Patents

Literature

30results about How to "Fully dry treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

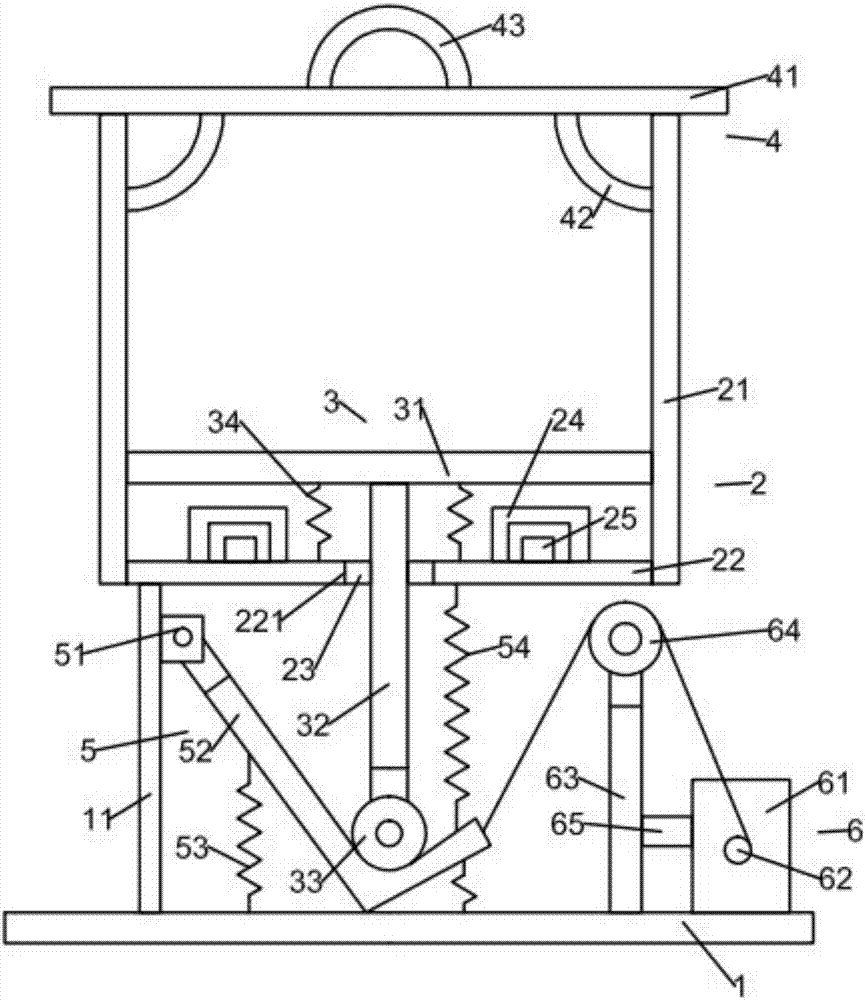

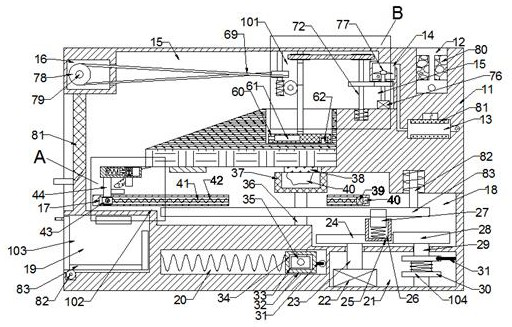

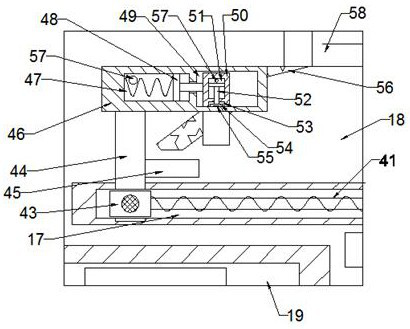

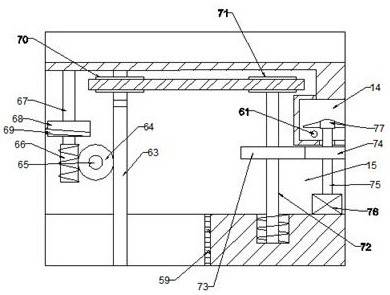

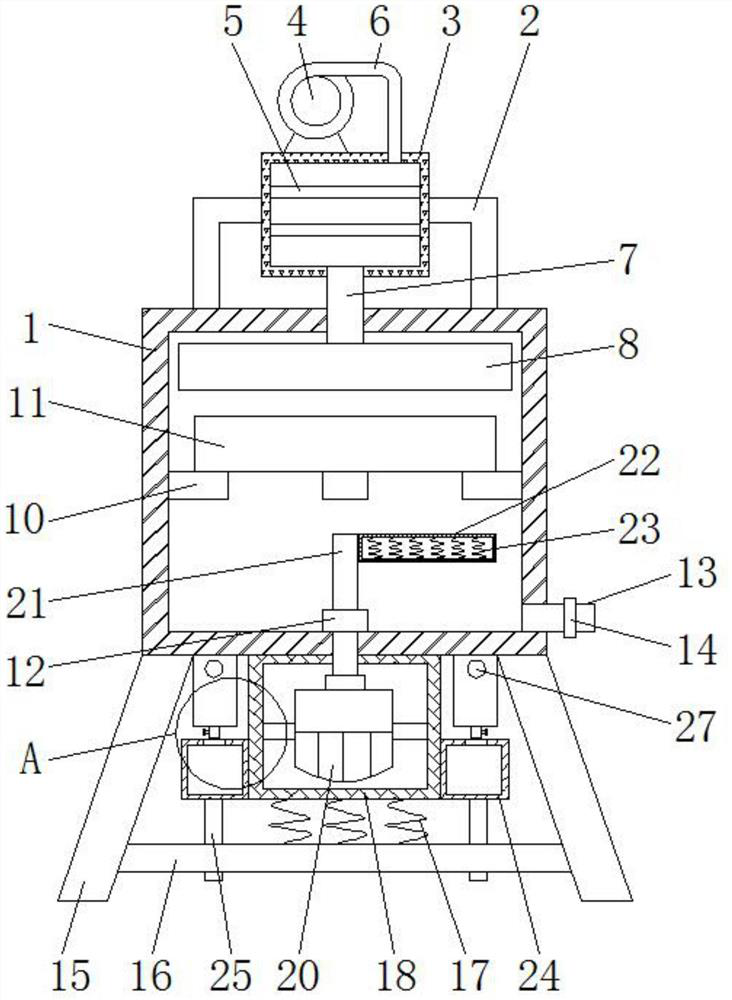

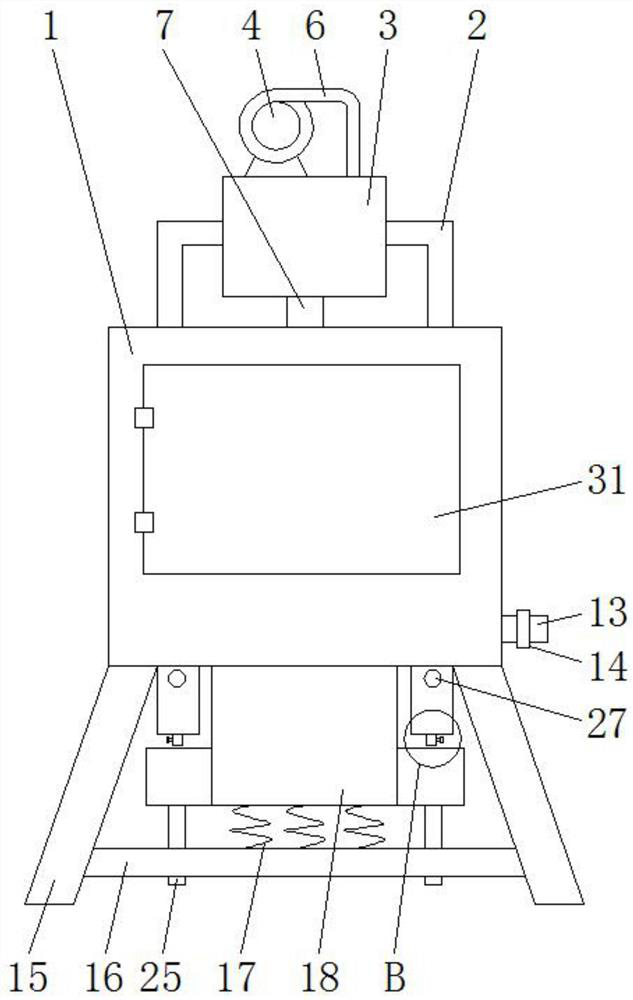

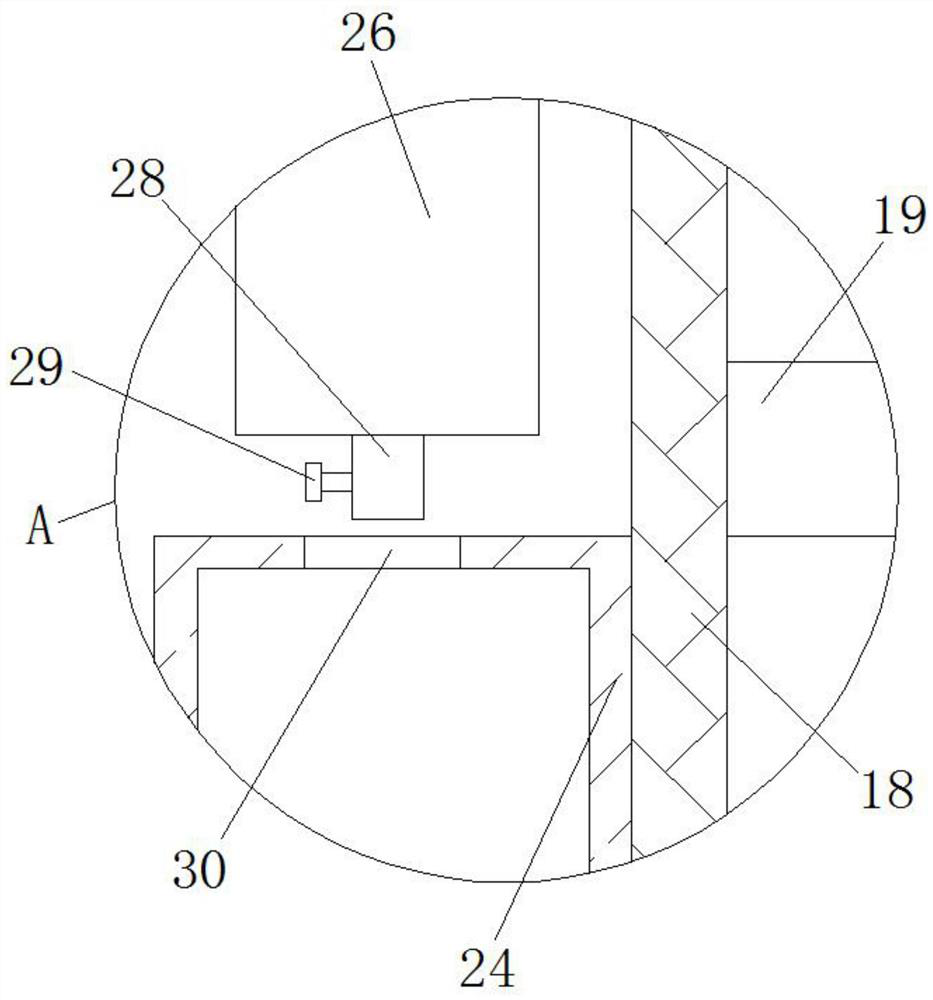

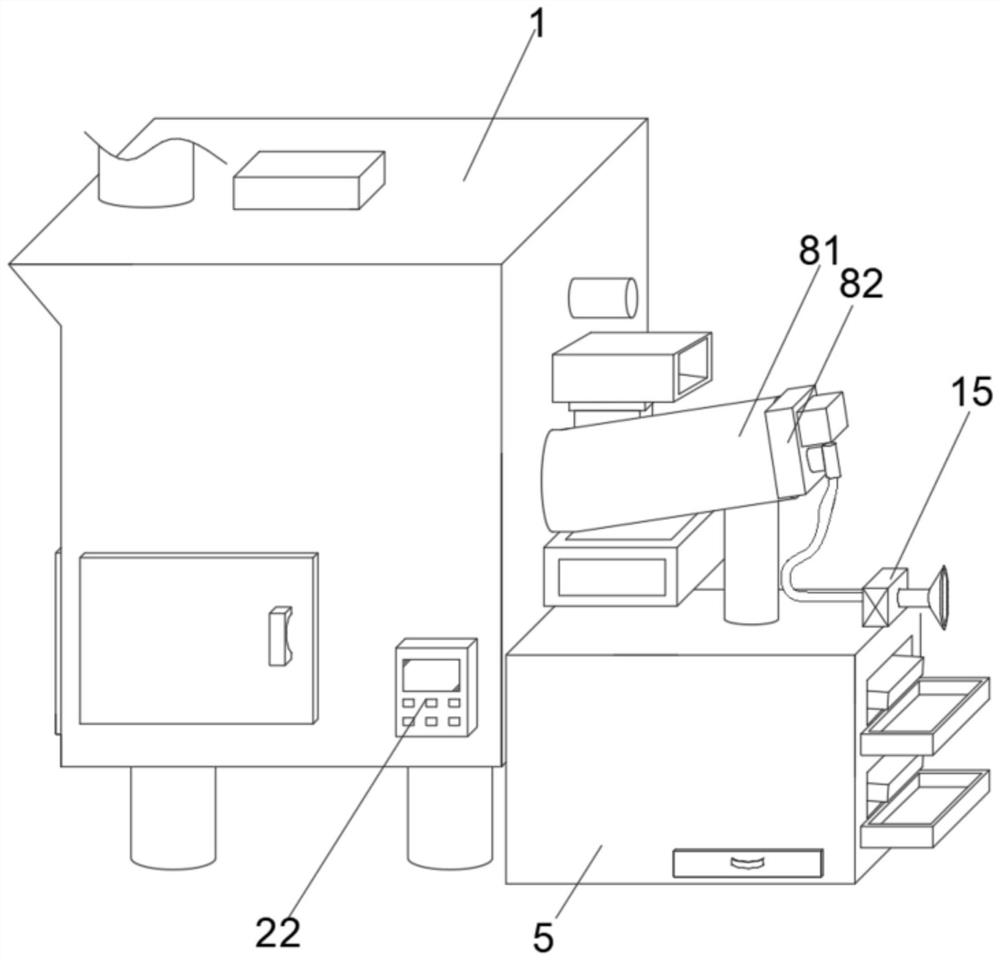

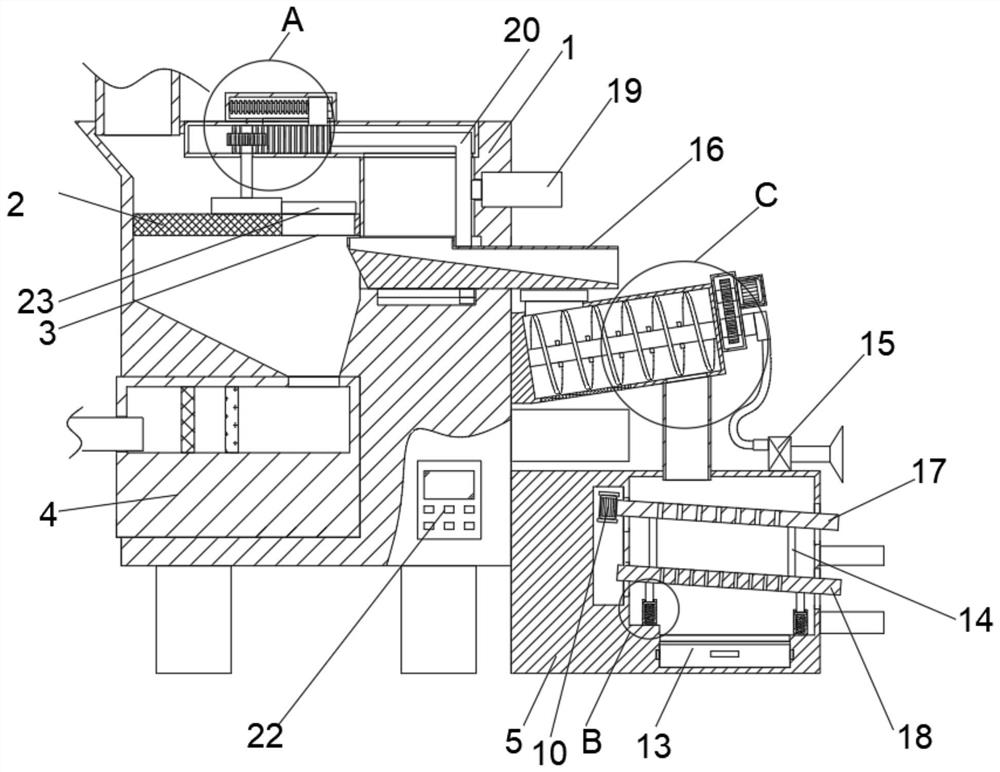

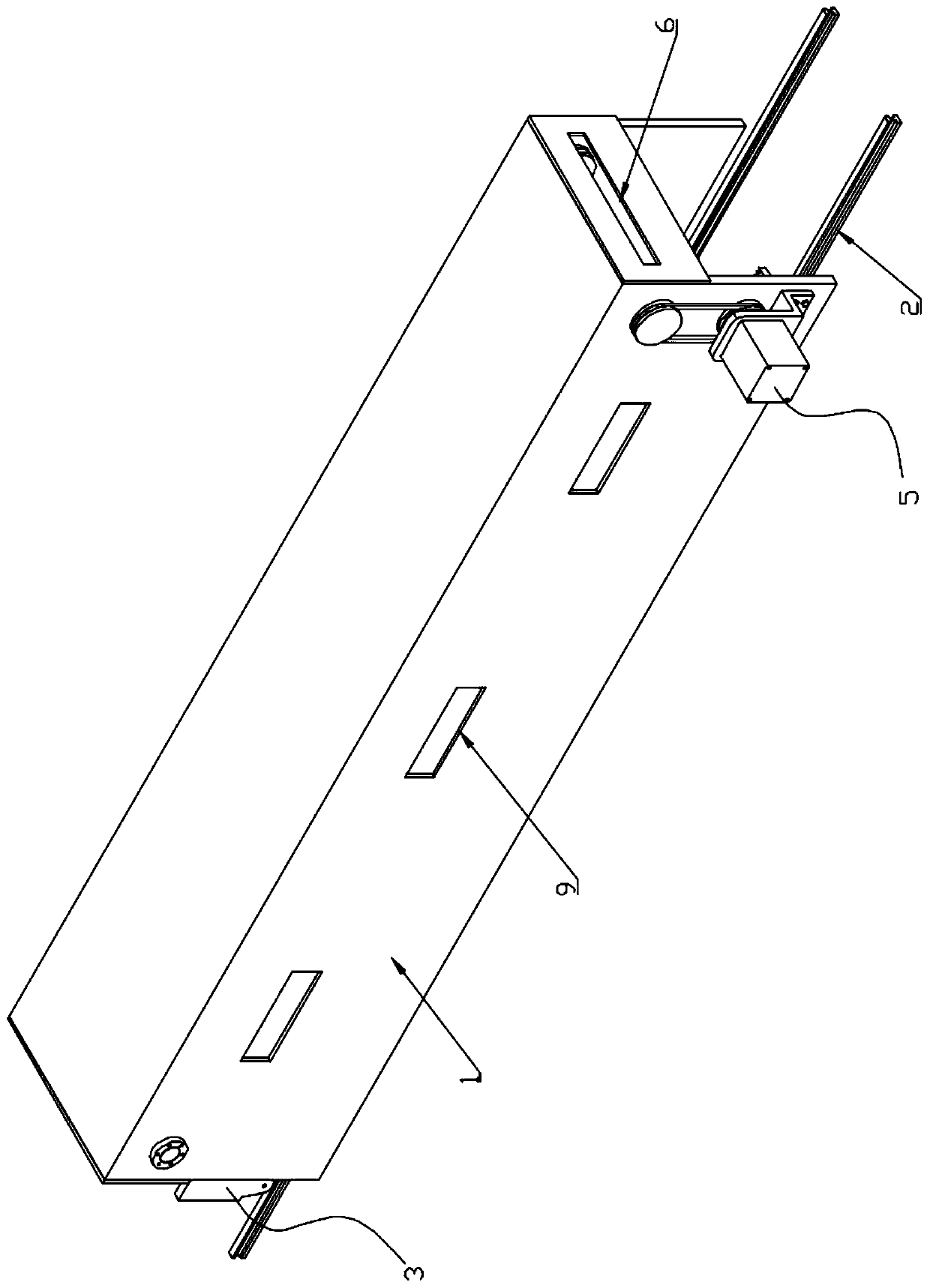

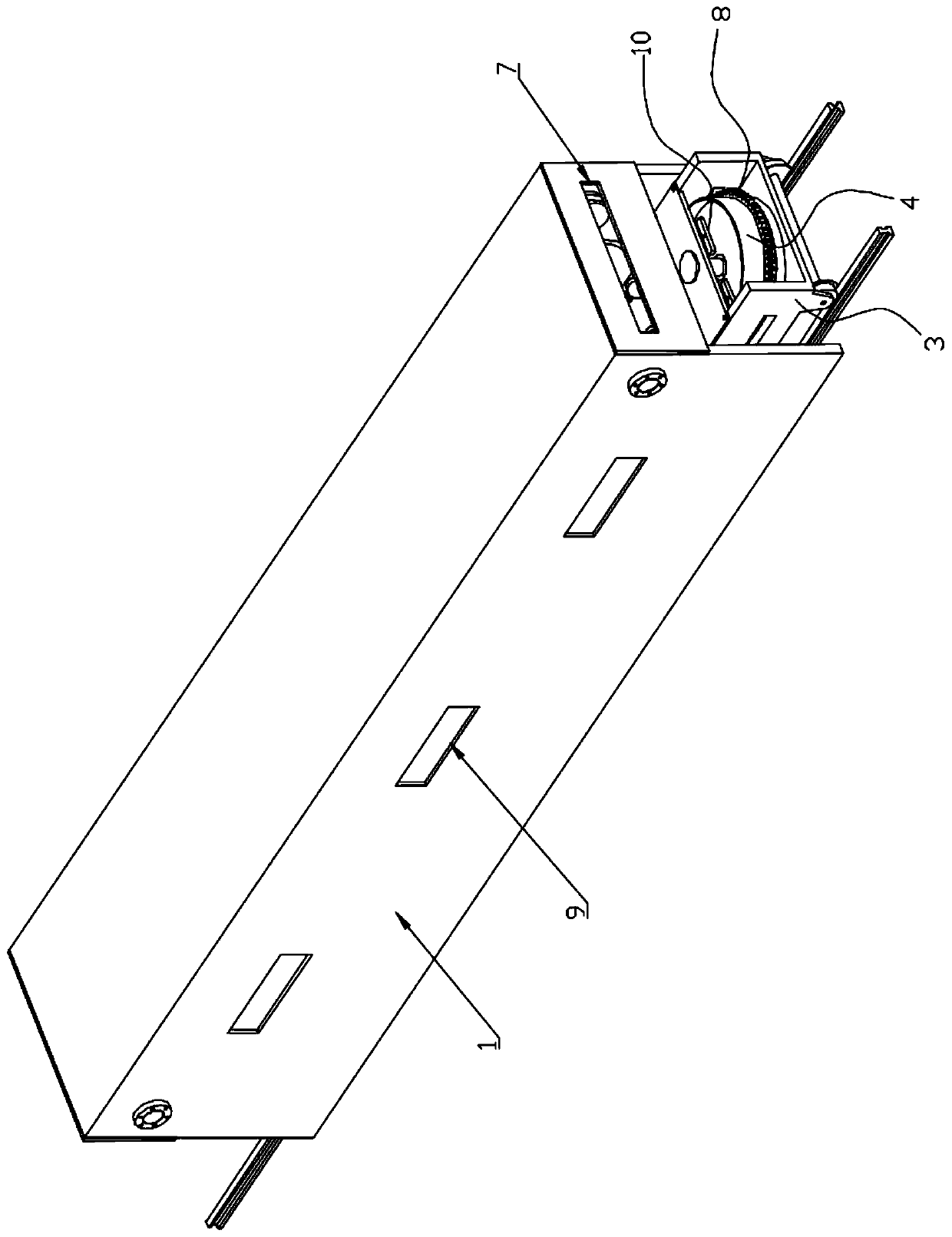

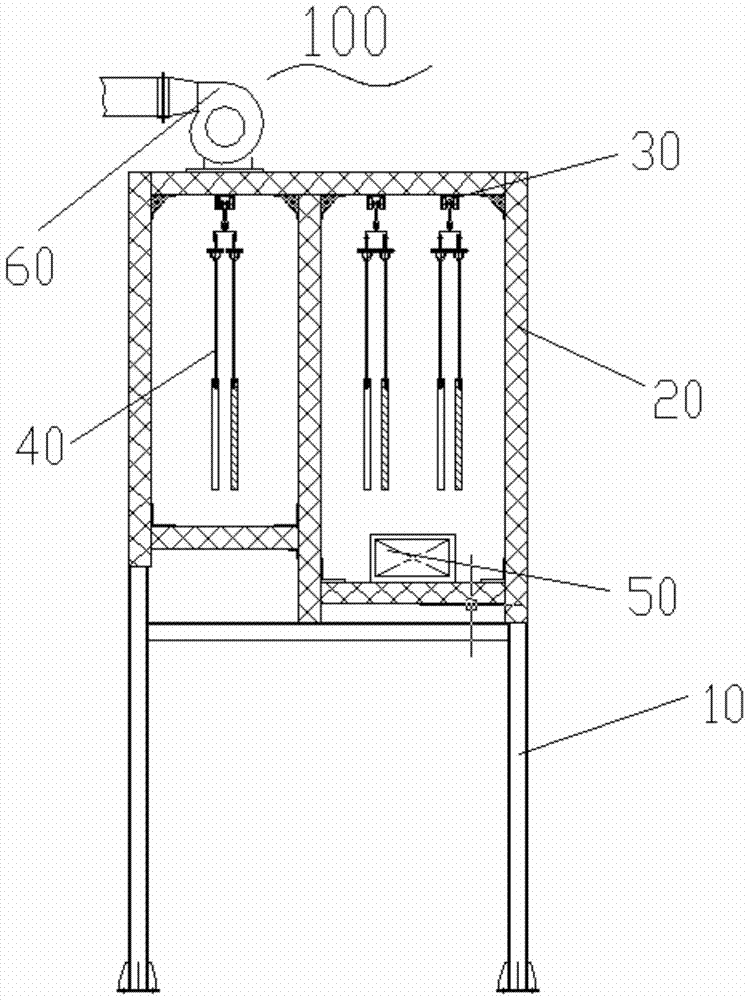

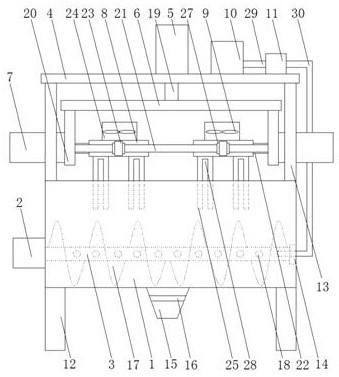

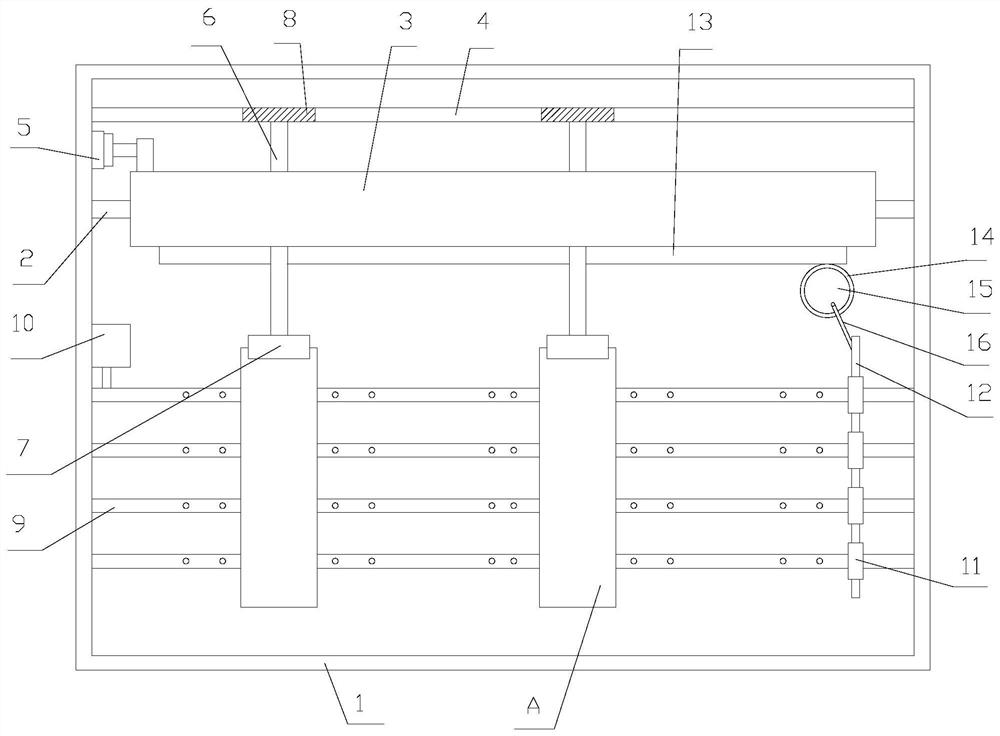

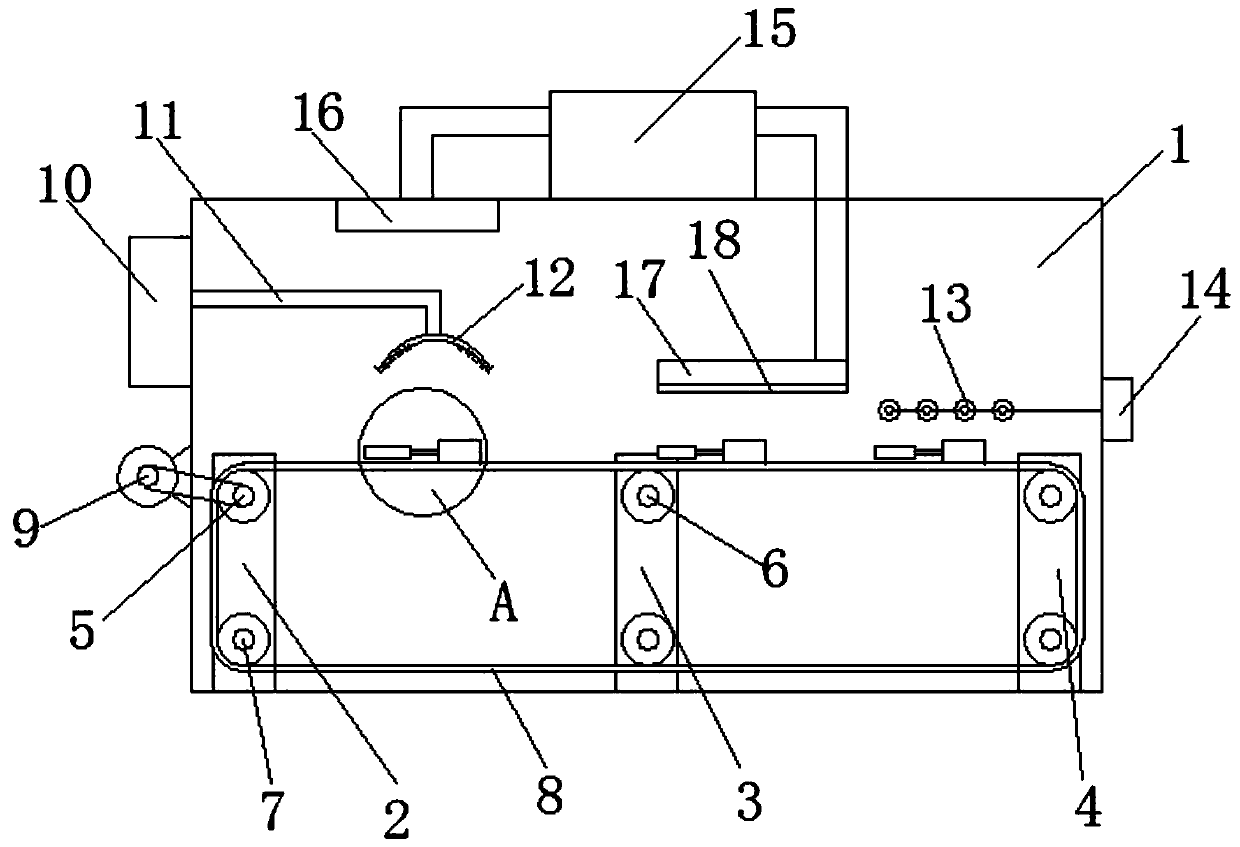

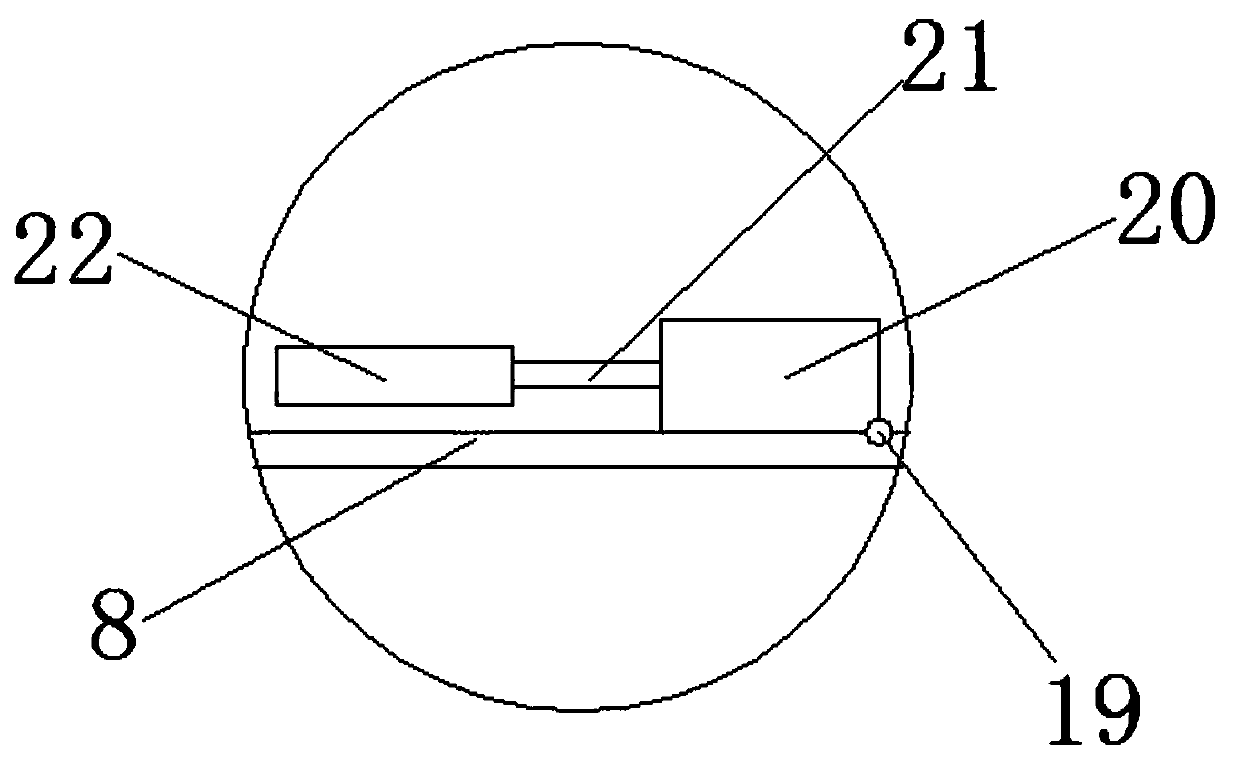

Drying device for cleaning electronic instrument part

InactiveCN106989581AFully dry treatmentMeet the needs of dryingDrying gas arrangementsDrying solid materialsElectronic instrumentEngineering

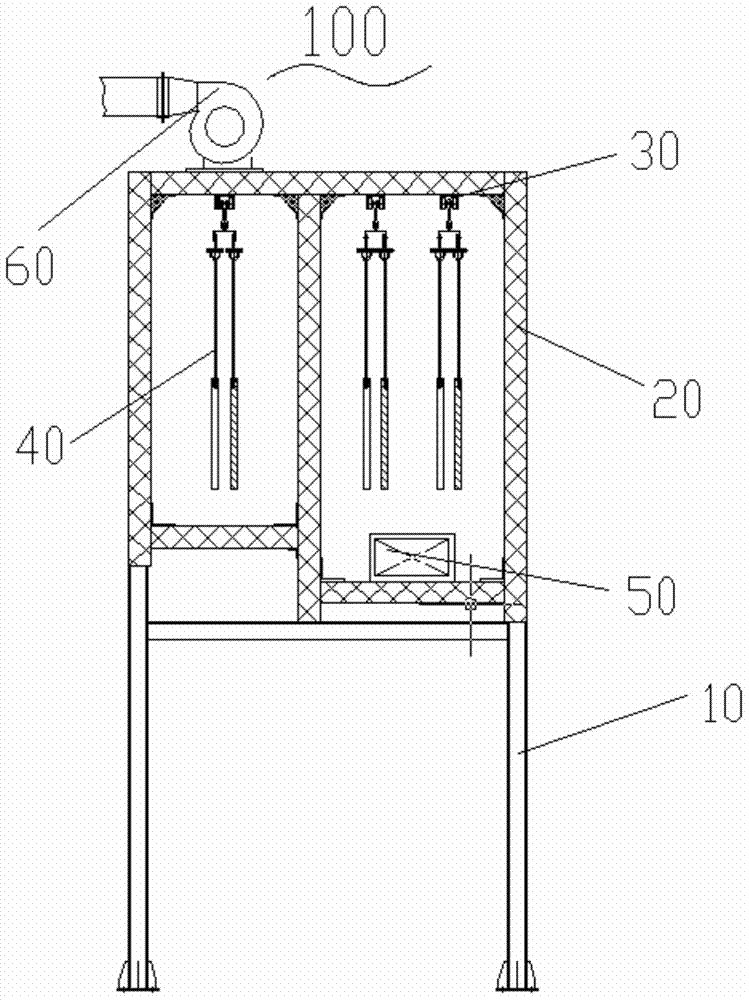

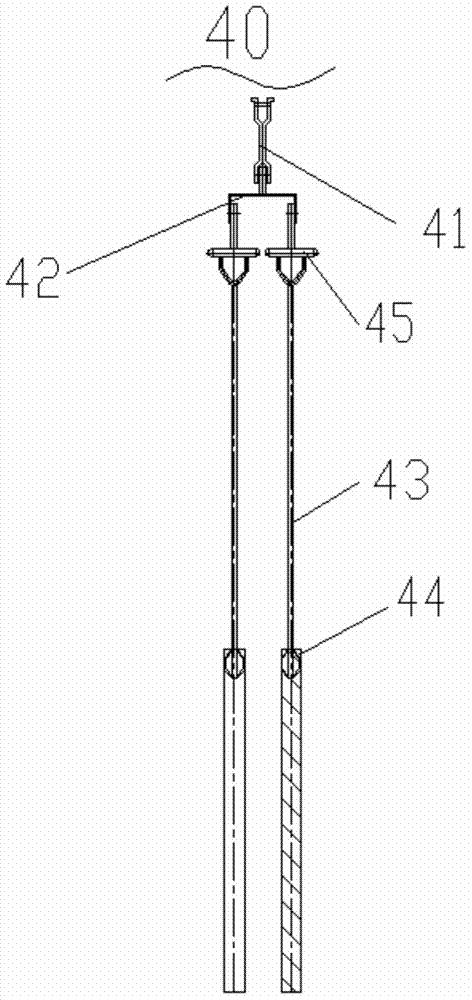

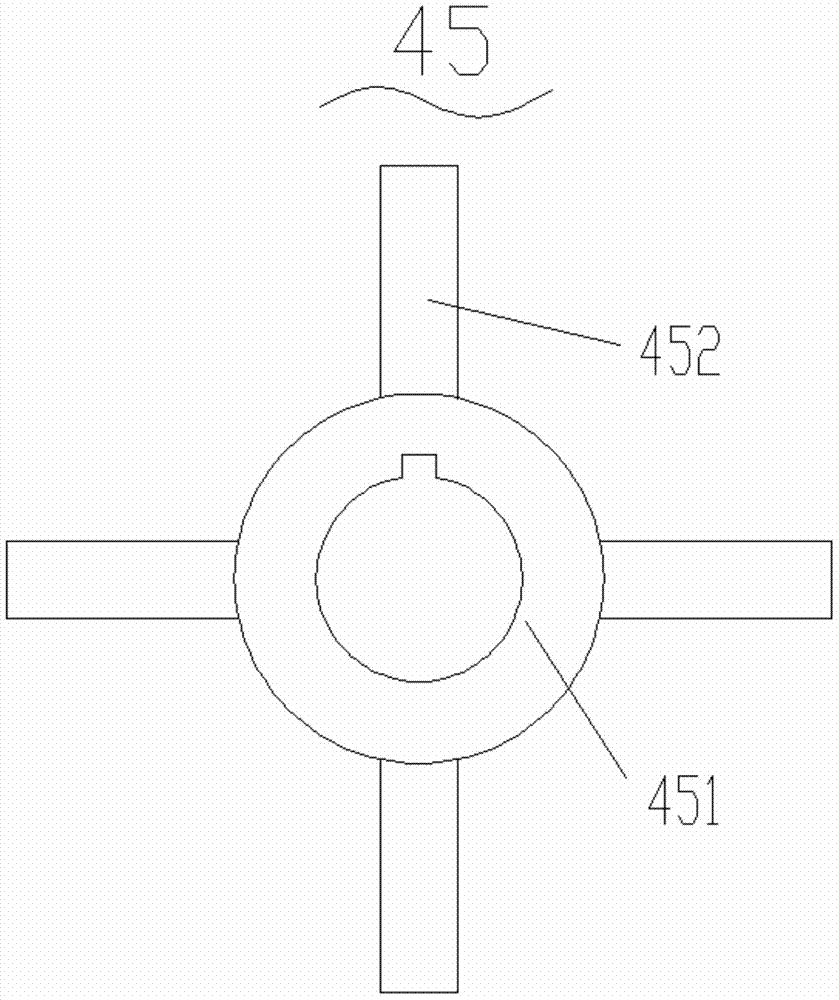

A drying device for cleaning electronic meter parts, the drying device for cleaning electronic meter parts includes a base plate, a frame device located above the base plate, a lifting device arranged on the frame device, a The cover device above the body device, the push device below the frame device, and the drive device on the right side of the push device. The drying equipment for cleaning electronic instrument parts of the present invention can realize sufficient contact between hot air and electronic instrument parts, and then can perform sufficient drying treatment on electronic instrument parts, with high drying efficiency and uniform drying, which can meet the requirements for electronic instrument parts. The need for instrument parts drying.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

Garbage anhydration processing apparatus

InactiveCN104713328AEasy to dryEasy to removeDrying using combination processesDrying gas arrangementsIncineration

The invention discloses a garbage anhydration processing apparatus, which comprises a roller, an air pipe, a feeding device and an exhaust fan, wherein a plurality of water outlet holes are distributed in the roller; the air pipe is mounted in the roller; a plurality of air outlet holes facing the water outlet holes are formed in the air pipe; the feeding device is communicated with an inlet of the roller; an air outlet of the exhaust fan is connected to one end of the air pipe; the other end of the air pipe is a sealed end; a cabin door used for opening or sealing the outlet of the roller is mounted at the outlet of the roller; an air inlet of the exhaust fan is connected to a hot air outlet of a garbage incinerator by a pipeline. While garbage is spin-dried by the invention, the garbage is subjected to anhydration treatment by hot air which is generated by garbage incineration, and thus the anhydration process of the garbage is greatly accelerated.

Owner:QINGDAO WATER WORLD ENVIRONMENTAL PROTECTION TECH

Drying method of sweet potato vermicelli

The present invention discloses a drying method of sweet potato vermicelli. The drying method is characterized by comprising the following steps: (1) cooking and cooling: vermicelli after vermicelli leaking is cooked in a pot at 79 DEG C for 4 min and the cooked vermicelli is cooled by using a circulating cold water tank; (2) an ''S''-type drying room comprises a purifying and filtering room 1, a drying channel 2, an air inlet 3 and an air outlet 4, can improve a drying effect of the vermicelli, conducts a batch drying and improves a drying efficiency; (3) vermicelli drying: firstly the vermicelli is air-dried and naturally dried, an energy consumption is reduced, then the vermicelli is placed in the drying room, and a low temperature and high temperature alternating drying is conducted; and (4) vermicelli desulfurizing: the vermicelli is placed into a desulfurization room, hot air containing 20% water vapor is ventilated, and the vermicelli is desulfurized.

Owner:肥西县金桥红薯专业合作社

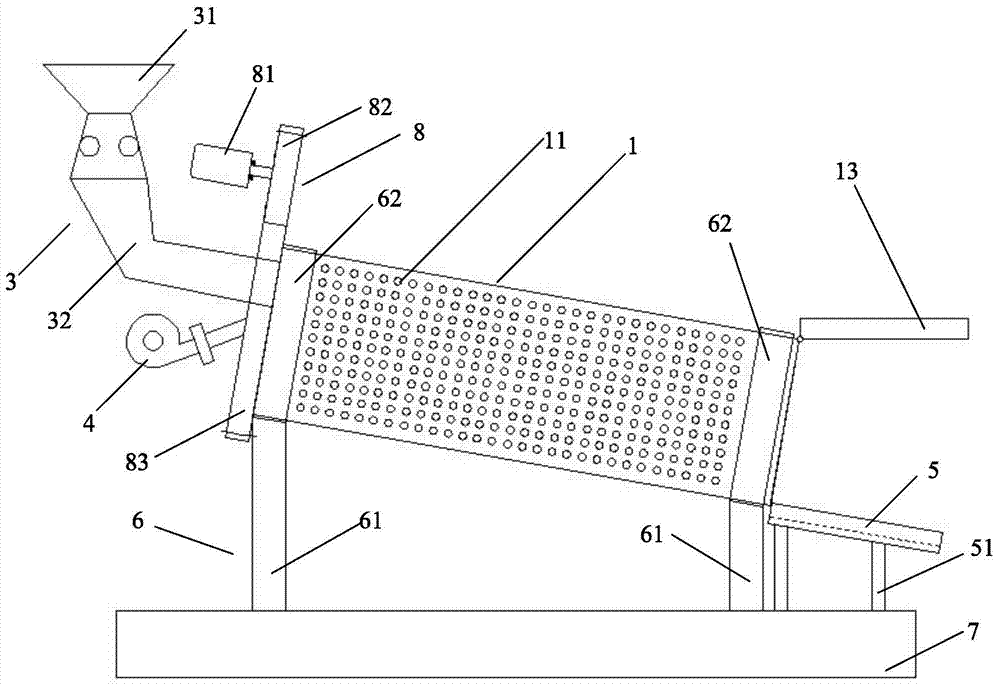

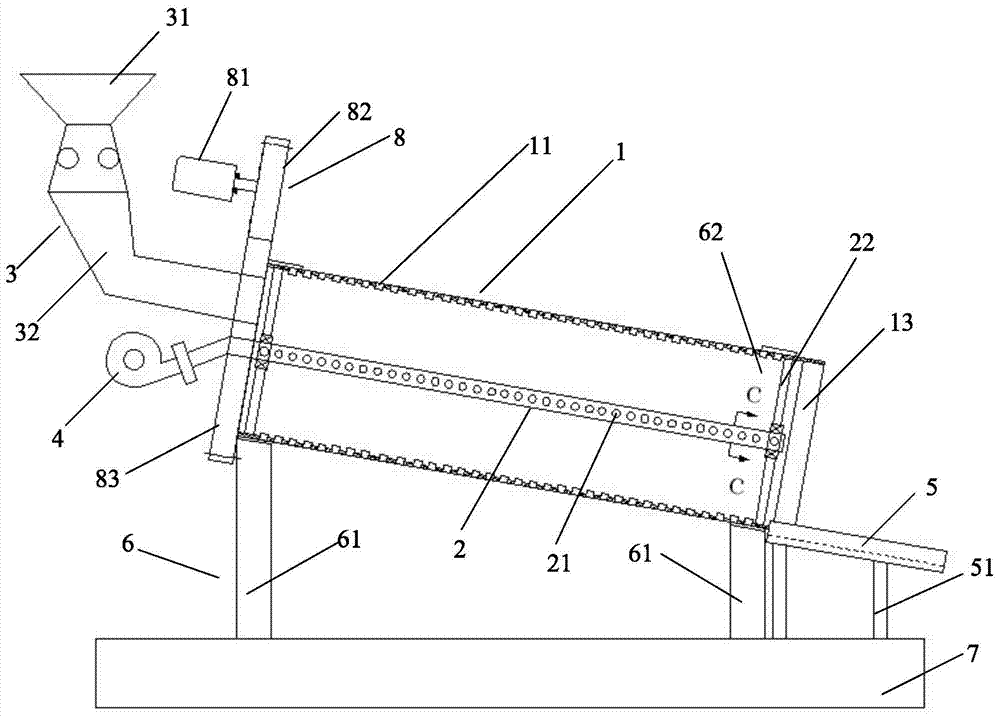

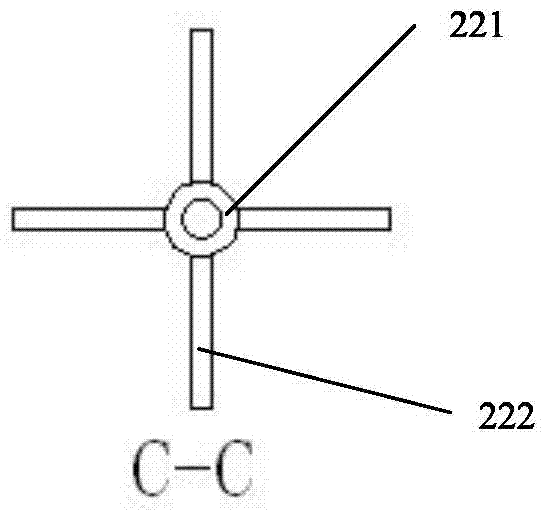

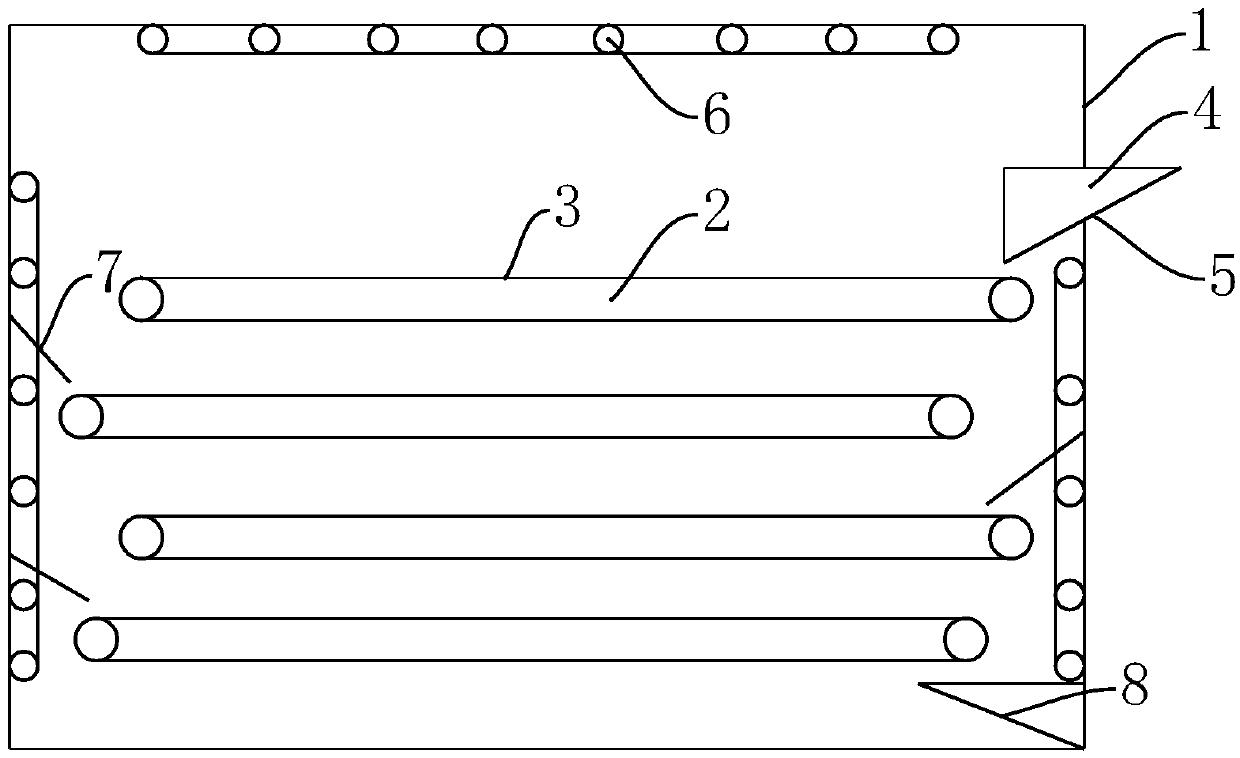

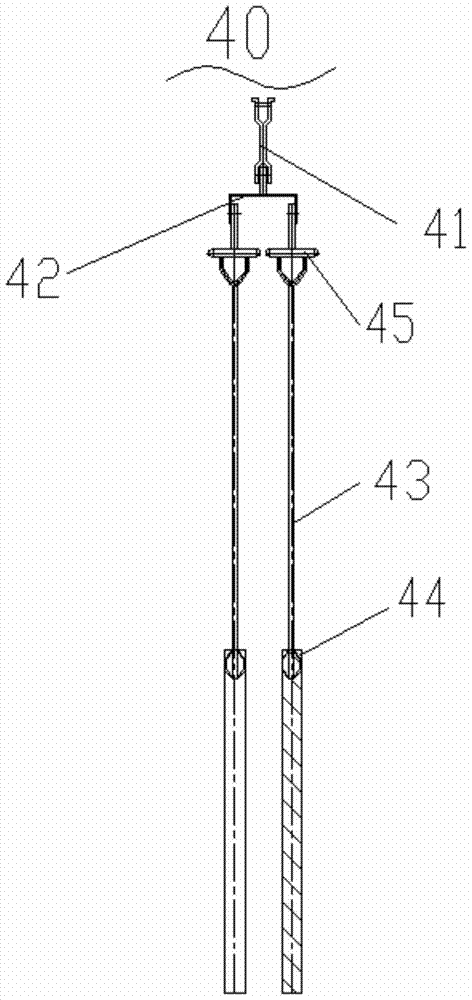

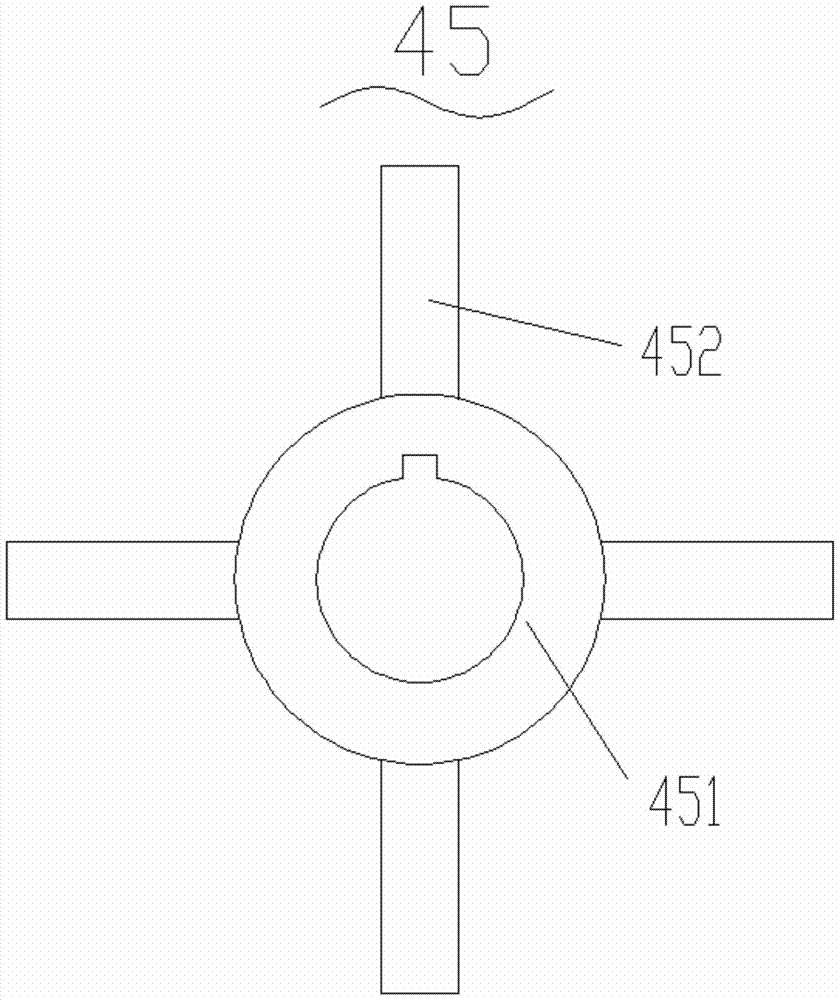

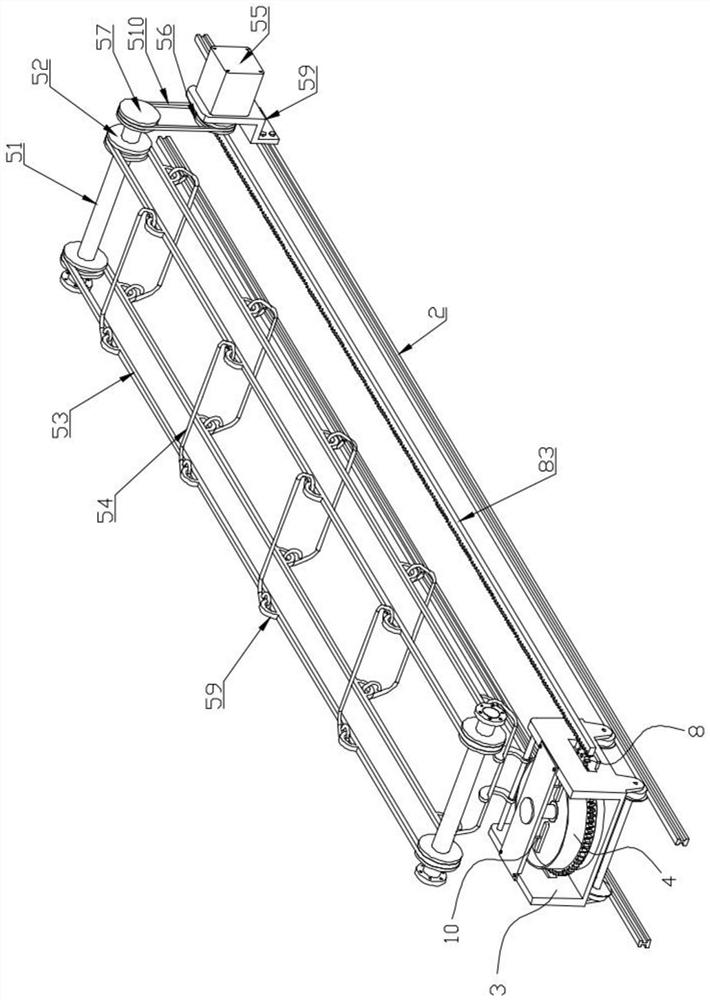

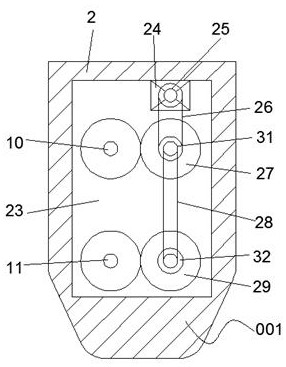

Drying device

ActiveCN104841623AFully dry treatmentMeet the requirements of spray treatment processPretreated surfacesCoatingsEngineeringMechanical engineering

The invention relates to a drying device which comprises a support and drying tunnels arranged in the support. A plurality of conveying chains are arranged on one sides, away from the support, of the drying tunnels, a rotary rack is hung on each conveying chain, and the rotary racks can be used for assembling workpieces; a steam pipe is arranged on one sides, adjacent to the support, of the drying tunnels, and steam is led into the steam pipe; a fan is arranged on the top portions of the drying tunnels, and an exhaust inlet of the fan is communicated with the drying tunnels. During use, the workpieces assembled in the rotary racks can be sufficiently dried so as to meet requirements on subsequent processing technology of the workpieces; meanwhile, during drying of the workpieces, use cost is lower, and drying requirement of enterprises on the workpieces are met.

Owner:NANTONG BEST MACHINE CO LTD

Rapid drying treatment equipment for garbage

InactiveCN104713093ARealize automatic controlReduce labor intensityDrying using combination processesGas current separationAutomatic controlAir drying

The invention discloses rapid drying treatment equipment for garbage. The rapid drying treatment equipment comprises a roller with a plurality of water outlets distributed, a radial blowing pipe, an air supply device, an axial blowing pipe, a driving device, an electric cabin door and a controller. The radial blowing pipe is mounted in the roller, and a plurality of air outlets facing water outlets are formed in the radial blowing pipe; the air supply device is connected with one end of the radial blowing pipe; the axial blowing pipe is connected with the air supply device and is aligned at the front end of the roller; the driving device is used for driving the roller to rotate, and the electric cabin door is mounted on an outlet of the roller and used for opening or closing the outlet of the roller; the controller is connected with the air supply device, the driving device and the electric cabin door and used for controlling the air supplying device to supply air to the radial blowing pipe and the axial blowing pipe respectively, controlling the electric cabin door to open or close the outlet of the roller and controlling the roller to rotate; and the other end of the radial blowing pipe is a closed end, and an air inlet of the air supply device is connected with a hot air outlet of a garage incinerator through a pipeline. According to the equipment, spinning drying and hot air drying treatment can be carried out on garbage at the same time, and automatic control over water removing treatment of the garbage is achieved.

Owner:QINGDAO WATER WORLD ENVIRONMENTAL PROTECTION TECH

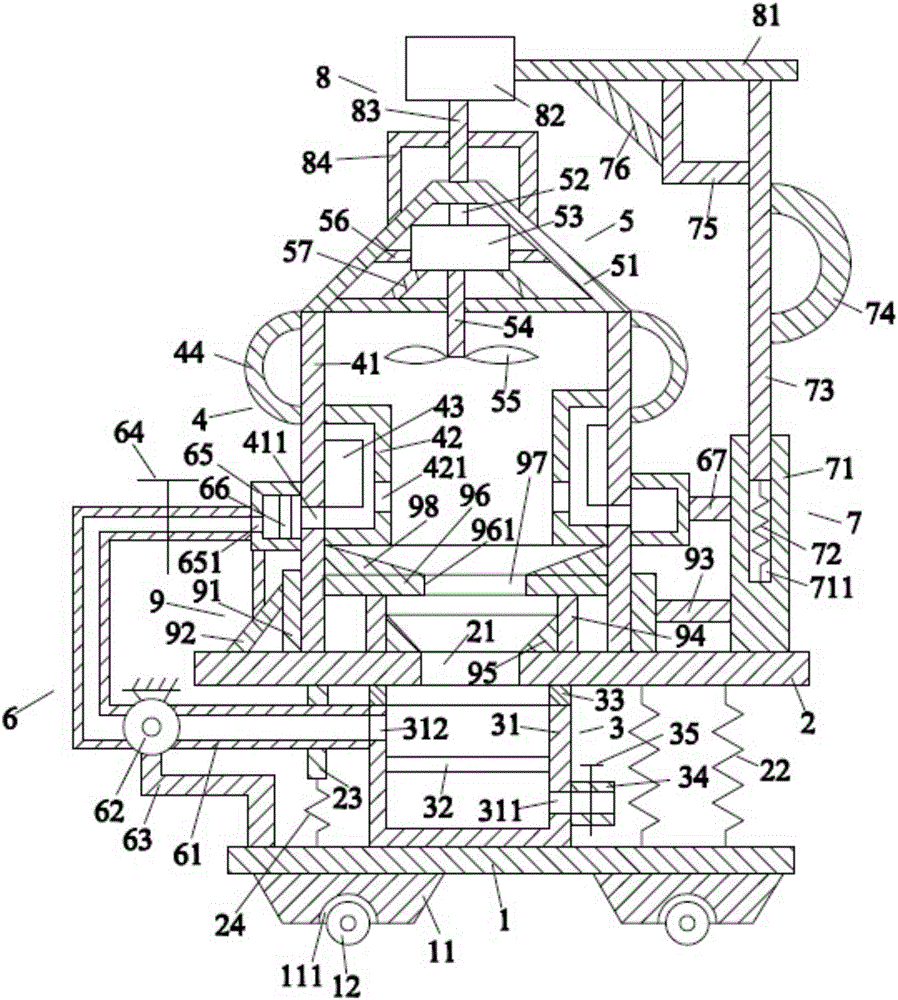

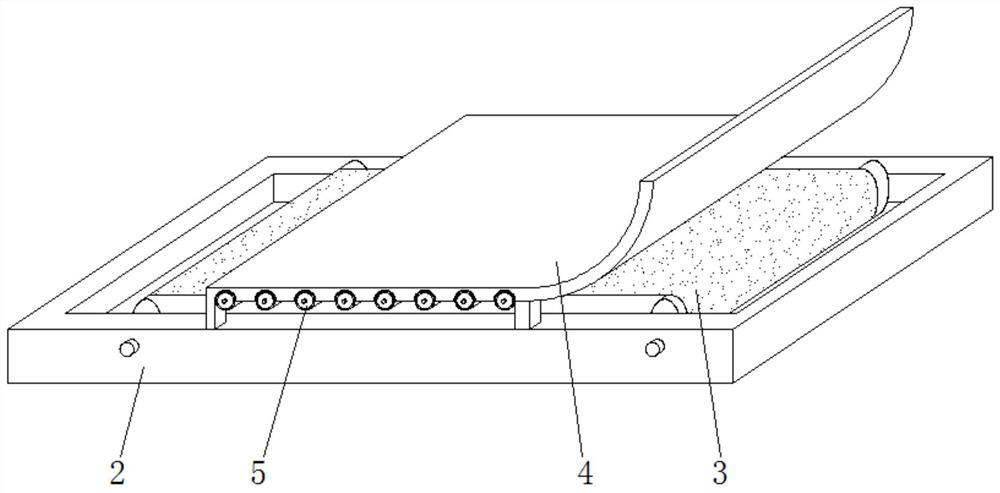

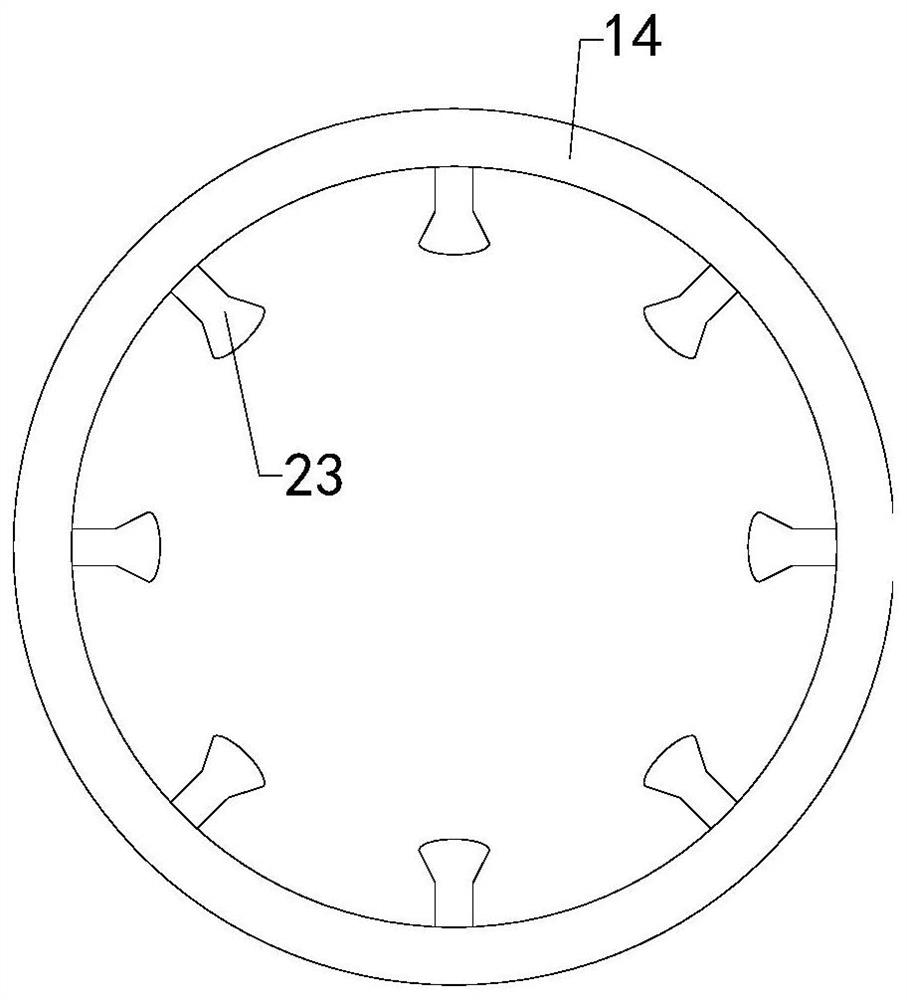

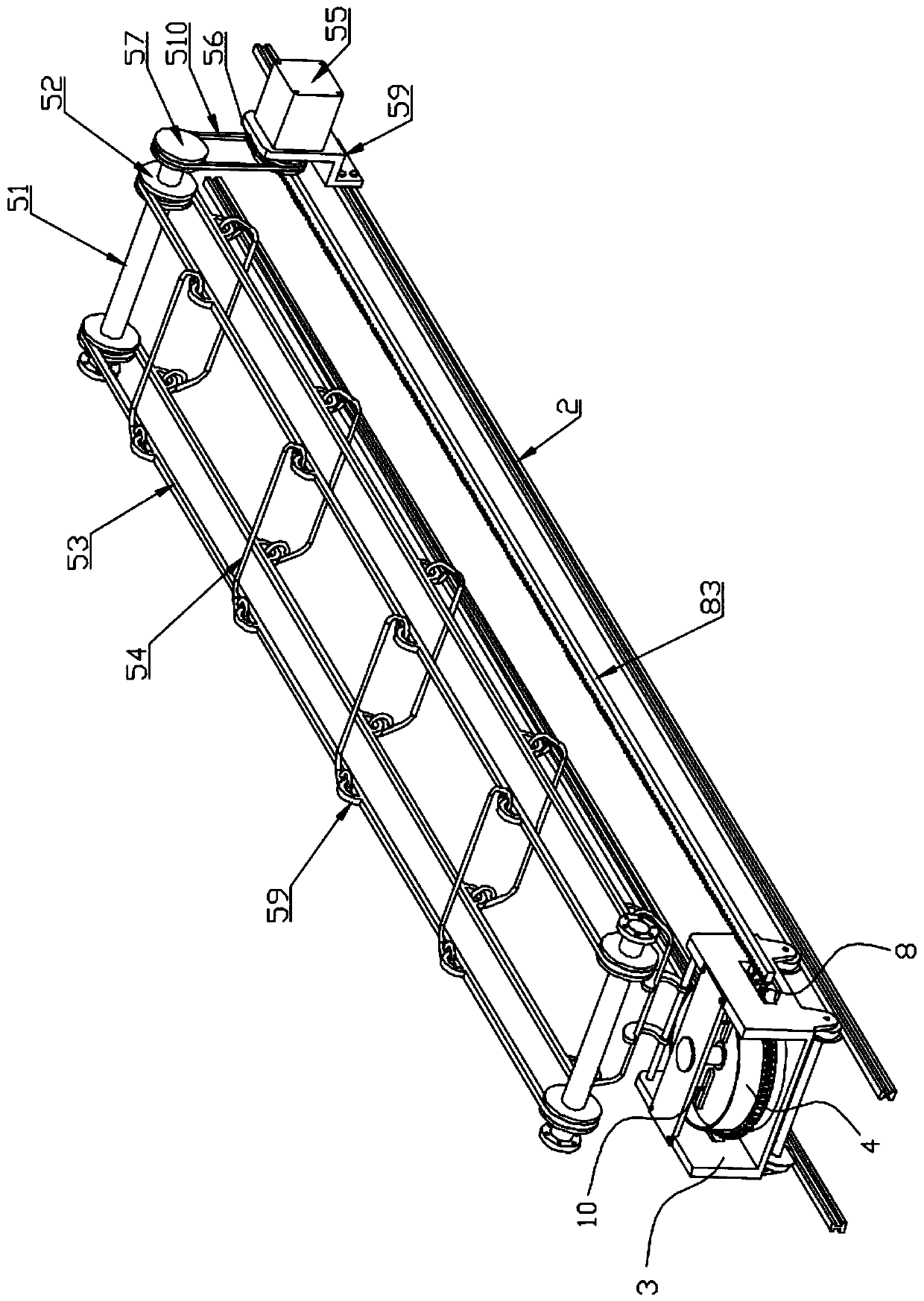

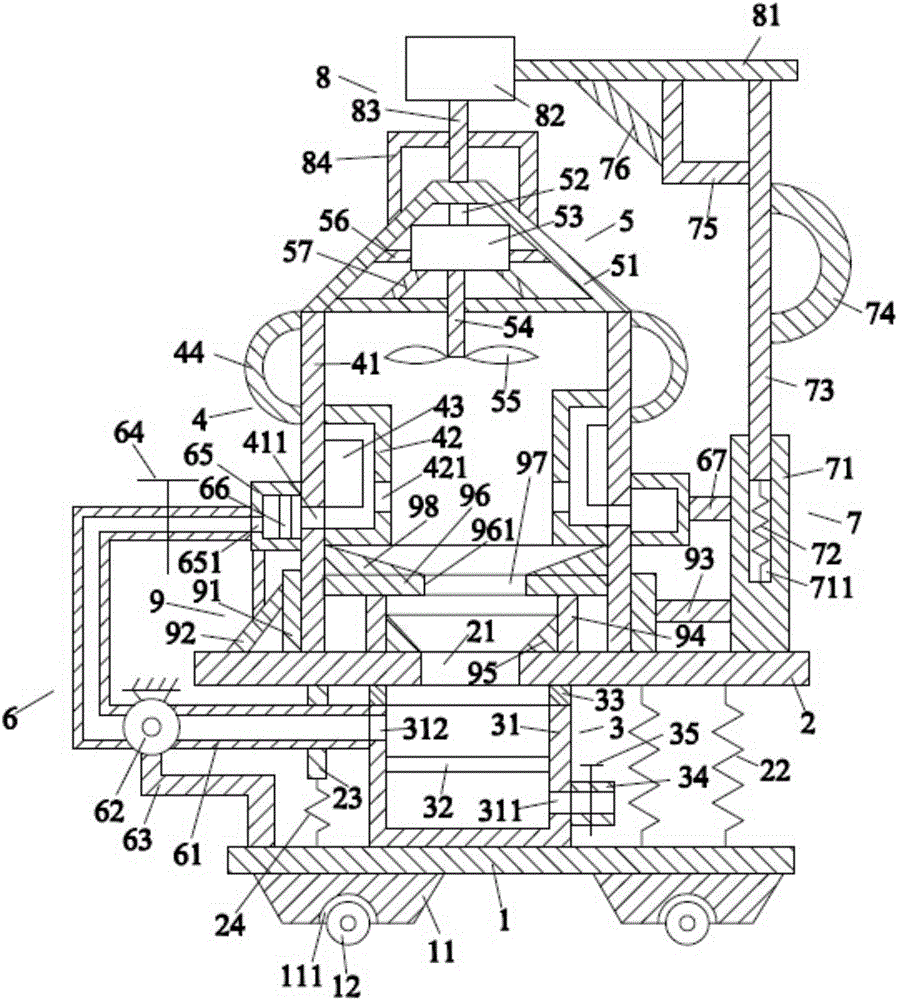

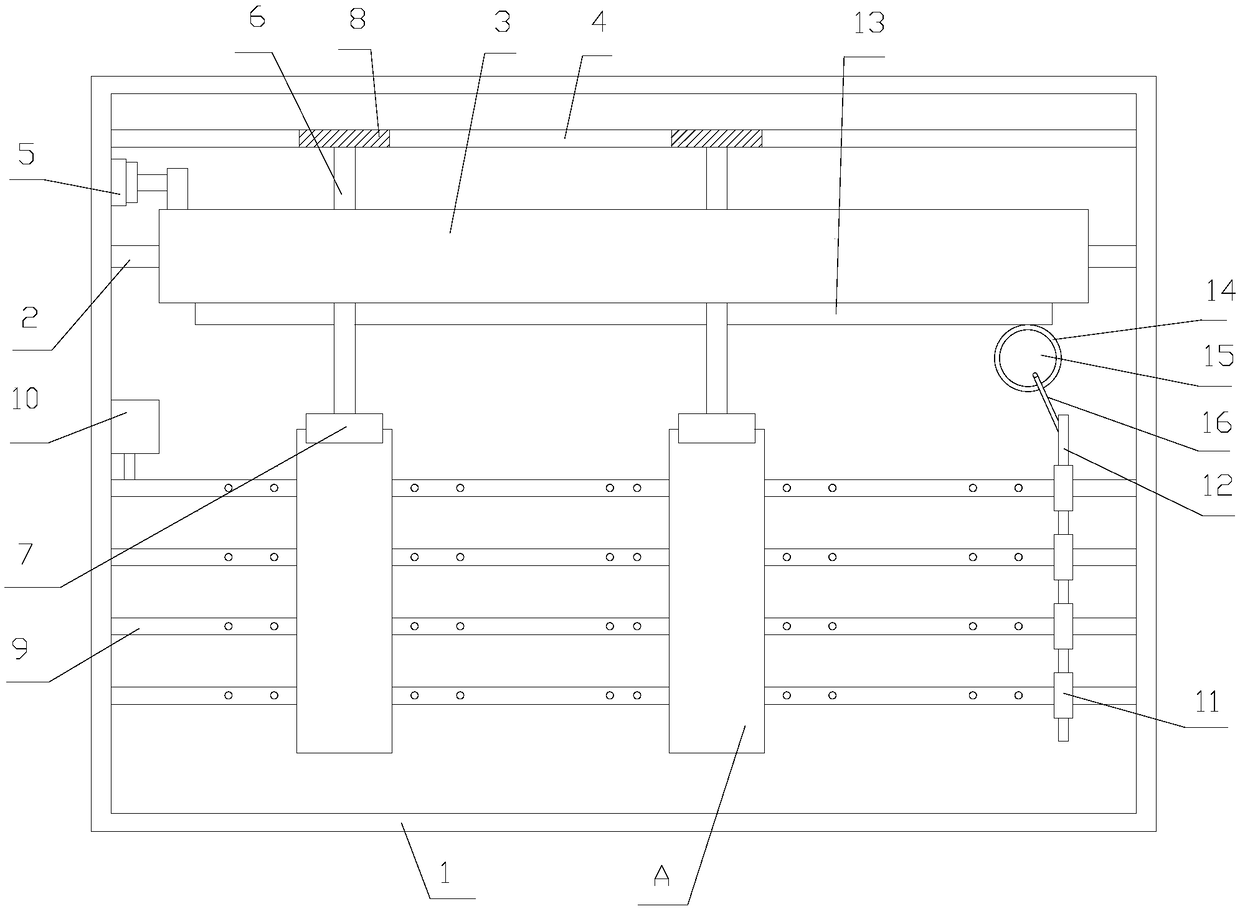

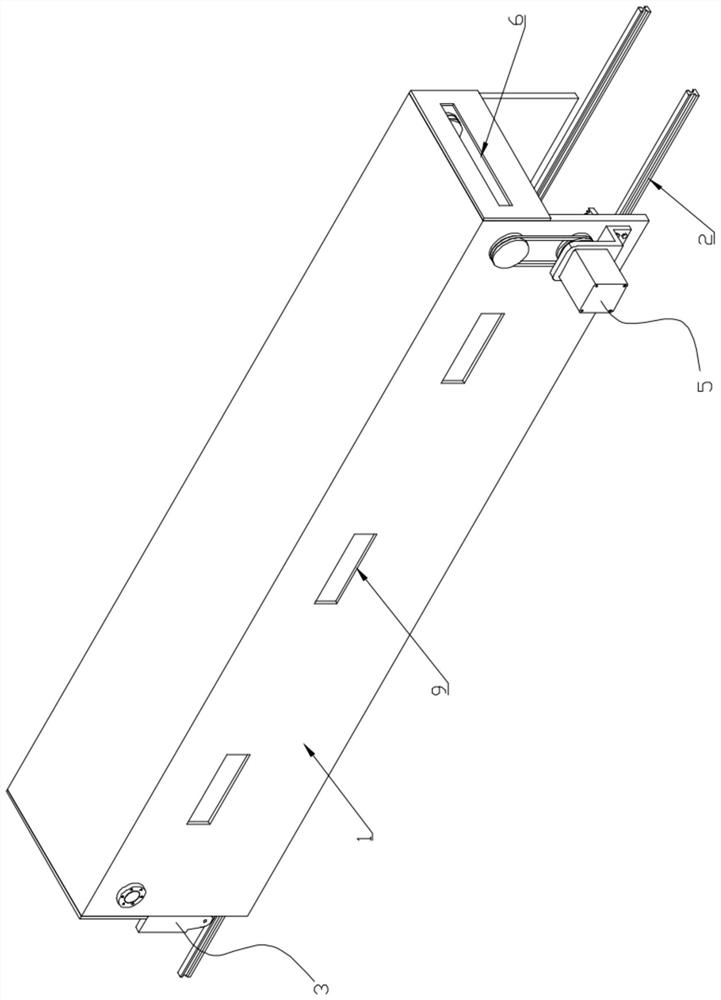

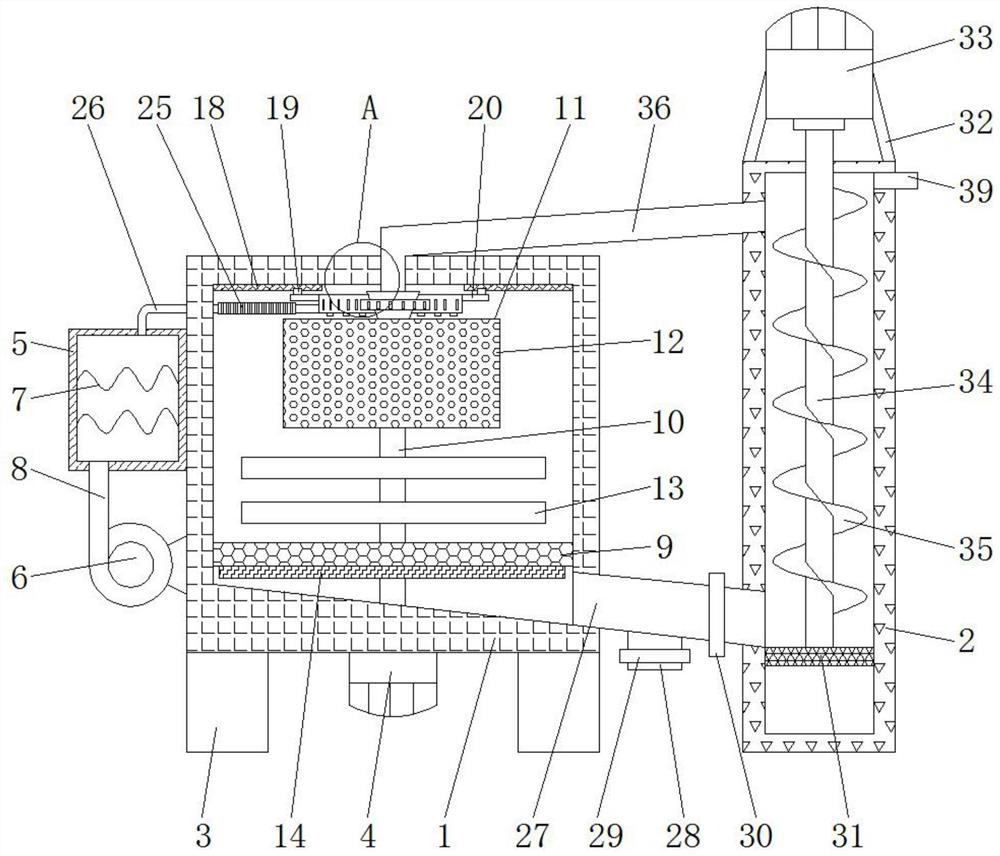

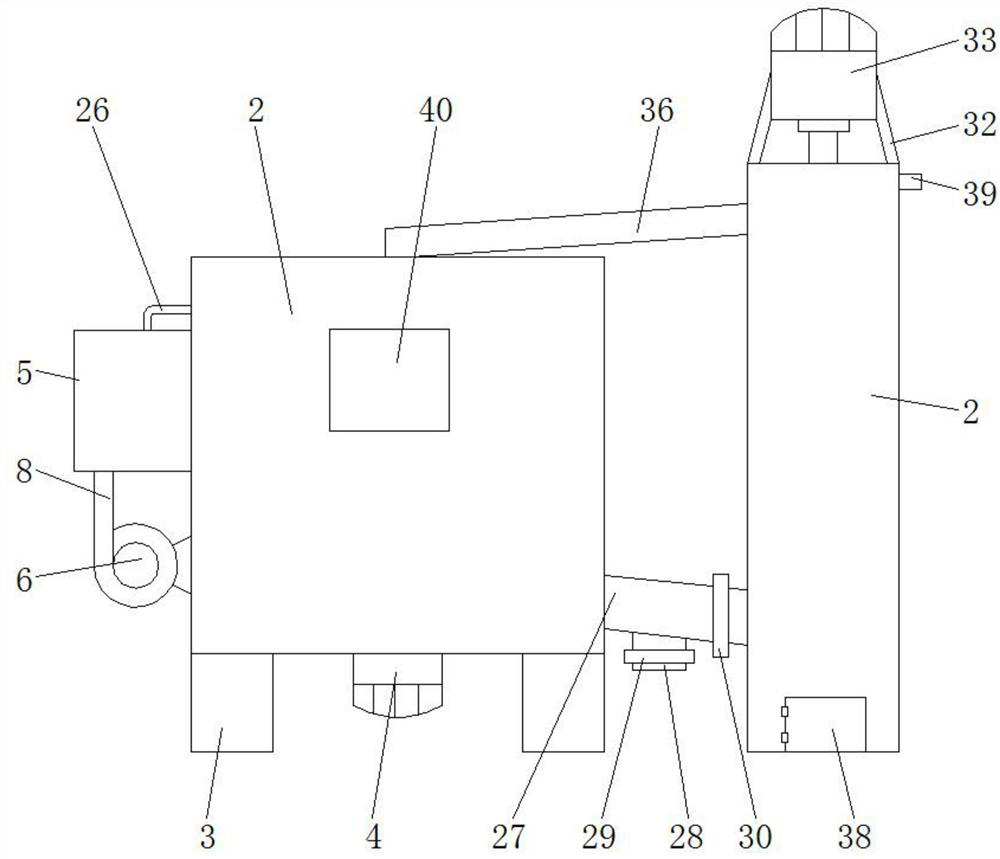

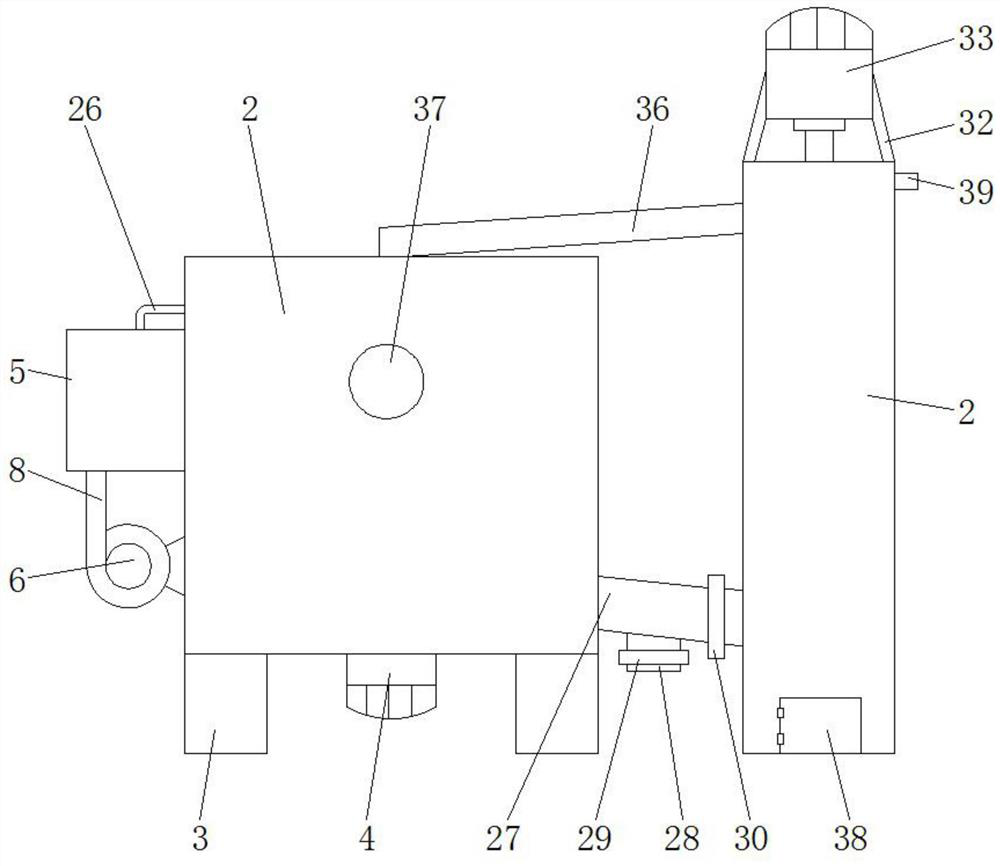

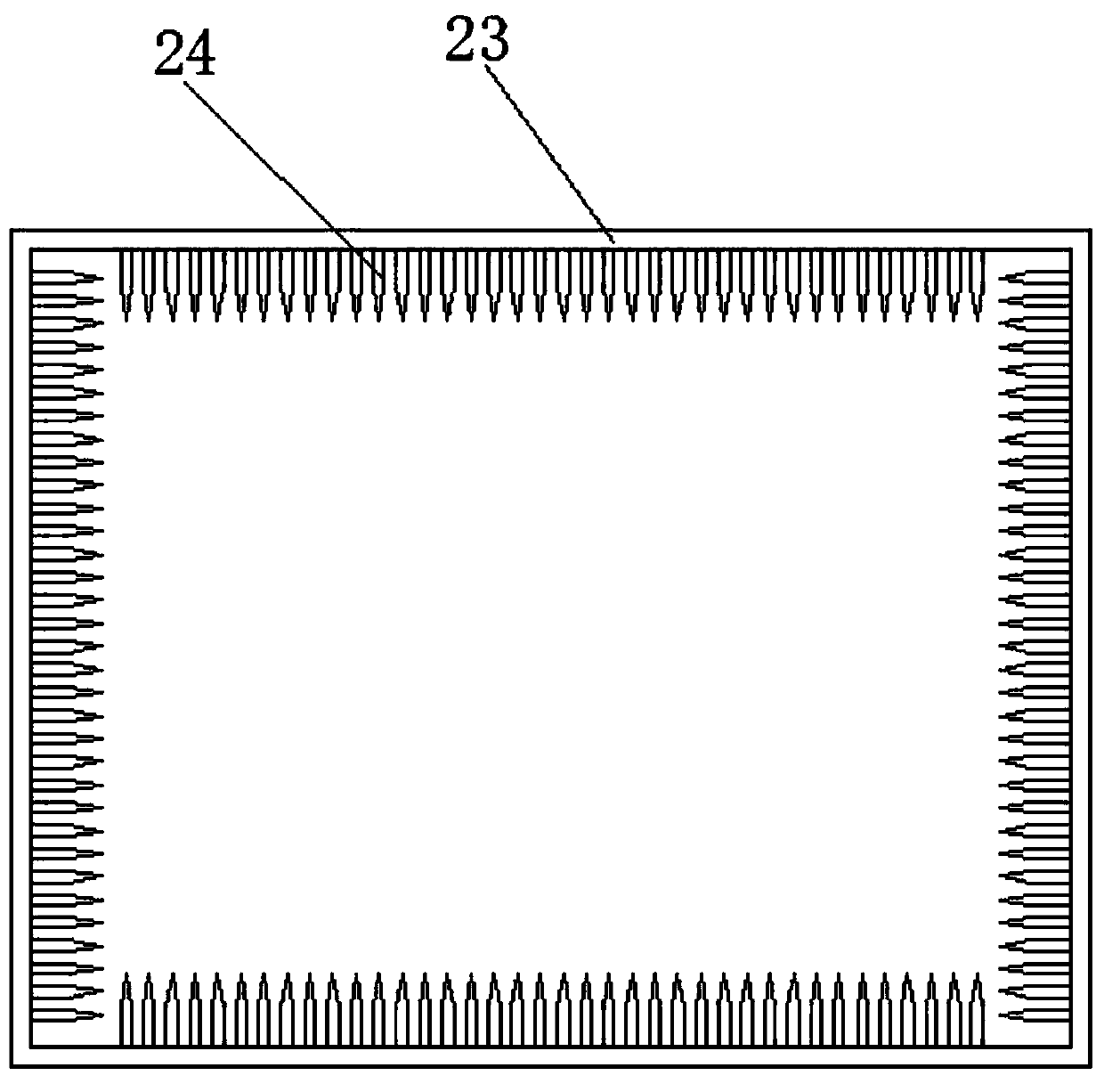

Sludge filtering and drying purification treatment system

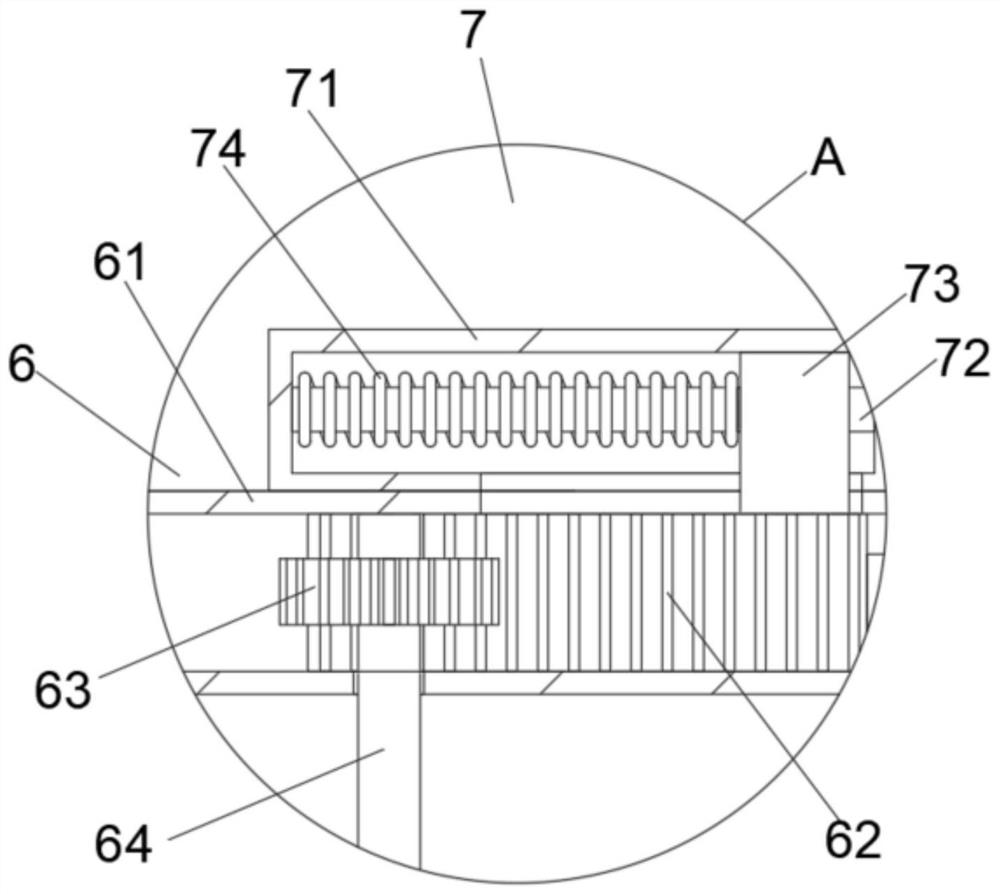

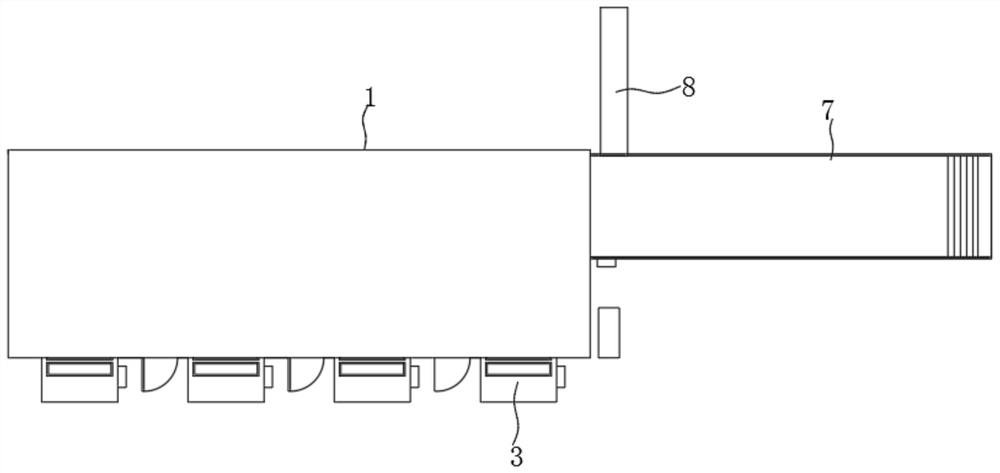

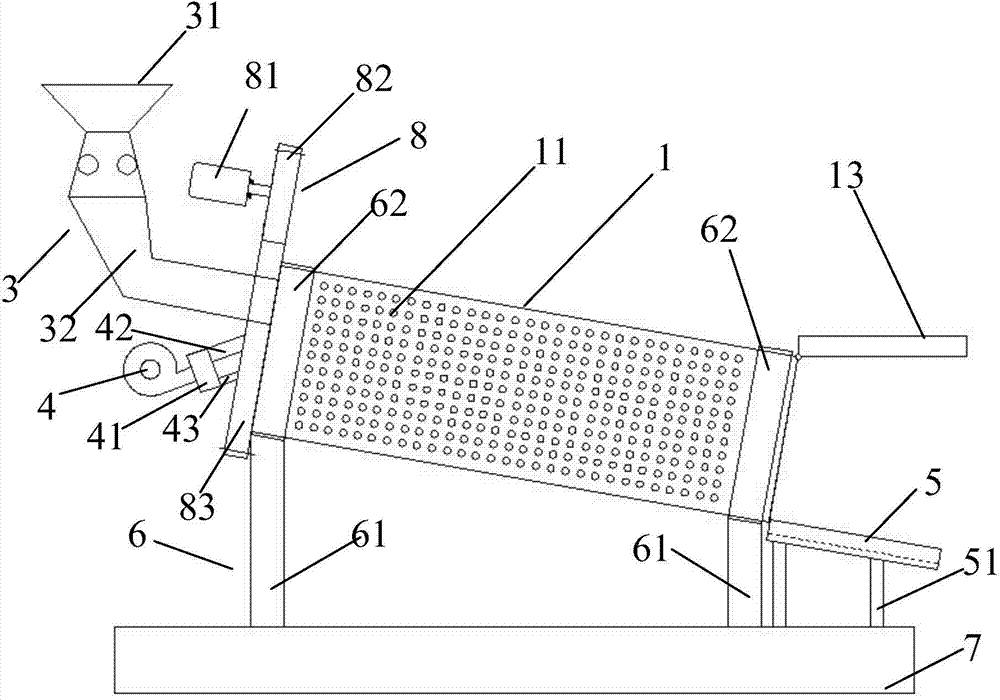

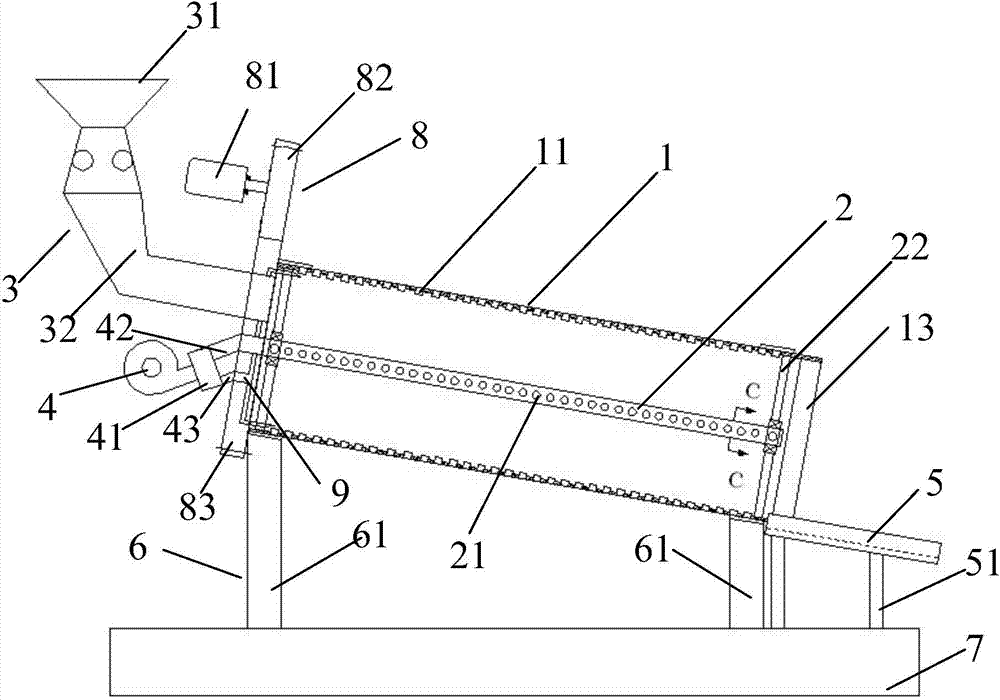

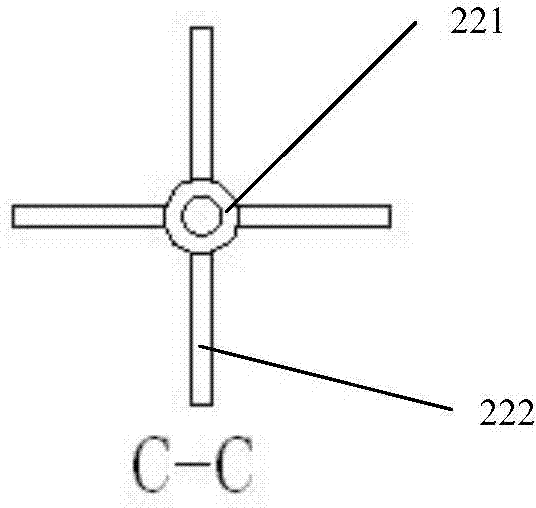

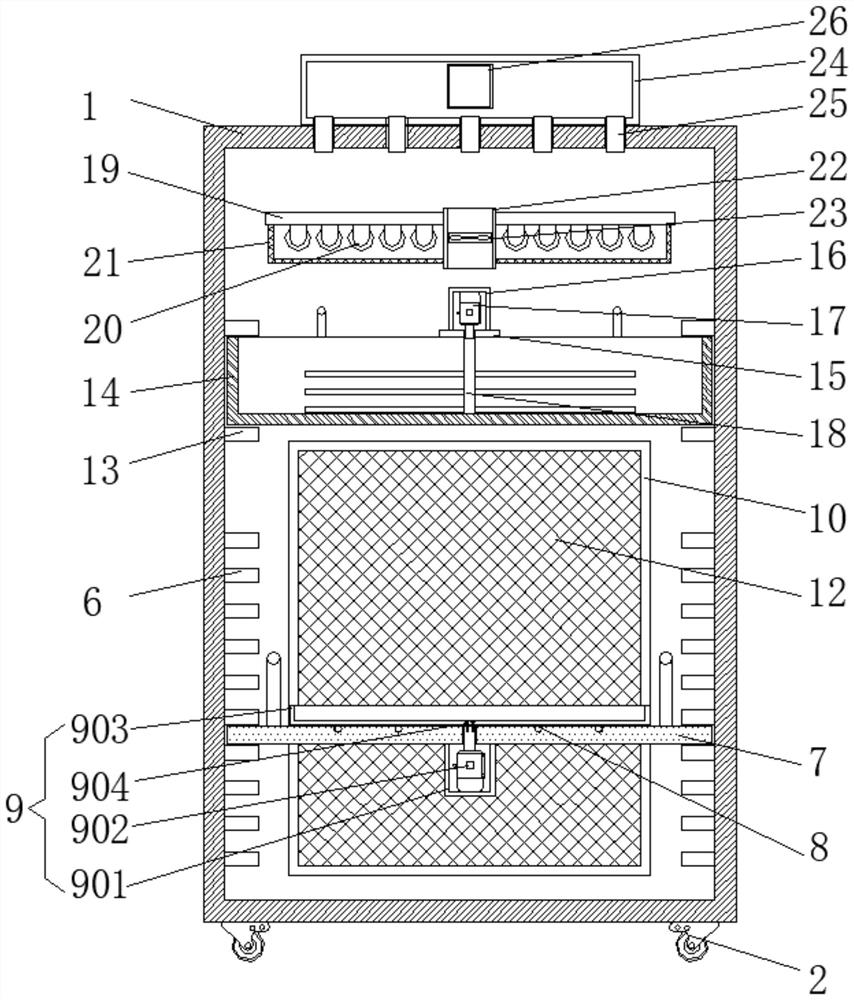

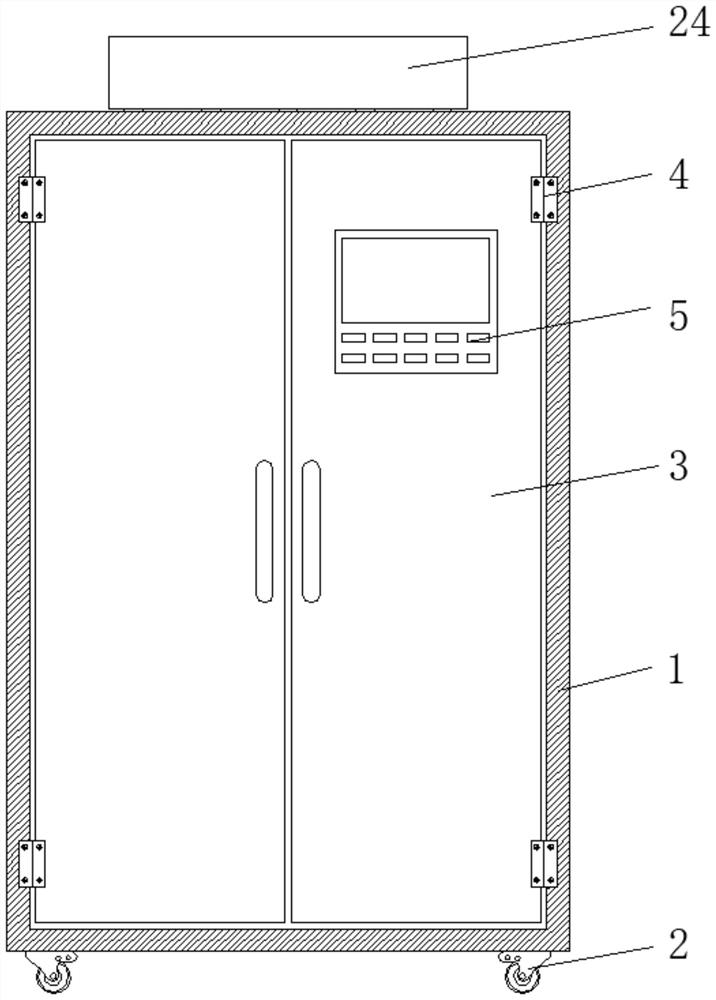

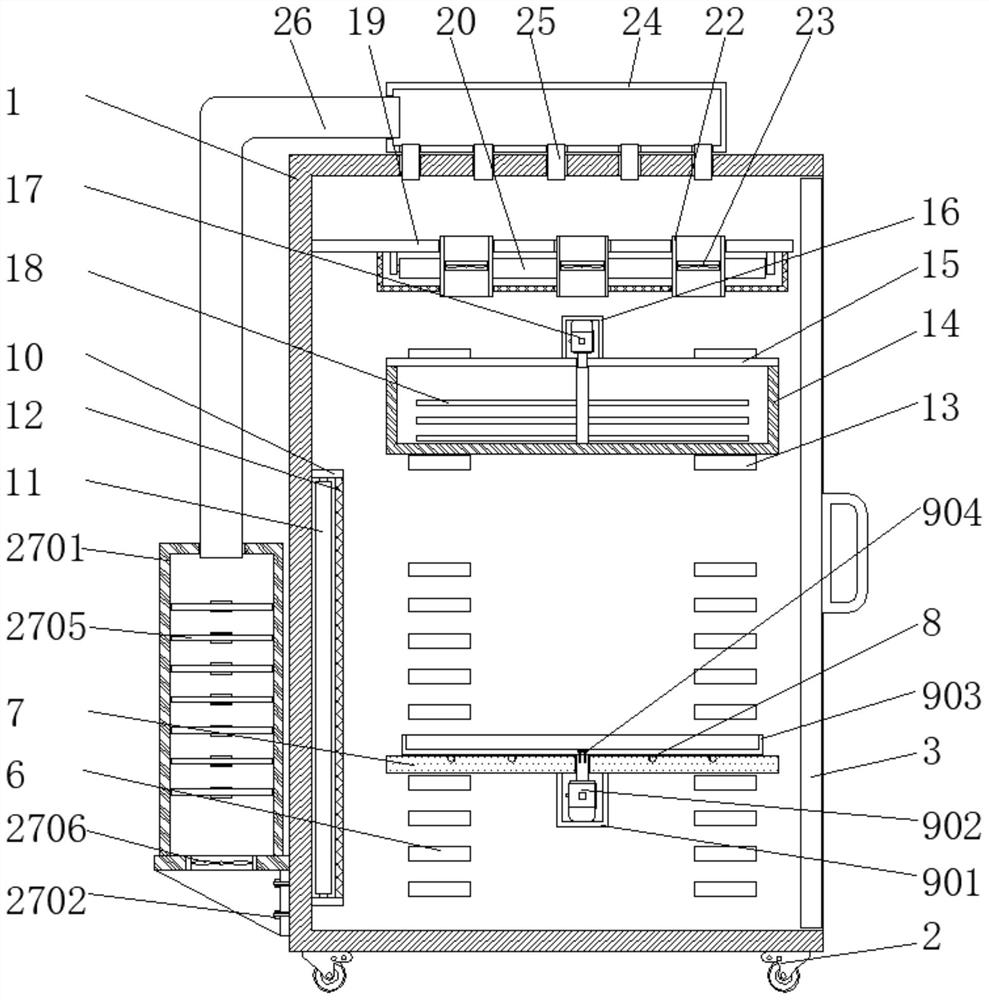

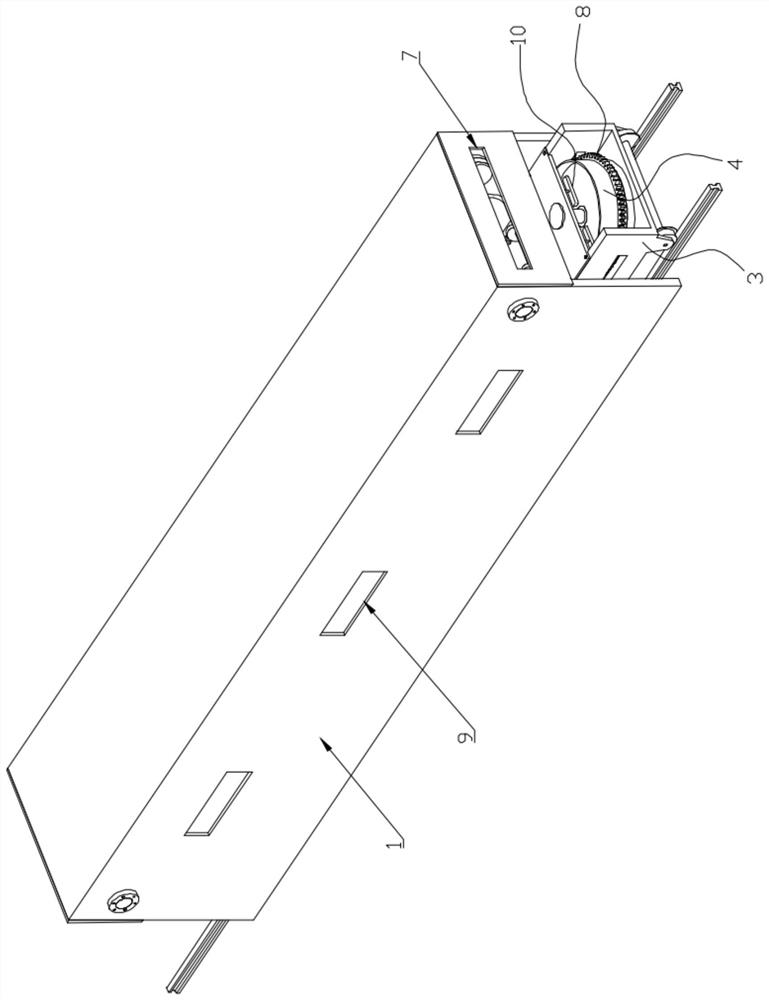

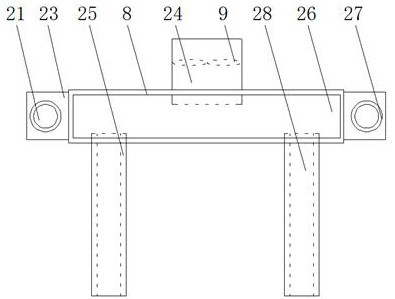

InactiveCN106365408AFully dry treatmentSpeed up the drying processSludge treatment by de-watering/drying/thickeningVertical barSludge

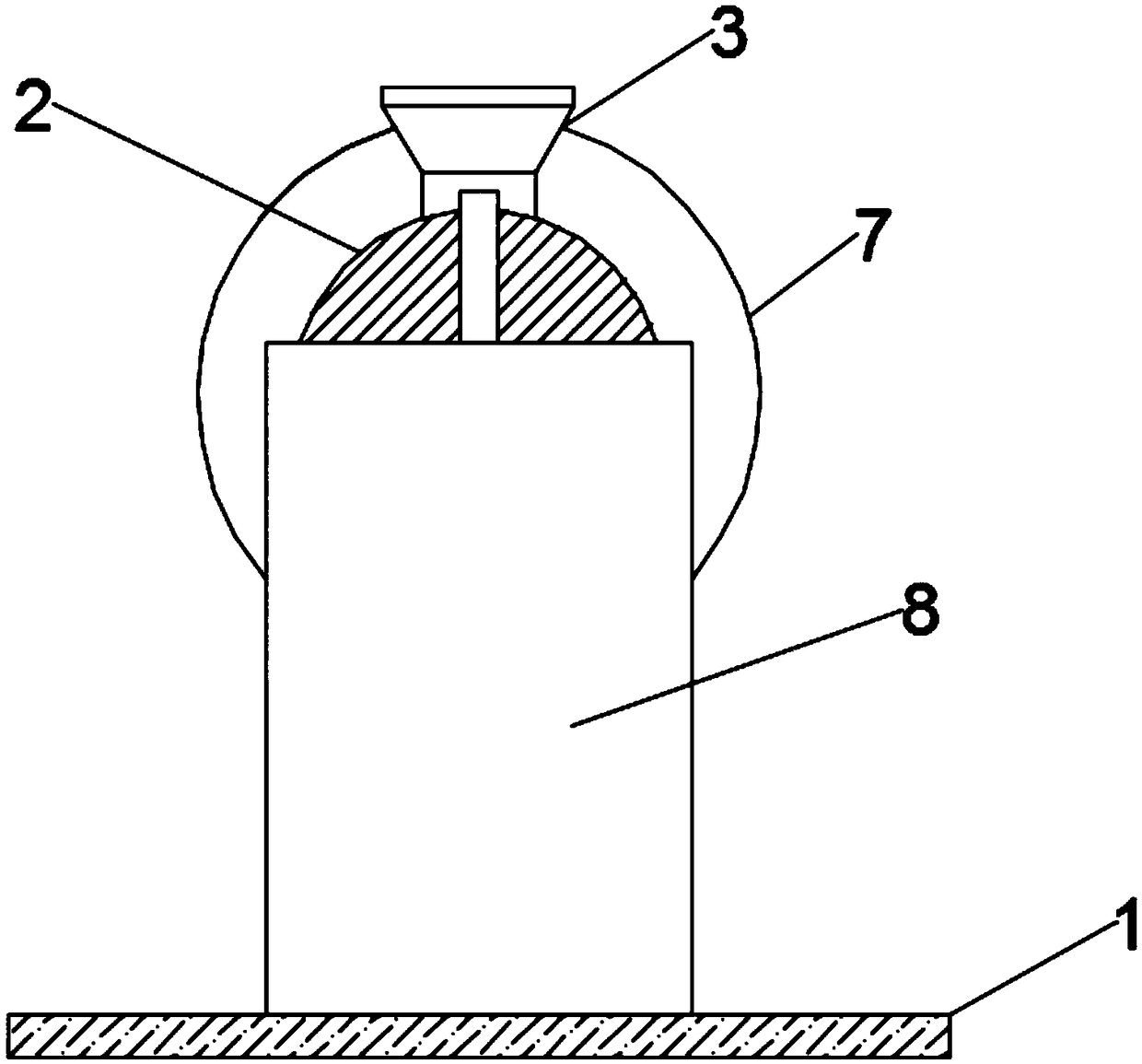

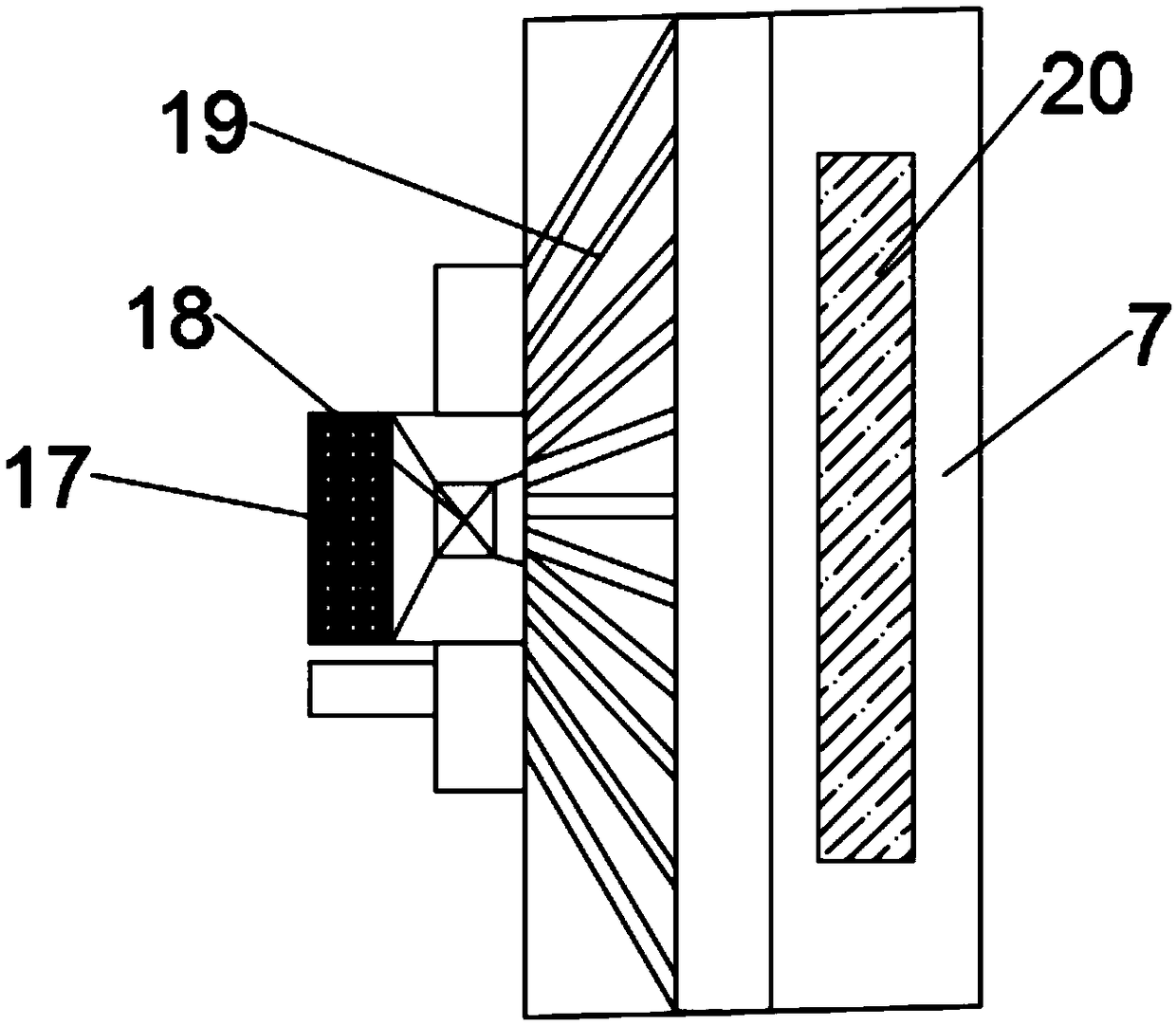

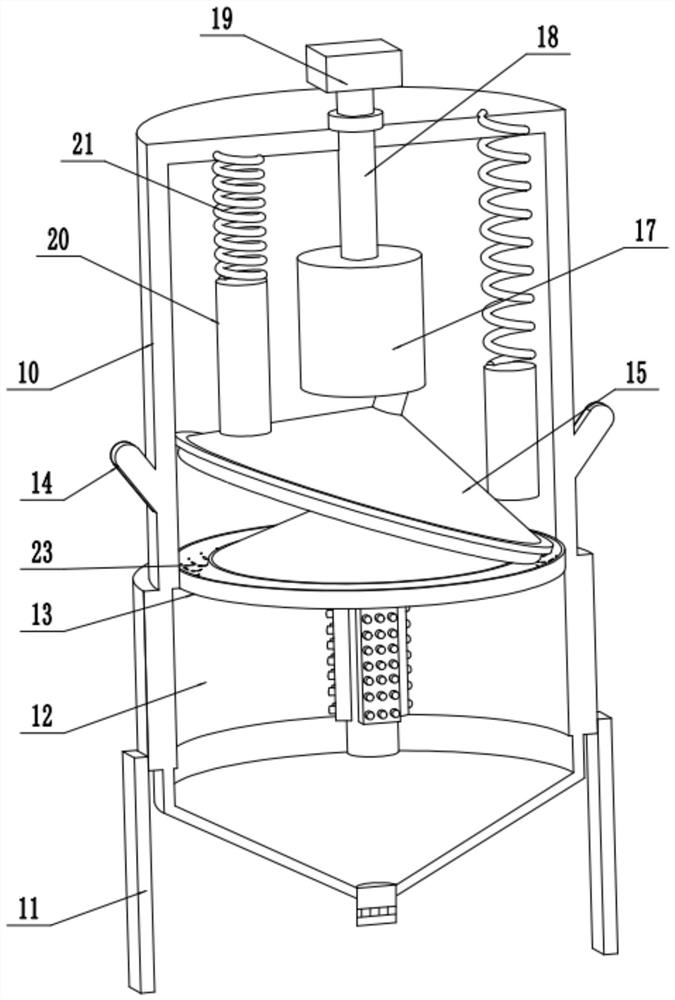

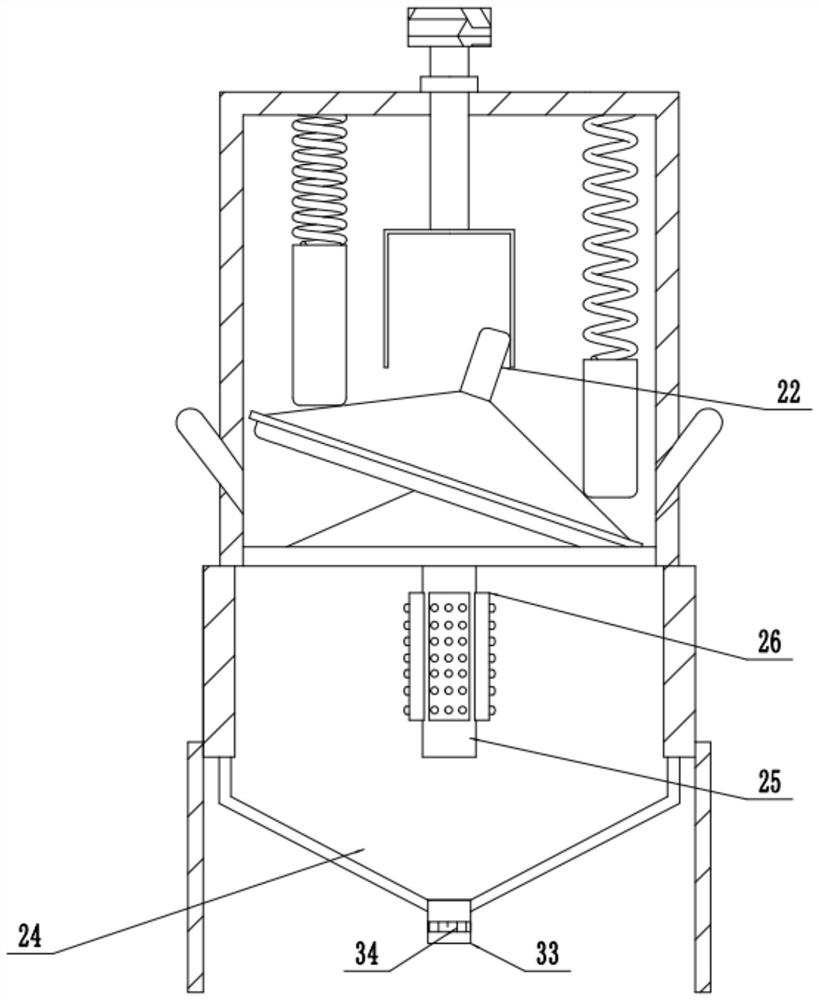

The invention relates to a sludge filtering and drying purification treatment system. The sludge filtering and drying purification treatment system comprises a bottom plate (1), a supporting plate (2), a recovery device (3), a frame body device (4), a fan device (5), a pipeline device (6), a lifting device (7), a motor device (8) and a concentrating device (9), wherein a first supporting block (11) and first roller wheels (12) are arranged on the bottom plate (1), the supporting plate (2) is provided with first through holes (21), a first spring (22), first vertical bars (23) and a second spring (24), the recovery device (3) comprises a recovery box (31), a first filter mesh (32), a sealing ring (33) and a first pipeline (34), the frame body device comprises a first frame body, a heat dissipating frame, a heating rod and a first bent rod, and the fan device comprises a second frame body, second vertical bars, a first motor, a first rotating shaft and fan blades. The system can be used for carrying out sufficient drying treatment on sludge.

Owner:CHENGDU GUANYU TECH

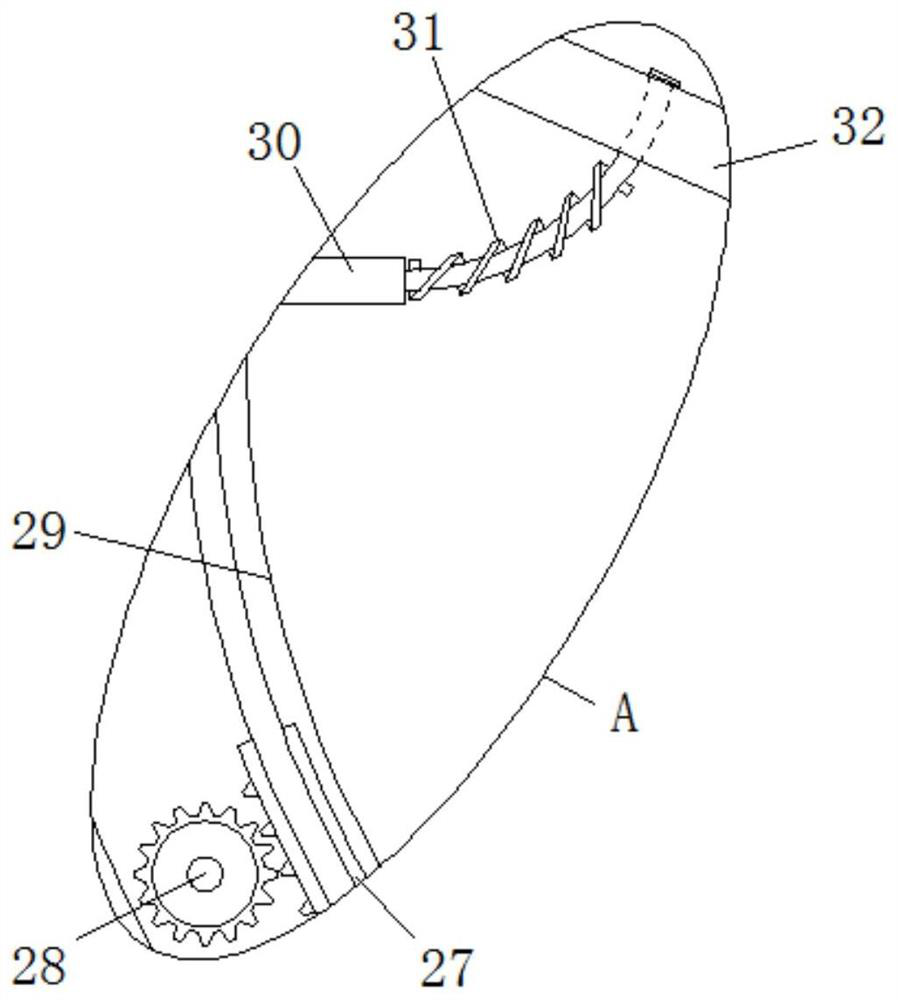

Anti-oxidation maintenance equipment capable of automatically pulling out nails for rubber sole shoes

InactiveCN112137248AFully dry treatmentAvoid affecting useNailingStructural engineeringMechanical engineering

The invention discloses anti-oxidation maintenance equipment capable of automatically pulling out nails for rubber sole shoes, which comprises a shell, a drying space is arranged on the right upper side of the shell, a heating space is arranged on the lower side of the drying space, a drying space is arranged on the left side of the heating space, and a fan space is arranged on the upper side of the drying space; and the fan space communciates with the drying space and the heating space. According to the shoe drying device, the range of the bottom of a whole shoe can be automatically detectedthrough the transmission device, whether thumbtacks are pricked into a shoe sole or not is detected, if yes, the pulling device is started, the thumbtacks are automatically pulled out through the transmission device, the thumbtacks can be recycled after pulling is completed. The shoes can be automatically and fully dried, and the situation that the rubber soles become yellow and use is affected due to the fact that the shoes are dried in the sun is prevented.

Owner:东莞市哼皓玩具有限公司

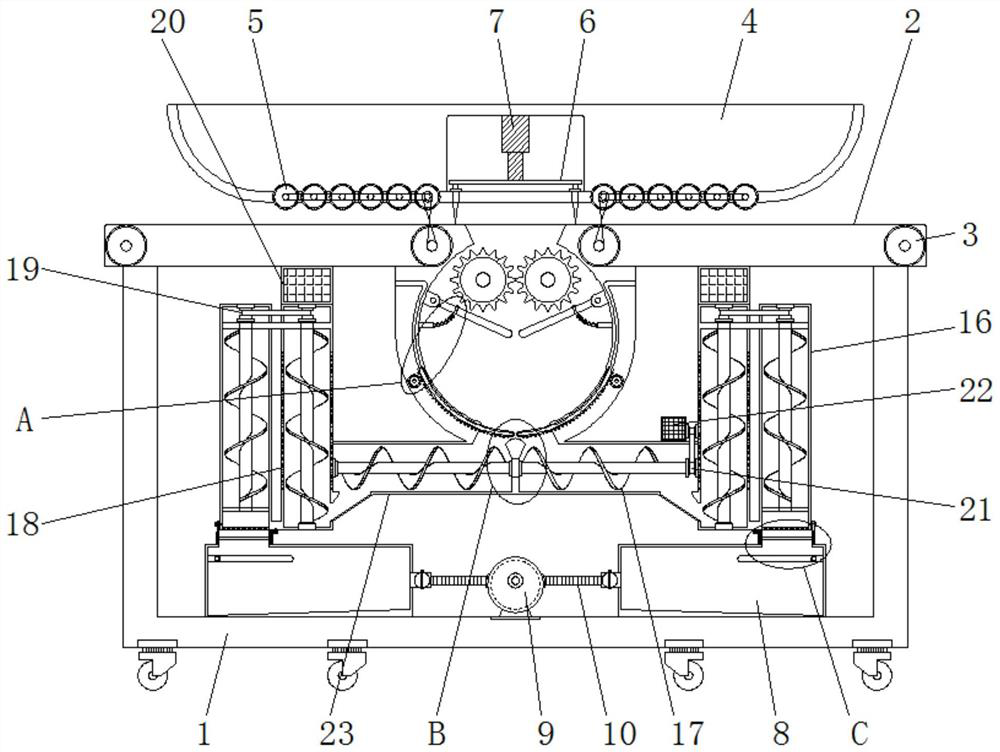

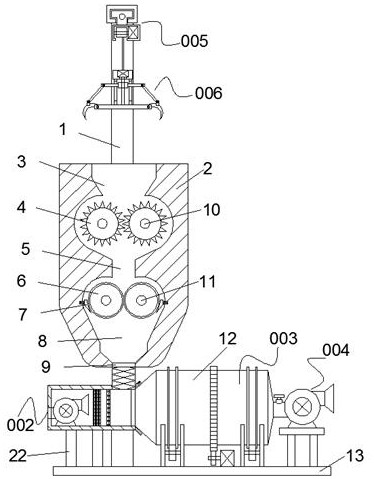

Biomass energy processing granulating device convenient for drying and smashing

InactiveCN112058180AEasy to handle with dust removalEasy to cut and crushCrop conditionersMowersElectric machineGear wheel

The invention discloses a biomass energy processing granulating device convenient for drying and smashing, which comprises a base, an electric telescopic rod, a sucking pump, a heating plate, a firstmotor, a second motor and a third motor, wherein a supporting table is fixedly connected to the upper end of the base, a limiting plate is fixedly installed at the upper end of the supporting table, extrusion hair rollers are rotatably connected to the left side and the right side of the lower surface of the limiting plate correspondingly, a conveying belt and the extrusion hair rollers are in transmission connection through an adjusting belt, the adjusting gear is mounted and connected to the rear end of a smashing roller, the crushing roller is rotatably connected to the interior of a smashing cylinder, and a sealing block is slidably connected to the interior of the lower end of the smashing cylinder. According to the biomass energy processing granulating device convenient for drying and smashing, straw can be fully dried conveniently, and dust prevention treatment can be conducted conveniently when the straw is processed. Meanwhile, biomass energy raw materials such as the straw can be cut off and smashed conveniently, the situation that the sizes are different is avoided, and granulating is convenient.

Owner:李姗姗

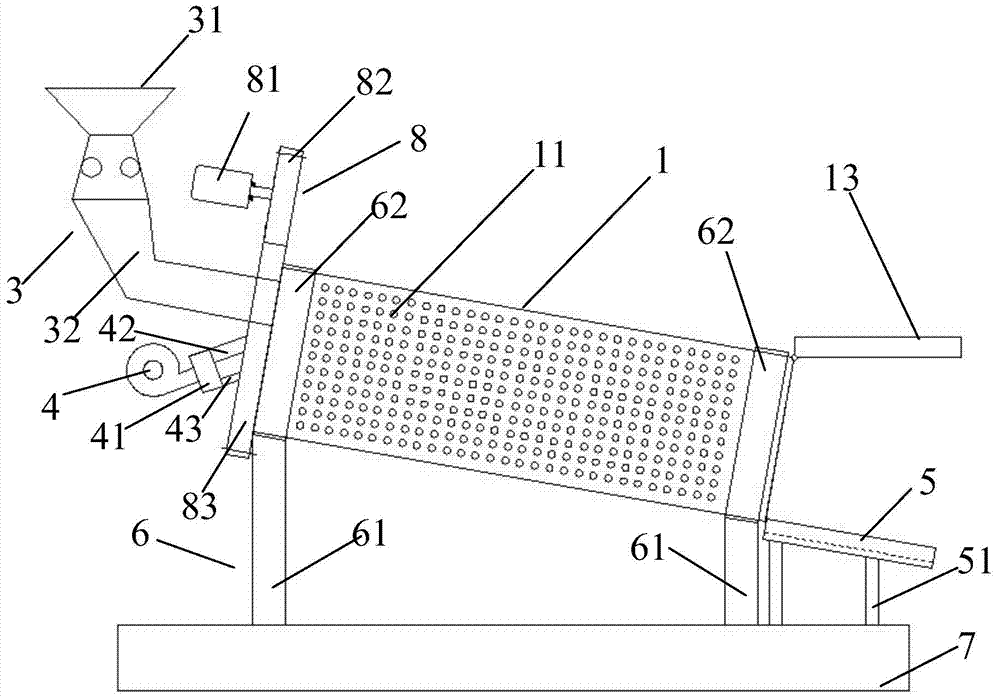

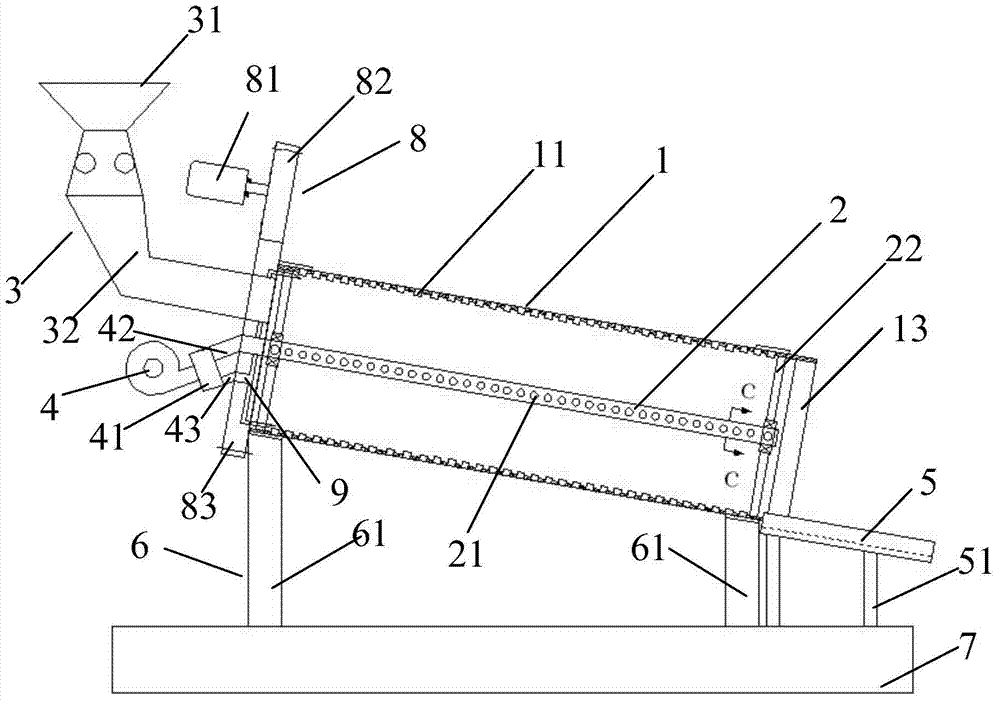

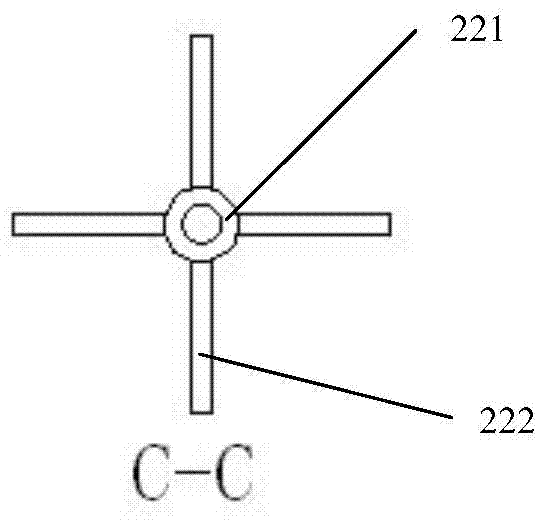

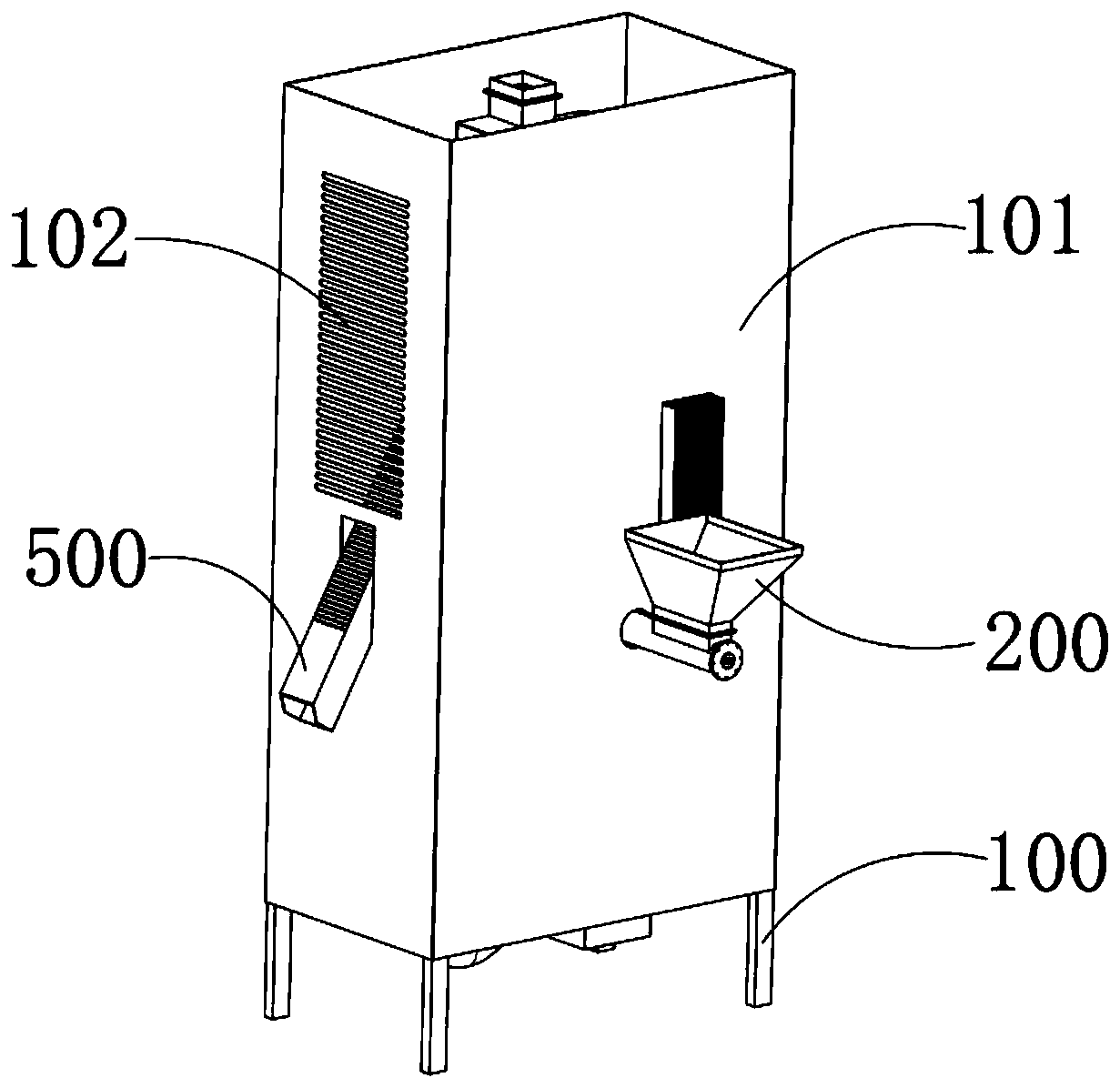

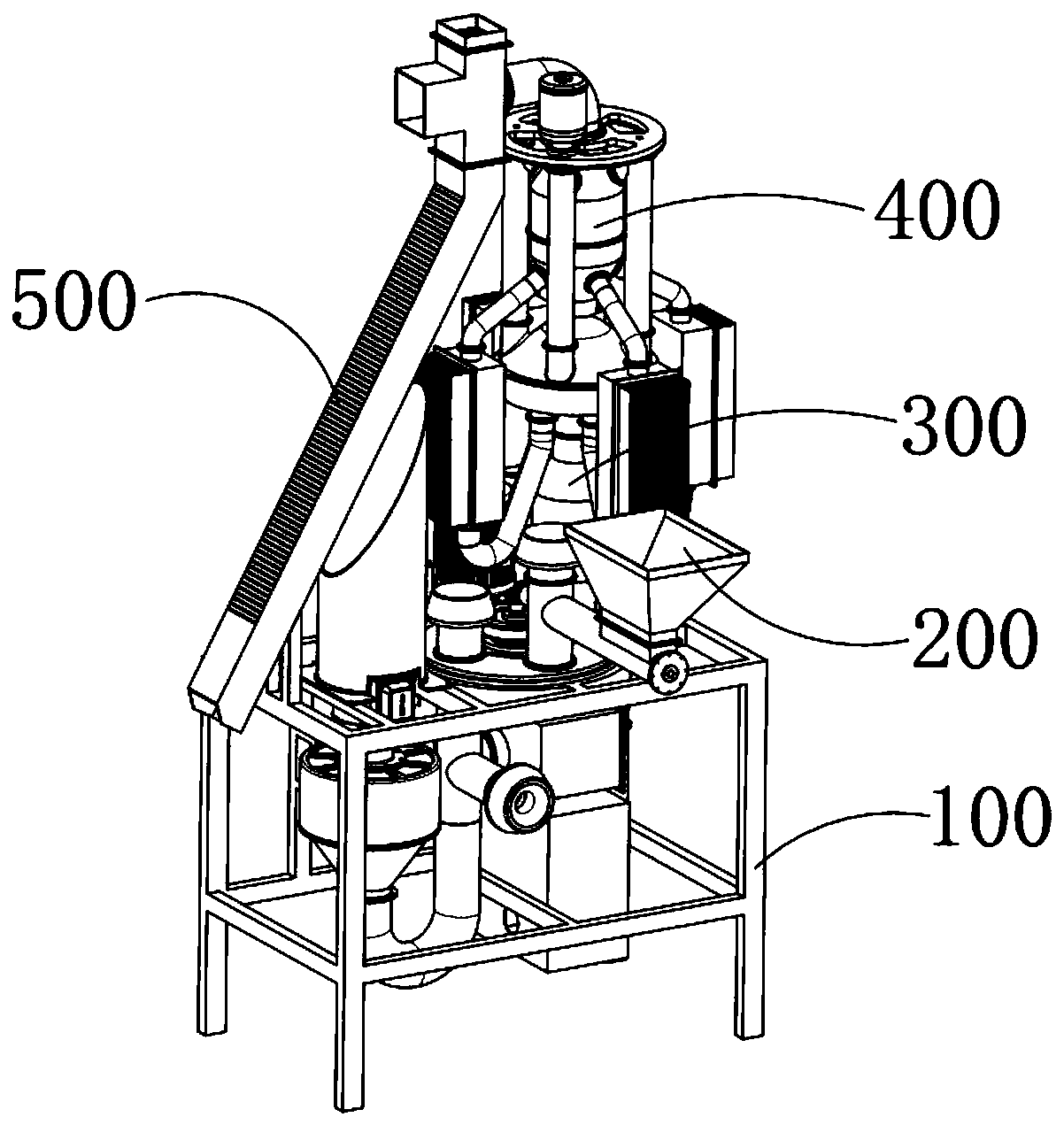

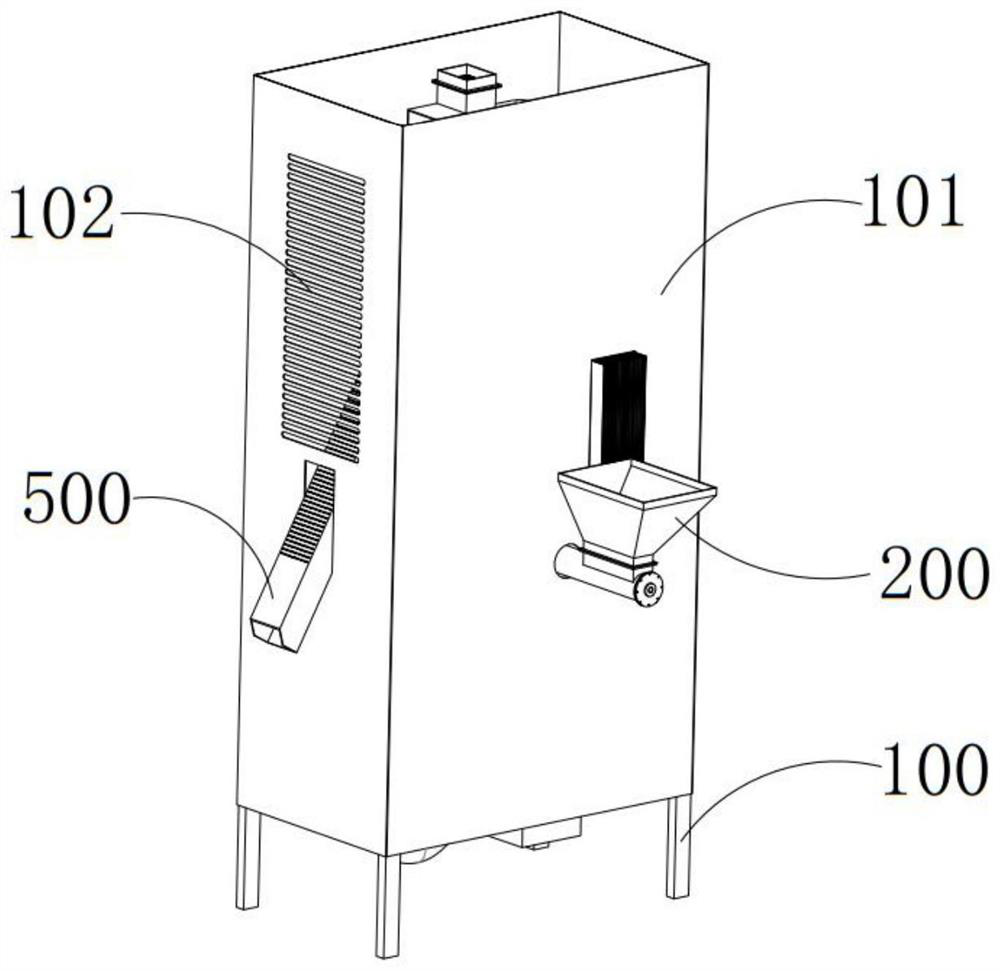

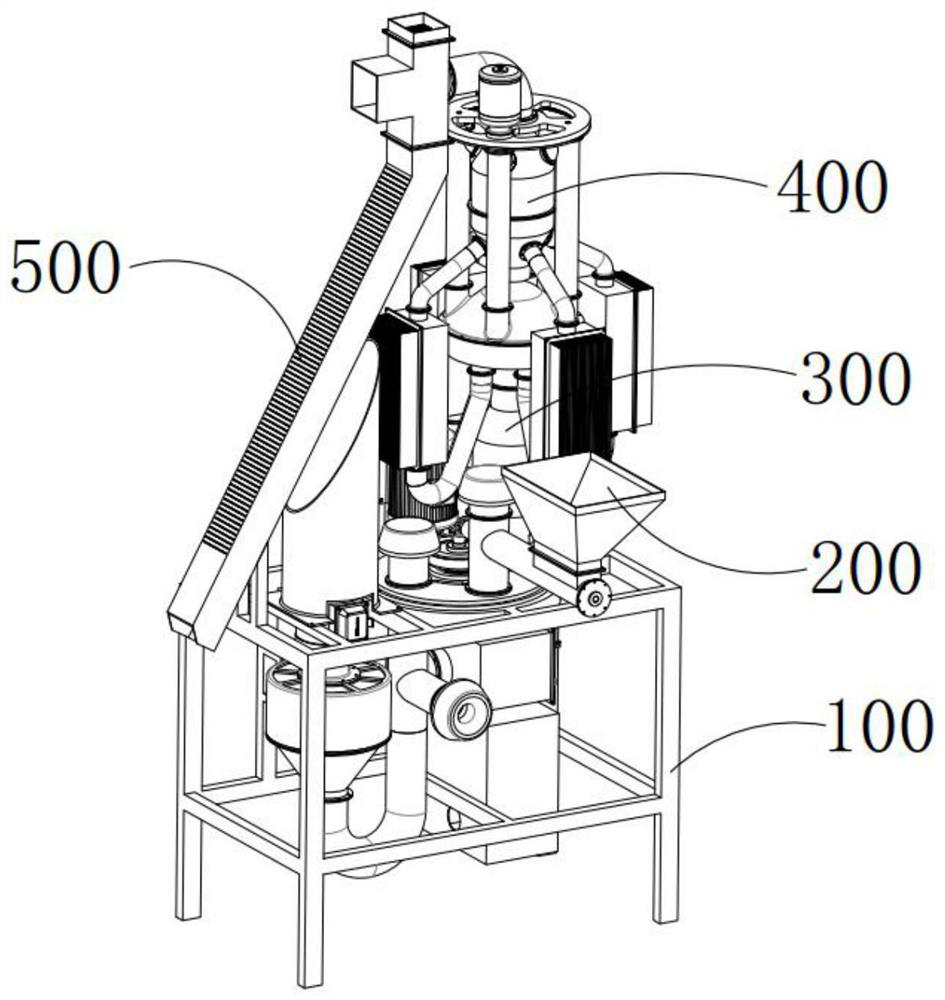

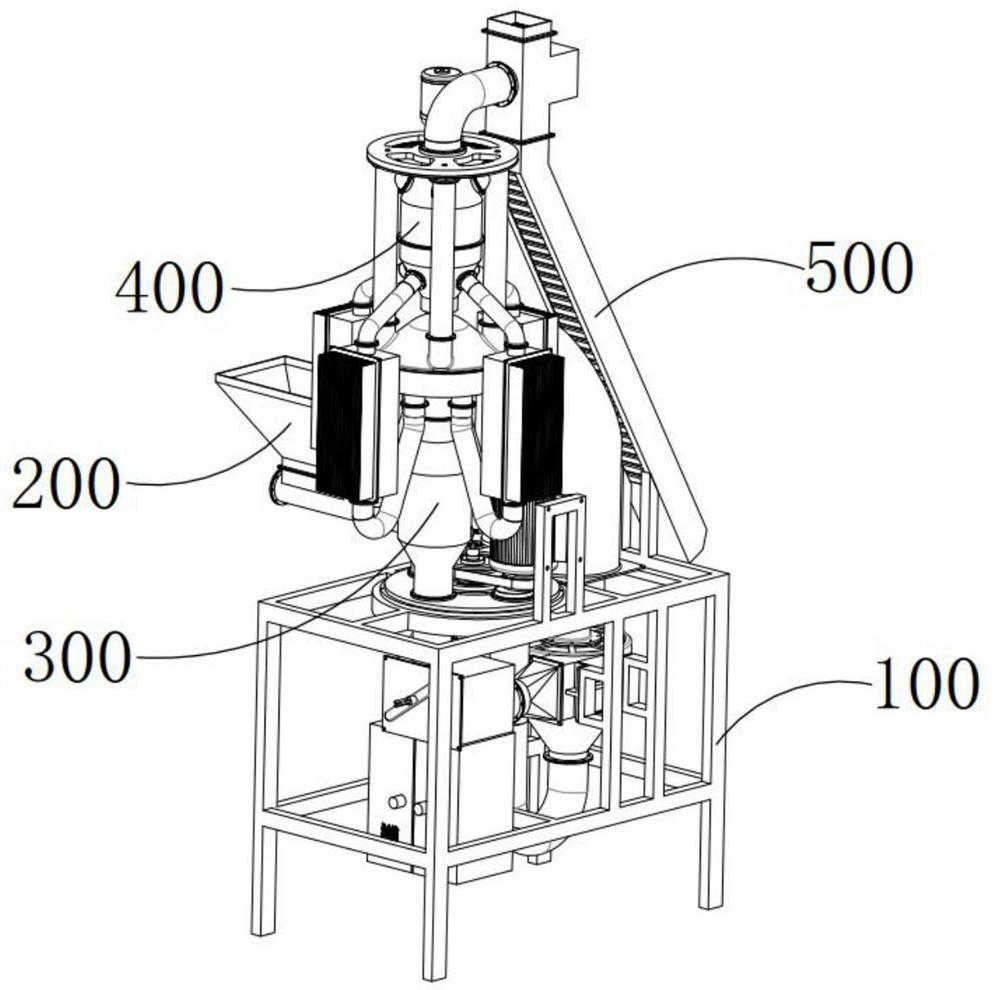

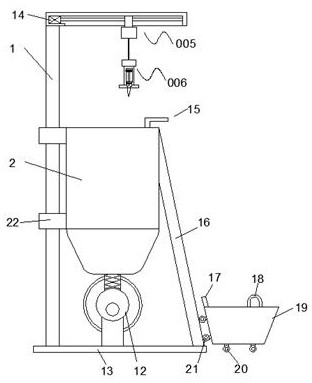

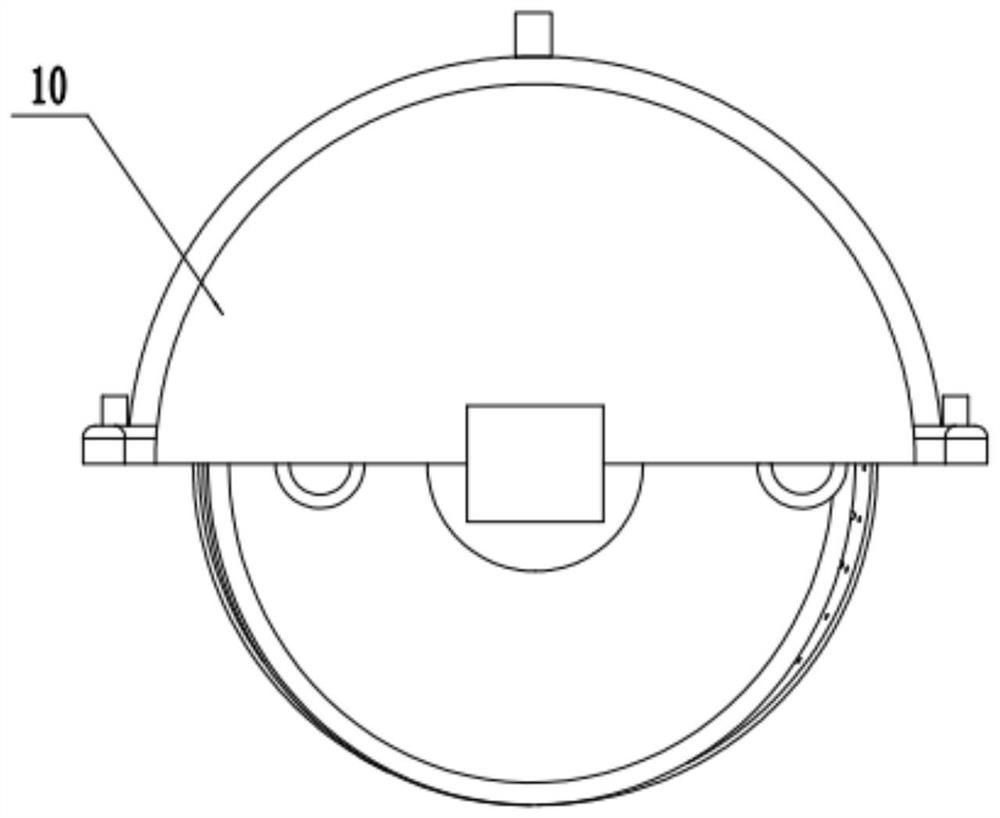

Grain dryer with quantitative feeding function

PendingCN110495491AImprove drying efficiencyFully dry treatmentConveyorsDomestic cooling apparatusMechanical engineeringConstant speed

The invention provides a grain dryer with a quantitative feeding function. The grain dryer comprises a mounting rack arranged on the floor, wherein a constant speed feeding mechanism is mounted on themounting rack and comprises a closed disc-shaped transition bin fixedly mounted on the mounting rack and a feeding hopper located outside a protecting cover and having a vertical and upward opening,the transition bin is vertically arranged in the axis direction and is formed by buckling an upper disc body and a lower disc body, a feeding port and a discharging hole which are communicated with the inside of the transition bin are formed in the eccentric positions of the upper end surface of the upper disc body, the feeding hopper is located above the transition bin and has a large opening located right above a small opening, the small opening of the feeding hopper is connected and communicated with the feeding port, and an input end of a drying mechanism is connected and communicated withthe discharging port. Grains can uniformly enter the drying mechanism from the transition bin at a uniform speed, and blocking of the grains in the drying mechanism can be avoided.

Owner:祝磊

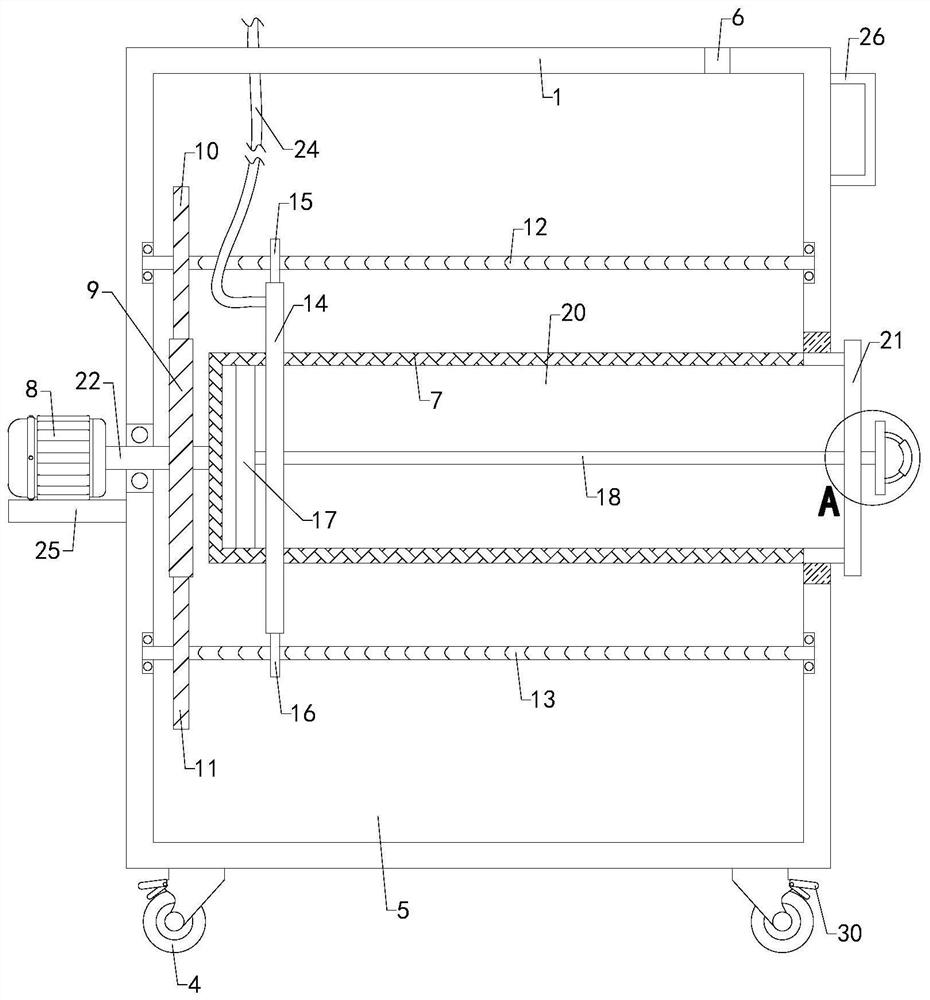

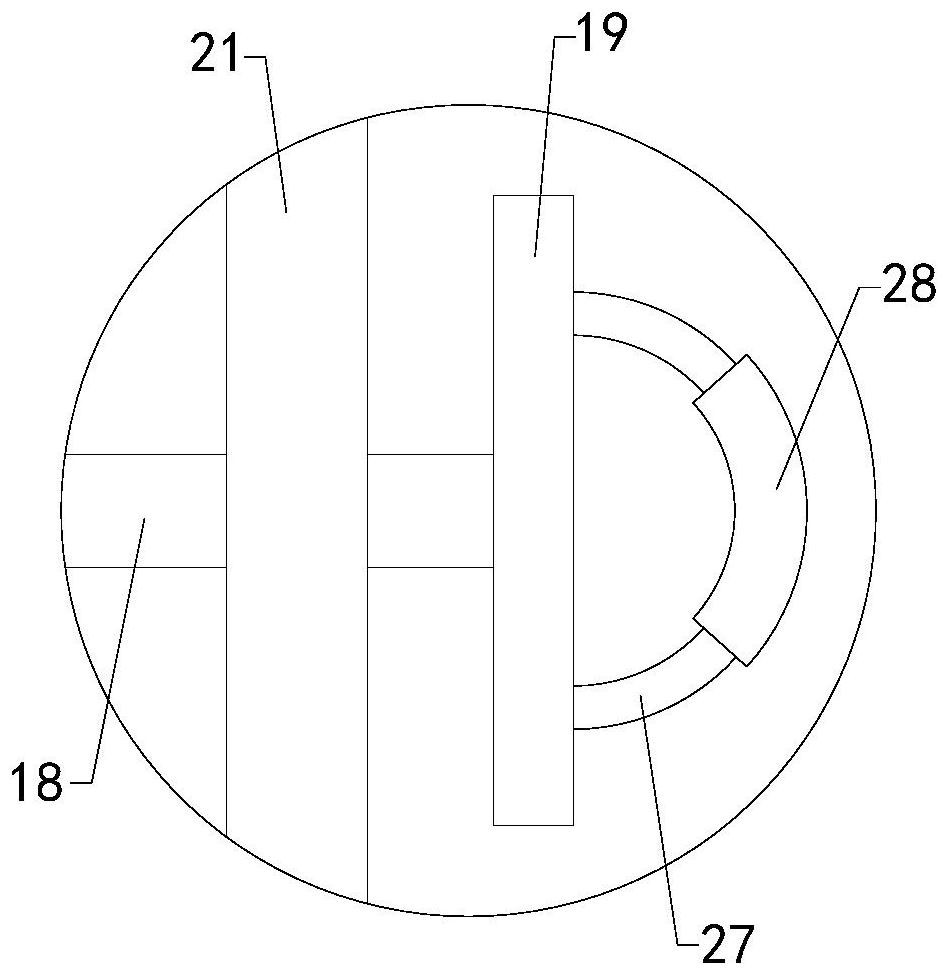

Agricultural and sideline product drying device

InactiveCN112212635APlay the role of flippingFully dry treatmentDrying gas arrangementsDrying chambers/containersElectric machineryAgricultural engineering

The invention relates to the technical field of agricultural and sideline product processing accessory devices, in particular to an agricultural and sideline product drying device capable of thoroughly and fully drying agricultural and sideline products. The device comprises a box body, a box door and a handle, wherein four sets of universal wheels are arranged at the bottom end of the box body, aworking cavity is formed in the box body, a box opening is formed in the front end of the box body, and an air outlet is longitudinally formed in the right half area of the top end of the box body. The device also comprises a net barrel, a motor, a driving gear, a first driven gear, a second driven gear, a first rotating rod, a second rotating rod, an annular pipe, a first support plate, a secondsupport plate, a push plate, a pull rod and a baffle plate, wherein a rotating hole is transversely formed in the central area of the left side wall of the box body, a through hole is transversely formed in the central area of the right side wall of the box body, an inner cavity is formed in the net barrel, a cover plate is detachably arranged at an opening, a transmission shaft is arranged at the output end of the right portion of the motor, and a ball bearing is arranged between the transmission shaft and the inner side wall of the rotating hole.

Owner:中方县原味农业开发有限公司

Ink printing, drying and cooling device for tempered glass

The invention discloses an ink printing, drying and cooling device for tempered glass. The ink printing, drying and cooling device for the tempered glass comprises a treatment box, two symmetrical L-shaped brackets are fixedly mounted at the top of the treatment box, a cooling box is fixedly mounted between the tops of the two L-shaped brackets, and an air blower and a cooling pipe are fixedly mounted at the top and inside of the cooling box separately. The output end of the air blower communicates with an air inlet pipe, the end, away from the air blower, of the air inlet pipe penetrates and extends into the cooling box, the bottom of the cooling box communicates with an air outlet pipe, the bottom of the air outlet pipe penetrates and extends into the treatment box and communicates with an air bellow, and ventilation holes are formed in the bottom of the air bellow. Supporting plates are fixedly mounted on the four inner side walls of the treatment box correspondingly, the tempered glass is placed between the upper surfaces of the four supporting plates, a bearing seat is fixedly mounted in the middle of the inner bottom wall of the treatment box, the bottom of the right side of the treatment box communicates with an exhaust pipe, and a valve is arranged on the exhaust pipe. The ink printing, drying and cooling device for the tempered glass is compact in structure, the drying strength is gradually reduced in the drying process, and the quality of the tempered glass is improved.

Owner:合肥金晋业实业有限公司

Drying device for recycling breeding excrement

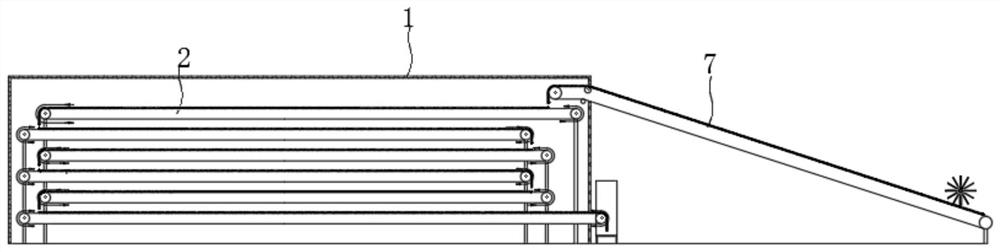

InactiveCN109253610AExtended stayThe overall structure is simpleDrying machines with progressive movementsDrying solid materialsWater contentEngineering

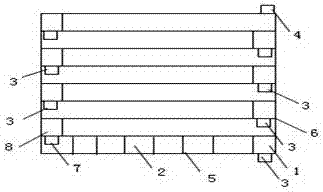

The invention discloses a drying device for recycling breeding excrement. The drying device for recycling the breeding excrement comprises a drying box, wherein multiple layers of conveying mechanismswhich are arranged at intervals are arranged in the drying box; each conveying mechanism comprises conveying rolls and a conveying belt arranged on the conveying rolls; each two adjacent conveying mechanisms are staggered from each other on the left side and the right side; a feeding opening is formed in one side of the drying box; a guiding groove is formed in the feeding opening; the guiding groove is obliquely downwards formed in the feeding opening; the lower end of the guiding groove extends to a position above one end of the conveying mechanism positioned on the top layer, and the otherend of the conveying mechanism is positioned on the right side of the corresponding end of the conveying mechanism below the conveying mechanism; and the conveying mechanisms are successively staggered, and thus, materials on the conveying mechanism on the upper layer can drop on the conveying mechanism on the lower layer; and heating tubes are arranged on the inner wall of the drying box. The conveying structures for circular conveying are arranged in the drying device, the retaining time of the excrement in the drying box is prolonged, therefore, the excrement is fully dried, the integral structure is simple, and the water content of the excrement discharged via a discharging groove is minimized.

Owner:宜宾市翠屏区远鹏养殖种植专业合作社

Filtering device for high-pressure jet descaling and use method thereof

ActiveCN114130083AImplement collection processingRealize sorting and filtering processingSievingScreeningJet flowSlag

The invention discloses a filtering device for high-pressure jet descaling and a using method thereof.The filtering device comprises a treatment box, an impurity filtering net is arranged in the treatment box, a slag outlet is formed in the impurity filtering net, the top of the impurity filtering net is rotationally connected with an impurity scraping plate matched with the slag outlet, a rotating mechanism is arranged in the treatment box and connected with the impurity scraping plate, and the impurity scraping plate is connected with the slag outlet; a rotating mechanism is arranged in the treatment box, a reset mechanism is arranged in the treatment box and connected with the rotating mechanism, and a discharging box matched with the slag outlet is slidably connected to the interior of the treatment box. The rotating rod drives the impurity scraping plate to rotate and treats impurities on the impurity filtering net, the discharging box is additionally arranged, so that the scraped impurities are collected, and the drying mechanism is additionally arranged, so that the collected impurities are fully dried.

Owner:SICHUAN HUIYUAN STEEL CONSTR SCI & TECH +1

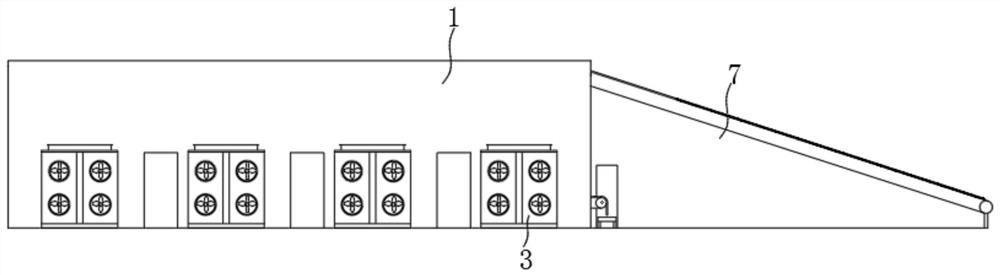

Tunnel furnace drying system

ActiveCN111551011ASave the process of repeated loading and unloadingSave labor costDrying gas arrangementsDrying chambers/containersIn vehicleProcess engineering

The invention discloses a tunnel furnace drying system, and relates to the field of tunnel furnace equipment. The tunnel furnace drying system comprises a furnace body, tracks, a loading vehicle, a loading disc and a driving mechanism. According to the drying system, the structural design of an existing tunnel furnace is optimized, the operation mode of furnace body + track + vehicle body is adopted, that is, materials are always located on the loading disc of a vehicle body (i.e, transfer equipment), the materials are transferred to the next station for subsequent processing after drying treatment, compared with a traditional conveying manner of a mesh conveyor belt, the process of repeated feeding and discharging is omitted, the cost of manpower and material resources is saved, the drying speed is high, the operation is convenient, and the structure is simple.

Owner:包头市海罗水泥制品机械有限公司

Sludge filtering and drying system with high efficiency and environmental friendliness

InactiveCN106348566ASimple structureEasy to useSludge treatment by de-watering/drying/thickeningFan bladeHandling system

An efficient and environmentally friendly sludge filtration and drying treatment system, comprising a bottom plate (1), a support plate (2), a recovery device (3), a frame device (4), a fan device (5), and a pipeline device (6) , a lifting device (7), a motor device (8) and a concentration device (9), the base plate (1) is provided with a first support block (11) and a first roller (12), and the support plate (2) is provided with a second A through hole (21), the first spring (22), the first vertical bar (23) and the second spring (24), the recovery device (3) includes the recovery box (31), the first filter screen (32), the sealing ring (33), the first pipeline (34), the frame device includes the first frame body, heat dissipation frame, heating rod, first bending rod, and the fan device includes the second frame body, the second vertical rod, the first motor, the first A rotating shaft and fan blades, the invention can fully dry the sludge.

Owner:CHENGDU GUANYU TECH

Mesh belt type air energy dryer unit based on 5G remote control

PendingCN113267032AIncrease the lengthExtended stayDrying gas arrangementsDrying chambers/containersEngineeringChili pepper

The invention provides a mesh belt type air energy dryer unit based on 5G remote control. The mesh belt type air energy dryer unit based on 5G remote control comprises a drying main machine, a remote control system and a transmission mechanism. According to the mesh belt type air energy drying machine unit based on 5G remote control, the drying main machine, the transmission mechanism, an air energy heat pump main machine and a heat supply draught fan are matched to form the drying machine unit, so that uninterrupted continuous drying operation on chilies can be achieved; and six transmission belt sets are arranged side by side, and the traditional mode of single transmission belt is changed, so that the length is guaranteed to be constant, the overall length of the transmission belts is effectively increased, the residence time of the chilies is longer during drying, then sufficient drying treatment on the chilies is guaranteed, repeated drying treatment on the chilies is avoided, excessive manual operation is not needed, use is very simple, and the chilies can be dried easily and effortlessly.

Owner:ANHUI OURUIDA ELECTRICAL APPLIANCE TECH

Efficient drying treatment equipment for garbage

InactiveCN104713100AEasy to removeEasy to sortDrying using combination processesGas current separationIncinerationTuyere

The invention discloses efficient drying treatment equipment for garbage. The efficient drying treatment equipment for the garbage comprises a roller with a plurality of water outlets distributed, a radial blowing pipe, a feeding device, an air supply device and an axial blowing pipe. The radial blowing pipe is mounted in the roller, and a plurality of air outlets facing water outlets are formed in the radial blowing pipe; the feeding device is communicated with an inlet of the roller, and the air supply device is connected with one end of the radial blowing pipe; the axial blowing pipe is connected with the air supply device and is aligned at the front end of the roller; and the other end of the radial blowing pipe is a closed end. A cabin door opening or closing an outlet of the roller is mounted on the outlet of the roller, and an air inlet of the air supply device is connected with a hot air outlet of a garbage incinerator through a pipeline. According to the equipment, hot air generated by garbage incineration is utilized for carrying out drying treatment on garbage while garbage is dried in a spinning manner, and therefore the drying process of the garbage is greatly accelerated.

Owner:QINGDAO WATER WORLD ENVIRONMENTAL PROTECTION TECH

Infrared drying device capable of treating harmful gas

InactiveCN112503859AFully dry treatmentEasy to dryDrying solid materials with heatDispersed particle separationActivated carbonInfrared lamp

The invention discloses an infrared drying device capable of treating harmful gas. The infrared drying device comprises a bearing box, a rotating mechanism, a ventilation pipeline, an air exhaust pipeline and a harmful gas purification mechanism, the rotating mechanism penetrates through a supporting plate, a bearing frame is fixed to the rear inner wall of the bearing box, a storage box is arranged on the upper side of the bearing frame, a supporting plate is fixed to the rear inner wall of the bearing box, the ventilation pipeline is fixed to the supporting plate and a mesh enclosure in a penetrating mode, the air exhaust pipeline penetrates through the top of the bearing box and communicates with an air exhaust channel, and the harmful gas purification mechanism is fixed to the rear side of the bearing box. According to the infrared drying device capable of treating harmful gas, in the process of drying materials through a first infrared lamp tube and a second infrared lamp tube, gas released from the materials can enter the gas storage box through the air exhaust channel, the air exhaust pipeline and a connecting pipeline in sequence, and an activated carbon plate can adsorb harmful substances in the gas, so that the purification effect can be achieved conveniently.

Owner:江苏汇能燃气催化科技有限公司

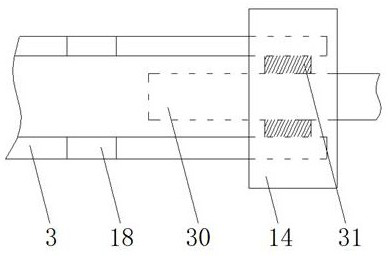

Steel backing drying unit

ActiveCN108716822AGood effectImprove efficiencyDrying gas arrangementsDrying solid materialsEngineeringMechanical engineering

The invention discloses a steel backing drying unit which comprises a box, a supporting part located on the inner side of the box and a drying part located on the inner side of the box. The supportingpart comprises a sliding rod, a moving plate, a plurality of supporting units, a first rack and a driving unit, and the sliding rod is connected with the box; the moving plate is in sliding connection with the sliding rod; the multiple supporting units are sequentially distributed in the length direction of the sliding rod; each supporting unit comprises a strut, a clamping assembly and a first gear; and the struts are rotationally connected with the moving plate. The clamping assemblies are installed on the struts, the first gears are installed on the struts, the first rack is connected withthe box and is parallel to the sliding rod, and the first rack is engaged with the first gears; and the driving unit is used for driving the moving plate to move, and the drying part is used for spraying out air.

Owner:ANHUI GUIDA AUTO PARTS

a drying equipment

ActiveCN104841623BFully dry treatmentMeet the requirements of spray treatment processPretreated surfacesCoatingsEngineeringMechanical engineering

The invention relates to a drying device which comprises a support and drying tunnels arranged in the support. A plurality of conveying chains are arranged on one sides, away from the support, of the drying tunnels, a rotary rack is hung on each conveying chain, and the rotary racks can be used for assembling workpieces; a steam pipe is arranged on one sides, adjacent to the support, of the drying tunnels, and steam is led into the steam pipe; a fan is arranged on the top portions of the drying tunnels, and an exhaust inlet of the fan is communicated with the drying tunnels. During use, the workpieces assembled in the rotary racks can be sufficiently dried so as to meet requirements on subsequent processing technology of the workpieces; meanwhile, during drying of the workpieces, use cost is lower, and drying requirement of enterprises on the workpieces are met.

Owner:NANTONG BEST MACHINE CO LTD

Grain drying and air drying integrated drying process

ActiveCN110542302BImprove drying efficiencyFully dry treatmentDrying gas arrangementsSeed preservation by dryingCold airThermodynamics

The invention provides a drying and air-drying integrated drying process of cereals. The drying and air-drying integrated drying process comprises the following steps that firstly, grains are uniformly conveyed in a drying mechanism at a uniform speed through a constant-speed feeding mechanism; secondly, the drying mechanism blows hot air from bottom to top to enable the grains to be suspended androlled and to move upwards slowly, and in the process, the grains are subjected to comprehensive drying treatment, and then hot air flow and the grains enter the air drying mechanism together; then,the air drying mechanism separates the grains from the hot air flow at the bottom of the air drying mechanism and converts the hot air flow into normal-temperature air flow; then, the grains and the normal-temperature air flow from bottom to top are converged in an air drying tank, and the normal-temperature air flow enables the grains to be suspended and rolled and move upwards slowly, and in theprocess, the grains are subjected to the comprehensive air drying treatment, and the normal-temperature air flow and the grains enter a cooling and discharging mechanism together; and finally, the cooling and discharging mechanism cools the grains with cold air and outputs the grains to a stacking point.

Owner:ANHUI OURUIDA ELECTRICAL APPLIANCE TECH

A tunnel furnace drying system

ActiveCN111551011BSave the process of repeated loading and unloadingEasy to operateDrying gas arrangementsDrying chambers/containersThermodynamicsIn vehicle

The invention discloses a tunnel furnace drying system, which relates to the field of tunnel furnace equipment, including a furnace body, a track, a charging car, a loading tray and a driving mechanism. The invention optimizes the structural design of the existing tunnel furnace, adopts The operation mode of body + track + car body, that is, the material is always located on the loading tray of the car body (that is, the transfer equipment). After drying, it is transferred to the next station for subsequent processing. Compared with the traditional mesh conveyor belt The unique conveying method saves the process of repeated loading and unloading, saves manpower and material costs, and has fast drying speed, convenient operation and simple structure.

Owner:包头市海罗水泥制品机械有限公司

Silicon carbide sealing element raw material drying device and operation method thereof

InactiveCN111637715AFully dry treatmentImprove drying qualityDrying gas arrangementsDrying chambers/containersRotational axisCarbide silicon

The invention discloses a silicon carbide sealing element raw material drying device. The silicon carbide sealing element raw material drying device comprises a drying box, a motor, a rotating shaft,a top plate, a first hydraulic cylinder, a connecting plate, a second hydraulic cylinder, a moving plate, a fan, an air blower and a heater, and is characterized in that the drying box is arranged ona support, wherein the motor is arranged on the outer wall of the drying box; the rotating shaft is arranged in the drying box; the top plate is arranged on a stand column; the first hydraulic cylinder is arranged on the top plate; the connecting plate is connected with a first piston rod; the second hydraulic cylinder is arranged on a fixed plate; the moving plate is connected with a second piston rod; the fan is arranged in an exhaust pipe; and the air blower is arranged on the top plate. According to the silicon carbide sealing element raw material drying device, an air inlet groove is formed in the side wall of a shifting rod, airflow in a silicon carbide sealing element raw material can conveniently enter an inner cavity through the shifting rod through the air inlet groove, the silicon carbide sealing element raw material can be prevented from being left in the hollow shifting rod, and waste of the silicon carbide sealing element raw material is reduced.

Owner:ANHUI DONGXUN SEALING TECH

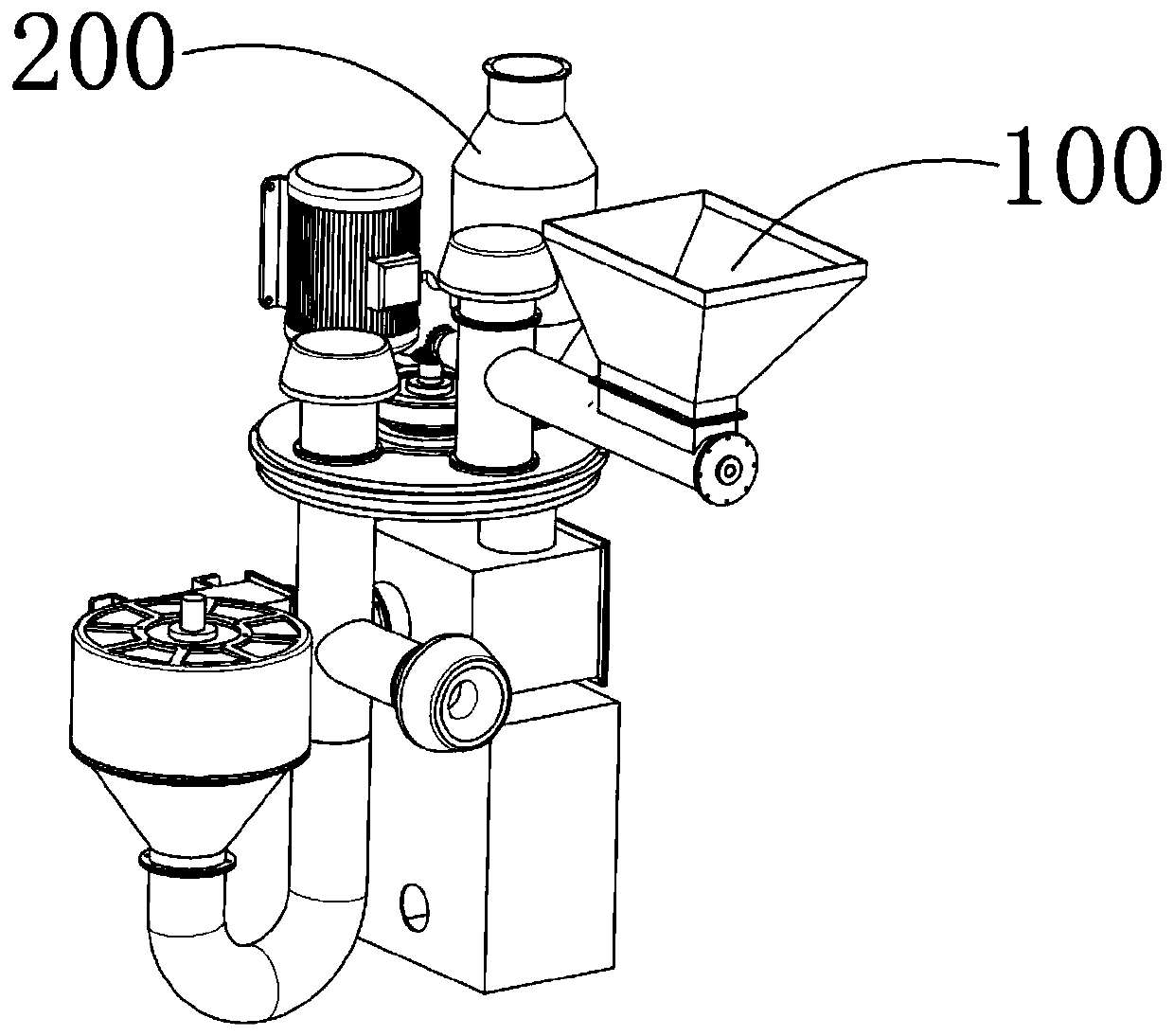

An integrated coal feeder for pulverized coal grinding and drying

ActiveCN111036334BEmission reductionIncrease profitDrying gas arrangementsDrying chambers/containersCoalCarbon dioxide

The invention discloses a pulverized coal grinding and drying integrated coal feeder, which comprises a coal grinding machine body, and a coal grinding device is arranged in the coal grinding machine body, and the coal grinding device includes upper and lower end faces respectively arranged on the coal grinding machine body The upper coal grinding cavity and the lower coal grinding cavity in the upper coal grinding cavity are provided with a through cavity that penetrates the upper coal grinding cavity and the lower coal grinding cavity to penetrate it up and down, and the left and right of the upper coal grinding cavity correspond to There is a crushing wheel that can crush large coal lumps, and the left and right sides of the lower coal grinding chamber are correspondingly equipped with grinding wheels that can grind small coal lumps. The present invention crushes coal lumps into coal powder by setting it in the coal grinding device. The drying device can dry coal powder, which is conducive to the full combustion of coal, saving resources and reducing carbon dioxide emissions.

Owner:江西宸兴机械设备有限公司

A device for removing impurities and drying rice

The invention discloses a device for removing impurities and drying rice, which includes a processing box and a lifting box. Support columns and positive and negative motors are fixedly installed on the left and right sides and the middle part of the bottom of the processing box, and the left side of the processing box automatically The heating box and the blower are fixedly installed in sequence from top to bottom. There is a heating wire inside the heating box. The output end of the blower is connected to an exhaust pipe, and the top of the exhaust pipe is connected to the bottom of the heating box. There is a sieve plate, the output end of the positive and negative motor is fixedly installed with the first rotating rod, and the end of the first rotating rod away from the positive and negative motor runs through the processing box and the sieve plate in turn and is fixedly installed with a cylinder. The material hole, the outer surface of the first rotating rod is fixedly sleeved with a stirring rod and a scraper, and the middle part of the top of the cylinder is provided with a receiving hopper. The invention uses hot air to fully and evenly dry the rice flung out when the cylinder rotates, and heats it in a continuous cycle in the lifting box and the processing box, so that the effect of drying and removing impurities is good.

Owner:宿松县佳兴米业有限公司

A steel back drying device

ActiveCN108716822BEasy to dryEfficient DryingDrying gas arrangementsDrying solid materialsGear wheelClassical mechanics

The invention discloses a steel backing drying unit which comprises a box, a supporting part located on the inner side of the box and a drying part located on the inner side of the box. The supportingpart comprises a sliding rod, a moving plate, a plurality of supporting units, a first rack and a driving unit, and the sliding rod is connected with the box; the moving plate is in sliding connection with the sliding rod; the multiple supporting units are sequentially distributed in the length direction of the sliding rod; each supporting unit comprises a strut, a clamping assembly and a first gear; and the struts are rotationally connected with the moving plate. The clamping assemblies are installed on the struts, the first gears are installed on the struts, the first rack is connected withthe box and is parallel to the sliding rod, and the first rack is engaged with the first gears; and the driving unit is used for driving the moving plate to move, and the drying part is used for spraying out air.

Owner:ANHUI GUIDA AUTO PARTS

A textile drying device

ActiveCN108265425BPrevent prolapseDoes not block processingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsTransmission beltElectric machinery

The invention discloses a textile shaping and drying device, and belongs to the technical field of textile equipment. The device is characterized by comprising a drying chamber, wherein a first support column, a second support column and a third support column are arranged at the bottom of the drying chamber from left to right sequentially; a transmission roller is arranged at the upper part of the first support column, support rollers are arranged at upper parts of the second support column and the third support column, and guide rollers are arranged at lower parts of the first support column, the second support column and the third support column; a conveying belt is arranged on the transmission roller, the support rollers and the guide rollers; a first motor is fixed in the middle of the left side of the drying chamber, and a transmission belt is connected between an output end of the first motor and the transmission roller. According to the textile shaping and drying device, steamshaping can be performed on textiles effectively, and the textiles can be dried.

Owner:SHAOXING JINCHEN BIOLOGICAL TECH CO LTD

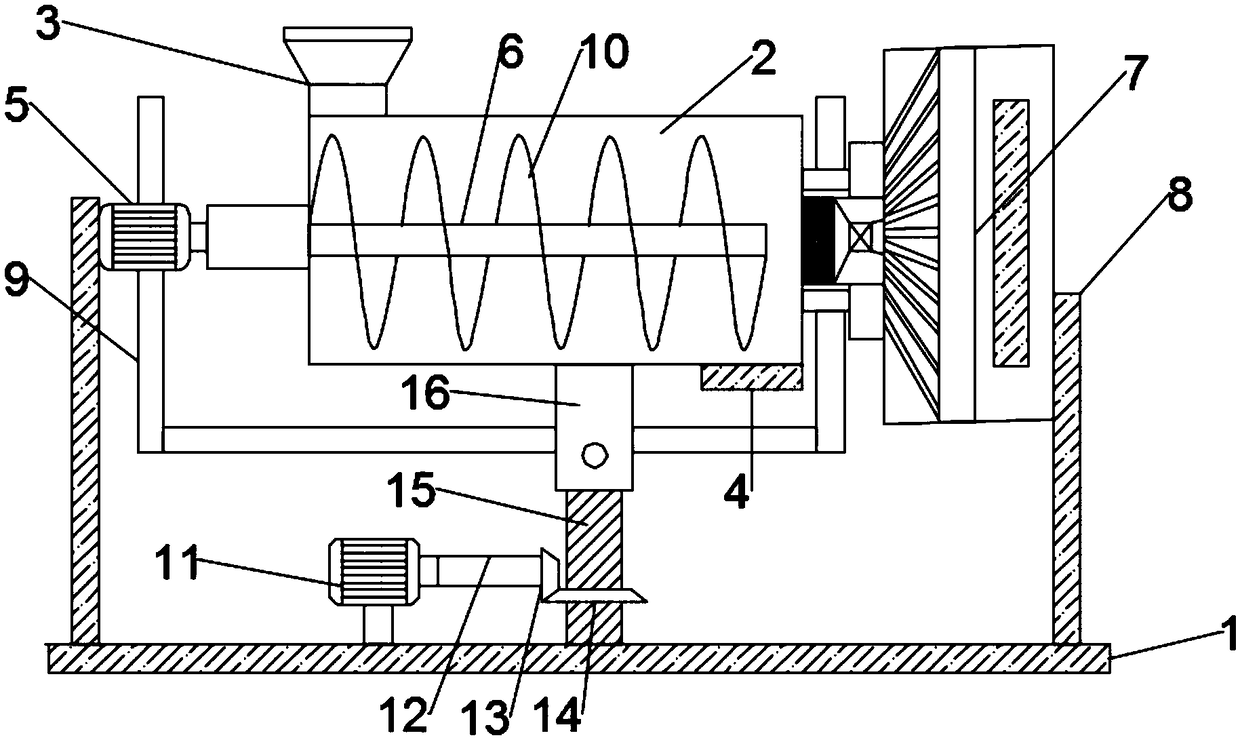

Agricultural drying machine capable of conveniently conveying grains

InactiveCN108645159AIncrease contact areaImprove drying efficiencyDrying gas arrangementsSeed preservation by dryingAgricultural engineeringSpiral blade

The invention discloses an agricultural drying machine capable of conveniently conveying grains. The agricultural drying machine capable of conveniently conveying the grains comprises a base, a grainconveying cavity, a first working motor and a heating device; supporting arms are welded to the two sides of the base; a grain conveying cavity is arranged between the supporting arms; the first working motor is arranged in the middle position of the left side of the grain conveying cavity and fixedly connected with a movable mounting frame; the right side of the first working motor is fixedly connected with a first rotary shaft, the right end of the first rotary shaft extends into an inner cavity body of the grain conveying cavity and is fixedly connected with spiral blades, and the spiral blades are arranged in the grain conveying cavity; and the heating device is arranged on the right side of the grain conveying cavity, and the left side of the heating device is fixedly connected with the movable mounting frame. By means of the agricultural drying machine capable of conveniently conveying the grains, the grains can be quickly conveyed, at the same time, the grains can be sufficiently dried in the grain conveying process, grain rotting caused by dampness is avoided, and resources are greatly saved.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

Grinding type air drying device for tea polyphenol processing

InactiveCN112595026AFully effective drying functionFully dry treatmentDrying gas arrangementsDrying chambers/containersPhenolic content in teaPolyphenol

The invention relates to the field of tea polyphenol production and processing, and discloses a grinding type air drying device for tea polyphenol processing. The grinding type air drying device comprises a shell, brackets, an air drying chamber, feeding holes and a discharging hole. A crushing disc of a conical structure is fixedly installed at the position, located at the bottom end of the feeding hole, in the shell, a crushing groove of an arc-shaped structure is formed in an outer ring of the bottom of the crushing disc, a set of rotating grooves are downwards formed in the top end of thecrushing disc, and a set of balls are connected into the rotating grooves in a rolling mode. A set of rolling discs of a conical structure are fixedly connected to the upper sides of the balls, a setof limiting rods are fixedly installed at the tops of the rolling discs, a set of rotating cavities with openings in the lower sides are formed in the upper sides of the limiting rods, two sets of pressing rods of the same structure are arranged on the left sides and the right sides of the rotating cavities, the air drying chamber is arranged in the position, below the crushing disc, of the shell,a vertical rotating cylinder is arranged in the middle of the air drying chamber, and an air heater is fixedly installed in the middle of the interior of the rotating cylinder.

Owner:长沙开湖设备有限公司

Fabric wearable radio frequency tag manufacturing method based on ink-jet printing technology

InactiveCN113191473ASolve the comfortAddress flexibilityLiquid/solution decomposition chemical coatingRecord carriers used with machinesAlcoholEngineering

The invention provides a fabric wearable radio frequency tag manufacturing method based on an ink-jet printing technology, which comprises the following operation steps: step 1, fabric base layer treatment: firstly, a user puts a fabric into absolute ethyl alcohol for ultrasonic treatment for 20 minutes, then suspends and dries the fabric in the air, then dissolves 5g of P4VP into 100ml of absolute ethyl alcohol (solution I), then dissolves 1.2 g of SU-8 in 100 ml of 1, 4-dioxane (solution II), fully mixes the solution I and the solution II according to a ratio of 1: 1, immerses the fabric into the mixed solution, and airs the fabric in the air after the immersion is completed. According to the invention, through cooperation of materials and step flows, an ink-jet printing frontier technology is adopted, and ink-jet printing can be carried out by the ink of the organic polymer and the metal oxide, so that the transistors can be manufactured on various plastic substrates in a large scale; therefore, the problems that a traditional fabric wearable radio frequency tag manufacturing method is low in wearing comfort, poor in flexibility and high in cost are directly solved.

Owner:SHANGHAI TECHN INST OF ELECTRONICS & INFORMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com