A three-layer conveyor belt adjustable biomass dryer integrated with visual pre-inspection

A conveyor belt and dryer technology, applied in biomass drying, dryer, drying and other directions, can solve the problems of waste of resources, polluted air, polluted atmospheric environment, etc., to increase the utilization rate of resources, large drying capacity, Avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

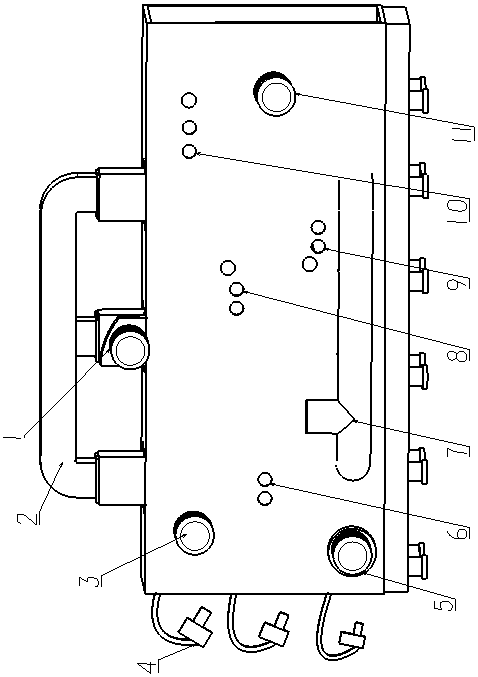

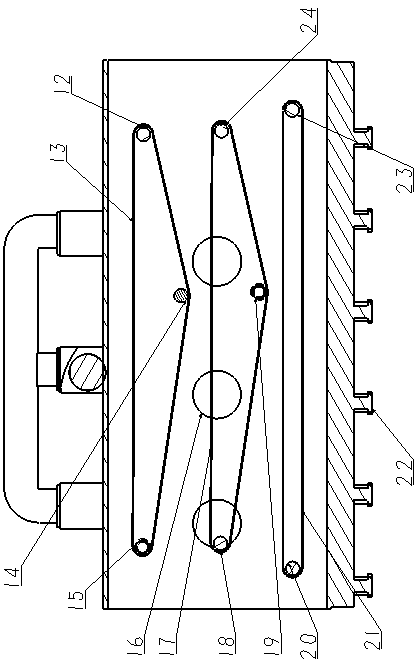

[0023] Such as figure 1 , 2 As shown, an adjustable biomass dryer with a three-layer conveyor belt integrated with visual pre-detection consists of a dehumidifier 1, a dehumidification pipe 2, a third-layer transmission motor 3, an industrial camera 4, and a first-layer transmission motor 5. Hole system, 6, air intake pipe 7, hole system 8, hole system 9, hole system 10, second layer transmission motor 11, first movable pin 12, third layer conveyor belt 13, second movable pin 14 , the first fixed pin 15, the observation window 16, the second conveyor belt 17, the third movable pin 18, the fourth movable pin 19, the second fixed pin 20, the first conveyor belt 21, the dryer The base 22, the third fixed pin shaft 23, and the fourth fixed pin shaft 24 are formed.

[0024] A biomass dryer with an adjustable three-layer conveyor belt integrated with vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com