Cloth drying device for cotton sock processing

A cloth drying and cloth technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems that the continuous change of the position cannot be realized, and the drying process cannot be realized, so as to achieve the improvement of efficiency and adequacy, and promote the air Flow, ensure the effect of drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

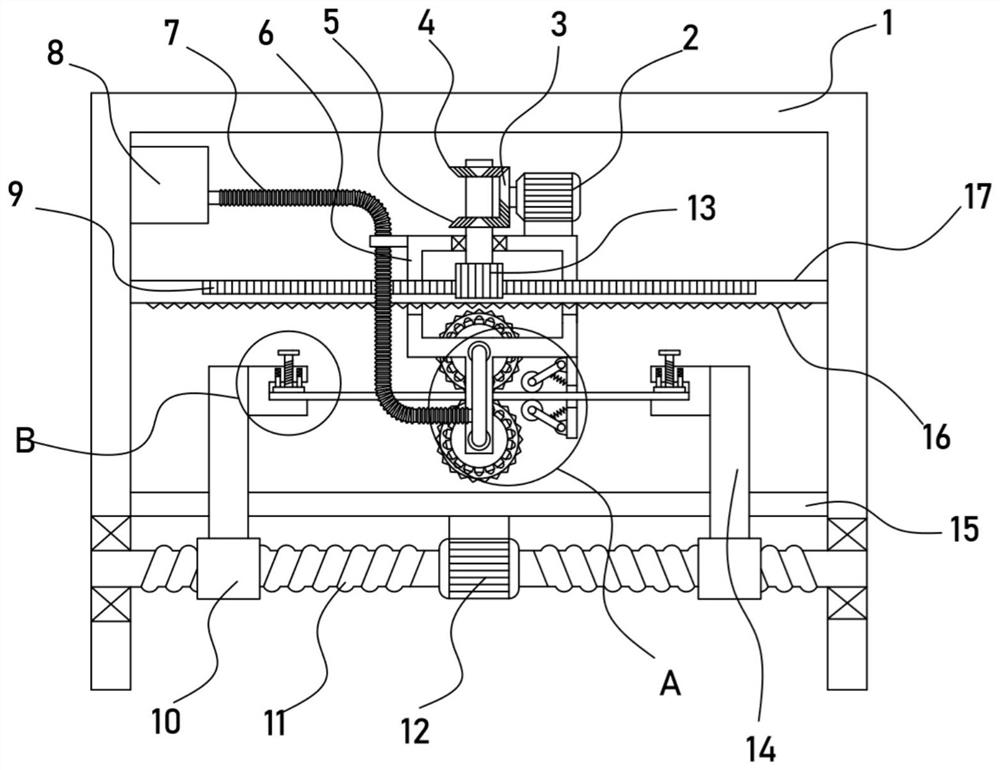

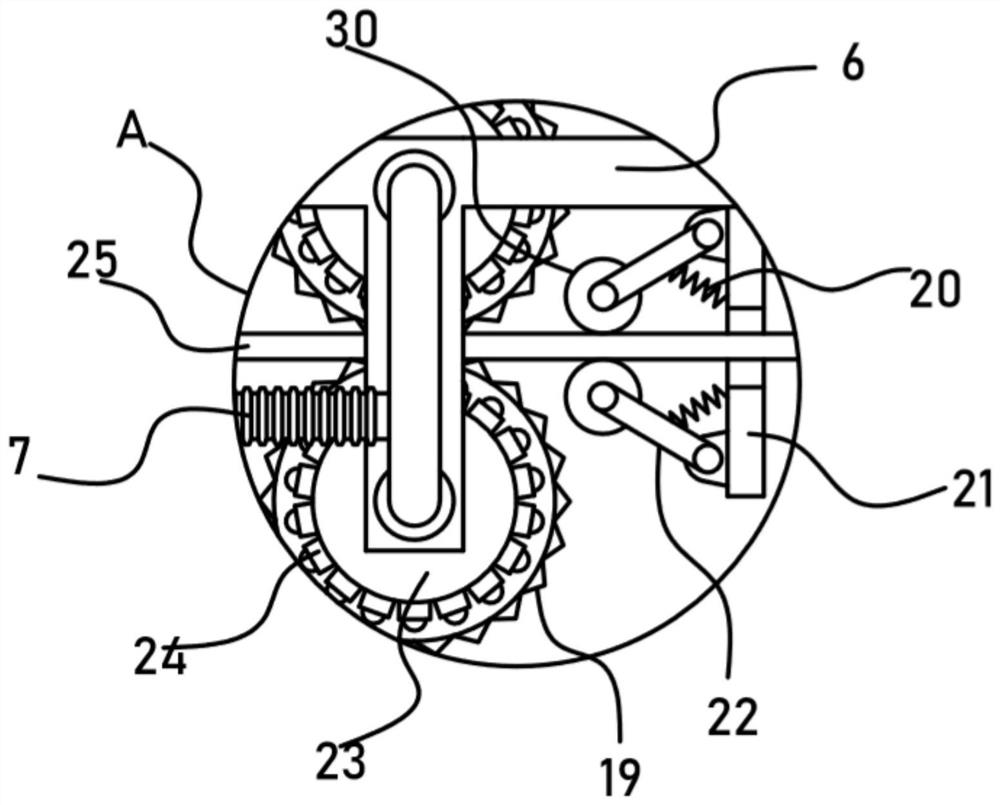

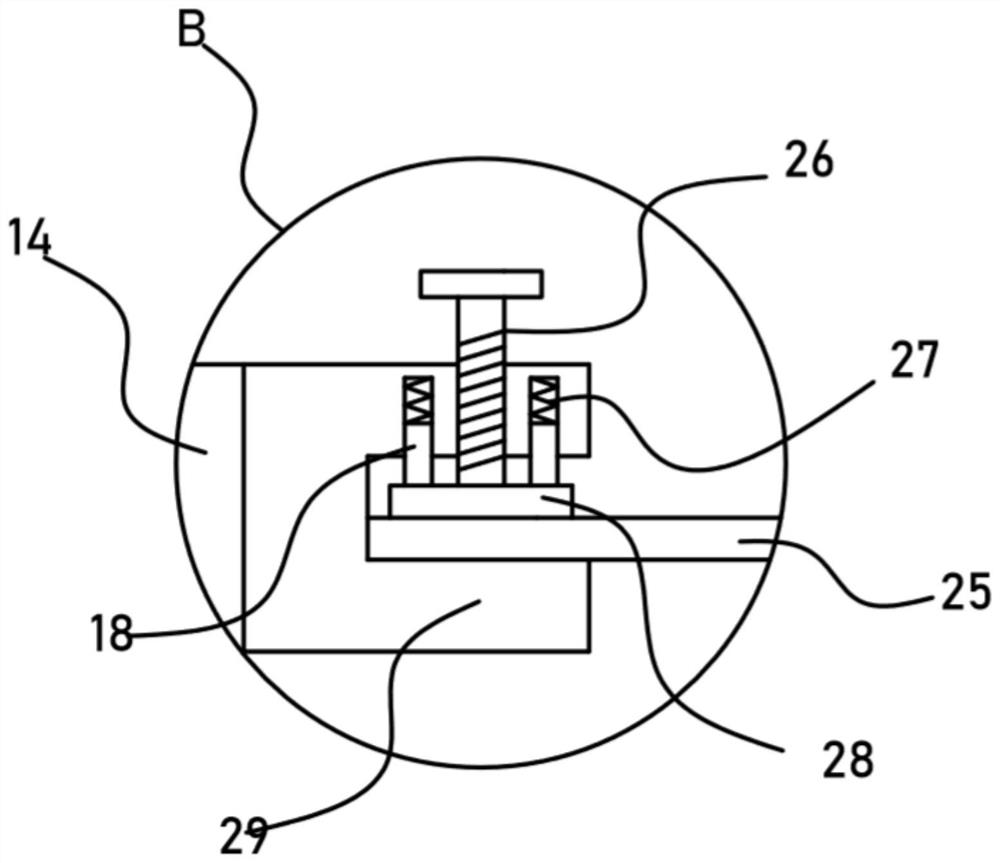

[0022] see Figure 1-4 , a cloth drying device for cotton socks processing, including a support frame 1, a biaxial motor 12 and a hot air blower 8 are fixed on the support frame 1, the biaxial motor 12 is driven and connected with a transverse translation mechanism, and the transverse translation mechanism is There is a clamping mechanism for clamping the cloth 25, a horizontal plate 17 is fixed horizontally on the support frame 1, and a moving frame 6 is slidably sleeved on the horizontal plate 17. For the drying mechanism for drying, the moving frame 6 is provided with a reciprocating mechanism for driving its lateral reciprocating motion, and the bottom of the moving frame 6 is provided with a rolling mechanism for flattening the cloth 25 .

[0023] The device can adjust the distance between the two vertical plates 14 through the provided lateral translation mechanism, so that the two clamping mechanisms can be brought close to each other, and the tension effect after clamp...

Embodiment 2

[0031] On the basis of Embodiment 1, in addition, the reciprocating mechanism of the device includes a drive motor 2 fixed on the moving frame 6 , an incomplete bevel gear 3 is drivingly connected to the drive motor 2, and a rack is fixed on the horizontal plate 17 I9, the rack I9 is meshed with a transmission gear 13, and the transmission gear 13 is coaxially fixed with a bevel gear I4 and a bevel gear II5 that are alternately meshed with the incomplete bevel gear 3.

[0032] Through the above settings, the drive motor 2 drives the incomplete bevel gear 3 to rotate, and the incomplete bevel gear 3 is meshed with the bevel gear I4 and the bevel gear II5 alternately. At this time, the transmission gear 13 rotates alternately clockwise and counterclockwise. Under the meshing action of I9, the moving frame 6 is driven to reciprocate laterally, so as to realize the lateral reciprocating translation of the drying mechanism, so as to fully dry the cloth 25 at different lateral posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com