A kind of cooling air-drying equipment for cable processing

A technology for cables and equipment, applied in the field of cooling and air-drying equipment for cable processing, can solve problems such as affecting the progress of work and water residue, and achieve the effects of low friction, comprehensive drying, and comprehensive cable drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

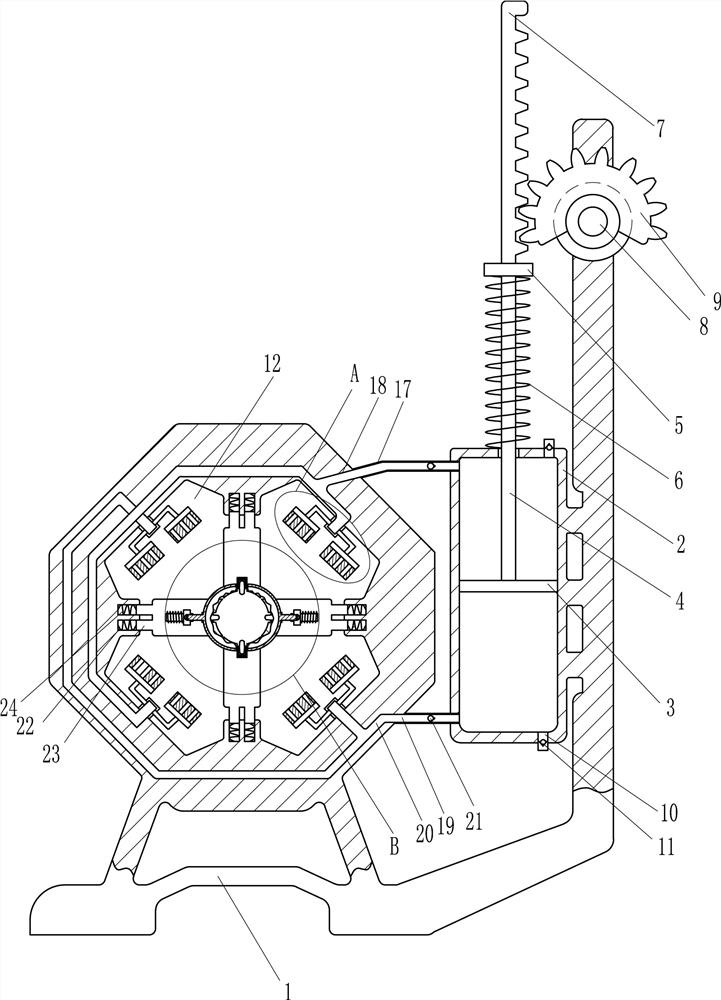

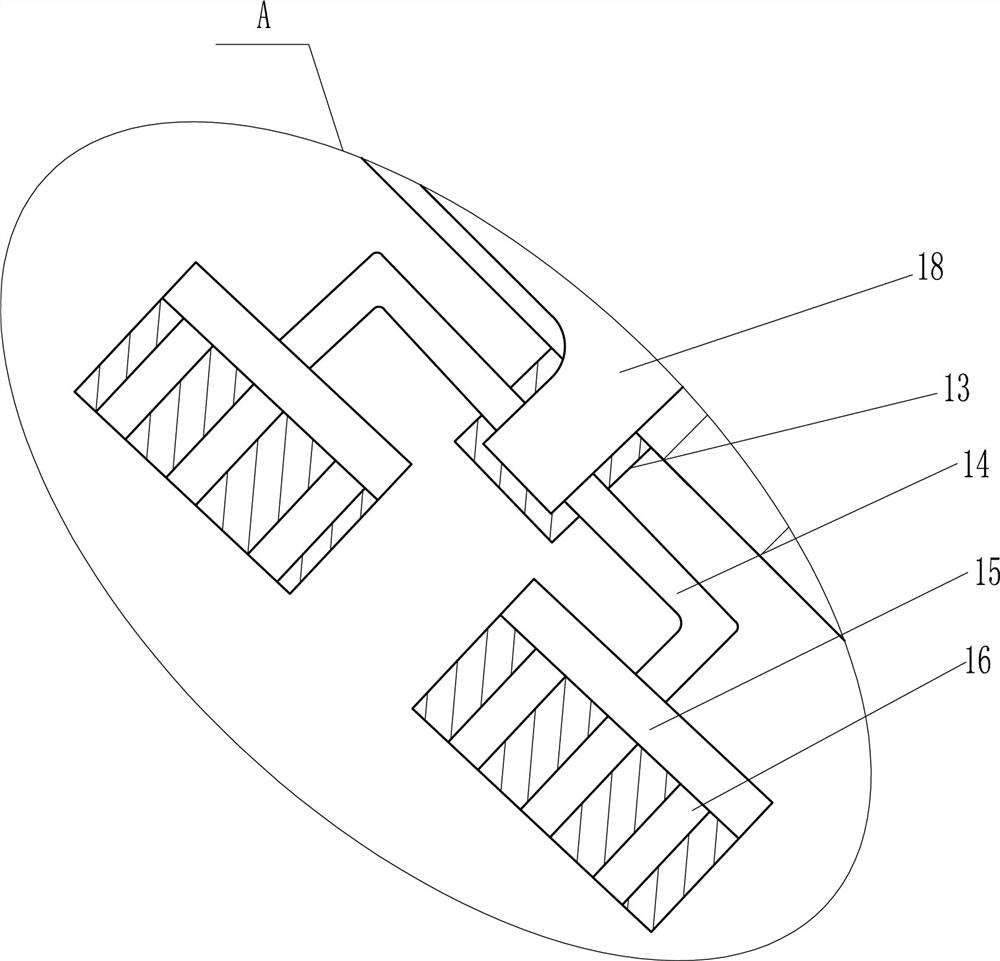

[0018] Such as figure 1 , 2 Shown in and 3, a kind of cooling and air-drying equipment for cable processing includes a special-shaped frame 1, a wind generating part, an air-drying part and a fixed part, and the right part of the special-shaped frame 1 is provided with a wind generating part that generates wind by pulling, The left part of the special-shaped frame 1 is provided with an air-drying part that is dried by blowing, and the middle part of the left part of the special-shaped frame 1 is provided with a fixing part that fixes cables by extrusion.

[0019] Such as figure 1 As shown, the wind power generation components include a cylinder 2, a piston 3, a push rod 4, a limit block 5, a first spring 6, a rack 7, a reduction motor 8, a sector gear 9 and a first one-way valve 11. The right part of the frame 1 is fixedly connected with the cylinder body 2 by bolts, the cylinder body 2 is slidingly provided with a piston 3, the top of the piston 3 is provided with a push ro...

Embodiment 2

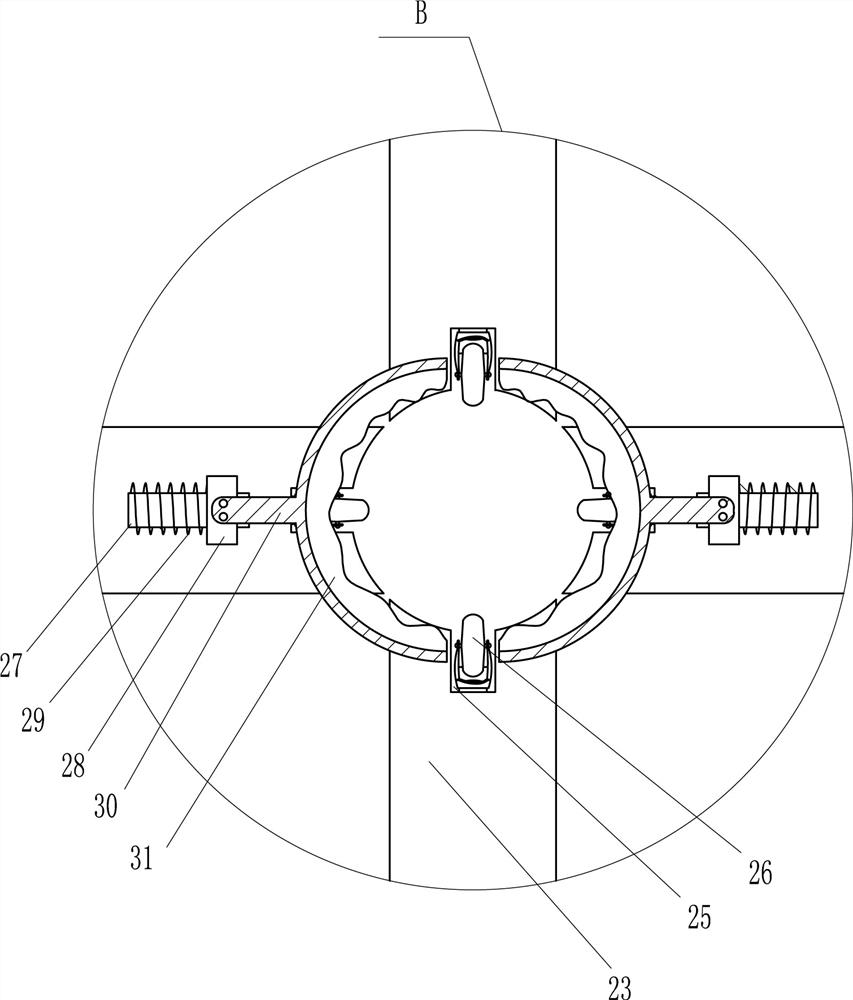

[0027] Such as image 3 As shown, on the basis of Embodiment 1, in order to dry the cable more comprehensively, it also includes a slide rail 27, a slider 28, a third spring 29, a wiping bar 30 and an absorbent cloth 31, and the front sides of the left and right fixing bars 23 are All are fixedly connected with slide rails 27 by bolts, slide rails 27 are provided with slide blocks 28 in a sliding manner, third springs 29 are provided between the outsides of slide block 28 and slide rails 27 outsides, and wipers are provided on the front sides of slide blocks 28. The rod 30 and the inner side of the wiping rod 30 are all provided with a water-absorbing cloth 31 .

[0028] The specific implementation of the above-mentioned embodiment: when the cable is air-dried, there may still be some small water droplets that have not been air-dried. The wiping bar 30 moves, the third spring 29 compresses or stretches, and after the cables are all air-dried, the slider 28 resets under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com