Energy-saving and environmentally-friendly combustion furnace for drier

An energy saving, environmental protection, dryer technology, applied in dryers, drying, heating devices, etc., can solve the problems of increasing power consumption and maintenance, and large dust content in flue gas, reducing power consumption and maintenance, Good preheating effect and the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

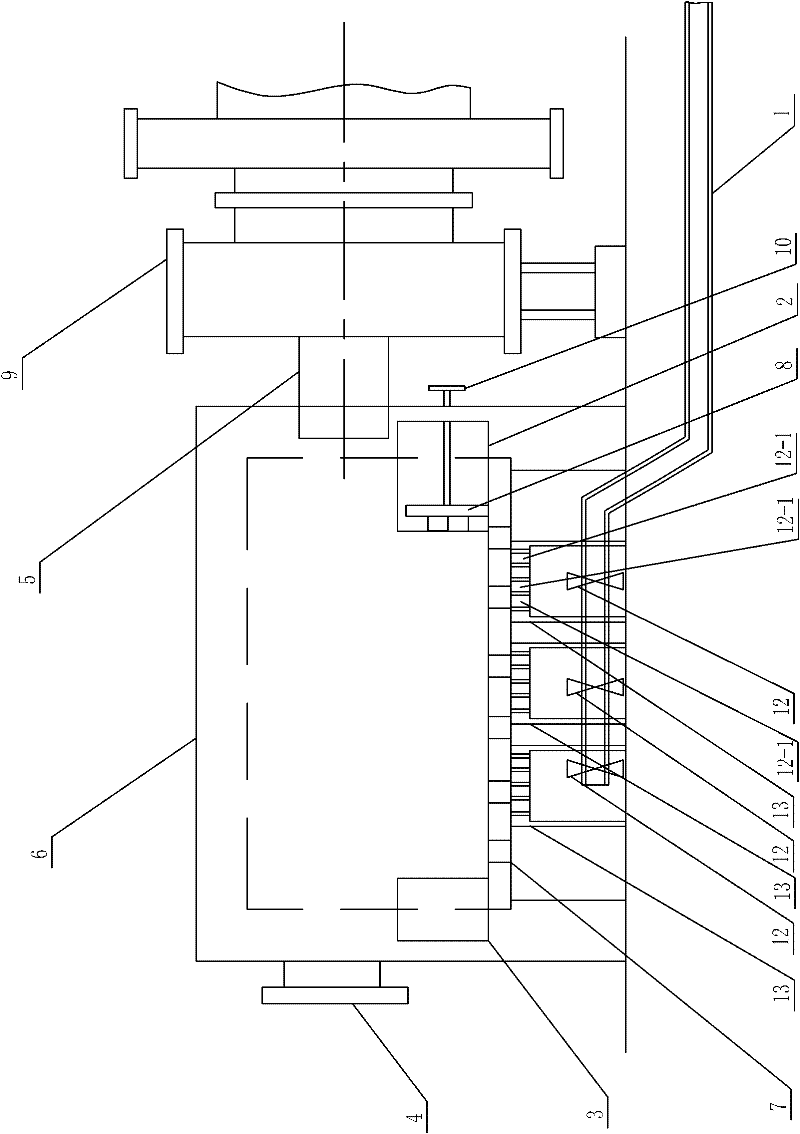

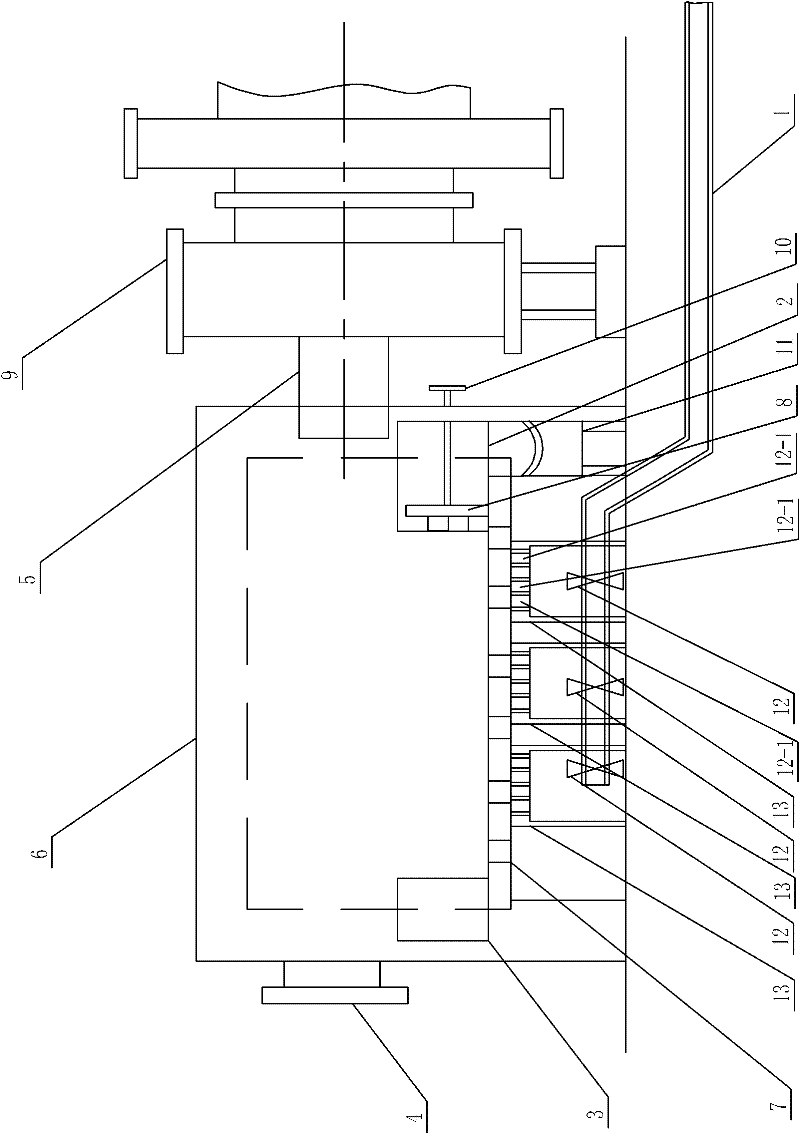

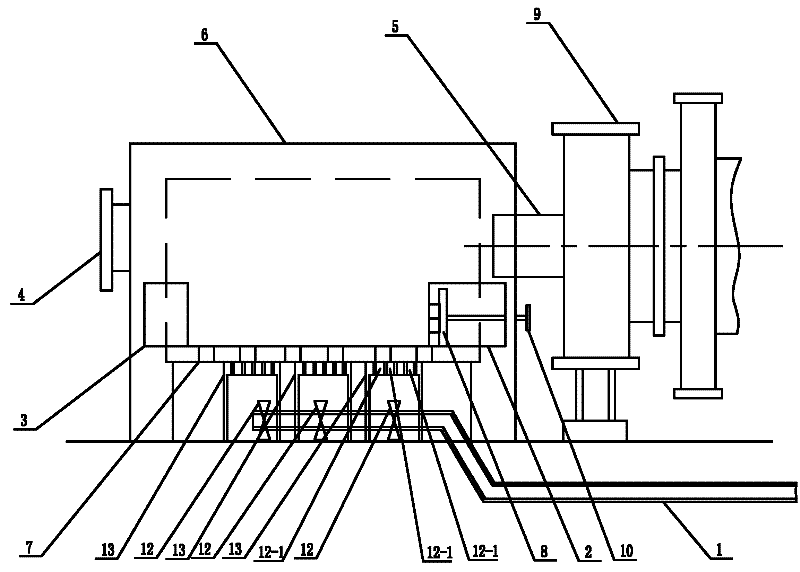

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the combustion furnace of an energy-saving and environment-friendly dryer in this embodiment includes a furnace body 6, and the combustion furnace also includes an oxygen supply pipeline 1, a briquette hole 2, a slag discharge port 3, an observation port 4, and a dryer Heating pipeline 5, furnace grate 7, transmission push plate 8, piston pull rod 10 and multiple oxygen supply valves 12, the heating pipeline 5 of the dryer is set in the furnace body 6, and the oxygen supply pipeline 1 is arranged at the bottom of the furnace body 6 , a plurality of oxygen supply valves 12 are set on the oxygen supply pipeline 1, the furnace grate 7 is clamped on the inner wall of the furnace body 6, and the furnace grate 7 is located above the oxygen supply pipeline 1, and the briquette hole 2 is opened in the furnace body 6, the molded coal hole 2 is connected with the combustion chamber of the ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the multiple oxygen supply valves 12 of this embodiment are located on the oxygen supply pipeline 1 below the furnace grate 7 . Such setting not only facilitates the direct supply of oxygen to the briquette for combustion, but also facilitates the adjustment of the oxygen supply according to the combustion situation, and at the same time, effectively reduces the waste of oxygen. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the combustion furnace of this embodiment also comprises a plurality of oxygen supply covers 13, offers a plurality of oxygen supply holes 12-1 on each oxygen supply cover 13, and an oxygen supply cover 13 is fastened on an oxygen supply valve 12 Above, the number of oxygen supply valves 12 is consistent with the number of oxygen supply covers 13 . Such setting facilitates the uniform discharge of oxygen. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com