Garbage anhydration processing apparatus

A technology for processing equipment and waste drying, applied in lighting and heating equipment, drying, dryers, etc., can solve the problems of long cycle, harsh operating environment, large amount of landfill leachate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

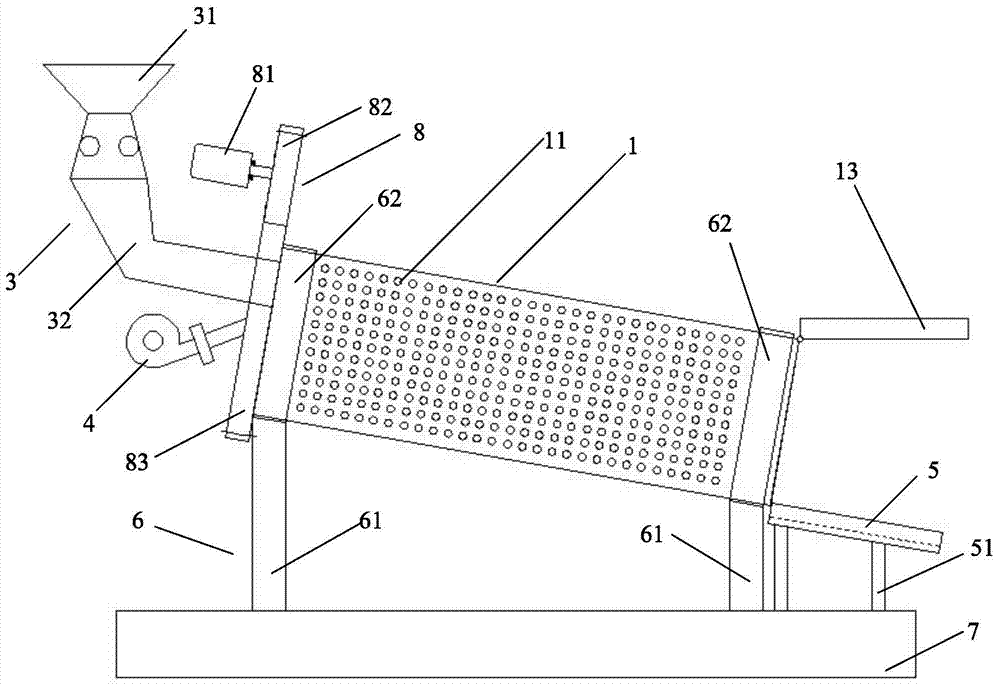

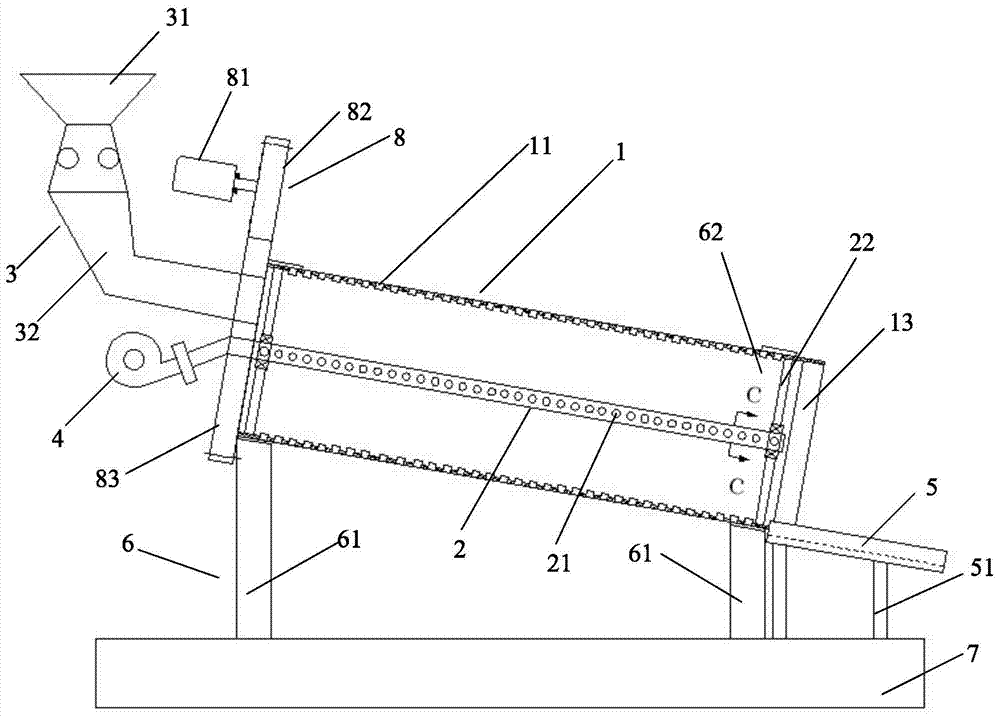

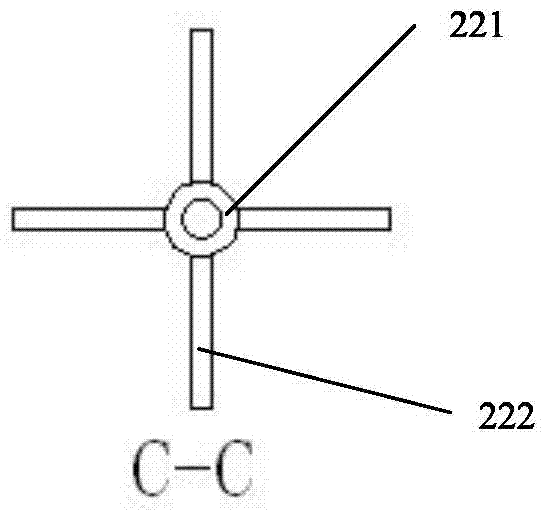

[0042] figure 1 with figure 2 Respectively show the garbage drying treatment equipment of the present invention, such as figure 1 with figure 2 As mentioned above, the garbage drying treatment equipment includes: a drum 1 with a plurality of water outlet holes 11 distributed thereon; an air duct 2 installed in the drum 1 with a plurality of outlets facing the water outlet holes 11; The tuyere 21; the feeding device 3 that communicates with the inlet 12 of the drum 1; the exhaust fan 4 whose air outlet is connected to one end of the air duct 2; wherein, the other end of the air duct 2 is a closed end; wherein the drum 1 is equipped with a hatch 13 for opening or closing the drum outlet; wherein, the air inlet of the exhaust fan 4 is connected to the hot air outlet of the garbage incinerator through a pipeline.

[0043] Figure 4 It shows a system in which the garbage drying treatment equipment of the present invention utilizes the heat energy of garbage incineration, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com