Comprehensive utilization method for separating, concentrating and purifying manganese sulfate, magnesium sulfate and calcium sulfate in high-salt waste water

A high-salt wastewater and manganese sulfate technology, applied in the direction of magnesium sulfate, manganese sulfate, calcium carbonate/strontium/barium, etc., can solve the problems of low concentration of manganese sulfate, difficult discharge of wastewater, waste of calcium and magnesium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

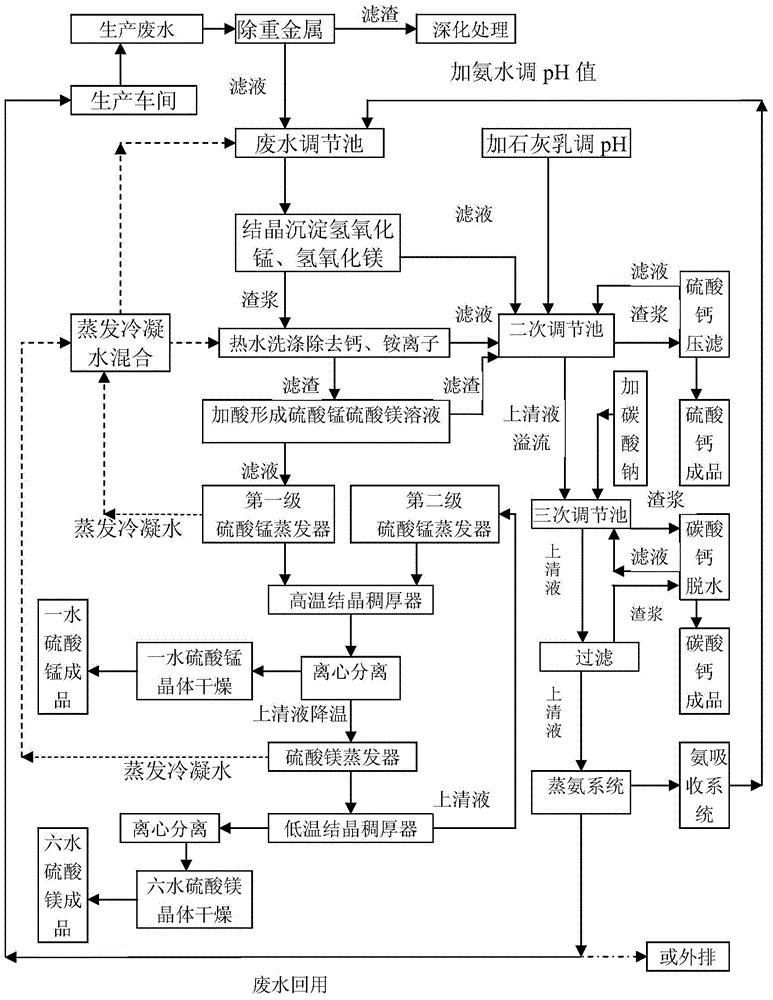

[0017] Process flow of the present invention is attached figure 1

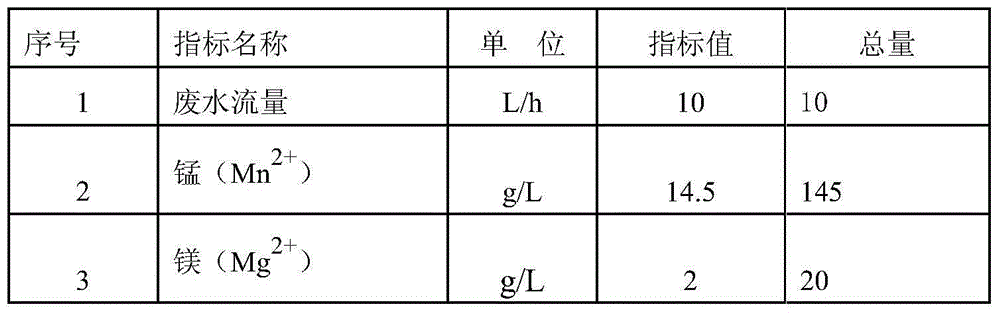

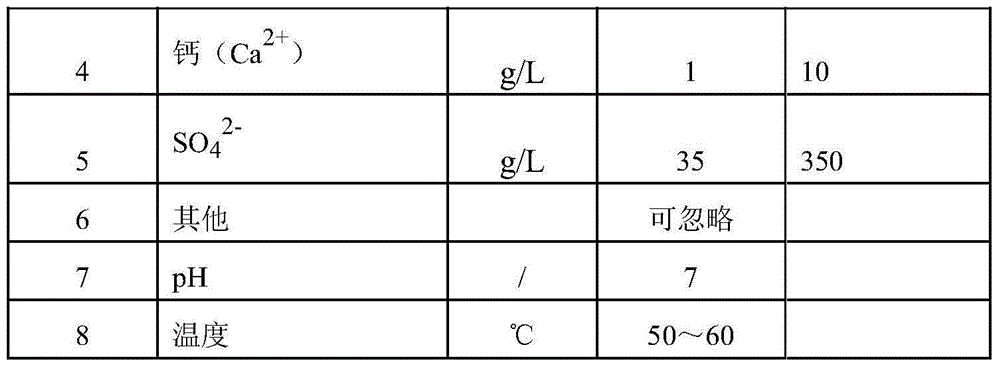

[0018] Main water quality index table of high-salt wastewater after heavy metal removal

[0019]

[0020]

[0021] (1) The high-salt wastewater mother liquor enters the closed wastewater regulating tank, and the temperature is kept at 50-60°C. First, quantitatively add ammonia water or liquid ammonia to the wastewater, and adjust the pH value of the wastewater to 10-10.5. Manganese and magnesium are mixed with Mn(OH) 2 and Mg(OH) 2 Precipitate in the form of precipitation; keep the pH value of the precipitation end point at 8-8.5, and filter the Mn(OH) 2 and Mg(OH) 2 Filter it out while it is hot, with a moisture content of 40%; at the same time, filter out the Mn(OH) 2 and Mg(OH) 2 The mixed slag is washed with 280g of hot water at 50-60°C. After washing, it is filtered twice and centrifugally dehydrated to remove impurities such as calcium ions and ammonium sulfate; Accounting for 0.02% of dry we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com