Method for producing vitriol and iron ore concentrate using ferrous sulfate

A technology of ferrous sulfate and iron concentrate, which is applied in the field of chemical industry and metallurgy, and can solve the problems that it is difficult to meet the requirements of ironmaking, and the grade of iron in sulfuric acid slag is low and not much.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

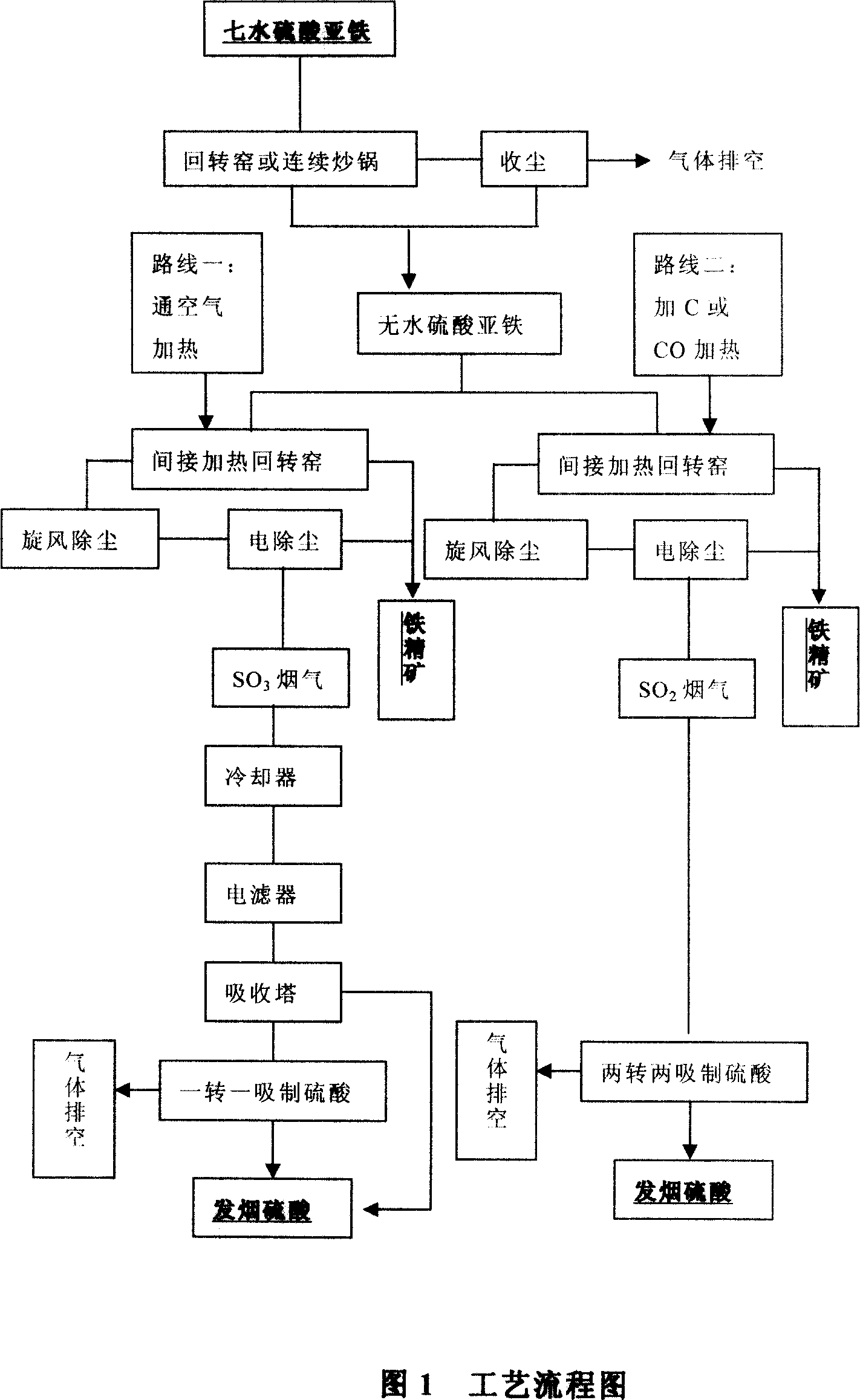

Image

Examples

Embodiment 1

[0046] Ferrous sulfate heptahydrate contains FeSO 4 ·7H 2 O97%, MgSO 4 ·7H 2 O 1.4%, water-insoluble matter 1.1%, other 0.5%.

[0047] The ferrous sulfate heptahydrate is added to the indirect heating rotary kiln, and the drying temperature is kept at 300°C to remove the seven crystal water. The total moisture content is controlled to 1% by adjusting the drying temperature and drying time. The flue gas is emptied after dust collection and purification. , Dust and dry materials are anhydrous ferrous sulfate.

[0048] Anhydrous ferrous sulfate is added to the indirect heating rotary kiln. At the same time, CO is added to the rotary kiln. The indirect heating temperature is controlled at 950℃. The time is controlled to make the decomposition rate of ferrous sulfate 99.0%. The amount of CO added is controlled to make the ferrous sulfate Among the decomposed gas products, the mass ratio K of sulfur trioxide and sulfur dioxide is 0.05. The flue gas of the rotary kiln is accelerated to 15 ...

Embodiment 2

[0055] Ferrous sulfate heptahydrate contains FeSO 4 ·7H 2 O96%, MgSO 4 ·7H 2 O 1.4%, water-insoluble matter 1.1%, others 1.5%.

[0056] The ferrous sulfate heptahydrate is added to the direct heating rotary kiln, and the drying temperature is maintained at 350°C to remove the seven crystal water. The total moisture content is controlled to 1% by adjusting the drying temperature and drying time. The flue gas is emptied after dust collection and purification. , Dust and dry materials are anhydrous ferrous sulfate.

[0057] Anhydrous ferrous sulfate is added to the indirect heating rotary kiln. At the same time, C is added to the rotary kiln. The indirect heating temperature is controlled at 1000℃. The time is controlled to make the decomposition rate of ferrous sulfate 99.9%. The amount of C added is controlled to make the ferrous sulfate Among the decomposed gas products, the mass ratio K of sulfur trioxide and sulfur dioxide is 0.01. The flue gas of the rotary kiln is accelerated ...

Embodiment 3

[0064] Ferrous sulfate heptahydrate contains FeSO 4 ·7H 2 O 94%, MgSO 4 ·7H 2 O 2.4%, water-insoluble matter 2.1%, others 1.5%.

[0065] The ferrous sulfate heptahydrate is added to the continuous wok, and the drying temperature is maintained at 250°C to remove the seven crystal water. The total moisture is controlled to 2% by adjusting the drying temperature and drying time. The flue gas is emptied after dust collection and purification. The dust and dry material is anhydrous ferrous sulfate.

[0066] Anhydrous ferrous sulfate is added to the indirect heating rotary kiln. At the same time, C is added to the rotary kiln. The indirect heating temperature is controlled at 700℃. The time is controlled to make the decomposition rate of ferrous sulfate 97%. The amount of C added is controlled to make the ferrous sulfate Among the decomposed gas products, the mass ratio K of sulfur trioxide and sulfur dioxide is 0.1. The flue gas of the rotary kiln is accelerated to 7 m / s by the fan, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com