Rubber ingredient raw material processing method

A raw material processing and compounding agent technology, which is applied in grain processing, chemical instruments and methods, and sieving, can solve the problems of high work intensity, low efficiency, and long drying time of powdery materials, so as to improve efficiency and effect, and ensure The effect of the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

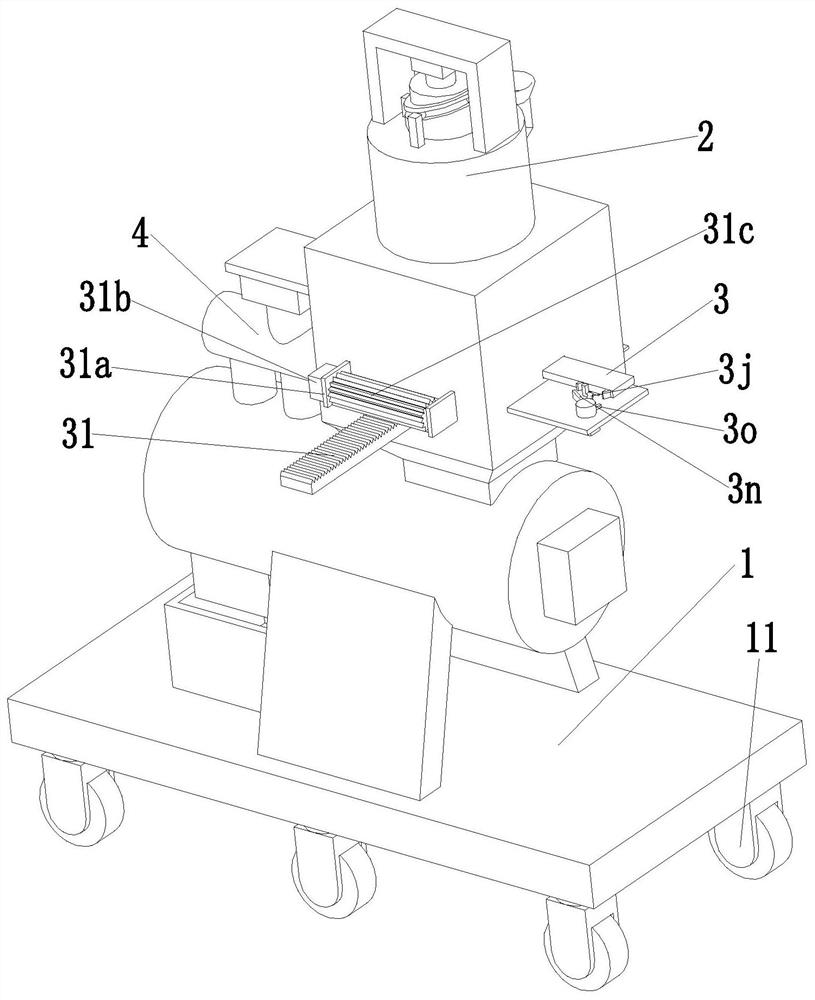

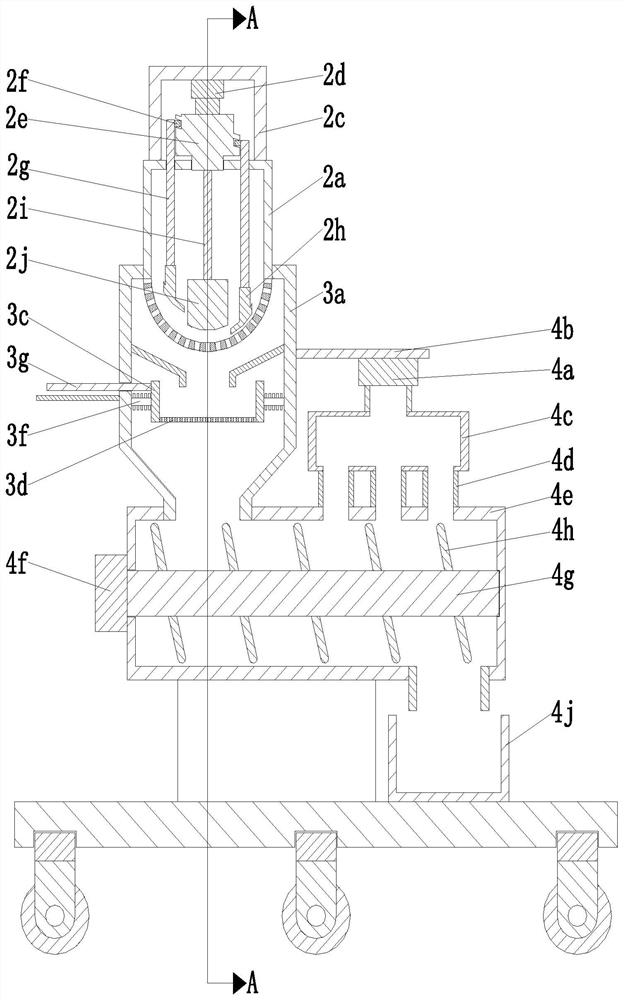

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

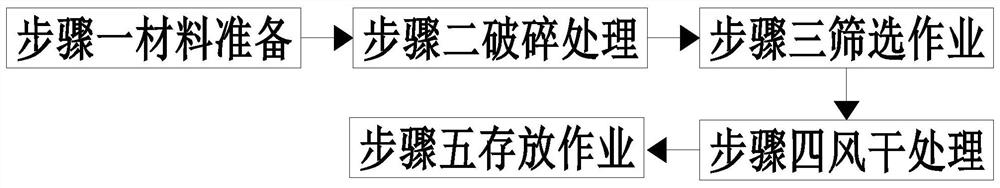

[0035] Such as Figure 1 to Figure 6 Shown, a kind of raw material processing method of rubber compounding agent mainly comprises the following steps:

[0036] Step 1, material preparation, prepare the powdery material of rubber compounding agent, obtain powdery raw material;

[0037] Step 2, crushing treatment, after the testing of the powdery raw material obtained in step 1 is completed, the powdery material after testing is ground by the grinding device 2, and the ground powdery material is obtained;

[0038] Step 3, screening operation, the screening operation is carried out on the ground powdery material obtained in step 2 through the screening device 3, and the screened powdery material is obtained;

[0039] Step 4, air-drying treatment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com