Lactobacillus fermentation culture medium and process for producing lactic acid at high yield

A lactic acid bacteria fermentation and culture medium technology, applied in the direction of microorganism-based methods, fermentation, microorganisms, etc., can solve the problems of high production cost and low acid production, and achieve the effect of prolonging the growth time and increasing the production of lactic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

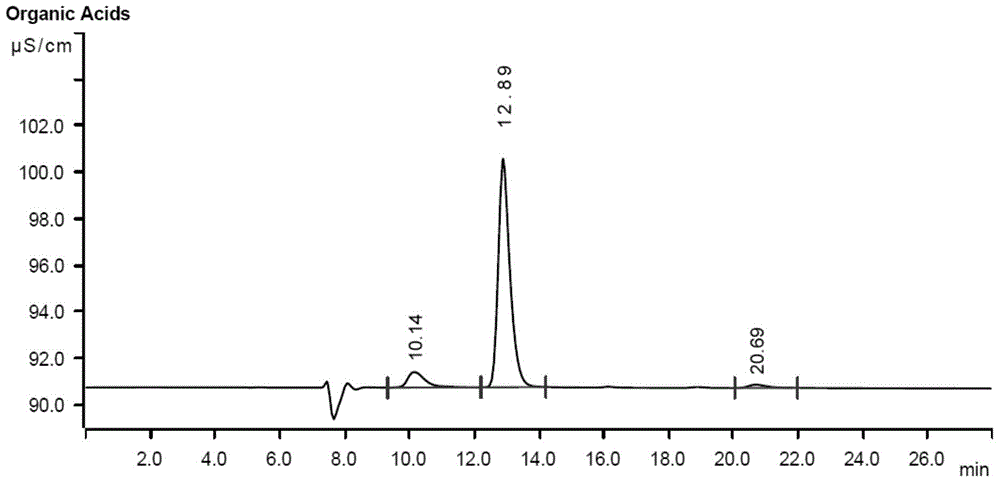

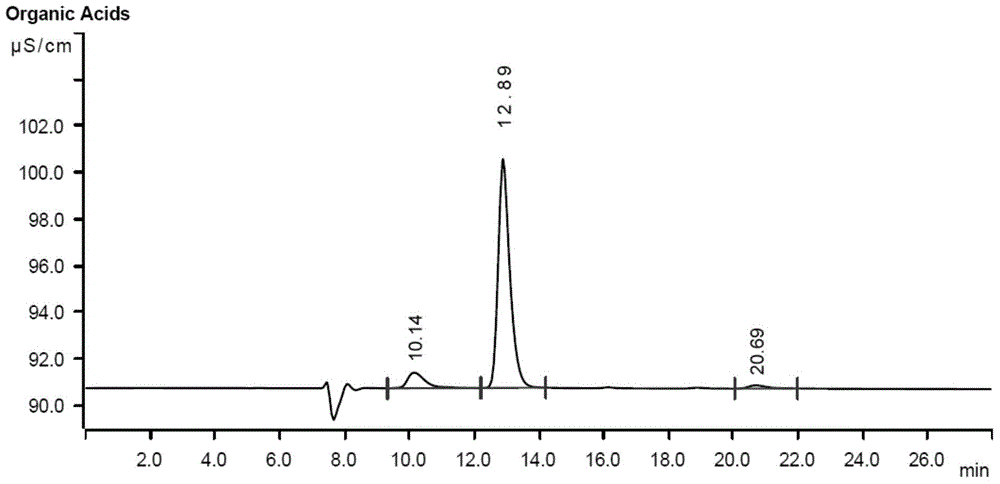

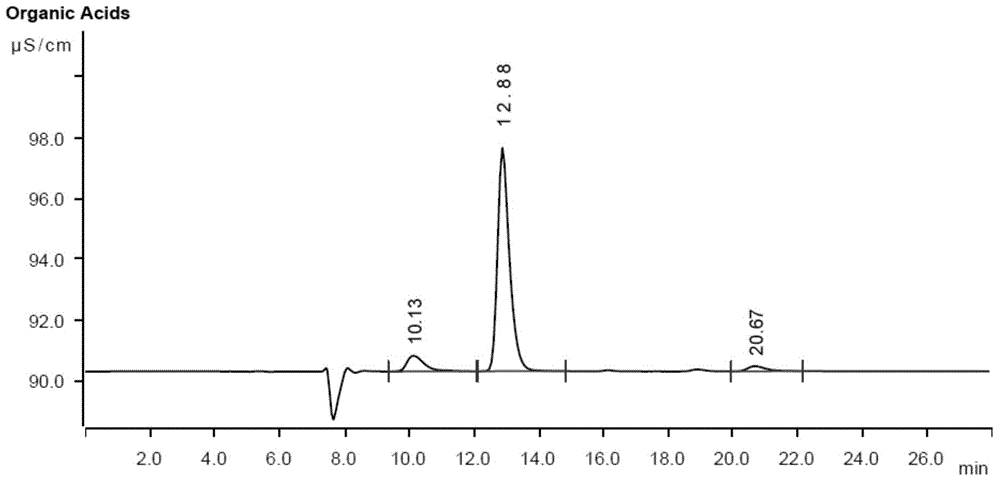

Image

Examples

Embodiment 1

[0047] Embodiment 1 Fermentation medium and technology production lactic acid in the present invention

[0048] Bacteria: Leuconostoc Mesenteroides

[0049] Anaerobic bottle seed medium formula (weight and volume percentage): peptone: 10g / L, beef extract: 10g / L, yeast extract powder: 5g / L, glucose: 20g / L, sodium acetate: 5g / L, citric acid Ammonium: 2g / L, dipotassium hydrogen phosphate: 2g / L, magnesium sulfate heptahydrate: 0.1g / L, manganese sulfate monohydrate: 0.05g / L, Tween-80: 1g / L, and the balance is water. The pH value was adjusted to 7.0 with 2mol / L sodium hydroxide.

[0050] Seed tank medium formula (weight and volume percentage): peptone: 10g / L, beef extract: 10g / L, yeast extract powder: 5g / L, glucose: 20g / L, sodium acetate: 5g / L, ammonium citrate: 2g / L, dipotassium hydrogen phosphate: 2g / L, magnesium sulfate heptahydrate: 0.1g / L, manganese sulfate monohydrate: 0.05g / L, Tween-80: 1g / L, and the balance is water. The pH value was adjusted to 7.0 with 2mol / L sodium hyd...

Embodiment 2

[0059] Embodiment 2 Fermentation medium and process production lactic acid in the present invention

[0060] Bacteria: Leuconostoc Mesenteroides

[0061] Anaerobic bottle seed medium formula (weight and volume percentage): peptone: 10g / L, beef extract: 10g / L, yeast extract powder: 5g / L, glucose: 20g / L, sodium acetate: 5g / L, citric acid Ammonium: 2g / L, dipotassium hydrogen phosphate: 2g / L, magnesium sulfate heptahydrate: 0.1g / L, manganese sulfate monohydrate: 0.05g / L, Tween-80: 1g / L, and the balance is water. The pH value was adjusted to 7.0 with 2mol / L sodium hydroxide.

[0062] Seed tank medium formula (weight and volume percentage): peptone: 10g / L, beef extract: 10g / L, yeast extract powder: 5g / L, glucose: 20g / L, sodium acetate: 5g / L, ammonium citrate: 2g / L, dipotassium hydrogen phosphate: 2g / L, magnesium sulfate heptahydrate: 0.1g / L, manganese sulfate monohydrate: 0.05g / L, Tween-80: 1g / L, and the balance is water. The pH value was adjusted to 7.0 with 2mol / L sodium hydrox...

Embodiment 3

[0069] Embodiment 3 Fermentation medium and process production lactic acid in the present invention

[0070] Bacteria: Leuconostoc Mesenteroides

[0071] Anaerobic bottle seed medium formula (weight and volume percentage): peptone: 10g / L, beef extract: 10g / L, yeast extract powder: 5g / L, glucose: 20g / L, sodium acetate: 5g / L, citric acid Ammonium: 2g / L, dipotassium hydrogen phosphate: 2g / L, magnesium sulfate heptahydrate: 0.1g / L, manganese sulfate monohydrate: 0.05g / L, Tween-80: 1g / L, and the balance is water. The pH value was adjusted to 6.5 with 2mol / L sodium hydroxide.

[0072] Seed tank medium formula (weight and volume percentage): peptone: 10g / L, beef extract: 10g / L, yeast extract powder: 5g / L, glucose: 20g / L, sodium acetate: 5g / L, ammonium citrate: 2g / L, dipotassium hydrogen phosphate: 2g / L, magnesium sulfate heptahydrate: 0.1g / L, manganese sulfate monohydrate: 0.05g / L, Tween-80: 1g / L, and the balance is water. The pH value was adjusted to 6.5 with 2mol / L sodium hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com