Patents

Literature

164 results about "Manganese sulphate monohydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese(II) sulfate monohydrate is one of the most abundant elements found in the earth's crust. Manganese occurs in the atmosphere from dust, volcanic activity, forest fires, and industrial emissions, and is also present in foods and drinking water.

Water-soluble organic liquid fertilizer and preparation method thereof

InactiveCN101723735APromote absorptionPromote vegetative growthClimate change adaptationBioloigcal waste fertilisersInsect pestPlant disease

The invention discloses a water-soluble organic liquid fertilizer and a preparation method thereof. The fertilizer is prepared from the following raw materials in percentage by weight: 40 to 80 percent of molasses fermentation liquid, 10 to 50 percent of biochemical potassium fulvate, 3 to 10 percent of boric acid, 2 to 8 percent of ethylene diamine tetra-acetic acid, 1 to 5 percent of heptahydrate zinc sulphate, 2 to 6 percent of manganese sulfate monohydrate, 0 to 5 percent of ferrous sulphate heptahydrate and the balance of water, wherein the sum of the raw materials is 100 percent. The production method for the fertilizer comprises the following steps: putting the molasses fermentation liquid in an amount which is one third of the formulation amount and the water into a reaction kettle, heating the mixture to 60 DEG C, and adding the ethylene diamine tetra-acetic acid into the mixture; adding the heptahydrate zinc sulphate, the manganese sulfate monohydrate and the ferrous sulphate heptahydrate into the mixture, and stirring the mixture for 30 minutes; and adding the boric acid, the residual molasses fermentation liquid and the biochemical potassium fulvate into the mixture, stirring the mixture for 30 minutes and cooling the mixture. The fertilizer is brown liquid, has multiple fertilization modes, can prevent multiple plant diseases and insect pests, increase the yield of crops, improve the quality and increase the yield by 10 to 20 percent, and makes a contribution to the development of organic agriculture.

Owner:SHAANXI HUAXIA AGRI TECH DEV

Organic liquid fertilizer containing chitosan

ActiveCN103011988AImprove the environmentPromote growthFertilizer mixturesAdditive ingredientInsect pest

The invention relates to an organic liquid fertilizer containing chitosan. The organic liquid fertilizer comprises the chitosan, humic acid, fulvic acid, phosphorus pentoxide, potassium hydroxide, boric acid, edetic acid, zinc sulphate, manganese sulfate monohydrate, glycine, glutamic acid, serine and lysine. Aqueous extract of traditional Chinese medicines is added into the organic liquid fertilizer. As various marine bioactive ingredients such as the chitosan are added into the organic liquid fertilizer, the organic liquid fertilizer can be used for culturing a great quantity of effective microbial communities of actinomycetes and the like within short time after being applied to soil. Antibiotics and other substances secreted from the effective microbial communities can inhibit harmful microbial communities of pythium aphanidermatum, rhizoctonia and the like, and thus a microbial environment of the soil can be improved rapidly. The chitosan also can be used for accelerating the growth of root systems and the combination of the root systems and the soil. In addition, as the aqueous extract with insecticidal efficacy of the traditional Chinese medicines is added into the organic liquid fertilizer, plant diseases and insect pests of leaf surfaces can be effectively reduced when the fertilizer is applied to the leaf surfaces.

Owner:QINGDAO JINGLING OCEAN TECH

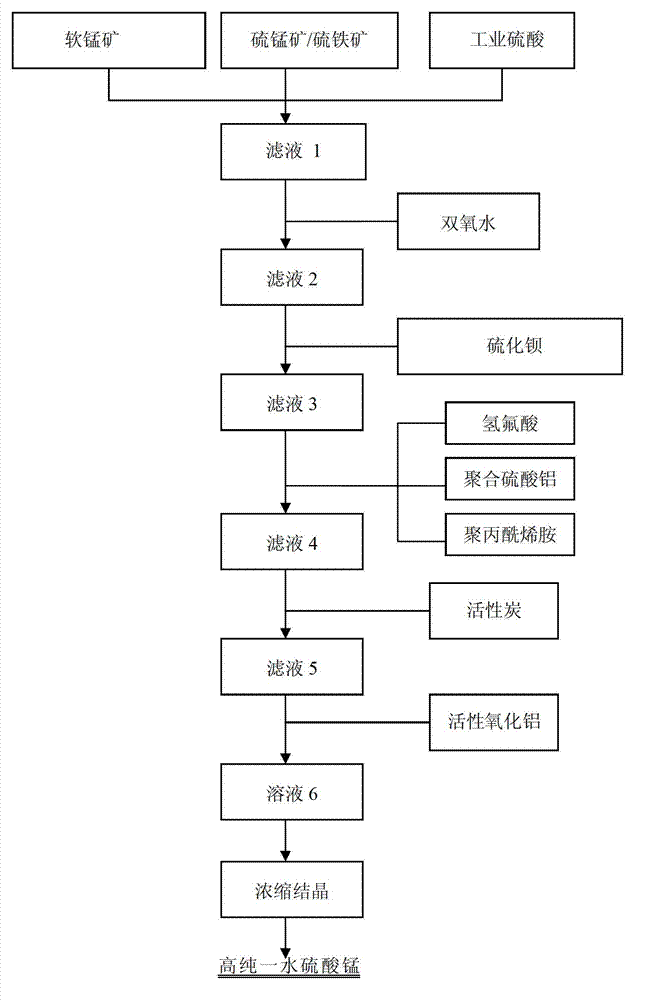

High purity manganese sulfate monohydrate and preparation method thereof

ActiveCN101875507AReduce contentEasy to getManganese sulfatesManganese sulphate monohydrateHeavy metals

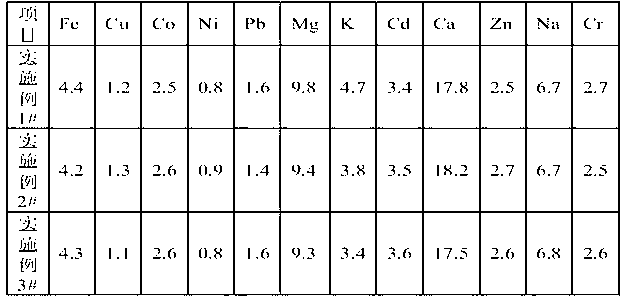

The invention relates to manganese sulfate and a preparation method thereof, in particular to high purity manganese sulfate monohydrate and a preparation method thereof. In the high purity manganese sulfate monohydrate, the content of manganese is more than 32%; the content of impurities of K, Na, Ca and Mg are lower than 50ppm; and contents of heavy metal and iron impurity are both lower than 10ppm. The preparation method comprises the steps of: firstly adjusting the pH value of solution to 3.5 to 5 for remove impurities for the first time by using iron sulfate as an impurity removing agent; then adjusting the pH value to 4 to 7 using manganese carbonate; adding an adsorbent to remove the impurities for the second time; removing the impurities for the third time by using manganese fluoride as an impurity removing agent under the condition that the pH value is 4 to 7; then removing the impurities for the fourth time by using barium sulfide as an impurity removing agent under the condition that the pH value is 4 to 7; and finally concentrating, crystallizing, washing and drying to obtain the high purity manganese sulfate monohydrate. In the manganese sulfate monohydrate of the invention, the contents of all main metal impurities are lower; the content of the manganese is high; and the requirement of the anode material of a lithium-ion battery can be satisfied.

Owner:贵州大龙汇成新材料有限公司

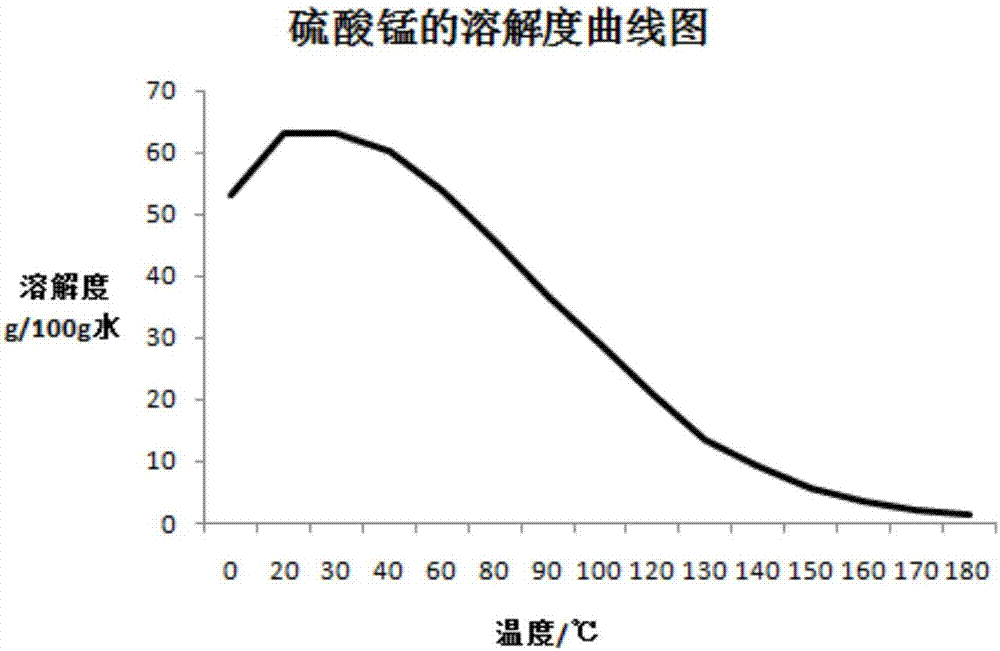

Method for producing manganese sulfate by high-temperature crystallization process

InactiveCN101224908AReduce manufacturing costImprove product qualityManganese sulfatesManganese sulphateManganese(II) carbonate

The invention provides a method for producing high-purity manganese sulfate by adopting a high temperature crystallization method, which includes that the ore pulp of manganese ore and sulfurous iron ore is heated, removed of iron, removed of heavy metal, neutralized, pressure-filtered to obtain a manganese sulfate solution with the content of 160-200g / L, which is pumped to a manganese sulfate solution for carrying out crystallization and purification; the crystallization and purification includes crystallization, solid-liquid separation, dissolution, pressure filtration and other technologies; the pressure-filtered manganese sulfate solution can be crystallized and purified repeatedly as required. The invention can adopt a large amount of low-grade manganese ore with the manganese content of 10-20 percent as the raw material to produce the high-purity manganese sulfate solution and further deep process various high-purity manganese products, such as: electrolytic manganese dioxide, high-purity manganese carbonate, electronic grade mangano-manganic oxide and manganese monoxide, chemical manganese dioxide, industrial grade manganese sulfate monohydrate, chemical grade manganese sulfate monohydrate, medicine grade manganese sulfate monohydrate, food grade manganese sulfate monohydrate, analytically pure manganese sulfate monohydrate and so on.

Owner:广西双德锰业有限公司

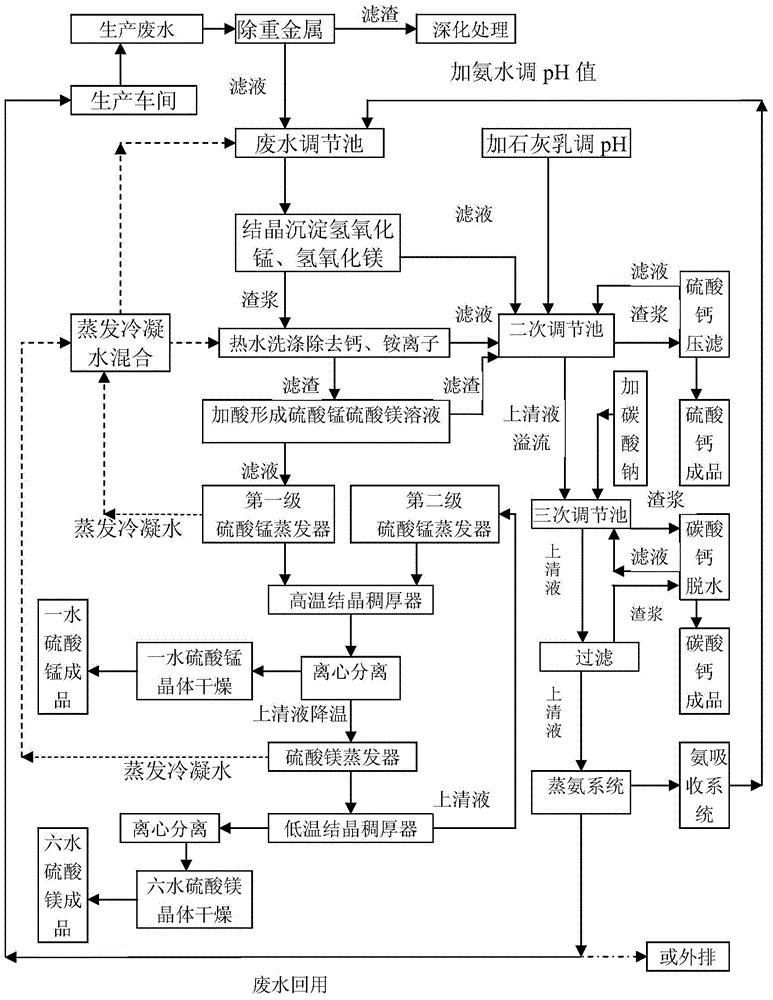

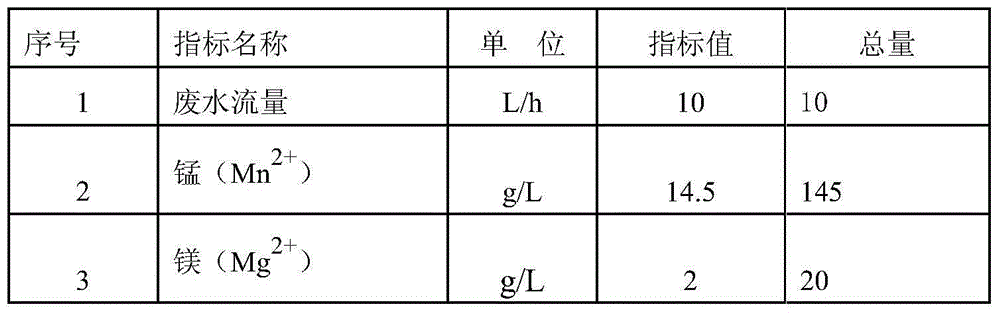

Comprehensive utilization method for separating, concentrating and purifying manganese sulfate, magnesium sulfate and calcium sulfate in high-salt waste water

ActiveCN103553138AAchieving circular economy goalsImprove energy savingCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesSulfateEvaporation

The invention relates to a comprehensive utilization method for separating, concentrating and purifying manganese sulfate, magnesium sulfate and calcium sulfate in high-salt waste water. The method is characterized by comprising the following steps of maintaining the temperature of mother liquor of waste water at 50DEG C to 60DEG C, utilizing ammonia water or liquid ammonia to adjust the pH value of the waste water to 10 to 1.5, collecting separating manganese ions and magnesium ions in the waste water in a form of manganese hydroxide and magnesium hydroxide, adding sulfuric acid into the separated manganese hydroxide and magnesium hydroxide to prepare a manganese sulfate solution and a magnesium sulfate solution, and adopting a segmented evaporation crystallization method to realize the separation to produce manganese sulfate monohydrate and magnesium sulfate hexahydrate; adding lime milk into the waste water after the manganese hydroxide and magnesium hydroxide are separated to adjust the pH value, crystallizing calcium sulfate, precipitating the calcium sulfate, and press filtering the calcium sulfate to produce calcium sulphate dehydrate. After being treated by utilizing the method, the waste water can reach the emission standard and can be externally discharged or recycled by the enterprise, and solid wastes in the waste water can be completely recycled. The investment is low, and the annual net investment return rate is more than 15 percent.

Owner:中诚和易(北京)国际科技有限公司

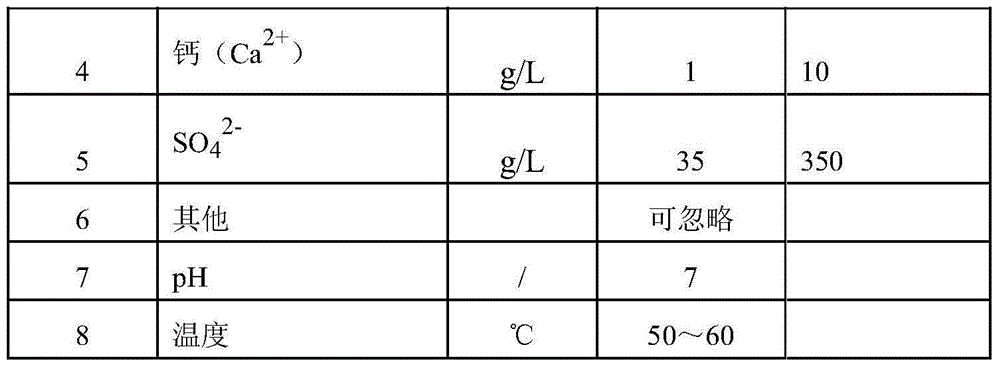

Method for high-purity manganese sulfate monohydrate

InactiveCN103342390ALess impuritiesQuality improvementManganese sulfatesElectrolysisChemical products

The invention relates to the preparation field of chemical products and particularly relates to a method for high-purity manganese sulfate monohydrate. The method specifically comprises the following steps of: taking tail powder of electrolytic manganese dioxide as a raw material, carrying out water washing and acid washing, then carrying out leaching and reducing on MnO2 by taking hydrogen peroxide as a reducing agent, adding barium hydroxide solution, removing Fe<3+>, Si<2+> and Al<3+>, adding barium sulfide solution into the obtained solution, heating the solution to 60-80 DEG C after uniform stirring, carrying out solid-liquid separation, and removing heavy metal elements such as Pb; adding activated carbon in the solution, carrying out stirring and solid-liquid separation at 60-80 DEG C, adding polyacrylamide as a flocculant into the solution after being subjected to activated carbon separation, standing for 24-36 hours after uniform stirring, and carrying out the solid-liquid separation; and carrying out high-temperature crystallization on the obtained solution so as to obtain a manganese sulfate monohydrate product. According to the method, the tail powder produced during the production of the electrolytic manganese dioxide is adequately utilized, the high-purity manganese sulfate monohydrate is produced at a relatively low cost, and then manganese sulfate for ternary materials applied to lithium battery industries is further obtained.

Owner:GUANGXI NANNING SHENGRUI METALLURGICAL & CHEM TECH

Method for preparing fertilizer containing humic acid concentrated chelating trace elements

InactiveCN104478574AIncrease concentrationReduce dosageOrganic fertilisersFertilizer mixturesZINC SULFATE HEPTAHYDRATEPlant growth

The invention relates to a method for preparing a fertilizer containing trace elements, and particularly relates to a method for preparing a fertilizer containing humic acid concentrated chelating trace elements. The method comprises the following steps of firstly, adding supernate containing humic acid, ethylene diamine tetraacetic acid and sodium hydroxide sequentially into a reaction kettle, and stirring until dissolving; then adding heptahydrate, manganese sulfate monohydrate, blue copperas and iron vitriol sequentially into the reaction kettle, chelating, and stirring until dissolving; and then adding boric acid, ammonium molybdate, citric acid, caprylyl / capryl glucoside APG0810 into a reaction kettle, and stirring until dissolving. The invention provides a plant growth adjusting agent which is high in nutritional element concentration, is stable and uniform in solution, contains biochemical humic acid and the like, is beneficial to plant absorption, is high in biodegradability and is low in blade and soil pollution.

Owner:NINGXIA KOCEL BIOLOGICAL CHEM

Lactobacillus fermentation culture medium and process for producing lactic acid at high yield

InactiveCN105087680AIncrease productionExtended growth timeMicroorganism based processesFermentationSodium acetateDipotassium phosphate

The invention relates to the field of lactobacillus fermentation and particularly relates to a lactobacillus fermentation culture medium and a process for producing lactic acid at high yield. The lactobacillus fermentation culture medium is composed of peptone, a beef extract, a yeast extract or yeast extract powder, glucose, sodium acetate, ammonium citrate, dipotassium phosphate, magnesium sulfate heptahydrate, manganese sulfate monohydrate, tween-80, inulin and water. Compared with the existing process for producing lactic acid through microbial fermentation, the process disclosed by the invention can be used for remarkably (P<0.05) prolonging the growth time of lactobacillus and remarkably (P<0.01) increasing the yield of lactic acid.

Owner:沈阳科纳提克生物科技有限公司

Battery grade high-purity manganese sulfate monohydrate and preparation method thereof

InactiveCN102923783AHigh in manganeseReduce manganese contentManganese sulfatesLithium-ion batteryPolyacrylamide

The invention relates to battery grade high-purity manganese sulfate monohydrate and a preparation method thereof. The content of the high-purity manganese sulfate monohydrate is over 32 percent, the contents of all impurities potassium, sodium, calcium and magnesium are less than 50 ppm, the content of heavy metal impurity is below 10 ppm, the content of impurity ferro is below 5 ppm, and the content of impurity fluorine is below 100 ppm. The preparation method comprises the following steps: gray manganese ore, manganese blende or sulfurous iron ore and industrial sulphuric acid are taken as the raw materials, hydrogen peroxide is added firstly, and the temperature is controlled within 50-70 DEG C; secondly, BaS is added, and the temperature is controlled within 30-50 DEG C; thirdly, hydrofluoric acid is added, and the pH is regulated to 5-6 by adding a neutralizing agent MnCO3; fourthly, polyaluminum sulfate and polyacrylamide solution are added to flocculate and deposit, activated carbon is added after filter, and standing and absorption are carried out; fifthly, polyaluminum sulfate and polyacrylamide solution are introduced into a circulation device equipped with an active alumina ball; and lastly, the high-impurity manganese sulfate is obtained via non-pressurized compaction and crystallization, washing and drying. The manganese content of the manganese sulfate monohydrate is high, the contents of each metal impurity and fluorine are lower, and the demand for the positive pole material of lithium ion batteries is completely satisfied.

Owner:HUNAN SPECIAL METAL MATERIALS CO LTD

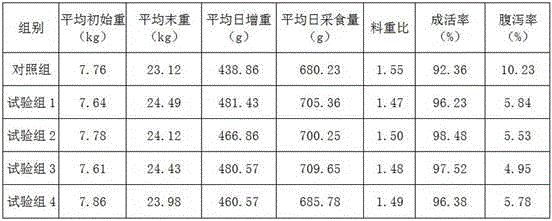

Gosling feed

The invention discloses a gosling feed, and relates to an animal feed, solving the problems of nutritional imbalance of a gosling in a breeding process, low growing speed of the gosling, and influence on the meat quality due to medicine residue in the feed. The gosling feed comprises corn, bean pulp, fish meal, lysine, calcium hydrophosphate, soya-bean oil, glucose, mountain flour, salt and premix compound, wherein the premix compound comprises vitamin A acetate, vitamin D3, vitamin E, vitamin K, vitamin B2, nicotinic acid, calcium pantothenate, vitamin B12, choline chloride, ferrous sulfate monohydrate, zinc sulfate monohydrate, copper sulfate pentahydrate, manganese sulfate monohydrate, potassium iodide, sodium selenite, compound enzyme, phytase, 66 percent ethoxyquin and mountain flour. The average daily gain of the 28-day-old gosling fed by the gosling feed is above 70g, the average weight is above 2kg, the feed conversion ratio is below 1.9; and meanwhile, the gosling is healthy, and is low in disease rate. The scheme is applied to the field of preparation of the gosling feed.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

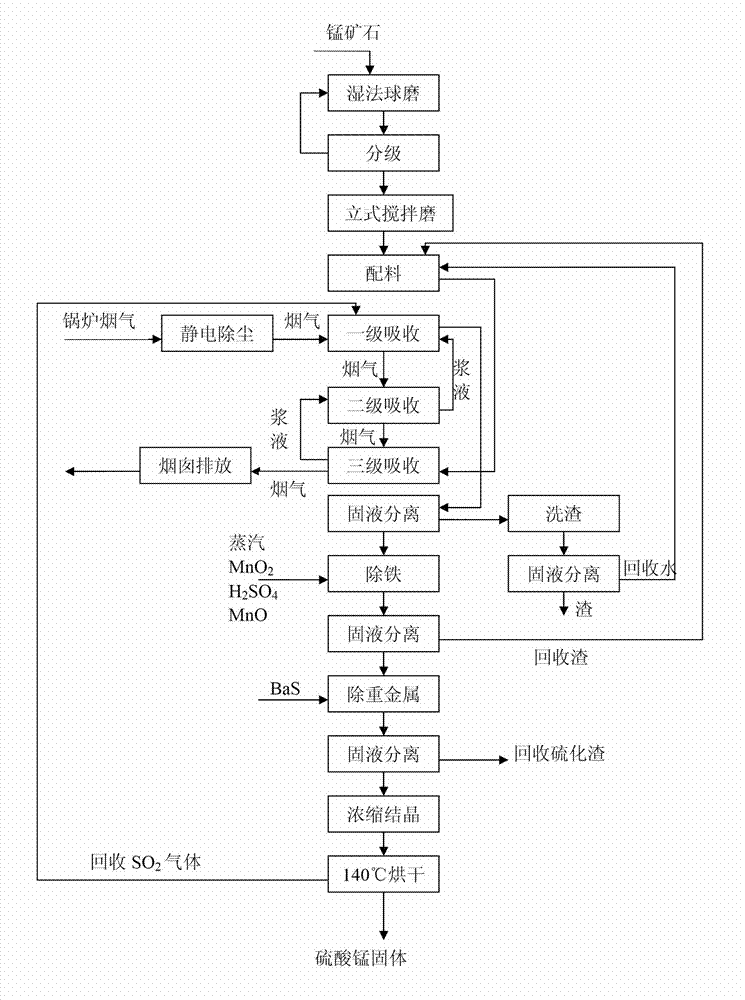

Method for preparing manganese sulfate by using manganese dioxide ore pulp to absorb sulfur dioxide in flue gases

ActiveCN102815750ALess solidMeet the requirements of flue gas desulfurizationChemical industryManganese sulfatesChemistryManganese sulphate monohydrate

The invention discloses a method for preparing manganese sulfate by using a manganese dioxide ore pulp to absorb sulfur dioxide in flue gases. The method includes following steps of subjecting manganese dioxide ore to wet ball milling and grading to obtain an initial ore pulp, and smashing the initial ore pulp through a vertical type stirring mill to obtain a reaction ore pulp; adding a manganese sulfate solution containing Fe<3+> and / or Fe<2+> to the obtained reaction ore pulp, then subjecting the reaction ore pulp and the high temperature flue gases containing the sulfur dioxide to absorption reaction with the reaction temperature controlled between 90 DEG C and 95 DEG C; and subjecting reaction products obtained after the absorption reaction to solid-liquid separation, iron removing and heavy metal removing, and then performing ordinary pressure concentration and crystallization to obtain the manganese sulfate monohydrate, wherein particle sizes of ore materials in the initial ore pulp are smaller than 149 mu m, and particle sizes of 90% of the ore materials in the reaction ore pulp below 50 mu m. The method for preparing the manganese sulfate by using the manganese dioxide ore pulp to absorb the sulfur dioxide in the flue gases has the advantages of being energy-saving, environment-friendly, high in resource utilization rate, high in product additional value, good in flue gas desulfurization effects, continuous and thorough in reaction, low in costs and the like.

Owner:贵州大龙汇成新材料有限公司

Special strawberry composite biological fertilizer as well as preparation method and application thereof

InactiveCN107827627AReduce pollutionReduce cost inputCalcareous fertilisersBio-organic fraction processingAureobasidium sp.Nutrients substances

The invention relates to a special strawberry composite biological fertilizer as well as a preparation method and application thereof. The special strawberry composite biological fertilizer comprisesthe following components: EDTA-Ca (Ethylene Diamine Tetraacetic Acid), magnesium sulfate heptahydrate, EDTA-Mg, heptahydrate, EDTA-Zn, manganese sulfate monohydrate, EDTA-Mn, boric acid, EDTA-Fe, EDTA-Cu, soybean molasses, polyglutamic acid fermentation broth, chitosan oligosaccharide, algin, compound amino acid, humic acid, bacillus thuringiensis fermentation broth, bacillus megatherium fermentation broth, bacillus mucilaginosus fermentation broth and streptomyces jingyangensis fermentation broth. Through bacterium activation, seed liquid preparation, fermentation culture and compounding, thecomposite biological fertilizer is prepared, the composite biological fertilizer is applied to strawberry planting, and a diluted composite biological fertilizer liquid is sprayed at different growthstages of strawberry respectively. Due to synergetic effects of substances such as inorganic salts, organic matters and microorganisms, long lasting nutrient substances are provided to strawberry crops, absorption of nutrients in soil by plants is promoted, the fertilizer amount is reduced, and the chemical fertilizer cost is reduced.

Owner:天津北洋百川生物技术有限公司

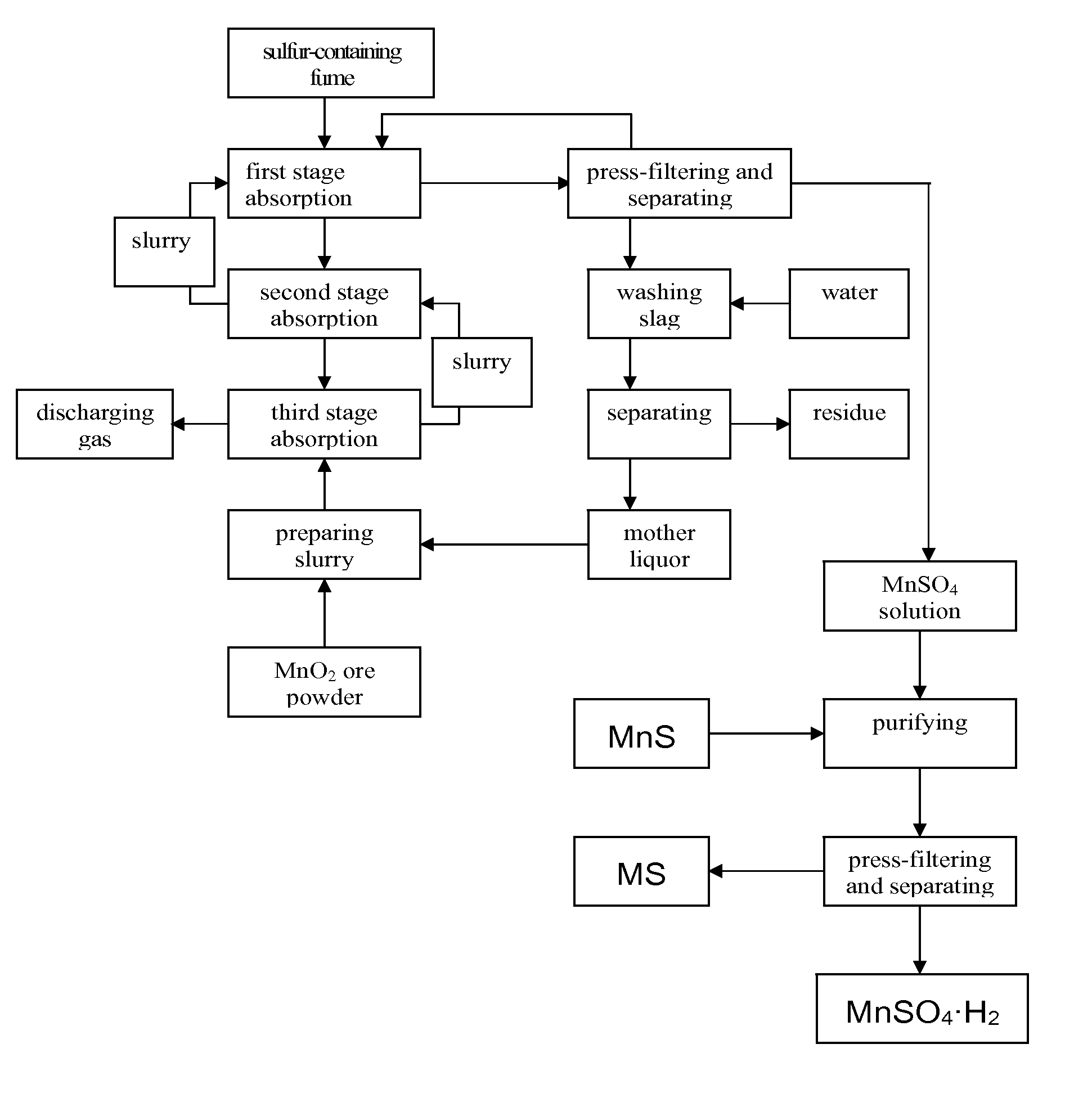

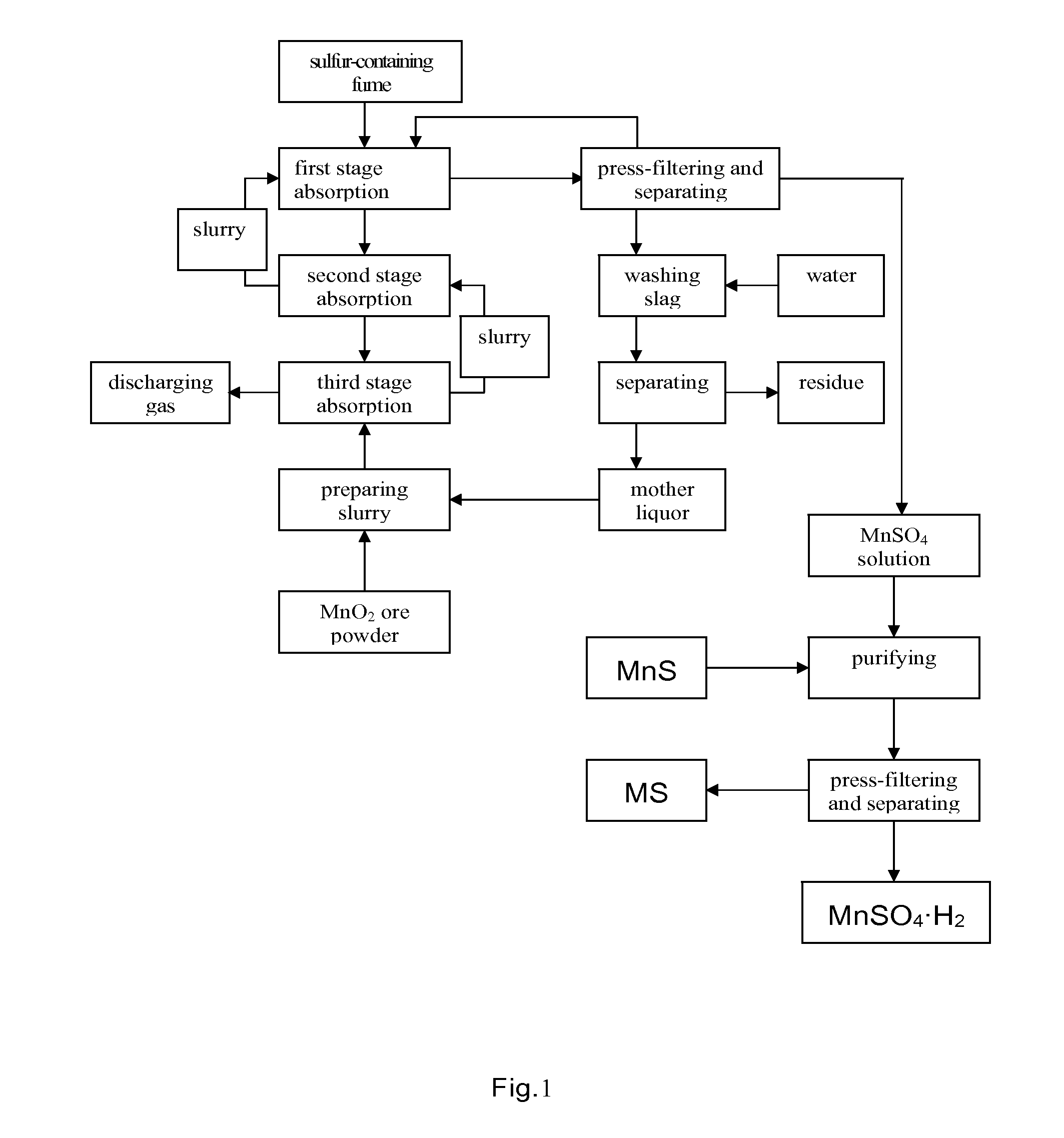

Method for preparing manganese sulfate monohydrate by desulfurizing fume with middle-low grade manganese dioxide ore

InactiveUS20120328495A1Low costImprove efficiencyDispersed particle separationManganese sulfatesSlurrySulfur containing

A method for preparing manganese sulfate monohydrate by desulfurizing fume with middle-low grade manganese dioxide ore, which includes: preparing a slurry by using middle-low grade manganese dioxide ore powder, putting sulfur-containing fume in an absorbing device and controlling gas velocity and gas-liquid ratio, and then adding manganese dioxide slurry and controlling the slurry to backwards flow relative to the sulfur-containing fume, discharging the desulfurized fume from the absorbing device, pressure-filtering and separating the slurry discharged from the absorbing device, recycling the mother liquor to the absorbing device, and continuing the recycling operation until the manganese sulfate in the mother liquor is >=200 g / l, the obtained filter cake at 60-70° C., adjusting pH value of the clear solution obtained to 2-4, adding manganese sulfide under agitation at 25-95° C., and removing impurities, continuing agitating, pressure-filtering and separating, vaporizing the obtained clear filtrate, and obtaining manganese sulfate monohydrate after drying in the air stream.

Owner:GUIZHOU REDSTAR DEVING

Feed additive replacingantibiotics for preventing weaned piggies from suffering from diarrhoea

ActiveCN106509439AInhibition of growth and reproductionEnsure balanceAnimal feeding stuffAccessory food factorsBacillus licheniformisMycotoxin

The invention provides a feed additive replacing antibiotics for preventing weaned piggies from suffering from diarrhoea. The additive is prepared from the following raw materials of bacillus licheniformis, enterococcus faecalis, clostridium butyricum, a sweetening agent (5% neotame), cupric sulfate pentahydrate, manganese sulfate monohydrate, ferrous sulfate monohydrate, zinc sulfate monohydrate, tributyrin, an antioxidant, montmorillonite and fermented apple pomace. The feed additive disclosed by the invention can improve the microenvironment of intestinal tracts of piggies, repair damaged intestinal mucosa, strengthen digestive absorption functions, strengthen the immunity of the piggies, promote the growth of the piggies, adsorb mycotoxin in feeds at the same time, effectively prevent the weaned piggies from suffering from diarrhoea and increase economic returns.

Owner:SHANXI DAYU BIOLOGICAL ENG CO LTD

Nutrient capsules for pregnant woman

A health-care nutrients softgel for gravida is prepared from 22 nutrients including VC, nicotinamide, VE, pantothenic acid, VB6, VB1, Vb2, beta-carrotin, folic acid, VD2, etc.

Owner:FERGUSON WUHAN BIOTECH

Duck premix for enhancing hatching egg fertilization rate

ActiveCN102948623AConsider comprehensivelyReduced stress resistanceAnimal feeding stuffVitamin K3Vitamin B12

The invention discloses a duck premix for enhancing the hatching egg fertilization rate. The premix is composed of various vitamins and trace elements necessary in a duck growth process and a ball-milled mixture of rice bran and hulls. Specifically, the vitamins include vitamin A, vitamin D3, vitamin E, vitamin B2, vitamin B1, vitamin B6, vitamin B12 and vitamin K3; and the trace elements include calcium pantothenate, niacin, folic acid, biotin, ferrous sulfate monohydrate, copper sulfate pentahydrate, zinc sulphate monohydrate, manganese sulfate monohydrate, sodium selenite, and chromium picolinate. The premix provided in the invention not only meets the basic nutritional needs of ducks, but also appropriately increases the content of some trace elements, thus being able to effectively prevent the decline of duck semen quality and ensure the fertilization rate and hatching rate of hatching eggs. By combining bulk raw materials with the premix provided in the invention, other nutritional substances needed by hatching drakes during a breeding period can be replenished. Therefore, the premix is very convenient and is easy for mass promotion.

Owner:唐山铁骑力士饲料有限公司

Granular feed for laying chicks

InactiveCN102210419ADoes not destroy nutritional valueReduce respiratory diseaseFood processingAnimal feeding stuffRapeseedCopper sulfate pentahydrate

The invention discloses a granular feed for laying chicks, and relates to a chicken feed. The granular feed comprises corn, wheat middling, bean pulp, cottonseed meal, rapeseed meal, corn albumen powder, fish meal, calcium hydrogen phosphate, fine rock powder, table salt, choline chloride, ferrous sulfate monohydrate, blue copperas, manganese sulfate monohydrate, zinc sulfate monohydrate, 1 percent sodium selenite, 98 percent lysine, 98 percent methionine, multiple chicken vitamins, 10 percent colistin, salinomycin, 1 percent calcium iodate and kitasamycin. The granular feed is prepared at a low temperature, so that the nutritional value of the feed is not destroyed, the crushing fineness of the feed is improved, and the feed has good palatability, is easily digested and can effectively reduce the respiratory diseases of chicks; and after the chicks are raised for 42 days by using 1Kg of the granular feed, the chick flock individuals are uniform, and the average weight can reach 480g and totally reaches the weight standard of medium laying chicks.

Owner:山西宏福农牧科技有限公司

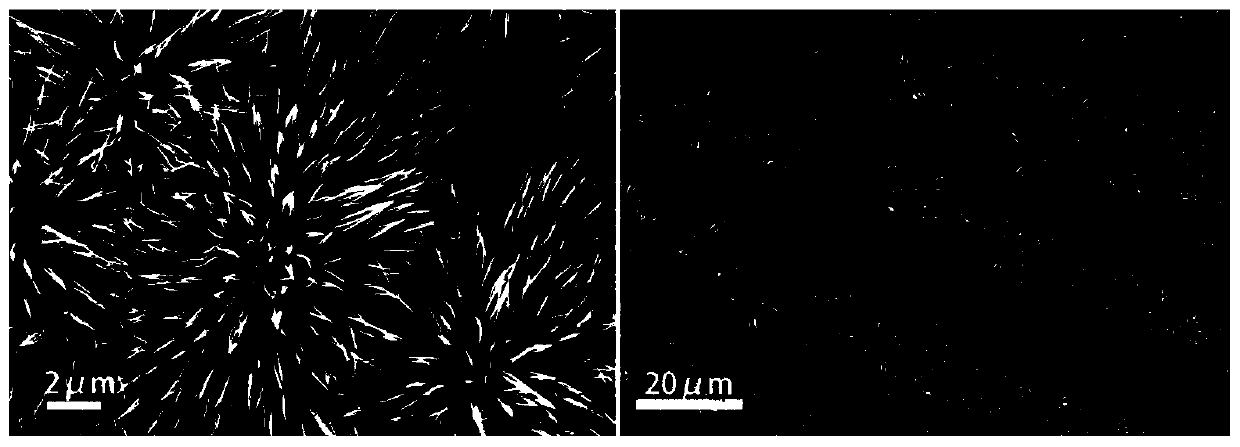

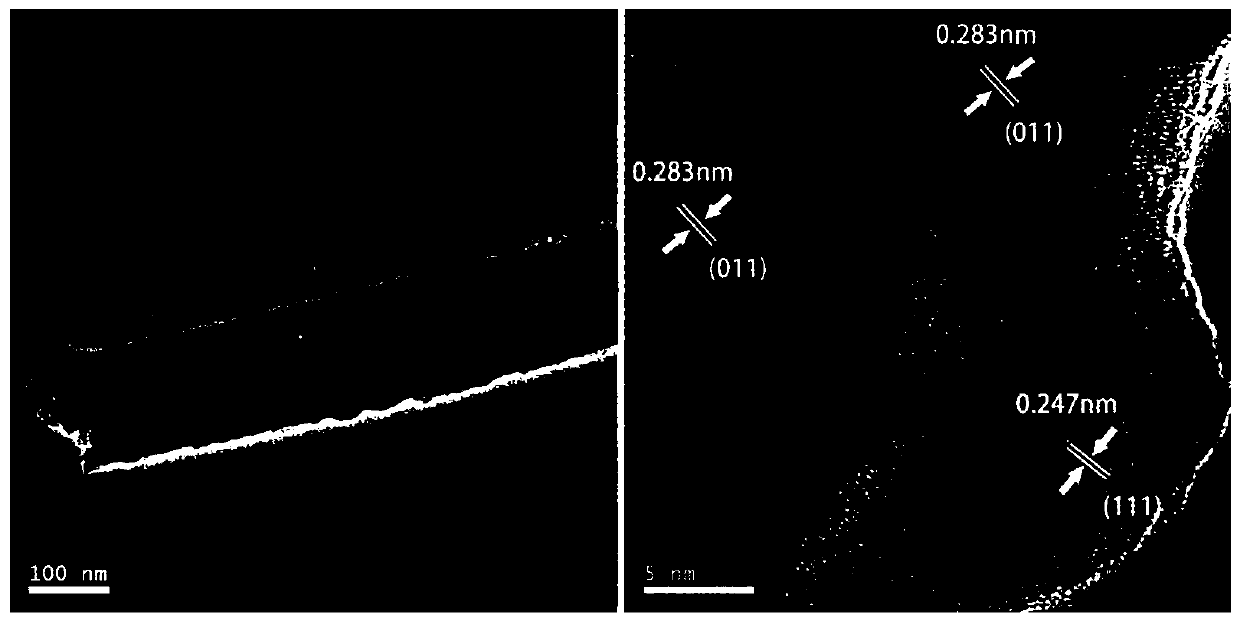

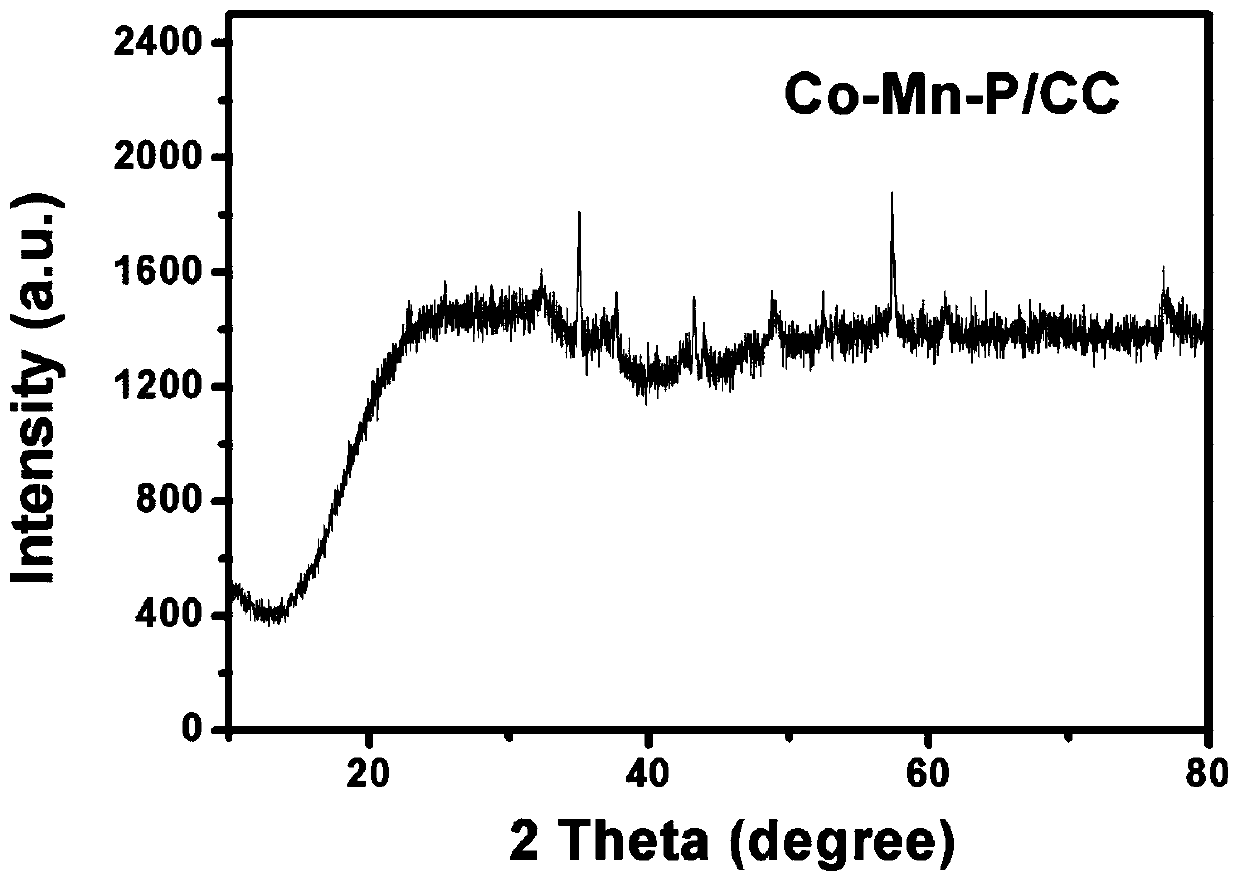

Cobalt-manganese-phosphorus urchin-like nano wire hydrogen evolution catalytic material growing on carbon cloth

InactiveCN110252360AUnique structureLarge specific surface areaPhysical/chemical process catalystsElectrodesNanowireSodium phosphates

The invention discloses a cobalt-manganese-phosphorus urchin-like nano wire hydrogen evolution catalytic material growing on carbon cloth. The preparation method comprises following steps: step one, hydrothermally synthesizing a precursor: weighing urea, ammonium fluoride, manganese sulfate monohydrate, and cobalt nitrate hexahydrate into deionized water, fully and evenly stirring to obtain a mixed solution, adding the mixed solution and preprocessed carbon cloth into a reactor, and carrying out hydrothermal reactions to obtain a precursor; and step two, generating the cobalt-manganese-phosphorus urchin-like nano wire hydrogen evolution catalytic material through phosphorization: preparing a porcelain boat, arranging sodium phosphate on the upstream of the porcelain boat, arranging the precursor on the downstream of the porcelain boat, finally, placing the porcelain boat in a tube furnace, introducing protective gas into the tube furnace, setting the program, and carrying out phosphorization to obtain the product. The provided material has a unique urchin-like nano wire structure, excellent hydrogen evolution catalytic activity, and extremely high stability, moreover, the raw materials are abundant, no precious metal is used, the repeatability is good, and the preparation method is simple.

Owner:ZHEJIANG SCI-TECH UNIV

Pig's feed pre-mixing material and preparing method

InactiveCN1977633AImprove immunityImprove qualityAnimal feeding stuffAccessory food factorsLicorice rootsCopper sulfate pentahydrate

The present invention discloses a pig feed premixed material and its preparation method. It is made up by using blue copperas, copper sulfate monohydrate, zinc sulfate monohydrate, calcium iodate, organic selenium, choline chloride, enzyme preparation, calcium hydrogen phosphate, stone powder, edible salt, astragalus root, lonicera flower, licorice root and zeolite powder according to a certain mixing ratio through a certain preparation process. Said invention can raise immunity of pig and can raise quality of pig meat.

Owner:民惠食品(重庆)有限公司

Method for recycling valuable metal in manganese-rich slag

InactiveCN102242267AHigh recovery rateShorten the recycling processProcess efficiency improvementManganese sulphateSlag

The invention discloses a method for recycling a valuable metal in manganese-rich slag. The method comprises the following process steps of: a, leaching out the manganese-rich slag by using a sulfuric acid solution with a concentration of 50-250g / L according to a ratio of solid to liquid of 1:1-1:5, and converting into a sulfate solution; b, carrying out constant-temperature crystallization on the leached sulfate solution at 180-250 DEG C for 10-30min; c, filtering at 180-250 DEG C to obtain a crystallization master liquid and manganese sulfate crystals; d, cooling down the manganese sulfate crystals to 20-50 DEG C for dissolving, and filtering to obtain a pure manganese sulfate solution; e, carrying out constant-temperature recrystallization on the pure manganese sulfate solution at 180-200 DEG C for 10-30min, filtering at 180-200 DEG C and drying the crystals to obtain manganese sulfate monohydrate crystals; and f, settling the filtered crystallization master liquid in the step c by using sodium sulfide with 2-5 times of theoretical amount to obtain a sulfate sediment. According to the method disclosed by the invention, the valuable metal in the manganese-rich slag is recycled by using a high-temperature recrystallization method, the recycling rate of the valuable metal is high, and the recycled valuable metal can be recycling with a responsive crude ore, thus the recycling process flow of is shortened, and the production cost is reduced.

Owner:JINCHUAN GROUP LIMITED

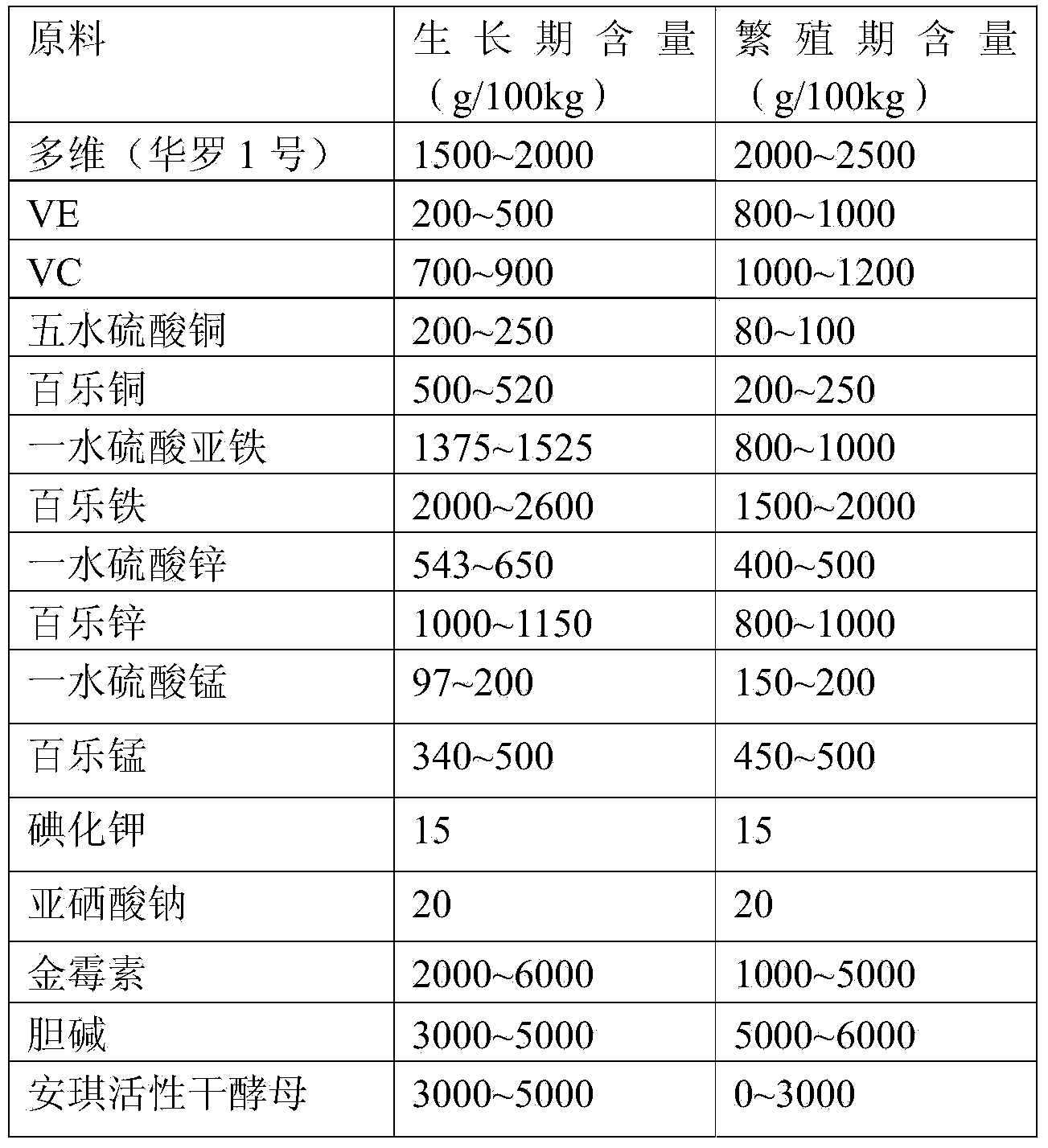

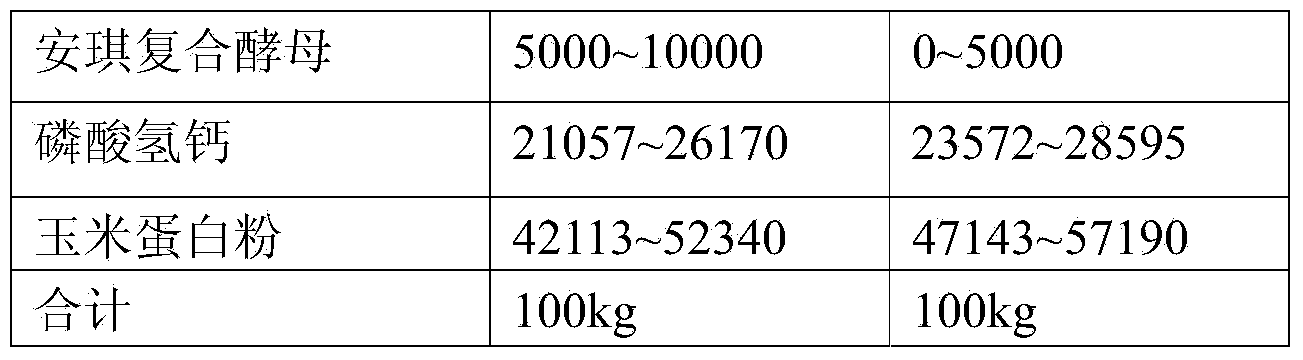

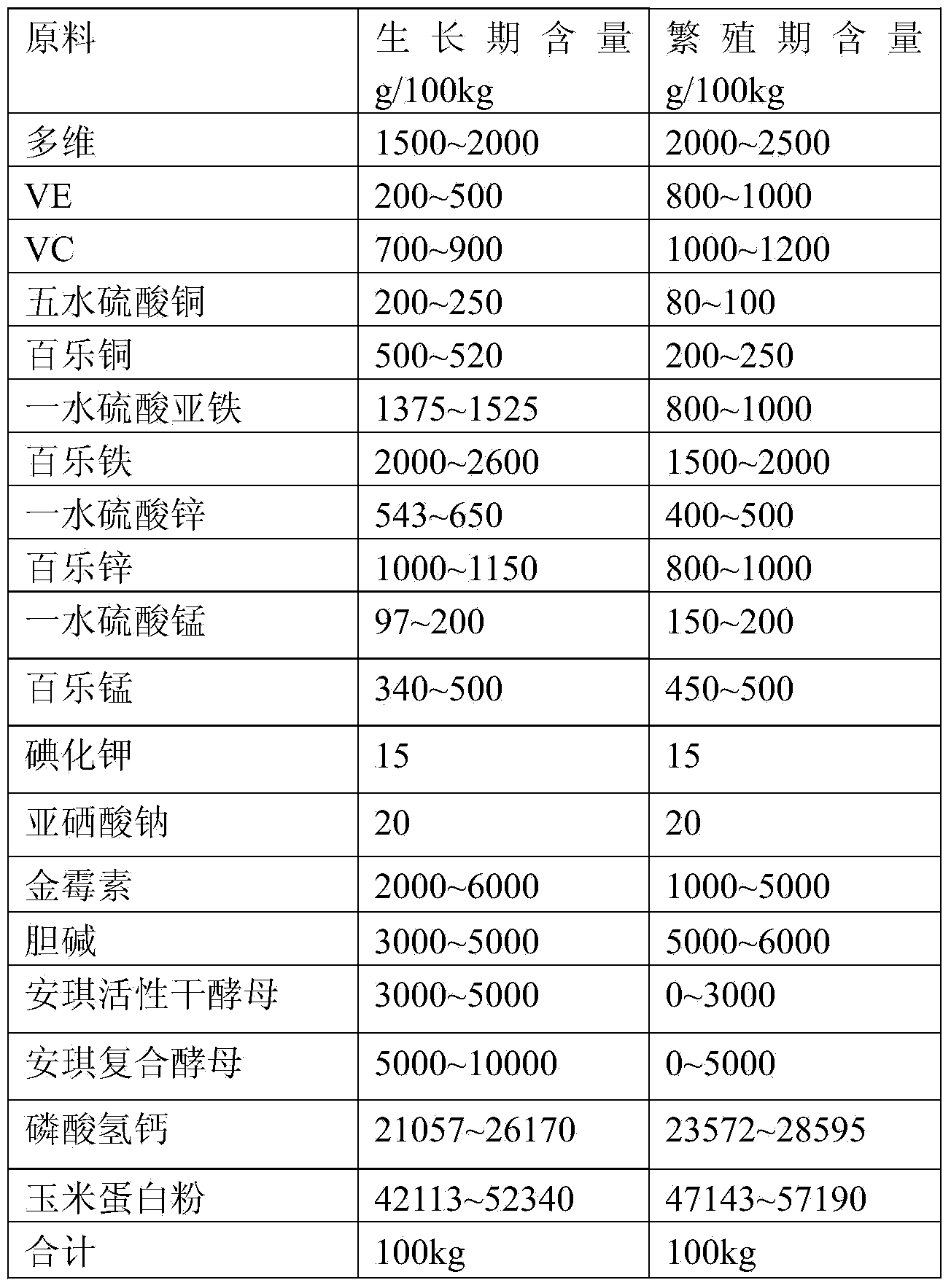

Composite premix feed for foxes and raccoon dogs

The invention relates to a composite premix feed for foxes and raccoon dogs. The composite premix feed is applied to the field of fox and raccoon dog breeding or the field of fur animal feed production and is particularly used for improving the productivity of the foxes and the raccoon dogs. The composite premix feed comprises formulas for the growth period and the reproduction period. The formula mainly comprises multi-vitamin, blue copperas, baile copper, ferrous sulfate monohydrate, baile iron, zinc sulfate monohydrate, baile zinc, manganese sulfate monohydrate, baile manganese, potassium iodide, sodium selenite, aureomycin, choline, angel active dry yeast, angel composite yeast, calcium hydrophosphate and corn protein powder. Composite premix feed constituents and contents of the constituents for two key production stages, namely the growth period and the reproduction period, of the foxes and the raccoon dogs are researched; the growth performance of the foxes and the raccoon dogs is improved, and the reproduction performance of seed beast is improved.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

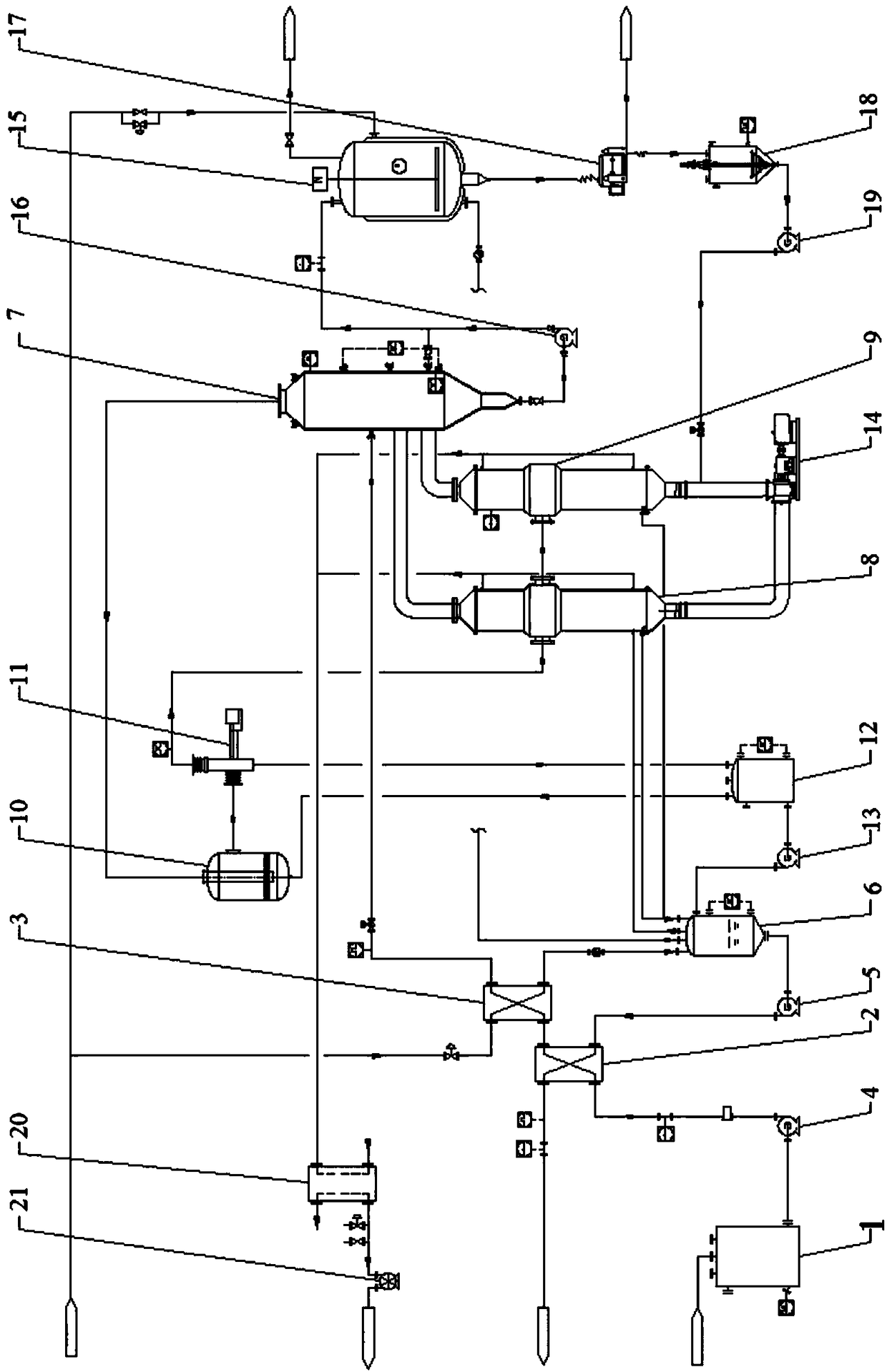

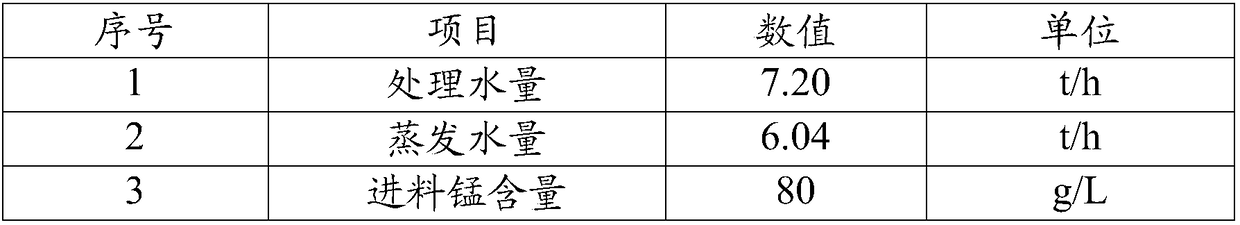

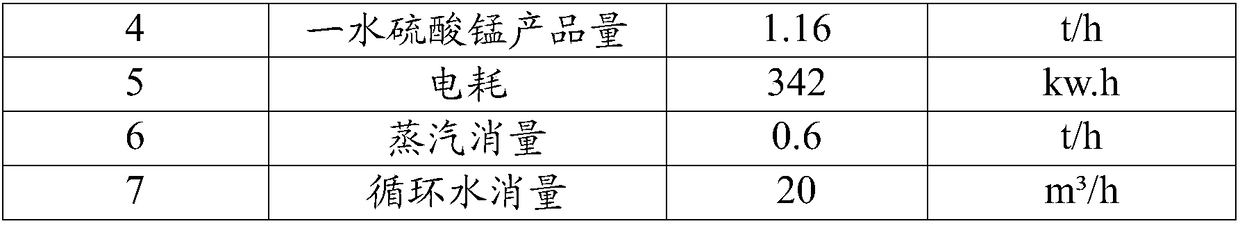

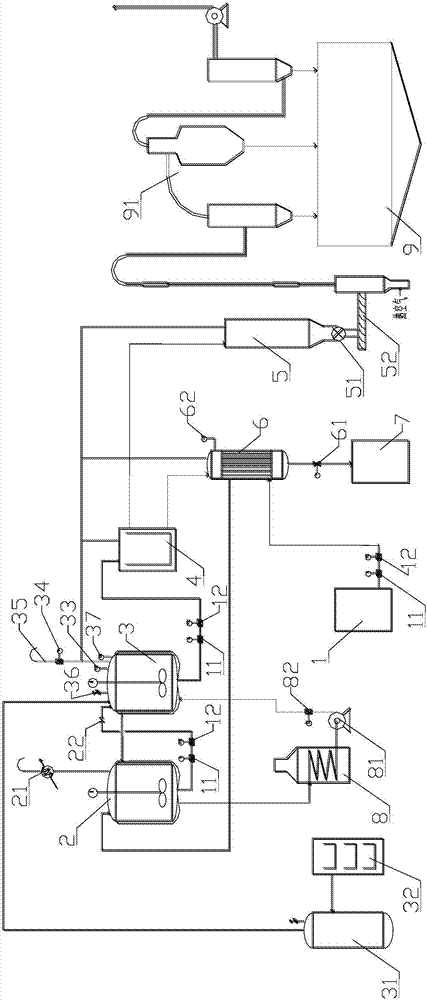

Manganese sulfate evaporative crystallization equipment and process

ActiveCN108568135AFree from destructionIncrease productivitySolution crystallizationCrystallization plant arrangementsSulfateSmall footprint

The invention discloses manganese sulfate evaporative crystallization equipment. The manganese sulfate evaporative crystallization equipment comprises a stock solution preheating system, an evaporative concentration system, a high-temperature crystallization system and a filtering-separating system which are sequentially connected, and further comprises a control mechanism, wherein the high-temperature crystallization system comprises an enamel high-temperature kettle; and the control mechanism is in signal connection with the stock solution preheating system, the evaporative concentration system, the high-temperature crystallization system and the filtering-separating system. The equipment can be used for directly evaporating and crystallizing lean manganese ore with relatively low manganese sulfate content to obtain manganese sulfate monohydrate, is simple in structure, is small in floor space, is low in investment, realizes an automatic production process of manganese sulfate monohydrate from manganese sulfate stock solution treatment to product package, is high in production efficiency, is free of damage to environment, and is the equipment with low energy consumption and highdegree of automation. The invention further discloses a process for preparing manganese sulfate by utilizing the equipment, and the process is simple in step, is low in energy consumption, is low in production cost, increases the yield of manganese sulfate produced by lean manganese ores, and is low in consumed steam amount.

Owner:SHENZHEN SUNEVAP TECH

Method for producing manganese sulphate by high temperature crystallization process

InactiveCN1803633AReduce energy consumptionHigh recovery rateManganese sulfatesManganese sulphateDissolution

The preparation method for manganese sulphate monohydrate by high temperature crystallization comprises: adding the manganese sulphate solution into crucible, stirring and heating to 152-245Deg, keeping for 5-55min; then, discharging some sewage, stopping stirring and heating, sending the solution to dissolution bath; after dissolving fully, pressure filtering, and keeping stable for more than 36h, pressure filtering again to obtain refined manganese sulphate solution; adjusting solution pH value to 2-3 with sulfuric acid, then pumping into crucible, stirring and heating to 152-199Deg within 20-80min, keeping for 5-55min, then discharging waste, and stirring again; heating to 152-199Deg and keeping for 5-55min, solid-liquid separating to obtain the final product. This invention has low energy consumption, high yield, no pollution to environment, and stable product quality.

Owner:广西双德锰业有限公司

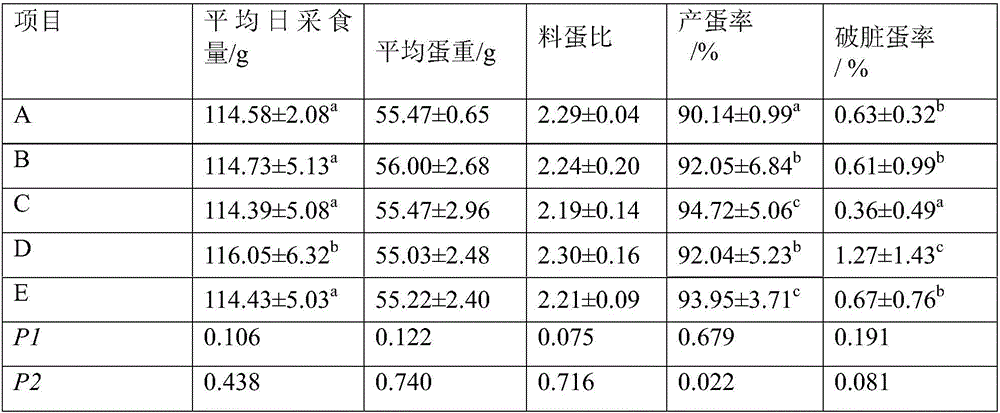

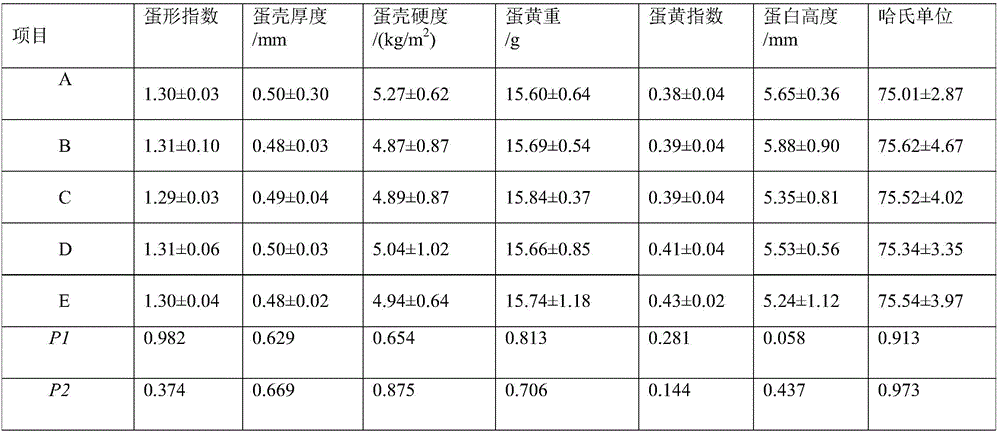

Production process of functional premix for regulating and controlling egg quality and relieving heat stress of laying hens

ActiveCN102907578AImprove stress resistanceIncrease intakeFood processingAnimal feeding stuffVitamin K3Tryptophan

The invention discloses a production process of a functional premix for regulating and controlling egg quality and relieving heat stress of laying hens and relates to the technical field of nutrition of laying hens and regulation and control. The production process comprises the following steps of: mixing and beating peeled fresh garlic with drinking water to prepare garlic paste; mixing the garlic paste with corn protein powder, dry red pepper powder, fruit oligose, bacillus subtilis and citric acid to form a mixture A; mixing vitamin A, vitamin D3, vitamin E, vitamin K3, vitamin B1, vitamin B2, vitamin B6, vitamin B12 and the like with rice hull powder to form a mixture B; mixing ferrous sulfate monohydrate, copper sulfate pentahydrate, zinc sulfate monohydrate, manganese sulfate monohydrate, iodine, selenium, cobalt chloride hexahydrate, zeolite powder, tryptophan, lysine and the like with calcium hydrogen phosphate to form a mixture C; and then evenly mixing the mixture A, the mixture B and the mixture C. The production process can be used for improving the dietary nutrient intake and utilization efficiency of metabolism of the laying hens, and promoting the deposition and metabolism of nutrients.

Owner:JIANGSU INST OF POULTRY SCI

Premix for production of selenium-rich eggs as well as preparation method and application of premix

A premix for production of selenium-rich eggs is prepared from raw materials as follows: maifanite, white middling flour, calcium hydrogen phosphate, feed-grade table salt, Cinergy, Nutri p, methionine, phytase, synthetic betaine, choline, decavitamin, zinc sulfate, calcium iodate, manganese sulfate monohydrate, ferrous potassium sulfate monohydrate, anhydrous cupric sulfate and selenium yeast. The premix is safe and healthy and contains no chemical additives harmful to human bodies, produced eggs have reliable quality and taste good, besides, after laying hens are fed with feed prepared from the premix, eggs laid by the laying hens contain rich selenium elements, the selenium content is larger than or equal to 0.3 mg / kg and 5-6 times higher than that of conventional eggs, and the requirement of human bodies for selenium can be met.

Owner:湖南省鹏晖农牧有限公司 +1

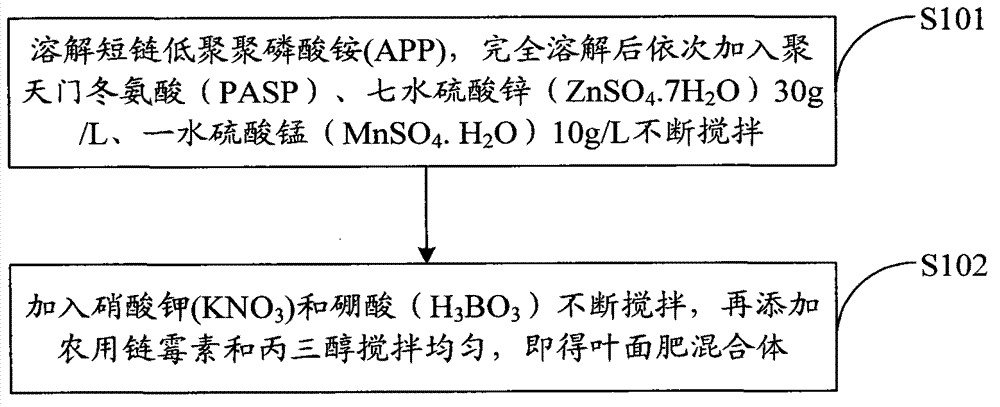

Leaf fertilizer mixture and preparation method thereof

The invention discloses a leaf fertilizer mixture and a preparation method thereof. The leaf fertilizer mixture comprises 200g / L of short-chain oligomeric ammonium polyphosphate (APP), 20g / L of polyaspartic acid (PASP), 20g / L of glycerol, 0.6g / L of agricultural streptomycin, 100 g / L of potassium nitrate (KNO3), 30g / L of heptahydrate (ZnSO4.7H2O), 10g / L of manganese sulfate monohydrate (MnSO4.H2O), and 10g / L of boric acid (H3BO3). When used, the leaf fertilizer mixture is diluted into 500-600 times; after being uniformly mixed, 100ml of the leaf fertilizer mixture is respectively sprayed on front and reverse surfaces of corn leaves and a part of stems per mu during the growth elongation period and the opening period of corns; the leaf fertilizer mixture is high in nutrient permeability; fertilizer drops easily permeate in leaves; the utilization rate of nutrients is high; and photosynthesis of leaves and lodging-resistant, disease- and insect-resistant and stress-resistant capabilities of corns are increased.

Owner:QINGDAO AGRI UNIV

Culture method for improving contents of cordyceps militaris hypha and cordycepin in silkworm chrysalis cordyceps

InactiveCN106810366AIncrease productionPromote secretionMagnesium fertilisersAlkali orthophosphate fertiliserTrace element compositionBiological activation

The invention belongs to the field of edible fungi cultivation, and particularly relates to a culture method for improving contents of cordyceps militaris hypha and cordycepin in silkworm chrysalis cordyceps. The method includes cultivation of cordyceps militaris hypha and cultivation of silkworm chrysalis cordyceps. The cultivation of cordyceps militaris hypha is prepared by performing culture activation in a solid culture base and cultivating liquid culture in a liquid culture base, wherein the solid culture base and the liquid culture base include 0.083-0.81% of trace element composition by weight; the trace element composition is selected from one or more of ferric sulfate tetrahydrate, zinc sulfate octahydrate, blue copperas, manganese sulfate monohydrate, sodium cobalt dehydrate; the technical scheme disclosed in the invention is simple in method, and high in efficiency.

Owner:北京新创青龙湖种植专业合作社

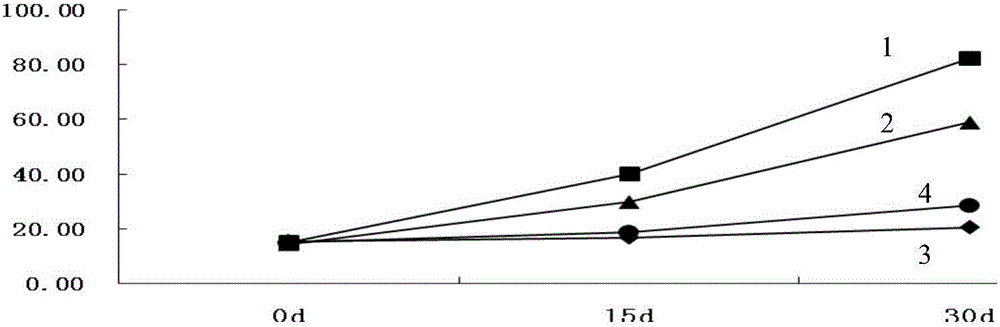

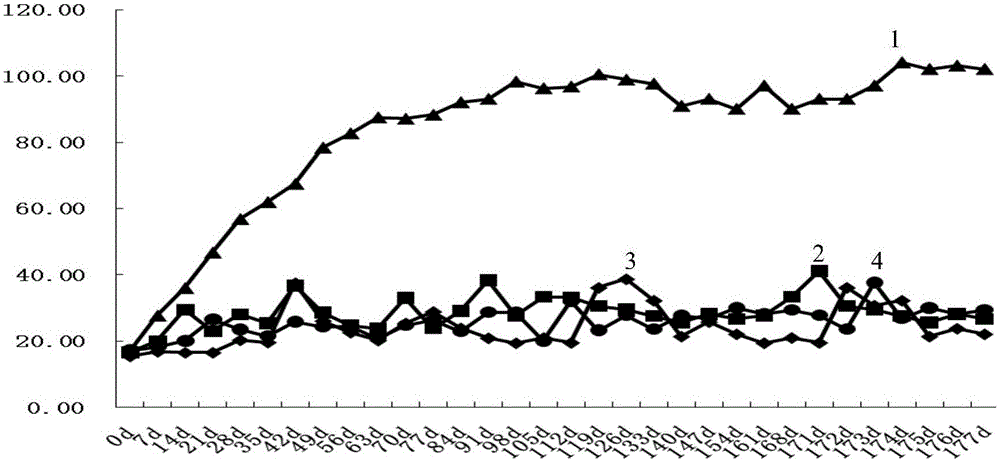

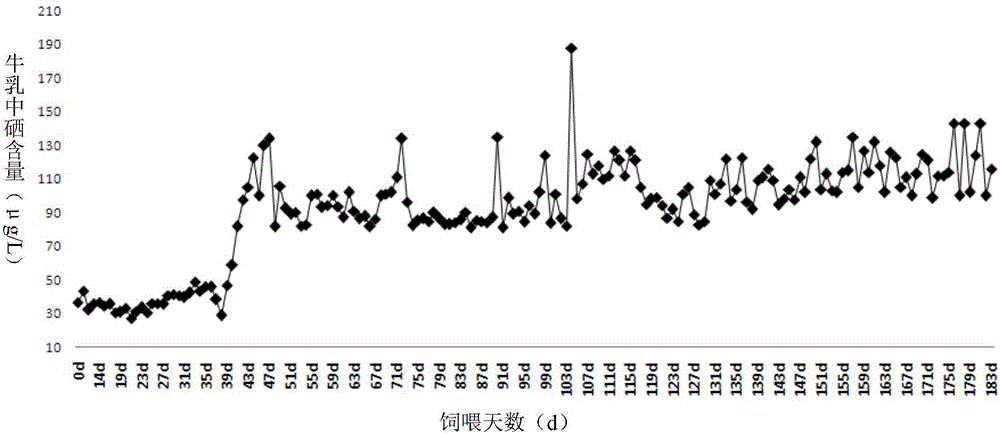

Method for raising cows capable of producing selenium-rich milk

ActiveCN105918249AIncrease contentStable productionMilk preparationFood processingAnimal scienceMilk cow's

The invention discloses a method for raising cows capable of producing selenium-rich milk and belongs to the technical field of cow raising. The raising method comprises the following steps: each cow in a lactation period is fed with selenium yeast in the adding amount of 20-30 mg / day, the content of vitamin E, zinc sulfate monohydrate and manganese sulfate monohydrate in feed is changed 40 days after feeding starts, and then the cows are fed with the feed with changed composition until the lactation period ends. With adoption of the method, the content of selenium in the milk produced by the cows can keep higher level for a long time, the feeding cost is low, and the method is applicable to production of the selenium-rich milk.

Owner:黑龙江克东瑞信达原生态牧业股份有限公司

Method for preparing manganese sulfate by using low grade manganese mud

The invention provides a method for preparing manganese sulfate from low-grade manganese slag, which comprises: the slurry of manganese ore and the slurry of iron pyrite are subjected to heating reaction, iron removal, heavy metal removal, neutralization and pressure filtration to form a manganese solution of which the concentration is 150 to 200g / L; and the manganese solution is pumped for crystallization and purification. The crystallization and purification comprises crystallization, solid-liquid separation, dissolution, pressure filtration and so on. The method uses rich low-grade manganese ore containing 10 to 20 percent of manganese as a raw material to produce a high-purity manganese sulfate solution which is used for deep processing of various high-purity manganese products such as electrolytic manganese dioxide, high-purity manganese carbonate, electronic grade trimanganese tetroxide and manganese monoxide, chemical manganese dioxide, industrial manganese sulfate monohydrate, chemical manganese sulfate monohydrate, medical manganese sulfate monohydrate, food manganese sulfate monohydrate, and analytical pure manganese sulfate monohydrate.

Owner:杜祖德

Process for preparing manganese sulfate by high-temperature crystallization method and automatic continuous production device

ActiveCN107055622AReduce consumptionAdvanced production technologyManganese sulfatesSulfateEnergy consumption

The invention discloses a process for preparing manganese sulfate by a high-temperature crystallization method and an automatic continuous production device. The process comprises the following steps: adding manganese sulfate solution which is impurity-removed and purified to a preheating kettle, and heating the added manganese sulfate solution to 90-100 DEG C by the preheating kettle; adding the heated manganese sulfate solution into a high-temperature crystallization kettle, and heating the added manganese sulfate solution to 160-180 DEG C in the high-temperature crystallization kettle for high-temperature crystallization; then adding the manganese sulfate solution of high-temperature crystallization into an automatic discharge centrifuge, putting a centrifuged water manganese sulfate crystal into a silo, and then obtaining a water manganese sulfate crystal through the drying of an air flow dryer unit. The process for preparing the manganese sulfate by the high-temperature crystallization method and the automatic continuous production device have the advantages that the production process is advanced; the design is scientific and reasonable; the safe, automatic and continuous production can be realized; the fixed investment is less; the labor intensity is reduced; the energy consumption is greatly reduced; the water consumption and production cost are saved, especially the water consumption and production cost of high-purity manganese sulfate production are saved; because soluble impurities are dissolved and saved in the mother liquor, several-time recrystallization is not required.

Owner:广州市三珍商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com