Rapid drying treatment equipment for garbage

A kind of processing equipment and fast technology, applied in the direction of garbage drying, lighting and heating equipment, drying, etc., can solve the problems of secondary pollution, serious secondary pollution, long cycle, etc., to reduce labor intensity and achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

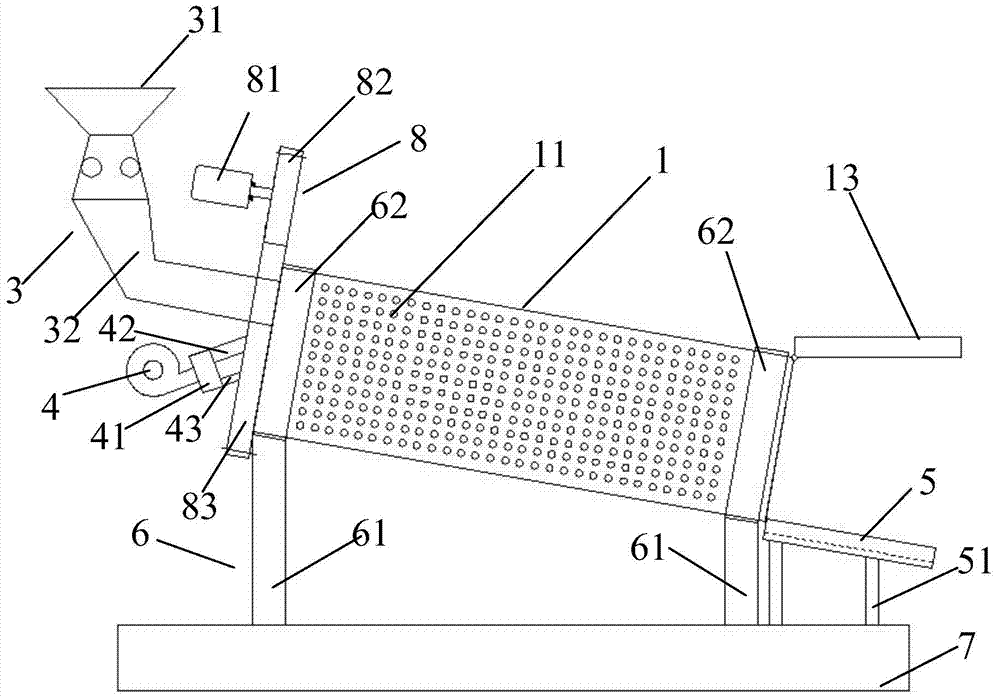

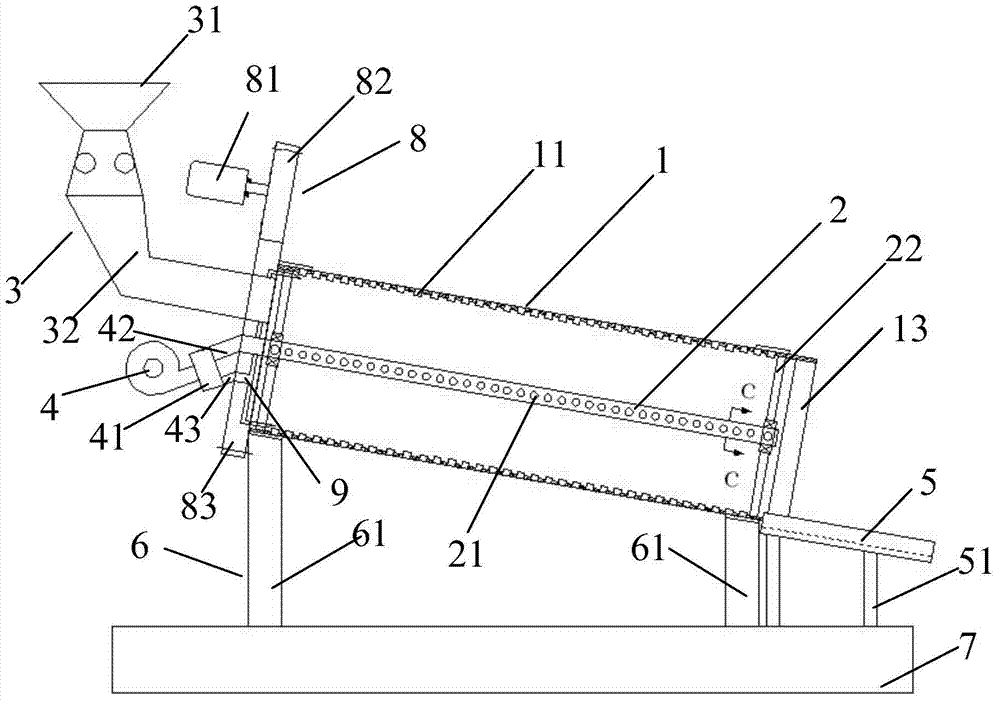

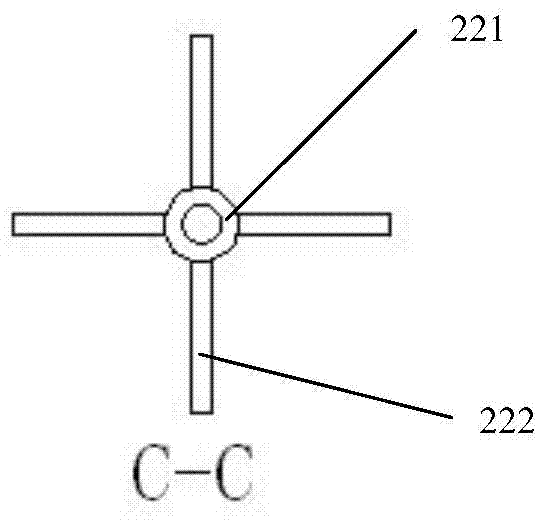

[0049] figure 1 and figure 2 Respectively show the garbage quick drying treatment equipment of the present invention, Figure 4 Shows the schematic diagram of the circuit used to control the automatic water removal of garbage in the present invention, as figure 1 , figure 2 and Figure 4 As shown, the garbage quick-drying treatment equipment includes: a drum 1 with a plurality of water outlet holes 11 distributed thereon; The air outlet 21 of 11; The feeding device 3 that communicates with the inlet 12 of the drum 1; The air supply device connected to one end of the radial blow pipe 2; Connect the air supply device and align with the axial direction of the front end of the drum 1 The blowing pipe 9; the driving device 8 used to drive the rotation of the drum 1; the electric hatch 13 installed at the outlet of the drum 1 to open or close the outlet of the drum; connect the air supply device, the driving device 8 and the electric motor respectively. The controller of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com