Drying method of sweet potato vermicelli

A drying method and a technology of potato flour, which are applied in the field of food processing, can solve the problems of vermicelli, easy breeding of harmful bacteria, and slow evaporation of water, and achieve the effects of saving energy consumption, increasing toughness, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A drying method for sweet potato vermicelli, comprising the following steps:

[0015] (1) Cooking and cooling: add water to the pot, set the water temperature in the pot to 79°C, add yam flour paste dough to the leaking sticks to start leaking flour, put the leaked vermicelli in the pot and cook for 5 minutes; steamed vermicelli After taking it out, quickly place it in a water tank with a cold water temperature of 4°C to cool, and the water in the water tank is circulating;

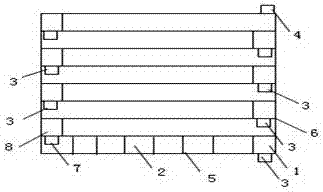

[0016] (2) "S" type drying room: It consists of a purification filter room 1, a drying channel 2, an air inlet 3 and an air outlet 4. The drying heating air enters the drying room through the air inlet 3 on the first floor, and the air inlet 3 Continuous with the purification and filtration room 1, the purification and filtration room 1 is located on the right side of the first floor, and the purification and filtration room is covered with 100-mesh gauze; Hanging horizontally on the drying channe...

Embodiment 2

[0020] Present embodiment 2 is compared with embodiment 1, and step changes in the following aspects:

[0021] For the drying of vermicelli described in step (3), the drying process parameters are set to:

[0022] The first stage is low-temperature drying, drying temperature is 46°C, humidity is 44%, and the time is 1.5h; the second stage is high-temperature drying, drying temperature is 77°C, humidity is 34%, and the time is 2h; then, low-temperature drying and high-temperature drying are staggered In the drying stage, 3 drying process cycles are performed to end.

[0023] Comparison 1:

[0024] This comparison 1 is compared with Example 1, the "S" type drying room in step (2) is not used, and other steps are the same as in Example 1.

[0025] Contrast 2:

[0026] Compared with Example 2 in this comparison 2, only high-temperature drying is used in step (3), wherein the drying temperature is 77°C and the humidity is 34%, and other steps are the same as in Example 2.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com