Patents

Literature

32results about How to "Large drying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

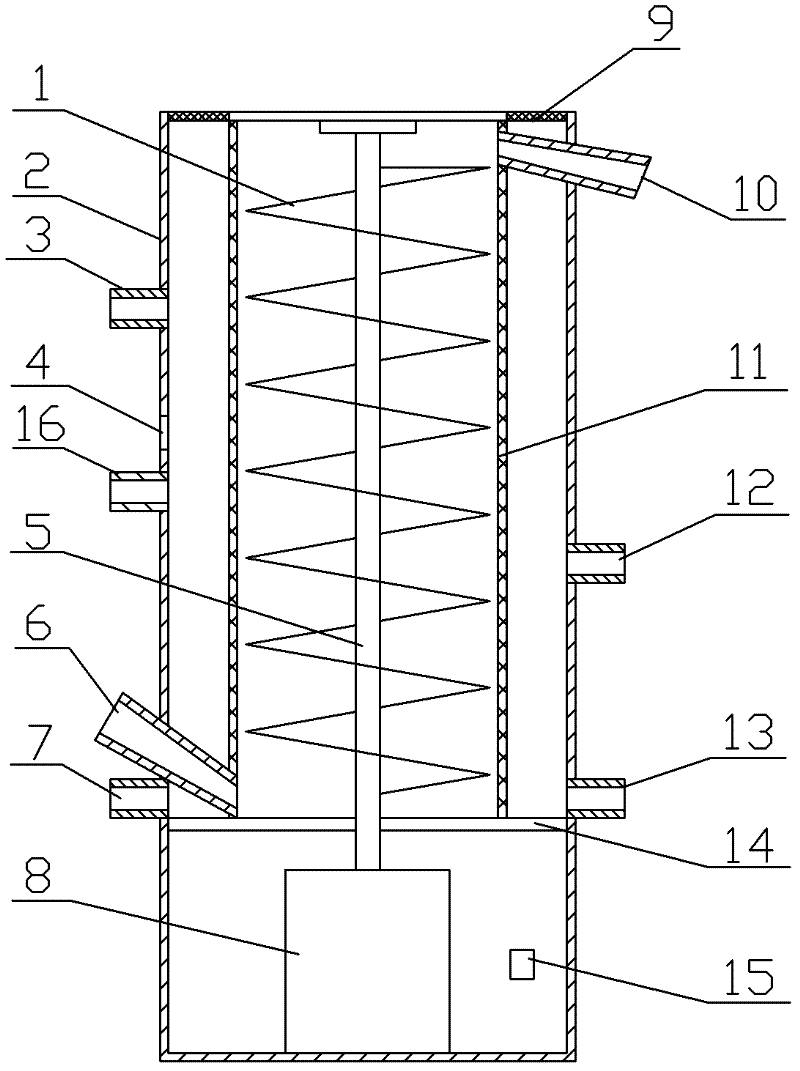

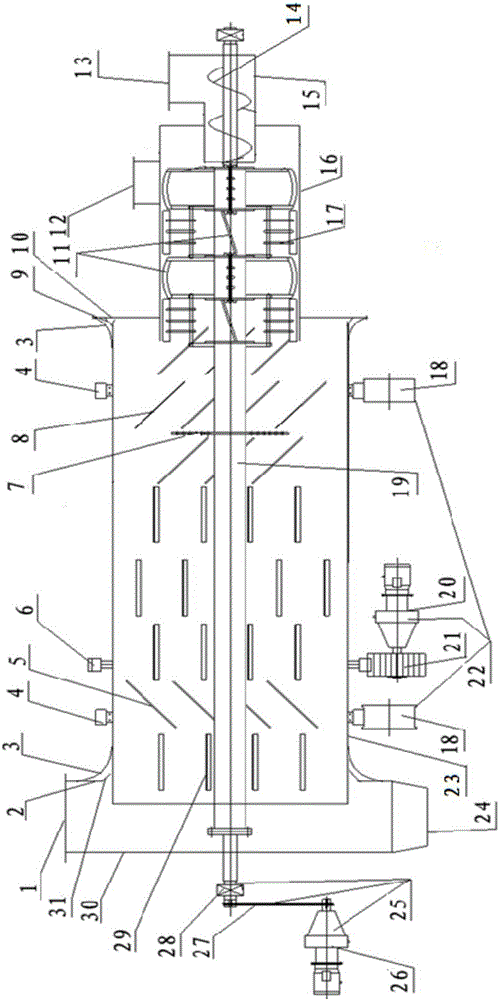

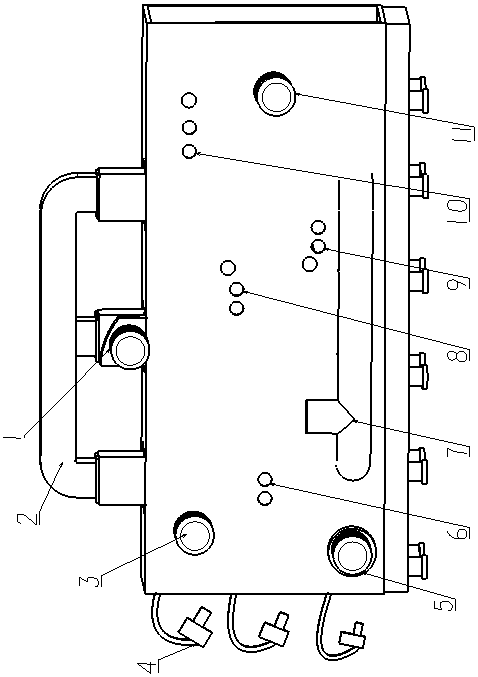

Push type medicinal materials drier

InactiveCN102393131ADry comprehensiveLarge drying capacityDrying solid materials with heatDrying gas arrangementsAgricultural engineeringLower upper

The invention discloses a push type medicinal materials drier which belongs to a drier. The structure comprises a shell, a mesh-typed sleeve, a speed-regulating motor, a spiral boosting piece and a hot wind inlet. Wherein a partition plate is arranged in the shell, the mesh-typed sleeve is arranged on the upper part of the partition plate, the speed-regulating motor is arranged at the lower part of the partition plate, a rotating shaft connected with the speed-regulating motor penetrates through the partition plate and is arranged in the mesh-typed sleeve, the spiral boosting piece is arranged on the rotating shaft, a speed-regulating switch connected with the speed-regulating motor is arranged on the shell, a material feeding opening and a material discharging opening are respectively arranged at the lower part and the upper part of the mesh-typed sleeve, a hot wind inlet and a viewing port are respectively arranged on the shell at the upper part of the partition plate, a primary dehumidification port is arranged on the side wall of the shell, and a moisture removing port is arranged on top of the shell. The push type medicinal materials drier has the characteristics that: weather effect can be avoided when the drier is dried, machining can be carried out at any time, drying quantity is large, whole area of the medicinal materials can be comprehensively contacted by hot wind, medicinal materials heating is comprehensive, drying speed is increased, and the like.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

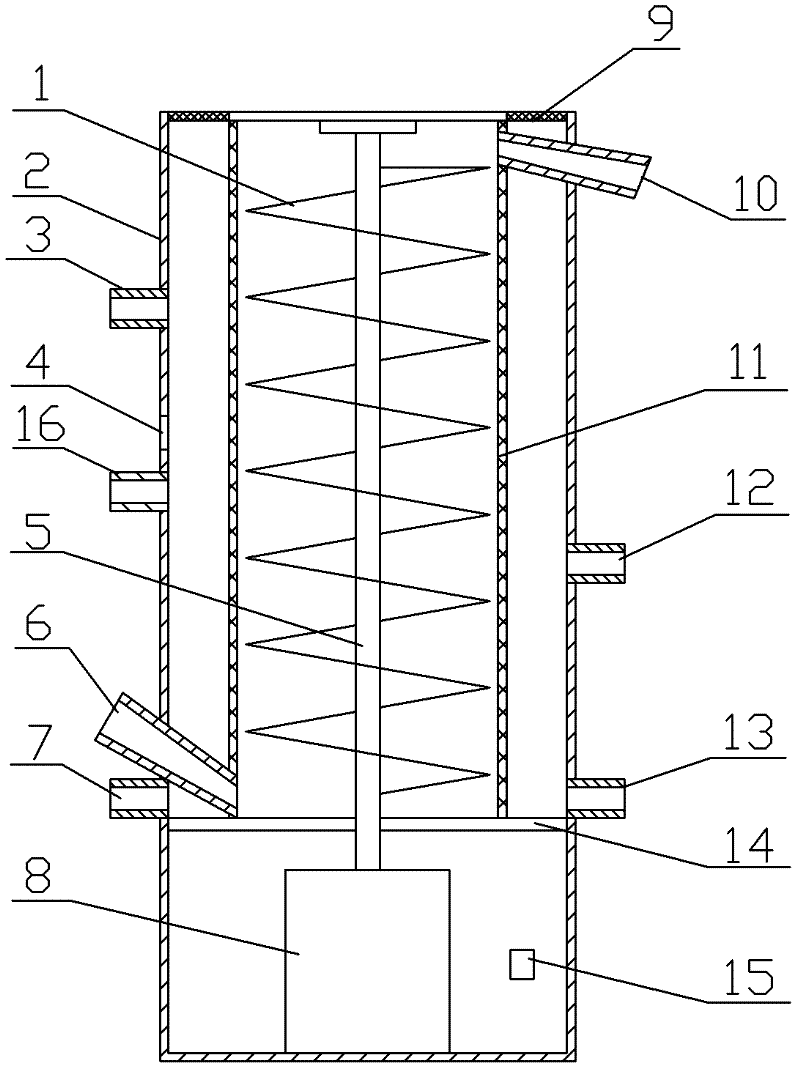

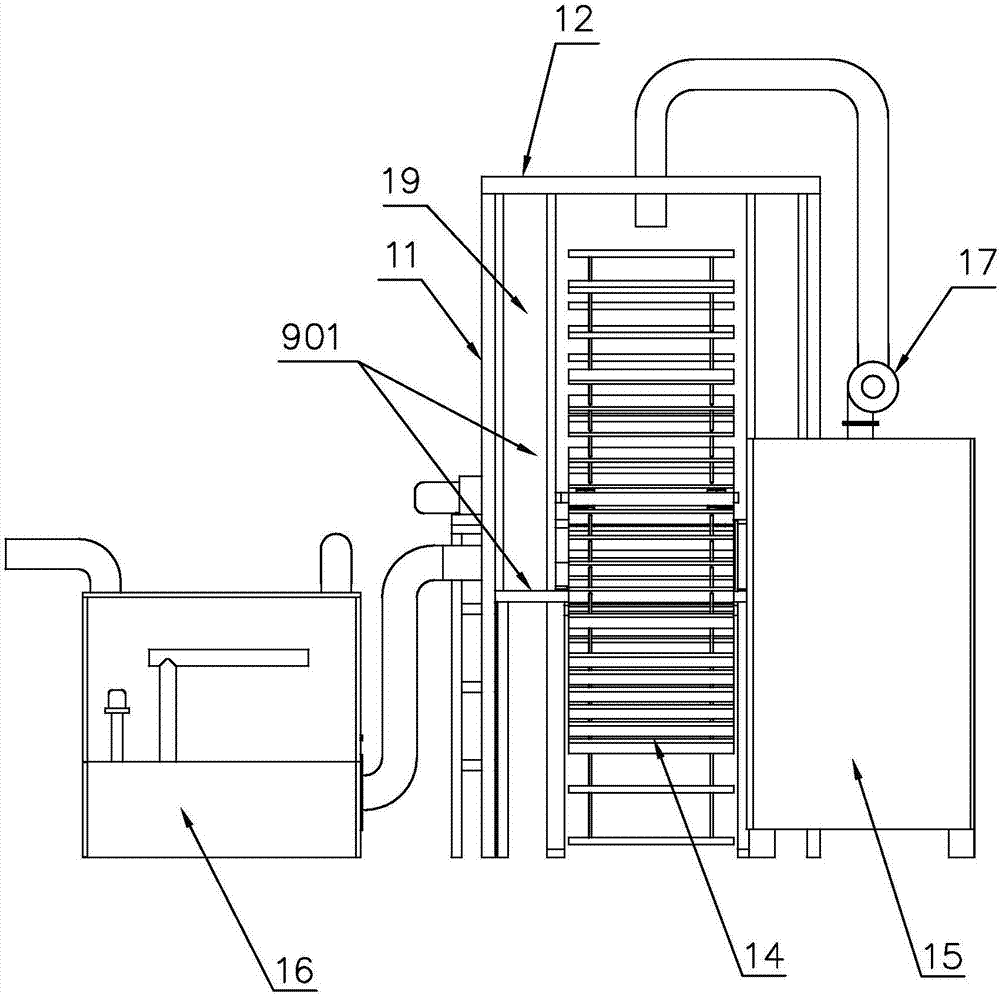

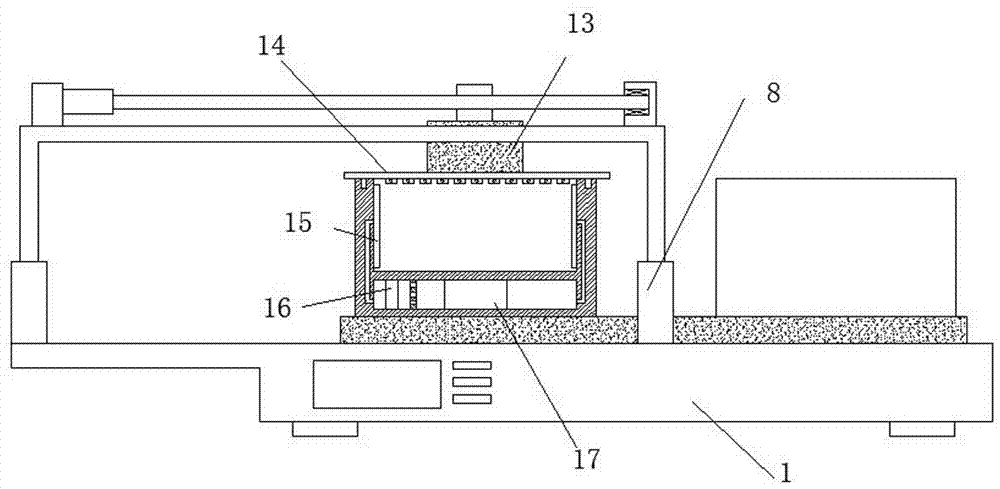

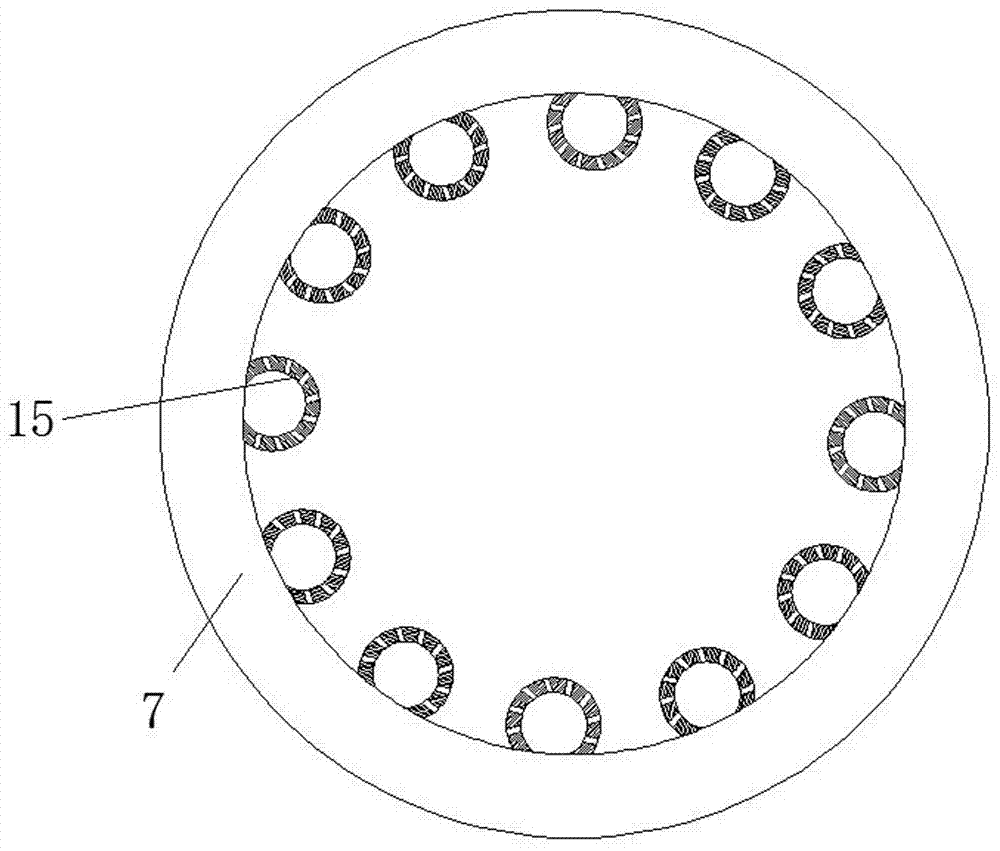

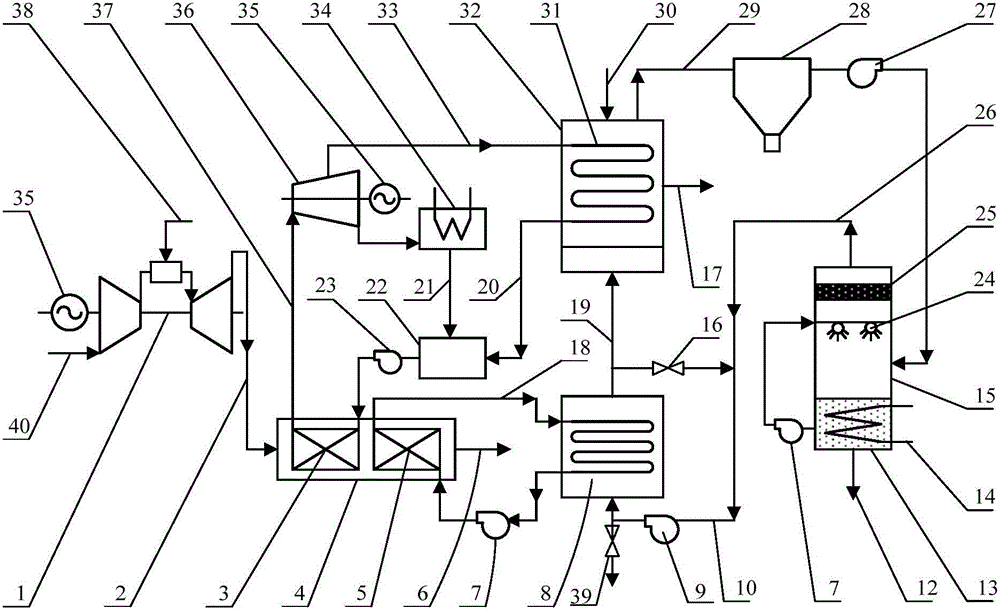

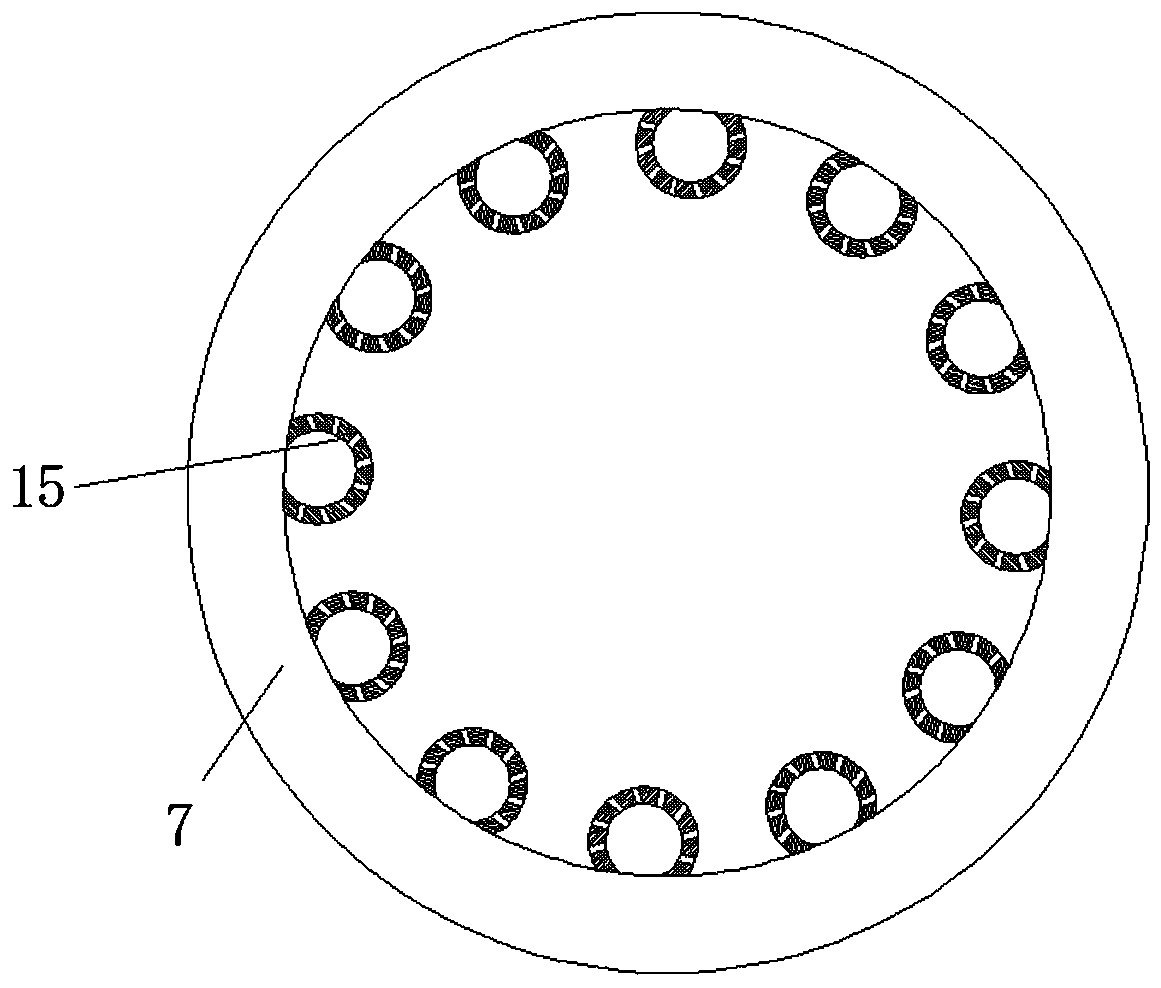

System and method for drying sludge through waste heat of gas turbine

ActiveCN103539333ALower fuel costsSolve the emission problemSludge treatment by de-watering/drying/thickeningSteam useFluidized bed dryingSludge

The invention provides a system and a method for drying sludge through the waste heat of a gas turbine. The gas turbine is connected with a generator; a flue gas outlet of the gas turbine is communicated with a waste heat boiler; a steam outlet of the waste heat boiler is communicated with a steam turbine; the steam turbine is connected with the generator; a steam extraction pipe of the steam turbine is communicated with an inlet of a heated surface pipe of an internal thermal type fluidized bed dryer; an air outlet of an air heater is communicated with an air inlet of the internal thermal type fluidized bed dryer; wet sludge enters the internal thermal type fluidized bed dryer through a wet sludge pipe, flows outside the heated surface pipe, is dried and then is discharged into a dry sludge pipe from a discharging hole. Steam is produced through the flue gas waste heat of the gas turbine to push a steam turbine generator set to generate power, and the waste heat of the steam turbine is taken as a heat source for drying the sludge, so that gradient energy utilization is realized, the heat efficiency is high, and a peculiar smell is not discharged; the fluidization air of the fluidized bed dryer is preheated by hot water, so that the energy utilization rate is further improved, and the environmental problems of groundwater pollution and the like caused by sludge burying and soil utilization are effectively solved.

Owner:凤阳县经济发展投资有限公司

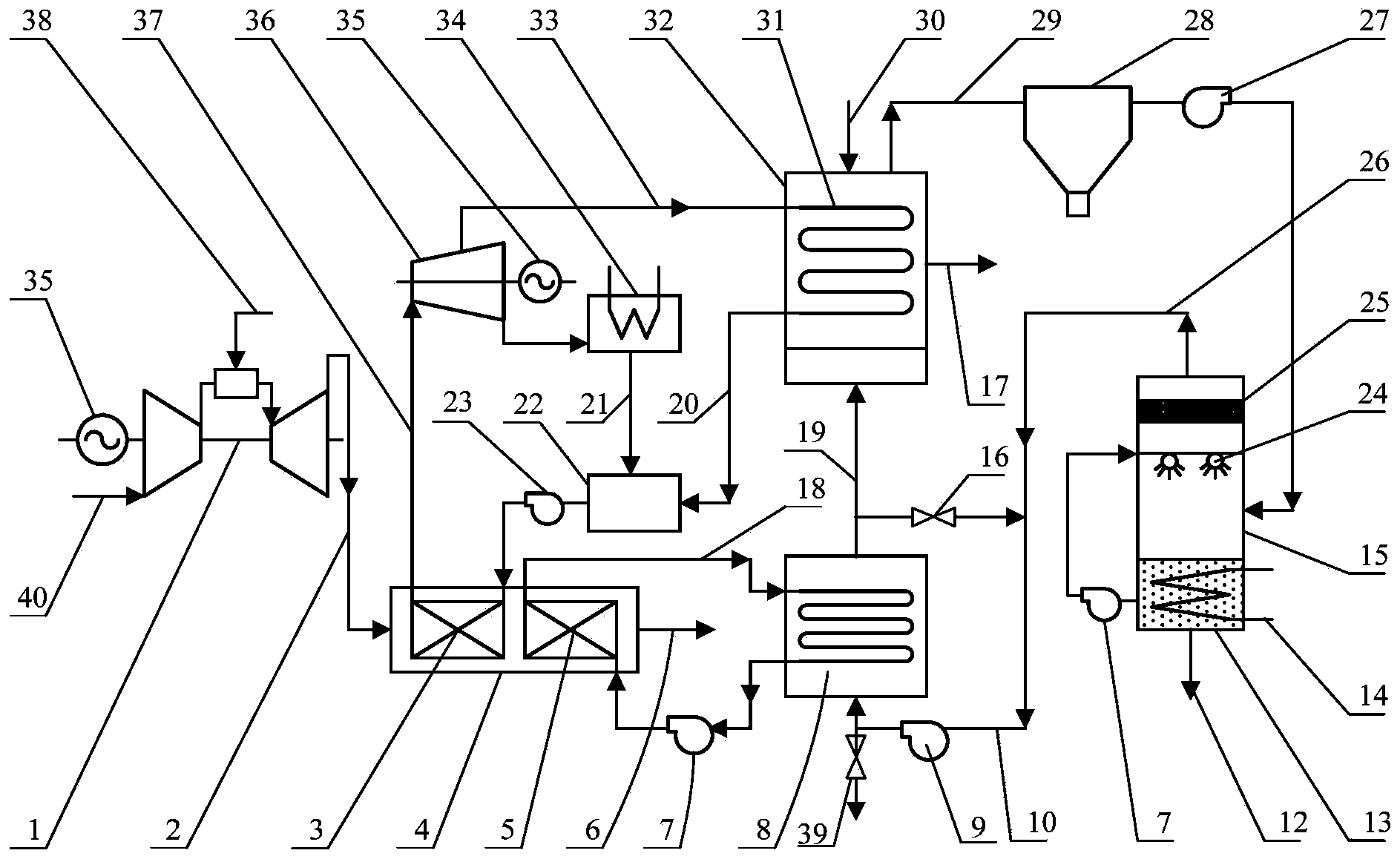

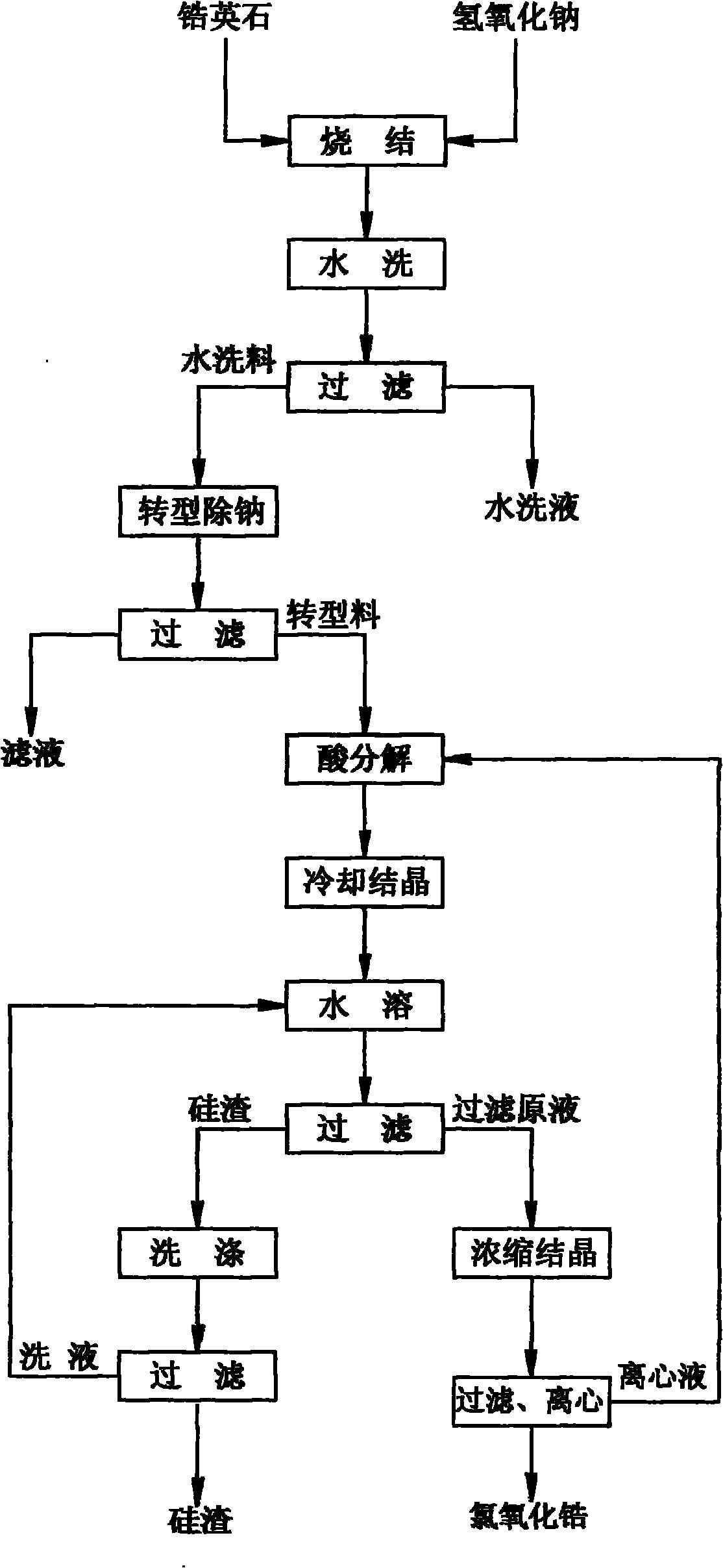

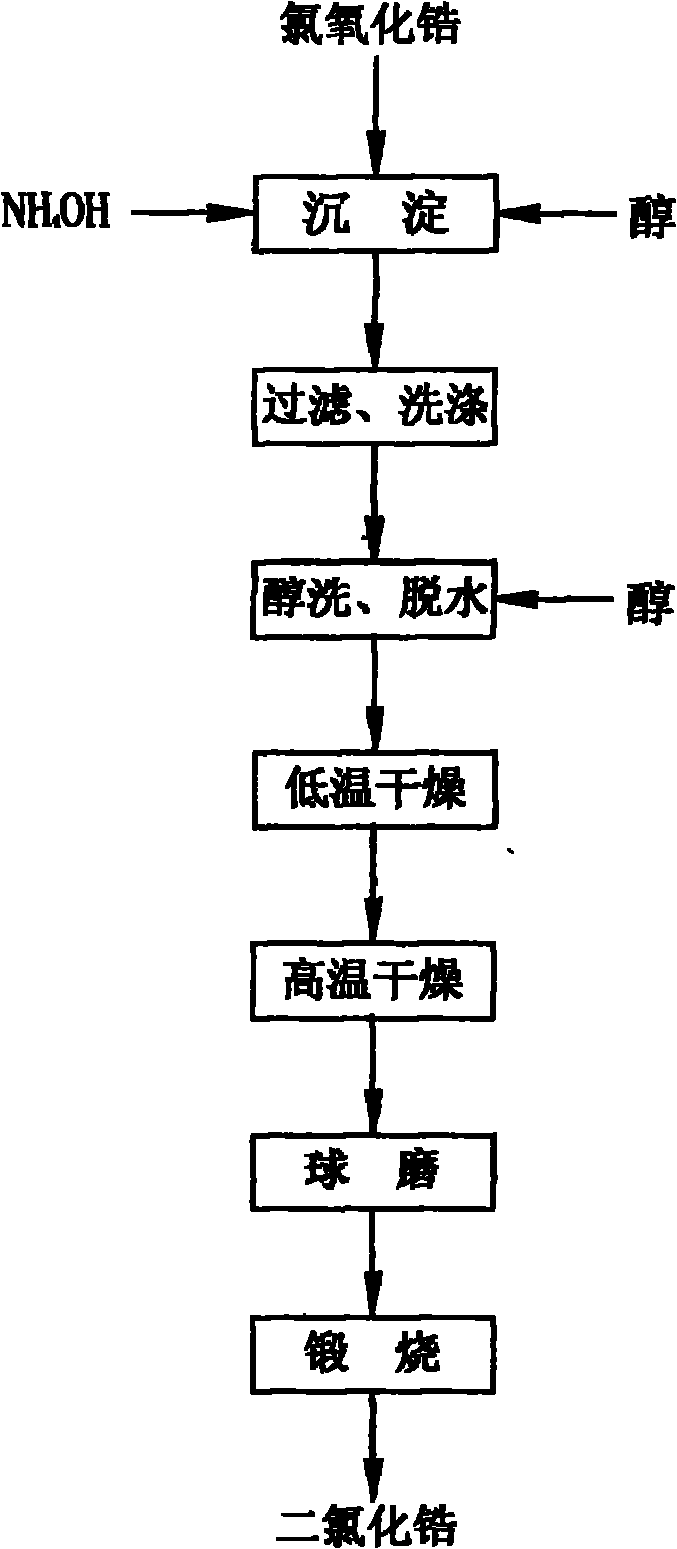

Preparation method of high-purity nano zirconium dioxide

InactiveCN101830506AAvoid reunionExtended reaction timeNanostructure manufactureZirconium oxidesMagnetic mediaBiological activation

The invention discloses a preparation method of high-purity nano zirconium dioxide, which comprises the following steps: firstly, preparing zirconium oxychloride by using zirconite as a raw material, then preparing 0.3 to 0.5 mol / L zirconium oxychloride solution, adding 25wt% to 30wt% of NH4OH into the zirconium oxychloride solution while stirring until the pH is in the range of 9 to 9.5, precipitating after stirring uniformly, and finally obtaining the high-purity nano zirconium dioxide by the processes of washing and filtering, dehydrating wit alcohol, drying, ball milling and roasting. The preparation method uses a liquid phase precipitation method to prepare nano zirconium dioxide powder. The invention solves the problem of nano zirconium dioxide aggregation, improves surface activation grade, has the advantages of large drying treatment capacity, high safety, convenient control, low aggregation of produced powder, small granularity of powder obtained after surface treatment, uniform distribution, regular appearance, and dry and loose prepared zirconium dioxide powder, and can be widely applied to the aspects of catalysis, filtering, photoabsorption, medicine, magnetic medium, structural ceramics, new materials and the like.

Owner:WEIFANG TIANFU CHEM TECH

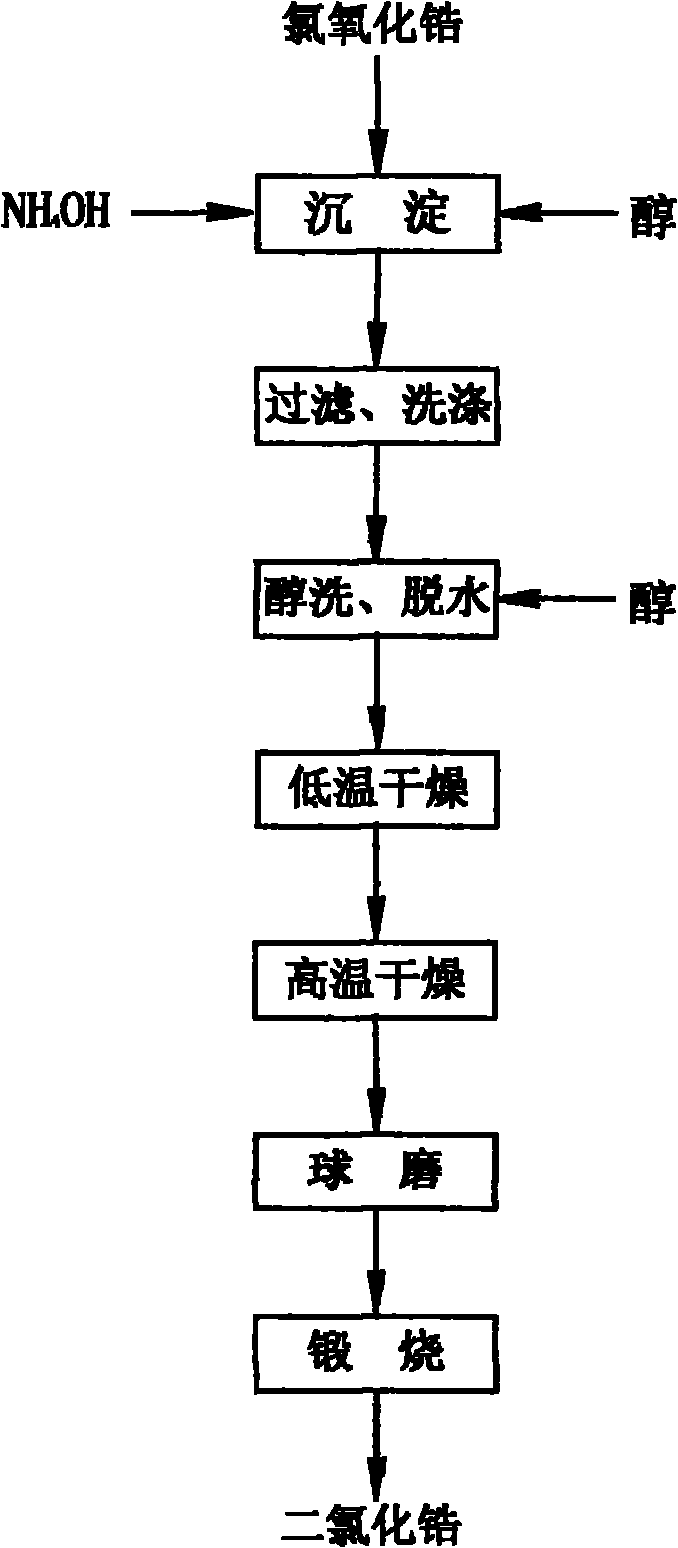

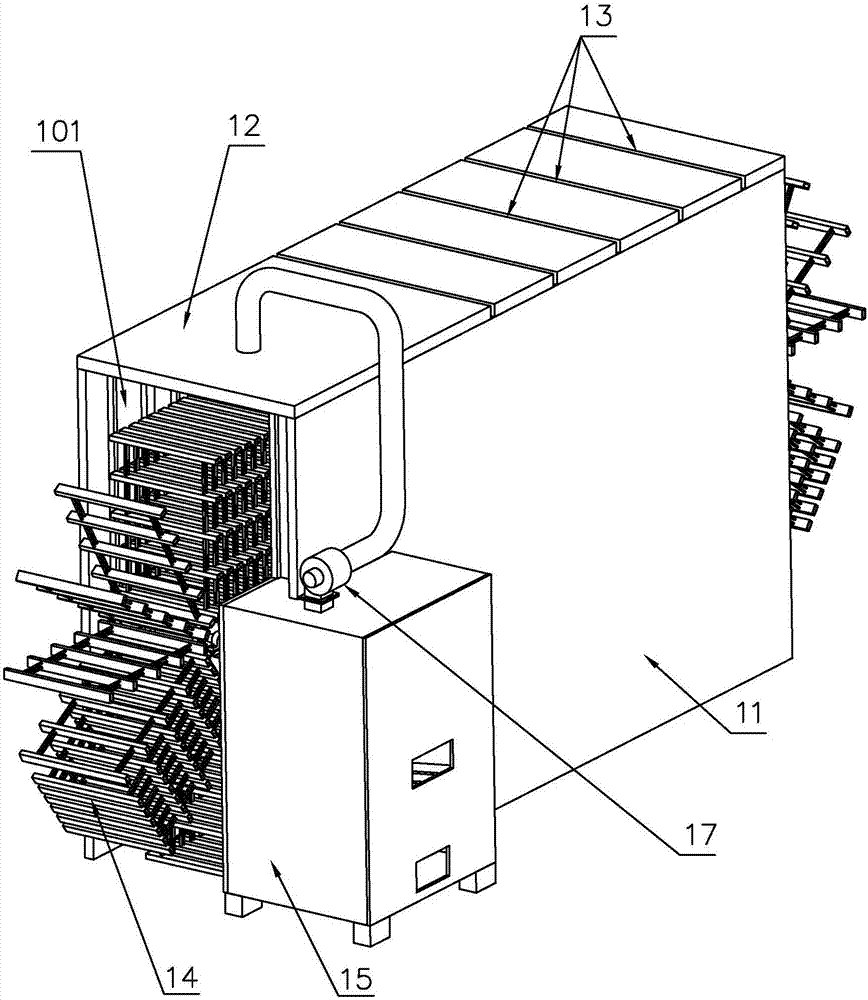

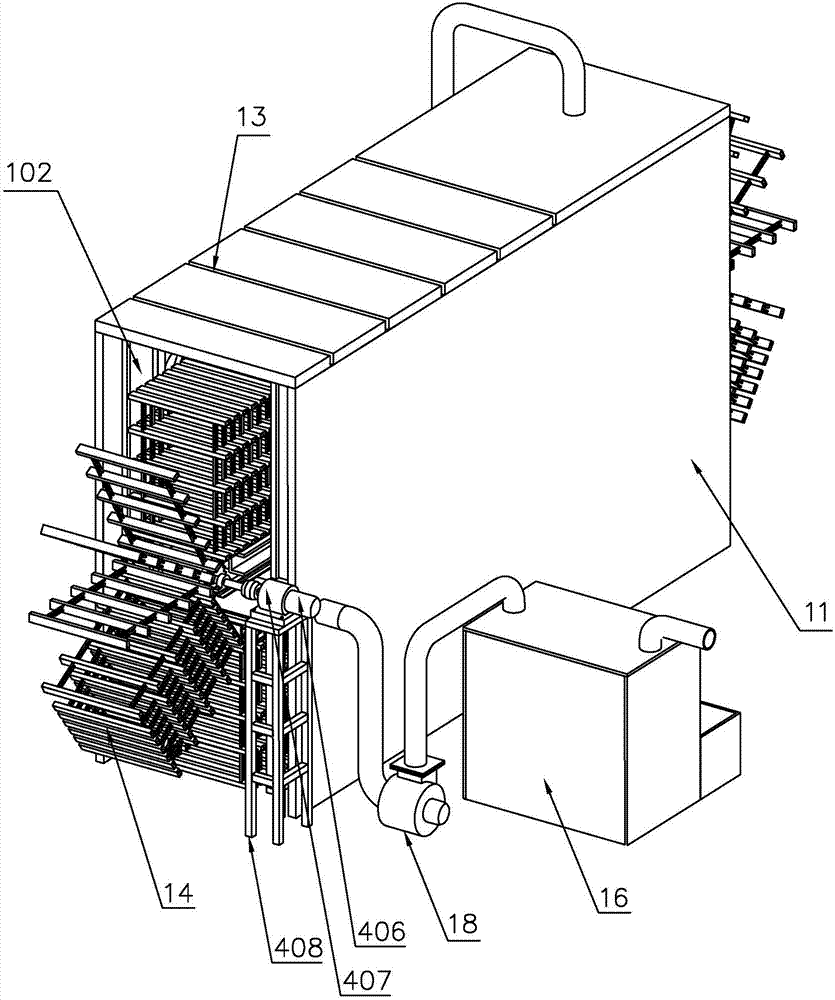

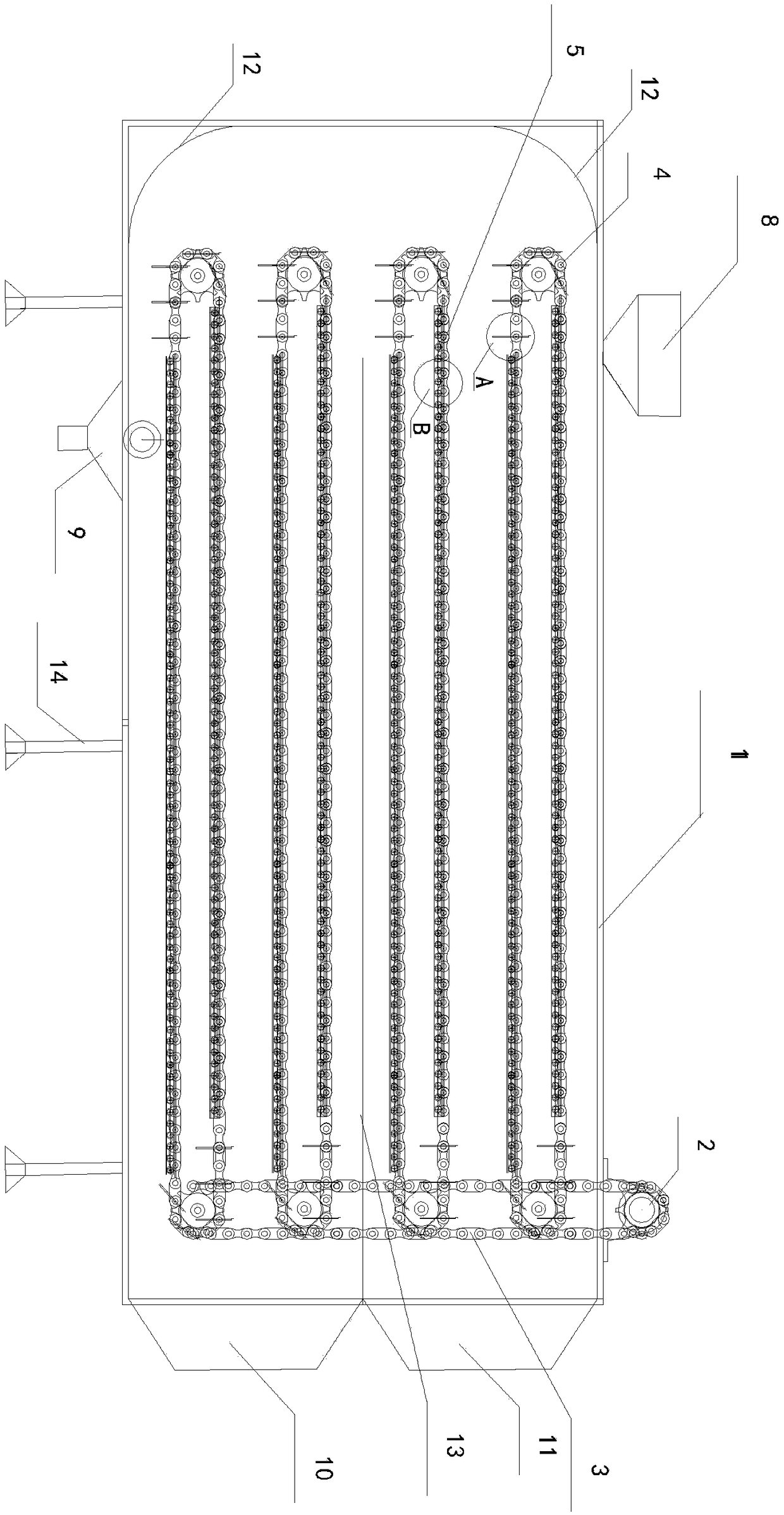

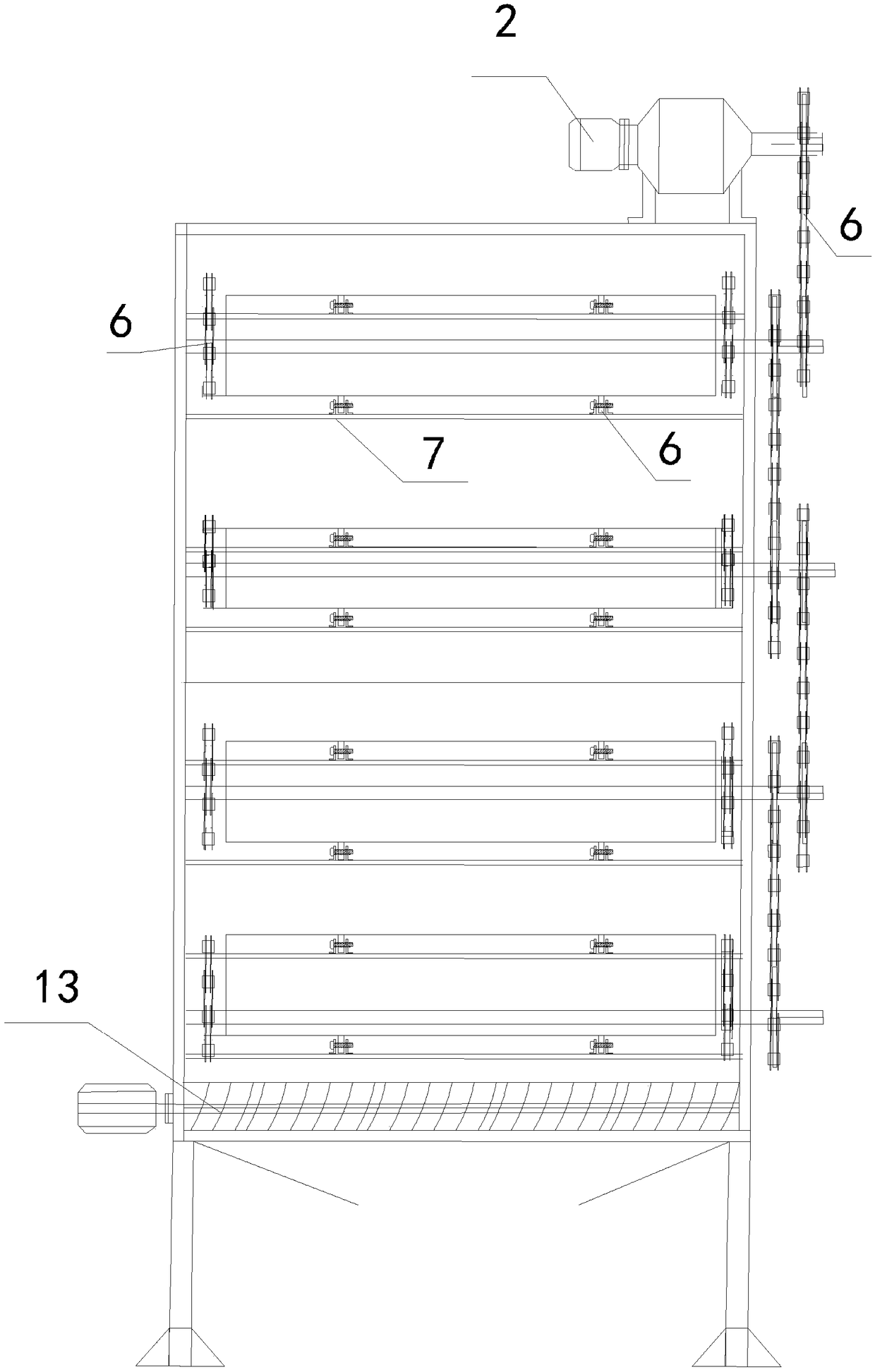

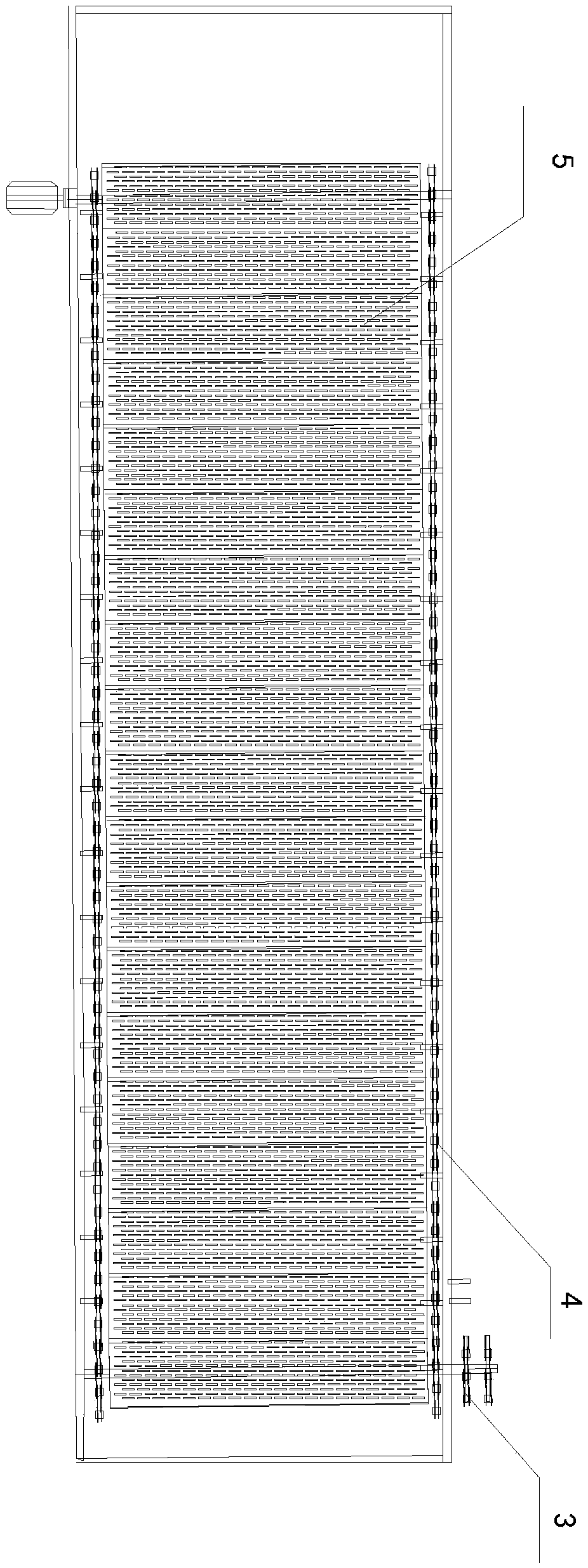

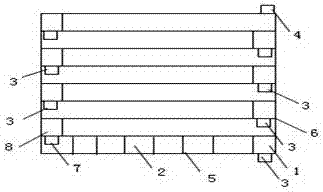

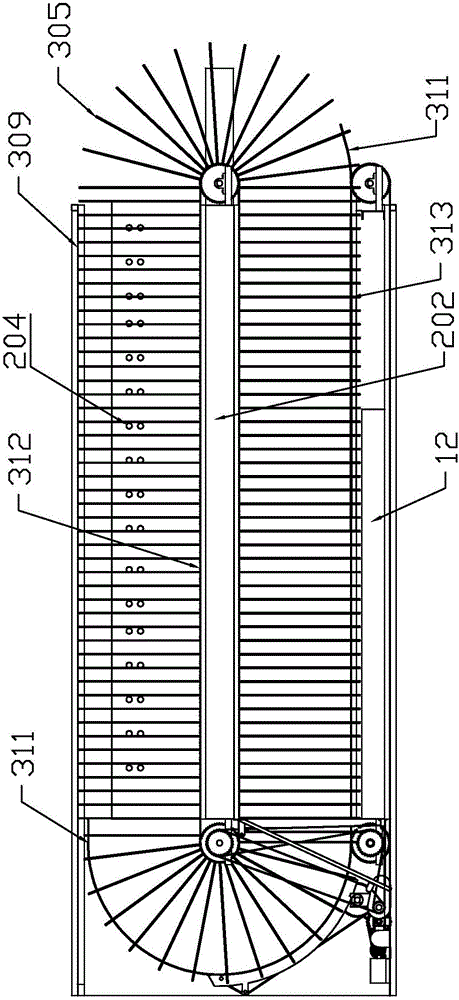

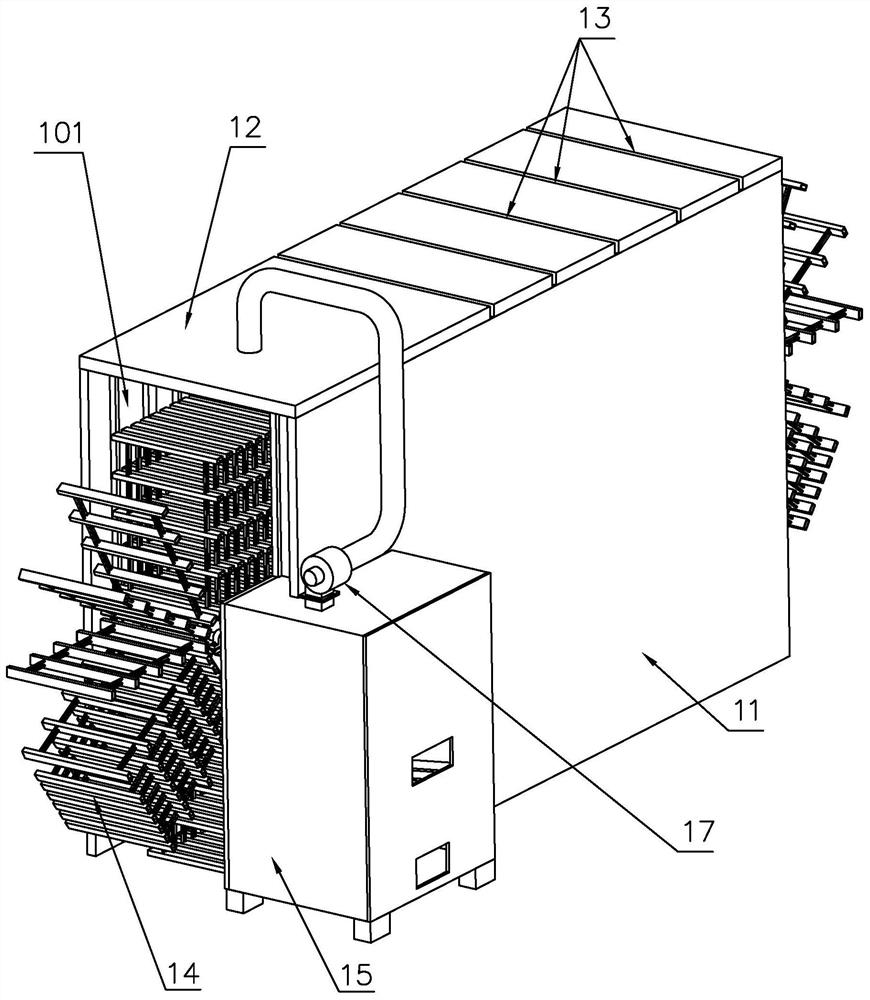

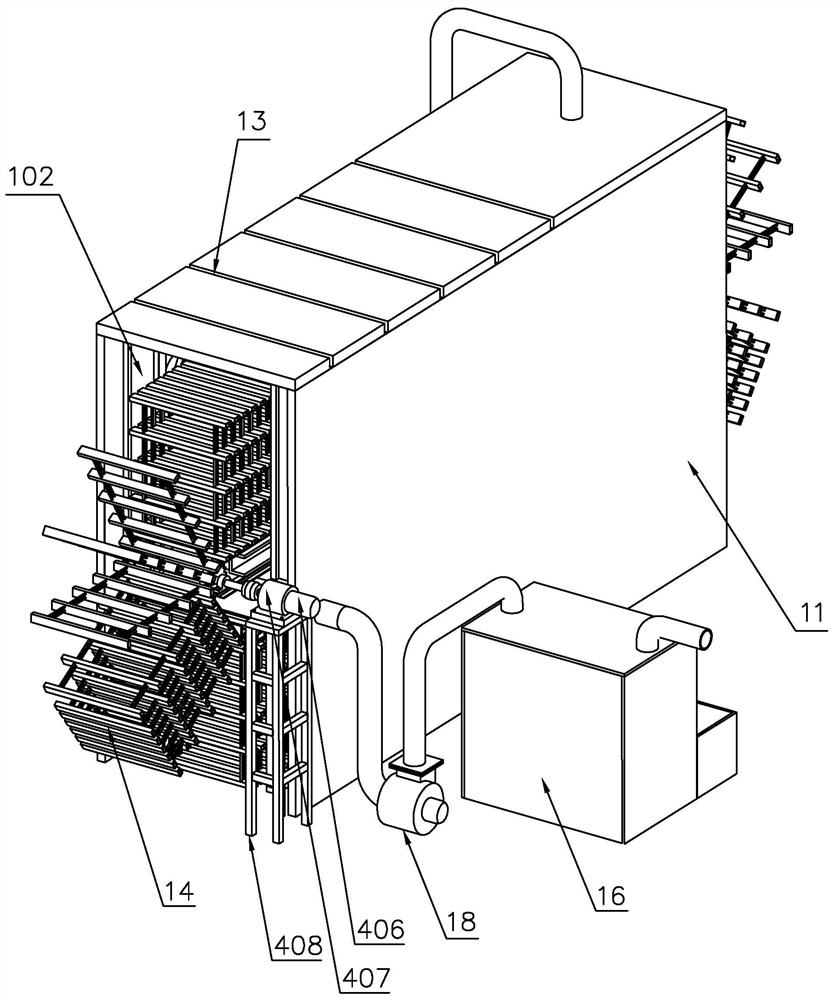

Environment-friendly efficient veneer drying device

ActiveCN107084607AUniform moisture contentImprove flatnessDrying gas arrangementsDrying chambers/containersDrive shaftFixed frame

The invention provides an environment-friendly efficient veneer drying device comprising a veneer inlet, a veneer outlet, a machine frame, a heat preservation box, a top cover, a plurality of moisture outlets, a conveying mechanism, air blowing devices, a flame path, smoke pipelines and a flue. The heat preservation box is arranged on the outer side of the machine frame. The upper portion of the heat preservation box is provided with a top cover. The top cover is provided with the multiple moisture outlets which are close to the veneer outlet. The conveying mechanism comprises a transmission shaft, clamping arms, supporting cushion blocks, a chain, chain wheels, carrier rollers, a motor, a speed reducer and a motor fixing frame. The supporting cushion blocks are arranged on the upper portion of the chain. The clamping arms are arranged on the upper portion of the supporting cushion blocks. The flame path, the smoke pipelines and the flue are fixedly connected to the machine frame. The air blowing devices are arranged on the two sides of an upper circulation position of the conveying mechanism and the two sides of the flame path. Each air blowing device comprises partition plates, air blowing fans and fan supports. The environment-friendly efficient veneer drying device is low in energy consumption, reduces the production cost of a traditional large-sized drying device, is good in veneer drying effect and solves the problem that after being dried, veneer naturally warps.

Owner:李学淑

Garbage drying device

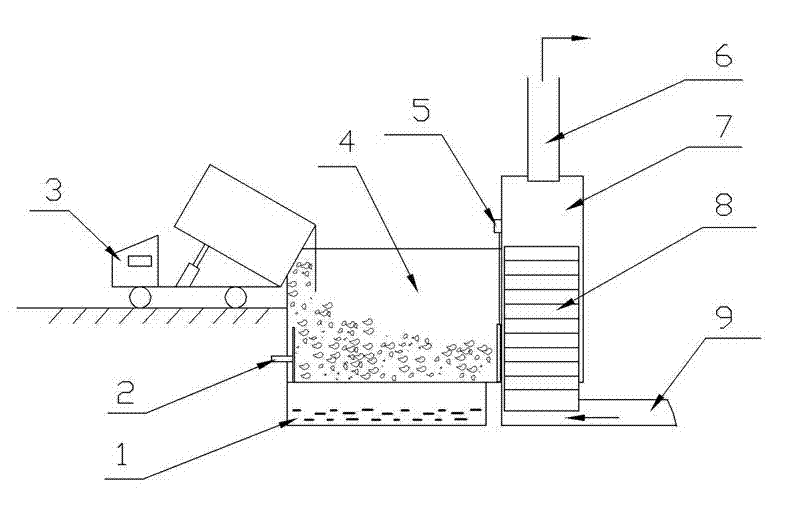

InactiveCN102853432AImprove drying effectImprove efficiencyIncinerator apparatusSufficient timeLitter

The invention relates to a garbage drying device which comprises a garbage diffusion tank, a garbage extrusion device, a garbage tank, a valve group, a smoke discharge pipeline, a drying bin, an upward conveying belt, a horizontal conveying belt, a burning smoke pipeline, a garbage hoist grab bucket, a burning furnace garbage feeding port, a garbage burning furnace and a dry garbage storage tank. Waste gases generated by the garbage burning furnace enter the drying bin through the smoke pipeline, hot air evaporates garbage moving on the upward conveying belt and takes away steam, garbage in unit can be dried by the hot air in enough time from the bottom of the upward conveying belt to the top end of the upward conveying belt, and dried garbage is conveyed to the dry garbage storage tank or directly conveyed to the burning furnace garbage feeding port to be burned. The garbage drying device is good in drying effect, low in manufacture cost, simple and convenient in garbage feeding and discharging, large in garbage drying amount, energy-saving, environment-friendly and economic, does not need other energy for assisting, uses burned smoke as the heat source, and is especially suitable for being used in large garbage burning places.

Owner:福州家禾机电成套设备有限公司

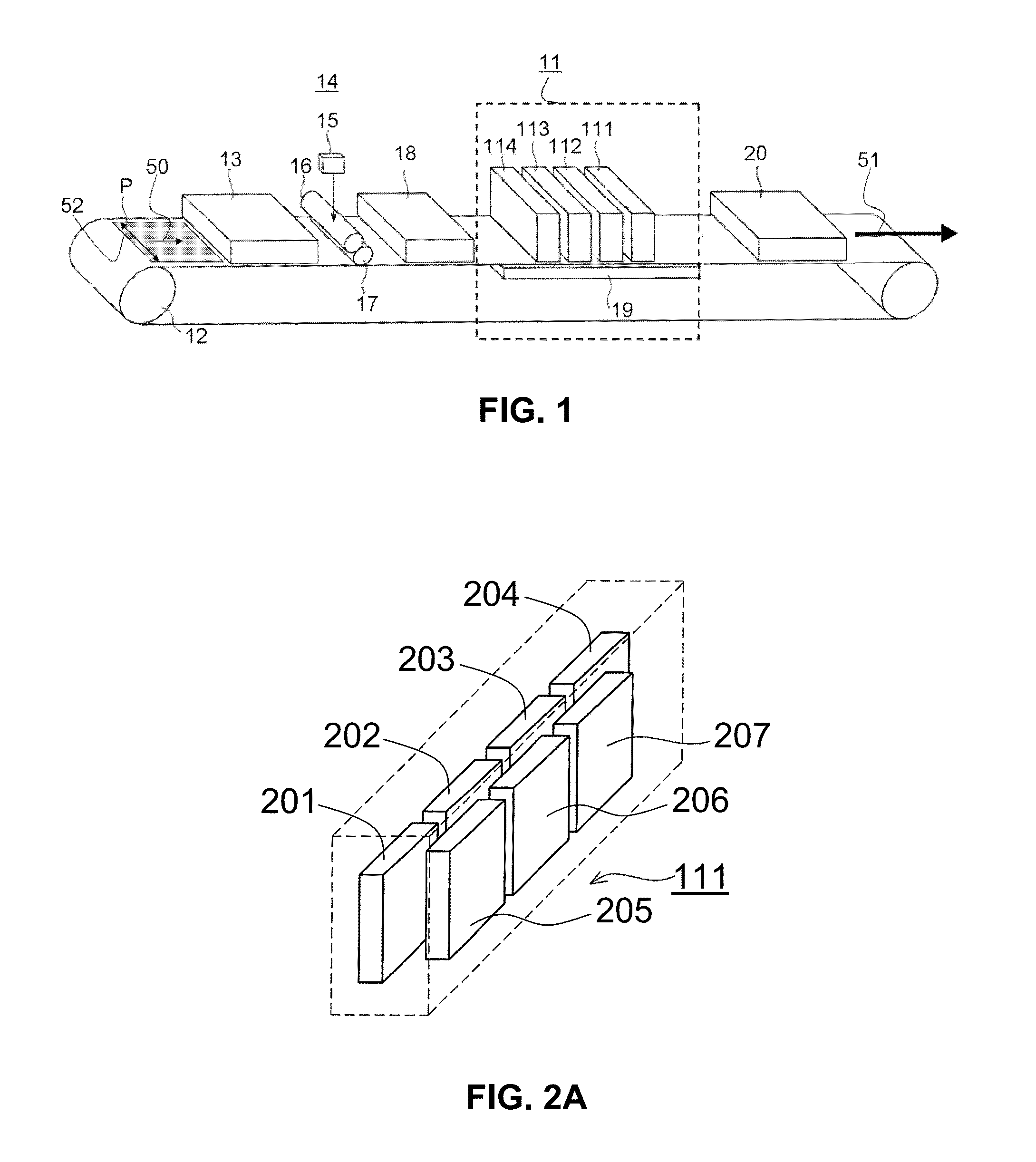

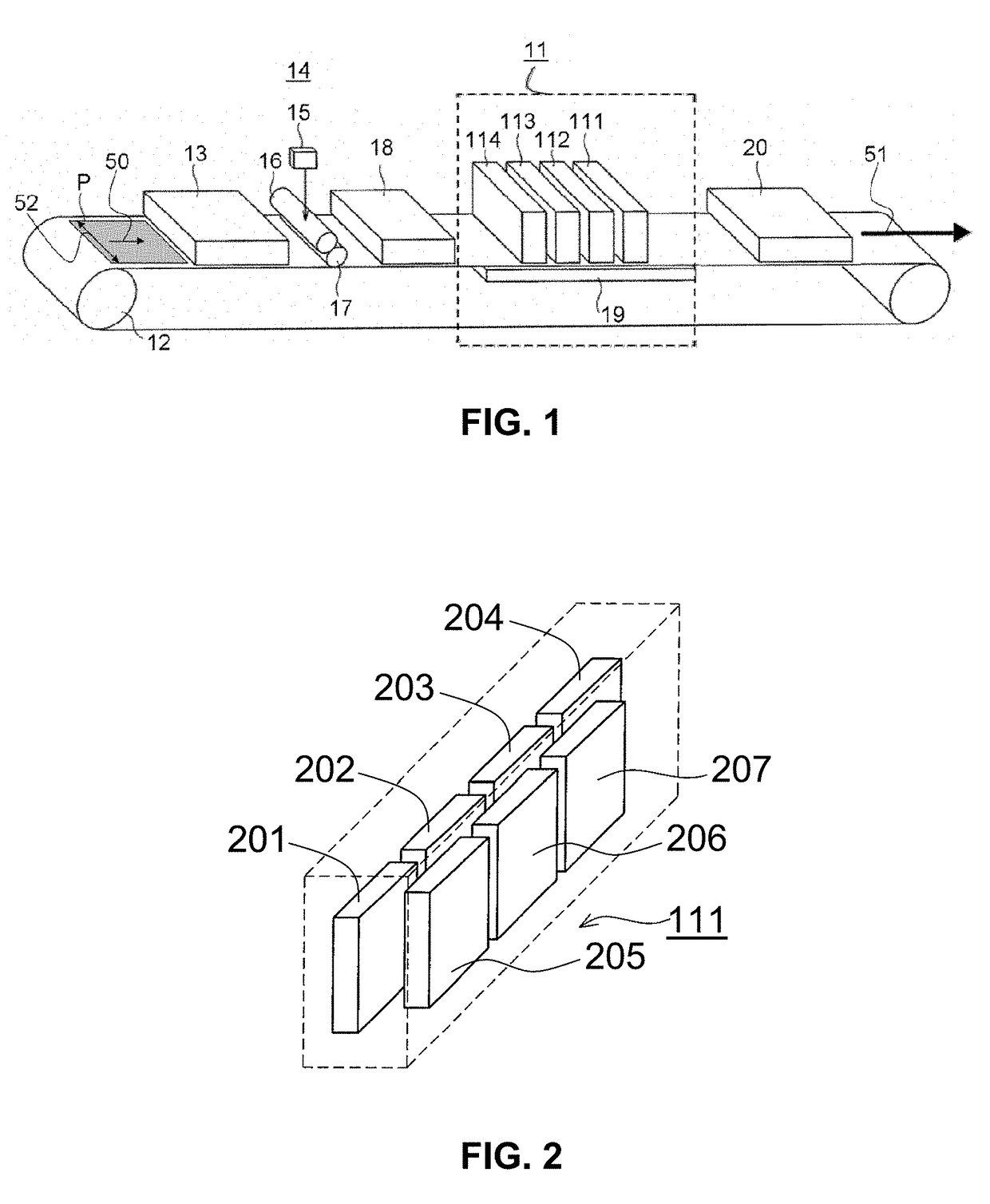

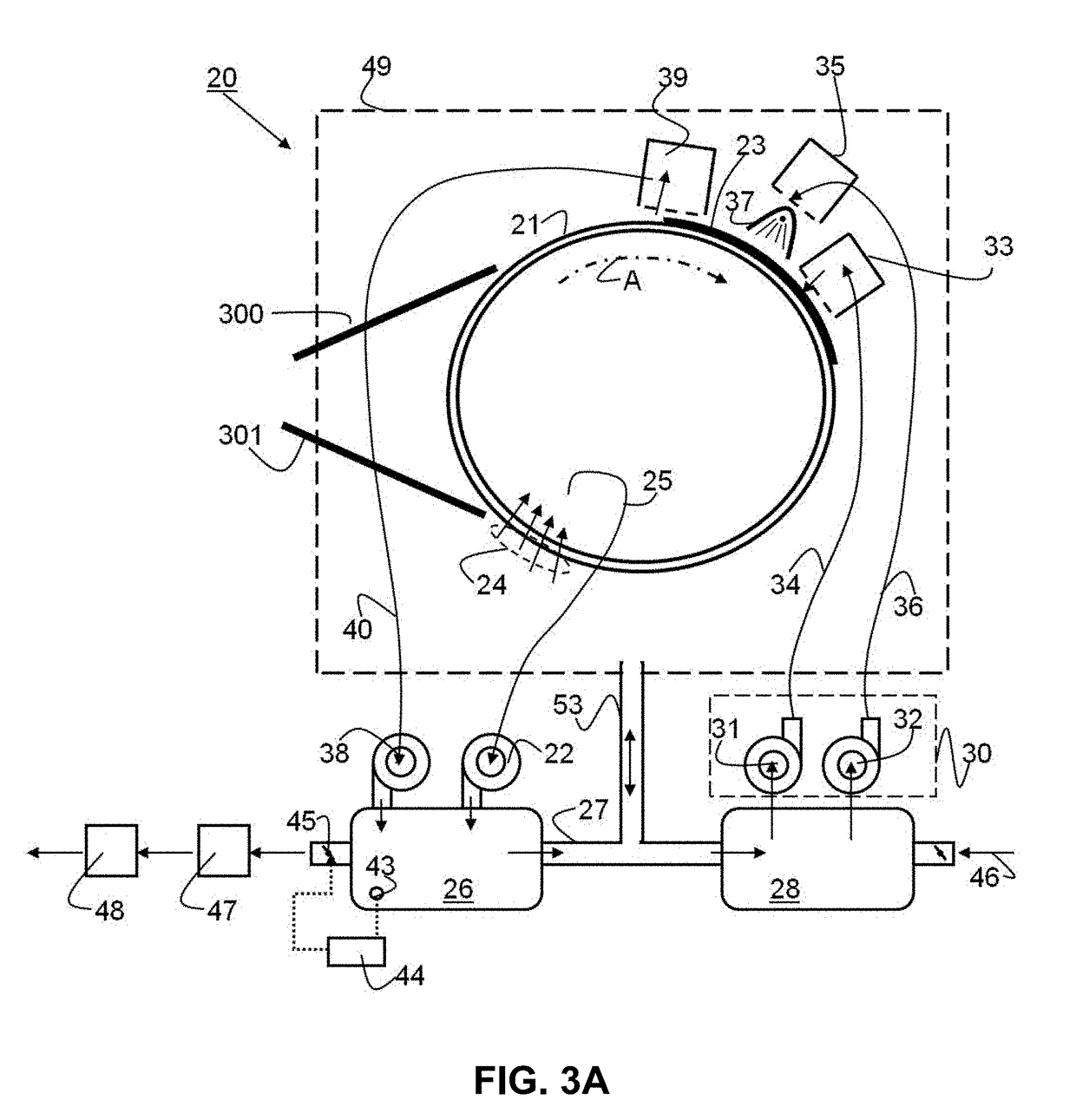

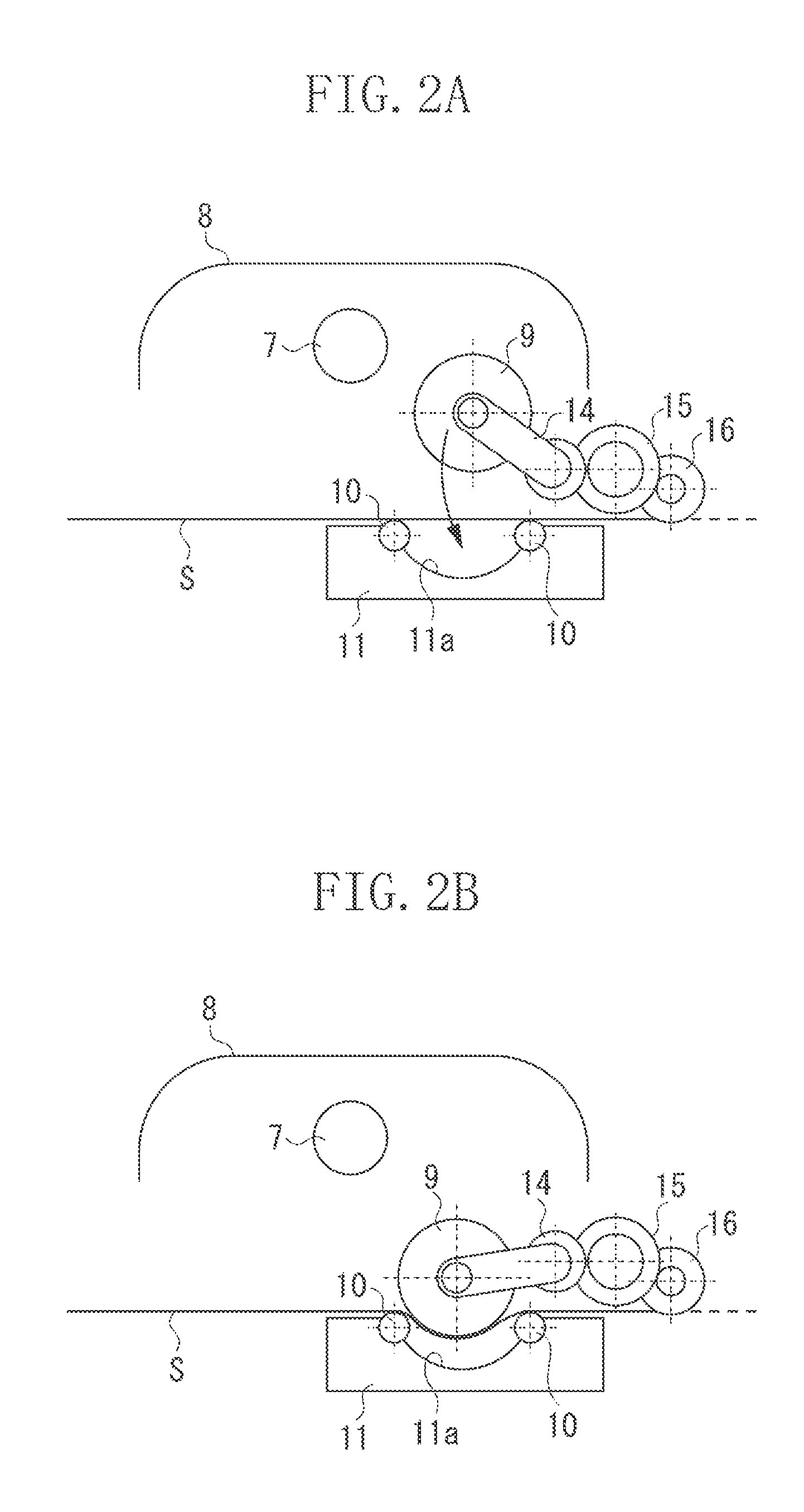

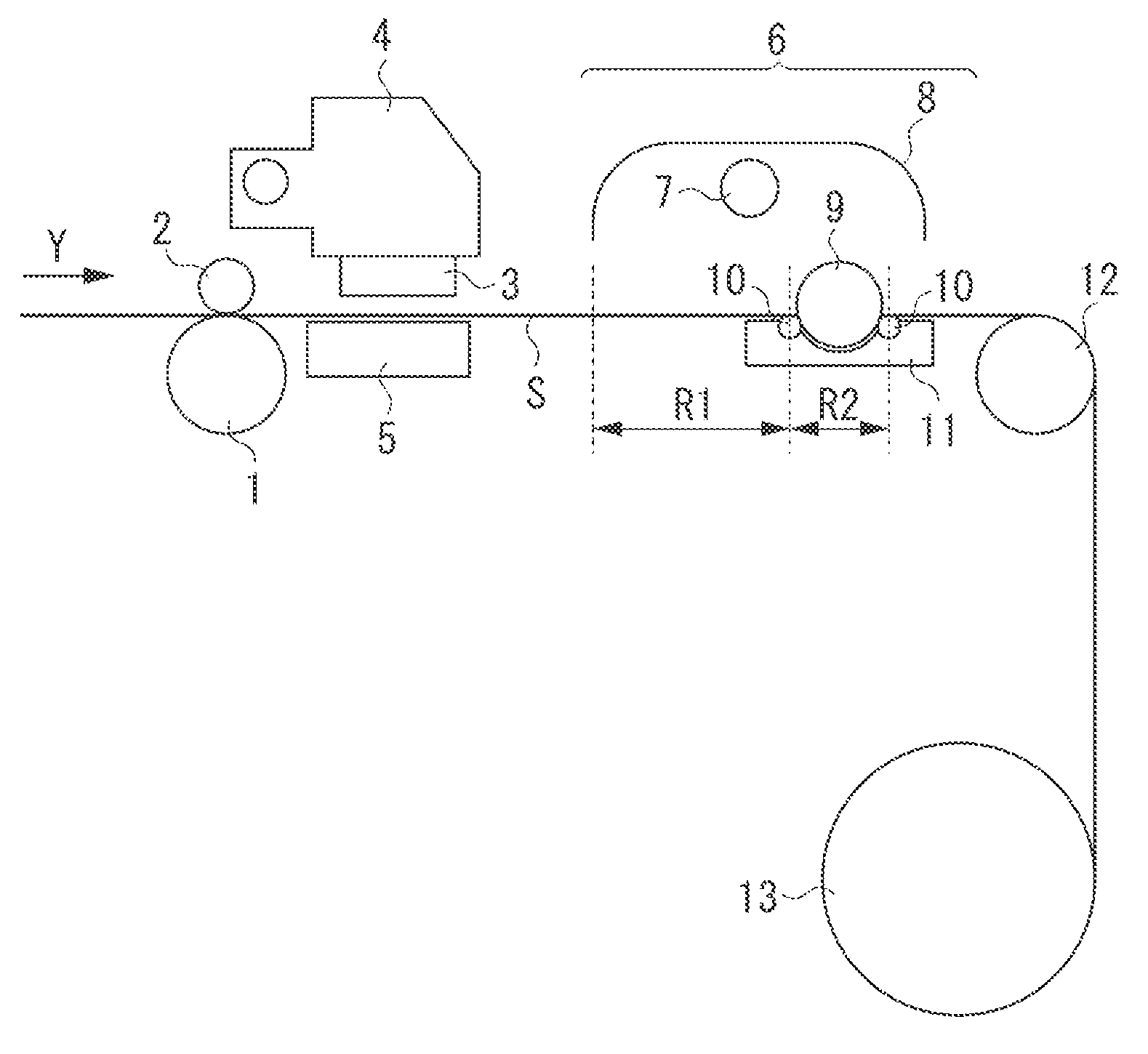

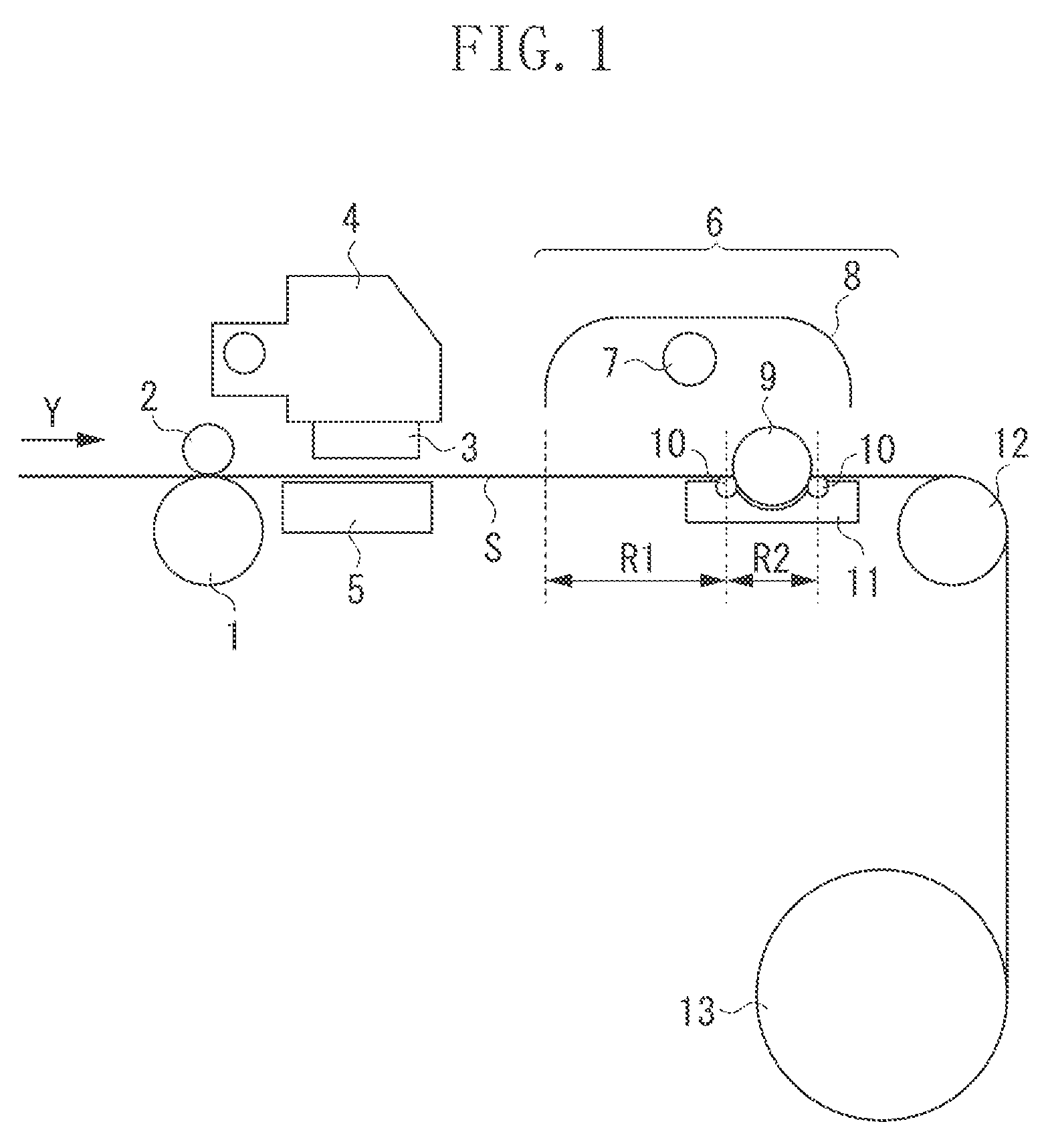

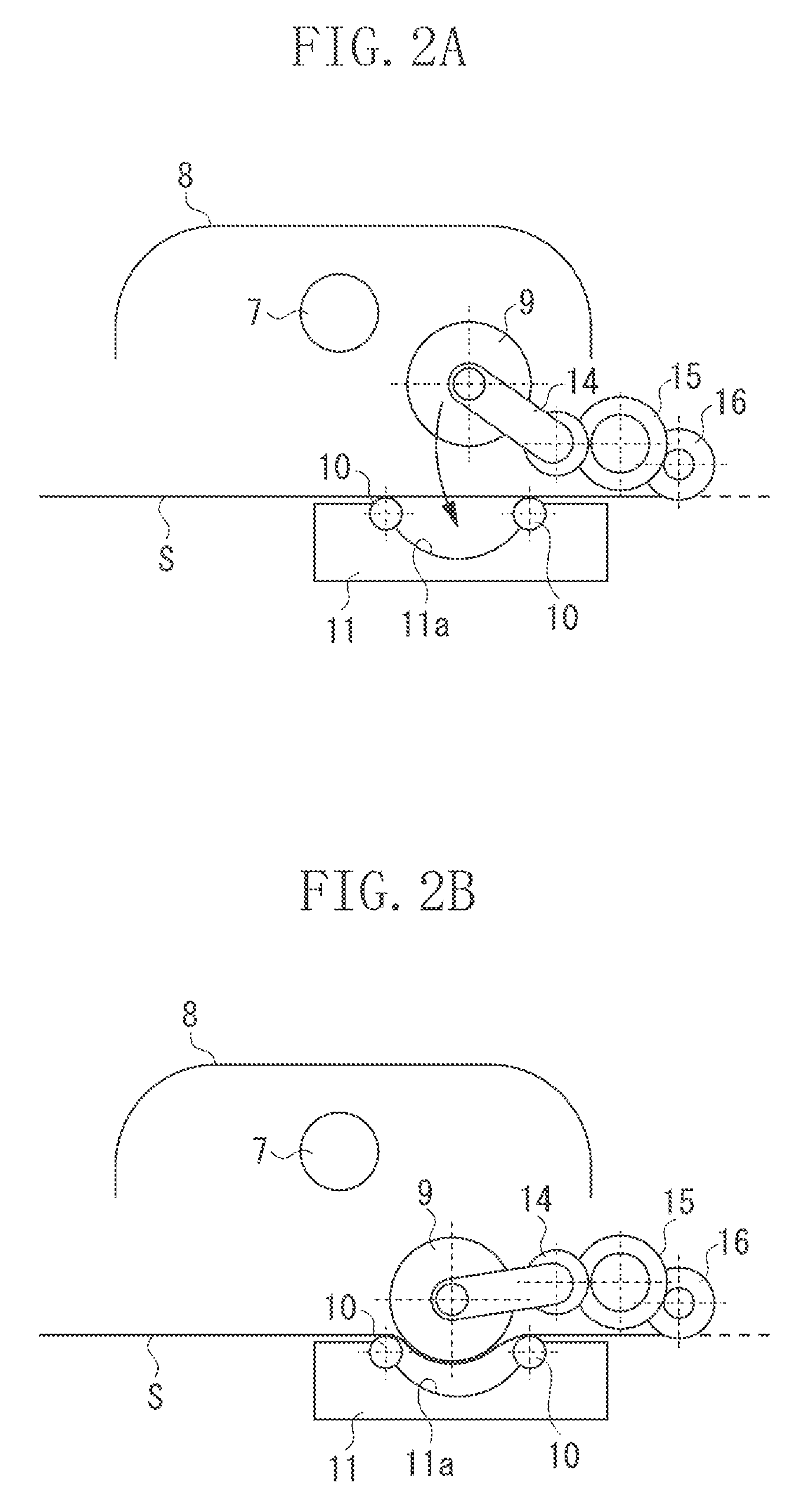

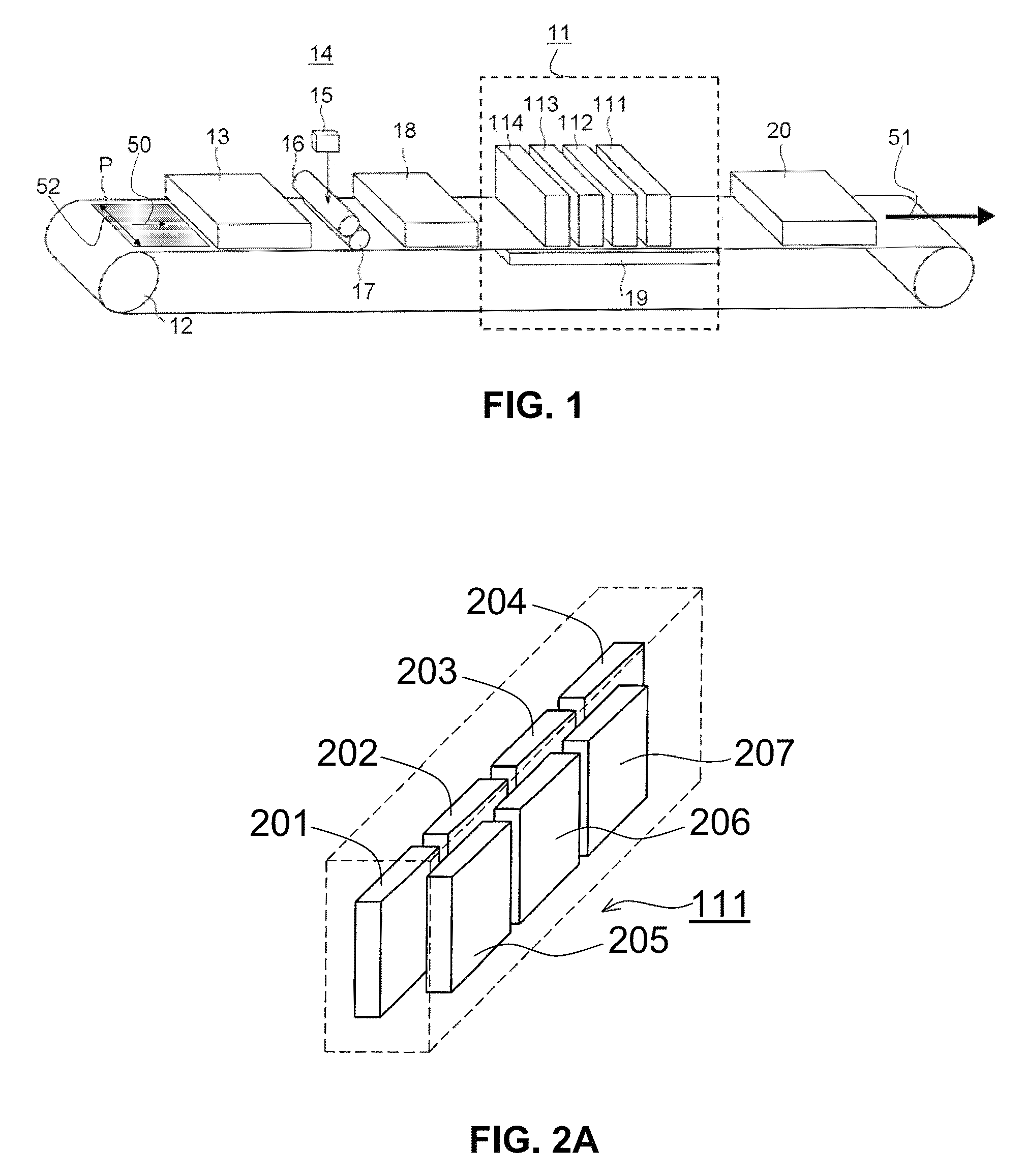

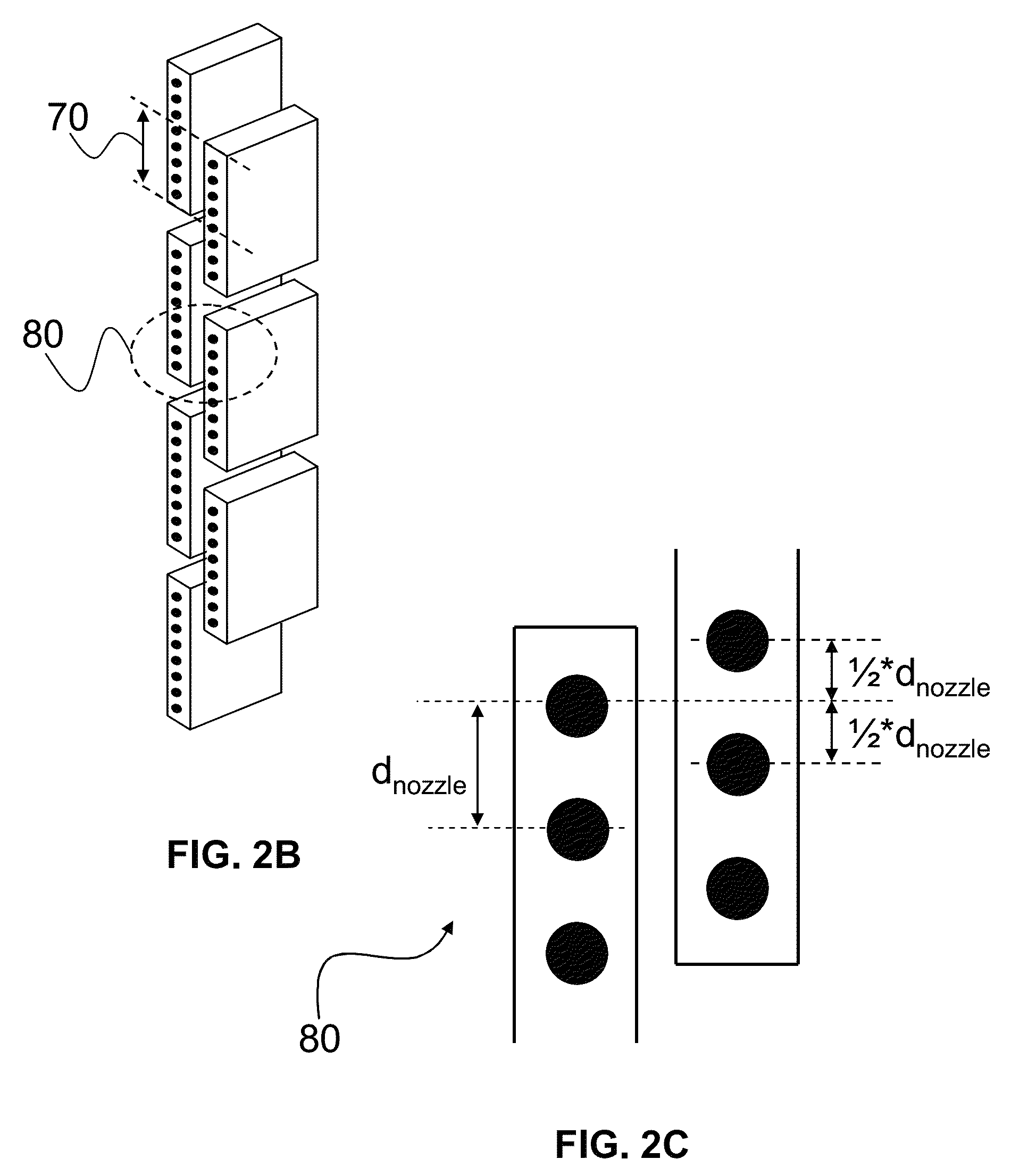

Recording substrate treatment apparatus, printing system and method of drying

ActiveUS20140375737A1Large drying capacityHigh productOther printing apparatusDirect heatingElectrical and Electronics engineering

A recording substrate treatment apparatus includes a transporting mechanism for transporting a sheet of a recording substrate; a suction device to provide an underpressure force at an outer surface of the transporting mechanism arranged for holding down a sheet of a recording substrate; a heater for directly heating the recording substrate; and a blower for providing a flow of a gaseous medium at the outer surface of the transporting mechanism, wherein in operation the blower receives the gaseous medium from the suction device. The present invention also pertains to a printing system comprising such a recording substrate treatment apparatus and a method of drying a recording substrate using such a recording substrate recording apparatus.

Owner:OCE TECH

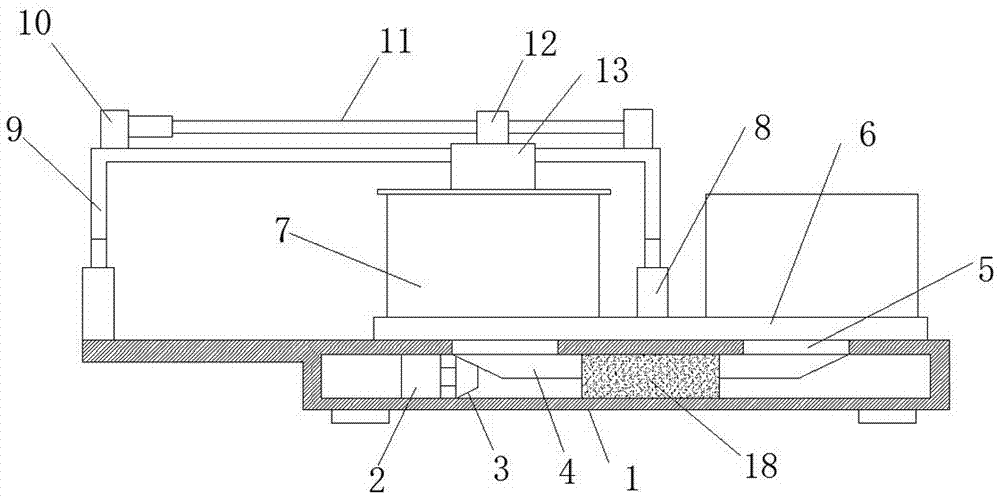

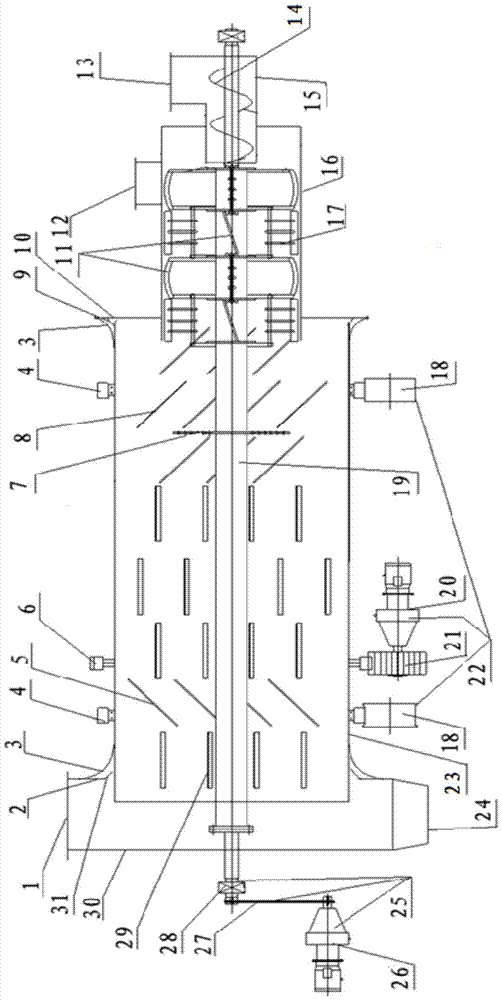

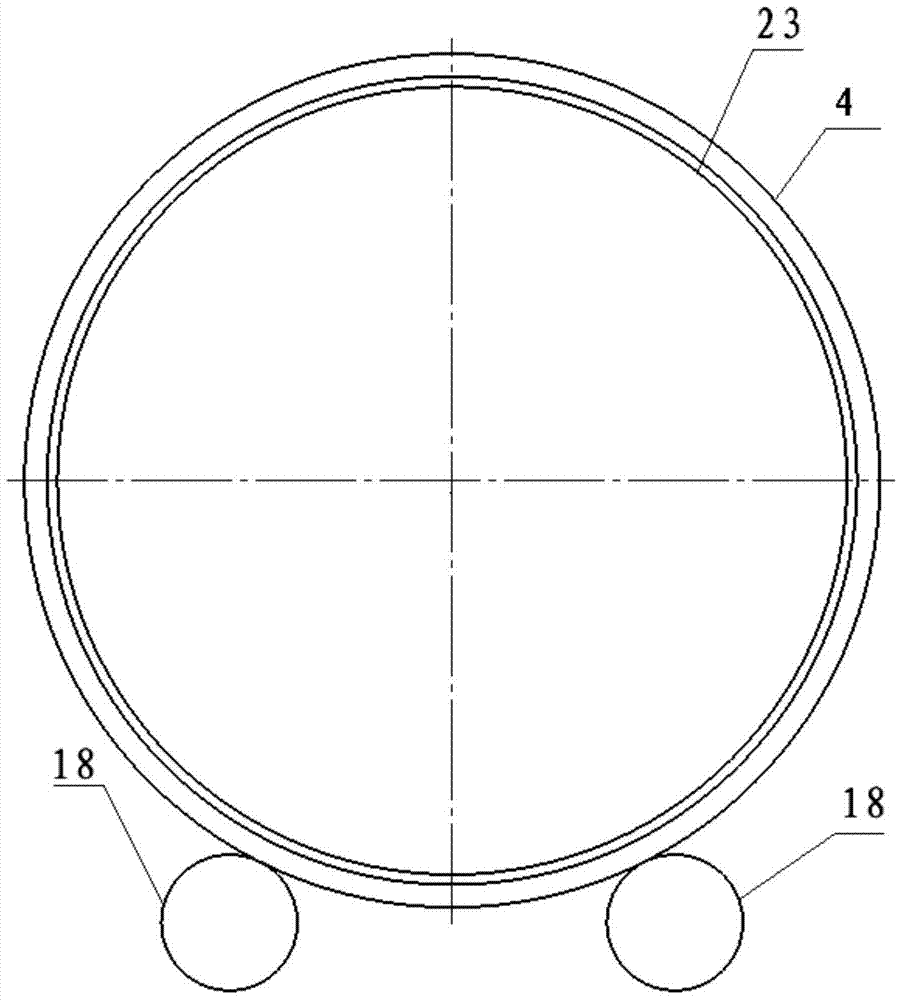

Ferrous sulfate heptahydrate dryer

ActiveCN105258469AImprove drying effectLarge drying capacityIron sulfatesDrying machines with non-progressive movementsPulp and paper industryFerrous sulphate heptahydrate

The invention discloses a ferrous sulfate heptahydrate dryer, relates to drying equipment, and provides a dryer suitable for drying ferrous sulfate heptahydrate. The dryer comprises a feeding mechanism, a fixed drying cylinder, a rotating drying cylinder, a discharge mechanism, a center shaft, a rotating drying cylinder support driving mechanism and a center shaft support driving structure, wherein the feeding mechanism, the fixed drying cylinder, the rotating drying cylinder and the discharge mechanism are arranged in sequence, and are communicated through internal spaces; a hot air inlet is formed in the fixed drying cylinder; push blades and dispersing blades connected with the center shaft are arranged in the fixed drying cylinder; the push blades are plane blades arranged slantwise corresponding to the axis of the center shaft; and two push blades and two dispersing blades are arranged on one axial position of the center shaft in a such manner of being centrosymmetric about the axis of the center shaft . The ferrous sulfate heptahydrate dryer is suitable for a drying process for drying a mixture of dried materials and free water-contained ferrous sulfate heptahydrate.

Owner:SICHUAN DONGLI TECH CO LTD

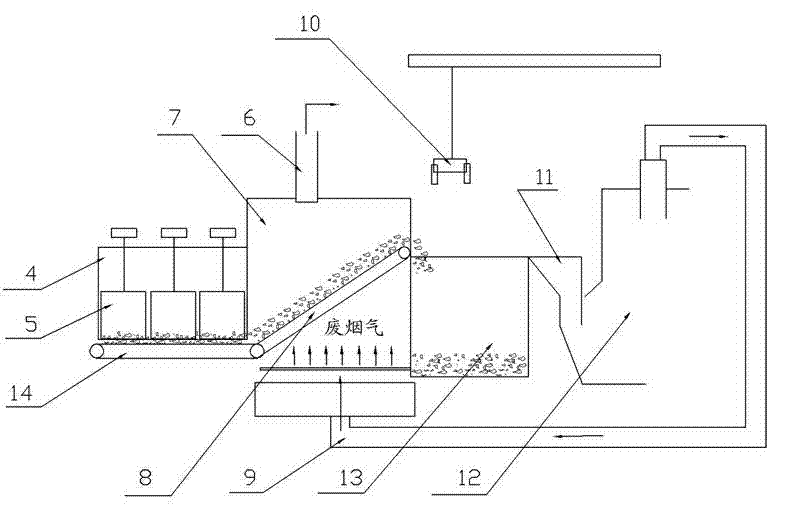

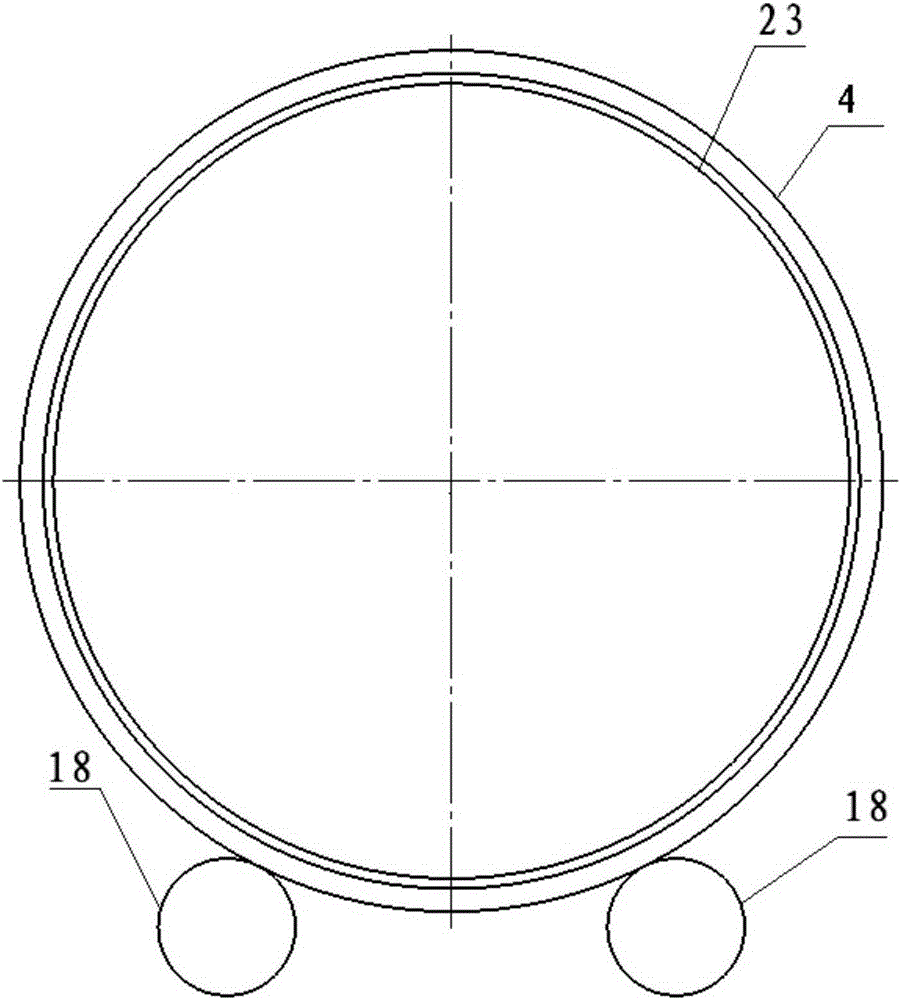

Grain drying machine with multiple layers of overturning plates

PendingCN108759435AEven air flowImprove qualitySeed preservation by dryingDrying solid materialsEngineeringAutomation

The invention discloses a grain drying machine with multiple layers of overturning plates. The grain drying machine with the multiple layers of overturning plates is provided with a shell, wherein a plurality of annular conveying belts horizontally running are further arranged in the shell from top to bottom; each annular conveying belt is formed by connecting a plurality of chain plates end to end; the plurality of annular conveying belts are a first annular conveying belt, a second annular conveying belt, ..., and an Nth annular conveying belt separately; grains fall onto the head end of theupper layer of the first annular conveying belt from a grain charge port; the chain plates overturn to enable the grains to fall onto the tail end of the lower layer of the first annular conveying belt when the grains run to reach the tail end of the upper layer of the first annular conveying belt; the chain plates overturn to enable the grains to fall onto the head end of the upper layer of thesecond annular conveying belt when the grains run to reach the head end of the lower layer of the first annular conveying belt; and the process is repeated until the chain plates overturn to enable the grains to fall onto the grain discharge port in the shell when the grains fall onto the head end of the lower layer of the Nth annular conveying belt, and drying for the grains is completed. The grain drying machine with the multiple layers of overturning plates increases the grain drying efficiency, and is convenient and rapid to install, capable of realizing full automation, unattended, and convenient to widely popularize and apply.

Owner:姜少华

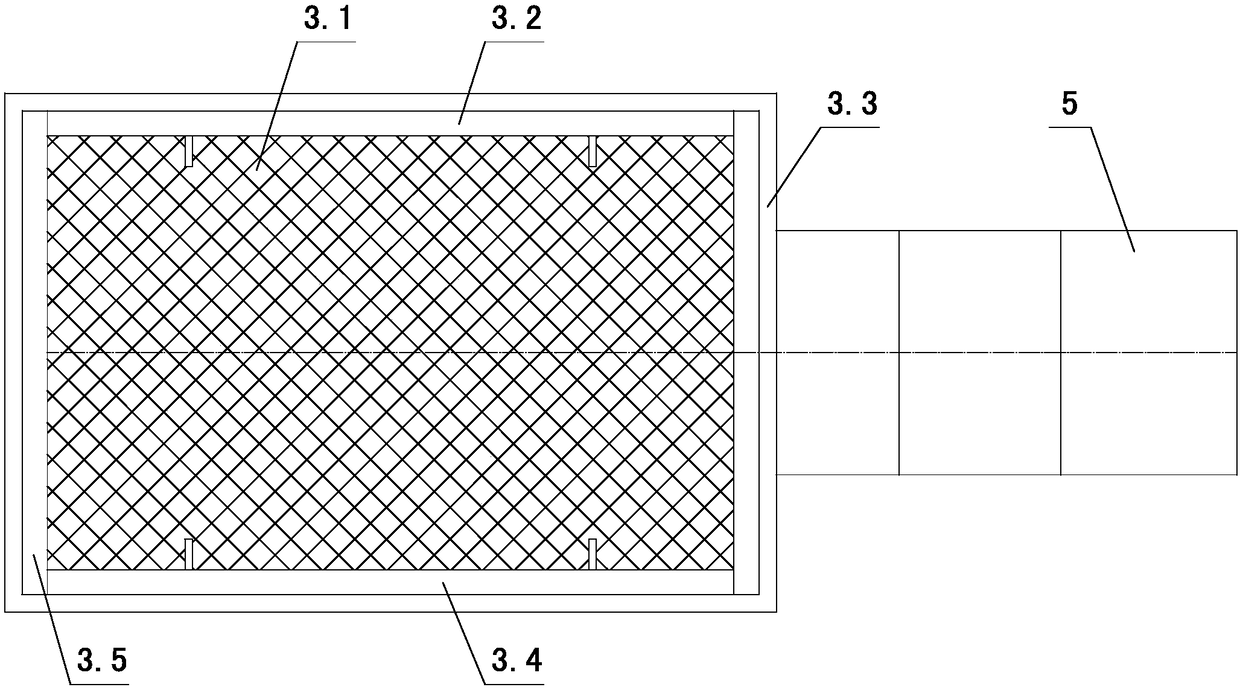

Drying method of sweet potato vermicelli

The present invention discloses a drying method of sweet potato vermicelli. The drying method is characterized by comprising the following steps: (1) cooking and cooling: vermicelli after vermicelli leaking is cooked in a pot at 79 DEG C for 4 min and the cooked vermicelli is cooled by using a circulating cold water tank; (2) an ''S''-type drying room comprises a purifying and filtering room 1, a drying channel 2, an air inlet 3 and an air outlet 4, can improve a drying effect of the vermicelli, conducts a batch drying and improves a drying efficiency; (3) vermicelli drying: firstly the vermicelli is air-dried and naturally dried, an energy consumption is reduced, then the vermicelli is placed in the drying room, and a low temperature and high temperature alternating drying is conducted; and (4) vermicelli desulfurizing: the vermicelli is placed into a desulfurization room, hot air containing 20% water vapor is ventilated, and the vermicelli is desulfurized.

Owner:肥西县金桥红薯专业合作社

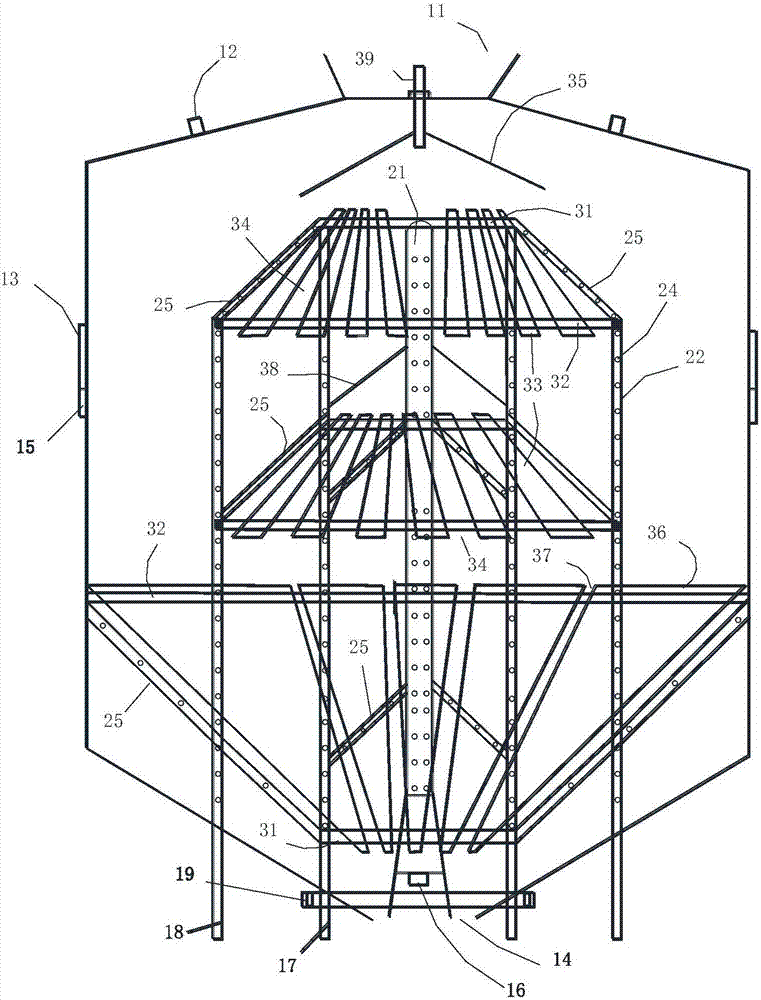

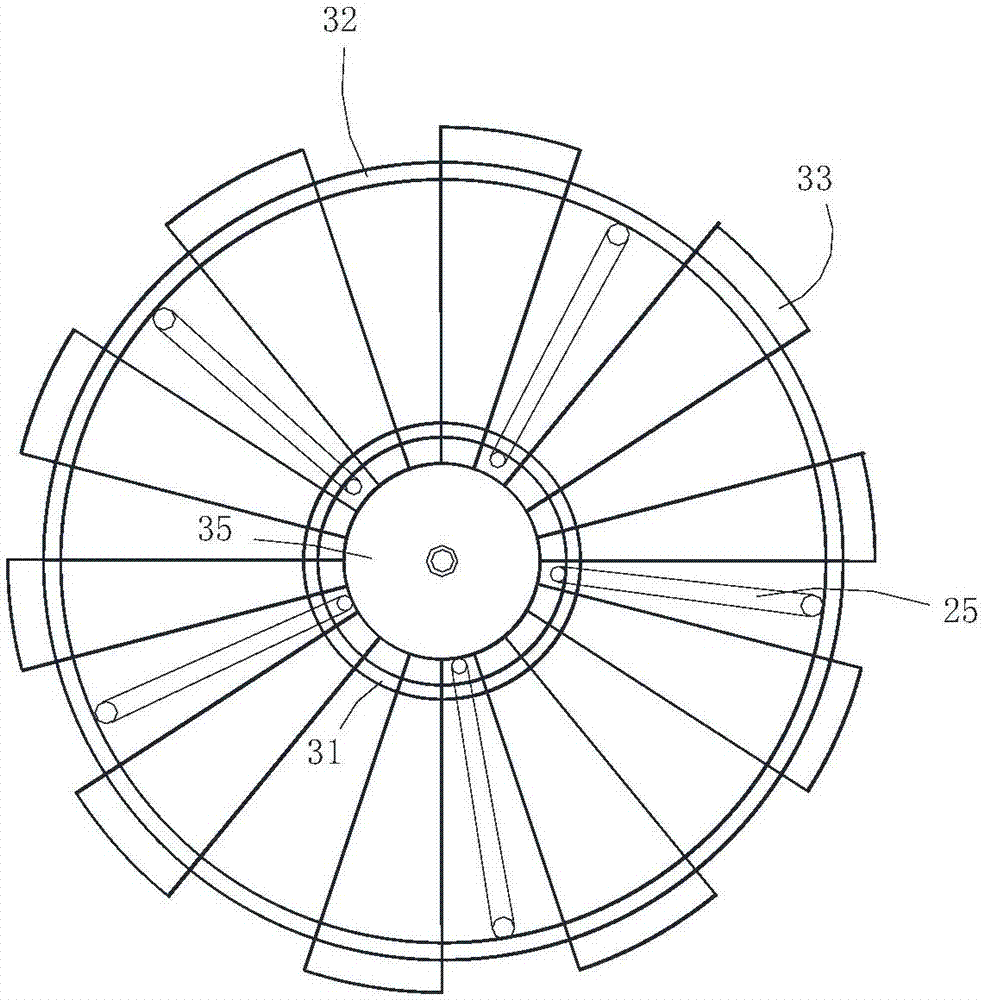

Vertical drying and screening tower

InactiveCN107152858AImprove protectionReduce crushGas current separationDrying gas arrangementsThermodynamicsEngineering

The invention discloses a vertical drying and screening tower. The vertical drying and screening tower comprises a tower body, a hot wind pipe, a screen plate and a distribution carriage plate; the hot wind pipe, the screen plate and the distribution carriage plate are arranged in the tower body; the distribution carriage plate is arranged above a grid section; the tower body is provided with a feed port and an exhaust port in the top, and is provided with a discharge port in the bottom; the hot wind pipe comprises a center hot wind pipe, longitudinal hot wind pipes and a hot wind inclined beam; the center hot wind pipe, the longitudinal hot wind pipes and the hot wind inclined beam are provided with hot wind holes; the grid section and the hot wind inclined beam are fixed between an inner ring beam and an outer ring beam; the hot wind inclined beam communicates with the longitudinal hot wind pipes and the center hot wind pipe; multiple longitudinal hot wind pipes are fixed on the inner sides or the outer sides of the inner and outer ring beams; two ends of the longitudinal hot wind pipes are closed; the bottoms of the longitudinal hot wind pipes outwards extend to support on the ground; and the bottoms of the longitudinal hot wind pipes on the inner ring outwards extend to support on the ground through a first hot wind box. The vertical drying and screening tower is uniform in ventilation, high in drying speed and low in cost.

Owner:郭大军

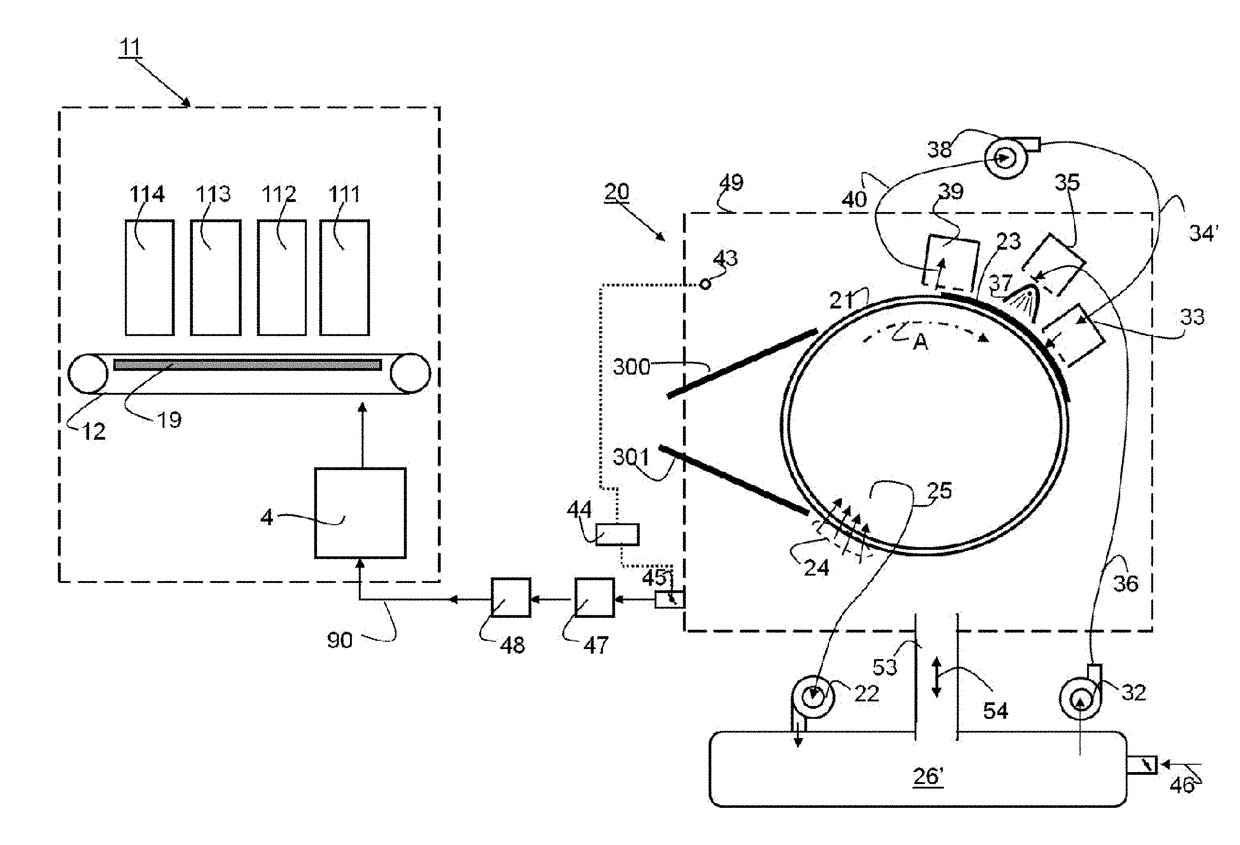

Recording substrate treatment apparatus, printing system and method of drying

ActiveUS20170266995A1Less complex in configurationLess complex in operationOther printing apparatusInterior spaceEngineering

A recording substrate treatment apparatus includes transporting mechanism for transporting a sheet of a recording substrate through a first chamber in the interior space of the recording substrate treatment apparatus; a first suction device arranged for removing a gaseous medium from the first chamber; and an impingement device, arranged for providing a first flow of the gaseous medium at the outer surface of the transporting mechanism. The first suction device is fluidly connected to the impingement device, such that in operation the impingement device receives a first flow of the gaseous medium from the first suction device. With this arrangement, the impingement flow is balanced with an air flow directly extracted from the first chamber of the recording substrate treatment apparatus. A printing system including such a recording substrate treatment apparatus and a method of drying a recording substrate using such a recording substrate recording apparatus are also disclosed.

Owner:OCE TECH

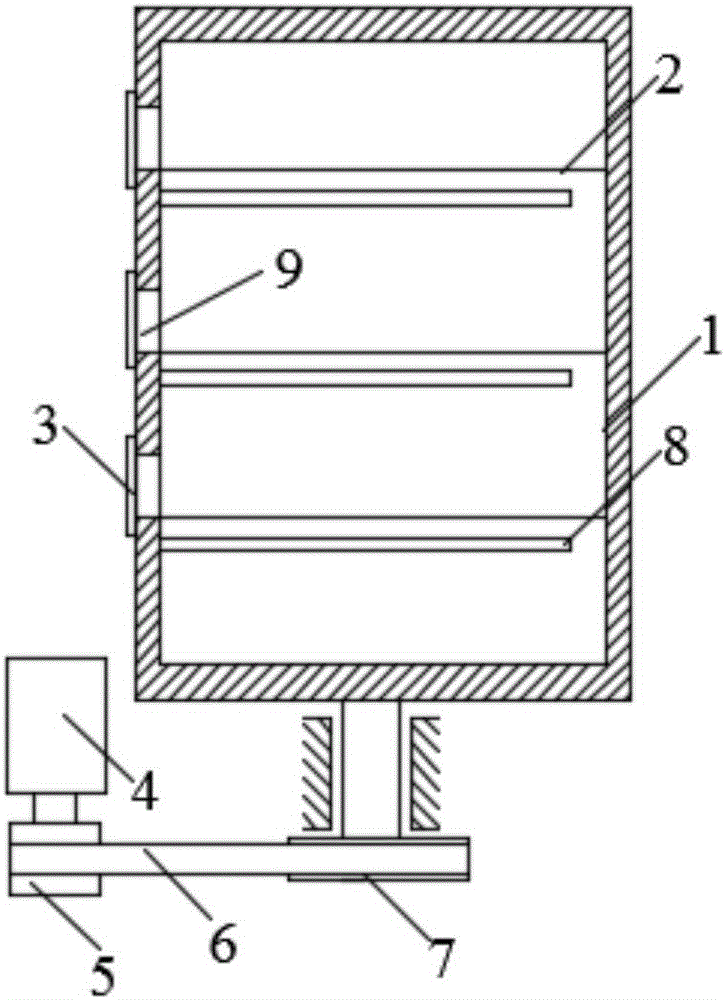

Tea leaf dryer

InactiveCN106440712ALarge drying capacityEvenly heatedPre-extraction tea treatmentDrying chambers/containersDrive shaftEngineering

The invention discloses a tea leaf dryer and belongs to the technical field of mechanical device design. The tea leaf dryer comprises a drying chamber, sieves, cover plates, a motor, a small belt wheel, a belt, a large belt wheel, lamp tubes and feed inlets. The drying chamber is of a cuboid structure. The middle of the drying chamber is hollowed into a cavity. The sieves are arranged on the inner wall of the drying chamber. The feed inlets are formed in the portions, tightly above the corresponding sieves, of the left side face of the drying chamber. The cover plates are mounted at the positions, located at the feed inlets, of the left side face of the drying chamber. The lamp tubes are fixed to the portions, located below the sieves, of the interior of the drying chamber. A shaft is fixed to the middle of the bottom face of the drying chamber. The large belt wheel is mounted on the shaft and connected with the small belt wheel through the belt. The small belt wheel is mounted on a driving shaft of the motor. The tea leaf dryer disclosed by the invention is large in tea leaf drying quantity and high in drying efficiency, and tea leaves on the sieves are uniformly heated and are not prone to being left in the drying chamber when being taken out.

Owner:ANHUI YOULI ENERGY SAVING EQUIP

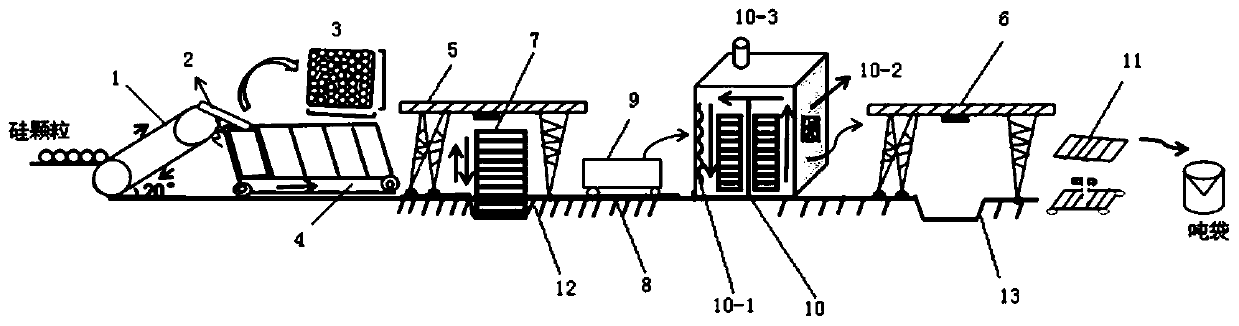

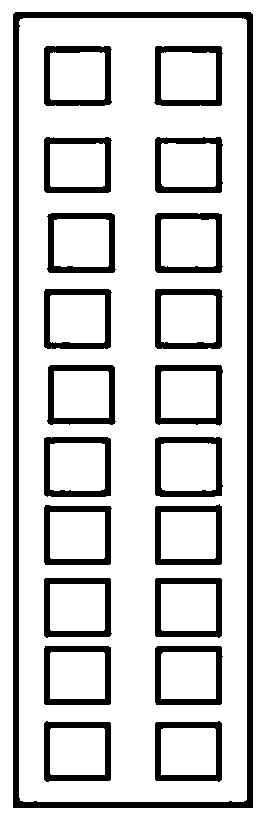

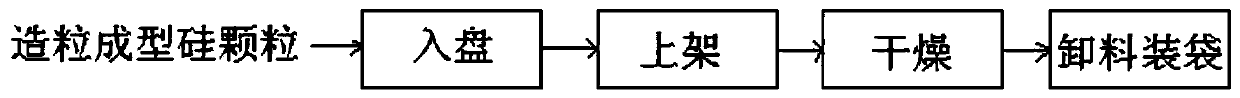

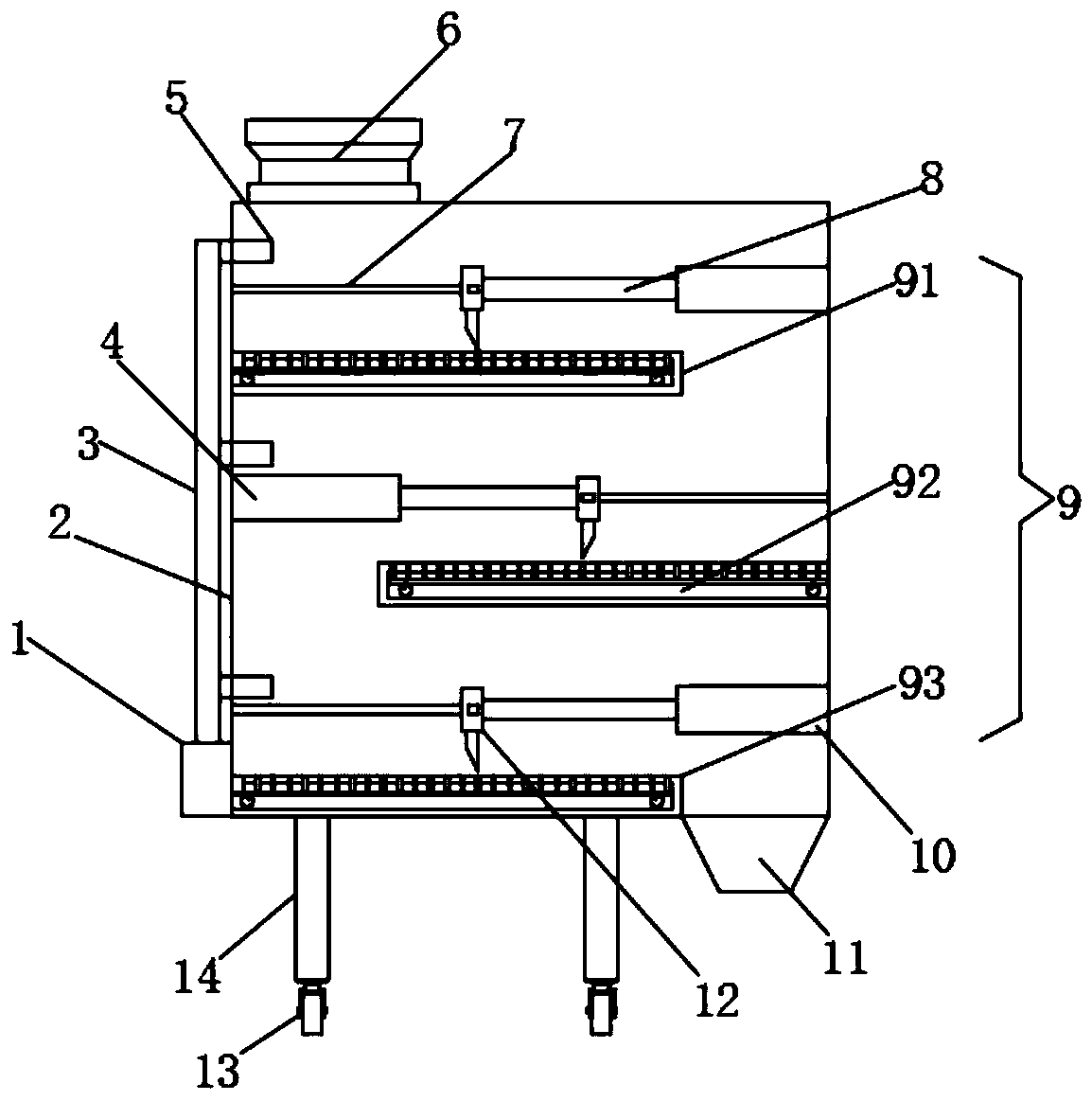

Waste silicon sludge granulation forming silicon particle conveying and drying method and device

PendingCN109780831AWide variety of sourcesCompact and reasonable designDrying gas arrangementsDrying solid materialsSludgeSilicon particle

The invention discloses a waste silicon sludge granulation forming silicon particle conveying and drying method and device, and belongs to the technical field of solid forming material transfer and drying. According to the method and device, silicon particles obtained after waste silicon sludge granulation forming are transported in batches through a mechanical conveying device to a drying room which is internally provided with a high-temperature heat source, a fan and a dehumidifying port, then static drying is performed, and dried formed materials are prepared. A technological process of themethod can comprise tray loading, support loading, drying and unloading. According to material characteristics of forming waste silicon sludge and physical requirements of the silicon particles during and after drying, key factors affecting silicon particle drying are combined, while the drying efficiency is improved and the energy consumption and labor cost are reduced, efficient conveying and drying of the waste silicon sludge after granulation are achieved, and therefore, the waste silicon sludge granulation forming silicon particle conveying and drying method and device are of crucial significance in the field of conveying and drying of solid materials.

Owner:江苏美科太阳能科技股份有限公司

Drying machine for biological feed processing

ActiveCN110887355AImprove drying efficiencyKeep dryDrying gas arrangementsDrying chambers/containersProcess engineeringFodder

The invention discloses a drying machine for biological feed processing, and belongs to the technical field of drying machines. The drying machine comprises a machine body, wherein fixing tables are fixedly connected to an inner cavity of the machine body; the fixing tables comprise the first fixing table, the second fixing table and the third fixing table which are distributed in a staggered modefrom top to bottom; and the left end of the first fixing table and the left end of the third fixing table are fixedly connected with the left side of the inner cavity of the machine body. According to the drying machine, biological feed to be dried is layered up and down, so that the drying amount at a time is increased, and the space is saved; meanwhile, the spreading area of each layer is increased, the thickness of the biological feed can be controlled, and therefore the drying efficiency of the biological feed is improved; and on the other hand, ejector rods at the top of a moving plate penetrate through each fixing table to eject the biological feed laid on the fixing table, the wet part in the biological feed is turned out, and the biological feed is subjected to drying treatment ofhot air again, so that the drying effect of the biological feed is improved, the drying effect is good, and the biological feed is prevented from being only dried on the outer surface.

Owner:ANHUI ZHENGZHENG FEED TECH

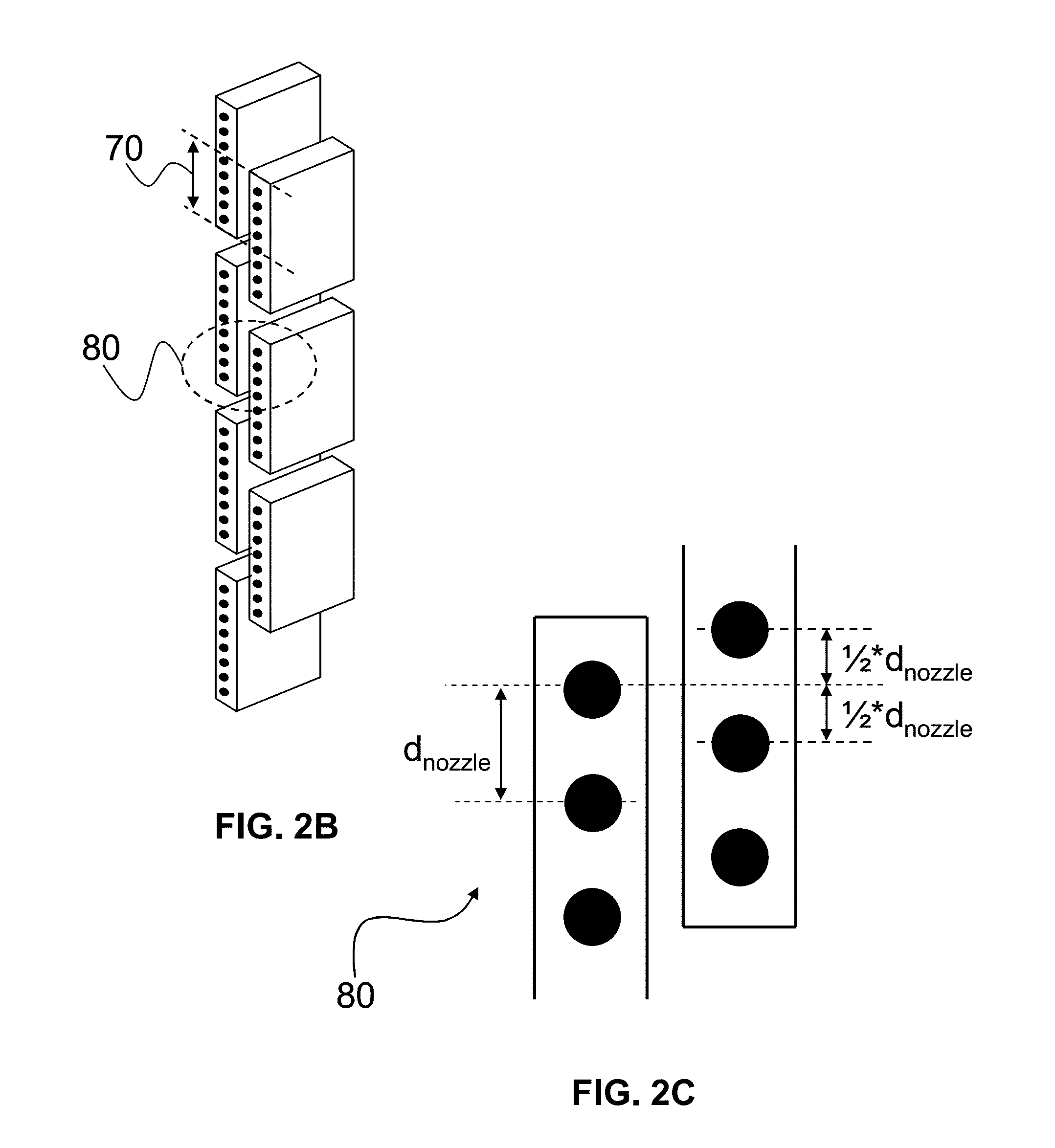

Sheet processing apparatus and printing apparatus

InactiveUS20130027486A1Reduce power consumptionImprove heat transfer efficiencyDuplicating/marking methodsOther printing apparatusEngineeringRadiant heat

A sheet processing apparatus includes a heater, an irradiation unit, and a contact unit. The irradiation unit irradiates a sheet with heat rays from the heater to heat the sheet by radiant heat. The contact unit includes a member that heats a region of the sheet by coming into contact with the radiant heated sheet on a downstream side of the irradiation unit. A part of the heat rays output from the heater is radiated onto a part of a structure constituting the contact unit to raise a temperature of the member.

Owner:CANON KK

Drying device for clothes dyeing

ActiveCN107401015AImprove drying efficiencyEasy to placeTextile treatment machine partsLiquid/gas/vapor removalHydraulic cylinderElectric machinery

The invention discloses a drying device for clothes dyeing. The drying device comprises a hollow mounting base; a set of parallelly arranged hydraulic cylinders are fixed on the top of the hollow mounting base; piston rods of the hydraulic cylinders are fixedly provided with a C-shaped connecting rod positioned over the top of the hollow mounting base; second driving motors are fixed on the top of the C-shaped connecting rod; output shafts of the second driving motors are fixedly provided with a threaded rod; an outer side of the threaded rod is threadedly sleeved with an internal thread block; the bottom of the internal thread block is fixedly provided with a fixed block; the top of the fixed block is fixedly provided with an enclosing plate; and the bottom of the enclosing plate is fixedly provided with an enclosing adhesive ring. Through cooperation of structures such as a first driving motor, a bevel gear, a bevel gear ring, a connecting ring, an annular installing plate, a dyeing tank and a drying tank, clothes dyeing and drying can be freely switched, continuity of dyeing and drying processes is achieved, time can be fully utilized, and therefore clothes drying efficiency is improved.

Owner:赣州邦帝体育用品有限公司

Energy-saving and environmentally-friendly combustion furnace for drier

ActiveCN102128544BGood preheating effectMeet the burning requirementsHeating arrangementSlagFlue gas

The invention discloses an energy-saving and environmentally-friendly combustion furnace for a drier, which relates to a combustion furnace and is used for solving the problems of high dust content of exhausted flue gas, the need of investment of dust removing equipment and sulfur removing equipment and the increase in power consumption and maintenance amount in the combustion process of conventional scattered coal. An oxygen supply pipeline of the combustion furnace is arranged at the bottom of a furnace body; a plurality of oxygen supply valves are arranged on the oxygen supply pipeline; a fire grate is clamped on the inner wall of the furnace body; a molded coal hole is formed on the furnace body; a slag outlet is formed on the furnace body; the molded coal hole and the slag outlet are horizontally arranged in sequence from right to left; the lower edges of the molded coal hole and the slag outlet and the upper end face of the fire grate are on the same horizontal plane; a transmission push plate is arranged in the furnace body; a piston type pull rod passes through the outer wall of the furnace body and is fixedly connected with the transmission push plate; and an observation port is formed at the left end of the furnace body. The combustion furnace is suitable for an indirect heat transfer rotary drum drier.

Owner:萝北瑞喆烯碳新材料有限公司

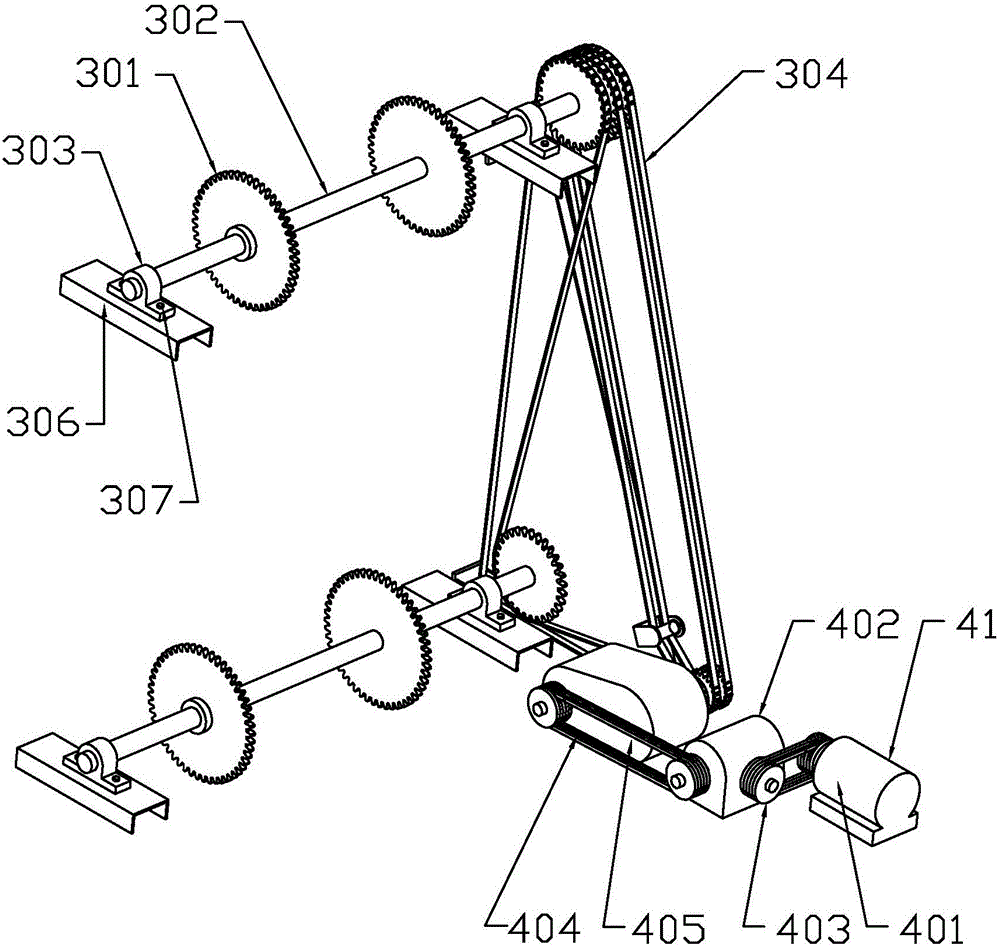

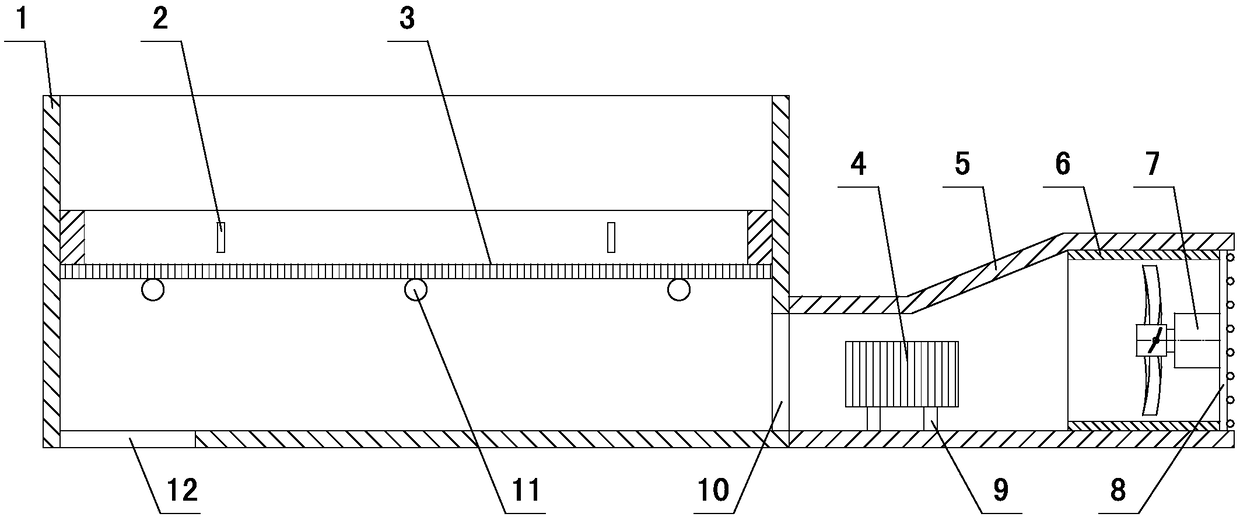

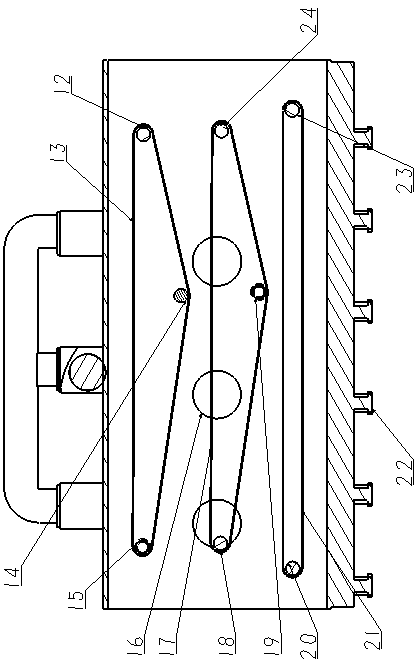

A high-efficiency energy-saving veneer drying device

ActiveCN104180628BUniform moisture contentImprove flatnessDrying gas arrangementsDrying chambers/containersSingle platePulp and paper industry

The invention provides a high-efficiency and energy-saving single-plate dryer which mainly comprises a heat-preservation box body, a drying device, a transmission device and a power device. The high-efficiency and energy-saving single-plate dryer is characterized in that the heat-preservation box body is composed of a plurality of fireproof heat-preservation plates; the drying device comprises lateral drying ovens and a central drying oven, the lateral drying ovens are located on the two sides of the heat-preservation box body, small holes are formed in the upper portions of the lateral drying ovens, and large holes are formed in the lower portions of the lateral drying ovens; the central drying oven is located in the middle of the heat-preservation box body, and vent holes are formed in the upper portion of the central drying oven; the transmission device mainly comprises gears, transmission shafts, bearings, chains, steel bars and supporting plates, the gears at the two ends of the central drying oven form an upper-layer transmission loop, the central drying oven is located in the middle of the upper-layer transmission loop, and the chains move on the corresponding gears cyclically; the power device comprises a motor, a speed reducer I, a belt wheel and a belt, and the motor provides power by converting belt transmission into chain transmission. The high-efficiency and energy-saving single-plate dryer is simple in structure, low in production cost, low in energy consumption and good in drying effect.

Owner:李学淑

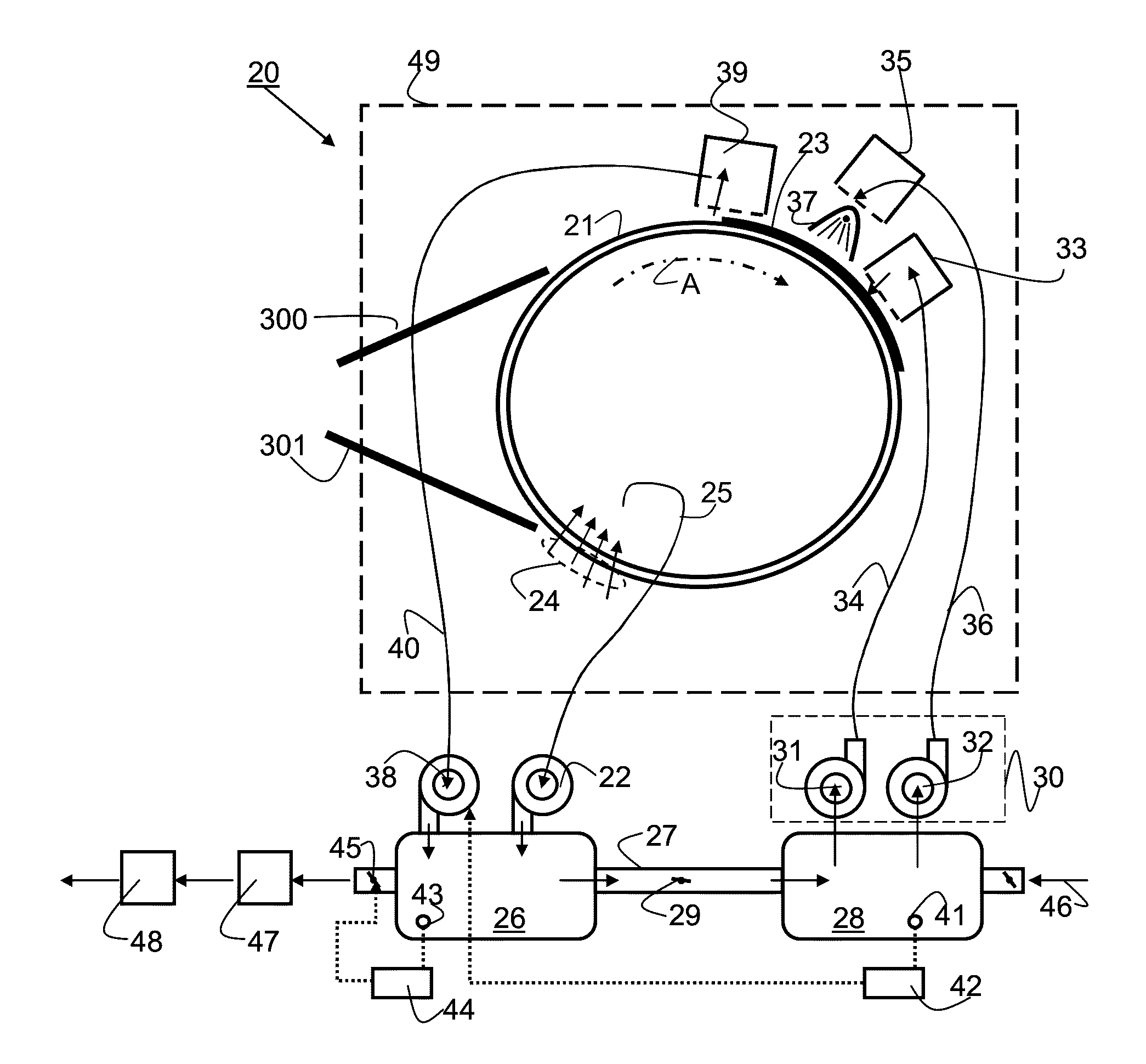

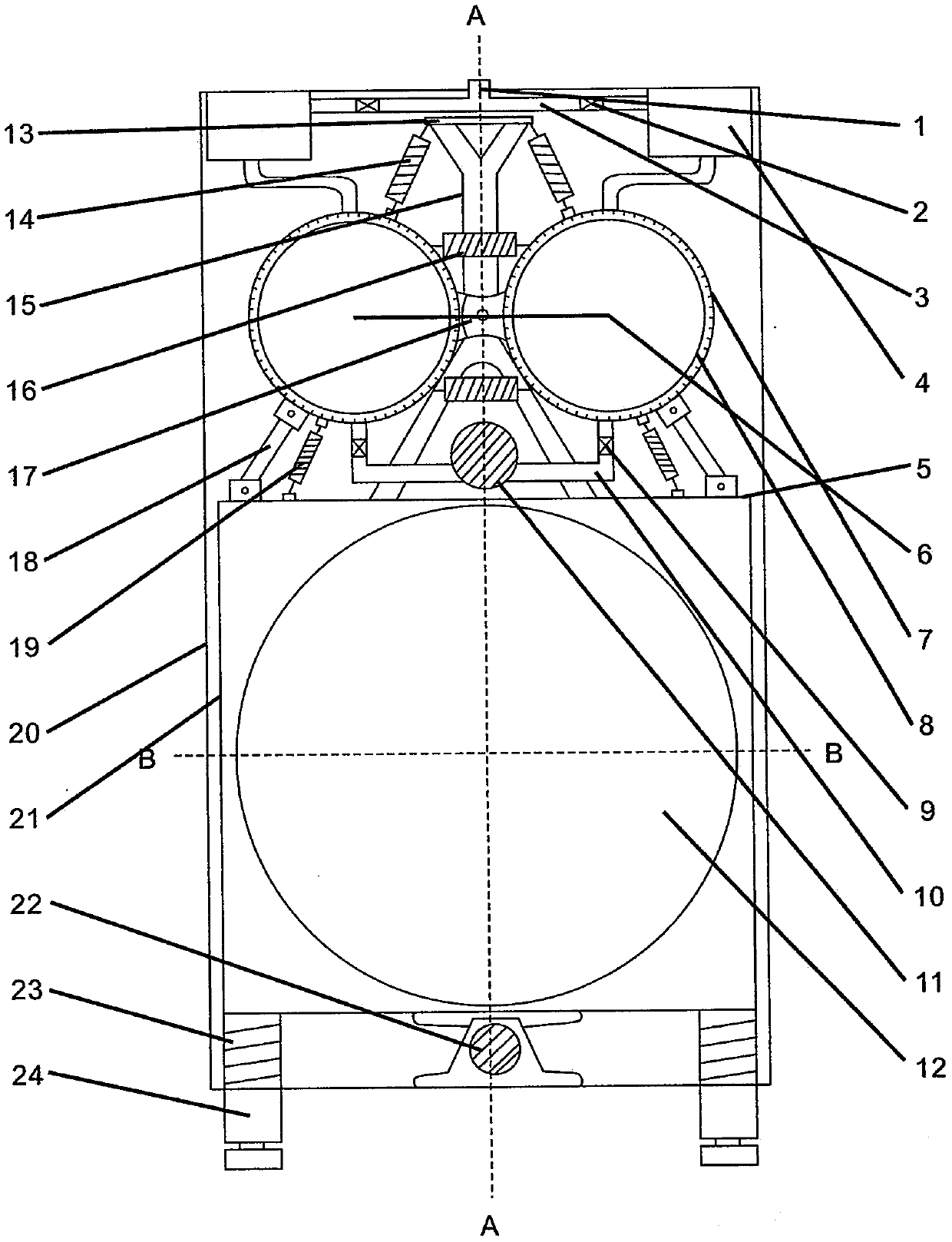

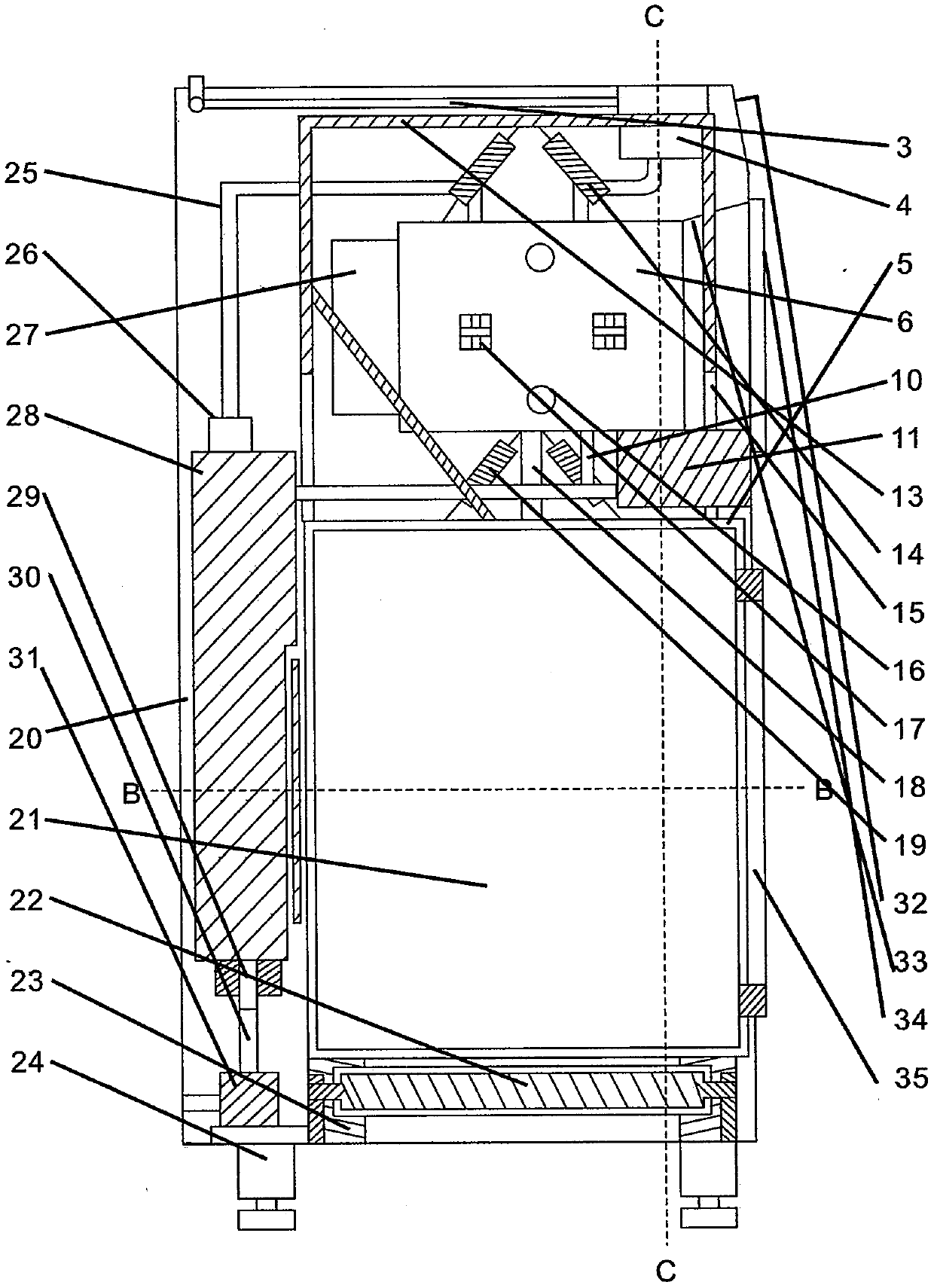

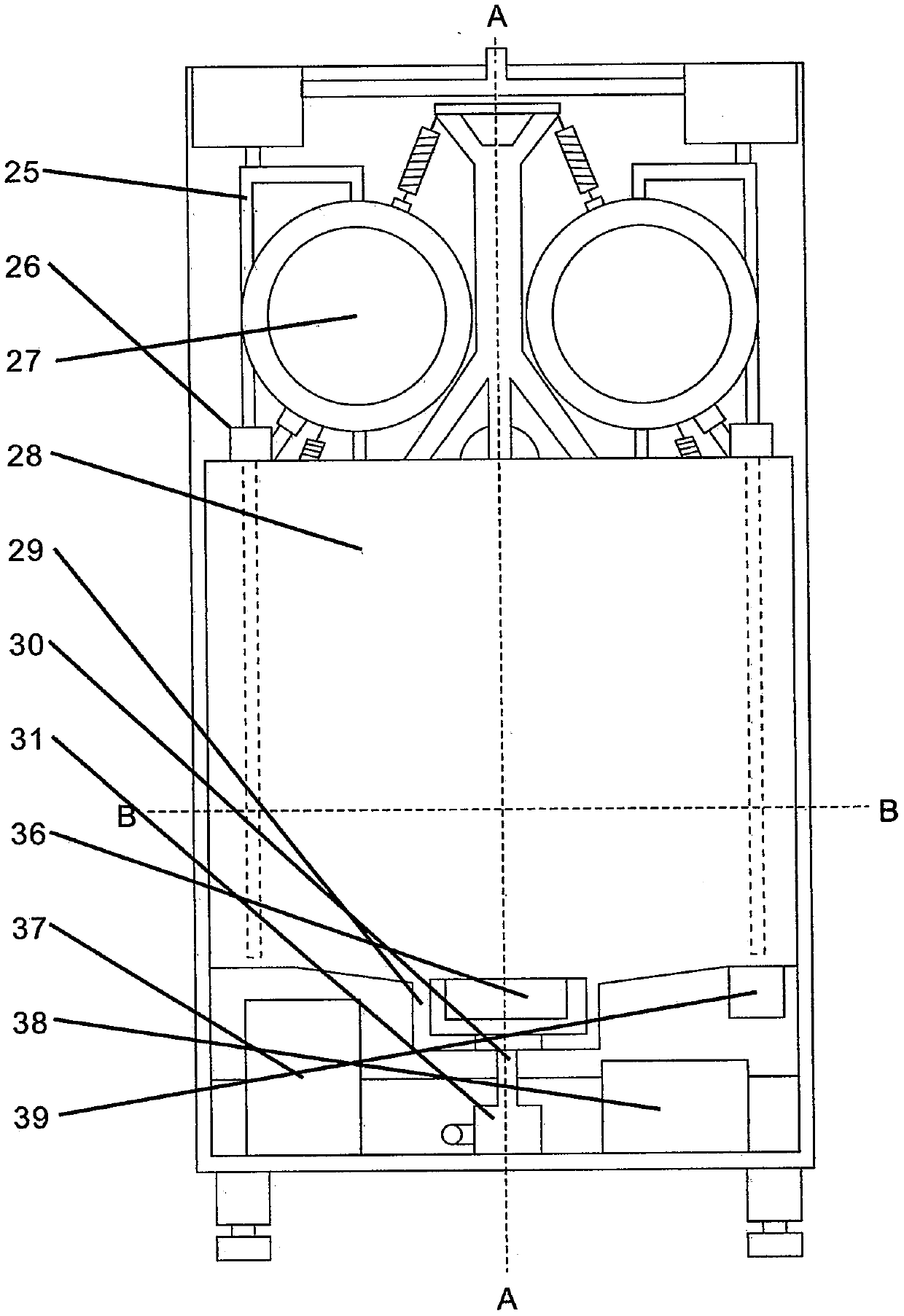

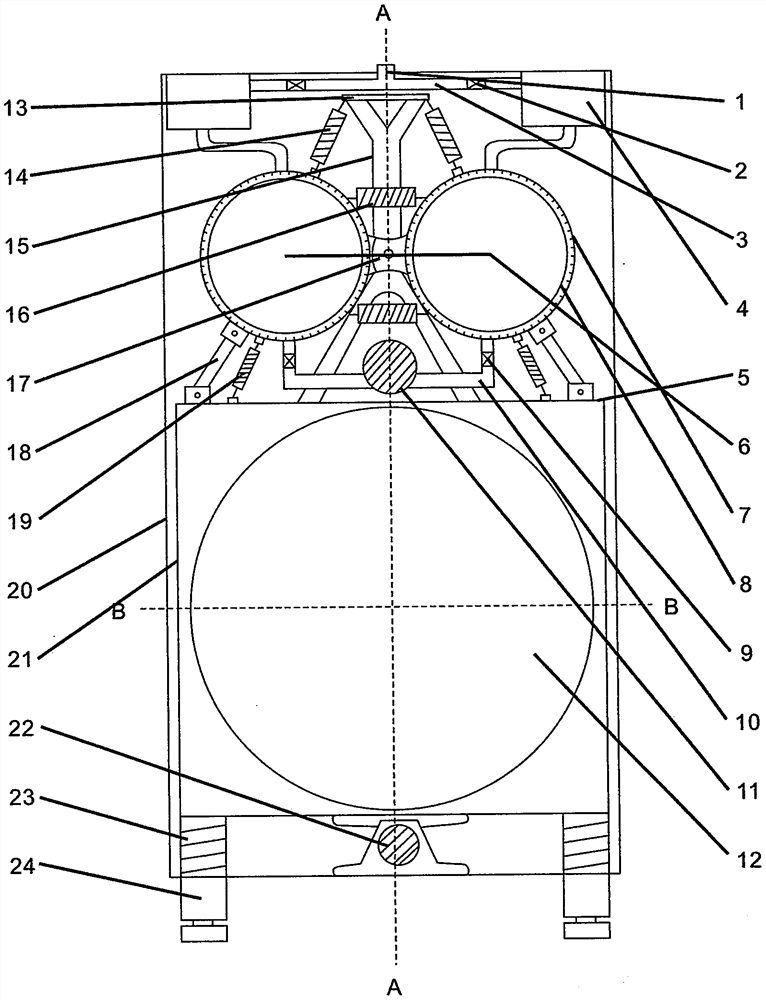

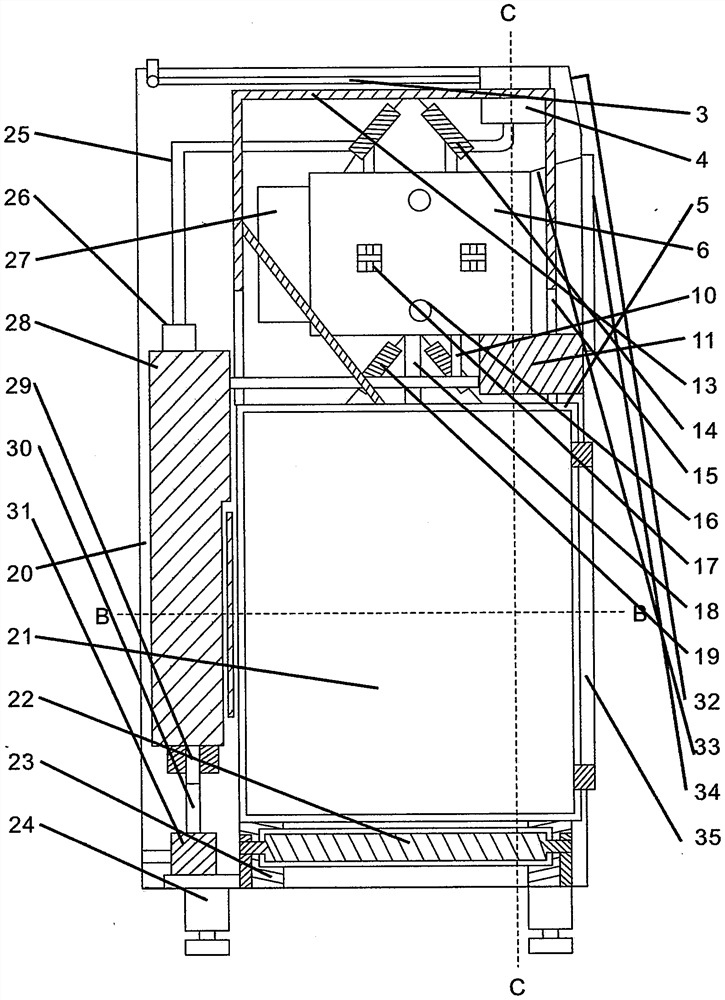

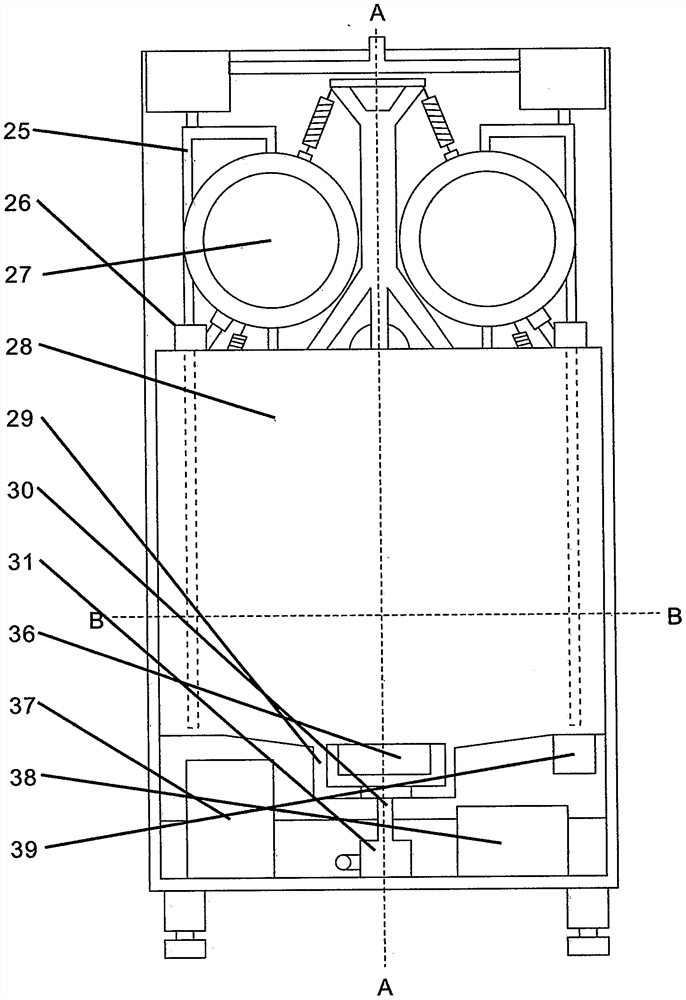

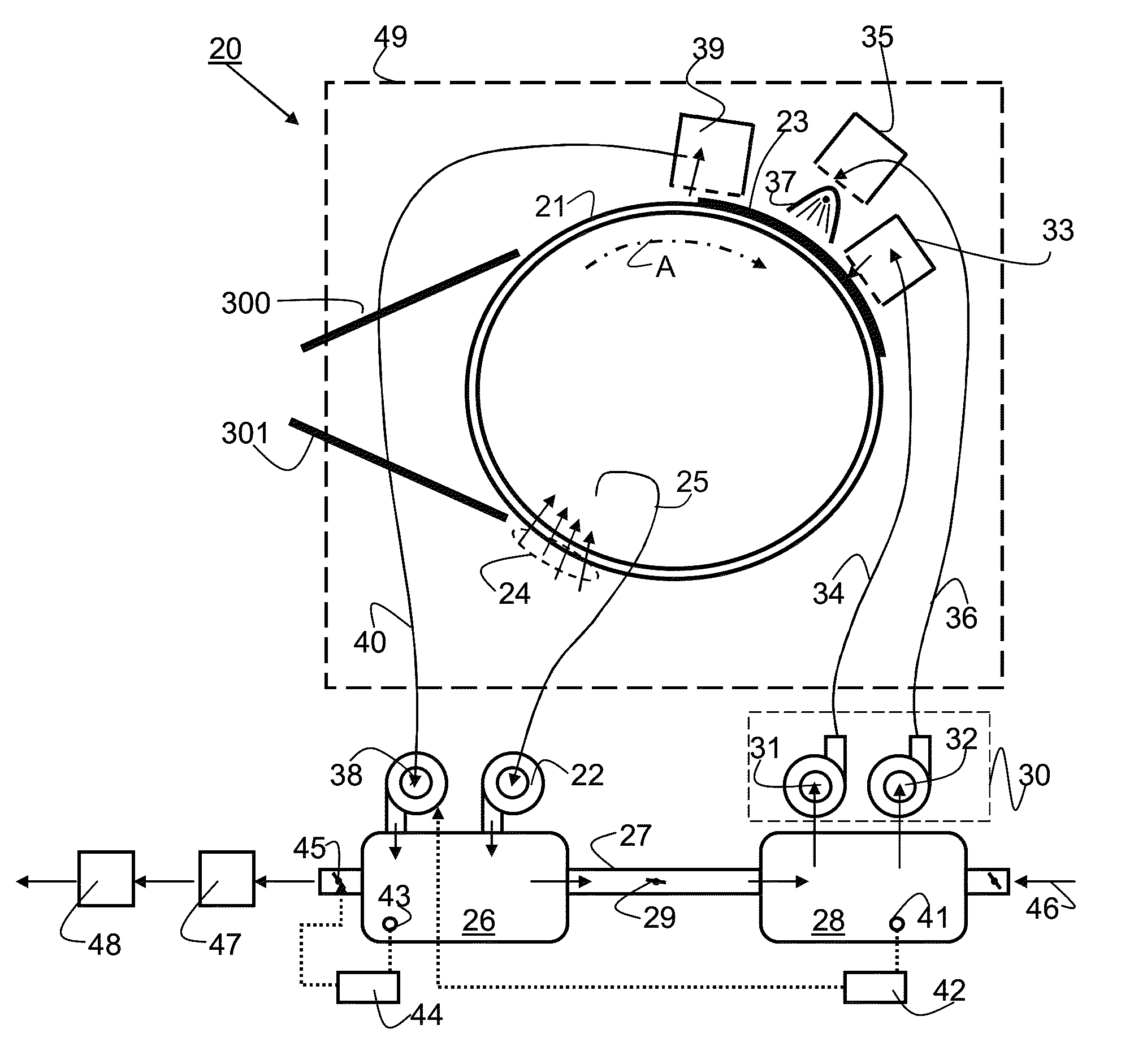

Squeezing and rubbing dual high window reciprocal drum washing machine

ActiveCN109537230AReduce the degree of biasExtended service lifeOther washing machinesControl devices for washing apparatusMoving partsCable stayed

The invention relates to a squeezing and rubbing dual high window reciprocal drum washing machine. The biggest and most obvious feature of the machine lies in that a reciprocal rotary conjoined dual drum assembly used is parallely arranged in the horizontal direction at the upper middle part of a machine body, stably hoisted on two sides of a central supported cable-stayed bridge type hanger fixedto a transverse center position of a mounting platform by the hanger, and hinged to and positioned on the mounting platform through plunger damping rods on left and right sides of the bottom of the conjoined dual drum assembly. The main features and advantages of the machine that can best reflect the advantages of the product are: efficient high-quality washing principle and washing method of 'centrifugal squeezing, rubbing and washing for dirt removal, rinsing and dehydration' completely different from 'squeezing and rubbing' of high imitated artificial washing of washing methods of varioustraditional washing machines are used, and left and right 'small-diameter, large-depth, easy-balance and weak vibrating drums' are used for reciprocal rotation, so that partial vibration of a low vibrational energy level can be further offset or greatly reduced; with the use of a brand-new original center-supported conjoined dual drum hanging and hoisting method, the moving parts in the body are completely contactless with the vertical surface and the top surface of an outer case body, thereby ensuring zero vibration of a machine case. The machine also has the advantages of high cleanliness, minimal wear rate, light weight, convenient and safe operation, health care, long service life and the like.

Owner:张建华

System and method for drying sludge through waste heat of gas turbine

ActiveCN103539333BLower fuel costsSolve the emission problemSludge treatment by de-watering/drying/thickeningSteam useFluidized bed dryingSludge

The invention provides a system and a method for drying sludge through the waste heat of a gas turbine. The gas turbine is connected with a generator; a flue gas outlet of the gas turbine is communicated with a waste heat boiler; a steam outlet of the waste heat boiler is communicated with a steam turbine; the steam turbine is connected with the generator; a steam extraction pipe of the steam turbine is communicated with an inlet of a heated surface pipe of an internal thermal type fluidized bed dryer; an air outlet of an air heater is communicated with an air inlet of the internal thermal type fluidized bed dryer; wet sludge enters the internal thermal type fluidized bed dryer through a wet sludge pipe, flows outside the heated surface pipe, is dried and then is discharged into a dry sludge pipe from a discharging hole. Steam is produced through the flue gas waste heat of the gas turbine to push a steam turbine generator set to generate power, and the waste heat of the steam turbine is taken as a heat source for drying the sludge, so that gradient energy utilization is realized, the heat efficiency is high, and a peculiar smell is not discharged; the fluidization air of the fluidized bed dryer is preheated by hot water, so that the energy utilization rate is further improved, and the environmental problems of groundwater pollution and the like caused by sludge burying and soil utilization are effectively solved.

Owner:凤阳县经济发展投资有限公司

Squeeze and rub type double-height window reciprocal drum washing machine

ActiveCN109537230BReduce the degree of biasExtended service lifeOther washing machinesControl devices for washing apparatusLaundry washing machineStructural engineering

The invention relates to a squeezing and rubbing dual high window reciprocal drum washing machine. The biggest and most obvious feature of the machine lies in that a reciprocal rotary conjoined dual drum assembly used is parallely arranged in the horizontal direction at the upper middle part of a machine body, stably hoisted on two sides of a central supported cable-stayed bridge type hanger fixedto a transverse center position of a mounting platform by the hanger, and hinged to and positioned on the mounting platform through plunger damping rods on left and right sides of the bottom of the conjoined dual drum assembly. The main features and advantages of the machine that can best reflect the advantages of the product are: efficient high-quality washing principle and washing method of 'centrifugal squeezing, rubbing and washing for dirt removal, rinsing and dehydration' completely different from 'squeezing and rubbing' of high imitated artificial washing of washing methods of varioustraditional washing machines are used, and left and right 'small-diameter, large-depth, easy-balance and weak vibrating drums' are used for reciprocal rotation, so that partial vibration of a low vibrational energy level can be further offset or greatly reduced; with the use of a brand-new original center-supported conjoined dual drum hanging and hoisting method, the moving parts in the body are completely contactless with the vertical surface and the top surface of an outer case body, thereby ensuring zero vibration of a machine case. The machine also has the advantages of high cleanliness, minimal wear rate, light weight, convenient and safe operation, health care, long service life and the like.

Owner:张建华

Dryer for biological feed processing

ActiveCN110887355BThickness is easy to controlImprove drying efficiencyDrying gas arrangementsDrying chambers/containersProcess engineeringFodder

The invention discloses a drying machine for biological feed processing, which belongs to the technical field of drying machines. The fixed platforms are arranged in a staggered manner from top to bottom, and the left ends of the first fixed platform and the third fixed platform are fixedly connected with the left side of the inner cavity of the machine body. In the present invention, the biological feed to be dried is layered up and down to increase the It can dry the amount at one time, save space, increase the spread area of each layer, and control the thickness of biological feed, so as to improve the drying efficiency of biological feed. The biological feed laid on the table is pushed up, and the wet part inside the biological feed is turned out, and then it is dried by hot air again to improve the drying effect of the biological feed. The drying effect is good, and the outer surface of the biological feed is prevented from drying out.

Owner:ANHUI ZHENGZHENG FEED TECH

Sheet processing apparatus and printing apparatus

InactiveUS8944582B2Reduce power consumptionImprove heat transfer efficiencyDuplicating/marking methodsOther printing apparatusRadiant heatIrradiation

A sheet processing apparatus includes a heater, an irradiation unit, and a contact unit. The irradiation unit irradiates a sheet with heat rays from the heater to heat the sheet by radiant heat. The contact unit includes a member that heats a region of the sheet by coming into contact with the radiant heated sheet on a downstream side of the irradiation unit. A part of the heat rays output from the heater is radiated onto a part of a structure constituting the contact unit to raise a temperature of the member.

Owner:CANON KK

Drying device for garment dyeing

ActiveCN107401015BImprove drying efficiencyEasy to placeTextile treatment machine partsLiquid/gas/vapor removalHydraulic cylinderElectric machinery

The invention discloses a drying device for clothes dyeing. The drying device comprises a hollow mounting base; a set of parallelly arranged hydraulic cylinders are fixed on the top of the hollow mounting base; piston rods of the hydraulic cylinders are fixedly provided with a C-shaped connecting rod positioned over the top of the hollow mounting base; second driving motors are fixed on the top of the C-shaped connecting rod; output shafts of the second driving motors are fixedly provided with a threaded rod; an outer side of the threaded rod is threadedly sleeved with an internal thread block; the bottom of the internal thread block is fixedly provided with a fixed block; the top of the fixed block is fixedly provided with an enclosing plate; and the bottom of the enclosing plate is fixedly provided with an enclosing adhesive ring. Through cooperation of structures such as a first driving motor, a bevel gear, a bevel gear ring, a connecting ring, an annular installing plate, a dyeing tank and a drying tank, clothes dyeing and drying can be freely switched, continuity of dyeing and drying processes is achieved, time can be fully utilized, and therefore clothes drying efficiency is improved.

Owner:赣州邦帝体育用品有限公司

Bed type drier

InactiveCN109000438AIncrease the areaLarge drying capacityDrying solid materials with heatDrying gas arrangementsEngineeringSieve

The invention relates to a bed type drier. The bed type drier comprises a box body which is horizontally arranged, wherein a plurality of positioning pins are vertically arranged on the front side plate of the box body in a penetrating mode, a plurality of positioning pins are vertically arranged on the rear side plate of the box body in a penetrating mode, a drying sieve is arranged in the box body, the drying sieve is arranged on the positioning pins, a first through hole is formed in the right side plate of the box body, and a heat supply box is arranged on the right side of the box body; an air outlet is formed in the left side of the heat supply box, and an air inlet is formed in the right side of the heat supply box; and an air outlet of the heat supply box is connected to the firstthrough hole, a net plate is vertically arranged on an air inlet of the heat supply box, a blower is arranged in the heat supply box, the blower is arranged on the right side of the heat supply box, and the blower is installed on the sieve plate. According to the bed type drier, the heating box and the drying sieve are separated, so that the area of the drying sieve is greatly improved, the dryingamount of each time is increased, and the cost is reduced.

Owner:重庆申基特机械制造有限公司

Recording substrate treatment apparatus, printing system and method of drying

A recording substrate treatment apparatus includes a transporting mechanism for transporting a sheet of a recording substrate; a suction device to provide an underpressure force at an outer surface of the transporting mechanism arranged for holding down a sheet of a recording substrate; a heater for directly heating the recording substrate; and a blower for providing a flow of a gaseous medium at the outer surface of the transporting mechanism, wherein in operation the blower receives the gaseous medium from the suction device.The present invention also pertains to a printing system comprising such a recording substrate treatment apparatus and a method of drying a recording substrate using such a recording substrate recording apparatus.

Owner:OCE TECH

An environmentally friendly and efficient veneer drying device

ActiveCN107084607BUniform moisture contentImprove flatnessDrying gas arrangementsDrying chambers/containersThermal insulationFlue gas

The invention provides an environment-friendly and high-efficiency veneer drying device, which includes a board inlet, a board outlet, a rack, a thermal insulation box, a top cover, a moisture outlet, a conveying mechanism, a blowing device, a fire duct, a flue gas duct, a flue; a thermal insulation box is arranged on the outside of the frame, a top cover is arranged on the upper part of the thermal insulation box, and a number of moisture outlets are arranged on the top cover near the outlet of the plate; the transmission mechanism includes a transmission shaft, a clamping arm, Support pads, chains, sprockets, idlers, motors, speed reducers, and motor fixing frames, the upper part of the chain is provided with a supporting pad, the upper part of the supporting pad is provided with a clamping arm, the fire channel, smoke The pipes and the flue are fixedly connected to the frame; the blowing device is arranged on both sides of the upper circulation part of the conveying mechanism and both sides of the fire channel, and the blowing device includes a baffle, a blowing fan and a fan support. The invention has low energy consumption, reduces the production cost of traditional large-scale drying equipment, has good veneer drying effect, and solves the problem of natural warpage of the veneer after drying.

Owner:李学淑

Ferrous sulfate heptahydrate dryer

ActiveCN105258469BImprove drying effectLarge drying capacityIron sulfatesDrying machines with non-progressive movementsInterior spacePulp and paper industry

The invention discloses a ferrous sulfate heptahydrate dryer, relates to drying equipment, and provides a dryer suitable for drying ferrous sulfate heptahydrate. The dryer comprises a feeding mechanism, a fixed drying cylinder, a rotating drying cylinder, a discharge mechanism, a center shaft, a rotating drying cylinder support driving mechanism and a center shaft support driving structure, wherein the feeding mechanism, the fixed drying cylinder, the rotating drying cylinder and the discharge mechanism are arranged in sequence, and are communicated through internal spaces; a hot air inlet is formed in the fixed drying cylinder; push blades and dispersing blades connected with the center shaft are arranged in the fixed drying cylinder; the push blades are plane blades arranged slantwise corresponding to the axis of the center shaft; and two push blades and two dispersing blades are arranged on one axial position of the center shaft in a such manner of being centrosymmetric about the axis of the center shaft . The ferrous sulfate heptahydrate dryer is suitable for a drying process for drying a mixture of dried materials and free water-contained ferrous sulfate heptahydrate.

Owner:SICHUAN DONGLI TECH CO LTD

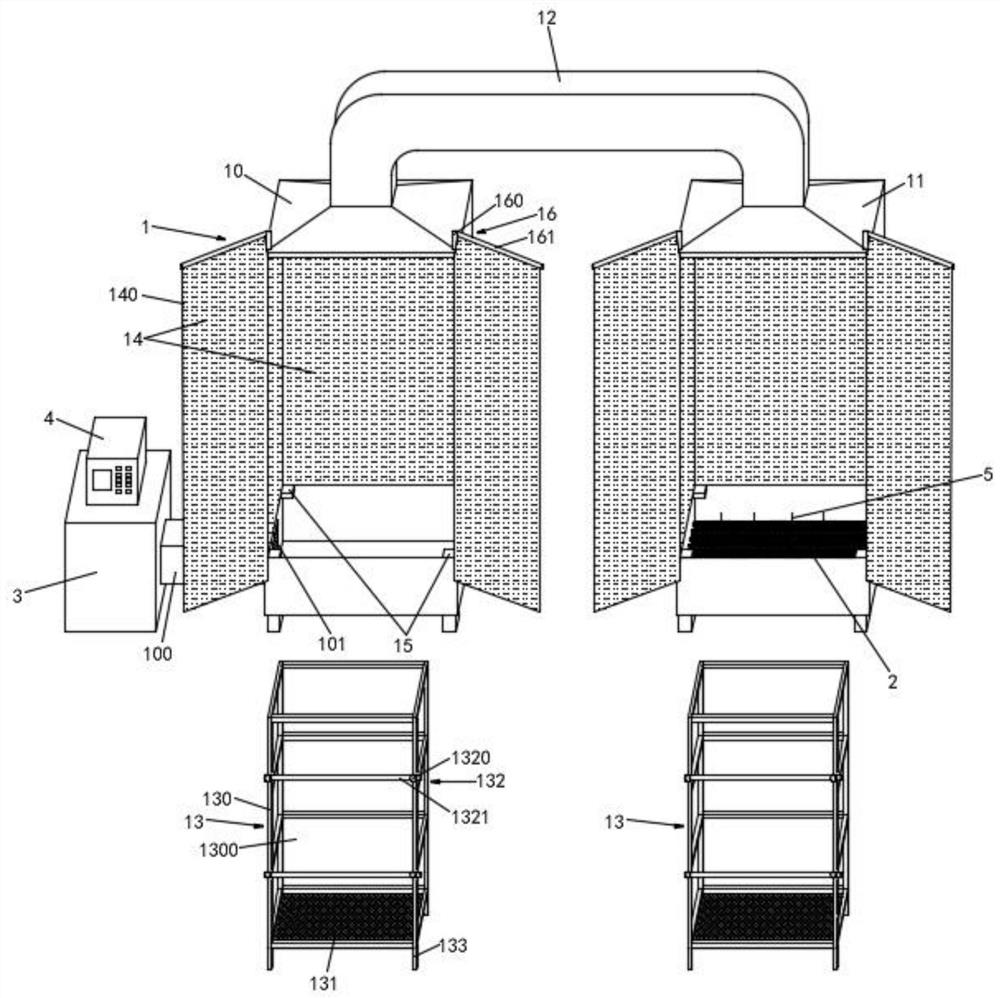

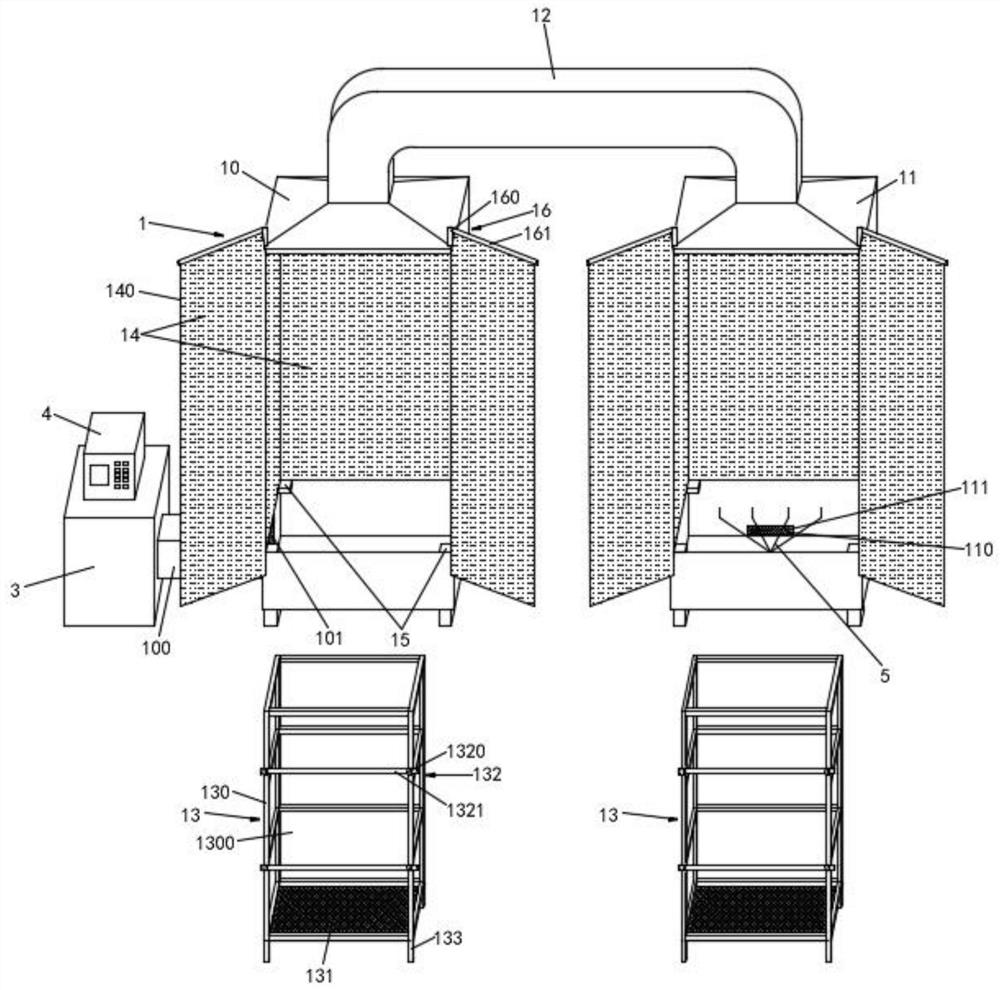

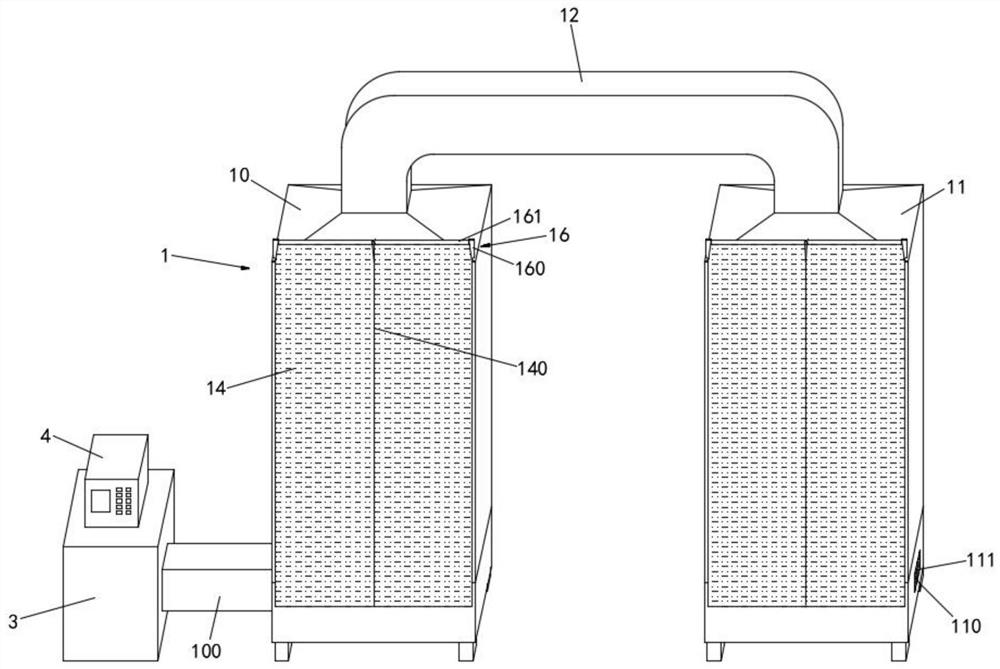

Negative pressure type bamboo drying machine

PendingCN112629193ALarge drying capacityFully contactedDrying gas arrangementsAir heatersProcess engineeringMechanical engineering

The invention discloses a negative pressure type bamboo drying machine. The negative pressure type bamboo drying machine comprises a drying main body, a heater and an exhaust fan; the drying main body comprises a preheating chamber and a drying chamber; the top ends of the preheating chamber and the drying chamber are communicated with each other through a gas conveying pipe; an air inlet is formed in the bottom end of the drying chamber; the heater is arranged in the drying chamber and above the air inlet, and air is heated through the heater; an air outlet is formed in the lower end of the preheating chamber, and the exhaust end of the exhaust fan communicates with the air outlet; containing frames used for longitudinally hooping bamboo to be dried are placed in the preheating chamber and the drying chamber; tarpaulin used for laterally wrapping the bamboo is arranged on the preheating chamber and the drying chamber on the outer side edges of the containing frames; and one side of the tarpaulin is provided with an opening and closing port used for mounting or dismounting the containing frames, the tarpaulin is adsorbed outside the containing frames through the exhaust fan, and hot air sequentially flows through the bamboo in the drying chamber and the preheating chamber. The energy loss can be effectively reduced, the heat utilization rate is high, and drying is uniform.

Owner:连城县竹匠新材料有限公司

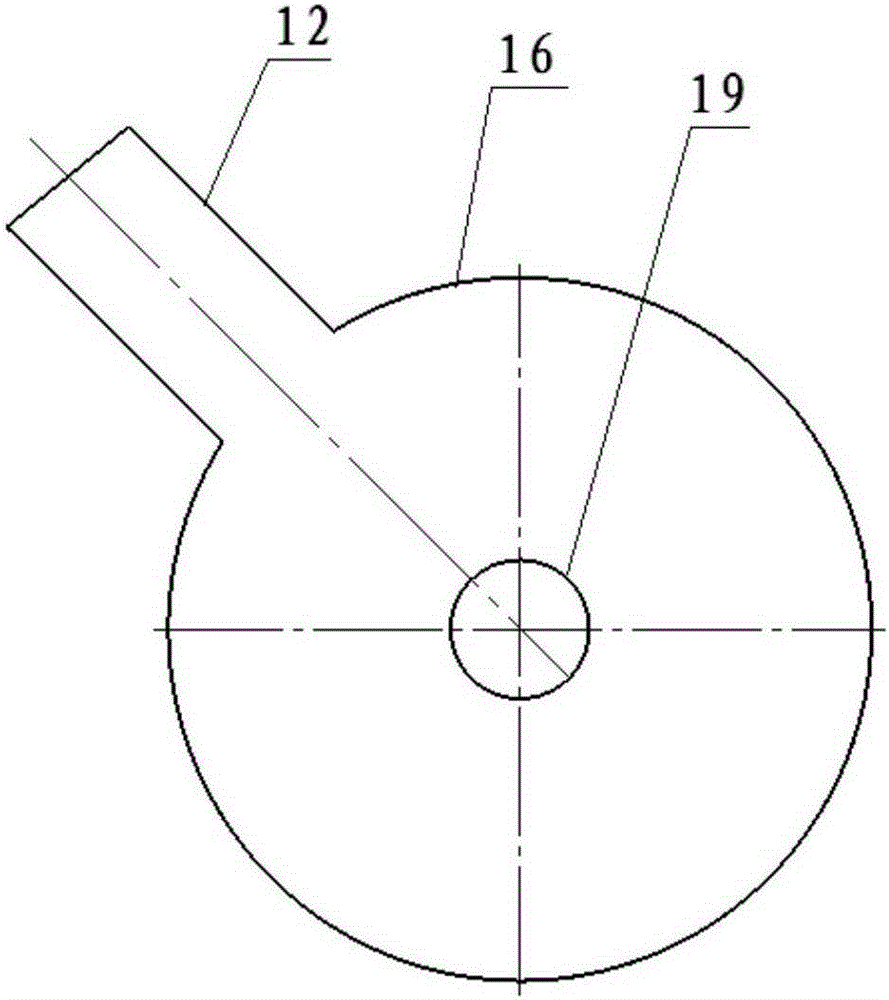

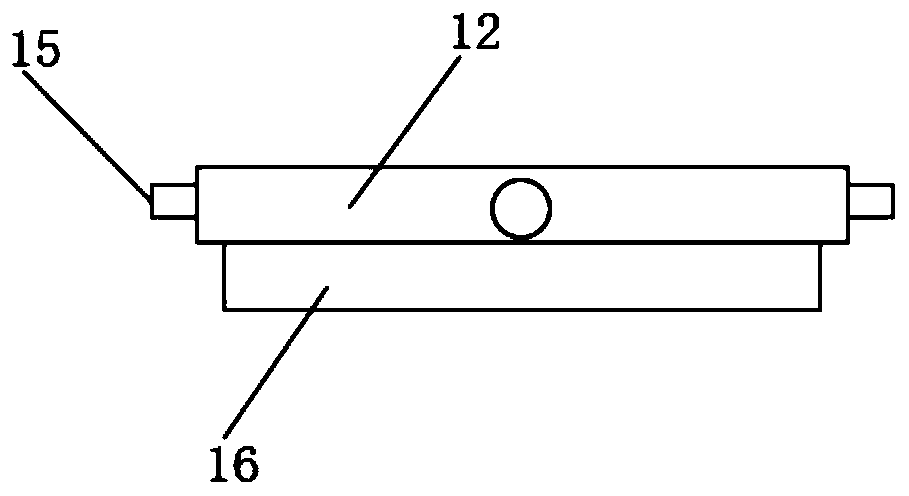

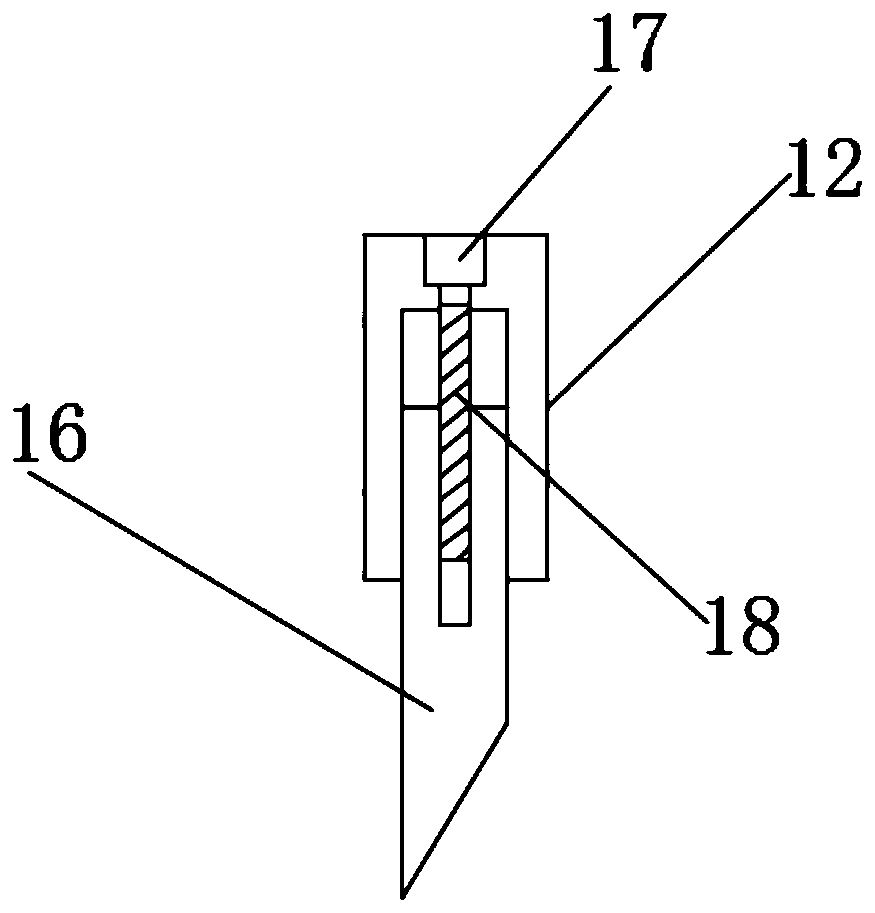

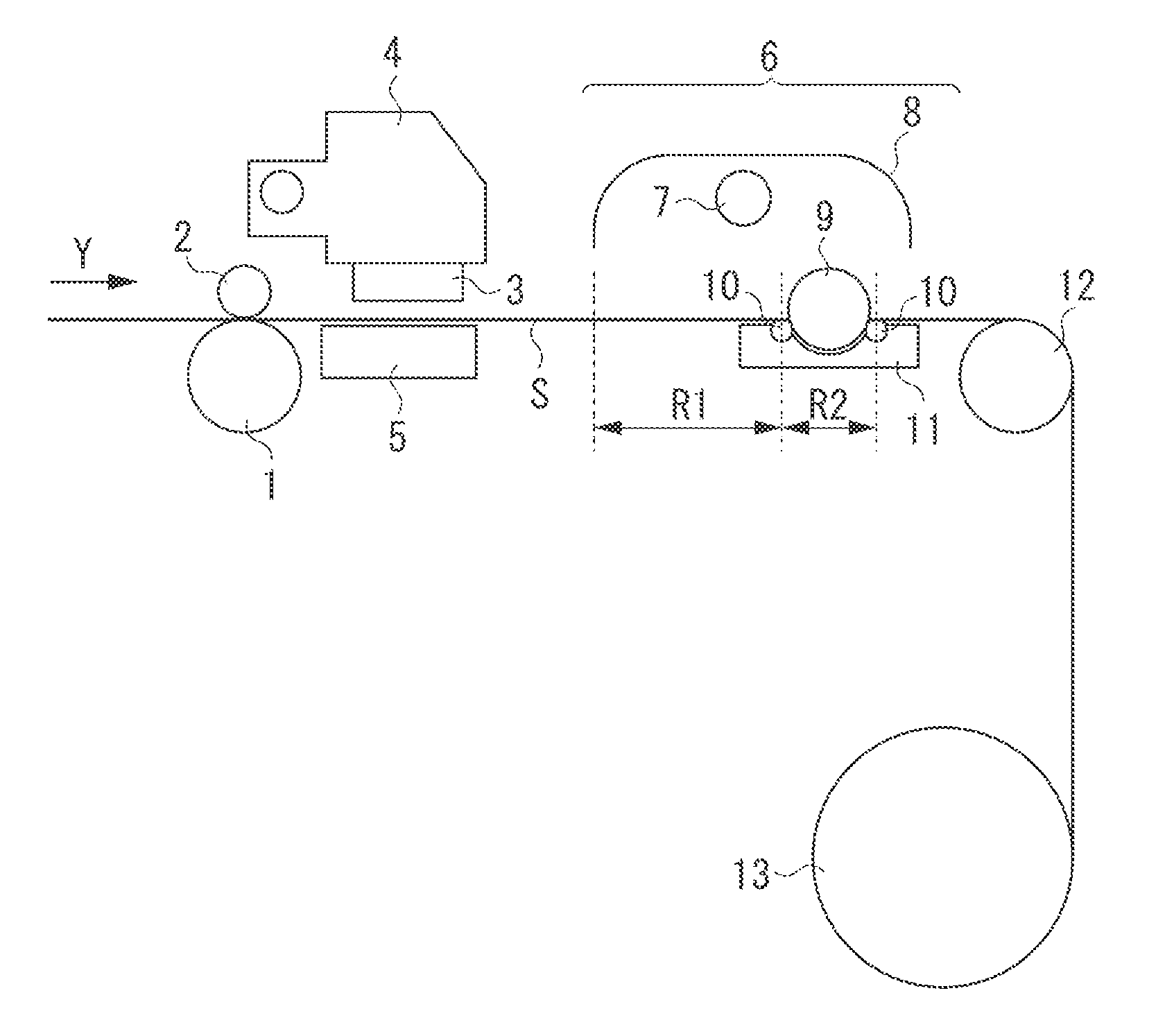

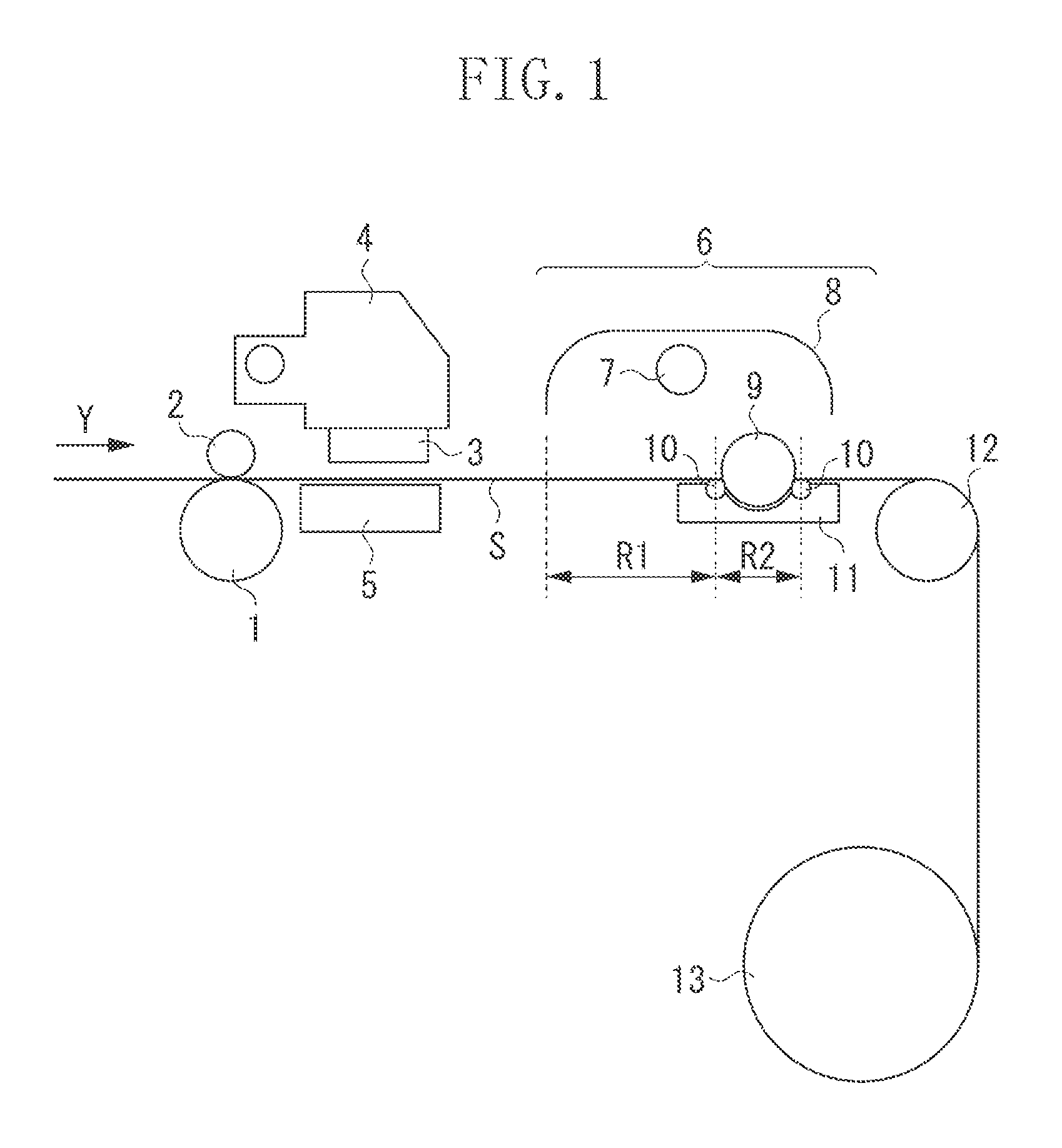

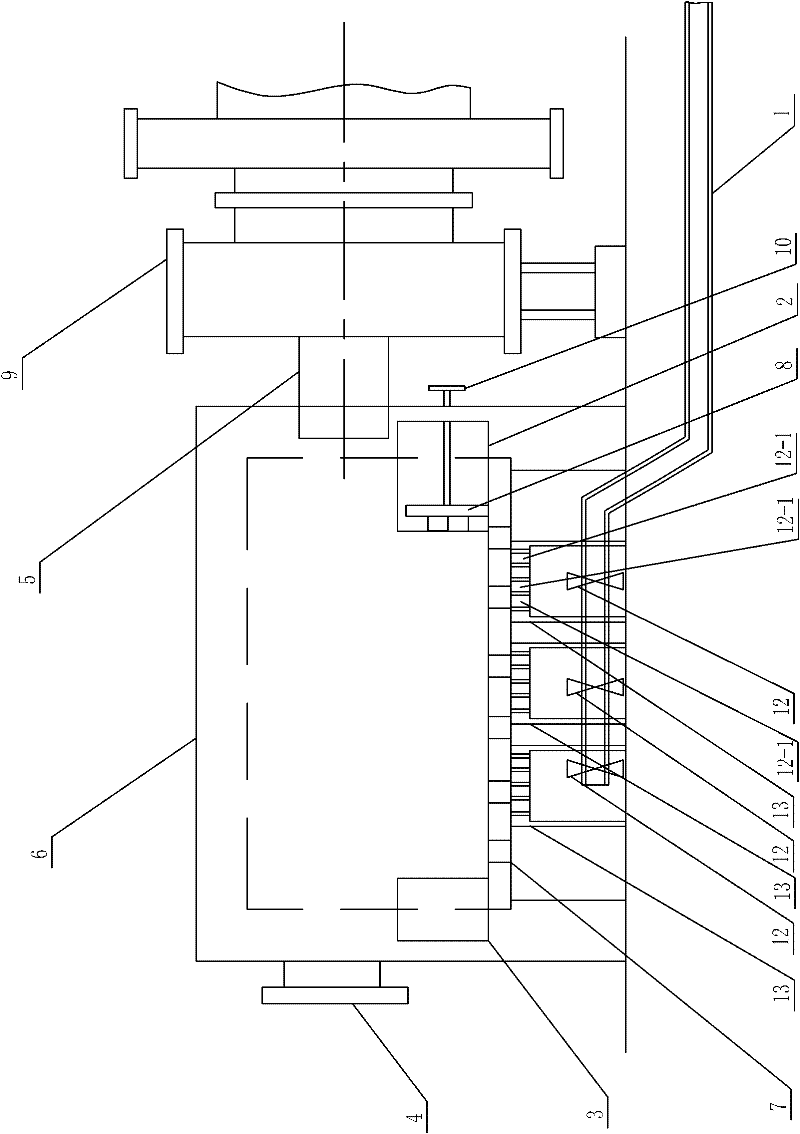

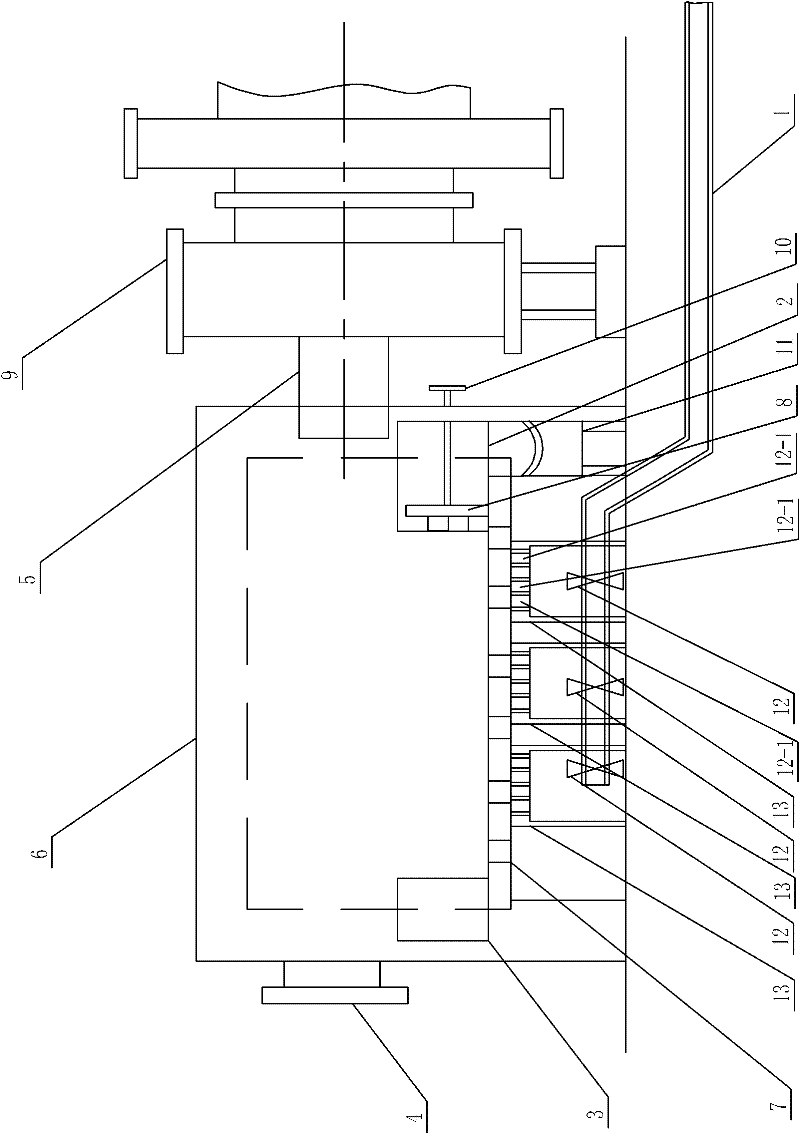

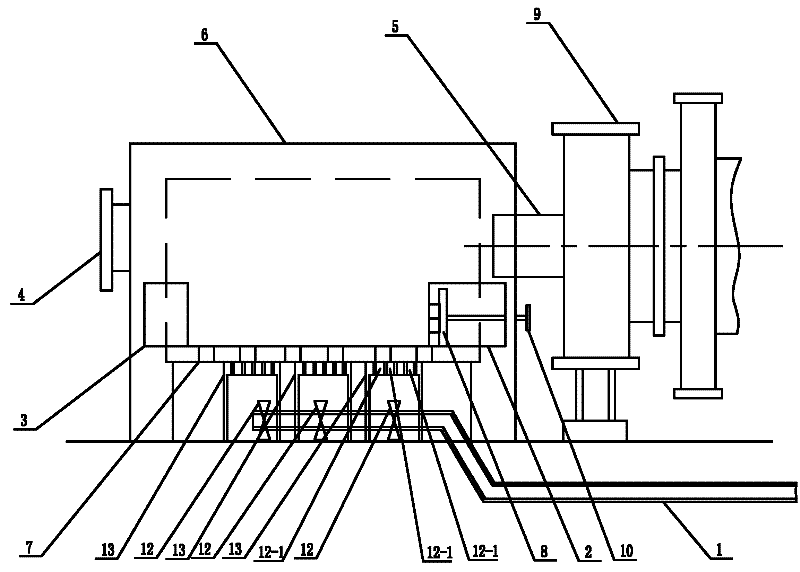

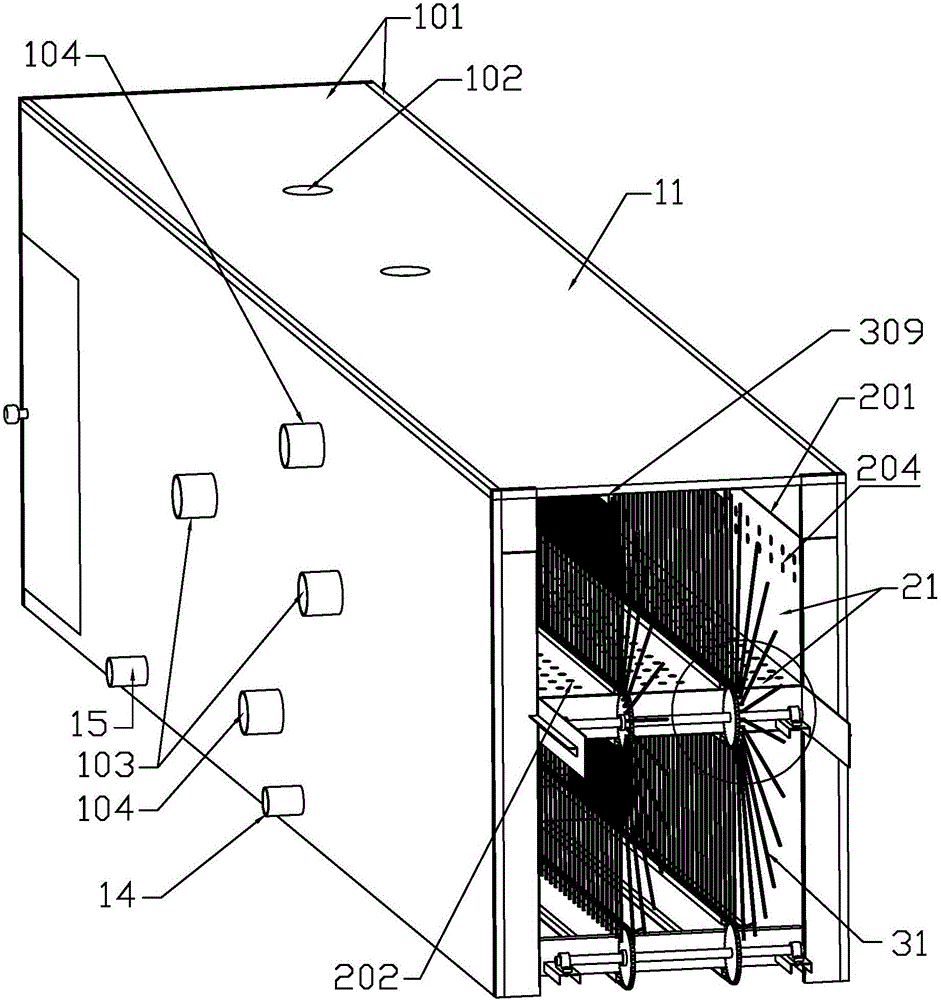

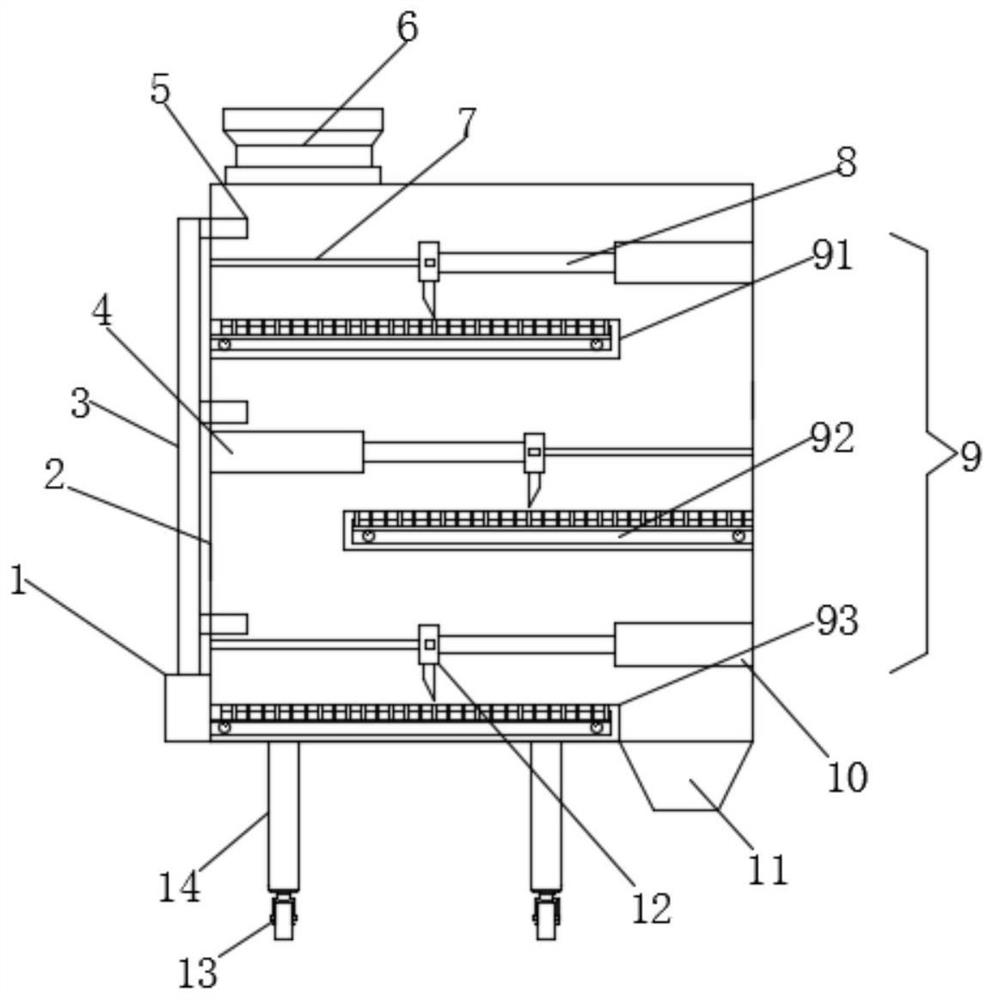

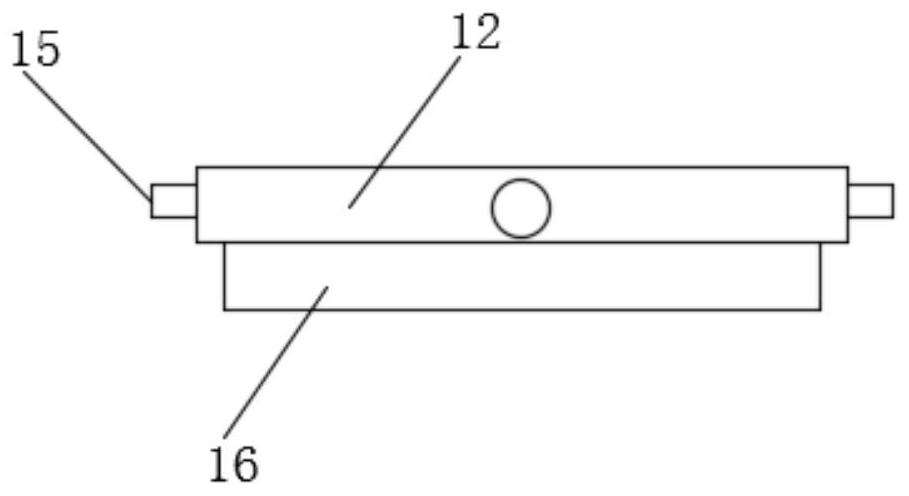

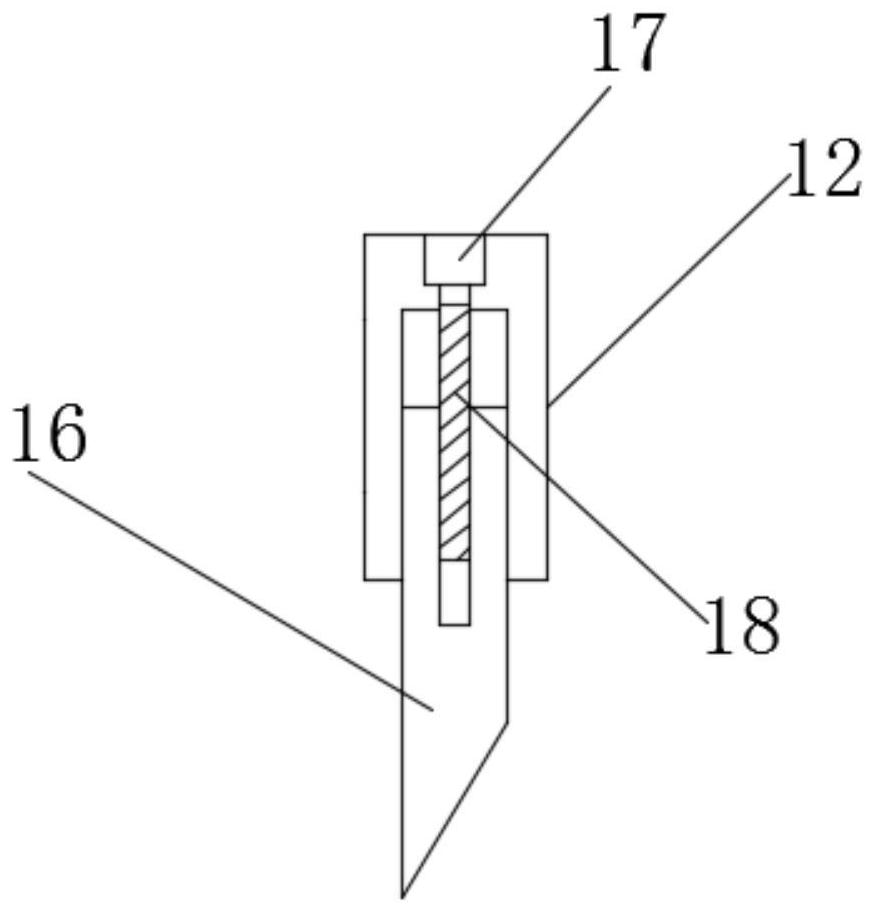

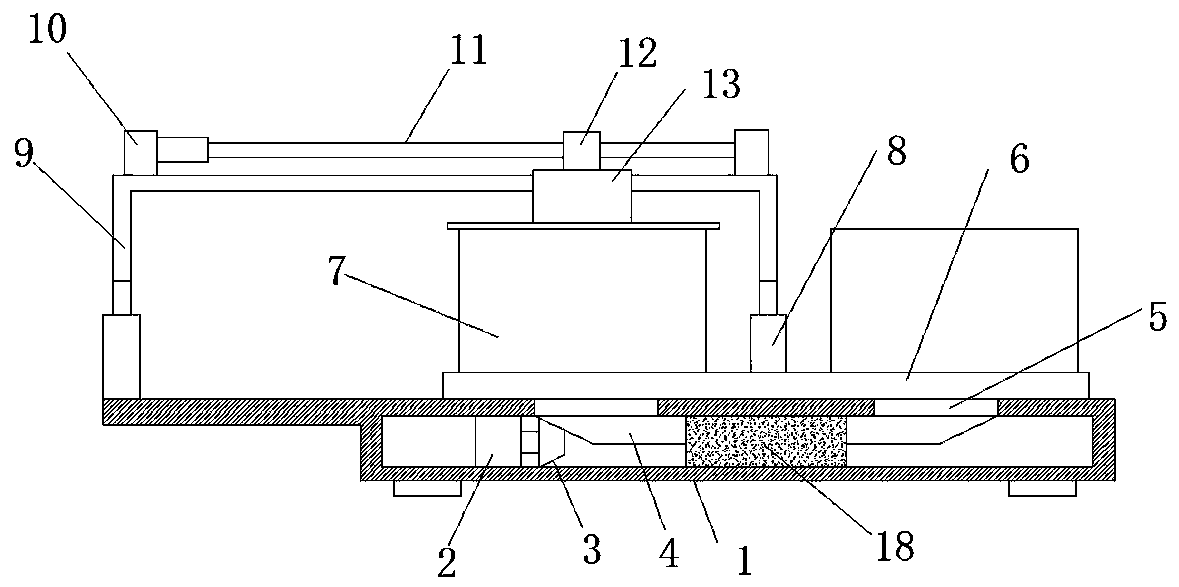

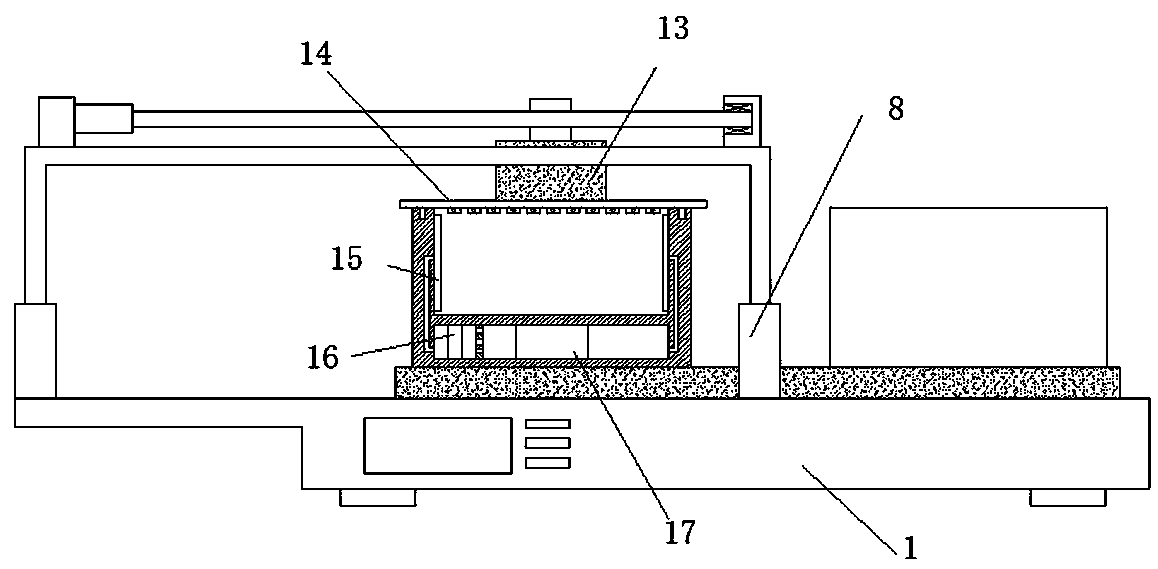

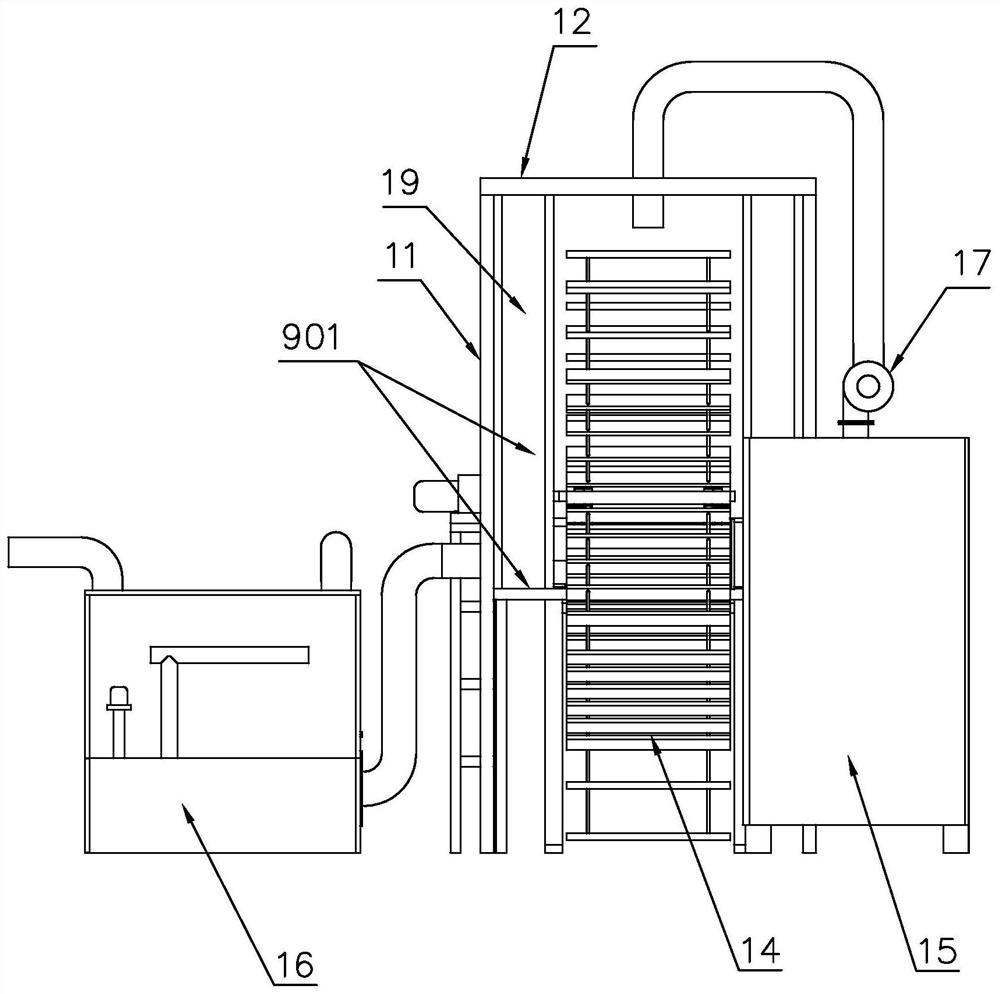

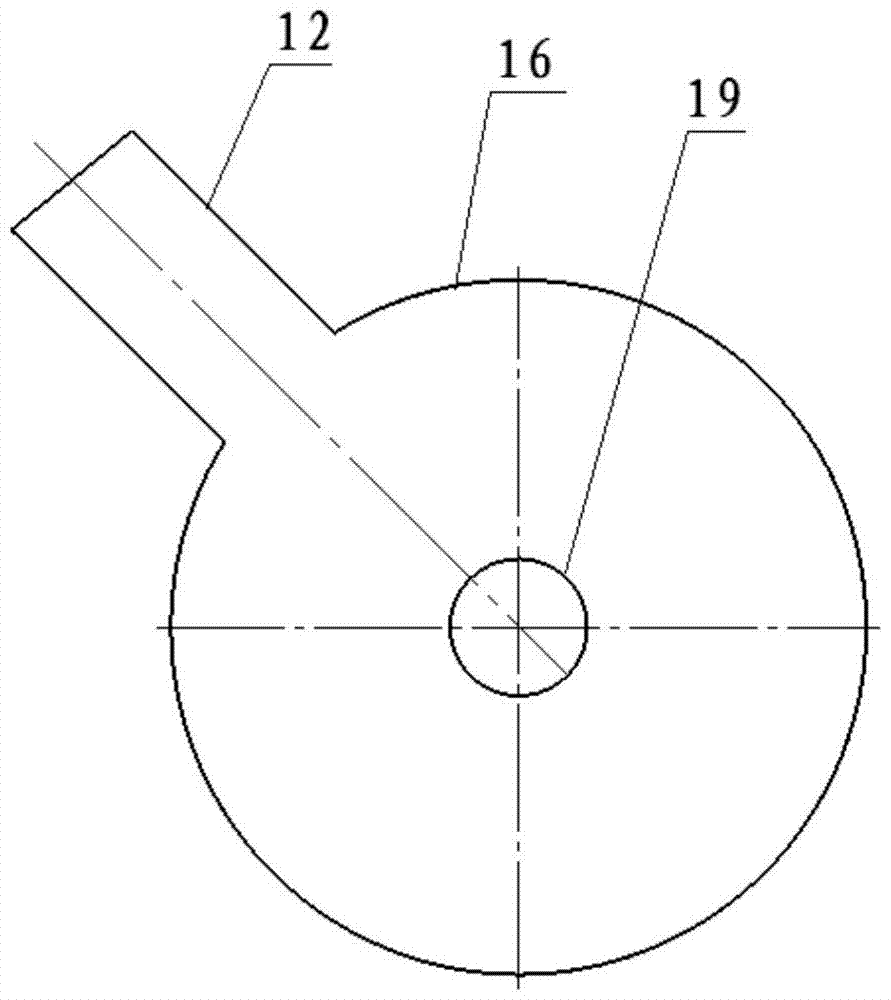

A three-layer conveyor belt adjustable biomass dryer integrated with visual pre-inspection

ActiveCN105841465BAvoid wastingLarge drying capacityDrying gas arrangementsDrying machines with progressive movementsEngineeringConveyor belt

The invention discloses a biomass dryer integrating visual pre-detection and having three layers of adjustable conveyor belts. A third conveyor belt (13), a second conveyor belt (12) and a first conveyor belt (21) are sequentially arranged in a dryer housing from top to bottom, wherein the length and the steering of the second conveyor belt (12) are adjustable; the length of the third conveyor belt (13) is adjustable; the third conveyor belt (12) is in driving connection with a transmission motor (3) at a third layer; the second conveyor belt (12) is in driving connection with a transmission motor (11) at a second layer; and the first conveyor belt (21) is in driving connection with a transmission motor (5) at a first layer. According to the biomass dryer, the visual pre-detection technology, adoption of boiler waste gas and three layers of adjustable conveyor belts for drying biomass are integrated; a proper drying temperature is automatically regulated; the three layers of the adjustable conveyor belts can simultaneously dry a great number of materials; and single-layer sufficient drying is carried out on materials in case of especially great material humidity, not high drying temperature and inconvenient regulation for speed of the conveyor belts.

Owner:SUZHOU AERTAI BUSINESS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com