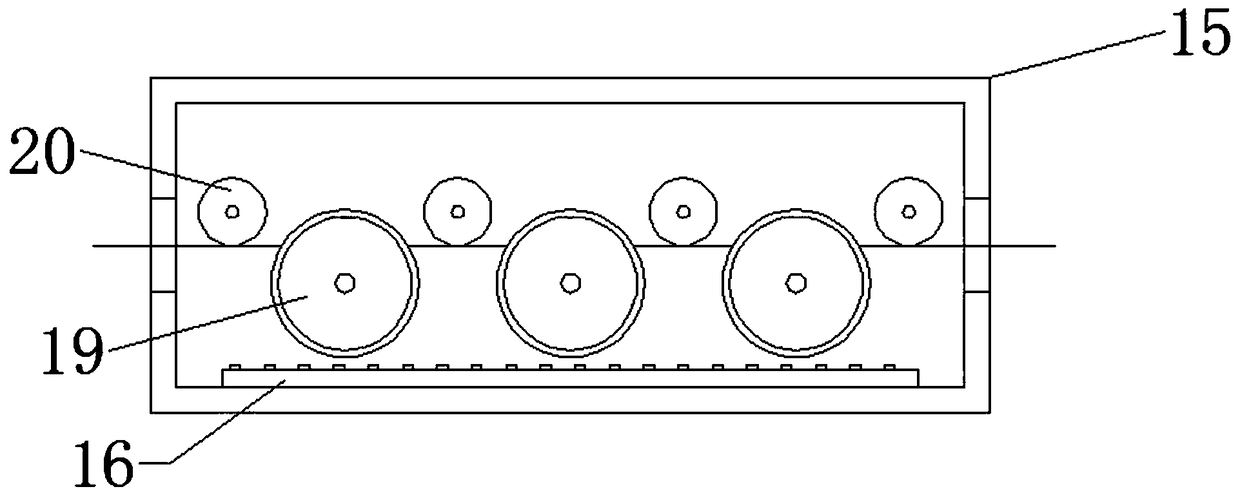

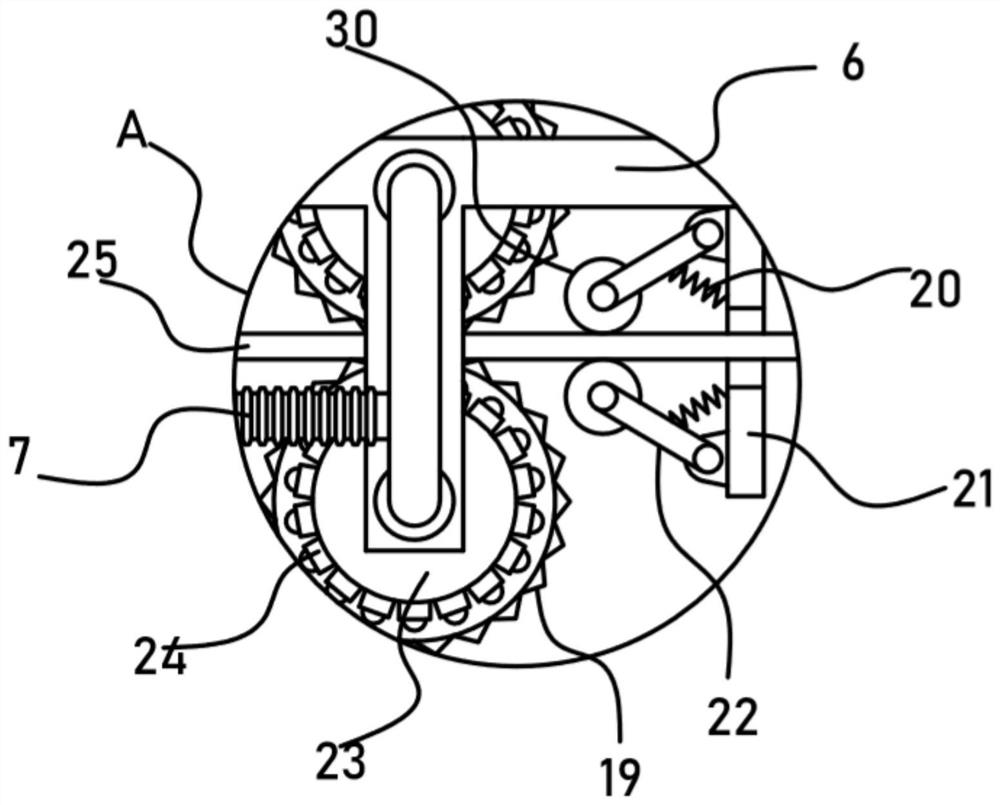

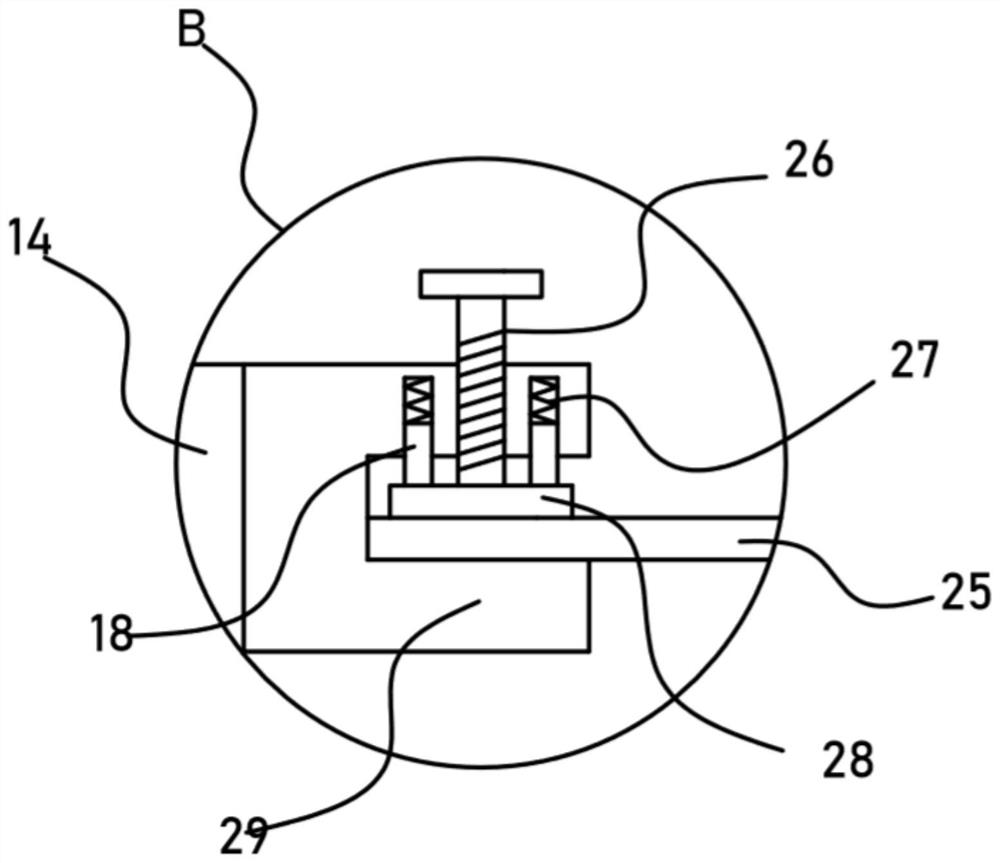

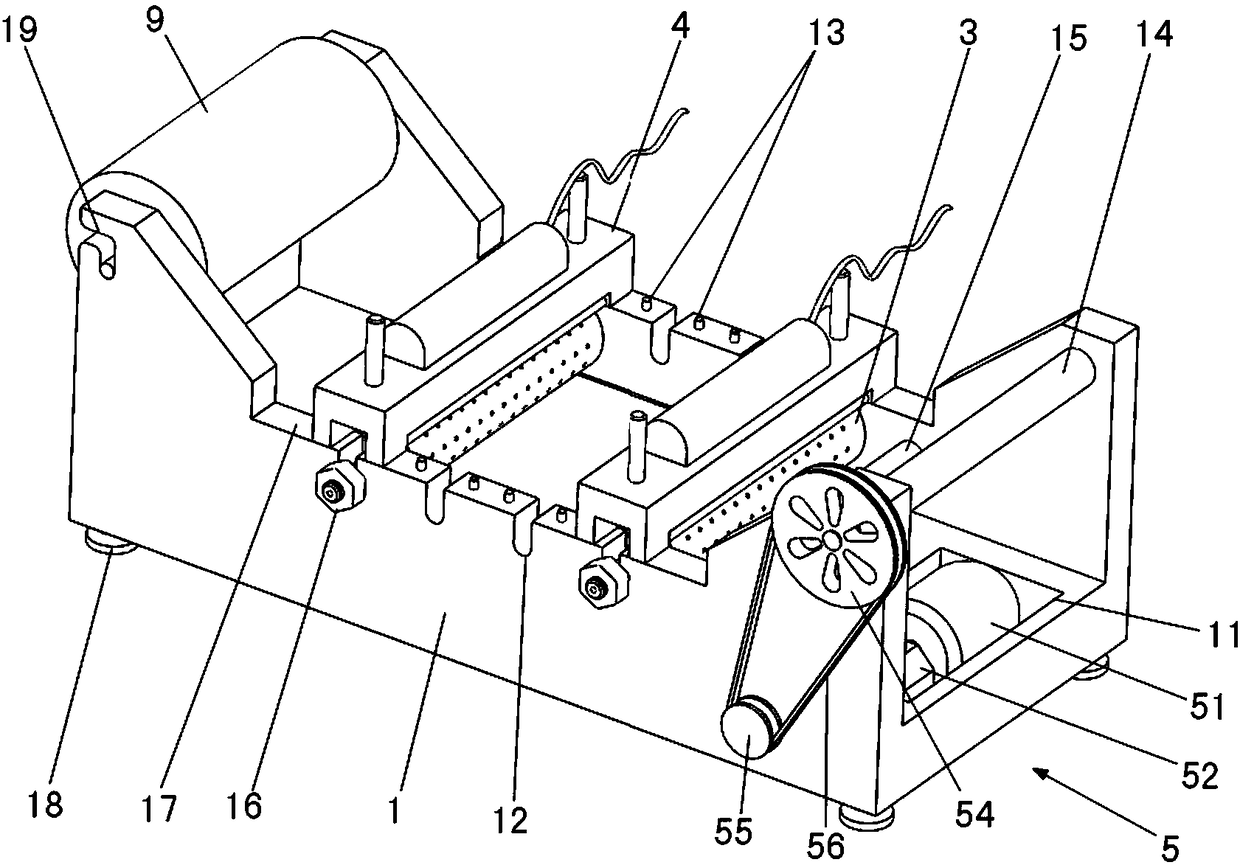

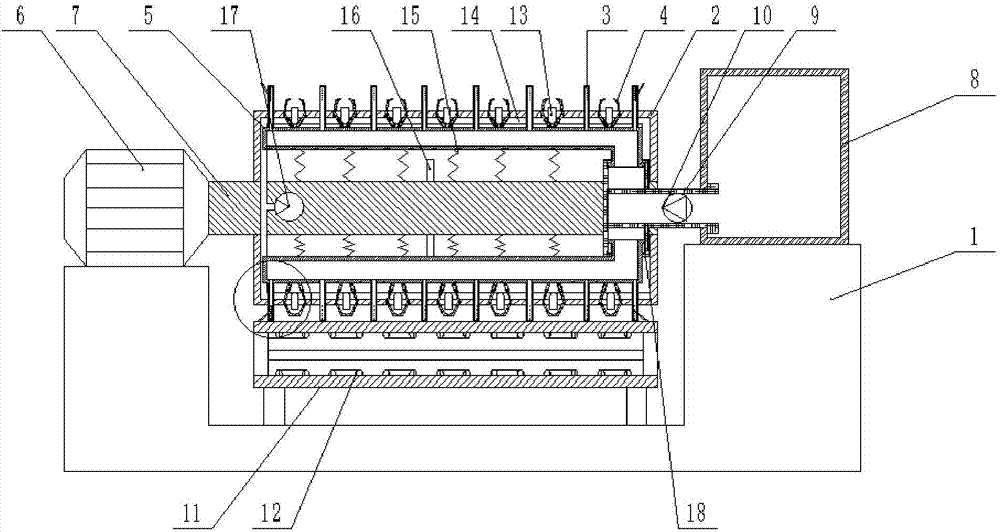

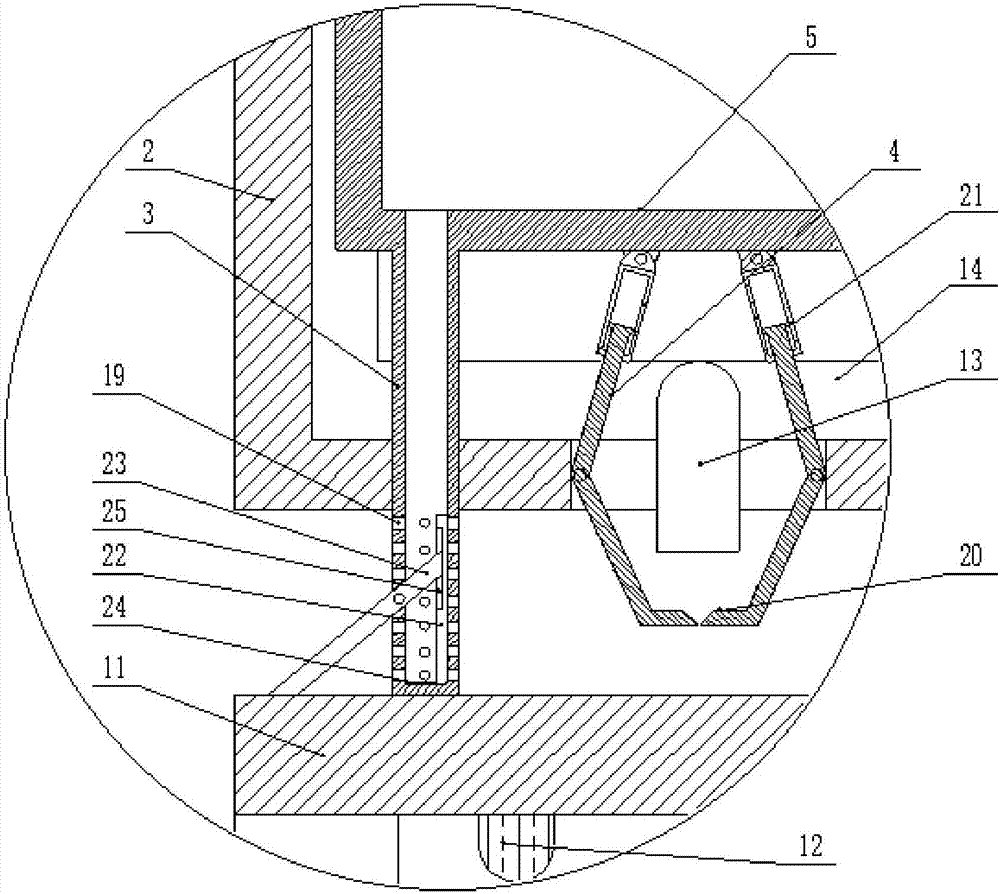

Singeing equipment with dedusting and drying functions

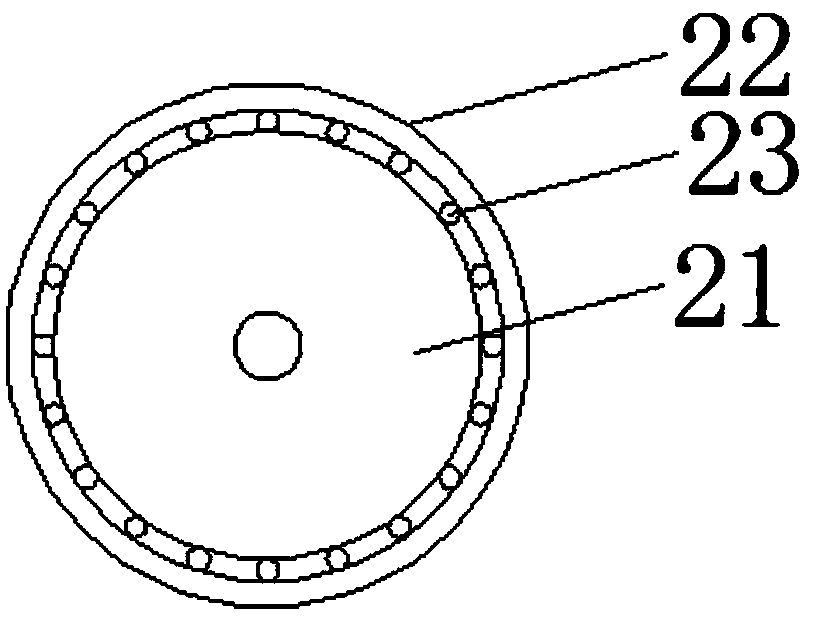

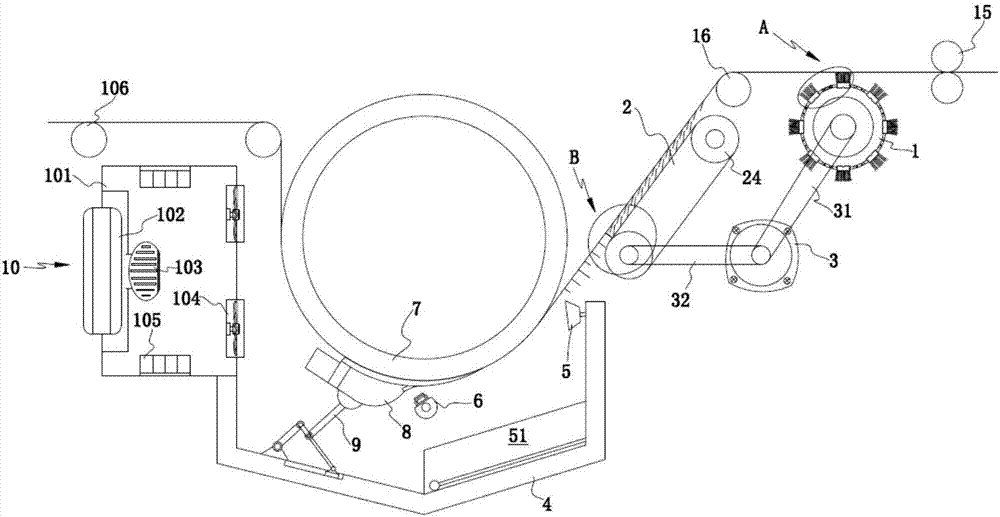

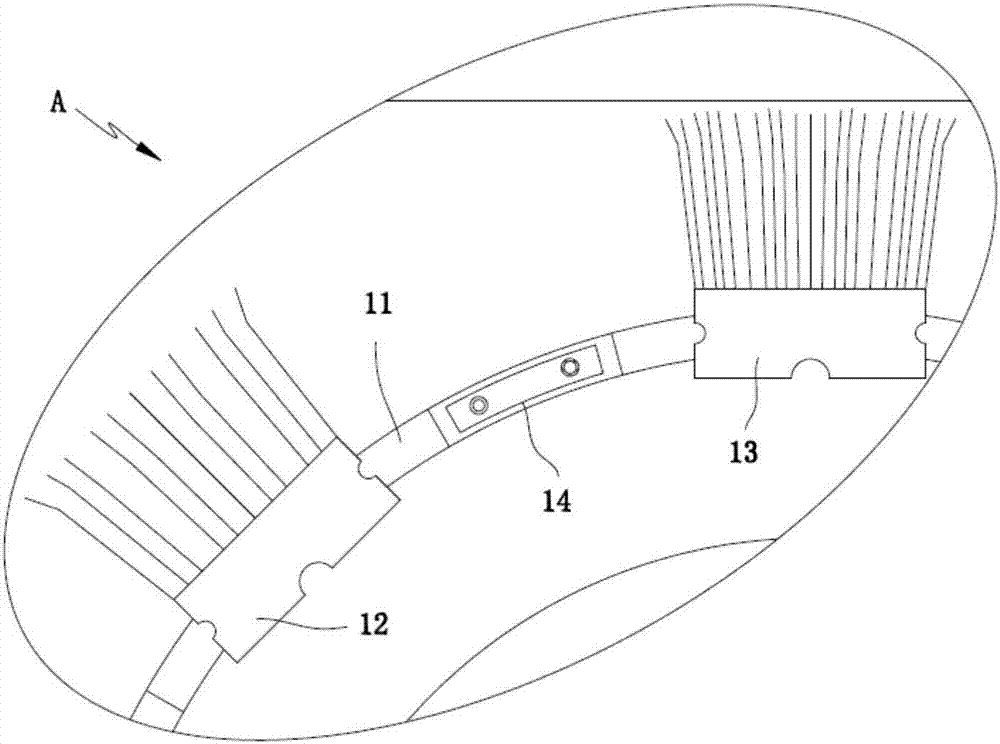

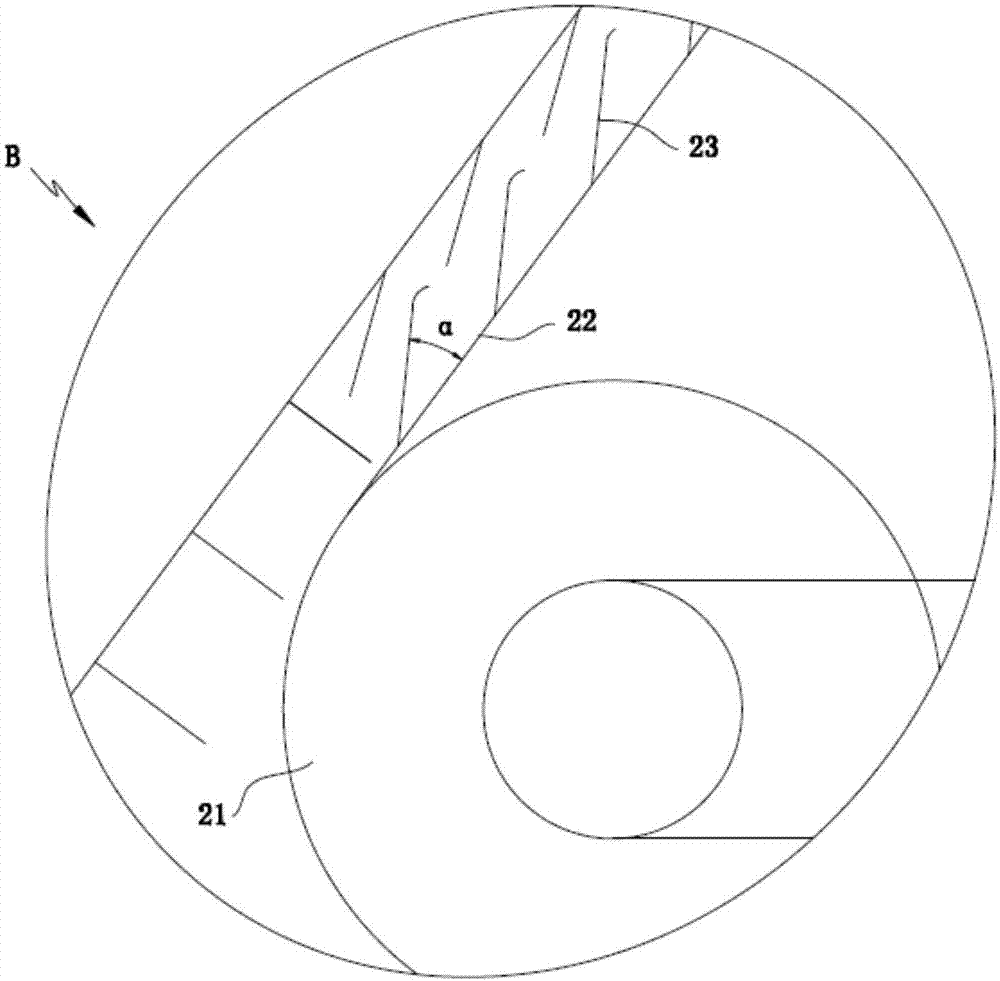

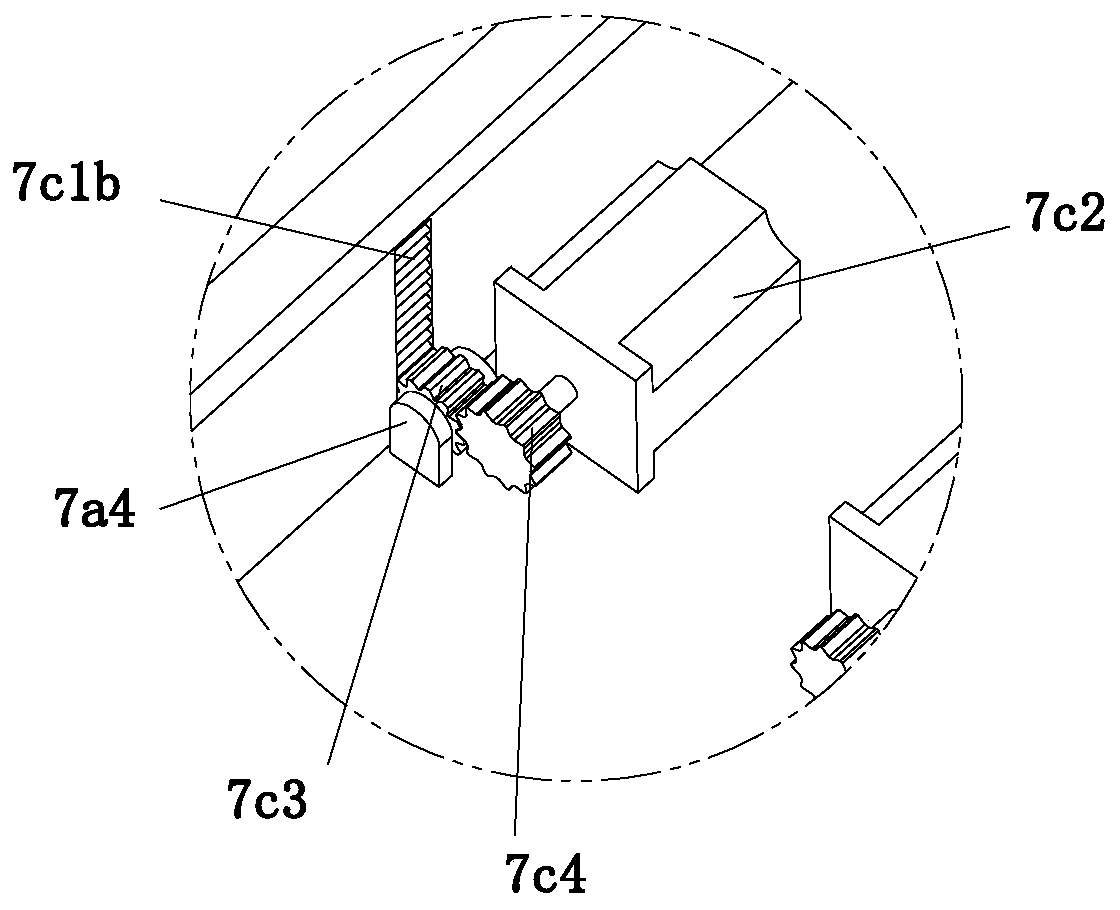

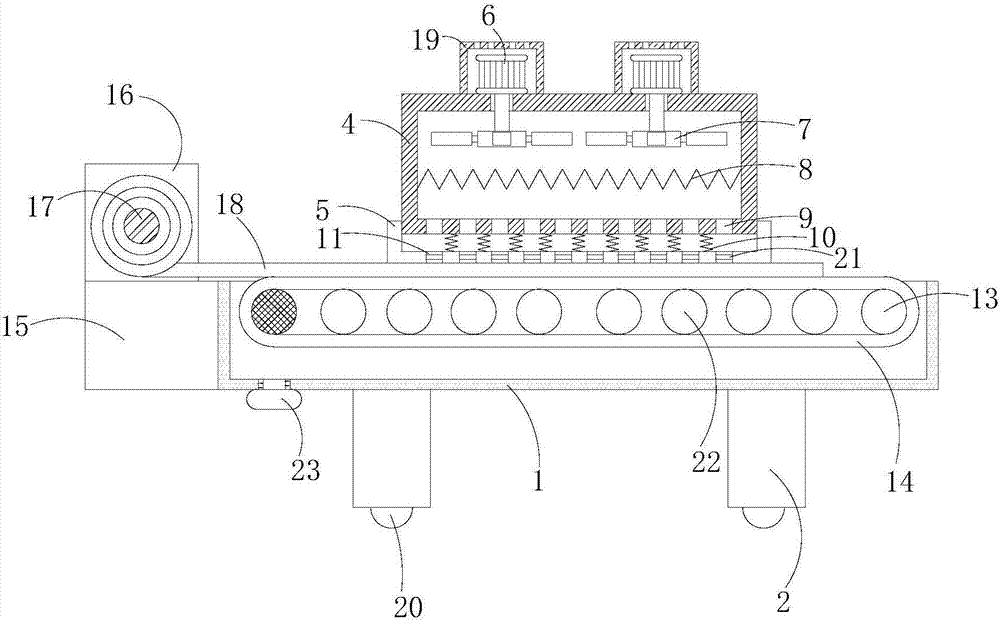

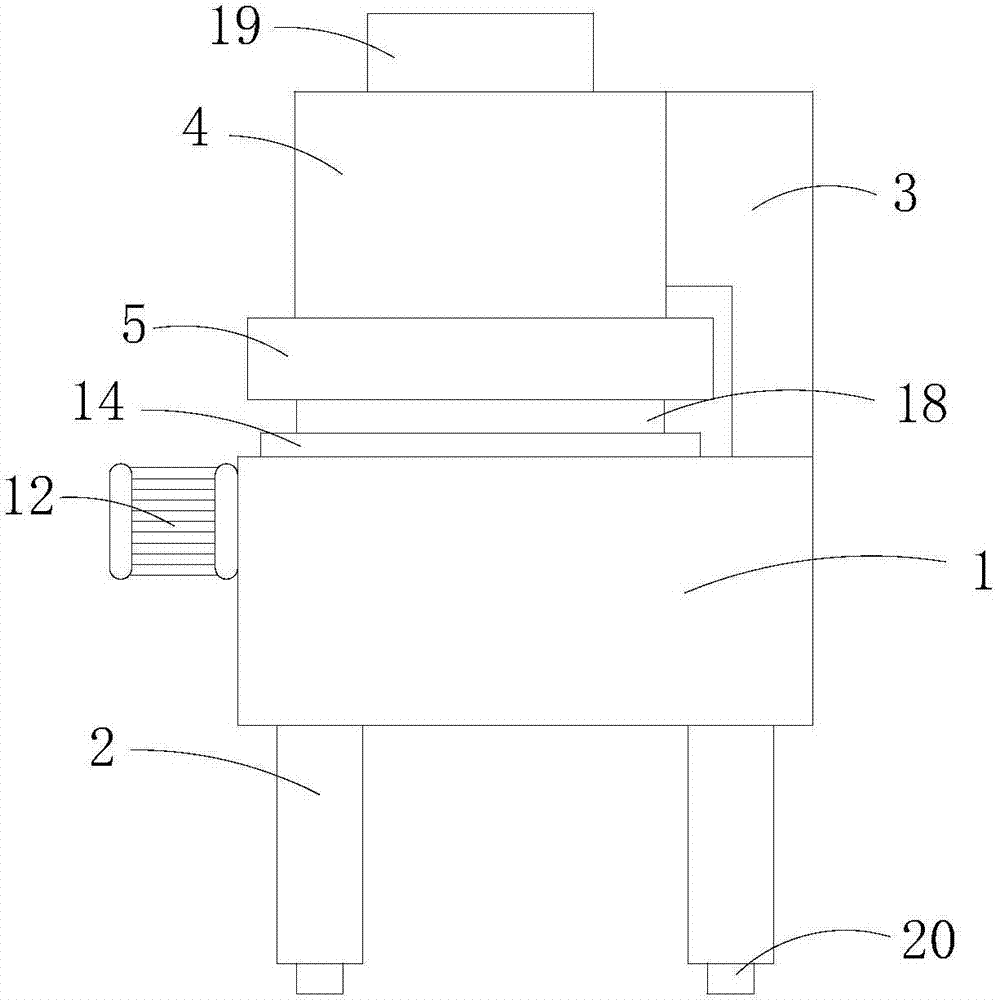

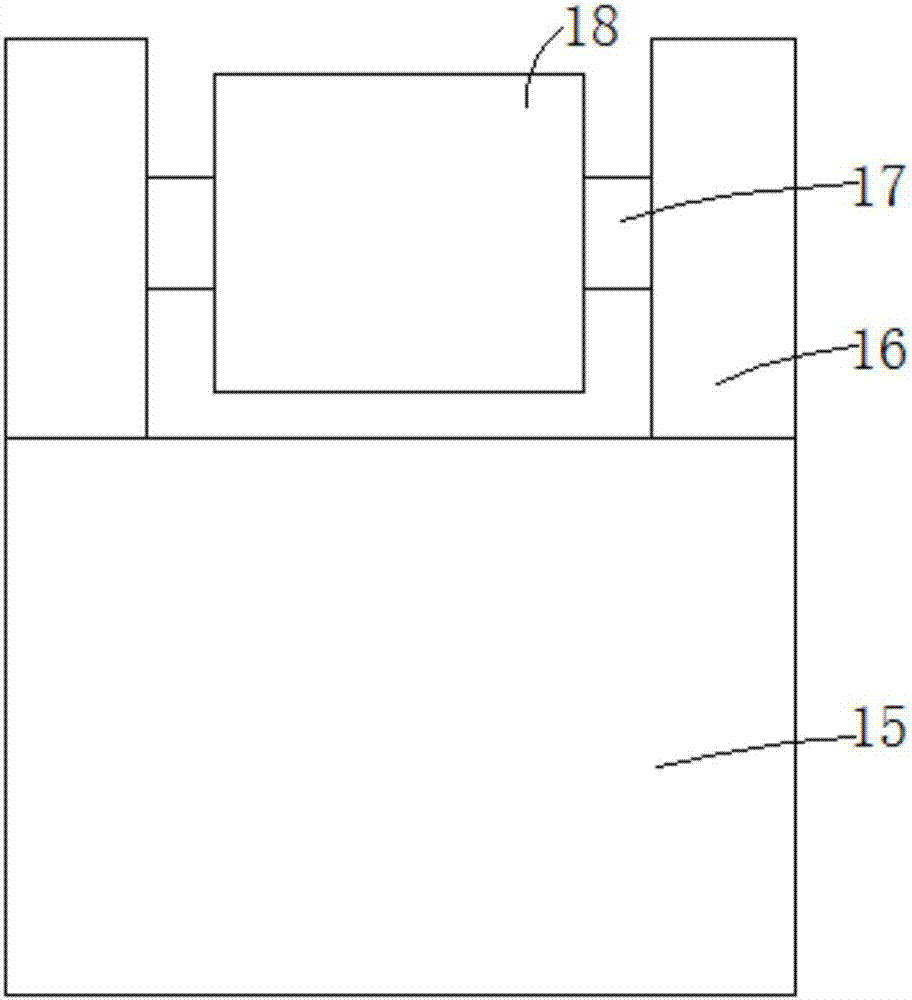

InactiveCN108004749AStraighten out fullyGood for singeingMechanical cleaningPressure cleaningDrive wheel

The invention discloses singeing equipment with dedusting and drying functions. The singeing equipment comprises a dedusting brush roller, a carding device, a singeing device and a drying device, wherein the dedusting brush roller, the carding device, the singeing device and the drying device are successively arranged from right to left. A static attracting board is arranged between dedusting brushes of a dedusting brush roller. The carding device comprises a driving wheel, a carding belt and a driven wheel. A plurality of carding needles are uniformly arranged on the carding belt. The singeing device comprises a singeing table and a mounting rack which are vertically arranged. The mounting rack is internally provided with a spraying head, a reservoir, a singeing machine, an isolating pawland an isolating pawl adjusting mechanism. The spraying head is mounted at the inlet of the mounting rack and is connected with the reservoir. The isolating pawl comprises a pawl body and a dust storage chamber which are vertically connected. The isolating pawl adjusting mechanism is mounted at the lower end of the isolating pawl. The dedusting brush roller and the carding device realize sufficient straightening of hairs on fabric, and then fine hairs on the fabric are singed through the singeing device. The singeing equipment ensures high singeing effect and realizes no fabric damage.

Owner:合肥摩天网络科技有限公司

Textile cleaning method

ActiveCN107988728AHas a bleaching effectEnsure hygieneInorganic/elemental detergent compounding agentsAnionic surface-active compoundsCleansing AgentsMechanical engineering

The invention belongs to the technical field of special methods for washing and cleaning textiles, and particularly discloses a textile cleaning method. According to the method, the effects of cleaning and pill cutting on the knitted textiles can be achieved through the steps of preparing a cleaning agent, squeezing and washing, cutting and collecting and drying, the problem of permanent deformation caused by excessive deformation of the knitted textiles when the knitting textiles are washed is avoided through squeezing and washing, pills on the surfaces of the knitted textiles are cleaned away through the step of cutting and collecting, and the quality of the textiles is improved. The textile cleaning method aims at solving the technical problems that the knitted textiles deform and the pills on the surfaces of the knitted textiles are hard to remove when the knitted textiles are cleaned in a high-speed rotating manner in the prior art.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Novel drying and sizing device

InactiveCN104372552ATake advantage ofReduce energy consumptionHeating/cooling textile fabricsLiquid/gas/vapor removalPulp and paper industrySizing

The invention discloses a novel drying and sizing device. The novel drying and sizing device comprises a shell, a sizing portion, a drying portion, middle rollers, a cloth feed roller, a cloth discharge roller, a circulating air portion, a temperature controller, a heating device and a control panel, wherein the sizing portion and the drying portion are arranged in a containing space of the shell, the middle rollers are arranged on one side of the drying portion, the cloth feed roller and the cloth discharge roller are arranged on two opposite sides of the exterior of the shell, the top and the bottom of the shell are connected through the circulating air portion, the temperature controller and the heating device are fixedly arranged on the inner wall of the shell, and the control panel is fixedly arranged on the outer side wall of the shell; a feed inlet is formed in the side wall, close to the cloth feed roller, of the shell, and a discharge outlet is formed in the side wall, close to the cloth discharge roller, of the shell; the heating device is fixedly arranged on the top of the containing space of the shell, the sizing portion is arranged below the heating device, the drying portion is arranged below the sizing portion, one end of the circulating air portion is connected with the top of the shell through a blowing opening, and the other end of the circulating air portion is connected with the bottom of the shell through an exhaust opening. The novel drying and sizing device can make full use of energy sources, save energy, reduce consumption and protect the environment.

Owner:ZHEJIANG JISHAN PRINTING&DYEING

Short-process water-free dyeing method of terylene velboa

ActiveCN109537327ANo difference in color fastnessShort processHeating/cooling textile fabricsTextiles drying apparatusDisperse dyePolymer science

The invention discloses a short-process water-free dyeing method of terylene velboa, and belongs to the field of spinning dyeing. The method is characterized in that a special drying working solutionis used for dyeing in an one-soaking one-rolling manner; the processes of increasing temperature, decreasing temperature and increasing temperature are carried out in the roasting stage, so that the dispersed dye can be spread fully in the fibers, and the heads of fibers can be dyed, and the color fixing can be completed. The dyed terylene velboa prepared with the method has the advantages that the light fastness is up to 6-7 levels, and the washing fastness is up to 4-5 levels, so that the water-free dyeing of the terylene velboa is realized.

Owner:苏州吴坤纺织品有限公司

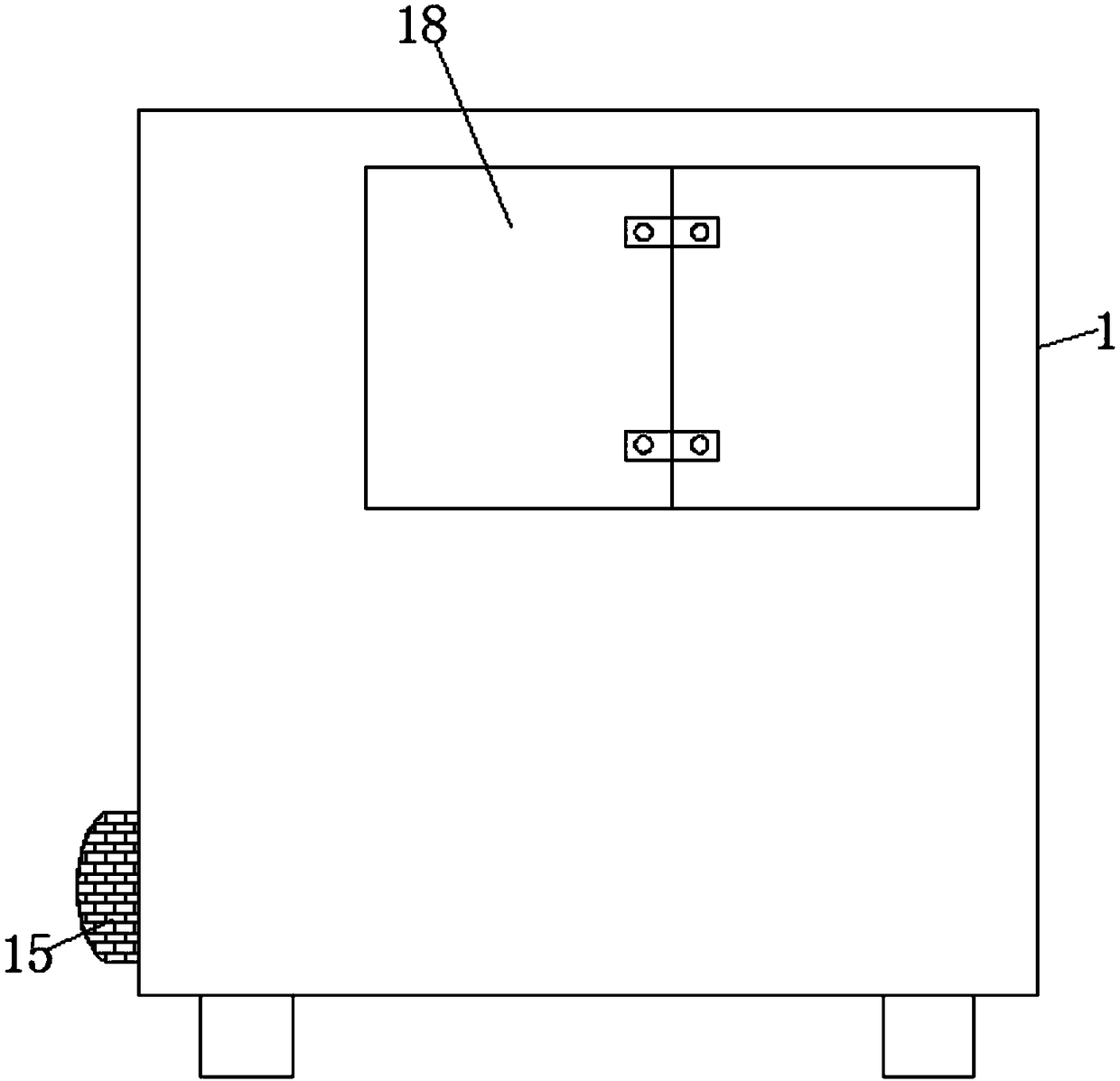

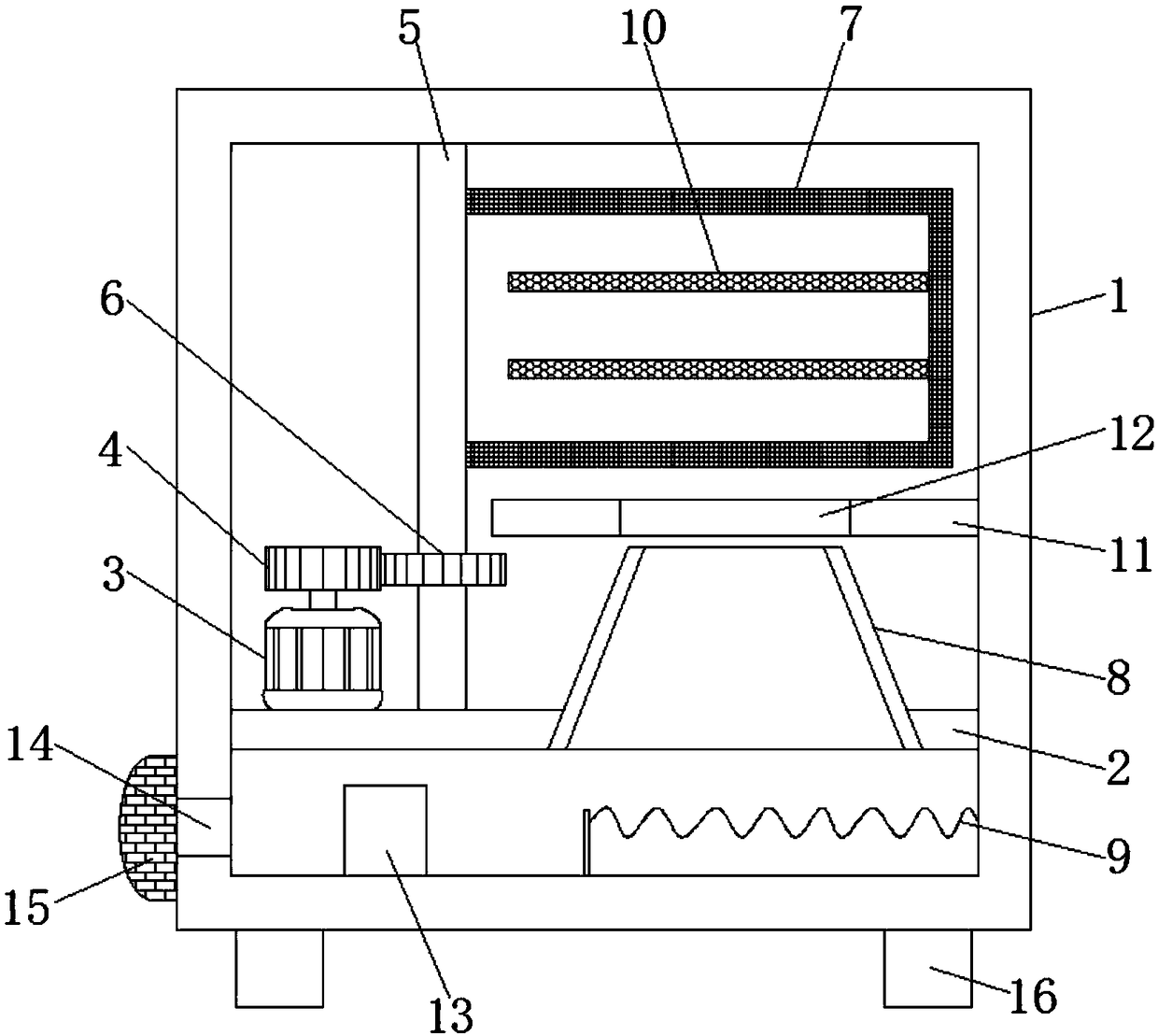

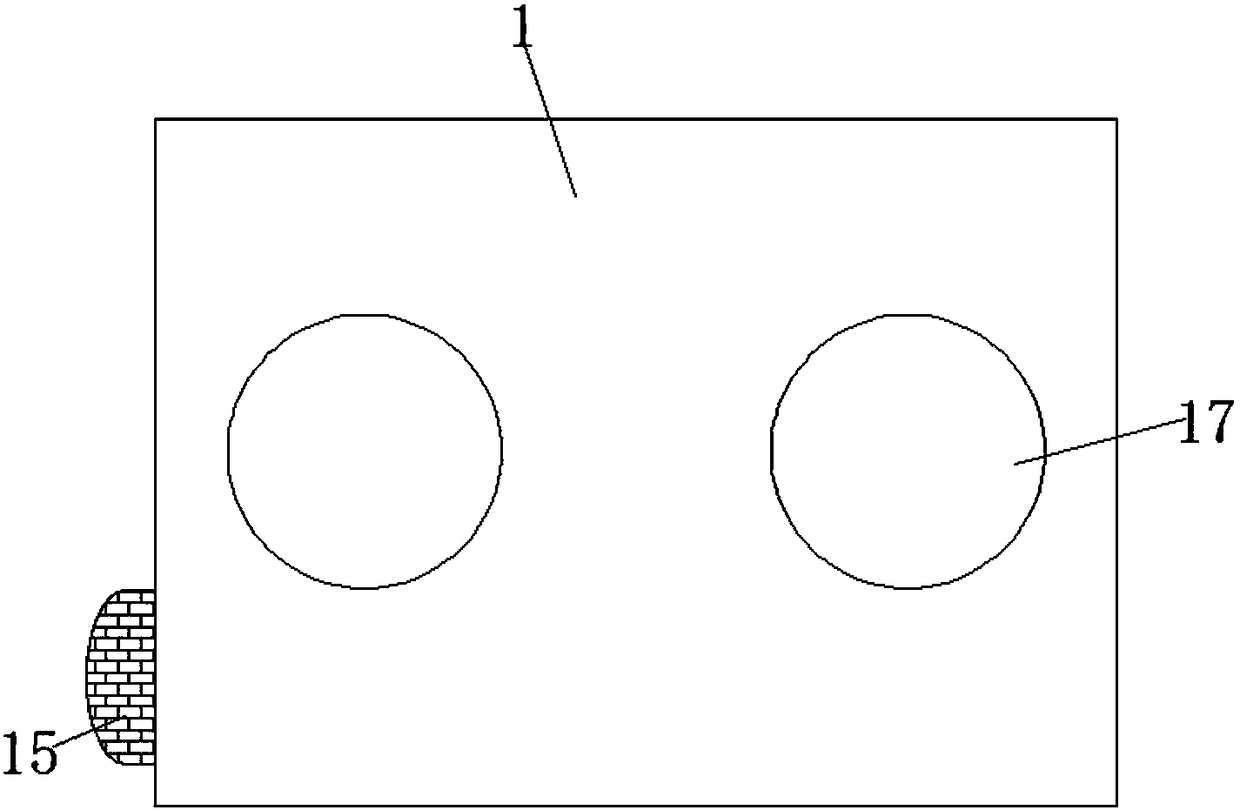

Sufficient and anti-wrinkling textile drying equipment

ActiveCN111380348AFully dryEnough timeDrying machines with progressive movementsFabric finishing guides/expandersStructural engineeringMechanical engineering

The invention discloses sufficient and anti-wrinkling textile drying equipment. The equipment comprises a box body, wherein a blocking door connected with the box body in a matched mode is arranged onthe front end wall of the box body, supporting blocks are fixedly connected to the rear end wall of the blocking door in a bilateral symmetry mode, the supporting blocks are rotationally connected with a spline shaft, the spline shaft is connected with a textile product containing shaft in a matched mode, textile products are arranged on the textile product containing shaft, the left textile product and the right textile product are connected through textile cloth, the textile product containing shaft is rotationally connected with the box body, an intermittent rotating mechanism is arrangedat the rear end of the textile product containing shaft, first sliding grooves with openings facing a textile product grooves are symmetrically formed in the upper end wall and the lower end wall of the textile product groove, the first sliding grooves are internally and slidably connected with first sliding blocks, flattening mechanisms are arranged in the first sliding blocks, drying mechanismsare arranged on the right sides of the first sliding grooves, repeating mechanisms are arranged at the left ends of the first sliding blocks, the two faces of the textile fabric can be fully dried atthe same time, flattening operation is conducted in time after drying, and wrinkles are reduced.

Owner:淄博玉华纺织有限公司

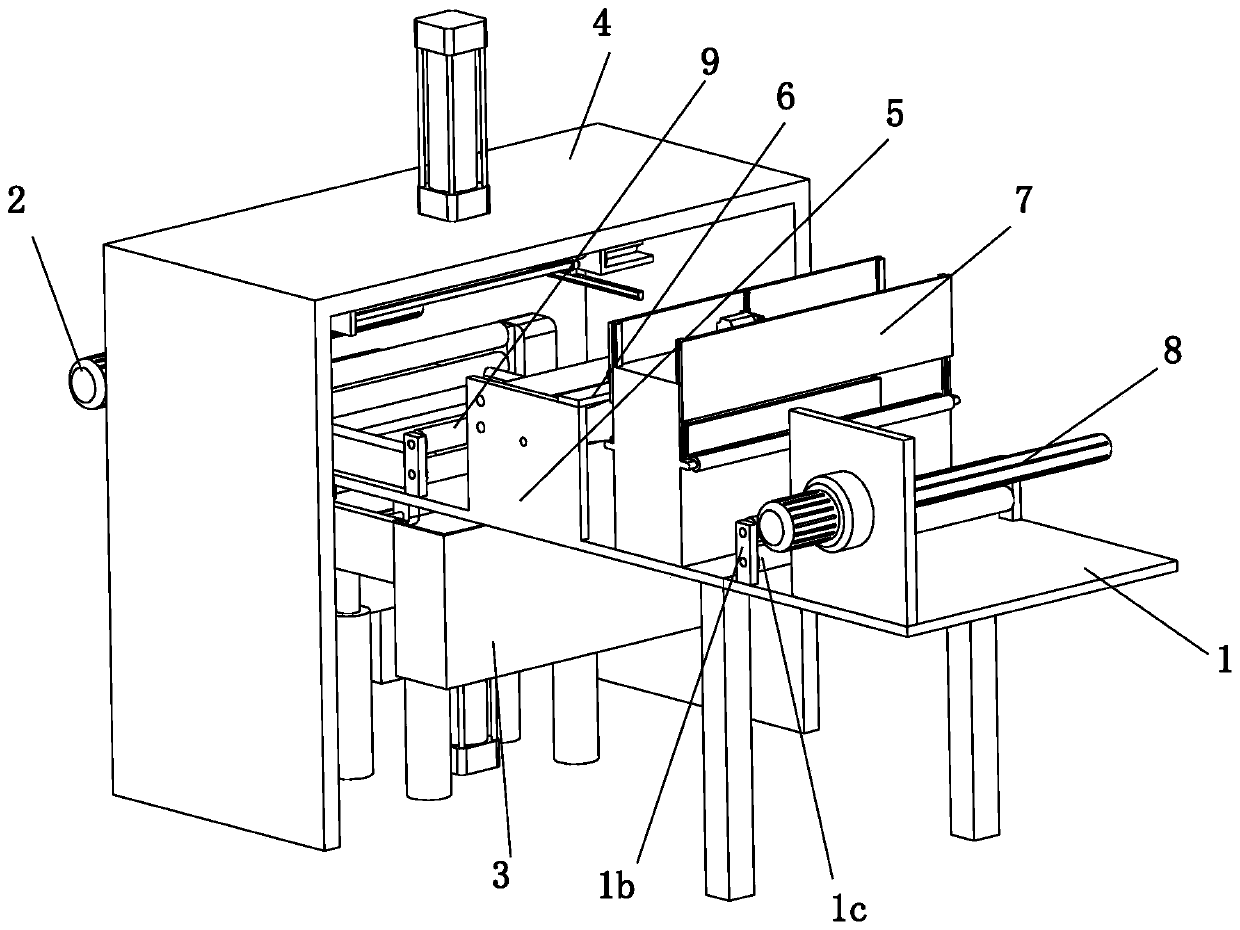

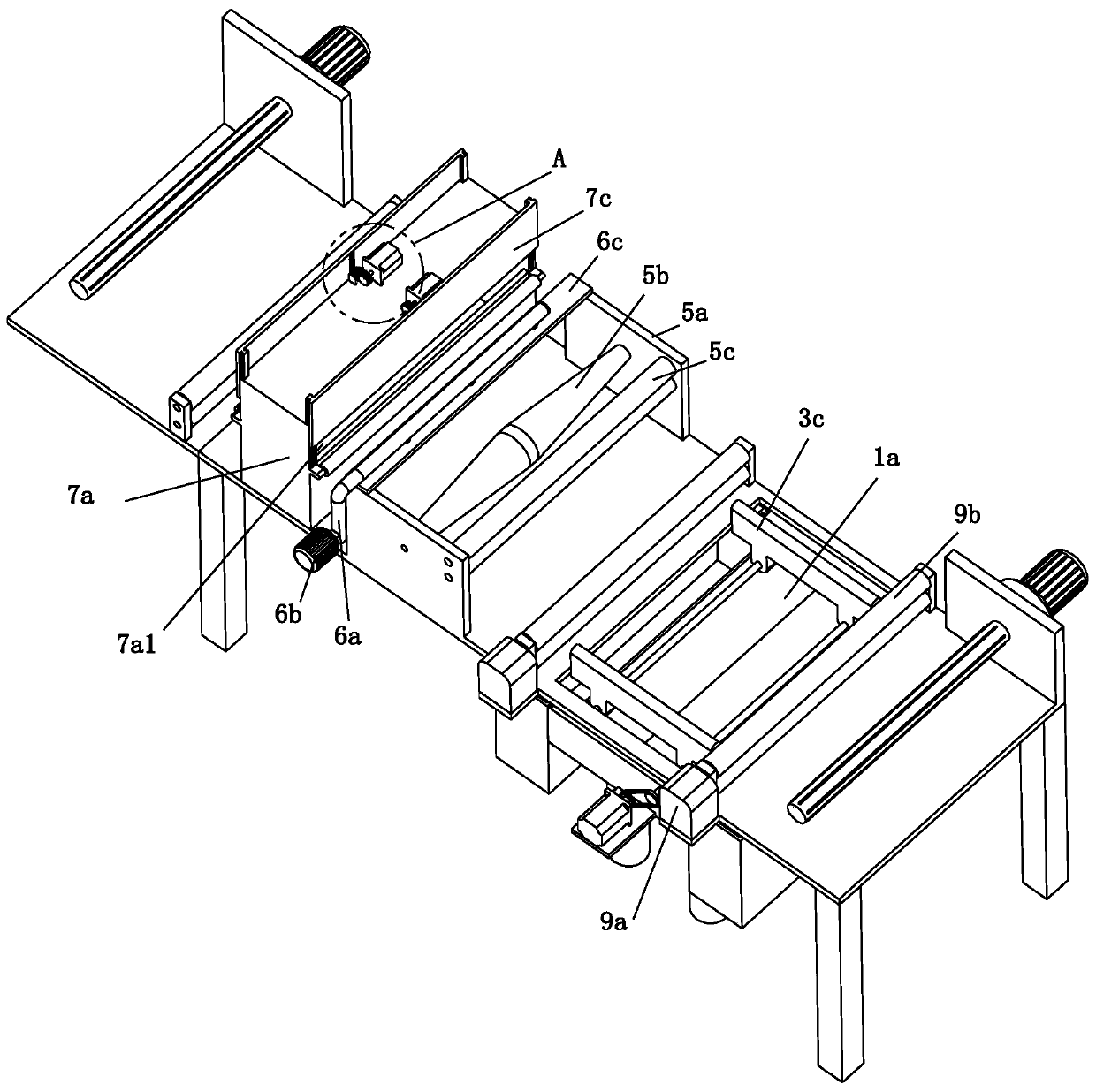

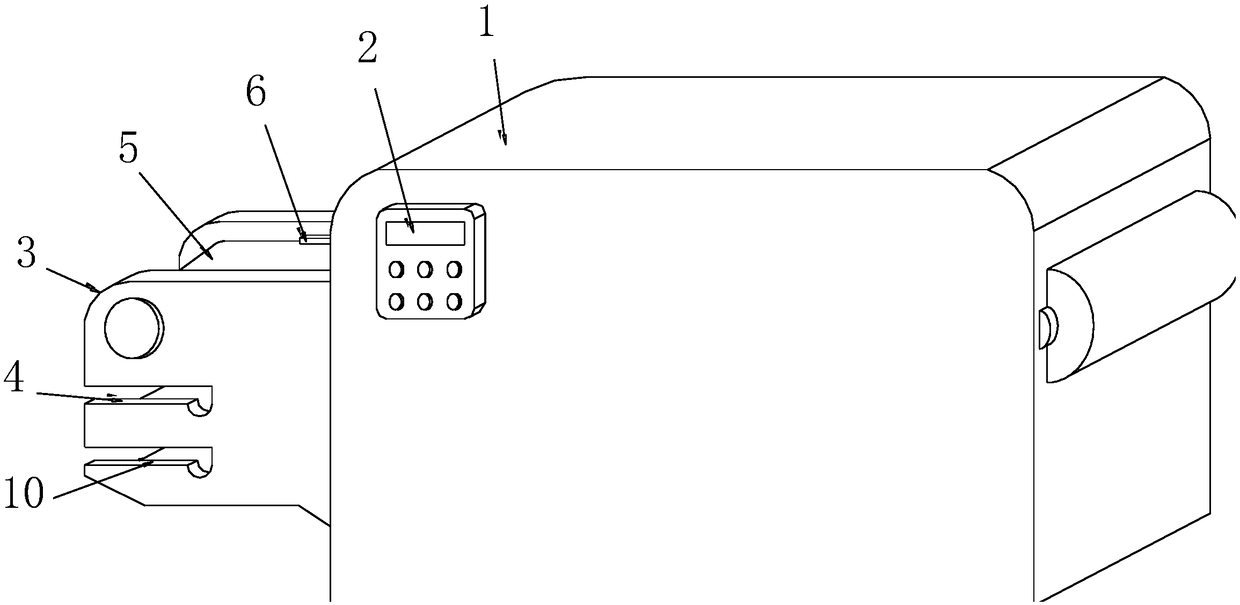

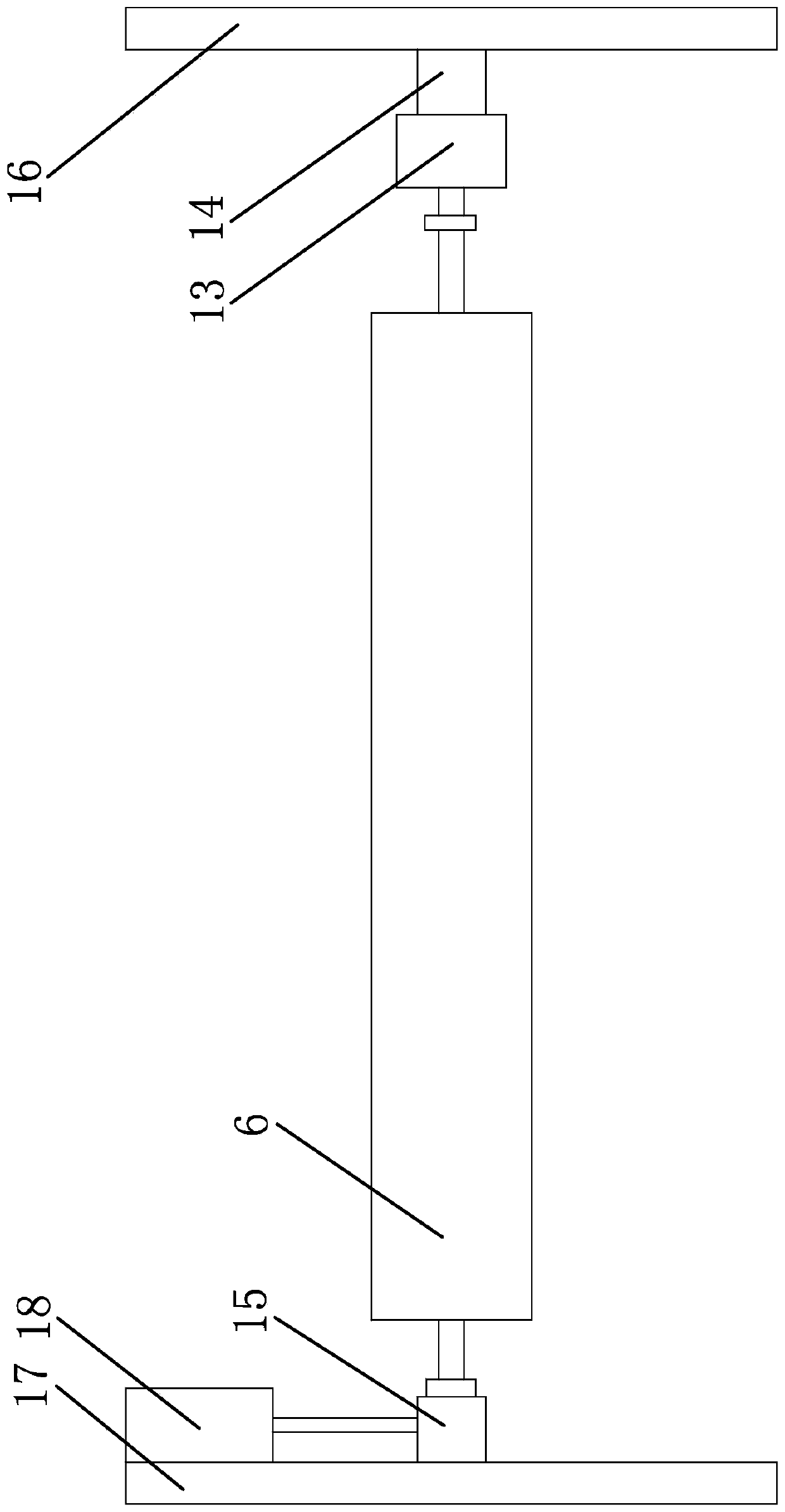

Lateral suction and pulling type fabric automatic ironing equipment

ActiveCN109457431ASolve the problem of pulling force and leaving horizontal foldsGuaranteed flatnessFabric finishing guides/expandersTextiles drying apparatusEngineeringMoisture

The invention discloses lateral suction and pulling type fabric automatic ironing equipment. The lateral suction and pulling type fabric automatic ironing equipment structurally comprises a main machine box, a control panel, a worktable, a fabric release roll clamping groove, a conveying mechanism, a lateral suction and pulling device, an ironing device, a leading-out mechanism, a hot moisture removal mechanism, and a fabric uncoiling roll clamping groove. The lateral suction and pulling type fabric automatic ironing equipment has the advantages that by arranging the lateral suction and pulling equipment, a mode of negative-pressure suction and pulling type and the crawler pressing and pulling type is adopted, the edges of the front part and back part of the fabric are pulled, and the pulling forces at the starting end and finishing end of the automatic ironing equipment are utilized to pull the surrounding edges of the fabric, so that the fabric can be more flatly ironed in the ironing process; by arranging the hot moisture removal mechanism, the remaining hot moisture in the ironing process can be absorbed by lime, the hot moisture removal mechanism is arranged in a spiral way and is in short-distance contact with the fabric to quickly absorb and remove the hot moisture, then the moisture is prevented, and the dampness and mildewing of the directly coiled fabric due to coiling of the hot moisture into the fabric can be prevented.

Owner:四会市永利布匹定型有限公司

A fabric setting machine

ActiveCN107938233BImprove stylingWrinkles disappearHeating/cooling textile fabricsFabric finishing guides/expandersEngineeringMechanical engineering

Owner:ZHEJIANG TEXWELL TEXTILE

Preheating drying anti-fold device for textile

ActiveCN107513839ASpeed up the flowImprove drying and preheating efficiencyFabric finishing guides/expandersTextiles drying apparatusWork in processEngineering

The invention discloses a preheating drying anti-fold device for textile. The device comprises a support control table and is characterized in that the two sides of the top end of the outer of the support control table are fixedly connected with a first gear transmission group and a second gear transmission group through a support frame, and both ends of the first gear transmission group are rotatably connected with the second gear transmission group through a rotation shaft, the top end of the support control table is provided with an air flow acceleration drying box which is at a position directly below a part between the first gear transmission group and the second gear transmission group, and the bottom of the support control table board is fixedly connected with a power box. The invention relates to the technical field of textile industry equipment. The preheating drying anti-fold device for the textile solves a series of problems of the existing textile products caused by incomplete preheating drying processes and the semi-finished products being easily damaged by different degrees due to unfixed reasons, meanwhile, also improves the preheating drying efficiency of the device, and achieves the purpose of reducing energy consumption.

Owner:天津市六福针织有限公司

Preparation method of anti-static fabric

InactiveCN107881771AImprove antistatic performanceImprove antibacterial propertiesBiochemical fibre treatmentLiquid/gas/vapor removalPulp and paper industryAntibacterial property

The invention discloses a preparation method of anti-static fabric. The fabric is subjected to presetting treatment through a presetting machine, the preset fabric is put in a dryer to be dried, and the dried fabric is put in a finishing liquid for double dipping and double padding treatment through a padder; the fabric subjected to dipping and padding treatment is steamed through a steam box, andthe steamed fabric is washed for 4-6 min with cold water at the temperature of 0 DEG C and then washed for 2-3 min with hot water at the temperature of 55-60 DEG C; the washed fabric is dried throughthe dryer, and a finished product is obtained. The invention provides the preparation method of the anti-static fabric. The method is convenient to operate, green and environmentally friendly, the finished fabric has excellent anti-static and antibacterial properties and high washing resistance and touches soft.

Owner:SUZHOU EMBROIDERY COLORFUL WORLD EMBROIDERY CRAFT CO LTD

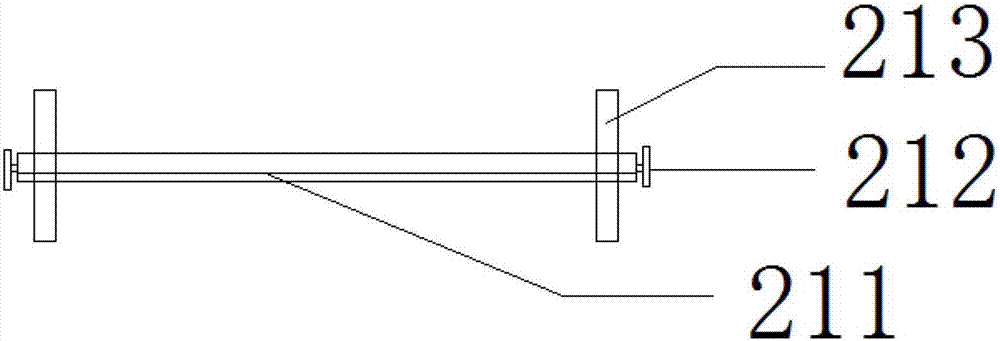

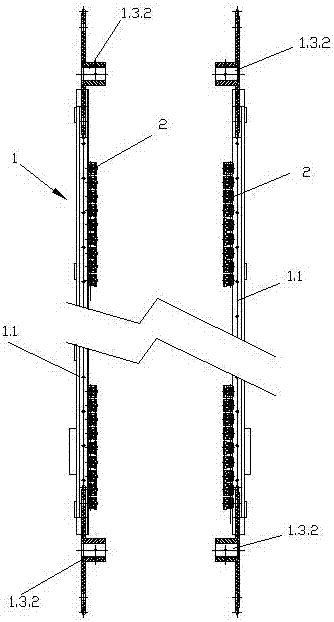

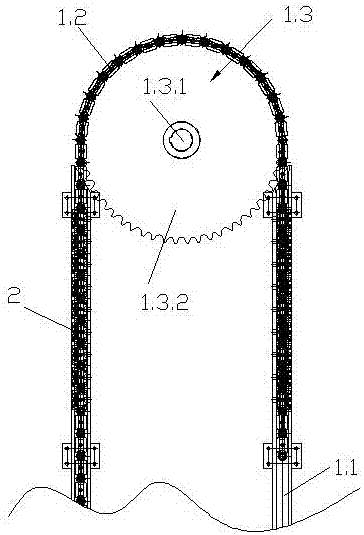

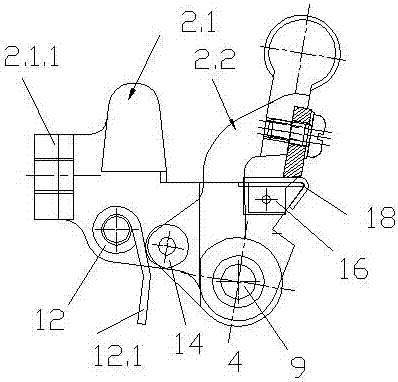

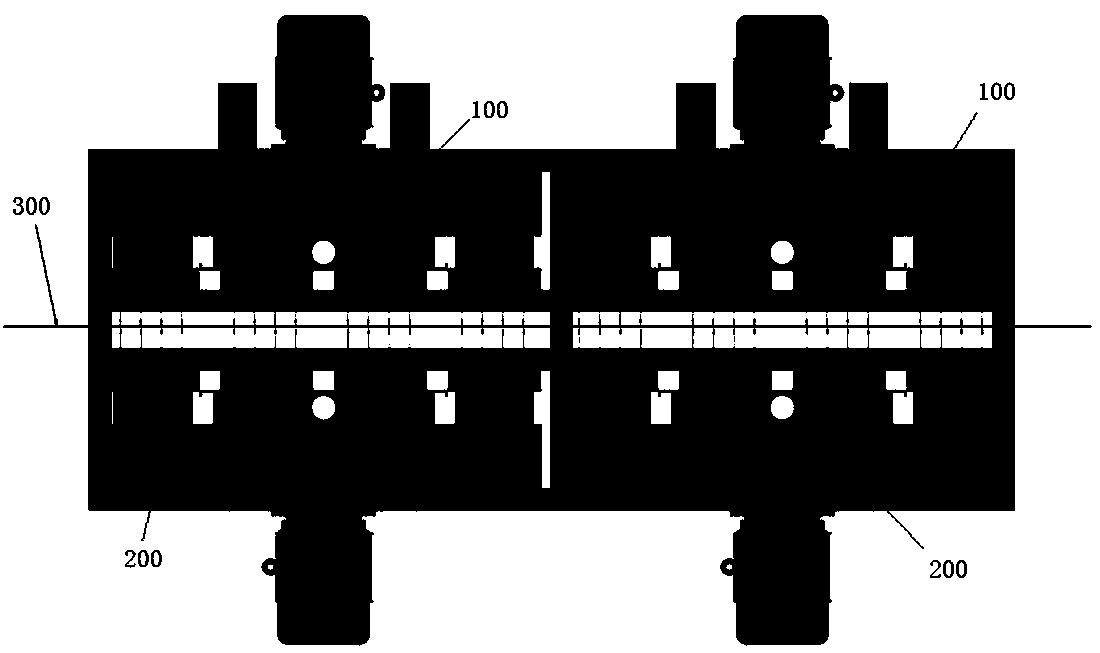

Upright type vertical conveying device for non-woven fabric drying and setting machine

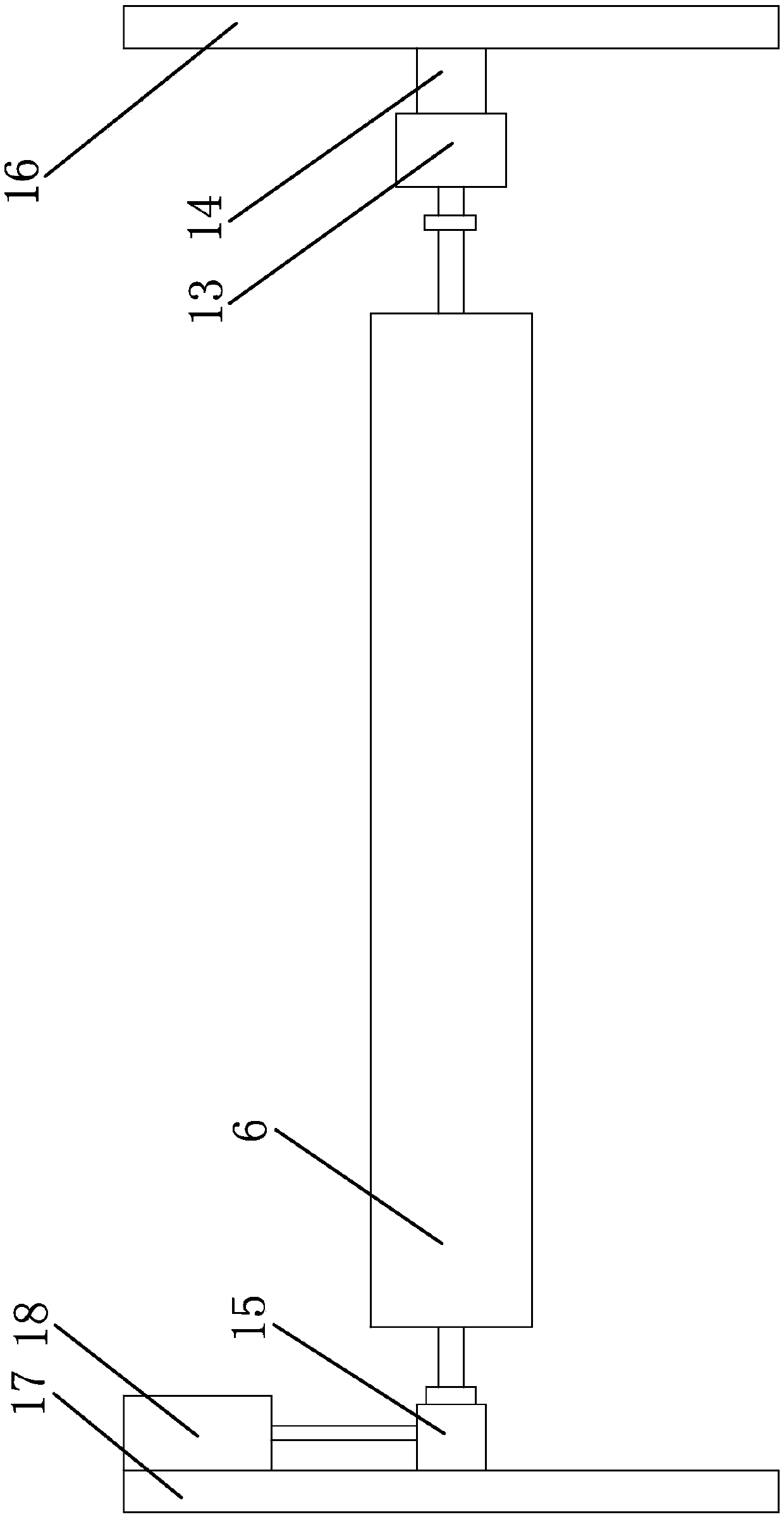

PendingCN107354652AImprove drying yieldReduced risk of tearingTextiles drying apparatusStretchingNonwoven fabricChain link

The invention provides an upright type vertical conveying device for a non-woven fabric drying and setting machine. The upright type vertical conveying device comprises left and right groups of symmetrical vertical conveying units, wherein a thin non-woven fabric is clamped between the two vertical conveying units at a vertical state; each vertical conveying unit comprises two upright type guide rails which are arranged in parallel and at interval, a conveying chain which is arranged in the two upright type guide rails and forms a closed loop, chain driving devices which are arranged above and below the two upright type guide rails and are used for driving the conveying chain to rotate along a clockwise direction, and a cloth clip which is arranged on each chain section of the conveying chain; the cloth clips and the chain sections are vertically mounted and two cloth edges of the thin non-woven fabric are clamped on the cloth clips. The upright type vertical conveying device has the effects of stably clamping and effectively preventing cloth edges of ultrathin non-woven fabric edges from being torn.

Owner:JIANGSU LITTLE SUN TECH DEV CO LTD

Tentering and shaping drying machine

InactiveCN110318197AReduce distanceSpeed up dryingHeating/cooling textile fabricsTextiles drying apparatusPulp and paper industryMoisture

The invention discloses a tentering and shaping drying machine. By arranging infrared heating tubes in air outlet boxes, the infrared heating tubes are energized to heat the air in the air outlet boxes into hot air. During running of fans, the hot air in the air outlet boxes is directly blown onto a fabric, air suction covers suck the hot air blown into the drying machine into fan casings throughfilter nets, and then the hot air is blown into the air outlet boxes through the fans, subjected to flow equalizing by air outlet plates and then blown onto the fabric through air outlet holes of theair outlet plates; at the same time, infrared light waves emitted by the infrared heating tubes are irradiated onto the fabric through the air outlet holes of the air outlet plates, drying of the moisture in the fabric is accelerated under the combined effect of infrared rays of the infrared heating tubes and the hot air, the drying and shaping speed is increased, the production efficiency is improved, and the drying and shaping effect is ensured. By replacing a traditional externally-mounted heating structure with an internally-mounted circulating hot air structure, the distance between a heat source and the fabric can be effectively reduced, and the energy consumption can be reduced; a traditional fuel or natural gas heating mode is replaced with an electric heating mode, so that energyis saved, the environment is protected, and the drying cost is reduced.

Owner:佛山市国特科技有限公司

A plane shaping machine

ActiveCN108691131BTextiles drying apparatusShaping/stretching tubular fabricsEngineeringMechanical engineering

A plane setting machine, including a turntable, a drying device, a sock delivery device, and a sock steam setting device, and is characterized in that: it also includes a sock removing device, a setting seat, and a plurality of setting seats are installed on the turntable and are in the form of Distributed in a circular array, the sock removing device is docked with the sock discharging conveying device, and the sock steam setting device, the drying device and the sock removing device are sequentially arranged outside the turntable. The socks of the invention are low in height and convenient for maintenance and repair. The operator can sit on a chair to load the socks, which reduces the difficulty of work.

Owner:DONGGUAN KEMEI MACHINERY

Fabric ironing machine with drying function

InactiveCN108677447AImprove ironing effectTextiles drying apparatusFabric steaming/decatisingWrinkle skinPulp and paper industry

The invention discloses a fabric ironing machine with a drying function. The fabric ironing machine comprises a base, supporting columns, a first roller body, a second roller body, a worktable, an ironing mechanism and fan mechanisms, wherein the worktable is arranged on the base through the supporting columns; the first roller body and the second roller body are arranged at parts, positioned on the two sides of the worktable, of the upper surface of the base; guide pulleys are arranged on two sides of the worktable; the ironing mechanism is arranged on the upper surface of the worktable; thefan mechanisms are respectively arranged on the two sides of the ironing mechanism; and the wind direction of the fan mechanisms faces downwards. The fabric ironing mechanism solves the problems thatin the prior art, fabric is subjected to wrinkle removal operation by means of steam generally, however, the temperature of the wrinkle-removed fabric is too high, the wrinkle-removed fabric is proneto getting damped, and the fabric is likely to go mouldy after collection.

Owner:WUHU PINDU ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com