Grain drying machine with multiple layers of overturning plates

A grain dryer and flap-type technology, applied in the agricultural field, can solve the problems of inconvenient use, increased cost, waste of energy, etc., and achieve the effects of convenient installation, improved quality, and uniform air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

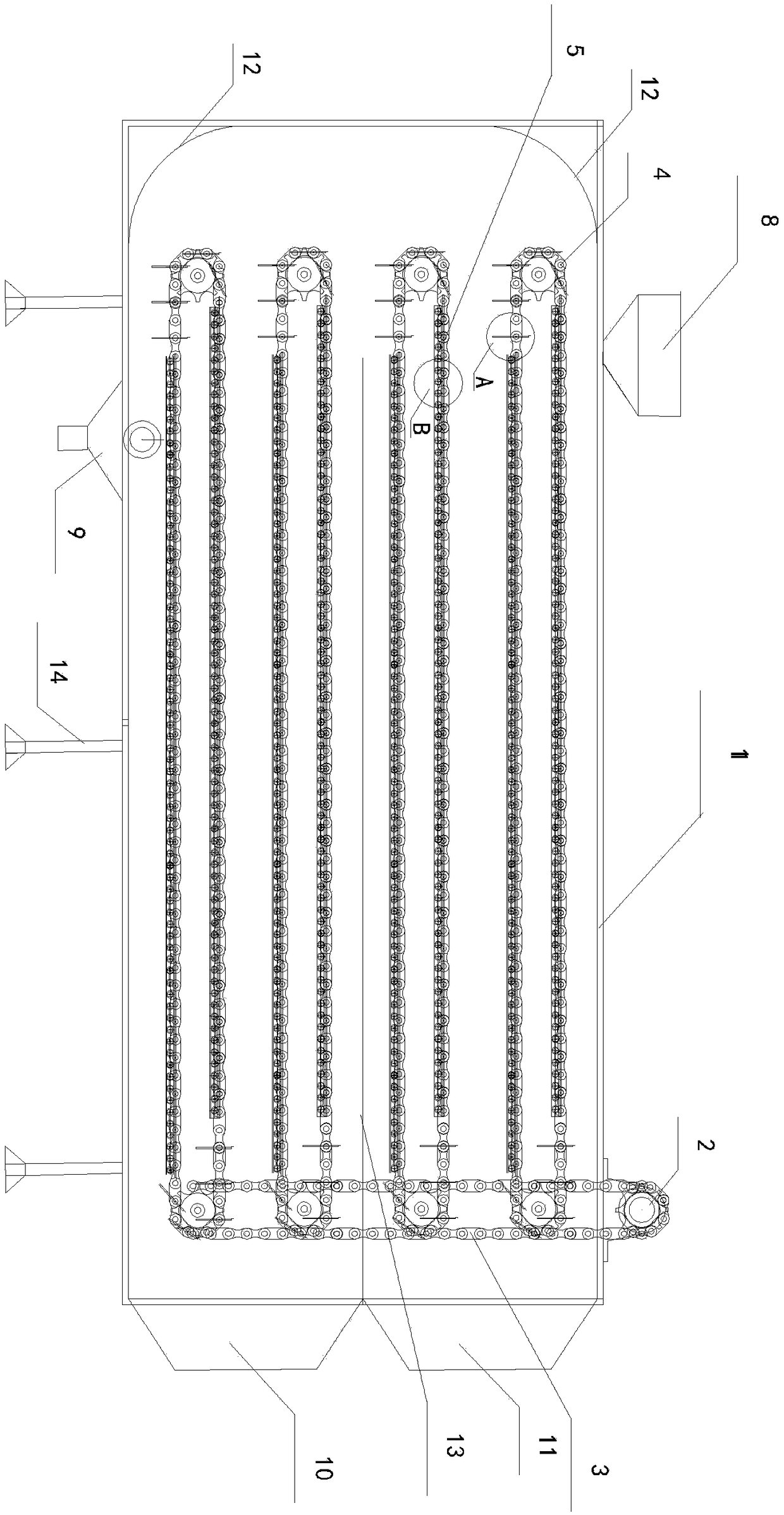

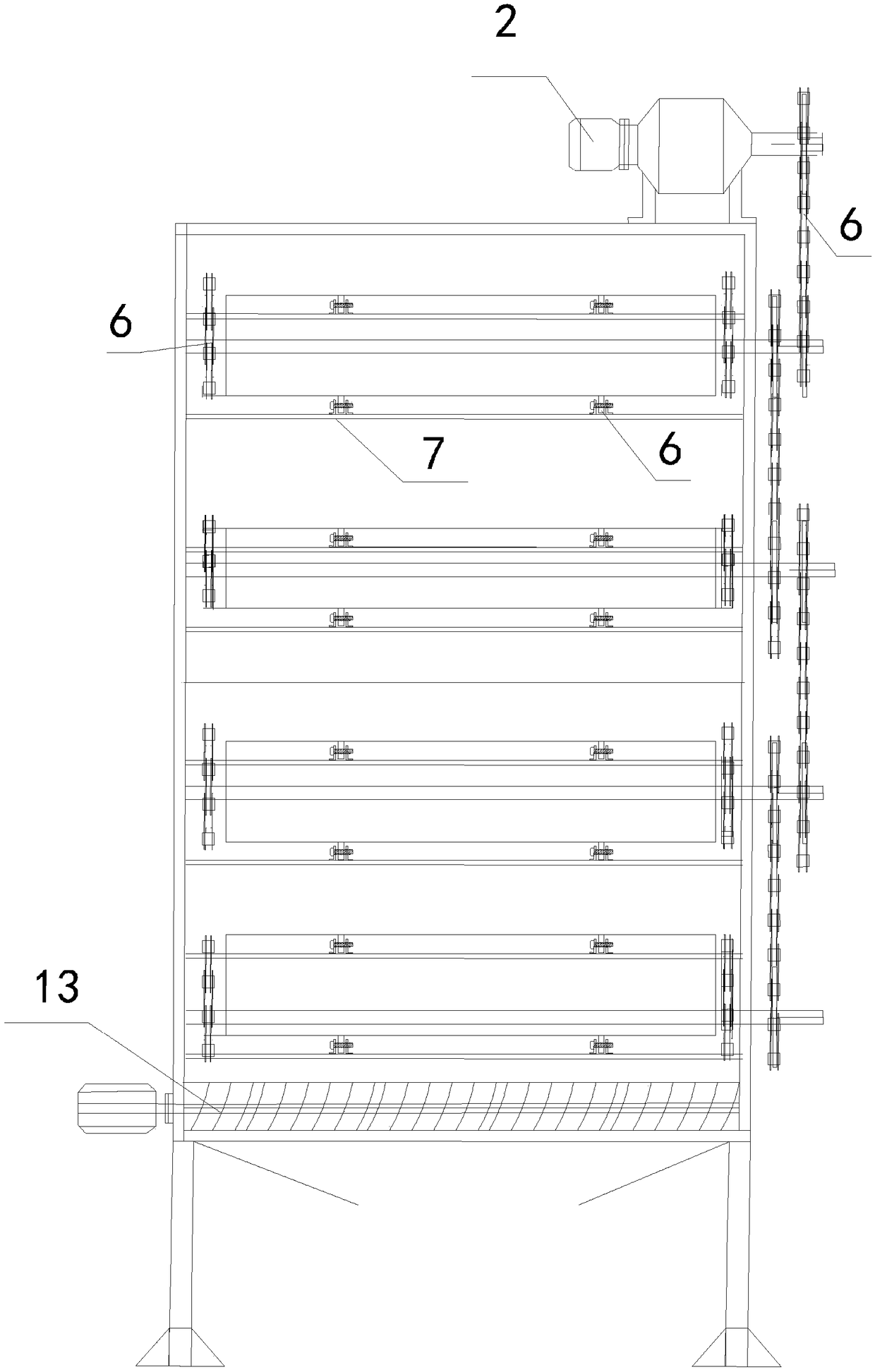

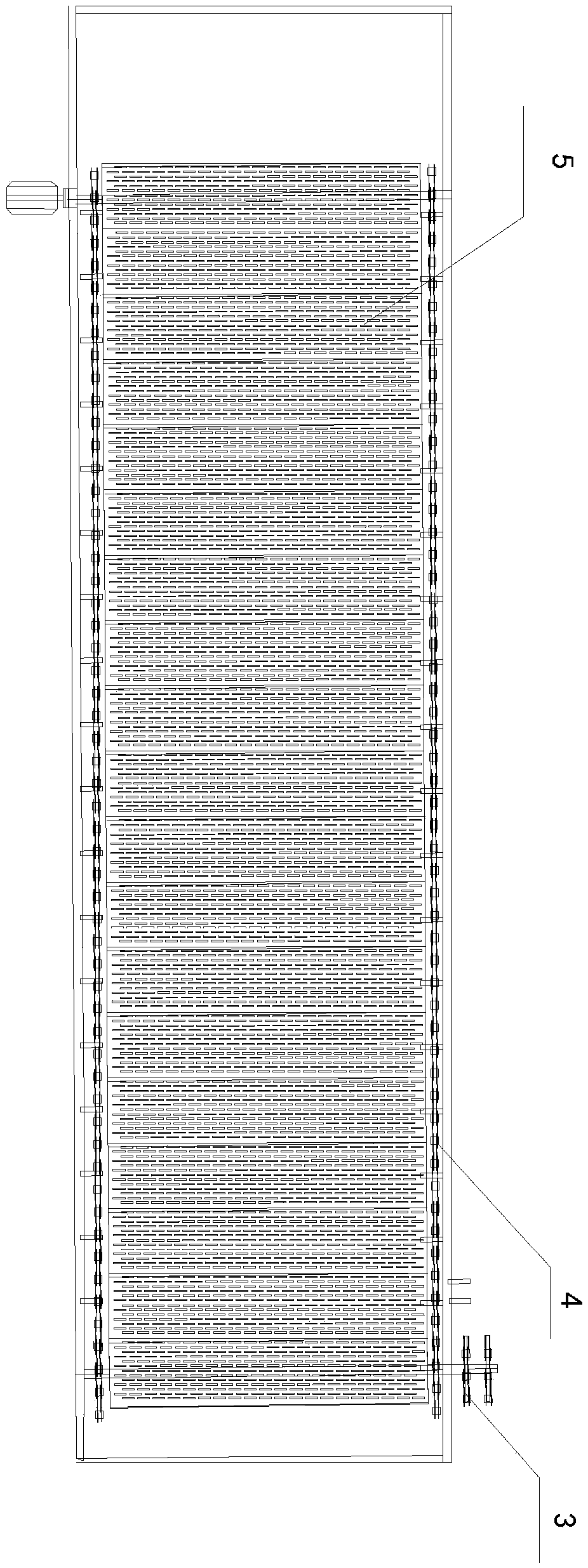

[0032] Such as Figure 1-7 A multi-layer flap type grain dryer is shown, which has a casing 1, and the casing 1 is designed for heat preservation in order to prevent heat from being conducted outward. When viewed from the outside, the cabinet 1 is a box. The interior of the cabinet 1 is divided into upper and lower parts. A horizontal partition 13 is arranged in the middle of the interior of the cabinet 1. The interior of the cabinet 1 is divided into upper and lower parts. It is a steel plate. The length of the partition 13 is less than the horizontal width of the cabinet 1, that is, there is no partition 13 in the front of the cabinet 1 (avoid the place where the grain falls), so that hot air blows in from the lower part of the partition 13 Turn the front part to the upper part to return to the host. The lower part of the casing 1 is an air inlet channel 10, correspondingly an air inlet is provided on the casing 1, and the upper part is an air outlet channel 11 correspondingl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com