Push type medicinal materials drier

A dryer and push-type technology, applied in dryers, drying solid materials, drying gas layout, etc., can solve the problems of slow drying speed, large land occupation, inability to heat medicinal materials, etc., achieving large drying capacity, convenient use, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

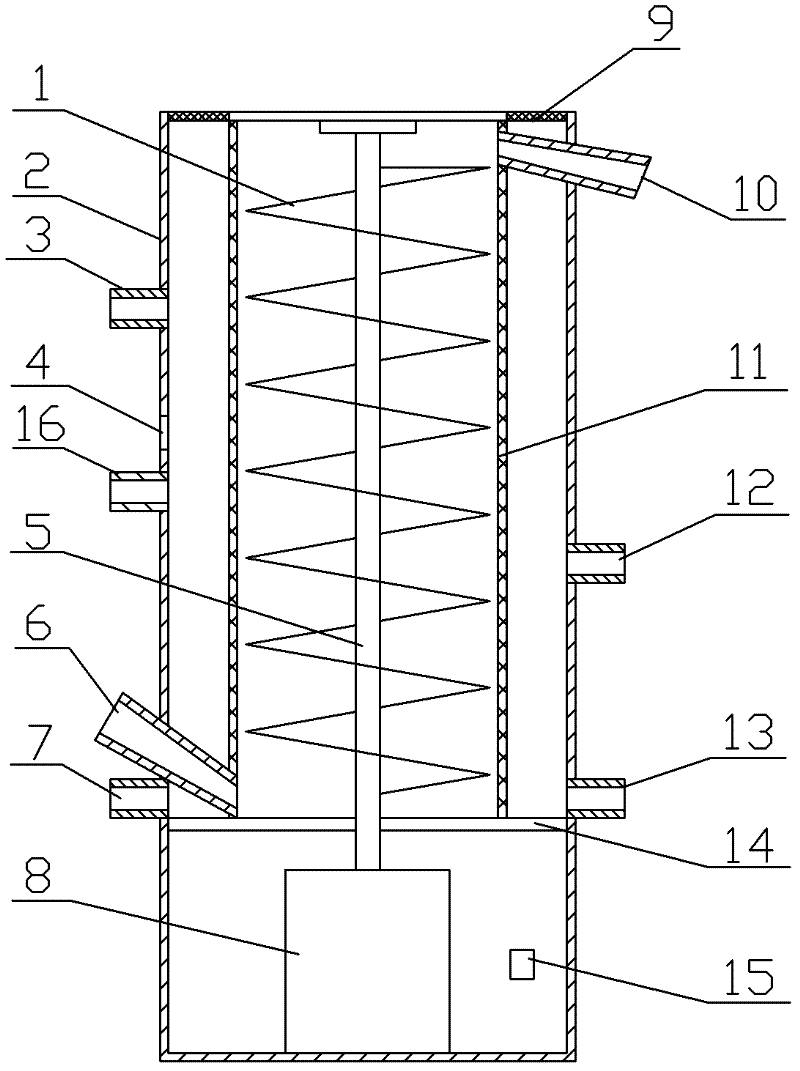

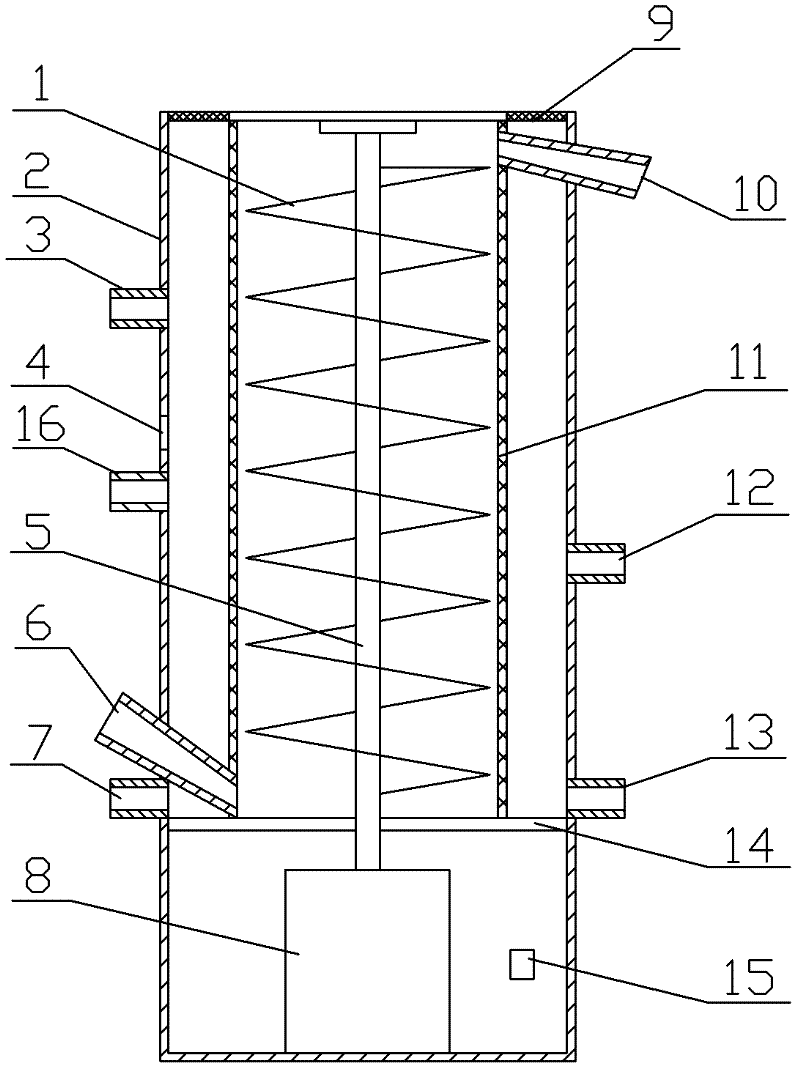

[0009] Refer to the attached figure 1 The push type medicinal material drying machine of the present invention will be described in detail below.

[0010] The push-type medicinal material dryer of the present invention comprises a shell 2, a mesh sleeve 11, a speed-regulating motor 8, a screw propulsion piece 1 and a hot air inlet, and a partition 14 is arranged inside the shell 2, and the The mesh sleeve 11 is arranged on the top of the partition 14, the speed regulating motor 8 is arranged on the bottom of the partition 14, and the rotating shaft 5 connected with the speed regulating motor 8 passes through the partition 14 and is arranged on the mesh In the shape sleeve 11, the said helical propulsion piece 1 is set on the rotating shaft 5, the said housing 2 is provided with the speed control switch 15 connected with the speed control motor 8, the said mesh sleeve 11 The lower part and the upper part are respectively provided with a material inlet 6 and a material outlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com