Patents

Literature

461 results about "Ferrous sulphate heptahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble organic liquid fertilizer and preparation method thereof

InactiveCN101723735APromote absorptionPromote vegetative growthClimate change adaptationBioloigcal waste fertilisersInsect pestPlant disease

The invention discloses a water-soluble organic liquid fertilizer and a preparation method thereof. The fertilizer is prepared from the following raw materials in percentage by weight: 40 to 80 percent of molasses fermentation liquid, 10 to 50 percent of biochemical potassium fulvate, 3 to 10 percent of boric acid, 2 to 8 percent of ethylene diamine tetra-acetic acid, 1 to 5 percent of heptahydrate zinc sulphate, 2 to 6 percent of manganese sulfate monohydrate, 0 to 5 percent of ferrous sulphate heptahydrate and the balance of water, wherein the sum of the raw materials is 100 percent. The production method for the fertilizer comprises the following steps: putting the molasses fermentation liquid in an amount which is one third of the formulation amount and the water into a reaction kettle, heating the mixture to 60 DEG C, and adding the ethylene diamine tetra-acetic acid into the mixture; adding the heptahydrate zinc sulphate, the manganese sulfate monohydrate and the ferrous sulphate heptahydrate into the mixture, and stirring the mixture for 30 minutes; and adding the boric acid, the residual molasses fermentation liquid and the biochemical potassium fulvate into the mixture, stirring the mixture for 30 minutes and cooling the mixture. The fertilizer is brown liquid, has multiple fertilization modes, can prevent multiple plant diseases and insect pests, increase the yield of crops, improve the quality and increase the yield by 10 to 20 percent, and makes a contribution to the development of organic agriculture.

Owner:SHAANXI HUAXIA AGRI TECH DEV

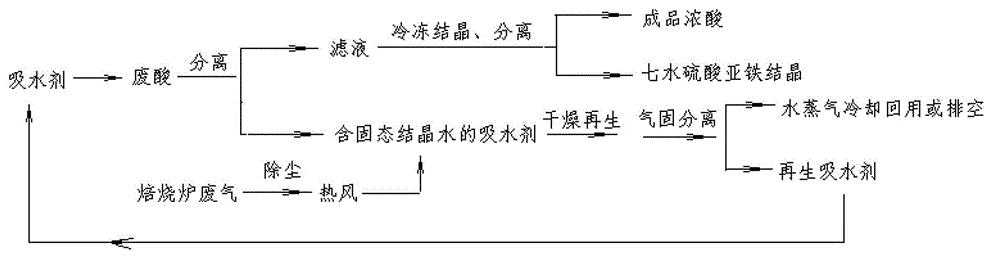

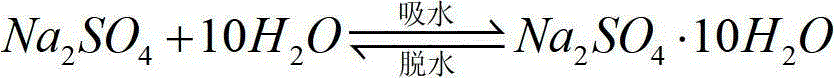

Method for concentrating waste sulfuric acid by utilizing waste heat of titanium dioxide calcinator

InactiveCN102910594ASolve manySolve process problemsSulfur compoundsEnergy inputLiquid waterOperability

The invention discloses a method for concentrating waste sulfuric acid by utilizing waste heat of a titanium dioxide calcinator, comprising the following steps: at normal temperature and pressure, proper amount of water absorbent is added to titanium dioxide waste acid, liquid water is dissolved out in the form of solid crystal water through the water absorbent, filtrate after solid-liquid separation is cooled, iron vitriol in the solution is crystallized and dissolved out, and the acid liquid is further concentrated; the two steps are repeatedly carried out until the concentration of sulfuric acid in the final filtrate reaches more than 60%, and then the final filtrate is utilized in the acid hydrolysis procedure; and the water absorbent is dehydrated and dried to be regenerated by taking dustproof tail gas of the calcinator, and the steam generated in the drying and regeneration is cooled and flows back to technological process as washing water in titanic acid rinsing or is drained. The method provided by the invention solves the problems of more equipment, long flow and easy blockage in the existing technology, and the equipment investment and operating cost are reduced; and the water absorbent is recycled after being regenerated, so that the energy is saved, the consumption is reduced, and the efficiency is obvious; no wastewater, waste gases and residues are generated in the whole technology, the operability is strong, the productivity of equipment is high, the flow is simple, the investment is less, the cost is low, energy is saved, emission is reduced, and the benefit is obvious.

Owner:黄正源

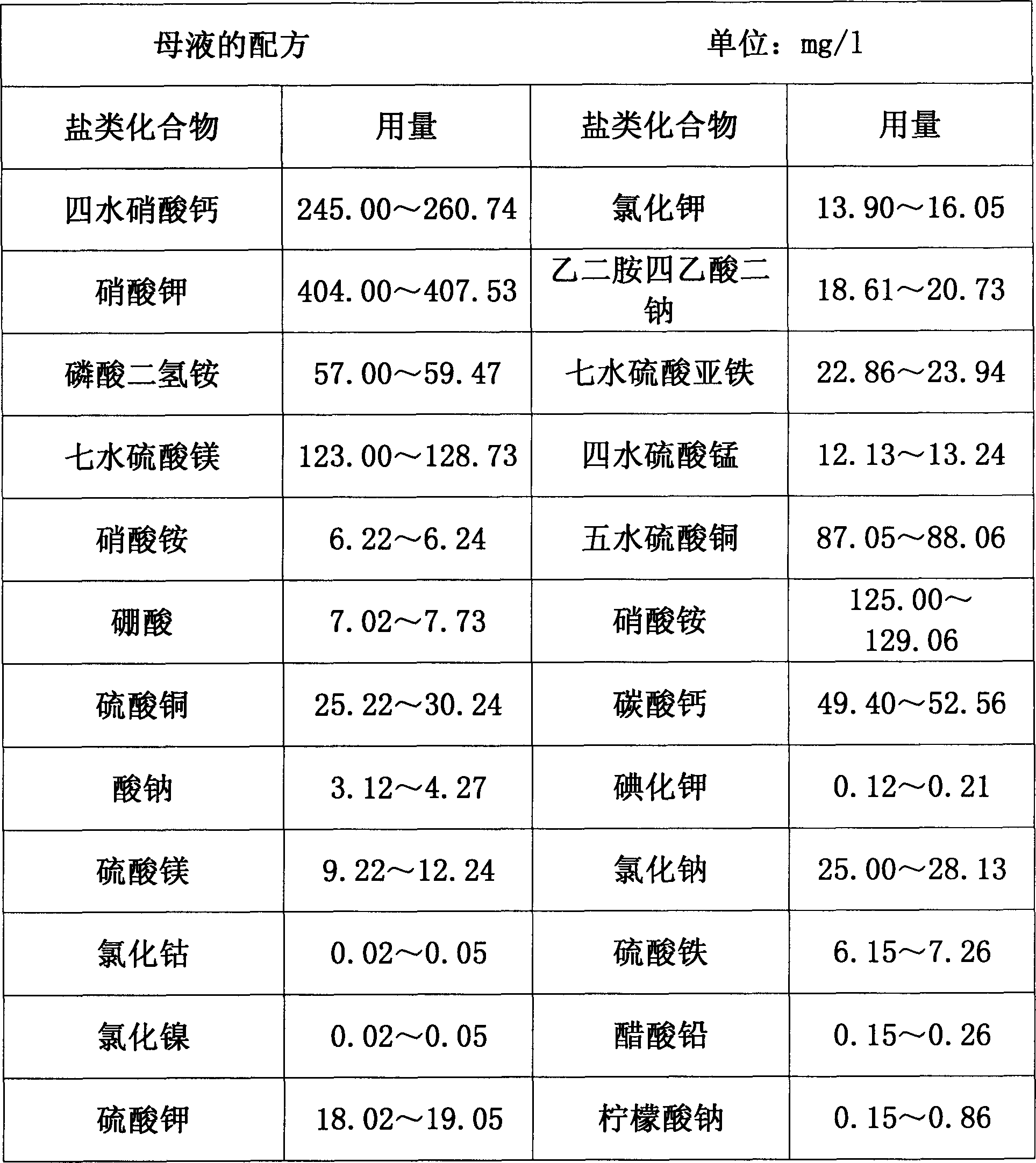

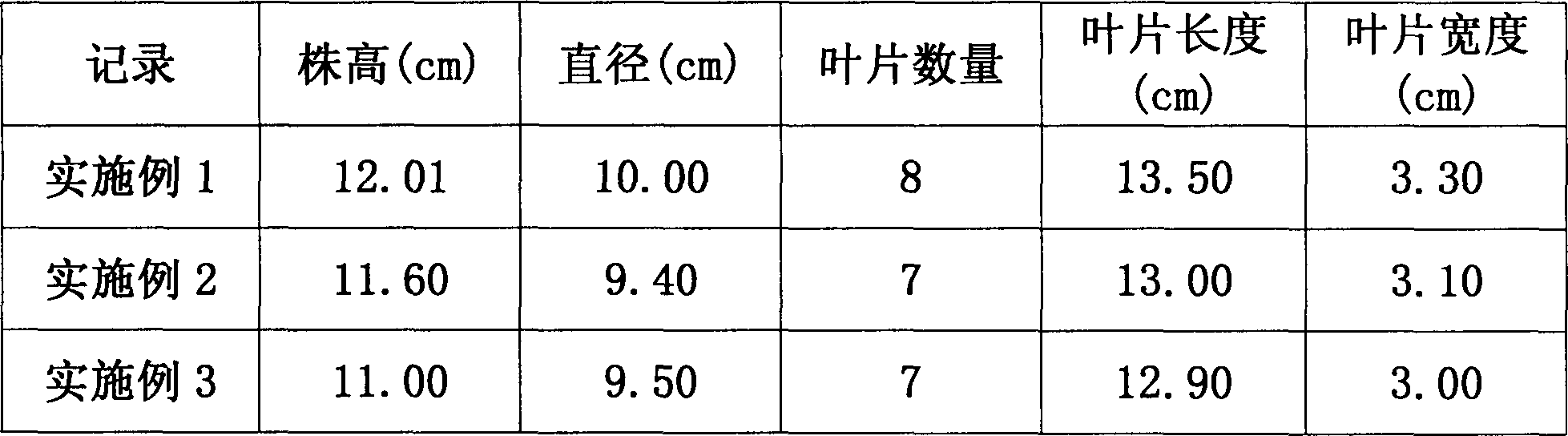

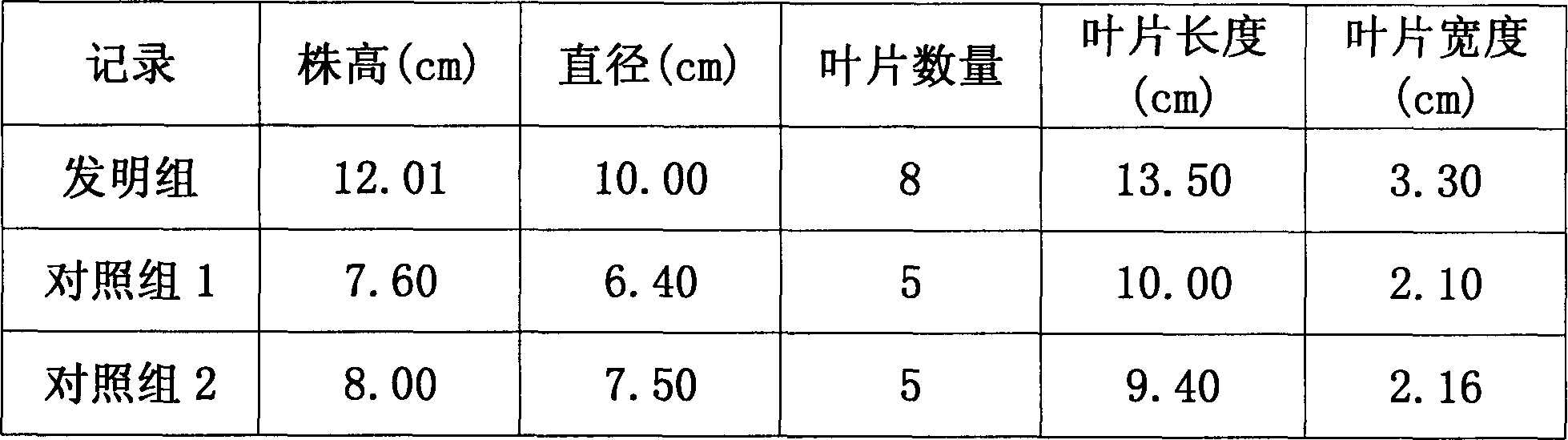

Aqueous culture method of anoectochilus

InactiveCN102100171AAbsorb evenlyAdequately meet nutritional needsCultivating equipmentsSoilless cultivationBiotechnologyCalcium nitrate tetrahydrate

The invention relates to an aqueous culture method of anoectochilus. In the method, anoectochilus germchits are cleaned and sterilized, transplanted in a culture dish and cultured in a culture groove filled with an aqueous culture solution; each 10L of aqueous culture solution contains the following components: 650 to 800mg of calcium nitrate tetrahydrate, 50 to 60mg of ammonium nitrate, 280 to 350mg of potassium nitrate, 100 to 130mg of potassium dihydrogen phosphate, 350 to 380mg of magnesium sulfate, 0.5 to 0.8mg of potassium iodide, 2 to 5mg of manganese sulfate, 0.2 to 0.3mg of sodium molybdate, 0.1 to 0.2mg of cobalt chloride, 2 to 4mg of boric acid, 0.5 to 1mg of zinc sulfate, 0.3 to 0.5mg of copper sulfate and 3 to 5ml of iron salt solution, wherein the iron salt solution is prepared by mixing water, green vitriol and ethylenediamine tetraacetic acid disodium. The method has the advantages of lowering production cost, simplifying production process, improving the growth of anoectochilus plants and improving the survival rate of anoectochilus plants.

Owner:福建永安天奇健金线莲生态实业有限公司

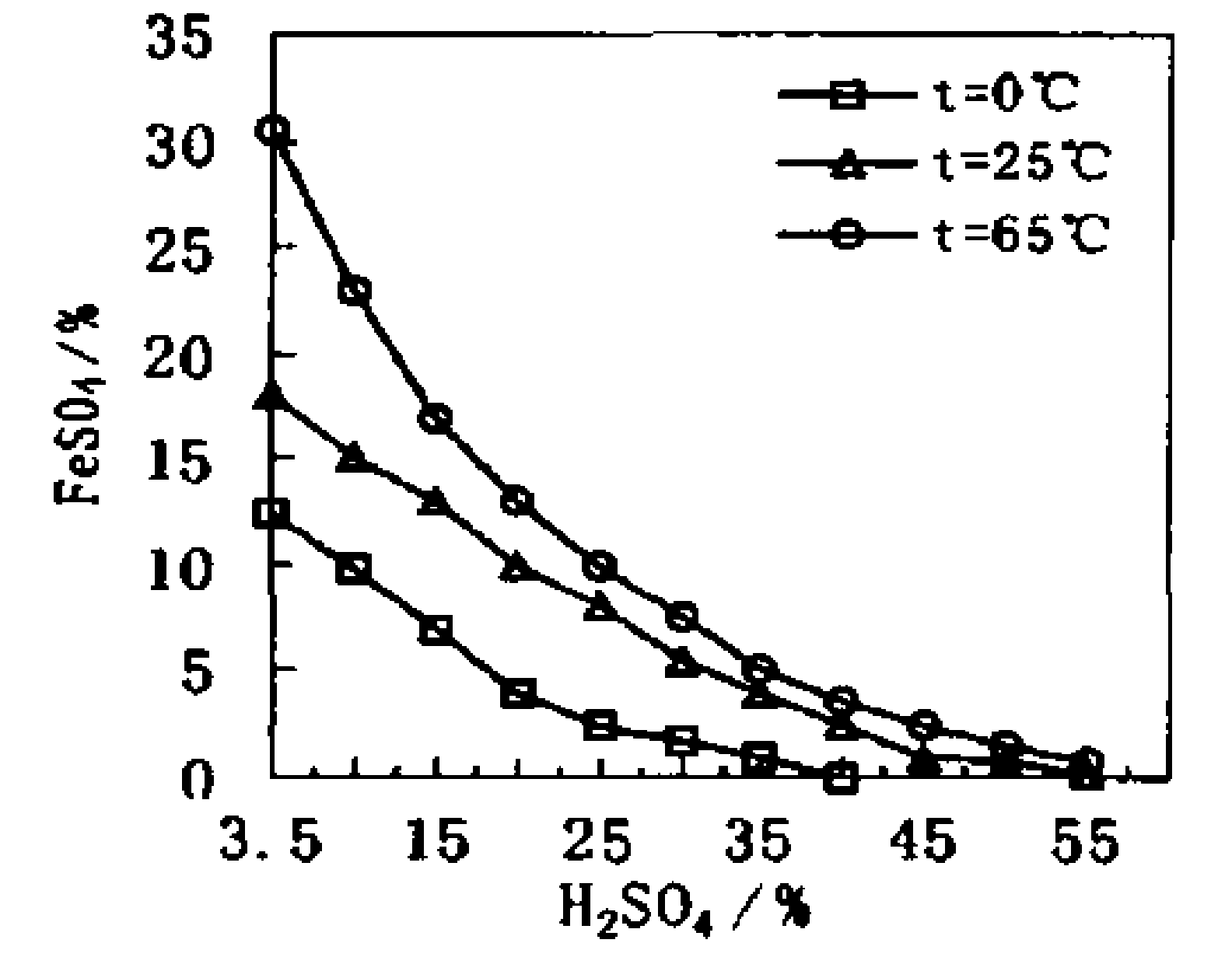

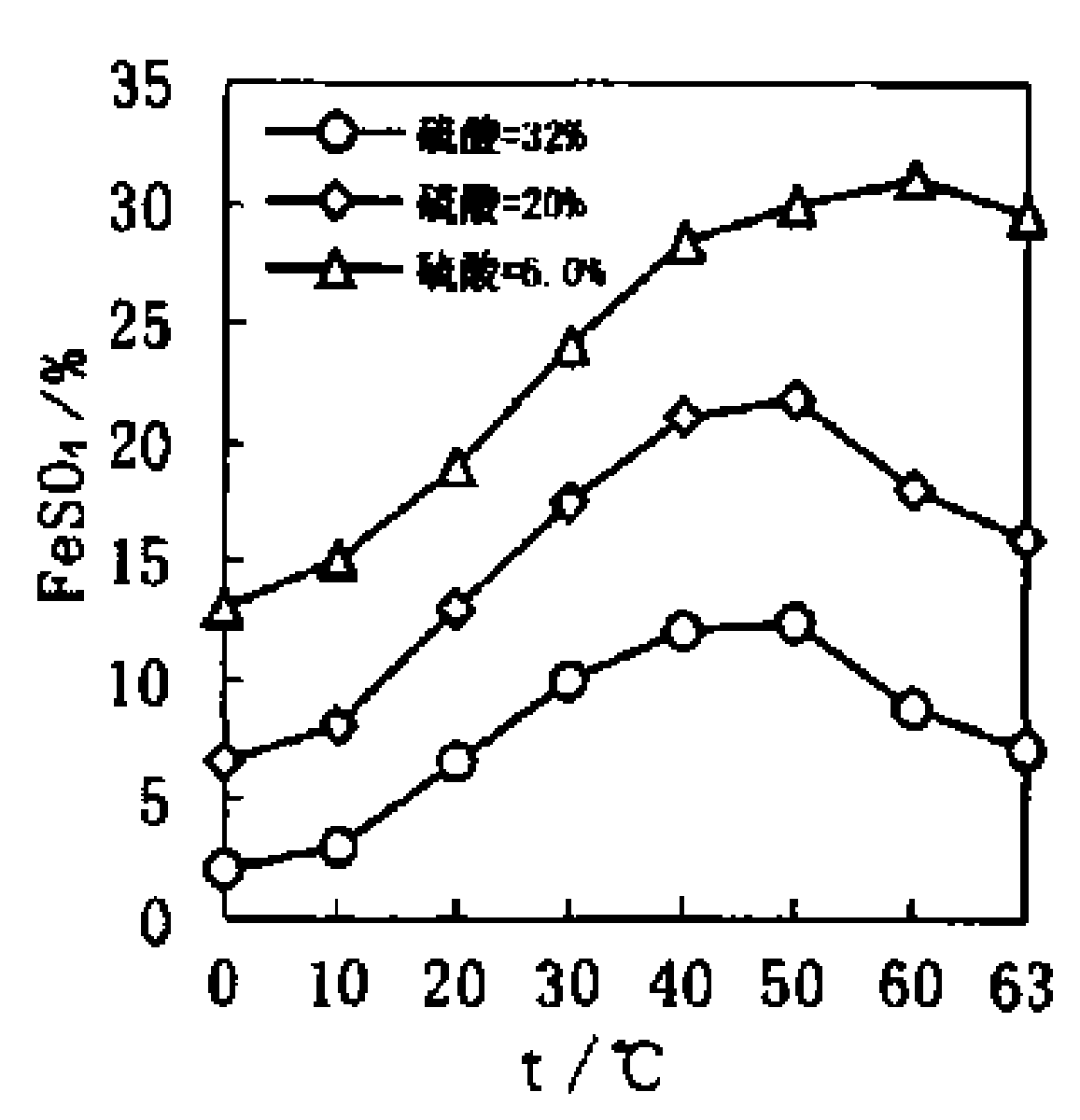

Method for purifying ferrous sulfate heptahydrate byproduct in titanium white production

The invention discloses a method for purifying a ferrous sulfate heptahydrate byproduct in titanium white production, which comprises the following steps of: (1) adding a solvent into the byproduct in titanium white production, heating to the temperature of between 65 and 105 DEG C, and stirring for dissolution to prepare saturated solution; (2) adding iron powder at the temperature of between 95 and 105 DEG C; (3) adding phosphoric acid and heating at the temperature of between 95 and 105 DEG C for 10 to 20 minutes; (4) cooling the mixture to the temperature of between 80 and 90 DEG C, adding sulfide, stirring for 30 to 60 minutes, and adding sulphuric acid; (5) adding polyacrylamide, stirring for 3 to 10 minutes, precipitating, and filtering to obtain ferrous sulfate solution; and (6) cooling and crystallizing the ferrous sulfate solution, filtering and separating to prepare ferrous sulfate crystals. The content of the ferrous sulfate heptahydrate prepared is over 20.1 percent, and the content of titanium, lead, cadmium, chromium and magnesium is less than 10ppm based on the lead. The process is simple and the process flow is short.

Owner:LOMON BILLIONS GRP CO LTD

Agent special for bioleaching municipal sludge and production process thereof

ActiveCN101913743AMeet growth needsPromote growthSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludgeDipotassium phosphate

The invention provides an agent special for bioleaching municipal sludge, which belongs to the technical field of engineering technology. The agent for bioleaching the municipal sludge contains a carbon source and nutrient substances, which are needed by the growth of thiobacillus and acid-resistant heterotrophic bacteria, including ammonium sulfate, potassium chloride, dipotassium phosphate, calcium nitrate, magnesium sulfate, vitamins, trace elements, carbon source substances, sodium thiosulfate, sulphur powder, finished pyrite or ferrous sulfate heptahydrate, surfactant, dressing and the like. The production process comprises the following steps of: adsorbing a liquid material on diatomite serving as the dressing; and fully mixing the liquid material, other solid materials and the diatomite serving as the dressing to obtain the agent. The agent can meet the growth demands of various microorganisms in a bioleaching composite microorganism at the same time and greatly improve sludge bioleaching efficiency.

Owner:NANJING AGRICULTURAL UNIVERSITY

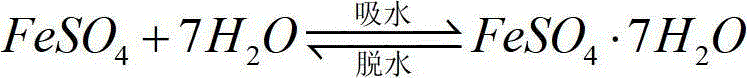

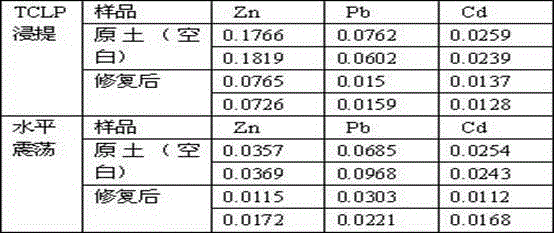

Calcium-based heavy metal soil repairing agent and preparation method

ActiveCN104804747ASolve resource problemsAchieve fixOrganic fertilisersSoil conditioning compositionsCalcium biphosphateSodium Bentonite

A calcium-based heavy metal soil repairing agent comprises the following materials by mass: 30 to 85 percent of recovered dust, 0.5 to 20 percent of industrial FeSO4.7H2O, 5 to 40 percent of bentonite, 1 to 20 percent of calcium humate, and 1 to 30 percent of calcium phosphate. The Ca-based heavy metal soil repairing agent is prepared according to a method comprising the following steps: milling bentonite into particles of 50 meshes or more; mixing industrial FeSO4.7H2O, bentonite, calcium humate, calcium phosphate and recovered dust to obtain a mixture I; stirring the mixture I to be uniform; adding 1 to 10 percent of water; stirring for 1 to 2 hours for mixing to obtain a mixture II; allowing the mixture II to stand still for 72 hours or longer to obtain the calcium-based heavy metal soil repairing agent.

Owner:HUNAN HENGSHAN BICHENG CALCIUM IND CO LTD

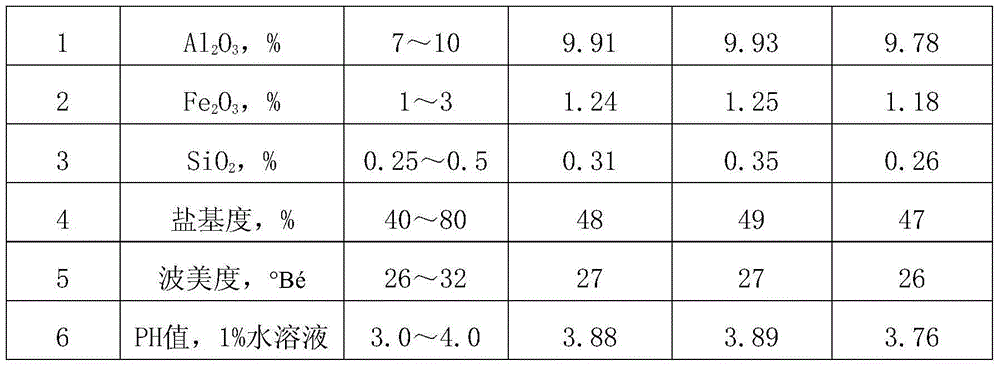

Preparation method of polymeric aluminum ferric sulfate flocculating agent (liquid)

InactiveCN102515330AWide variety of sourcesReduce manufacturing costWater/sewage treatment by flocculation/precipitationWater bathsIron(III) sulfate

The invention discloses a preparation method of polymeric aluminum ferric sulfate. The preparation method comprises the following steps of: with ferrous sulfate heptahydrate as industrial waste of titanium white as a main raw material, adding water to dissolve and adding concentrated sulfuric acid to acidize; then adding industrial aluminum sulfate to heat and stir under the condition that the bath temperature is 60-100 DEG C; stirring and adding concentrated nitric acid to oxidate; and carrying out polymerization for 30-60 min to obtain the polymeric aluminum ferric sulfate. The preparation method has the advantages of simple process, low cost and short reaction period. The flocculation performance of the polymeric aluminum ferric sulfate is better than that of the traditional industrial product and can be widely applied to feed water treatment and sewage treatment.

Owner:CHONGQING UNIV

Specialized biological compound fertilizer for grape

The invention discloses a specialized biological compound fertilizer for grape. A first formula is that a total amount of nitrogen phosphor and potassium is 30% with a ratio of 1: 0.8 : 1.2; and the proportion (by weight) of each raw material is as follows: 62.8 parts of fresh semi-dried chicken manure, 0.2 part of a calcium magnesium phosphate fertilizer, 23.8 parts of potassium fulvic acid, 2 parts of borax, 1 part of copper sulfate pentahydrate, 1 part of zinc sulfate heptahydrate, 1 part of ferrous sulfate heptahydrate, 3.2 parts of amino acids, 2 parts of microbial agents, 1 part of a synergist and 2 parts of a conditioner. A second formula is that a total amount of nitrogen phosphor and potassium is 25% with a ratio of 1: 0.8 : 1.38; and the proportion (by weight) of each raw material is as follows: 76 parts of fresh semi-dried chicken manure, 4 parts of potassium sulphate, 2 parts of amino acid chelated (complexed) zinc, boron, copper and ferrum, 8.5 parts of nitrohumate,3.5 parts of amino acids, 3 parts of a microbial preparation, 1 part of a synergist and 2 parts of a conditioner. A product is obtained by stirring the above materials uniformly, spray granulating, and drying at a low temperature or air drying.

Owner:NANTONG ZHONGKE RUIZHI TECH SERVICE

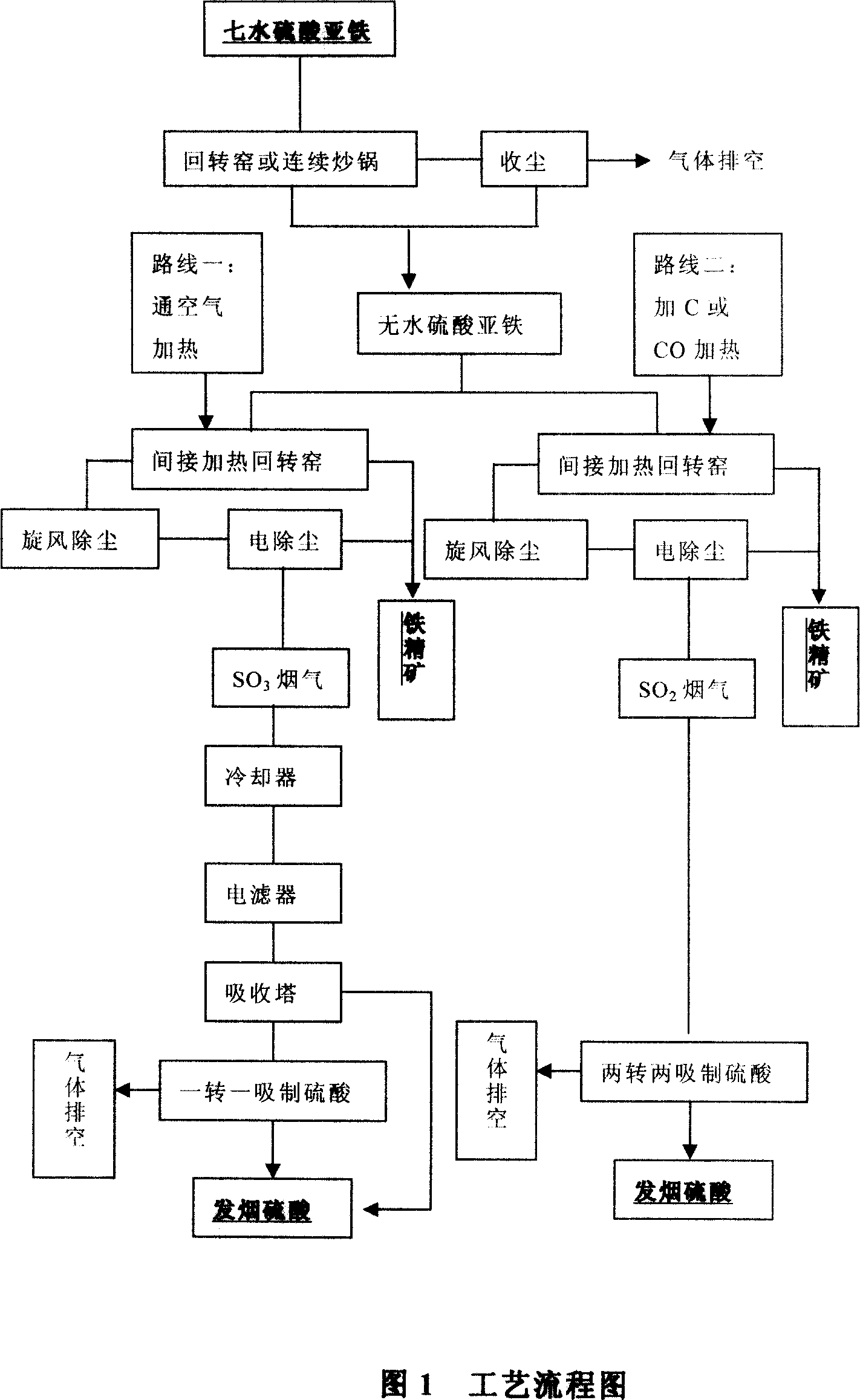

Method for producing vitriol and iron ore concentrate using ferrous sulfate

InactiveCN1994868AReduce adverse effectsAchieve mass productionSulfur-trioxide/sulfuric-acidFerric oxidesTitanium oxideMaterials science

The invention discloses a manufacturing method of sulfuric acid and fine ferric ore based on ferrous sulfate heptahydrate as by-product of titanium oxide, which is characterized by the following: heating anhydrous ferrous sulfate in the rotary kiln at 700-1000 deg. c; decomposing to obtain fine ferric ore and sulfur oxide gas under reducing atmosphere; using normal two-rotation two-adsorption technique to make sulfuric acid; purifying flue gas for sulfur trioxide and little of sulfur dioxide; adsorbing sulfur trioxide through concentrated sulfuric acid to produce fuming nitric acid; making residual sulfur dioxide gas into normal one-rotation one-adsorption technique to make sulfuric acid.

Owner:KUNMING UNIV OF SCI & TECH

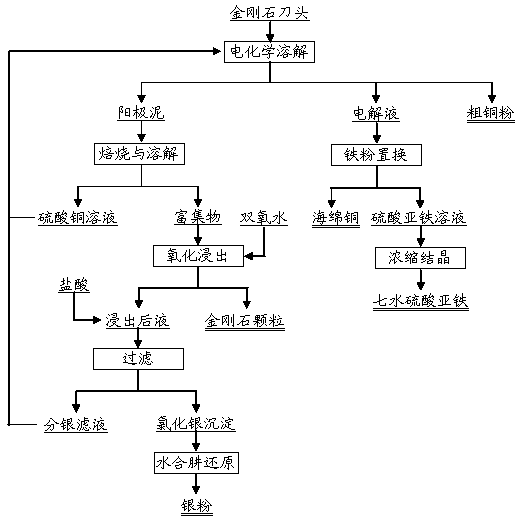

Method for processing waste copper/iron-based diamond tool bit

InactiveCN104046785AEfficient separationRealize closed loopProcess efficiency improvementIron sulfateClosed loop

The invention provides a method for processing waste copper / iron-based diamond tool bit. The method comprises the following steps: firstly, electrochemically dissolving the waste diamond tool bit in a sulfuric acid system so that most part of copper and iron are dissolved into the solution, while silver, diamond and the like are enriched into anode mud; secondly, roasting and oxidizing the anode mud and then adding the oxidized anode mud to the sulfuric acid so that the residual most part of copper is dissolved; next, adding the rest undissolved copper, silver and diamond particles to the sulfuric acid solution of hydrogen peroxide for further oxidizing leaching, recovering the diamond particles which are not dissolved, precipitating the silver in the solution by use of the hydrochloric acid and reducing the hydrazine hydrate to generate simple substance silver powder; finally, after displacing copper with iron powder, concentrating and crystalizing the electrolyte to directly prepare iron sulfate heptahydrate. The recovery rate of the copper is above 96%, while the recovery rate of the diamond particles and the silver is above 99%; the industrial-grade iron sulfate heptahydrate is directly produced, the recovery rate of iron is greater than 98%, closed-loop circulation can be realized, the production labor intensity is low and the method is environmental friendly.

Owner:CENT SOUTH UNIV

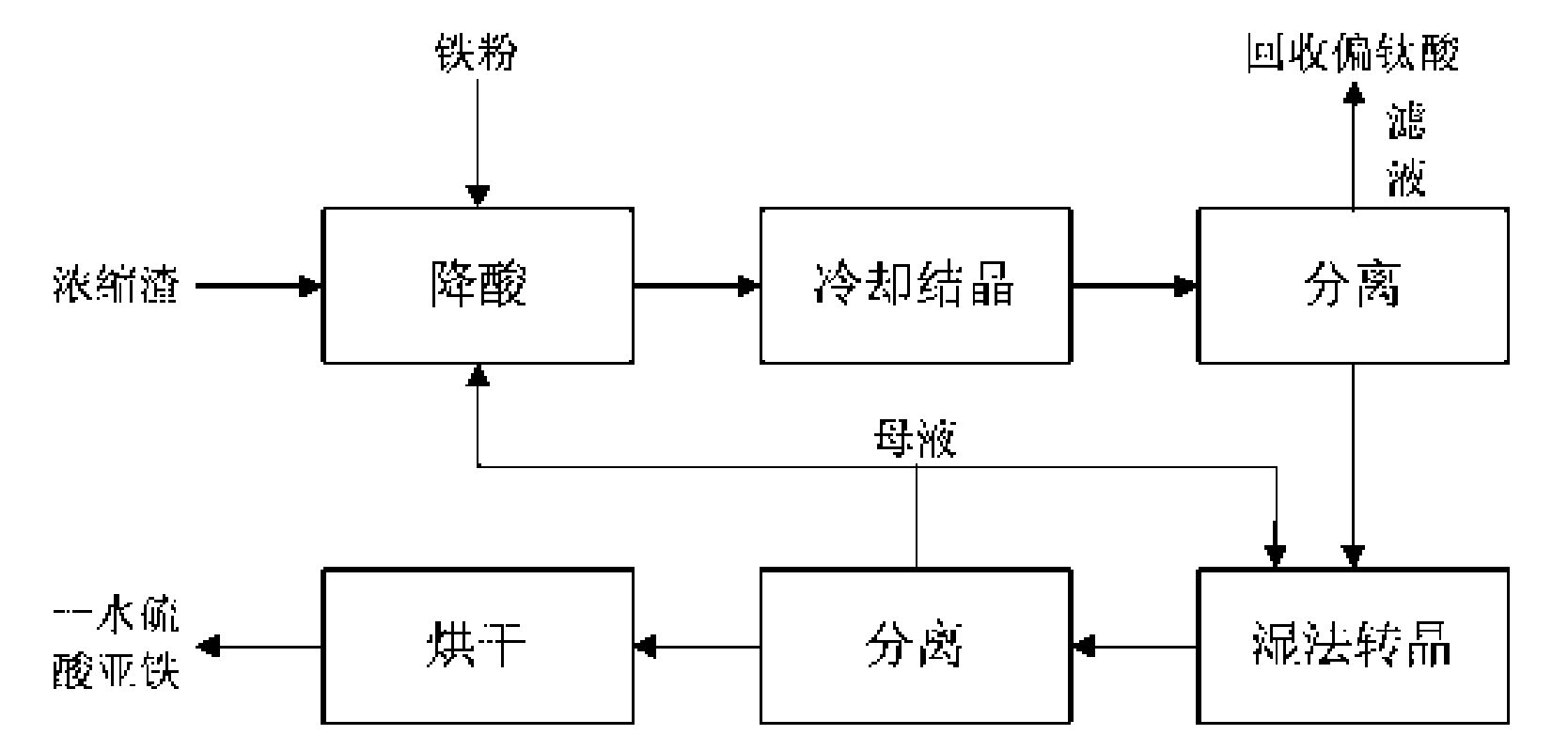

Method for producing feed grade ferrous sulfate monohydrate from titanium pigment waste acid condensed slag

The invention discloses a production method of feed grade ferrous sulfate monohydrate. Titanium white waste acid condensed slag is used as the raw material, and is subject to the processes of deacidification, pexitropy, separation, crystal transform and the like to produce the feed grade ferrous sulfate monohydrate, thereby realizing the comprehensive utilization of the titanium pigment waste acid condensed slag as the byproduct for the sulfuric acid method. The method comprises the following steps: mixing mother solutions generated in the ferrous sulfate monohydrate production processes by condensed slag and wet method, using iron powder to reduce the sulfuric acid content to 4% or so, slowly cooling and crystallizing the slurry to generatecoarse ferrous sulfate heptahydrate crystals, and separating impurities from the ferrous sulfate by using the particle size differences between the ferrous sulfate heptahydrate crystals and the impurity particles, thereby purifying the ferrous sulfate in the condensed slag and widening the application field of the condensed slag. The ferrous sulfate heptahydrate is transformed into ferrous sulfate monohydrate at high temperature to produce the qualified feed grade ferrous sulfate monohydrate in huge market demands, thereby changing the waste slag into valuable resources.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Method for removing nitrate nitrogen in water body

InactiveCN103964550AHigh removal rateLarge specific surface areaWater/sewage treatment using germicide/oligodynamic-processPotassium borohydrideNitrate nitrogen

The invention provides a method for removing nitrate nitrogen in a water body, which comprises the following steps: 1, adding ferrous sulfate heptahydrate, polyethyleneglycol and graphene into deoxidized distilled water, mixing to prepare a suspension, then adding a potassium borohydride solution into the suspension, stirring, filtering, and washing to obtain graphene loaded nano iron; and 2, uniformly mixing the graphene loaded nano iron and a water body to be treated, and then performing constant-temperature oscillation treatment, thus ensuring that the removal rate of nitrate nitrogen in the water body is above 85%. According to the invention, the nitrate nitrogen in the water body is removed by using the graphene loaded nano iron, so that the method is simple in technical process, low in production cost and easy to realize popularization and application, maximally keeps the favorable characteristics of graphene and nano iron, and can efficiently and quickly remove the nitrate nitrogen in the water body, thereby obviously improving the nitrate nitrogen removal effect and having wide application value.

Owner:CHANGAN UNIV

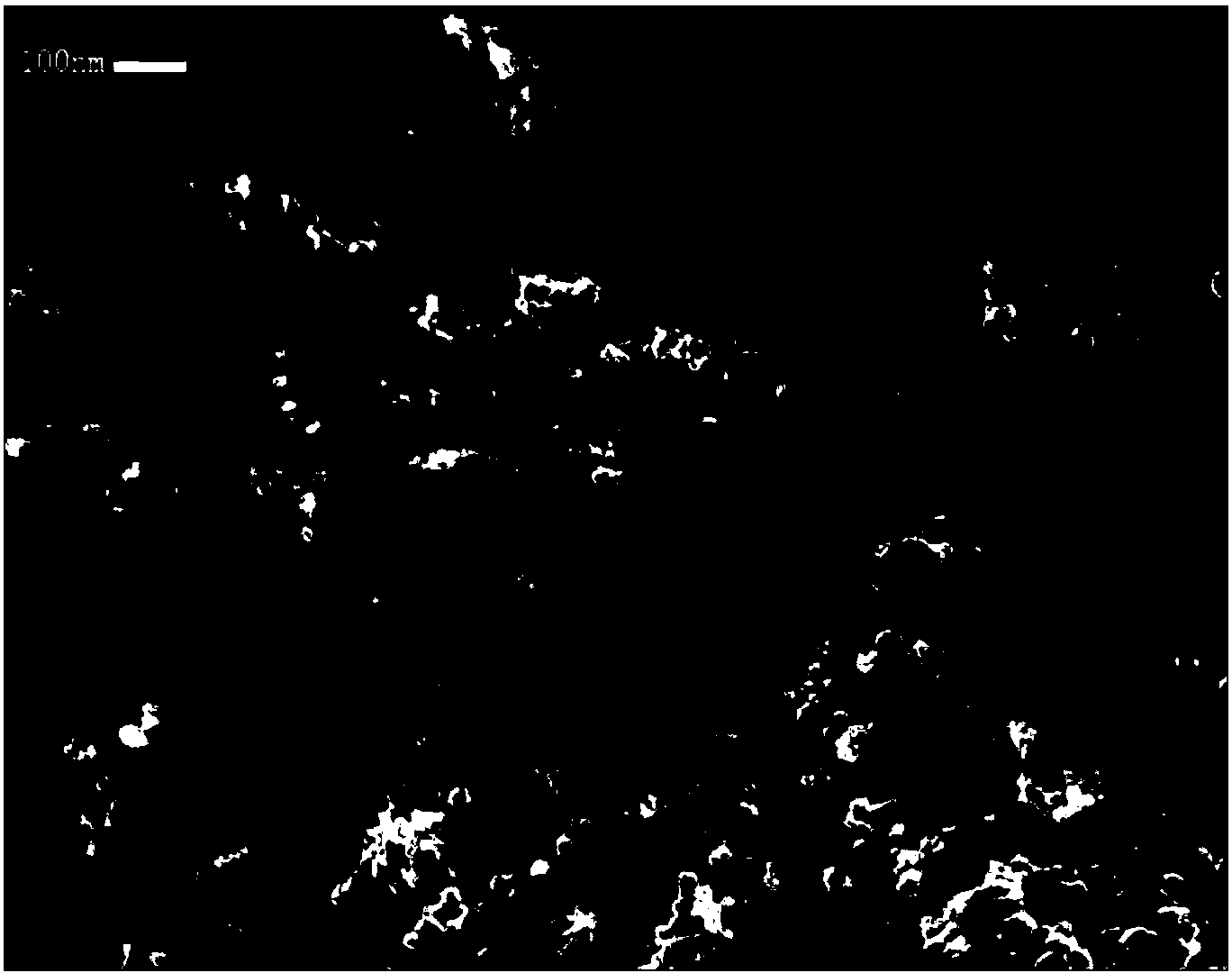

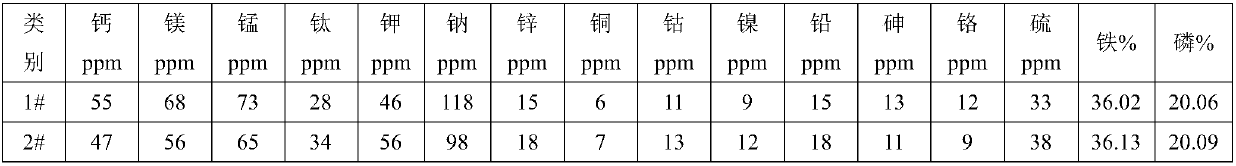

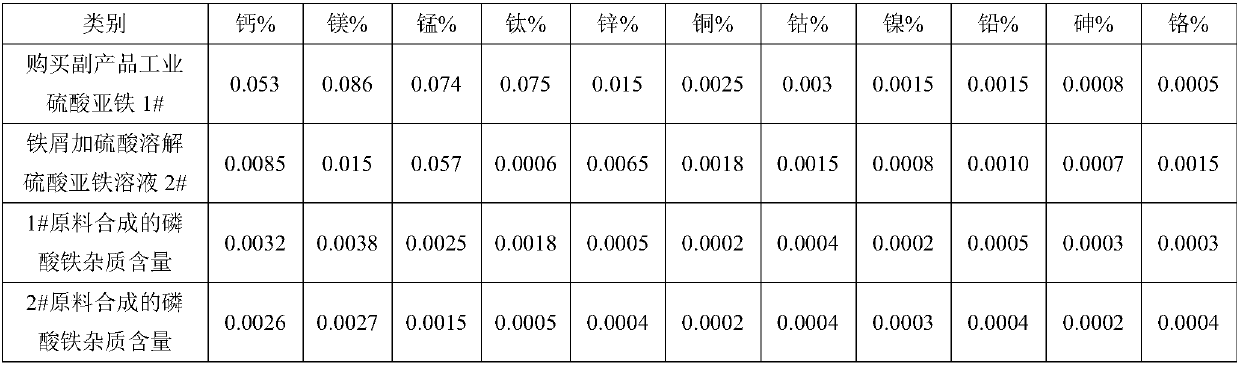

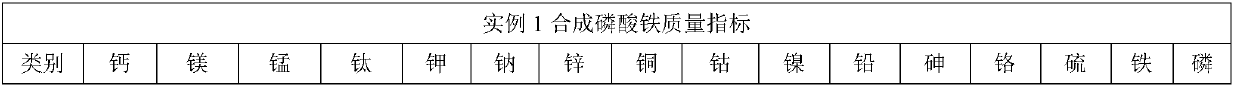

Production method for high-purity ferric phosphate

The invention relates to a production method for high-purity ferric phosphate. Ferrous sulfate solution dissolved by a raw material, i.e., iron sulfate heptahydrate crystal used for producing ferric phosphate or ferrous sulfate solution generated by the reaction of iron and sulfuric acid is subjected to three-time impurity-removal and purification processing; the purified ferrous sulfate solutioncarries out oxidation reaction with hydrogen peroxide to generate ferric sulfate solution; under the condition of emulsifier, phosphate solution is dripped to react to synthesize ferric phosphate precipitates, or phosphoric acid is added into the purified ferric sulfate solution; after evenly mixing, hydrogen peroxide is added for oxidation, emulsifier is added, and ferric phosphate precipitates are synthesized; then, the ferric phosphate precipitates are aged, rinsed, filtered and dried to prepare aqueous or anhydrous high-purity ferric phosphate. The synthesized high-purity ferric phosphatehas an impurity index that potassium, sodium, calcium, magnesium and manganese are less than 50ppm, titanium and aluminum are less than 20ppm, and heavy metal ions, i.e., cobalt, nickel, zinc, copper,lead, chromium are less than 5ppm. By use of the production method, the problems of low purity and more impurity of a product obtained in the prior art are overcome.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

Method for making positive material positive ferric phosphate of lithium battery

InactiveCN101237042AHigh activityImprove performanceElectrode manufacturing processesPhosphatesSulfate radicalsPhosphate

The present invention discloses a preparation method for ferric orthophosphoric acid which is lithium battery anode material, using 100 portions of ferrous sulfate heptahydrate, 41.8-48.8 portions of phosphoric acid, 21.8-38.5 portions of hydrogen peroxide or 6.36-10.0 portions of sodium chlorate, 12.0-12.5 portions of sodium hydroxide or 15.0-18.0 portions of sodium carbonate and 500-1000 portions of water for preparation. The ferrous sulfate heptahydrate, the phosphoric acid and the water are compounded into solution in a reaction vessel; the hydrogen peroxide or the sodium chlorate is added into the solution; the temperature of the solution is 50-55 DEG C, and the sodium hydroxide or the sodium carbonate is added into the solution under the condition of stirring; then the solution temperature is increased to be between 85 DEG C and 95 DEG C; the temperature is kept for 5-15 hours, and in the meantime, the solution is led into a swirler to be separated till the sulfate radical content in products is less than 0.2 percent; the solution is cooled to be at 50 DEG C for carrying out the solid-liquid separation of the products and liquid; the particle diameter of obtained ferric orthophosphoric acid is 1-2 mu m; the specific surface area of the ferric orthophosphoric acid is 48-55.5m2 / g; the tap density of the ferric orthophosphoric acid is greater than 1.6g / cm3. When the ferric orthophosphoric acid prepared with the method is used as raw material for preparing lithium iron phosphate via solid phase synthesis, the lithium battery anode material with excellent performance can be obtained.

Owner:河南瑞贝佳生物科技有限公司

Plant infusion nutrient solution and preparation method thereof

InactiveCN101811909AImprove stress resistanceHigh activityFertilizer mixturesCalcium nitrate tetrahydrateHigh absorption

The invention discloses plant infusion nutrient solution and a preparation method thereof and aims to provide nutrient solution which can be directly infused into the plants, stimulate the tree activity, promote the plants to rapidly take root and sprout, quickly supply nutrition to the trees, and enhance the tree stress resistance, and a preparation method of the nutrient solution. The proportion of the nutrient solution is that: every 1,000ml of deionized water contains 0.05 to 0.1g of monopotassium phosphate, 0.02 to 0.045g of potassium nitrate, 0.15 to 0.3g of calcium nitrate tetrahydrate, 0.11 to 0.2g of magnesium sulfate heptahydrate, 0.03 to 0.06g of ferrous sulphate heptahydrate, 0.07 to 0.15g of disodium ethylene diamine tetraacetate, 0.015 to 0.025g of manganese sulfate tetrahydrate, 0.012 to 0.018g of zinc sulfate heptahydrate, 0.04 to 0.06g of copper sulfate pentahydrate, 0.015 to 0.022g of ammonium molybdate, 0.015 to 0.02g of indolebutyric acid, and 0.008 to 0.015g of 6-benzylaminopurine. The plant infusion nutrient solution satisfies the needed nutrient in the process of transplanting big trees, has high absorption utilization ratio, quick response, stable form, high activity, and is easily absorbed by the plants.

Owner:TIANJIN LVDONG PLANT NUTRITION TECH DEV

Preparation method for battery grade ferrous sulfate heptahydrate crystal

The preparation method for battery grade ferrous sulfate heptahydrate crystal of the present invention includes using ferrous sulphate which is the by-product in the titanium dioxide production as raw material, using the operation of purification, filtration, crystallization and dryness, and preparing ferrous sulfate heptahydrate by using the difference of the solubility of ferrous sulphate changing with the temperature. The operation of purification includes performing reduction of ferric iron in ferrous sulphate which is the by-product in the titanium dioxide production to ferrous iron by using a reducing agent, adding ferrous sulfide to remove the heavy metal ions such as cobalt, nickel, zinc, copper, plumbum and cadmium, and using fluoride to remove calcium and magnesium ions. The preparation method uses vacuum drying and packaging, and the main content of ferrous sulfate heptahydrate in the dried material is more than 99.7%. The preparation method has simple technology and low cost, can recycle fluorinion by precipitation conversion, and can reduce the discharge of hazardous waste. Moreover, the prepared product has high purity, low impurity and ferric iron contents, and can be long-term storage. The recovery rate of ferrous sulphate is greatly improved.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Nutrient solution for improving transplanting survival rate of trees

InactiveCN103193545AImprove transplant survivalImprove survival rateFertilizer mixturesCalcium nitrate tetrahydrateMonopotassium phosphate

The invention relates to a nutrient solution for improving the transplanting survival rate of trees. The nutrient solution comprises the following components in parts by weight: 0.2-0.4 part of calcium nitrate tetrahydrate, 0.03-0.05 part of ferrous sulfate heptahydrate, 0.0001-0.0003 part of ferric citrate, 0.03-0.05 part of monopotassium phosphate, 0.07-0.09 part of ethylene diamine tetraacetic acid disodium, 0.04-0.06 part of anhydrous cupric sulfate, 0.12-0.15 part of magnesium sulfate heptahydrate, 0.0005-0.0009 part of potassium chloride, 0.002-0.004 part of ammonium molybdate, 0.012-0.014 part of ammonium sulfate, 0.0025-0.0029 part of boric acid, 0.0012-0.0015 part of indolebutyric acid and 1000-1050 parts of water. The invention aims at providing the nutrient solution which can be used for rapidly and comprehensively replenishing nutrients for various trees, motivating the activities of the trees, promoting rapid development of root systems and further improving the transplanting survival rate of the trees.

Owner:万少侠

Liquid compound trace element fertilizer and preparation method thereof

ActiveCN104892208AImprove absorption efficiencyImprove absorption and utilization efficiencyFertilizer mixturesVitamin CAntioxidant

The invention discloses a liquid compound trace element fertilizer and a preparation method thereof. The fertilizer comprises the following ingredients by weight percent: 0-1.0% of citric acid, 0-1.0% of ascorbic acid (vitamin C), 0-1.0% of hydroxylamine hydrochloride, 0-1.0% of sorbitol, 0-1.0% of xylitol, 0-1.0% of mannitol, 0.46-38% of ferrous sulfate heptahydrate, 0.13-24% of manganese sulfate monohydrate, 0.18-3.3% of copper sulfate pentahydrate, 0.25-2.3% of zinc sulphate monohydrate, 0.25-4% of disodium octaborate tetrahydrate, 0.08-1.5% of ammonium molybdate, and the balance of pure water, wherein the dosage of the citric acid, the dosage of the ascorbic acid and the dosage of the hydroxylamine hydrochloride cannot be 0 at the same time, and the dosage of sorbitol, the dosage of xylitol and the dosage of mannitol cannot be 0 at the same time. According to the invention, an antioxidant prepared from one, two or more of the citric acid, ascorbic acid and hydroxylamine hydrochloride can effectively inhibit ferrous ions from being hydrolyzed into ferric ions, so that the iron ion absorption efficiency is improved, and the color of the product does not change at a high temperature; the raw material resources are rich, the production cost is low, and the equipment and production technologies are simple.

Owner:中化农业(新疆)生物科技有限公司

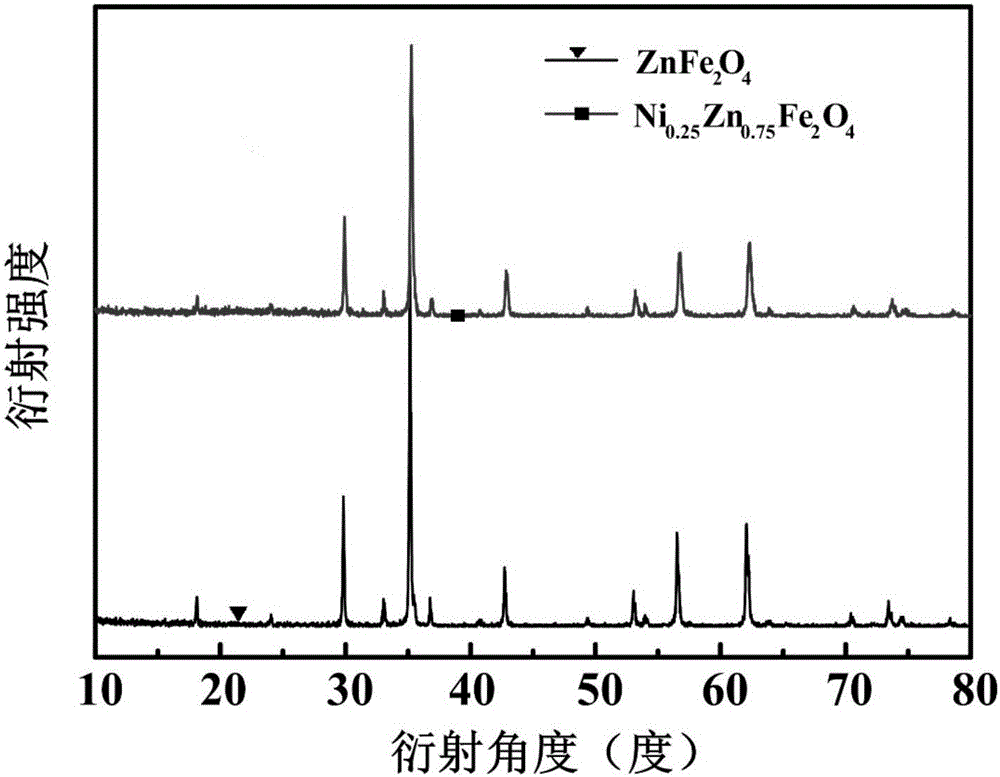

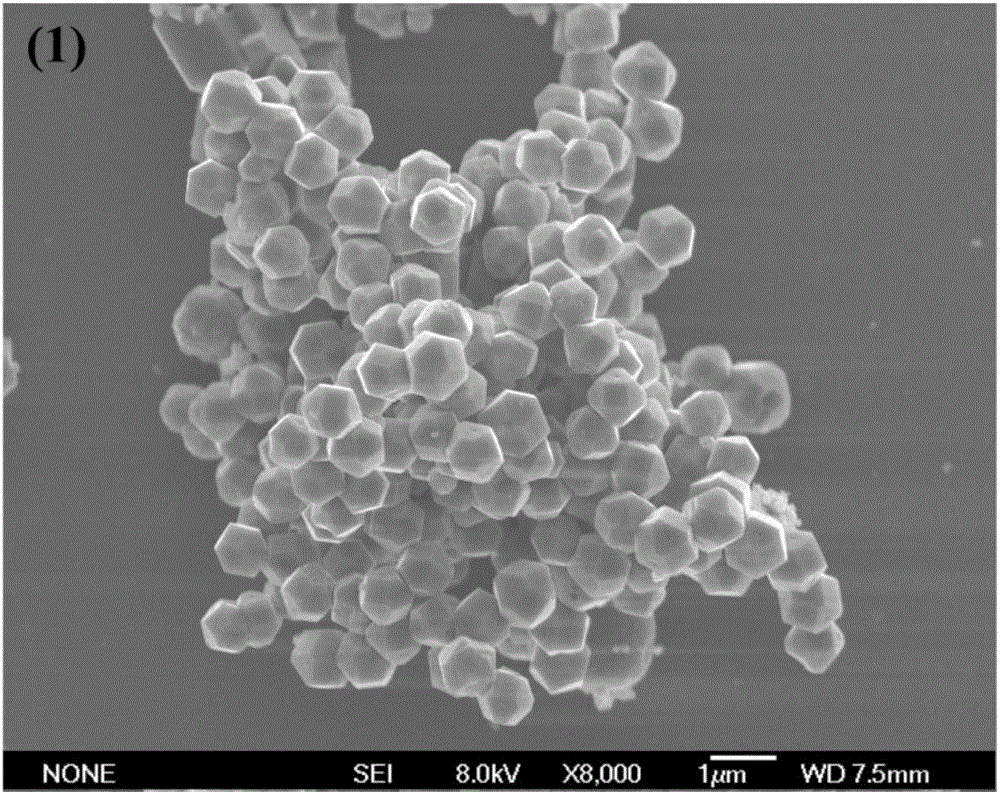

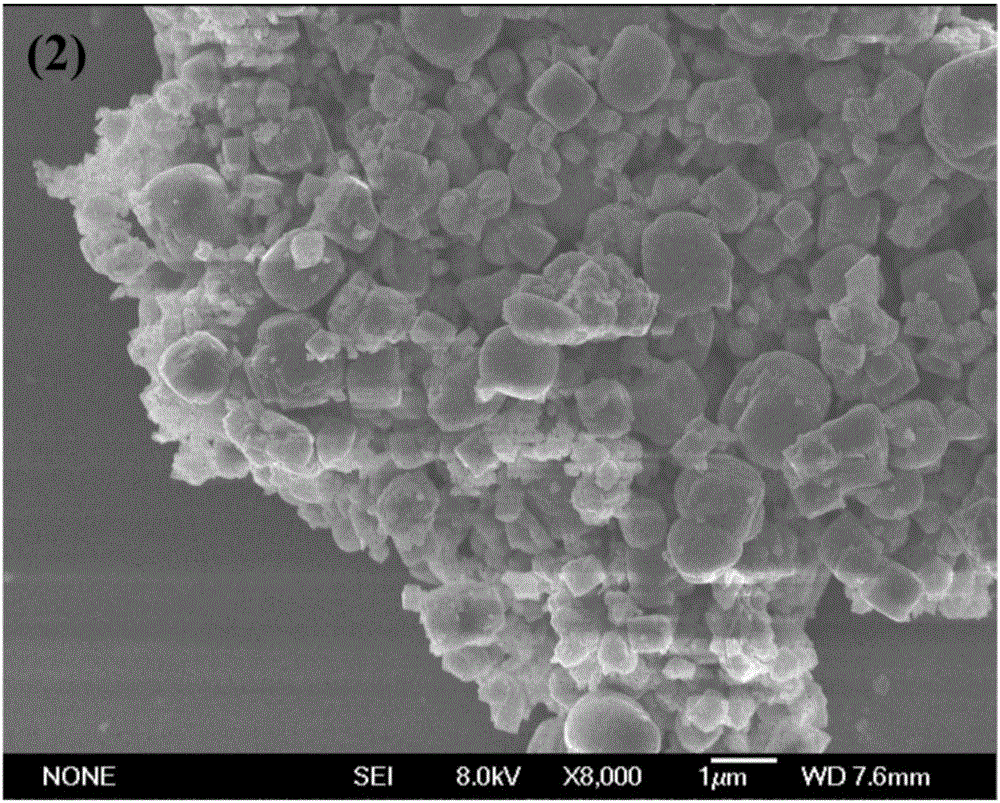

Method for improving electrochemical performance of zinc ferrite by doping nickel element and application

ActiveCN105958032AWide variety of sourcesThe synthesis method is simpleMaterial nanotechnologyCell electrodesCharge dischargeElectrochemistry

The invention discloses a method for improving charge-discharge cycling capacity of zinc ferrite by doping nickel element and application, and relates to the field of lithium ion battery anode composite material preparation. The method comprises the following steps: forming a ternary metallic oxide by doping the nickel element in zinc ferrite, selecting and using, and mixing and stirring nickel nitrate hexahydrate, zinc nitrate hexahydrate, ferrous sulfate septihydrate, urea and ammonium fluoride according to a certain molar mass ratio to form a uniform mixed solution; and carrying out hydro-thermal synthesis and calcinations to obtain NixZn1-xFe2O4(x being greater than 0 and smaller than 1) metallic oxide. According to the method, the NixZn1-xFe2O4(x being greater than 0 and smaller than 1) metallic oxide with excellent electrochemical performance can be prepared; and moreover, the synthetic method is relatively simple, low in energy consumption, good in controllability, high in yield and low in cost, and is applicable for large-scale production. The invention also discloses application of the NixZn1-xFe2O4(x being greater than 0 and smaller than 1) metallic oxide, the NixZn1-xFe2O4(x being greater than 0 and smaller than 1) metallic oxide is used for lithium ion battery anode materials, and the metallic oxide has the characteristics of high charging and discharging specific capacity and high cycling stability.

Owner:JILIN UNIV

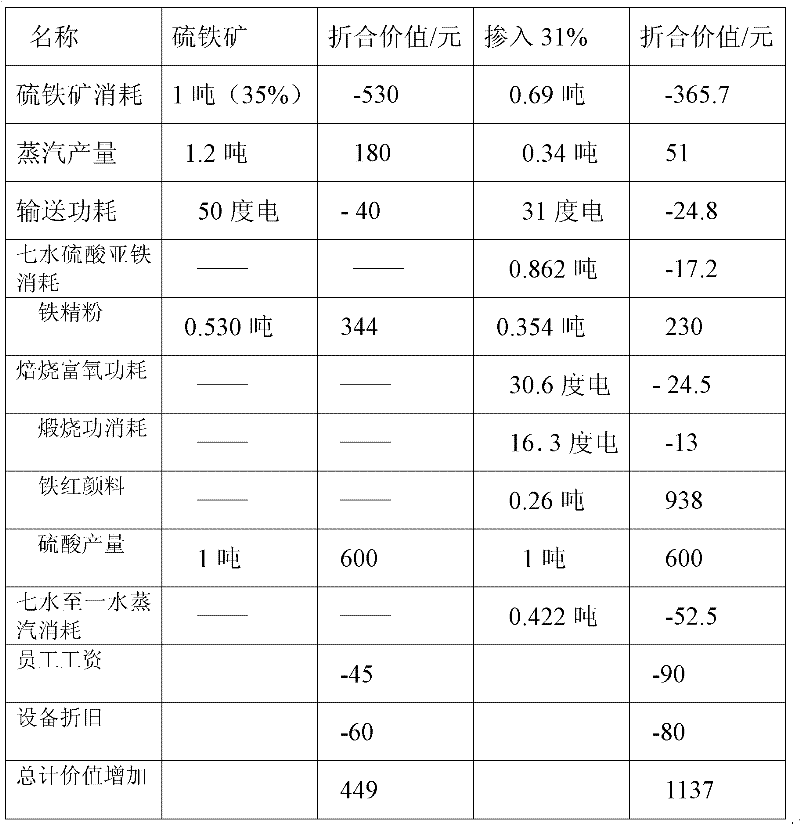

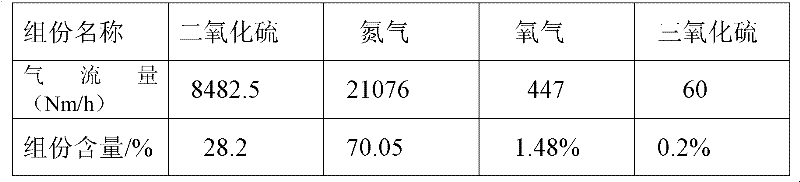

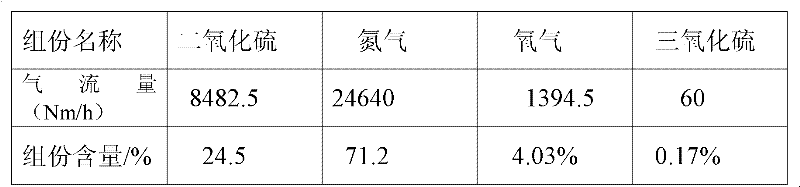

Process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite

ActiveCN102344124AIncrease incorporationImprove Pigment PerformanceSulfur compoundsEnergy inputResource utilizationFractionation

The invention provides a process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite and relates to the process technology of resource utilization of titanium dioxide byproduct solid waste ferrous sulfate. The process comprises the following steps: adopting titanium dioxide byproduct ferrous sulfate heptahydrate and pyrite as raw materials; increasing the mixing amount of the ferrous sulfate heptahydrate as much as possible through transforming the ferrous sulfate heptahydrate into ferrous sulfate monohydrate, oxygen-enriched roasting, preheating air in front of a furnace, controlling the sulfur content of the pyrite entering the furnace and the moisture and other technical means; and realizing the integrated co-production of the sulfuric acid, the fine iron powder and iron oxide red pigments through cinder fractionation, oxygen-enriched calcining and other process technologies. The process effectively improves the economic value of the heptahydrate ferrous sulfate and has an important significance on efficient and comprehensive utilization of the titanium dioxide byproduct solid waste ferrous sulfate heptahydrate.

Owner:HUNAN HENGGUANG TECH

Refining method of titanium dioxide by-product ferrous sulphate

The invention provides a refining method of titanium dioxide by-product ferrous sulphate. The method comprises: (1) preparing a ferrous sulfate heptahydrate solution by using the titanium dioxide by-product ferrous sulphate; (2) adjusting a pH value of the solution to 1-2.5, and performing titanium hydrolysis of the titanium dioxide by-product ferrous sulphate; (3) adding iron powder or iron sheets into the ferrous sulfate heptahydrate solution after the titanium hydrolysis, reducing Fe<3+> in the solution, adjusting a pH value of the solution to 6.0-6.5, and performing a magnesium, manganese and zinc precipitation treatment for the titanium dioxide by-product ferrous sulphate; and (4) adding a flocculating agent into the above solution, stirring, standing, settling and filtering to obtain the refined ferrous sulphate solution. The method can effectively remove impurities such as titanium, magnesium, zinc, manganese and other ions in the titanium dioxide by-product ferrous sulphate, and obtain the high-purity refined ferrous sulphate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Water culture nutrient solution of spinach beet

InactiveCN103626559APromote growthShorten the growth cycleFertilizer mixturesCalcium nitrate tetrahydrateManganese

The invention discloses a water culture nutrient solution of spinach beet. The water culture nutrient solution comprises macroelements, microelements and water as well as calcium nitrate tetrahydrate, potassium nitrate, ammonium dihydrogen phosphate, magnesium sulfate heptahydrate, ammonium nitrate, boric acid, copper sulfate, sodium silicate, magnesium sulfate, cobalt chloride, nickel chloride, potassium sulfate, potassium chloride, ethylene diamine tetraacetic acid, ferrous sulfate septihydrate, manganese sulfate tetrahydrate, copper sulfate pentahydrate, ammonium nitrate, calcium carbonate, potassium iodide, sodium chloride, ferric sulfate, lead acetate and sodium citrate. According to the water culture nutrient solution of the spinach beet, the absorption utilization rate is high and the waste caused by nutrition excess or deficiency resulted by no pertinence of a water culture nutrient solution of the spinach beet in the past is avoided.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

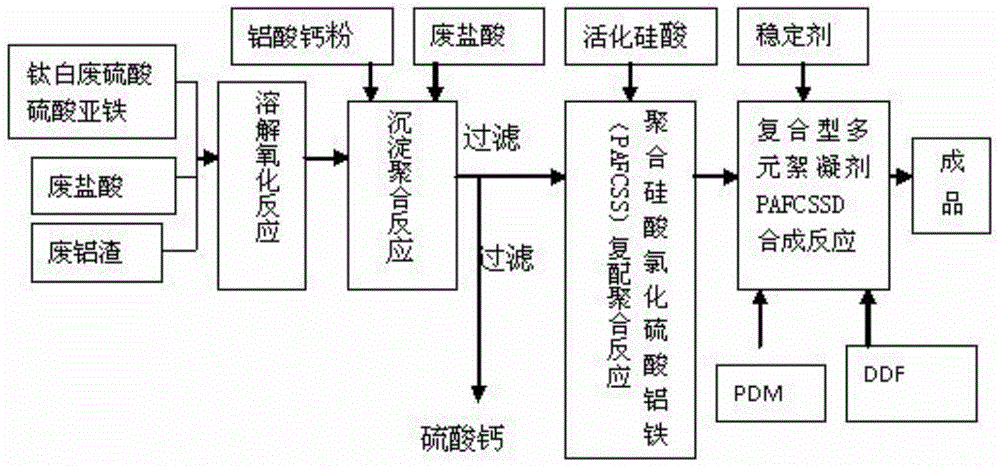

Method for preparing compound type multi-element flocculating agent aluminum ferric sulfate chloride polysilicate by utilizing waste acid

ActiveCN104085969AReduce moisture contentEasy to chargeWater/sewage treatment by flocculation/precipitationTreatment effectSlag

The invention relates to a method for preparing a compound type multi-element flocculating agent aluminum ferric sulfate chloride polysilicate. The method comprises the following 4 steps of: dissolving and oxidizing; precipitation polymerization and filtering; compound polymerization; synthesis of the aluminum ferric sulfate chloride polysilicate. The method disclosed by the invention can be used for producing the compound type multi-element flocculating agent aluminum ferric polysilicate by integrally utilizing the waste sulfuric acid liquor, ferrous sulfate heptahydrate, waste aluminum slag and waste hydrochloric acid liquor of a titanium dioxide plant, a chemical plant and a steel and ion plant in a recycling way. The prepared flocculating agent can be widely applied to the treatment of domestic sewage and industrial wastewater, has higher turbidity, color and COD removing capacity compared with the treatment effect of polyaluminium chloride and polyaluminum ferric chloride and has the advantages of high floc forming velocity, large and compact floc, high sedimentation velocity and small sedimentary sludge size.

Owner:GUANGXI PINGGUO FENGHUA TECH

Method for preparing fertilizer containing humic acid concentrated chelating trace elements

InactiveCN104478574AIncrease concentrationReduce dosageOrganic fertilisersFertilizer mixturesZINC SULFATE HEPTAHYDRATEPlant growth

The invention relates to a method for preparing a fertilizer containing trace elements, and particularly relates to a method for preparing a fertilizer containing humic acid concentrated chelating trace elements. The method comprises the following steps of firstly, adding supernate containing humic acid, ethylene diamine tetraacetic acid and sodium hydroxide sequentially into a reaction kettle, and stirring until dissolving; then adding heptahydrate, manganese sulfate monohydrate, blue copperas and iron vitriol sequentially into the reaction kettle, chelating, and stirring until dissolving; and then adding boric acid, ammonium molybdate, citric acid, caprylyl / capryl glucoside APG0810 into a reaction kettle, and stirring until dissolving. The invention provides a plant growth adjusting agent which is high in nutritional element concentration, is stable and uniform in solution, contains biochemical humic acid and the like, is beneficial to plant absorption, is high in biodegradability and is low in blade and soil pollution.

Owner:NINGXIA KOCEL BIOLOGICAL CHEM

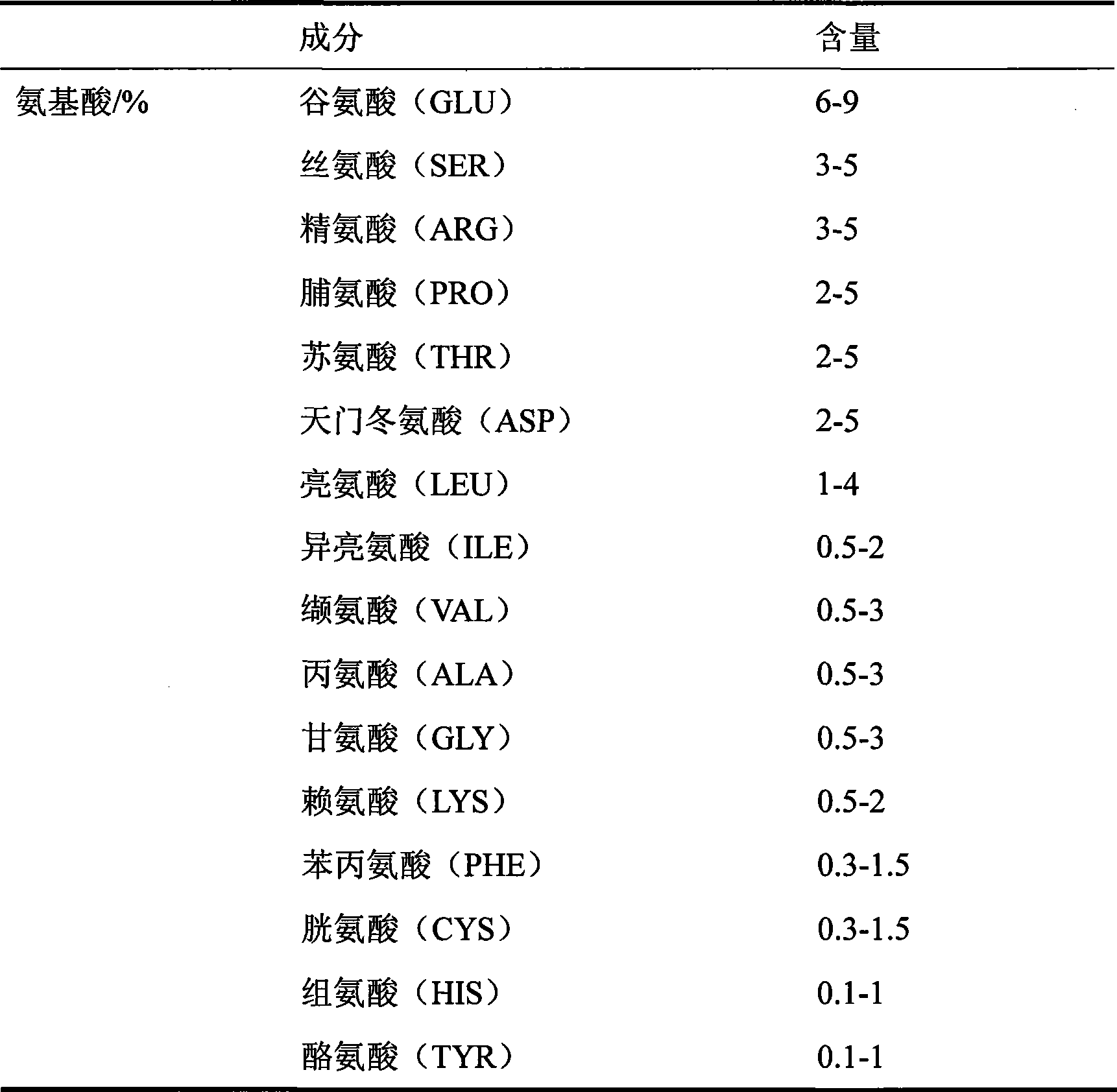

Aminoacid foliar fertilizer and use thereof

ActiveCN101376612AImprove fertilizer efficiencyFortified Iron NutritionOrganic fertilisersFertilizer mixturesGenotypeSurface-active agents

The invention provides amino acid leaf fertilizer which is composed of 20-50 percent of compound amino acids, 1-50 percent of nicotinic amide, 10-20 percent of green vitriol, 10-20 percent of urea, 5-10 percent of boric acid, 1-5 percent of ascorbic acid and 1-5 percent of surface active agent, namely polysorbate 80. The pH value is required to be 5.0-6.0. The fertilizer efficiency of the amino acid leaf fertilizer is stable, the fertilizer can obviously strengthen the iron nutrient of paddy rice seeds with different genotypes, averagely, the content of iron in winnowed paddy can be obviously increased by above 15 percent, the content of protein and amino acid in the winnowed paddy rice can be obviously increased, the nutrition and the quality of paddy rice can be enhanced all sidedly, the quality is excellent and the cost is low. Therefore, the amino acid leaf fertilizer can be applied in the highly effective biological strengthening of the iron nutrient in paddy seeds and the remarkable promotion of the nutrition and the quality of paddy rice.

Owner:ZHEJIANG UNIV

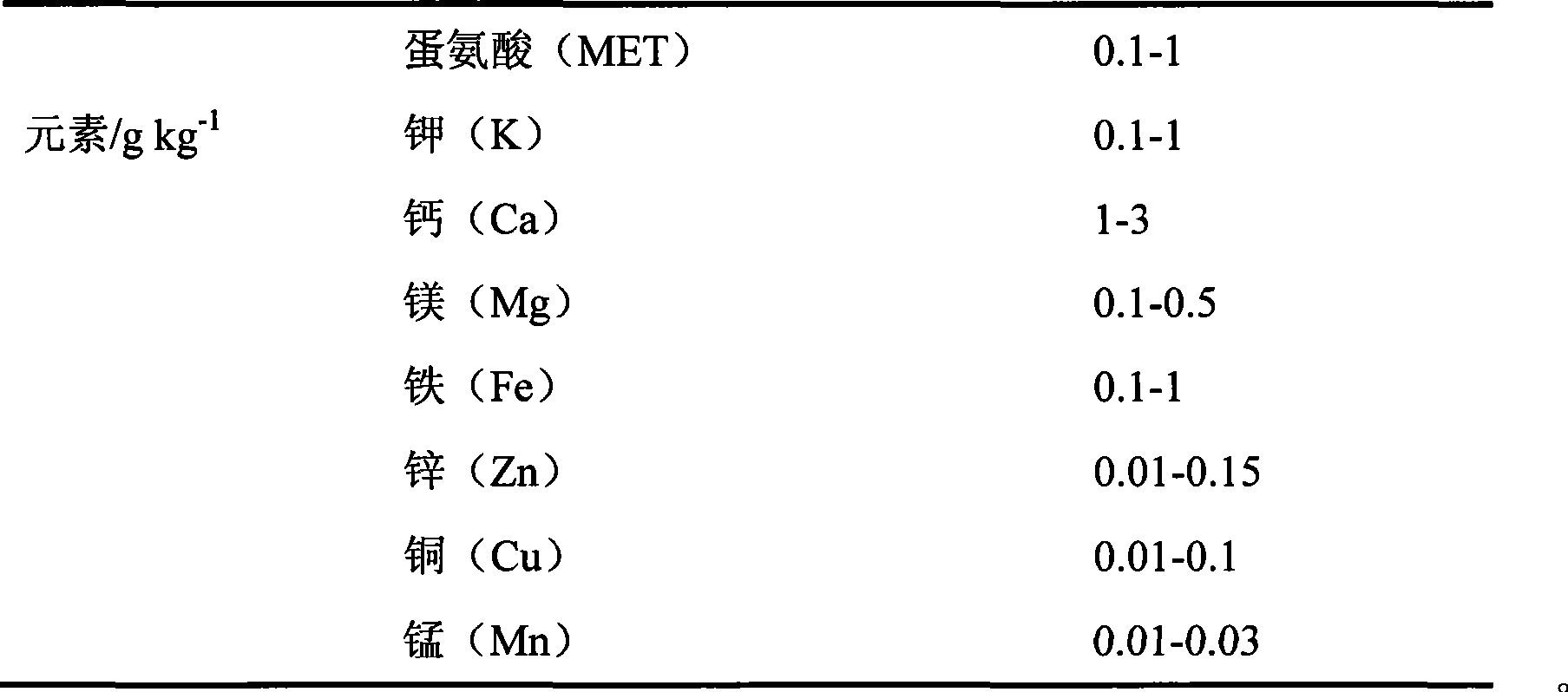

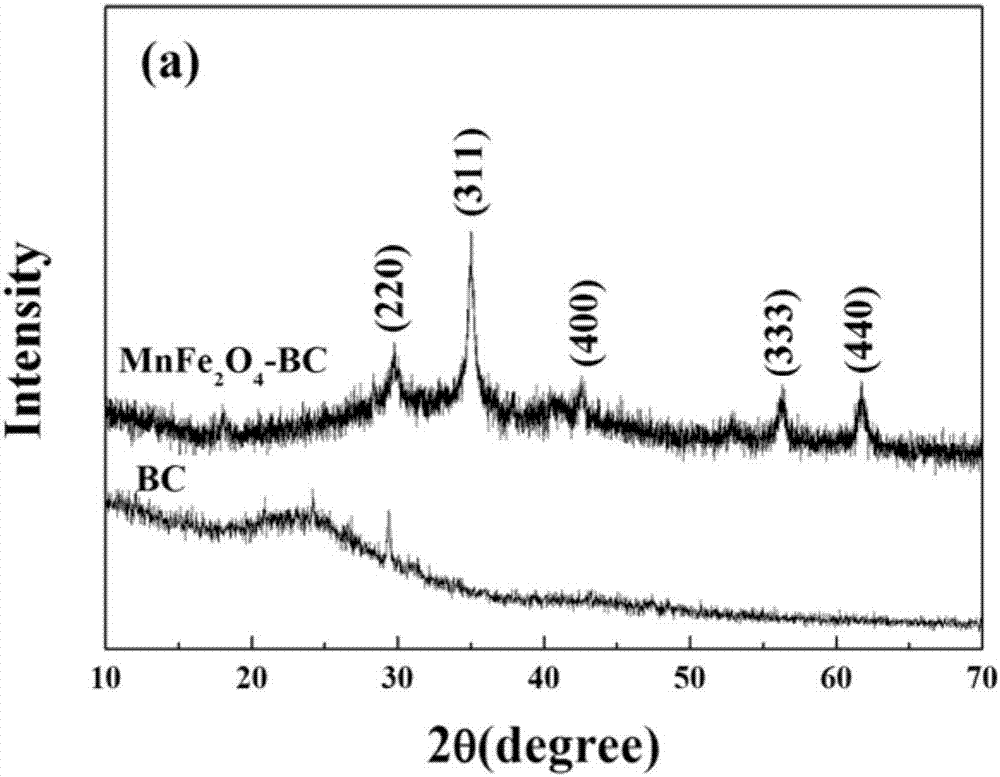

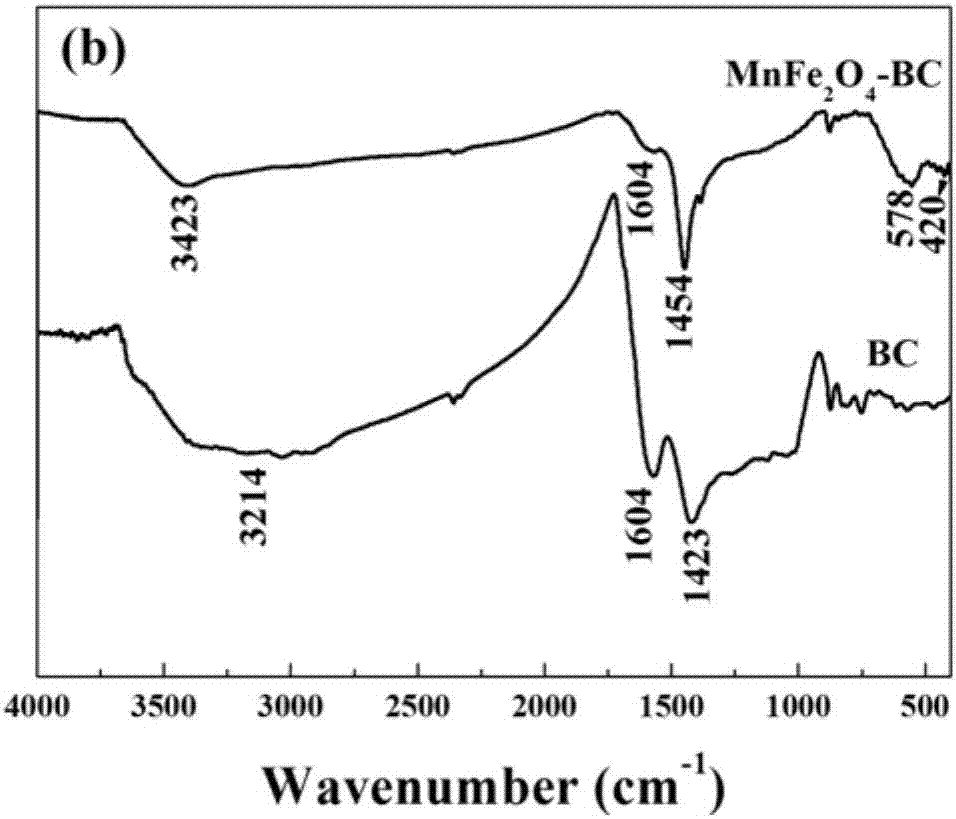

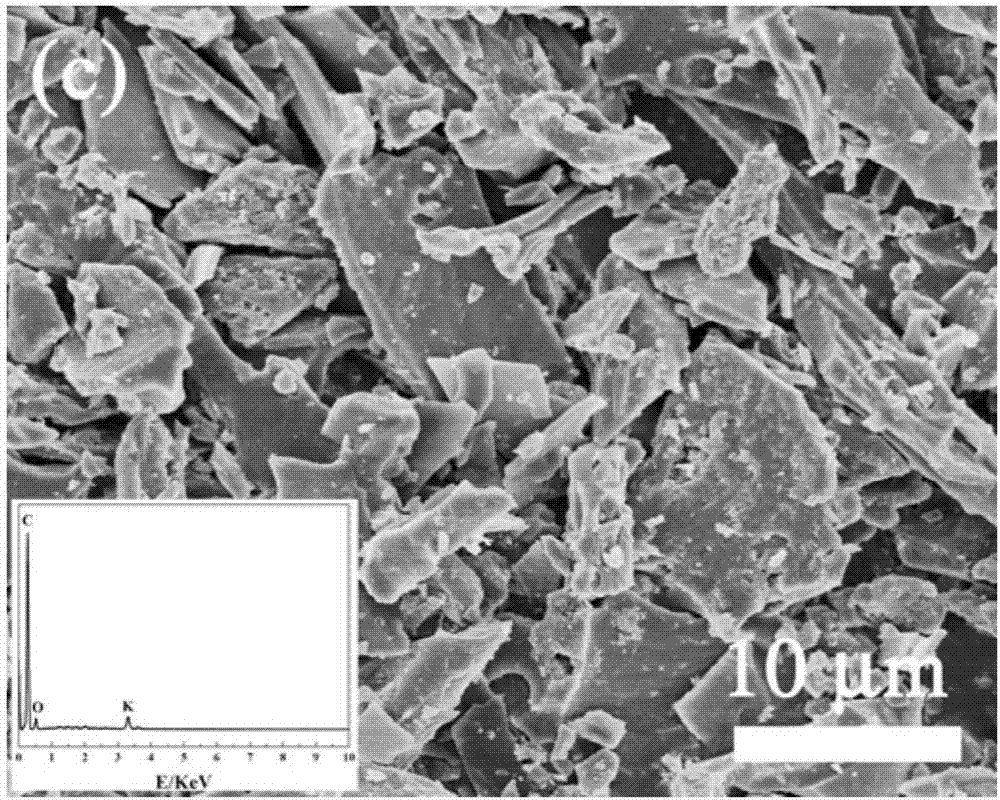

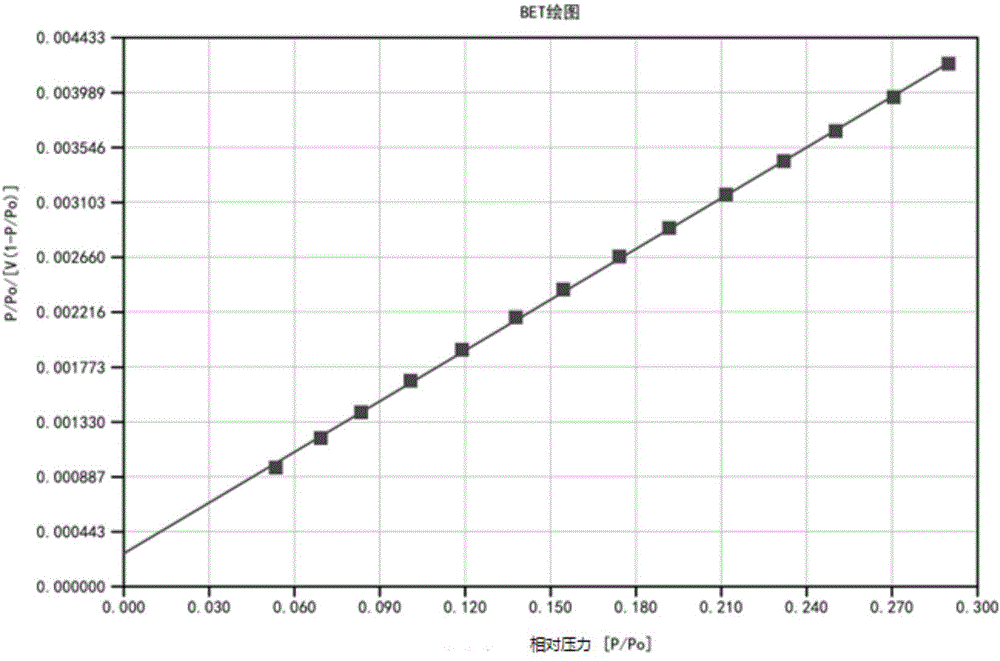

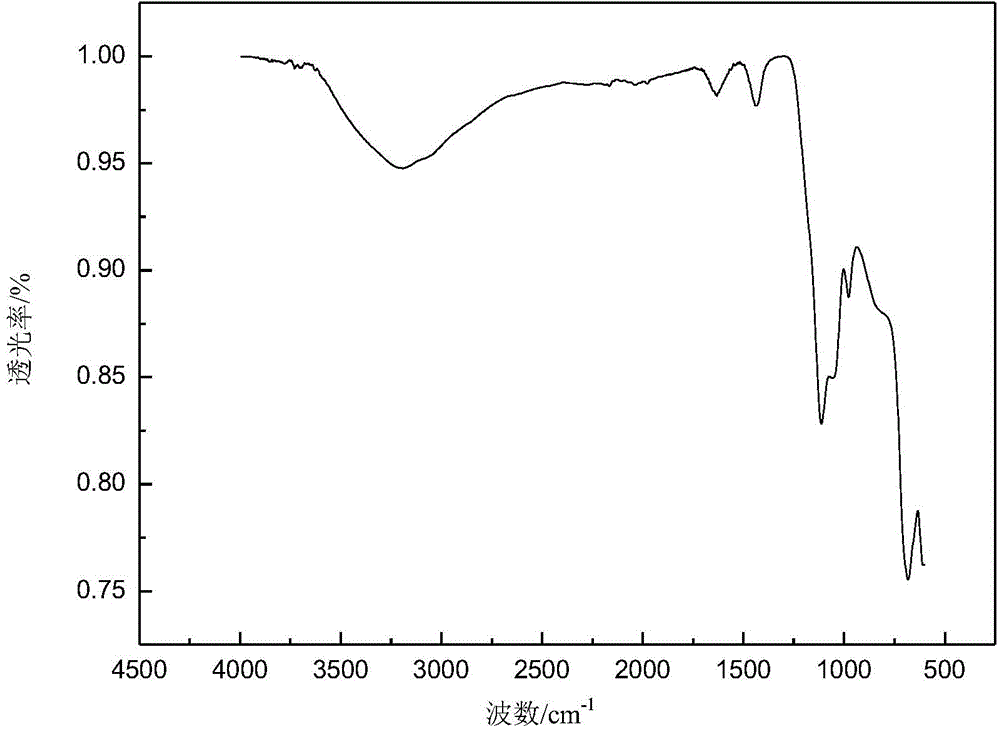

Biochar, iron and manganese spinel composite material for adsorbing heavy metal antimony and cadmium

ActiveCN107413296AIncrease the areaLarge porosityOther chemical processesWater contaminantsPorosityCadmium Cation

The invention belongs to the technical field of adsorption materials, and discloses a biochar, iron and manganese spinel composite material for adsorbing heavy metal antimony and cadmium. Solution B is dripped into suspension A at the constant speed, the solution B and the suspension A are stirred for 2.5-3.5 hours and are centrifuged, washed and dried to obtain the biochar, iron and manganese spinel composite material. The solution B is potassium permanganate solution with the concentration of 0.1 mol / L, and the suspension A comprises water, ferrous sulfate heptahydrate and from tea leaf and branch biochar according to a weight ratio of 100:(8.0-8.5):(0.8-1.2). The biochar, iron and manganese spinel composite material has the advantages that the biochar, iron and manganese spinel composite material has a large specific surface area and is large in porosity and favorable for adsorbing the heavy metal; adsorption environments are mild, and the heavy metal can be efficiently adsorbed in neutral and slightly weakly acidic environments; excellent adsorbing and removing effects can be realized by the biochar, iron and manganese spinel composite material for single heavy metal environments, and excellent heavy metal adsorbing and removing effects also can be realized by the biochar, iron and manganese spinel composite material for heavy metal antimony and cadmium co-existence environments.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Efficient fruits nutrition physiology hyperchromic fertilizer and preparation thereof

InactiveCN101274864ANon-toxicNo pollution in the processOrganic fertilisersPotassium fertilisersNutritionAdditive ingredient

The invention relates to a high-efficiency fruit-nutritive physiological hyperchromic fertilizer and a preparation method thereof. Currently, the hyperchromic products in the market such as phytohormone, including products of ethane, abscisic acid, daminozide, most of such products adopt or contain hormone, have instable effect and easily cause adverse side effects, thus leading fruits to be soft and lowered in bin stability. The invention is a high-efficiency fruit-nutritive physiological hyperchromic fertilizer, the active ingredients of which comprise aminofusin, potassium sulfate, potassium chloride, borax, zinc vitriol, iron vitriol (FeSO4 question mark 7H2O), compound sodium nitrophenolate, chlormequat chloride with 50 percent of aqua and white sugar; the ingredients do not contain hormone, are non-poisonous and pollution-free, and have no adverse side effects. The high-efficiency fruit-nutritive physiological hyperchromic fertilizer contains various aminophenols, active substances for plant growth, a plurality of major elements and chelate trace elements, which are necessary for the growth and development of the fruit trees and vegetables, and is a novel organic and inorganic hyperchromic product integrating the advantages of various foliar fertilizers of inorganic nutrition type, organic type and growth conditioner type, etc. into a whole.

Owner:翟丙年

Preparation method for amorphous FeOOH water-purifying agent

InactiveCN105800762AHigh arsenic removal efficiencyEfficient removalWater/sewage treatmentAluminum IonHydrolysis

The invention provides a preparation method for an amorphous FeOOH water-purifying agent. The preparation method comprises the following steps: preparing a ferrous sulfate solution from industrial ferrous sulfate heptahydrate; adding a proper amount of sulfuric acid into the ferrous sulfate solution so as to provide an acidic environment; adding hydrogen peroxide into the solution and allowing ferrous sulfate to be oxidized into ferric sulfate under the condition of hydrolysis promotion by sulfuric acid; subjecting an industrial alkali source and the ferric sulfate solution to a precipitation reaction so as to produce iron hydroxide colloid; and dehydrating the iron hydroxide colloid under proper conditions so as to prepare the amorphous FeOOH water-purifying agent. The amorphous FeOOH water-purifying agent can effectively arsenic in water, has arsenic removal efficiency of 98% or above, does not contain aluminum ions or pose secondary pollution to a water body; after arsenic removal with the water-purifying agent, scorodite stably existing in the nature is produced, so pollution is not posed to the environment; moreover, raw materials used in the invention are of an industrial grade, and the preparation method is low in production cost and simple to operate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

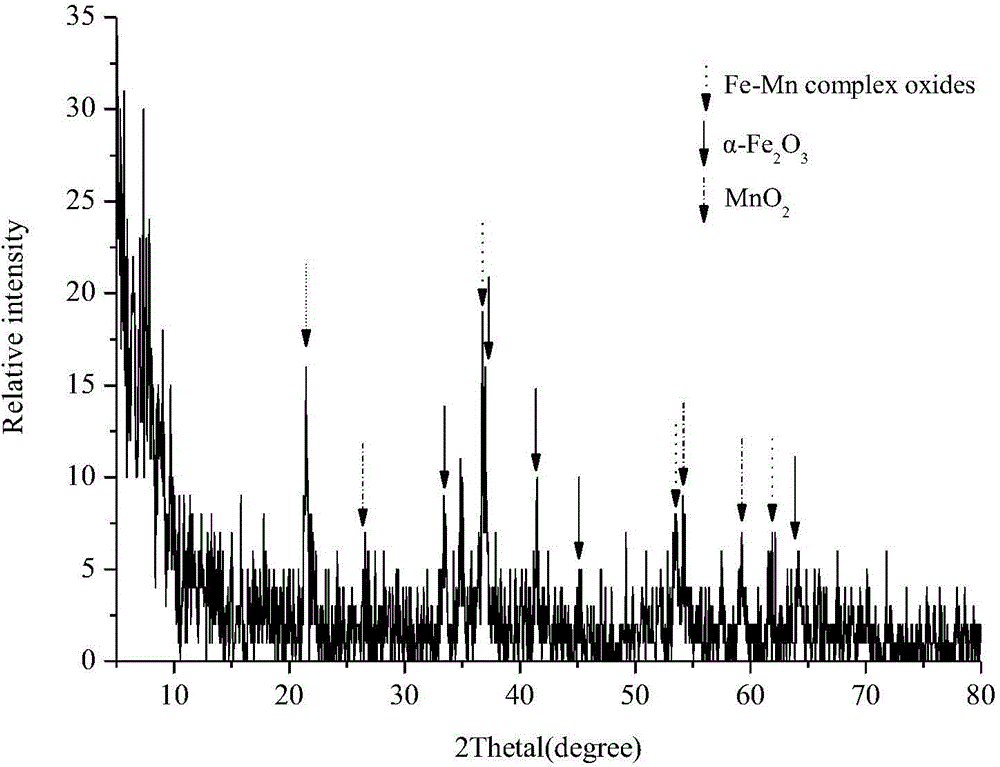

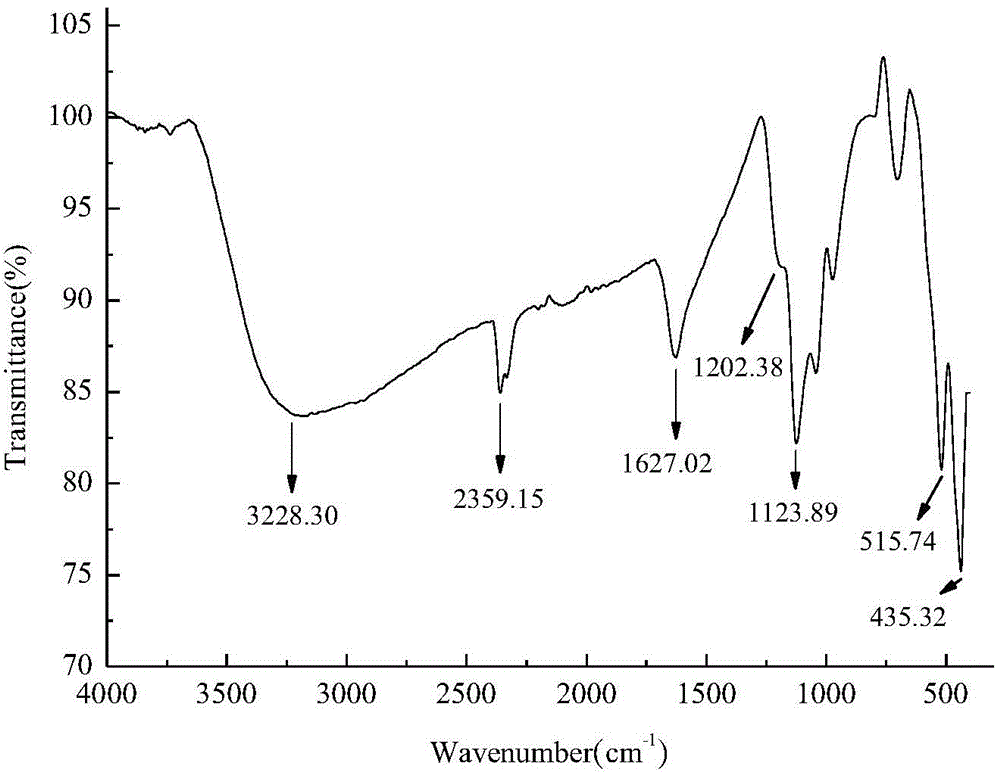

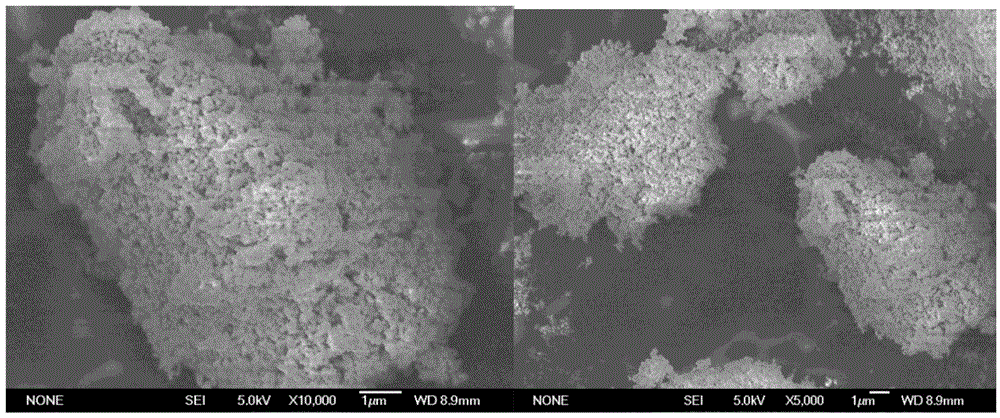

Fe/Mn composite oxide, preparation method and application thereof

ActiveCN104815609AEasily hydrolyzedUniform particle sizeOther chemical processesWater contaminantsCentrifugationWastewater

The invention discloses a preparation method of a Fe / Mn composite oxide, wherein the preparation method includes following steps: (1) adding dropwisely a FeSO4.7H2O solution into a KMnO4 solution, carrying out a reaction at 15-25 DEG C for 1-1.5 h to obtain a brown-red suspension, wherein the pH of the solution is regulated to be 3.0-4.0 in the reaction; (2) moving the brown-red suspension into a reaction kettle, carrying out a reaction for 5-7 h at 160-200 DEG C, cooling a reaction product and performing centrifugation to obtain a brown-red precipitation, and washing the brown-red precipitation until electric conductivity of a washing liquid does not change; and (3) aging the brown-red precipitation at room temperature for 3.5-4.5 h, drying and grinding the aged precipitation to obtain the Fe / Mn composite oxide powder. The Fe / Mn composite oxide is crude in surface and is large in specific surface area. A uniform pore structure is formed among fine particles on the surface of the composite oxide, so that chromium ion in water can be adsorbed therein easily. The Fe / Mn composite oxide is suitable for treatment of chromium-containing waste water in different concentrations, is high in removal rate and is low in cost.

Owner:SHANDONG NORMAL UNIV

Polymeric ferric sulfate water treatment agent and preparation method thereof

InactiveCN102951713ASimple and fast operationDischarge safetyWater/sewage treatment by flocculation/precipitationHydrolysisImpurity

The present invention discloses a polymeric ferric sulfate water treatment agent and a preparation method thereof. The method comprises the following steps: (1) preparing an acidic aqueous solution of ferrous sulfate: controlling a mass ratio of ferrous sulfate heptahydrate to sulfuric acid to 1:(0.44-0.45), and preparing an aqueous solution, wherein the mass of the ferrous sulfate is 10-20% of the total mass of the solution; and (2) introducing ozone-containing gas to the aqueous solution, carrying out a reaction for at least 0.5 h, and carrying out hydrolysis and polymerization of ferric ions to obtain the polymeric ferric sulfate water treatment agent. According to the present invention, ozone is adopted as an oxidizing agent, an additional catalyst is not required to be poured, heating on the solution is not required during the whole reaction, the reaction can be performed under atmospheric pressure, the reaction is fast, production efficiency is high, high value-added products are obtained while the ozone is utilized and removed by the production process, impurities harmful for human body or equipment or byproducts can not be produced, and an environment protection characteristic is provided.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com