A high-efficiency energy-saving veneer drying device

A drying device, high-efficiency and energy-saving technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of uneven water content, low production efficiency, high production cost, etc., and achieve good drying effect and high production efficiency High, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-12 , to further specifically describe the technical solution of the present invention.

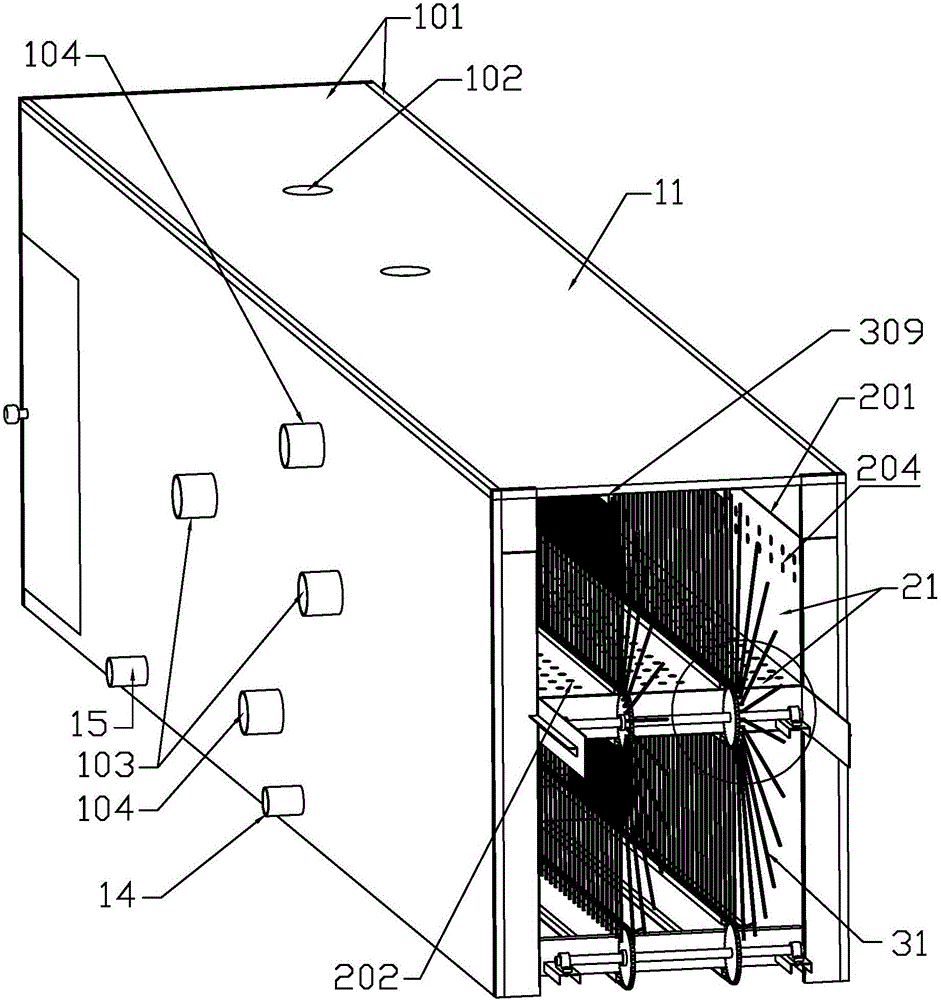

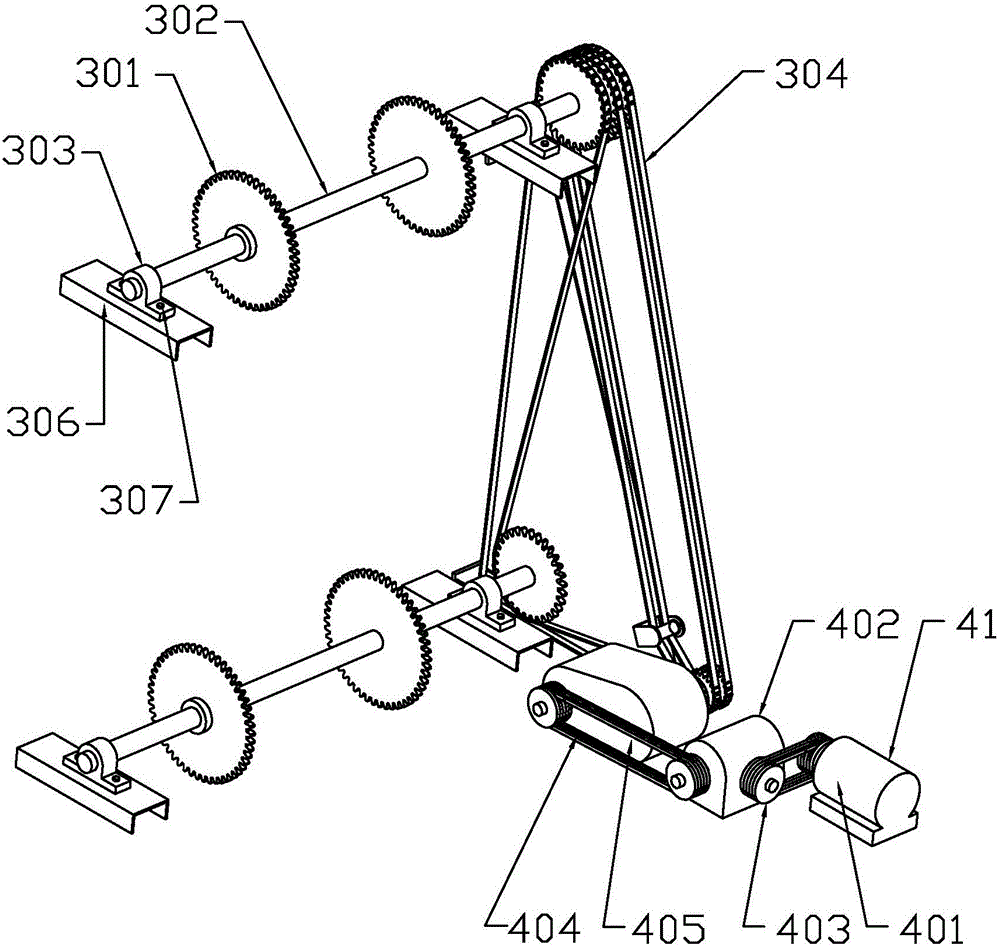

[0031] As shown in the figure, a high-efficiency and energy-saving veneer drying device mainly includes a thermal insulation box 11 , a drying device 21 , a transmission device 31 , and a power device 41 .

[0032] Described thermal insulation box body 11 is made up of several fireproof insulation boards 101, and several fireproof insulation boards are connected to rectangular frame body, and top fireproof insulation board 101 is provided with some air outlets 102; The air outlet 104, the lower right side of the rear side fireproof insulation board is provided with a cooling outlet 105, which is used for the heat dissipation of the motor and the reducer.

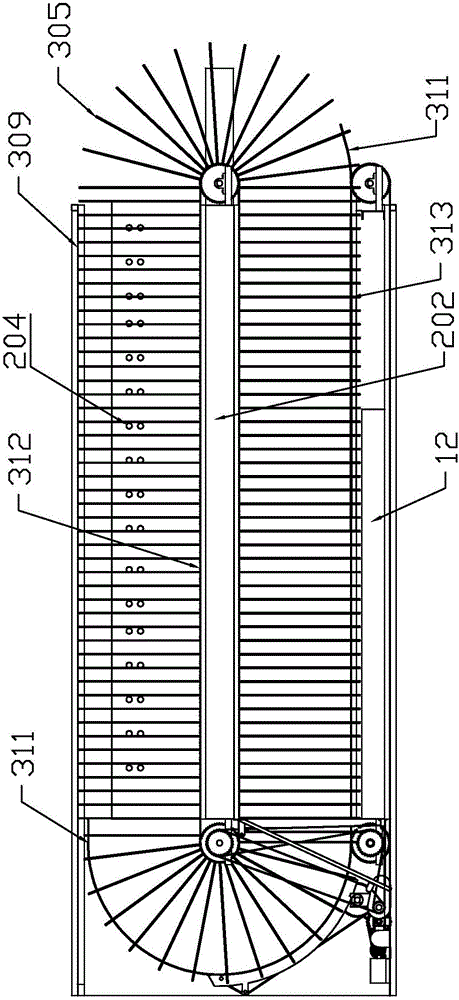

[0033]The drying device 21 mainly includes a side oven 201 and a central oven 202. The side oven 201 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com