Drying method for abamectin crystal

A technology of abamectin and drying method, which is applied in the direction of drying solid materials, dry cargo handling, drying gas arrangement, etc., which can solve the problems of inconsistent product content, low safety and high energy consumption, so as to achieve no safety risk and ensure fast The effect of evaporation and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

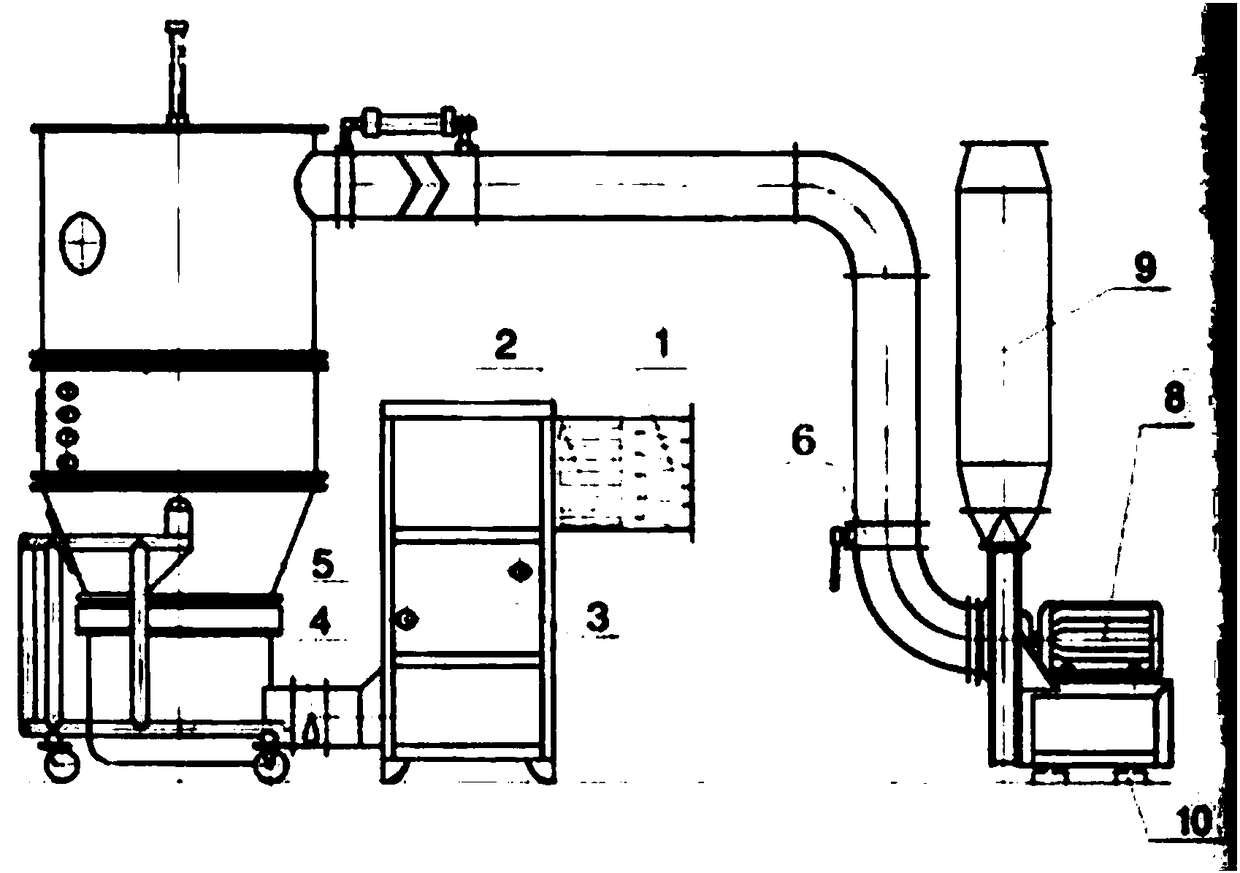

Image

Examples

Embodiment 1

[0048] The invention provides a method for drying abamectin crystals, which comprises the following steps:

[0049] (1) Push the unloading truck out, put the abamectin crystals to be dried on the wire mesh, spread them evenly, and then push the unloading truck back into the boiling dryer.

[0050] (2) Turn on the heater 3 and simultaneously turn on the induced draft fan 8 to control the temperature of the heater 3 to 115°C. At this time, the air is filtered twice through the primary filter 1 and the intermediate filter 2 and then heated by the heater 3 and enters the boiling dryer through the air inlet; the heated air is blown up from under the wire mesh, blowing the abamectin The element crystals boil and take away the moisture on the abamectin crystals. The boiling dryer is also equipped with a cooler to assist in controlling the temperature in the boiling dryer to 80°C when the temperature in the boiling dryer is too high.

[0051] (3) During the drying process, use the first an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com