Zero-carbon-emission fossil fuel power generation method and device system

A technology for fossil fuels and power generation devices, applied in the field of zero-carbon emission fossil fuel power generation methods and device systems, can solve the problems of high cost, zero, slow development, etc., and achieve the effect of omitting transportation costs and omitting transportation links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

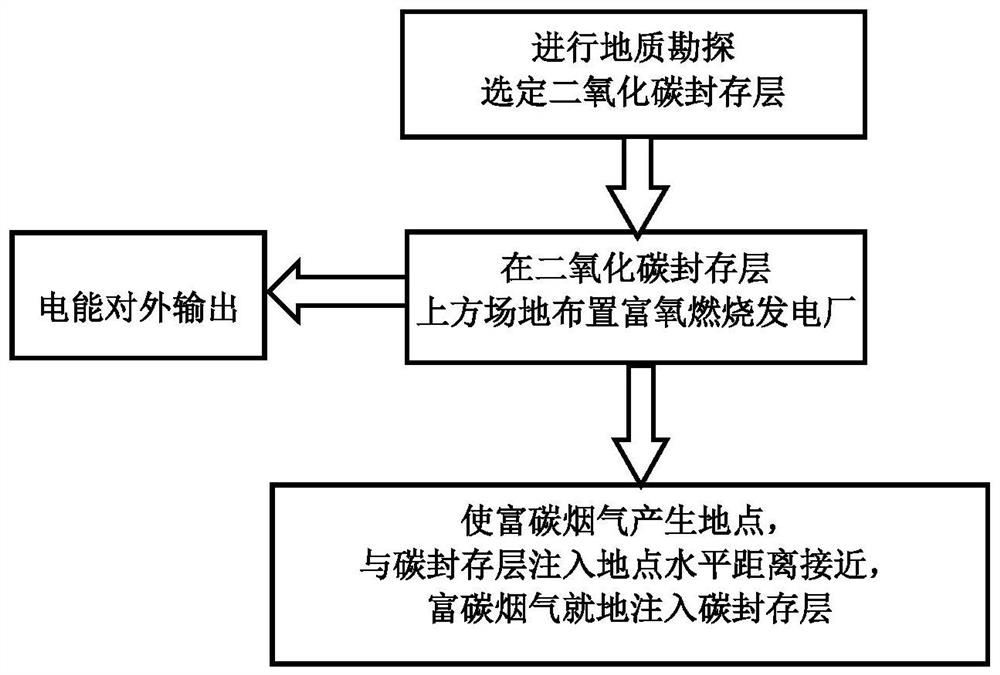

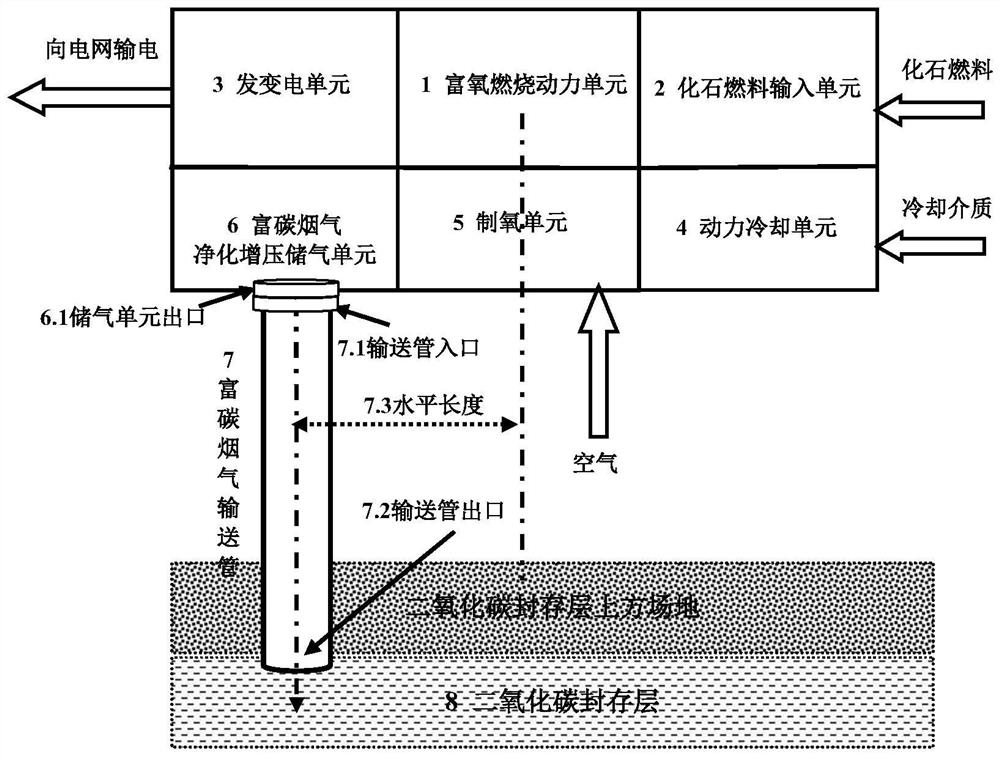

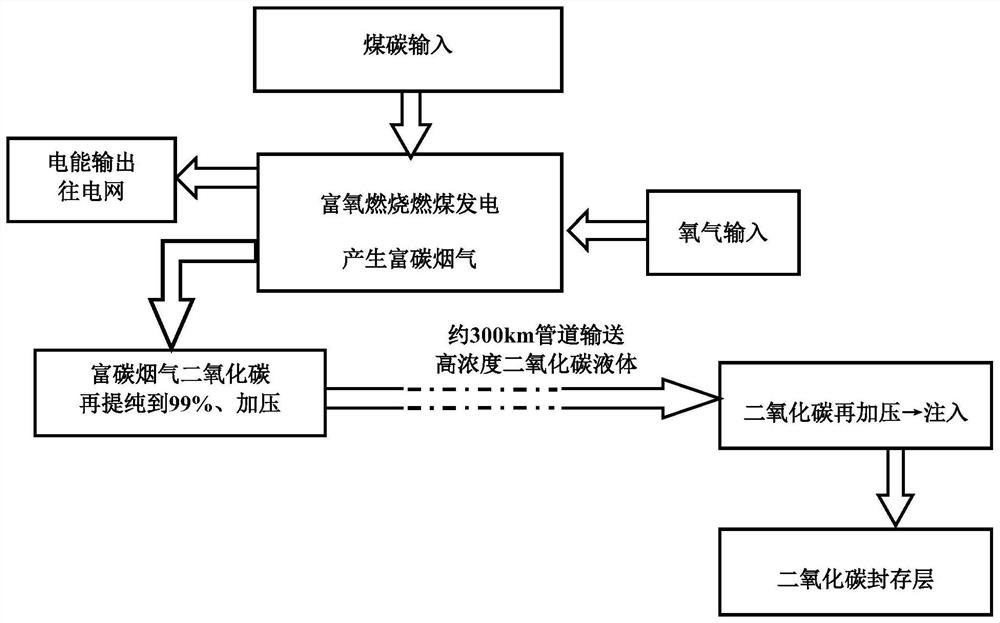

Embodiment 1

[0036] Embodiment 1: It is the basic embodiment of the zero-carbon emission fossil fuel power generation method of the present invention. as attached figure 1As shown, the steps of the zero-carbon emission fossil fuel power generation method include: conducting geological surveys to select a carbon dioxide storage layer, arranging a fossil fuel power plant on the site above the selected carbon dioxide storage layer, and bubbling the fossil fuel with oxygen in the power plant Oxygen-enriched combustion power generation, generating electric energy and carbon dioxide-rich flue gas, the generated electric energy is transmitted externally, and the generated carbon dioxide-rich flue gas is injected into the carbon dioxide storage layer on the spot; the method of injecting the carbon dioxide storage layer on the spot is to use The place where the carbon dioxide-rich flue gas is generated, the place where the carbon dioxide is injected into the carbon dioxide storage layer, and the h...

Embodiment 2

[0038] Embodiment 2: It is a further embodiment based on Embodiment 1. The carbon dioxide-rich flue gas is injected into the carbon dioxide storage layer on the spot, which is a carbon dioxide-rich gas with a ratio of about 50% of the mass of carbon dioxide to the total mass of the flue gas. The flue gas is injected into the carbon dioxide storage layer on site.

[0039] Another embodiment is that the carbon dioxide-rich flue gas is injected into the carbon dioxide storage layer on-site, that is, the carbon dioxide-rich flue gas whose mass ratio of carbon dioxide to the total mass of the flue gas is about 60% is injected into the carbon dioxide storage layer on-site.

[0040] Another embodiment is that the carbon dioxide-rich flue gas is injected into the carbon dioxide storage layer on-site, that is, the carbon dioxide-rich flue gas whose mass ratio of carbon dioxide to the total mass of the flue gas is about 85% is injected into the carbon dioxide storage layer on-site.

[0...

Embodiment 3

[0042] Embodiment 3: It is another embodiment on the basis of Embodiment 1. The place where the smoke rich in carbon dioxide is produced, and the place where the carbon dioxide is injected into the carbon dioxide sequestration layer, the method for approaching the horizontal distance between the two places is to make A method with a horizontal distance of about 100km between two locations.

[0043] Another embodiment is that the horizontal distance between the place where the carbon dioxide-rich flue gas is generated and the place where the carbon dioxide is injected into the carbon dioxide storage layer is about 50 km.

[0044] Still another embodiment is to make the place where the flue gas rich in carbon dioxide is generated, and the place where the carbon dioxide is injected into the carbon dioxide storage layer, the horizontal distance between the two places is about 20km. Another embodiment is that the horizontal distance between the place where the carbon dioxide-rich f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com