Continuous trapping and generating apparatus for carbon dioxide in cement kiln flue gas

A carbon dioxide and cement kiln technology, applied in carbon capture, cement production, steam engine installations, etc., to achieve the effect of simple equipment, small investment, and reduced capture costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

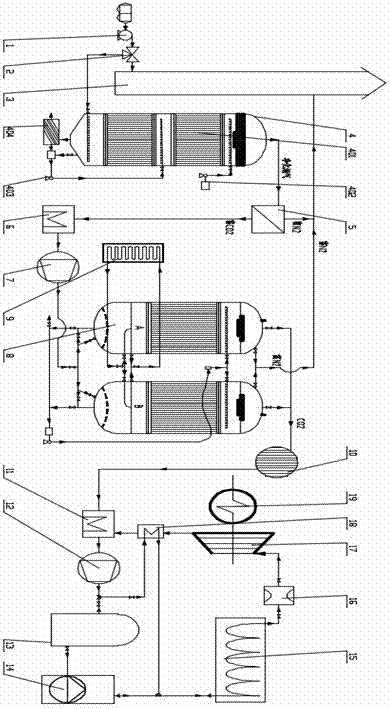

Embodiment 1

[0037] refer to figure 1 , a method suitable for CO in cement kiln flue gas 2 Continuous capture and CO 2 The power generation device mainly includes tail exhaust fan 1, electric three-ventilation valve 2, chimney 3, flue gas oxidation purifier 4, membrane separation device 5, cooler 6, flue gas compressor 7, CO 2 Circulation capture tower 8, waste heat energy storage device 9, dehydration dryer 10, CO 2 Cooler 11, CO 2 Compressor 12, liquefied CO2 storage tank 13, CO 2 High pressure pump 14, CO 2 Energy storage device 15, flow stabilizer 16, turbine 17, regenerator 18 and generator 19, the electric three-ventilation valve 2 is arranged in the flue gas between the exhaust fan 1 and the chimney 3 connected to the kiln tail dust collector On the pipeline, the air outlet of the tail exhaust fan 1 is connected with the air inlet of the electric three-ventilation valve 2, and the first exhaust port of the electric three-ventilation valve 2 is connected with the flue gas inlet ...

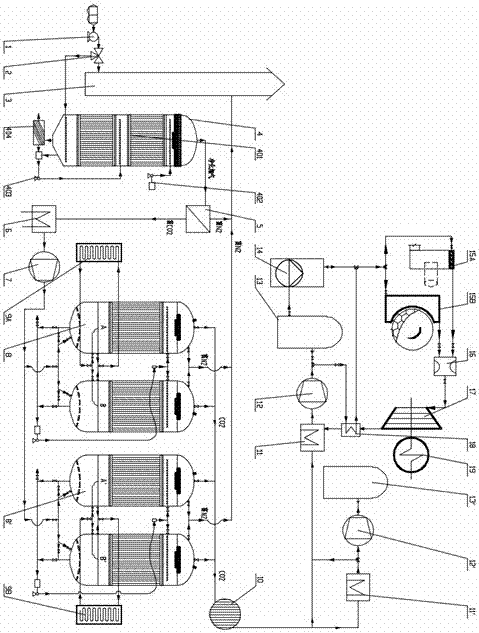

Embodiment 2

[0043] refer to figure 2 , a cement kiln flue gas containing 2 sets of CO 2 Circulation capture tower parallel capture, 2 sets of CO 2 The energy storage device is used in parallel to generate power, mainly including tail exhaust fan 1, electric three-ventilation valve 2, chimney 3, flue gas oxidation purifier 4, membrane separation device 5, cooler 6, flue gas compressor 7, CO 2 Circulation capture tower 8, the second CO 2 Circulation capture tower 8ˊ, head row exhaust gas energy storage device 9A, kiln tail exhaust gas energy storage device 9B, dehydration dryer 10, CO 2 Cooler 11, second CO 2 Cooler 11', CO 2 Compressor 12, second CO 2 Compressor 12′, liquefied CO2 storage tank 13, second liquefied CO2 storage tank 13′, CO 2 High pressure pump 14, kiln tail smoke chamber CO 2 Energy storage device 15A, kiln head cover CO 2 Energy storage device 15B, flow stabilizer 16, turbine 17, regenerator 18 and generator 19, the electric three-ventilation valve 2 is set in the...

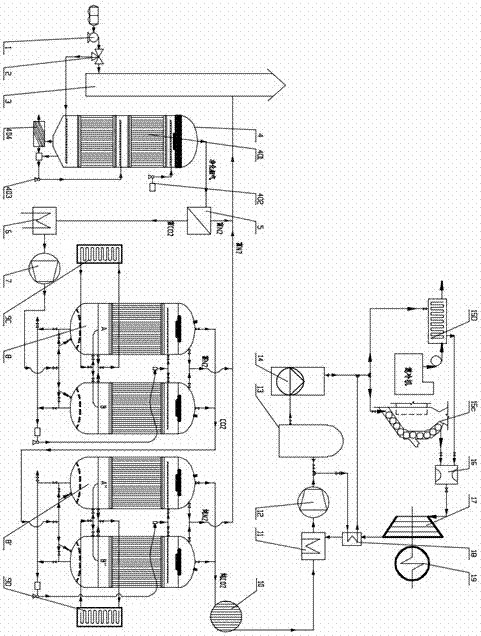

Embodiment 3

[0048] refer to image 3 , including 2 sets of CO 2 Circulation capture towers connected in series for CO in cement kiln flue gas 2 The equipment system for continuous capture and power generation mainly includes tail exhaust fan 1, electric three-ventilation valve 2, chimney 3, flue gas oxidation purifier 4, membrane separation device 5, cooler 6, flue gas compressor 7, CO 2 Circulation capture tower 8, the second CO 2 Circulating collection tower 8ˊ, kiln body energy storage device 9C, head exhaust gas energy storage device 9D, dehydration dryer 10, CO 2 Cooler 11, CO 2 Compressor 12, liquefied CO 2 Storage tank 13, CO 2 High pressure pump 14, preheater material CO 2 Energy storage device 15C, built-in CO in grate cooler 2 Energy storage device 15D, current stabilizer 16, turbine 17, generator 19 and regenerator 18, the electric three-ventilation valve 2 is placed in the flue gas between the exhaust fan 1 connected to the kiln tail dust collector and the chimney 3 On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com