Patents

Literature

71 results about "Fossil fuel power plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

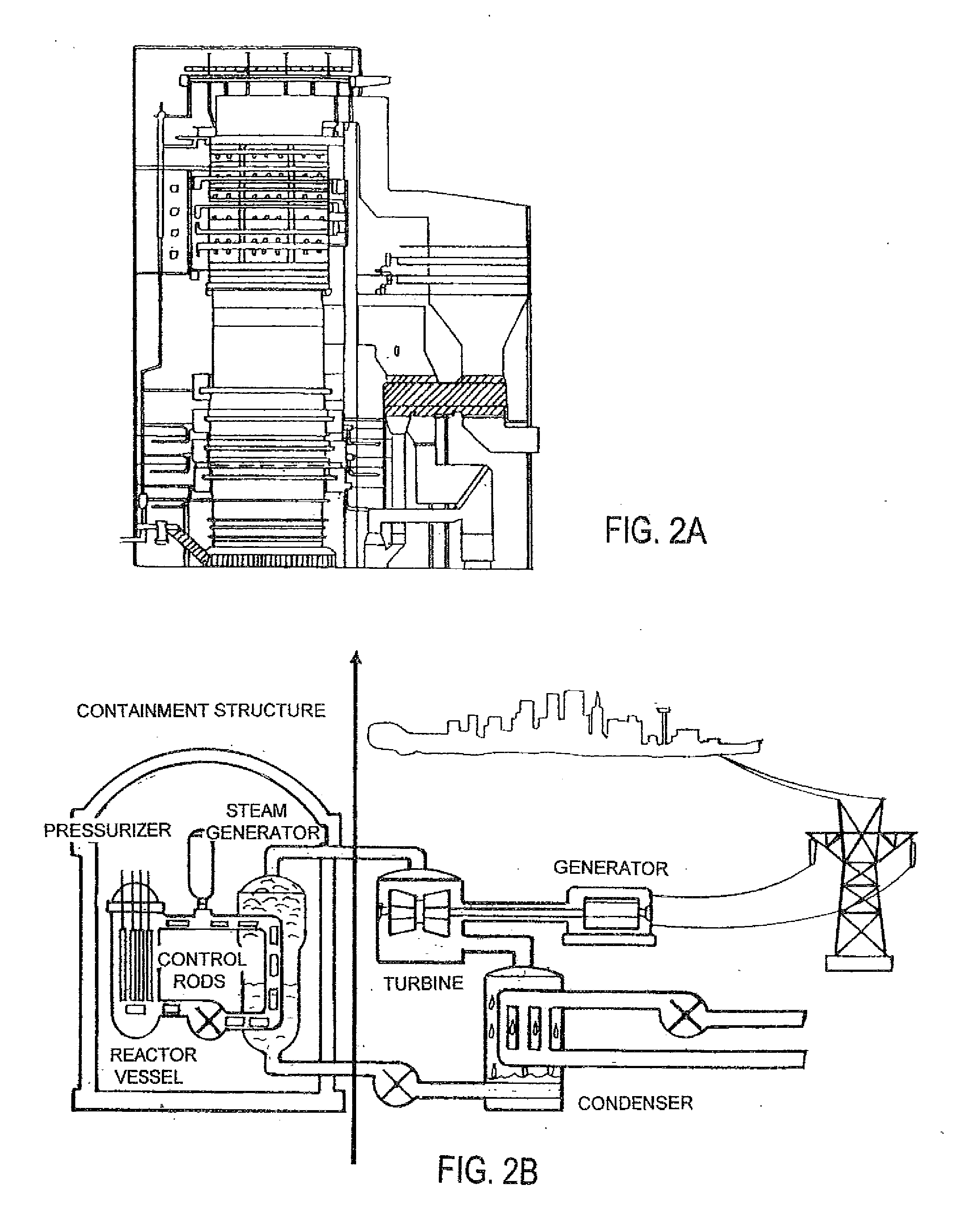

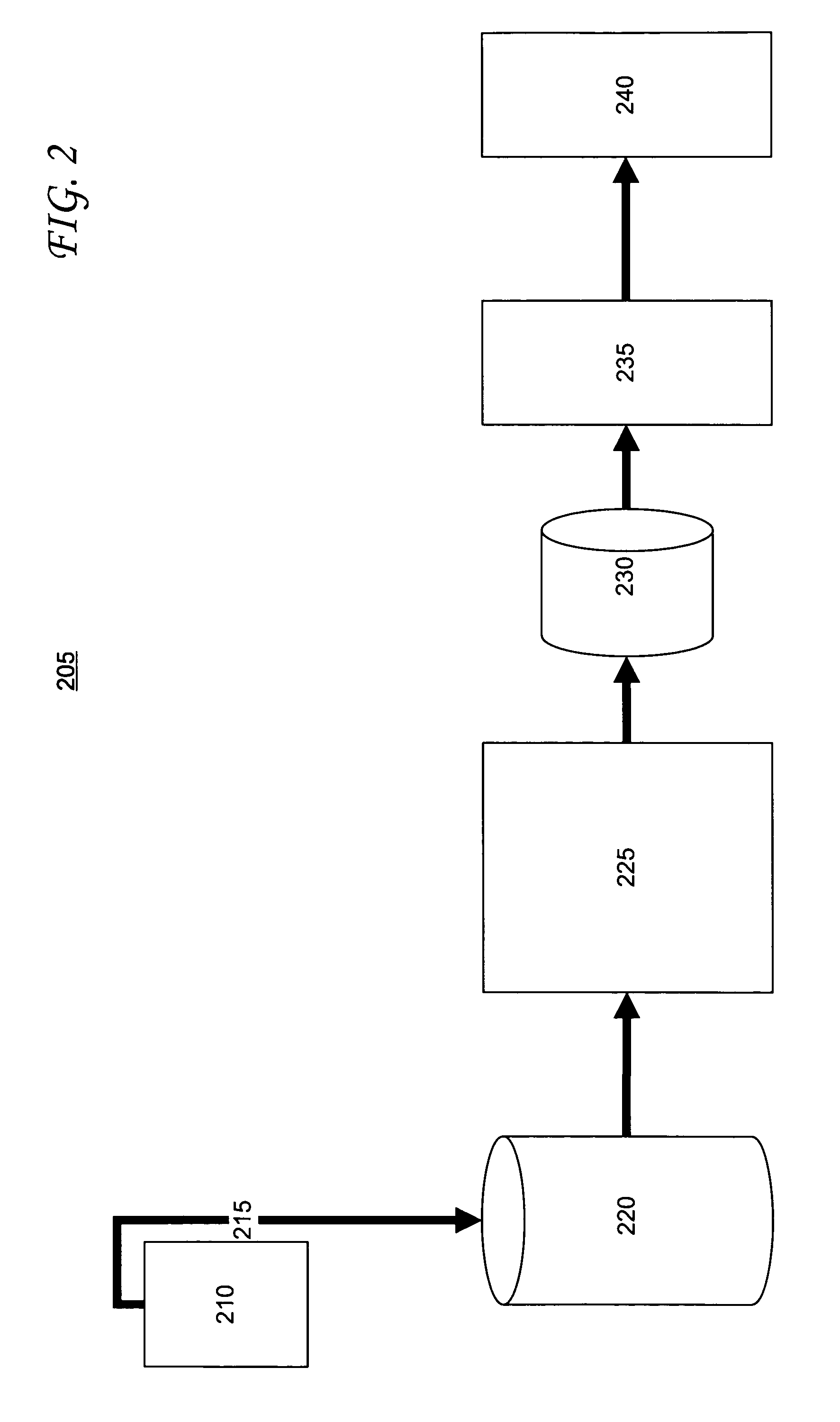

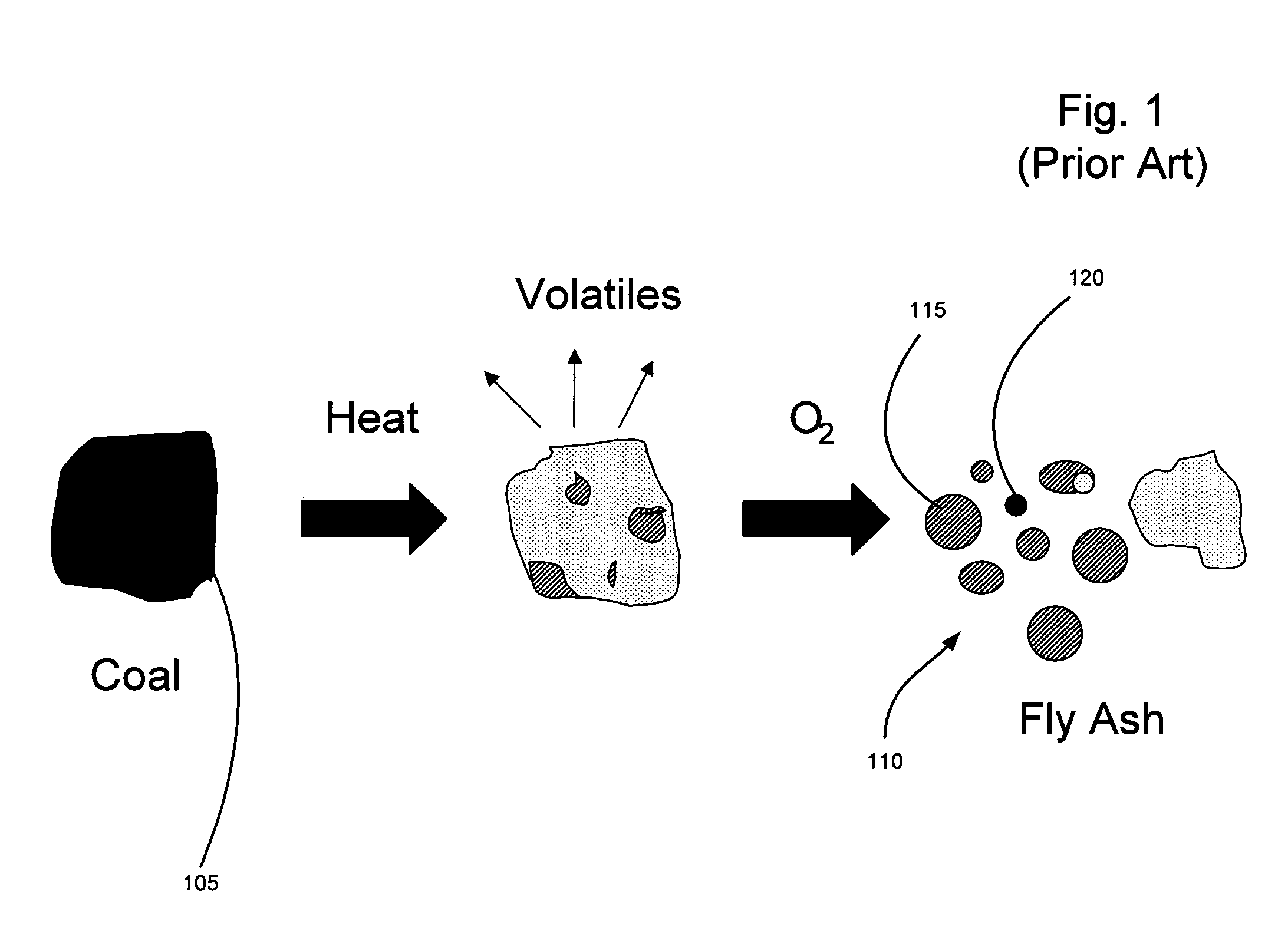

In a fossil fuel power plant the chemical energy stored in fossil fuels such as coal, fuel oil, natural gas or oil shale and oxygen of the air is converted successively into thermal energy, mechanical energy and, finally, electrical energy.

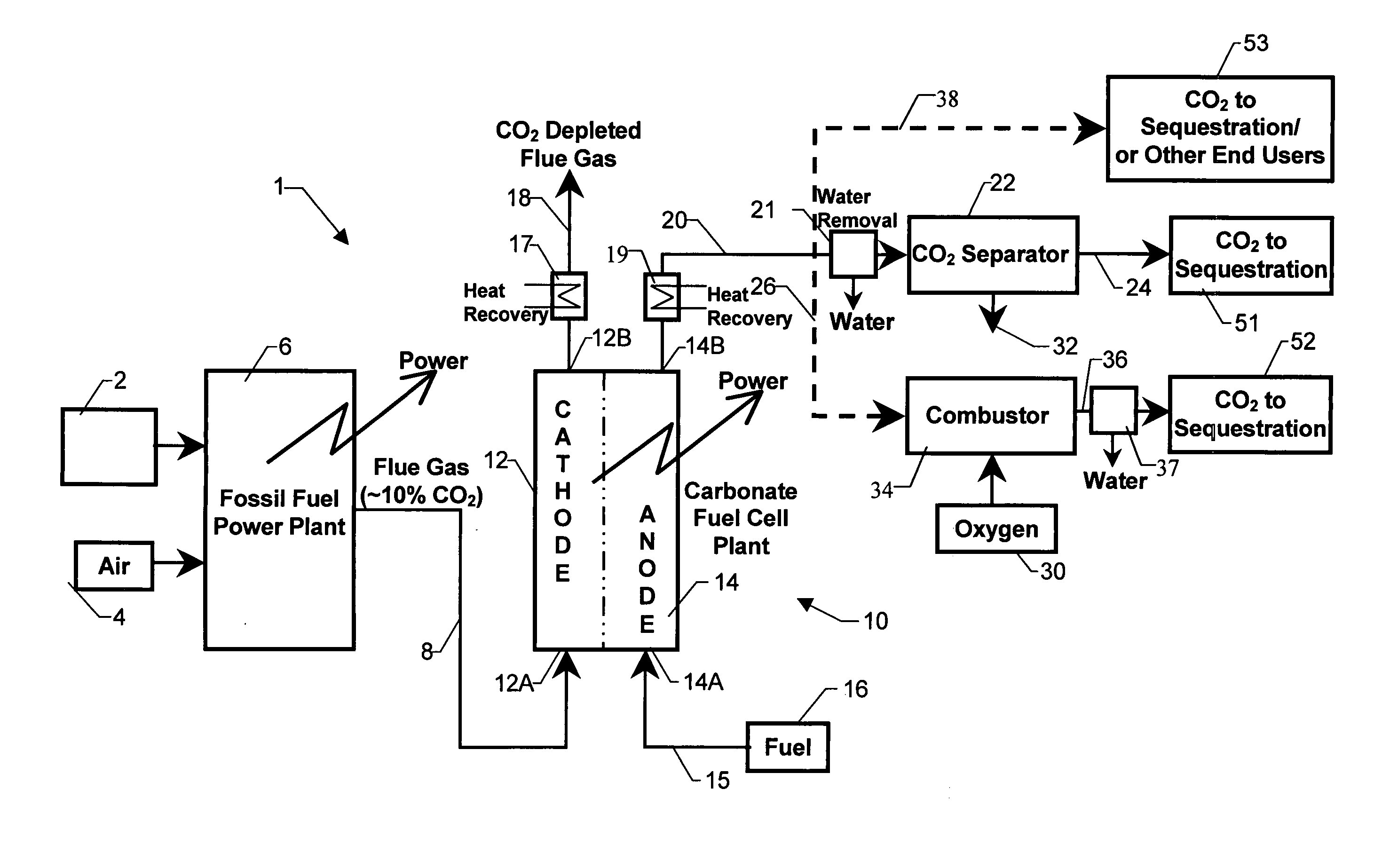

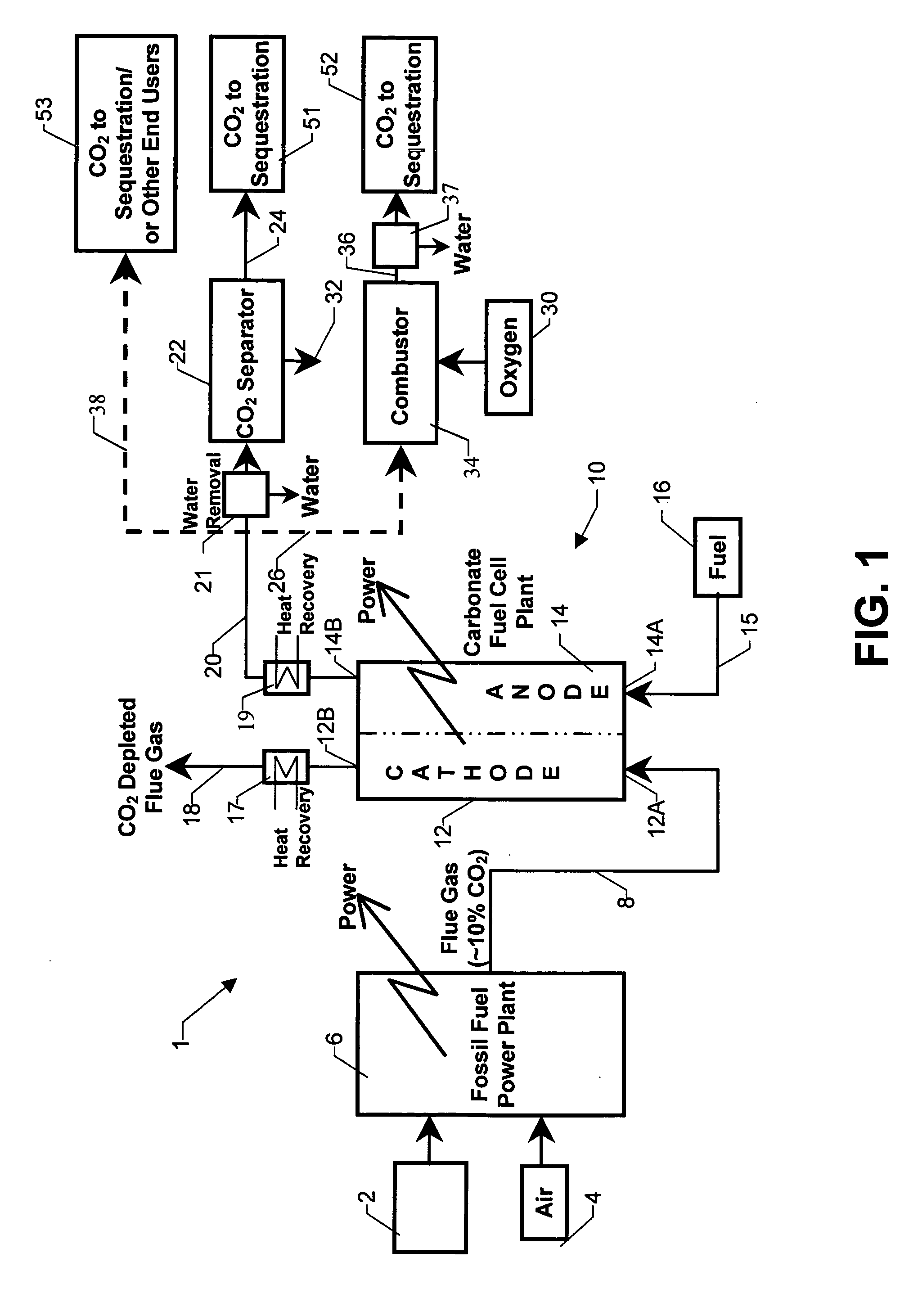

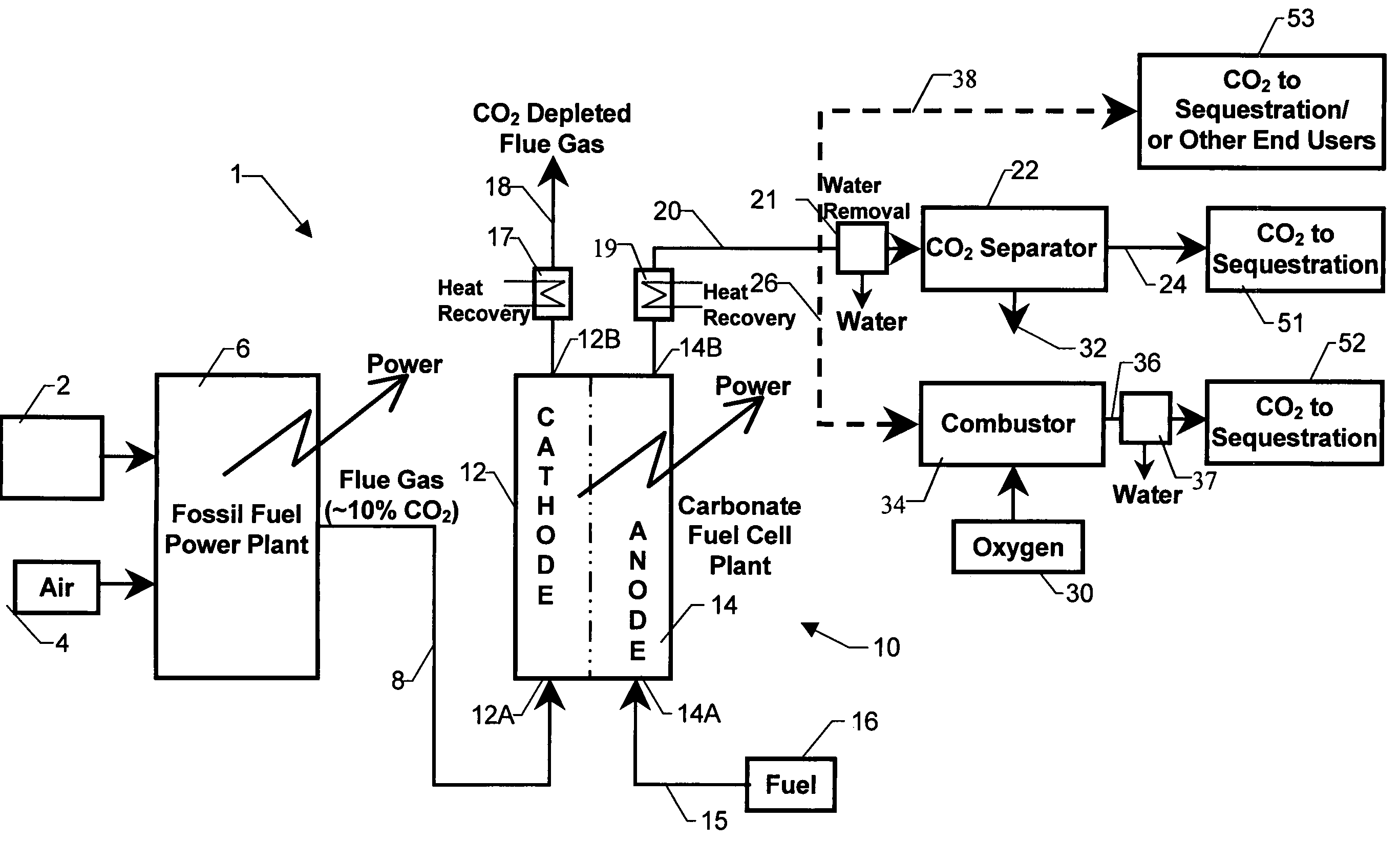

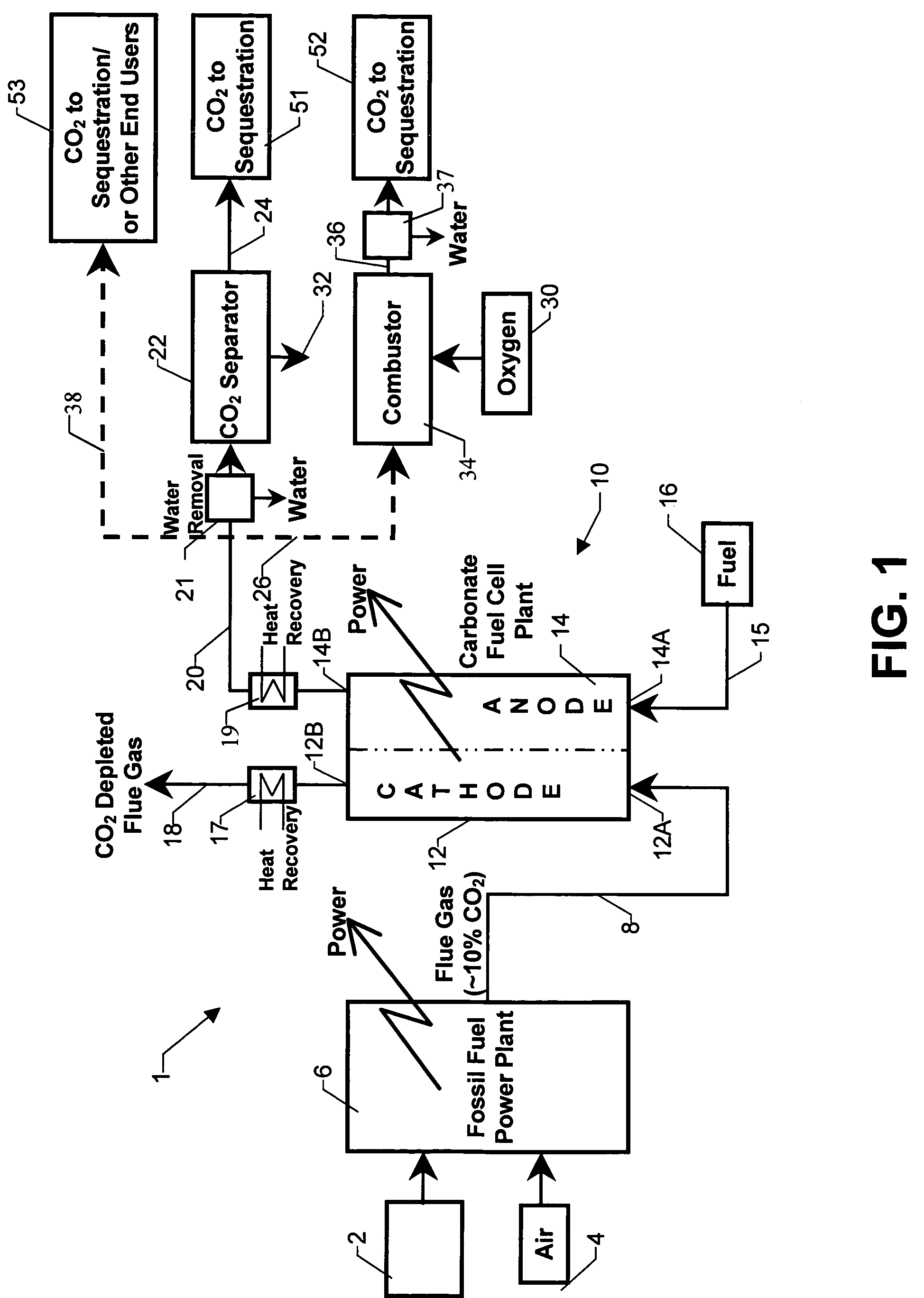

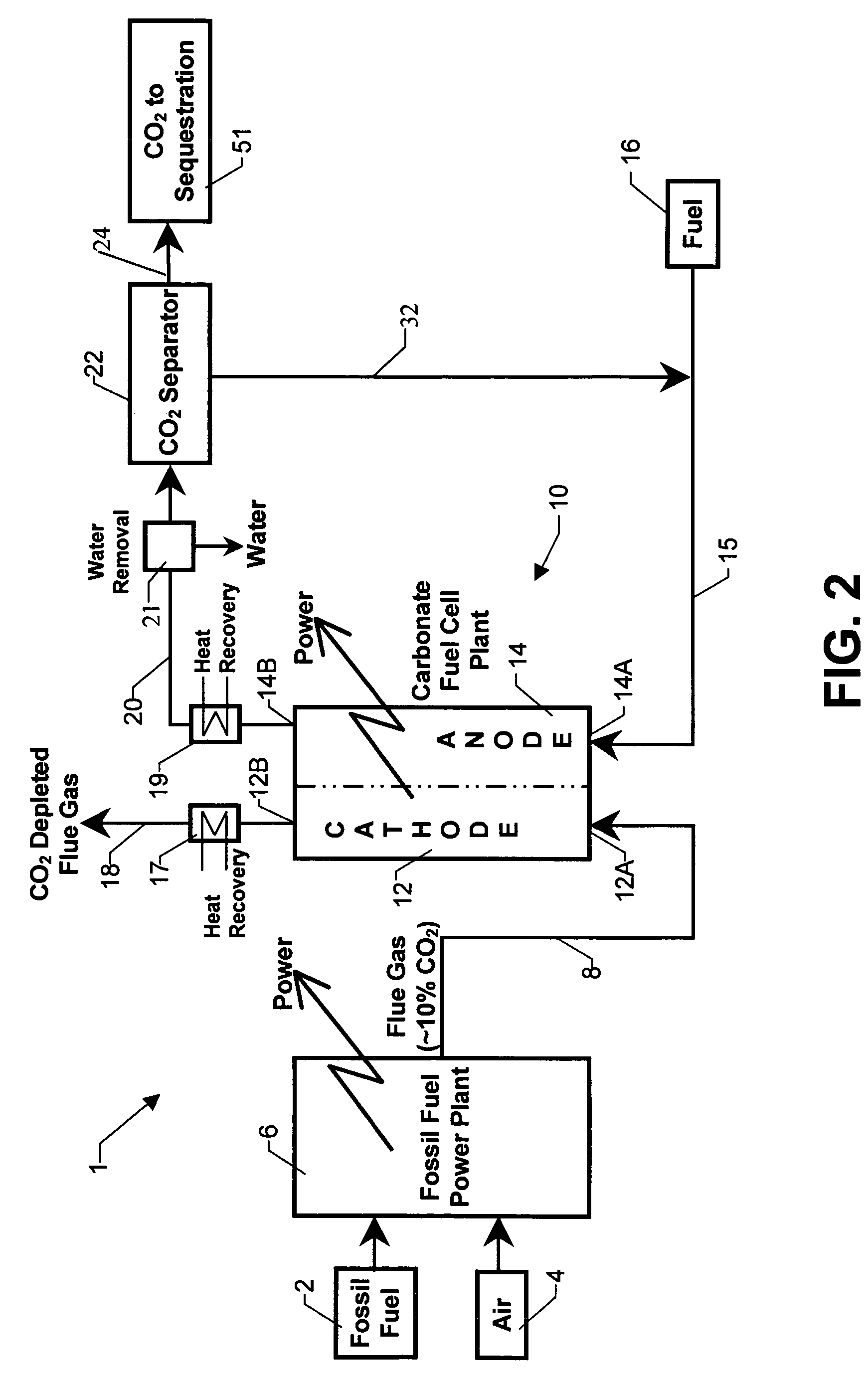

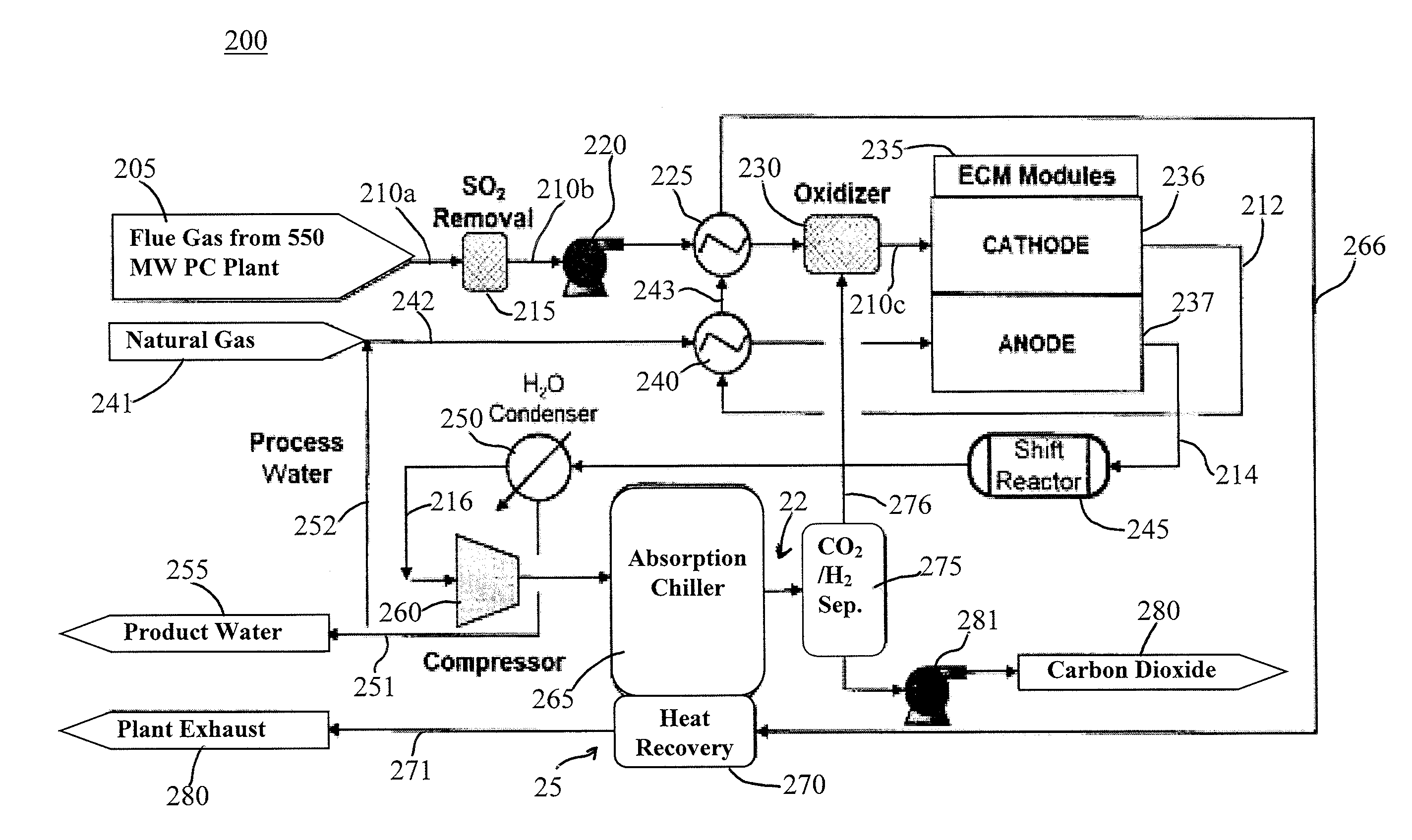

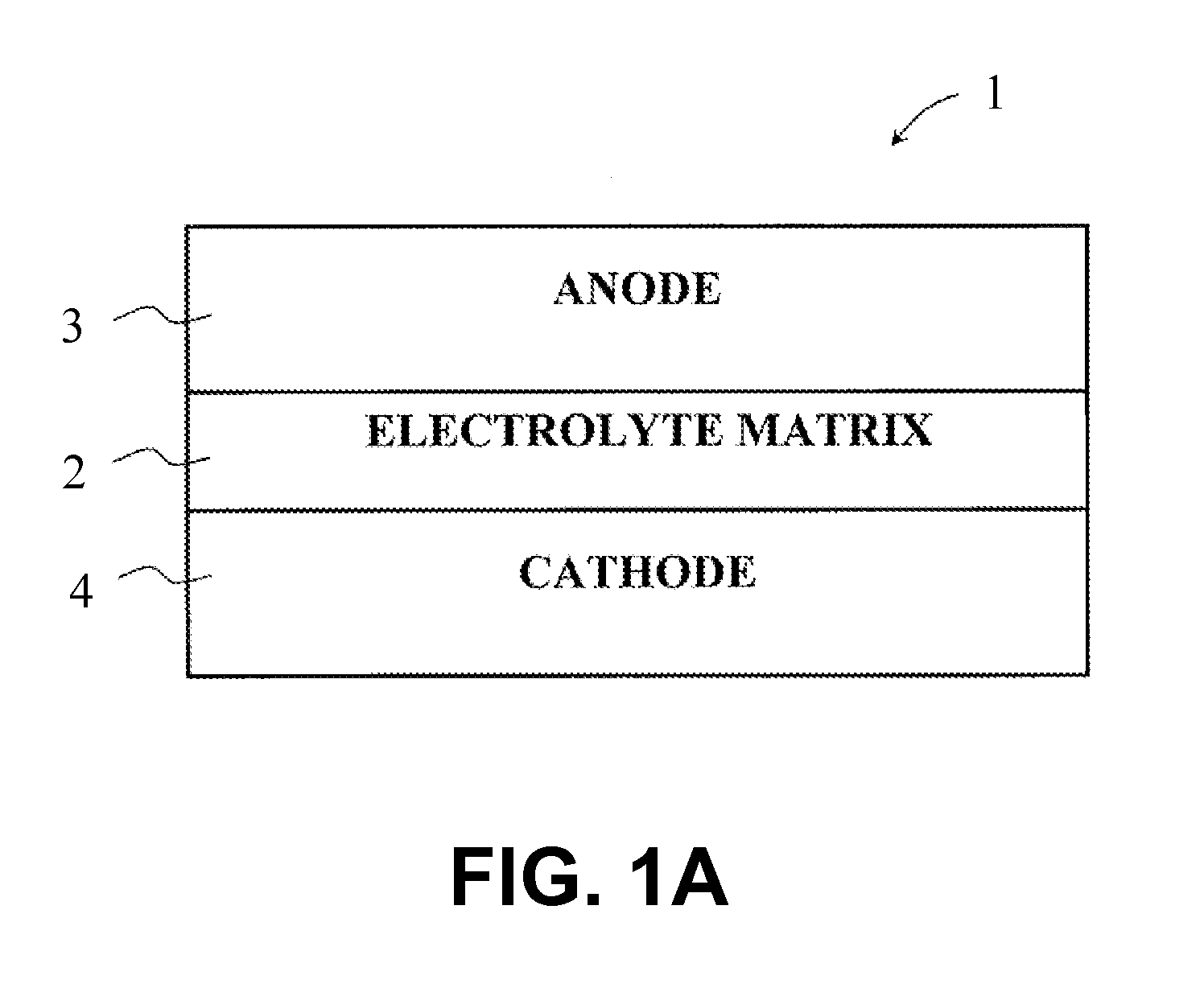

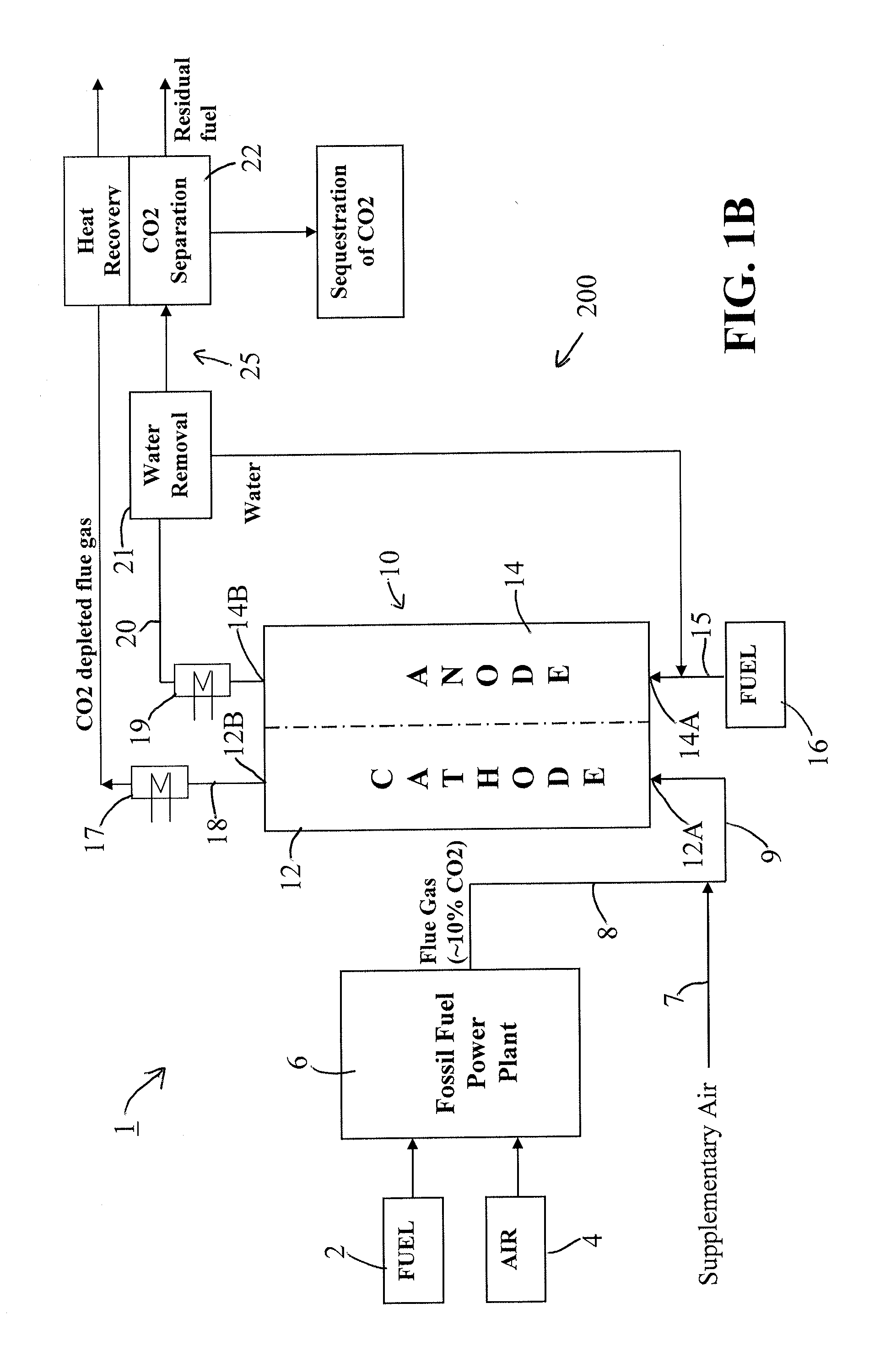

Integrated high efficiency fossil fuel power plant/fuel cell system with CO2 emissions abatement

An integrated power production system including a fossil fuel power plant for processing fossil based fuel such as coal or natural gas arranged in tandem with a carbonate fuel cell having an anode and a cathode section. The flue gas of the power plant serves exclusively as the inlet gas for the cathode section of the fuel cell. Anode exhaust gas leaving the anode section of the fuel cell is subjected to processing including sequestration of the carbon dioxide in the exhaust gas.

Owner:FUELCELL ENERGY INC

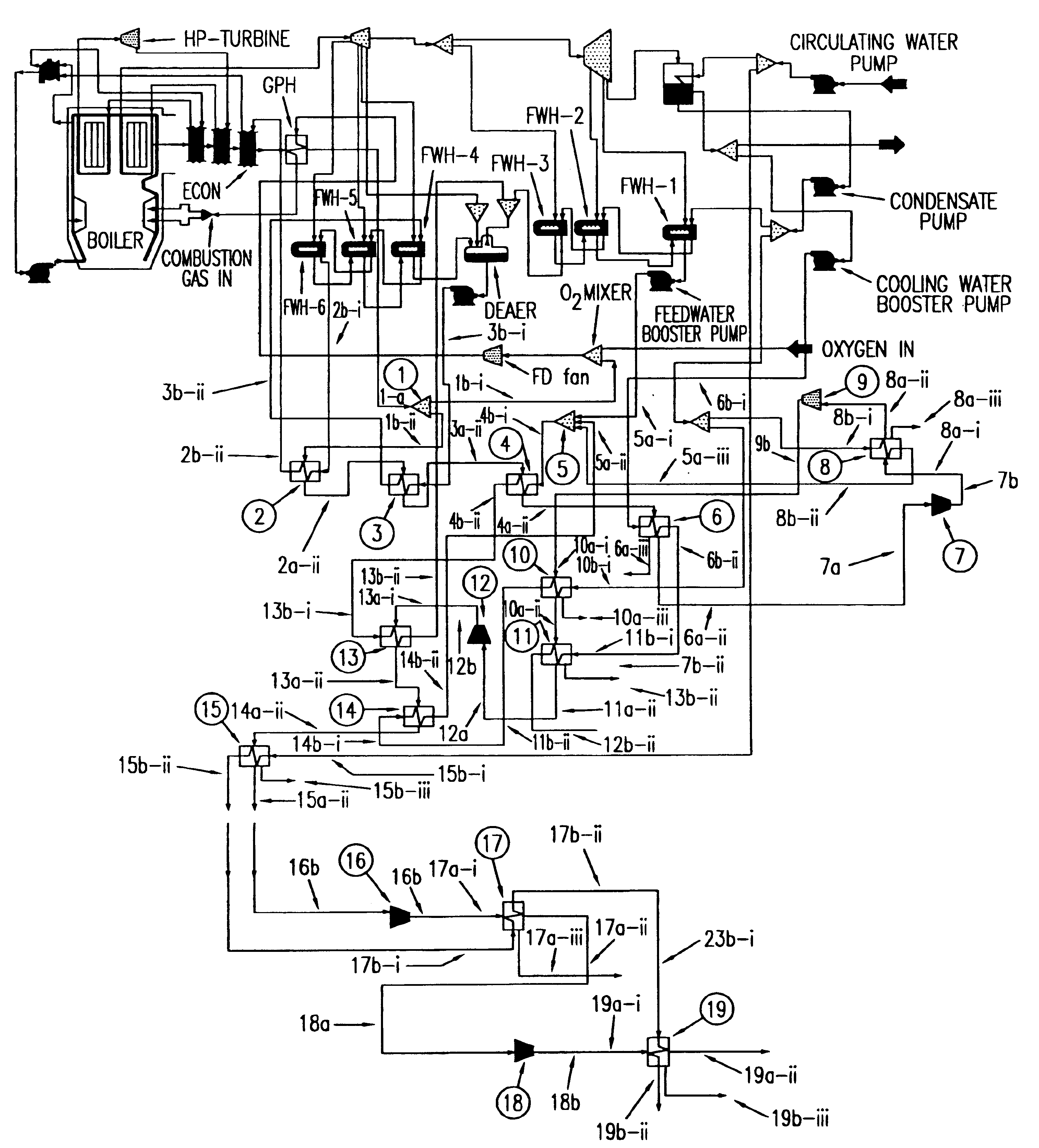

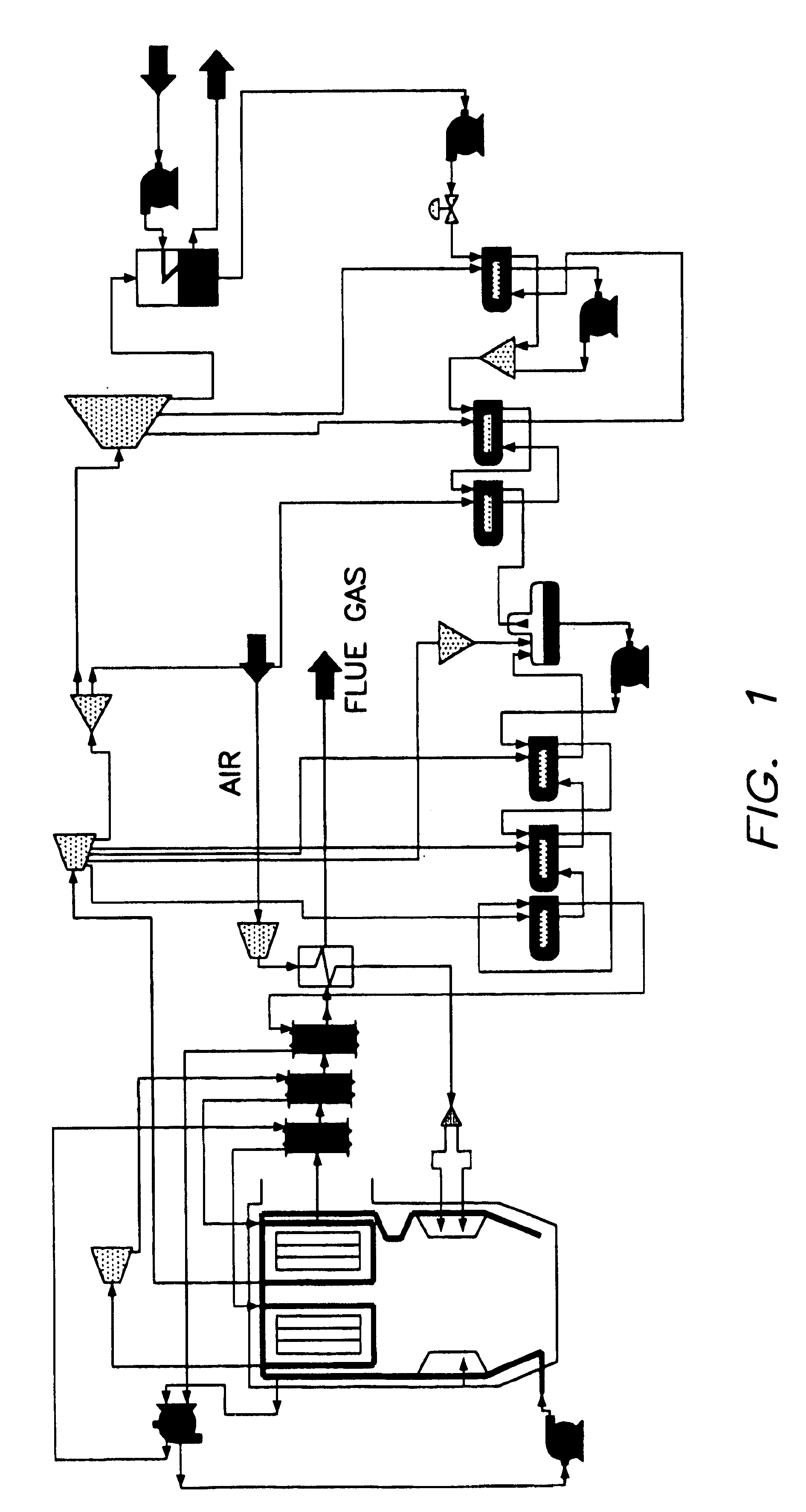

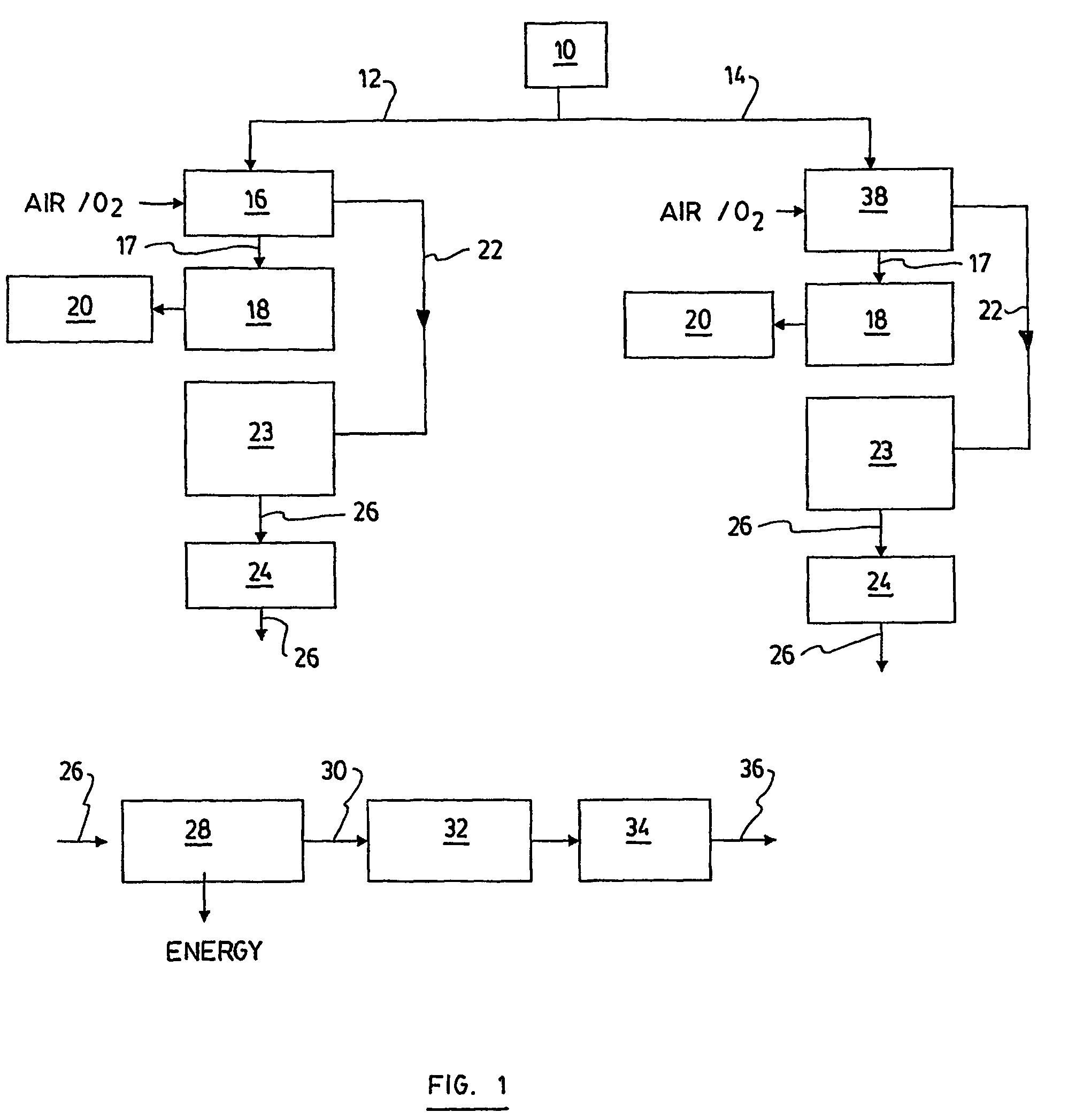

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Integrated high efficiency fossil fuel power plant/fuel cell system with CO2 emissions abatement

ActiveUS7396603B2Fuel cell heat exchangeElectricity cogenerationNuclear engineeringEmission abatement

Owner:FUELCELL ENERGY INC

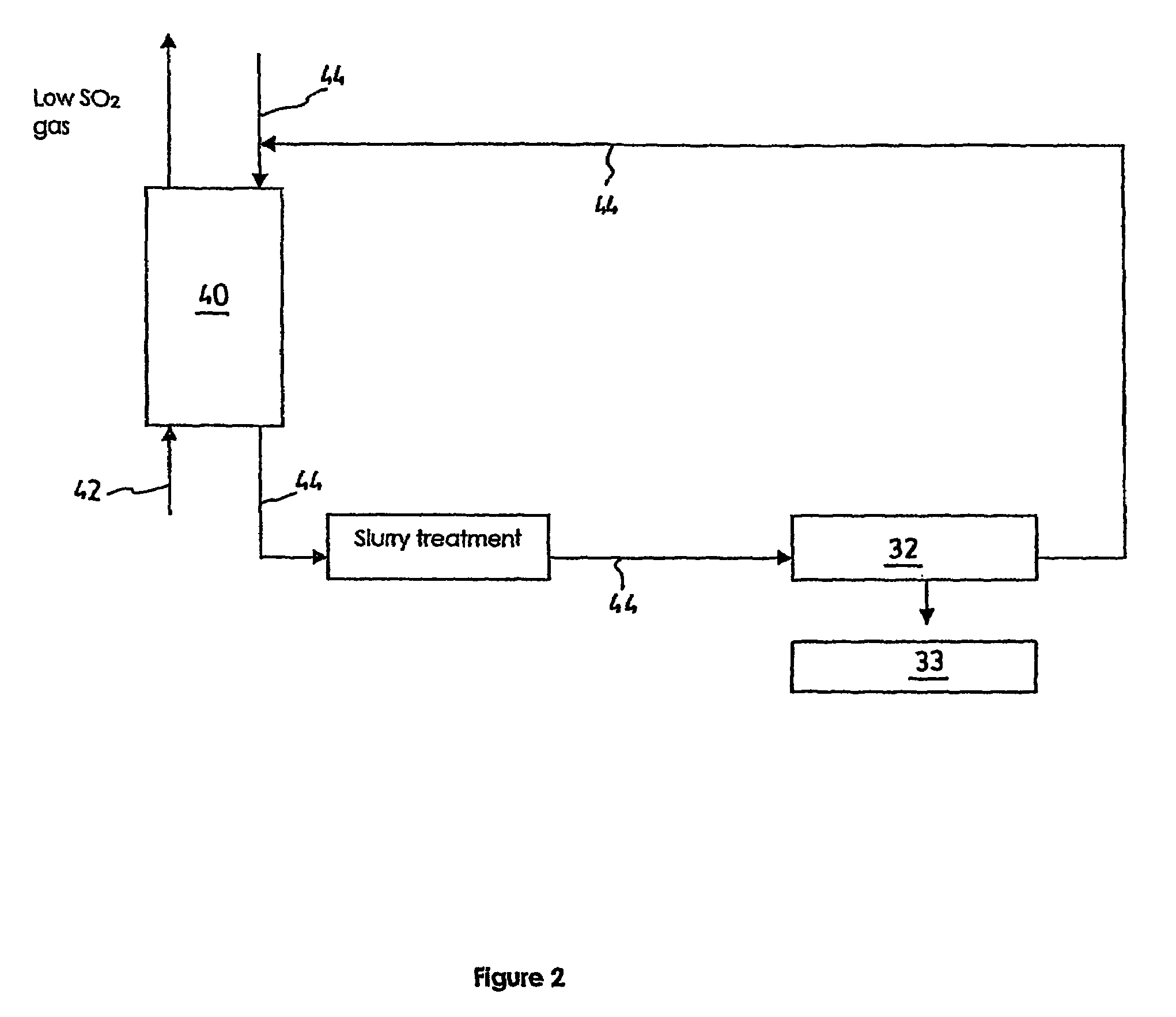

Process and a plant for recycling carbon dioxide emissions from power plants into useful carbonated species

ActiveUS7596952B2Useful carbonated speciesEnvironment safetyCalcium/strontium/barium carbonatesGas turbine plantsAtmospheric airNegative carbon dioxide emission

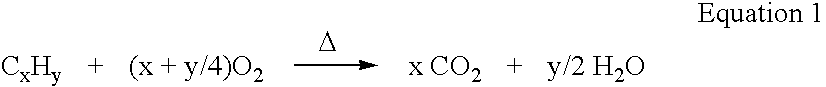

A process is disclosed for recycling carbon dioxide emissions from a fossil-fuel power plant into useful carbonated species The process primarily comprises the steps of: a) burning the fossil fuel, thereby generating heat and a hot exhaust gas containing CO2; and b) converting the heat into energy. The process is characterized in that it further comprises the steps of: c) cooling the exhaust gas; and d) biologically transforming the CO2 contained in the cooled exhaust gas into carbonated species, thereby obtaining a low CO2 exhaust gas and producing useful carbonated species. The low CO2 exhaust gas obtained in step d) can be released in the atmosphere without increasing the problem of greenhouse effect.

Owner:SAIPEM SPA

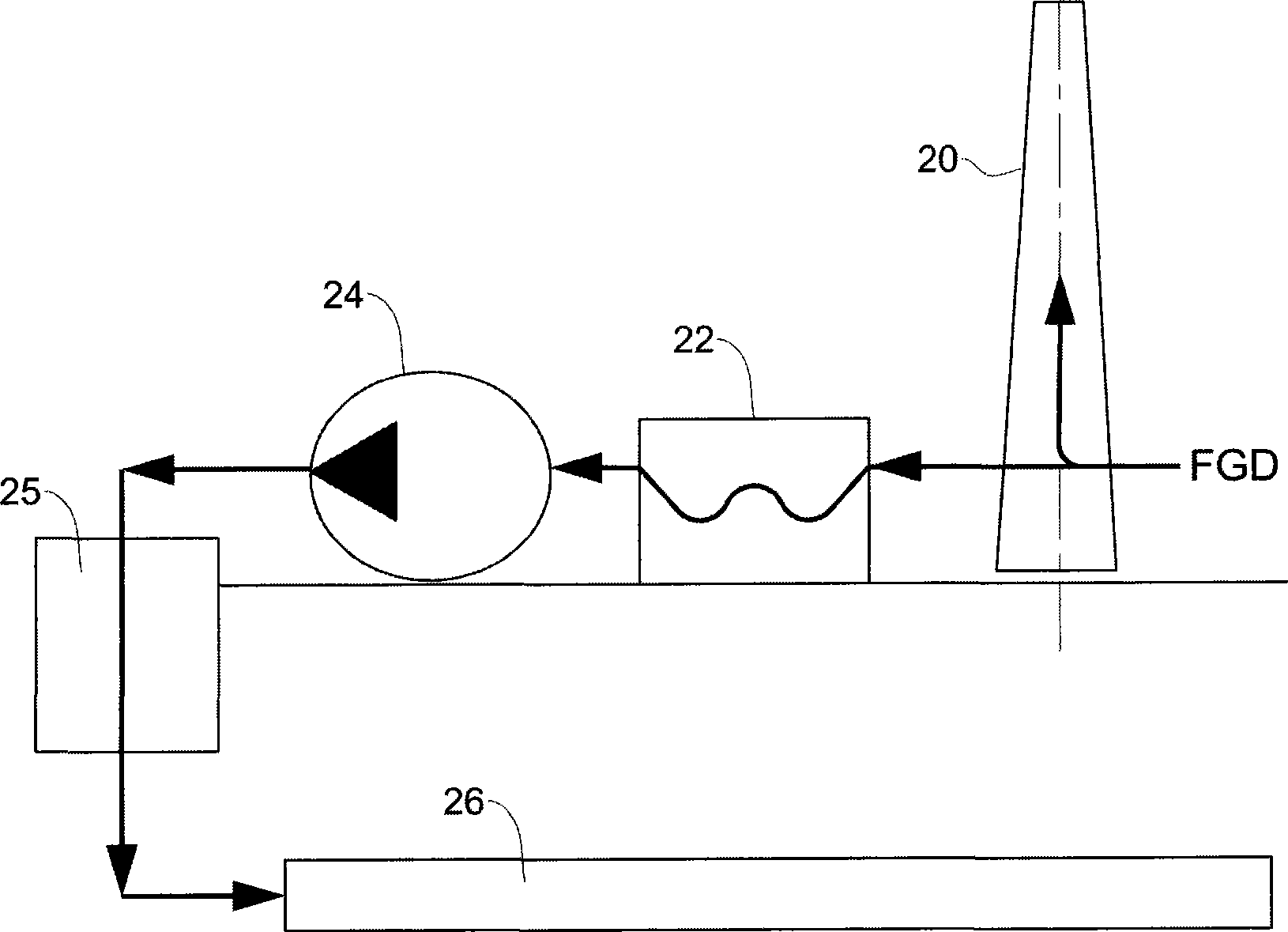

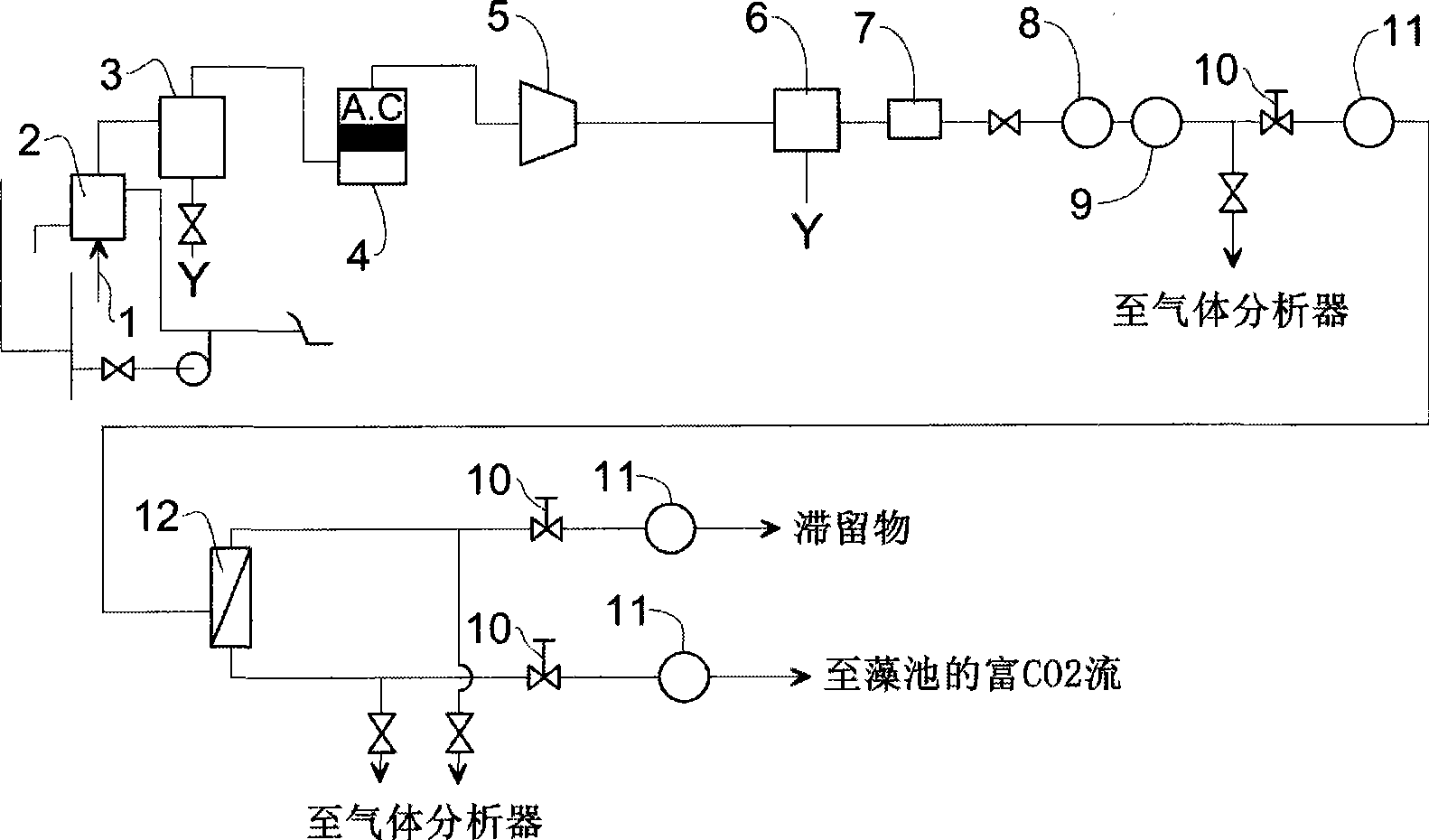

Method for growing photosynthetic organisms

InactiveUS20080220486A1Increase carbon dioxide concentrationEffective dispersionMaterial nanotechnologyOrganic active ingredientsFlue gasBiofuel

A method of growing photosynthetic organisms comprising providing the organisms with flue gases from a fossil-fuel power plant, the gases being previously treated by desulfurization. The carbon dioxide (CO2) concentration of the flue gases may be increased over the CO2 concentration as released from the power plant. Also disclosed is a method for producing ω fatty acids and bio-fuels comprising growing microalgae by providing said microalgae with flue gases from a fossil-fuel power plant.

Owner:SEAMBIOTIC LTD

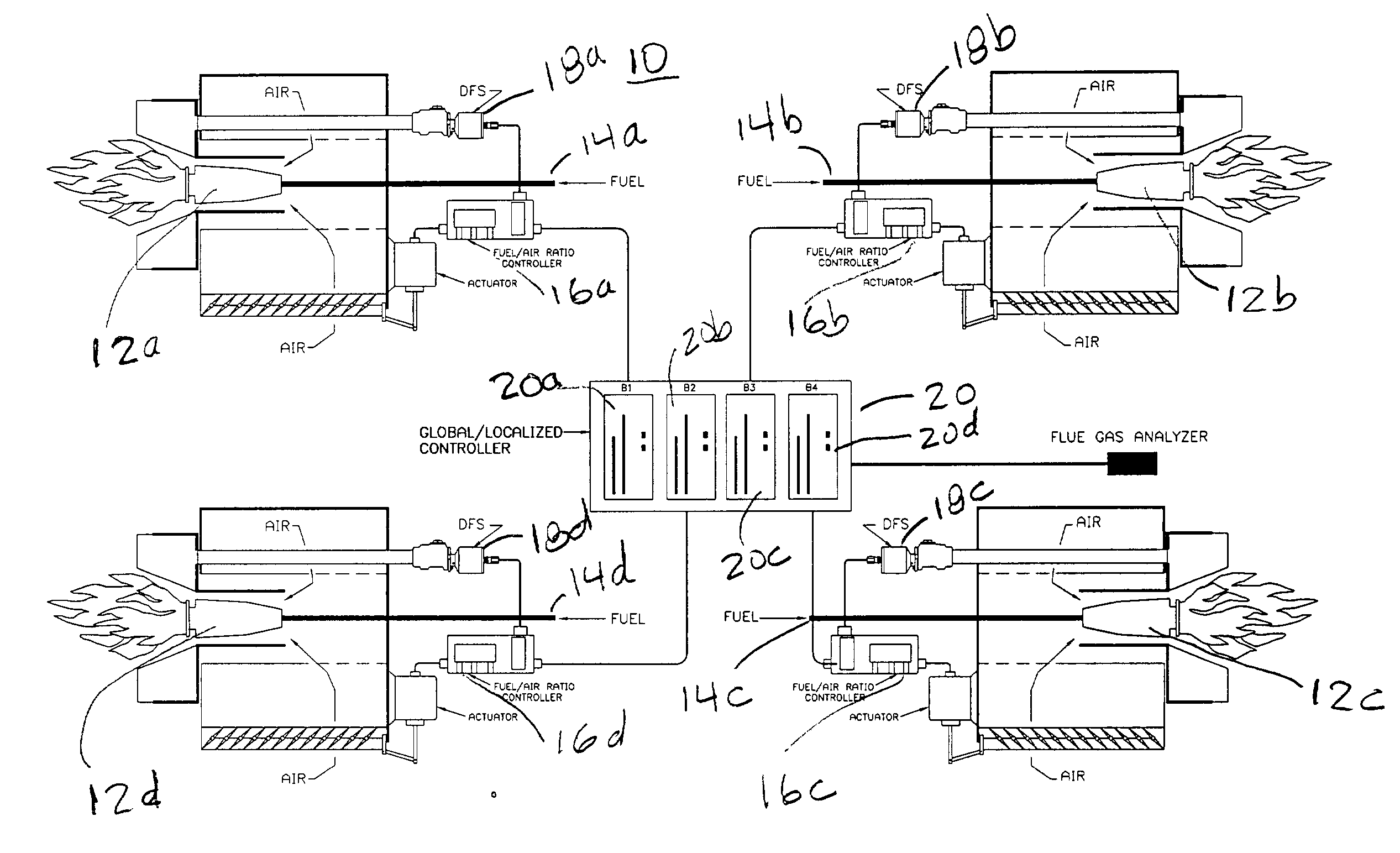

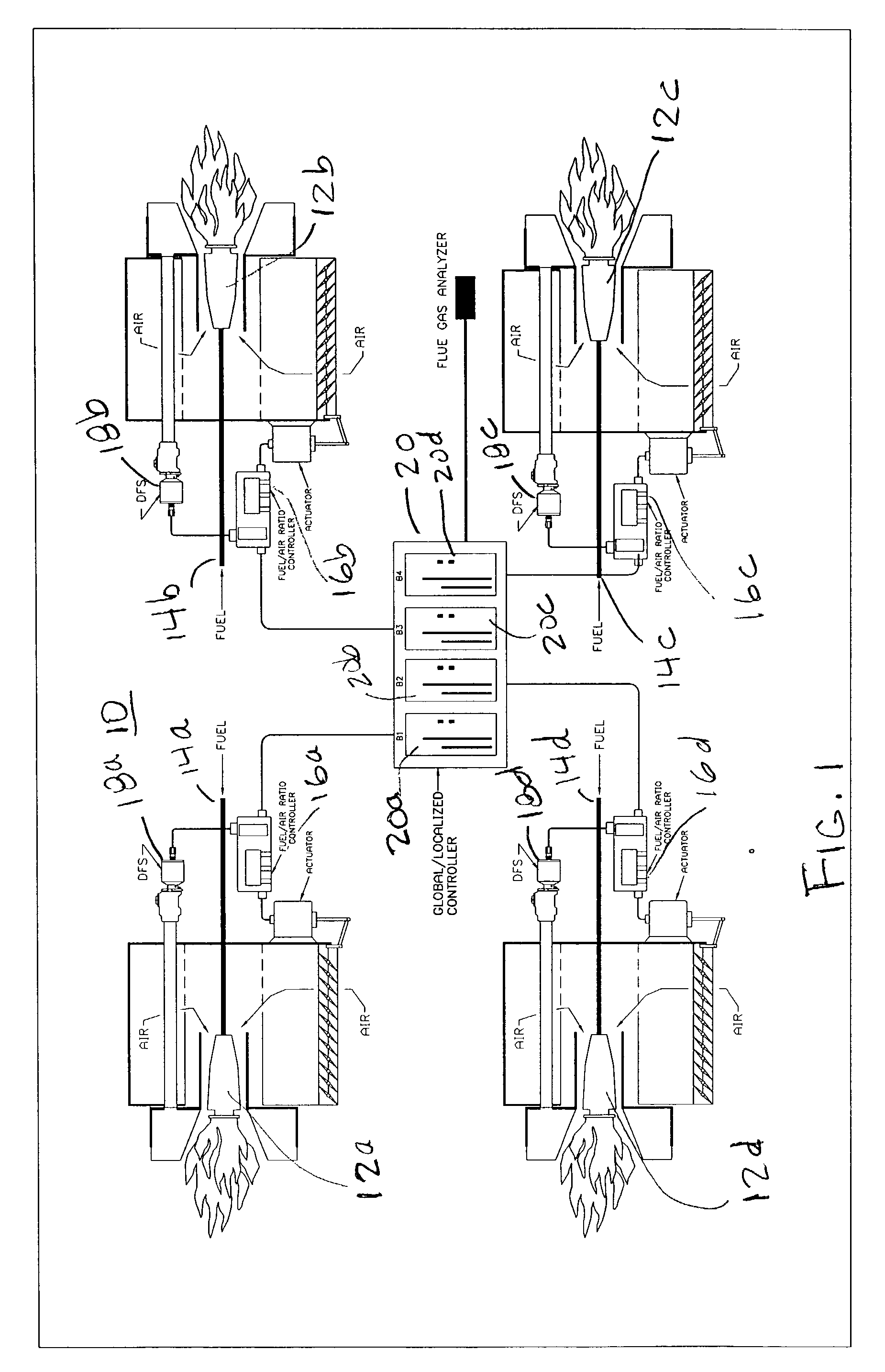

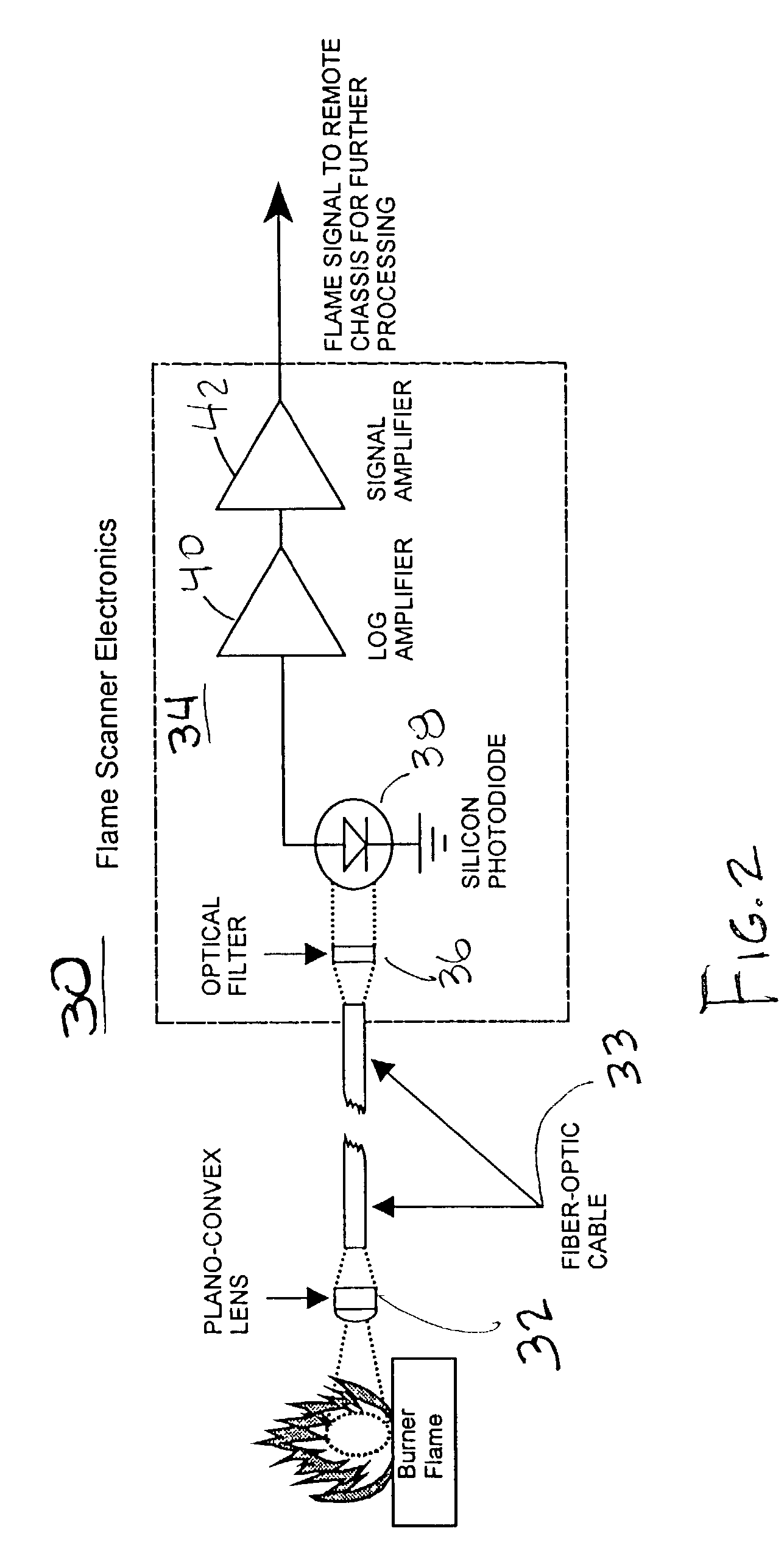

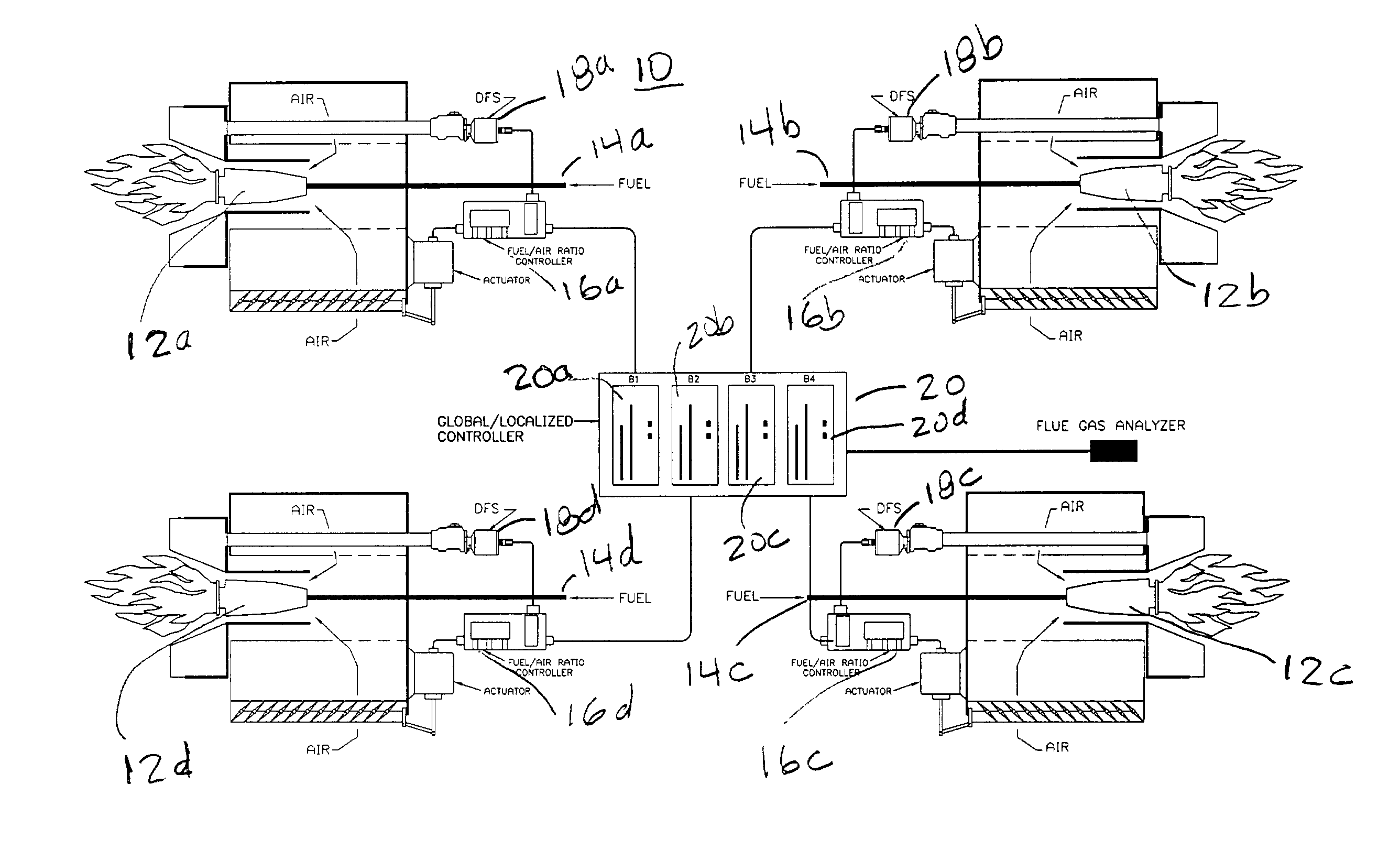

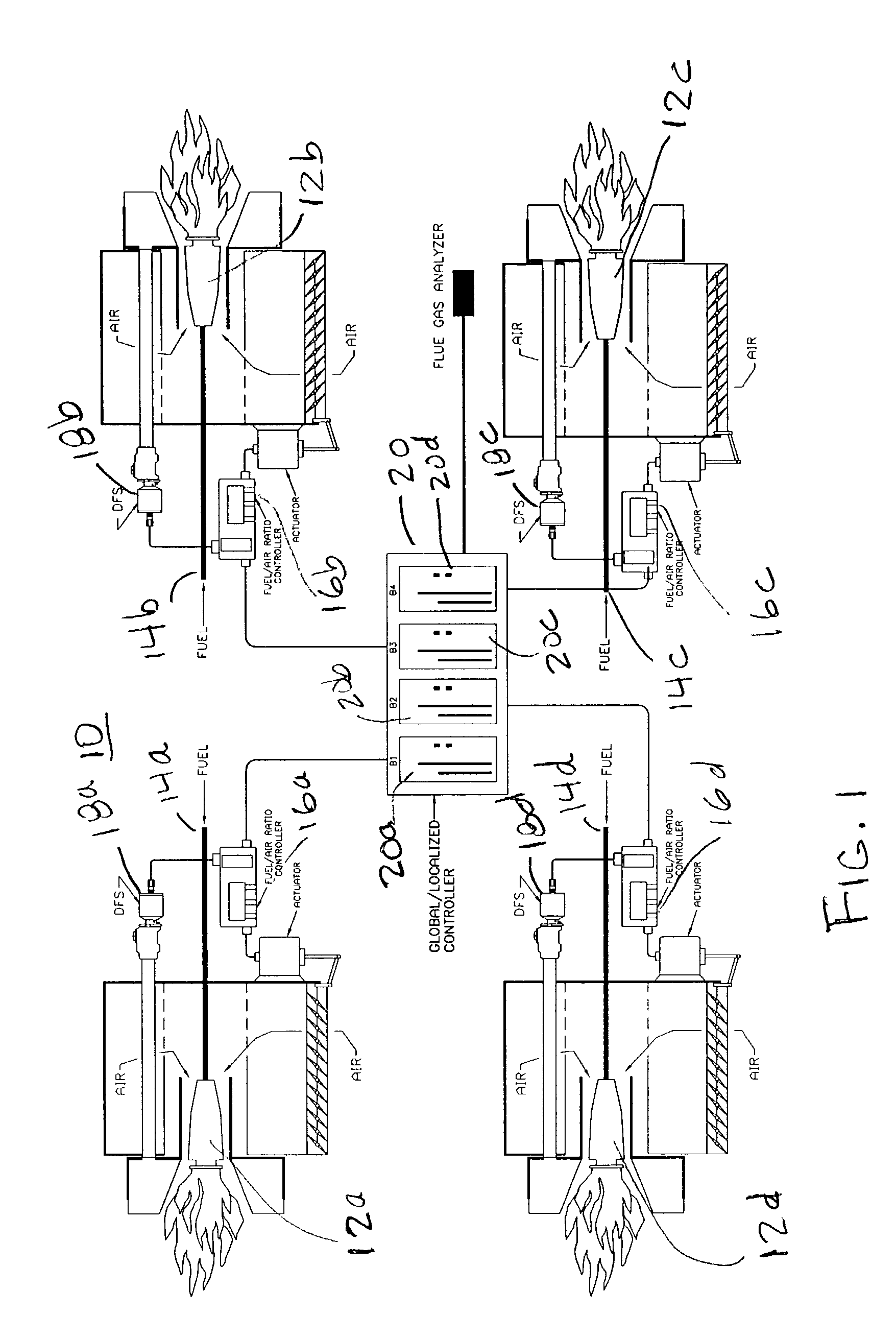

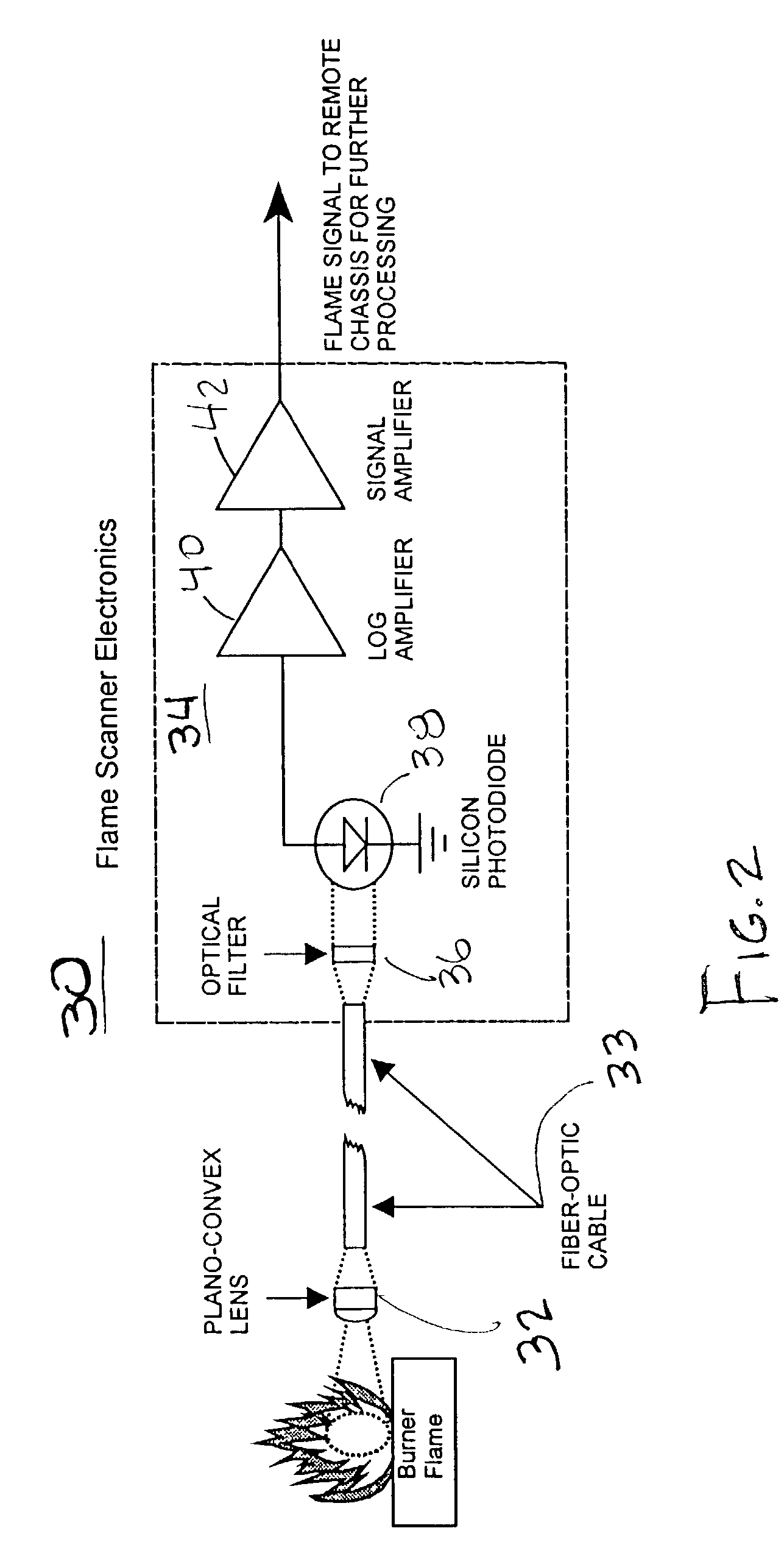

Combustion emission estimation with flame sensing system

InactiveUS20040033457A1High frequencyAddressing Insufficient SensitivityFuel supply regulationPilot flame ignitersCombustorEngineering

There is described a method and apparatus for controlling the combustion by-product formation rate in at least one burner of a fossil fuel fired power plant. The burner has an associated flame scanner which is focused on a small area of the burner flame to obtain an image signal of the flame. A flame signal that represents properties of temporal combustion in the visible light spectrum of the burner is generated from the image signal. Combustion turbulence at the burner is analyzed from the flame signal by a dynamic invariant that has a relationship to the combustion by-product values and different combustion by-product levels at the burner and the combustion turbulence is correlated to the combustion by-product formation rate at the burner. The method and apparatus can also be used to correlated the combustion turbulence at a multiplicity of burners to the associated combustion by-product formation rate.

Owner:ABB INC

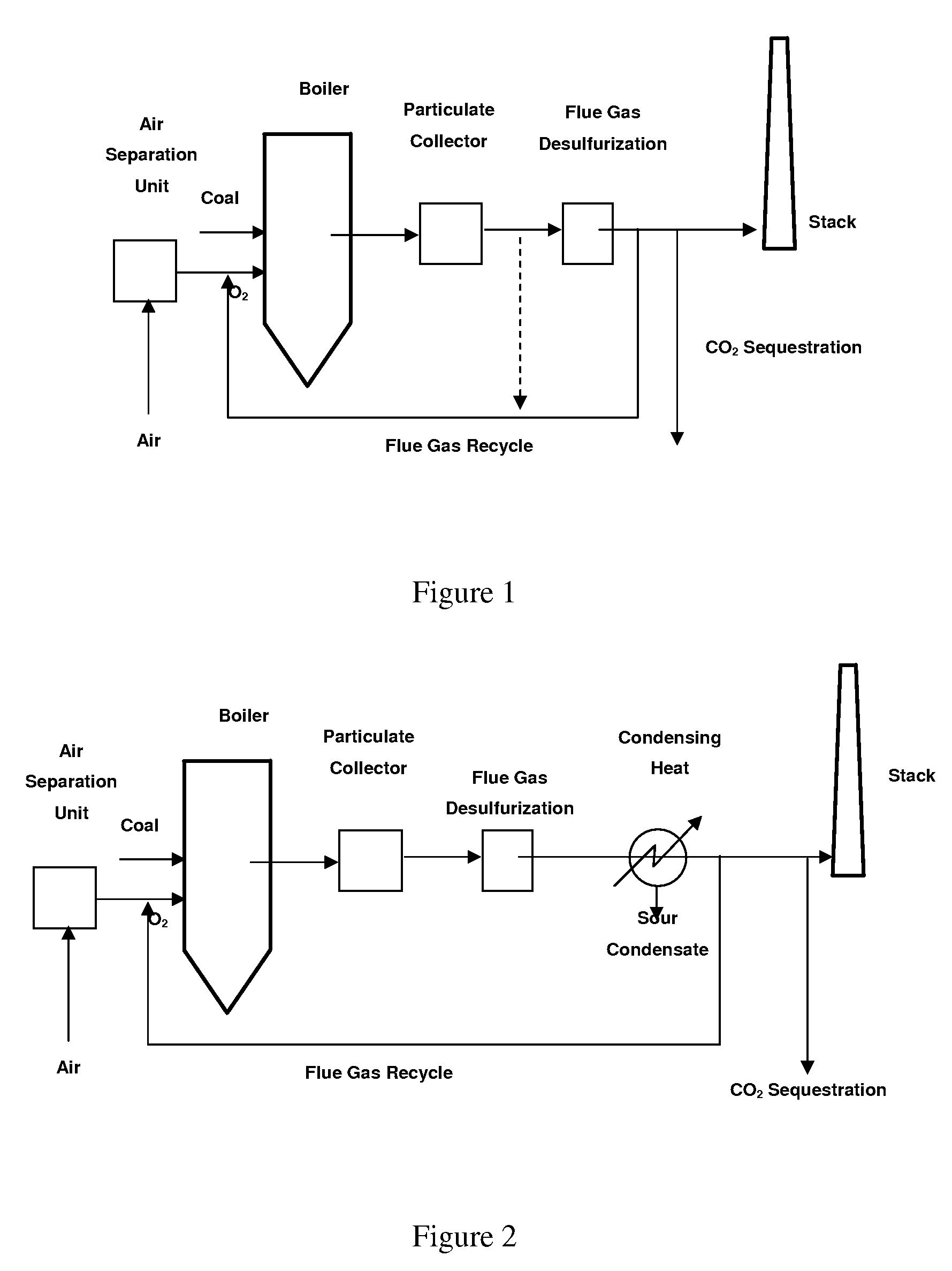

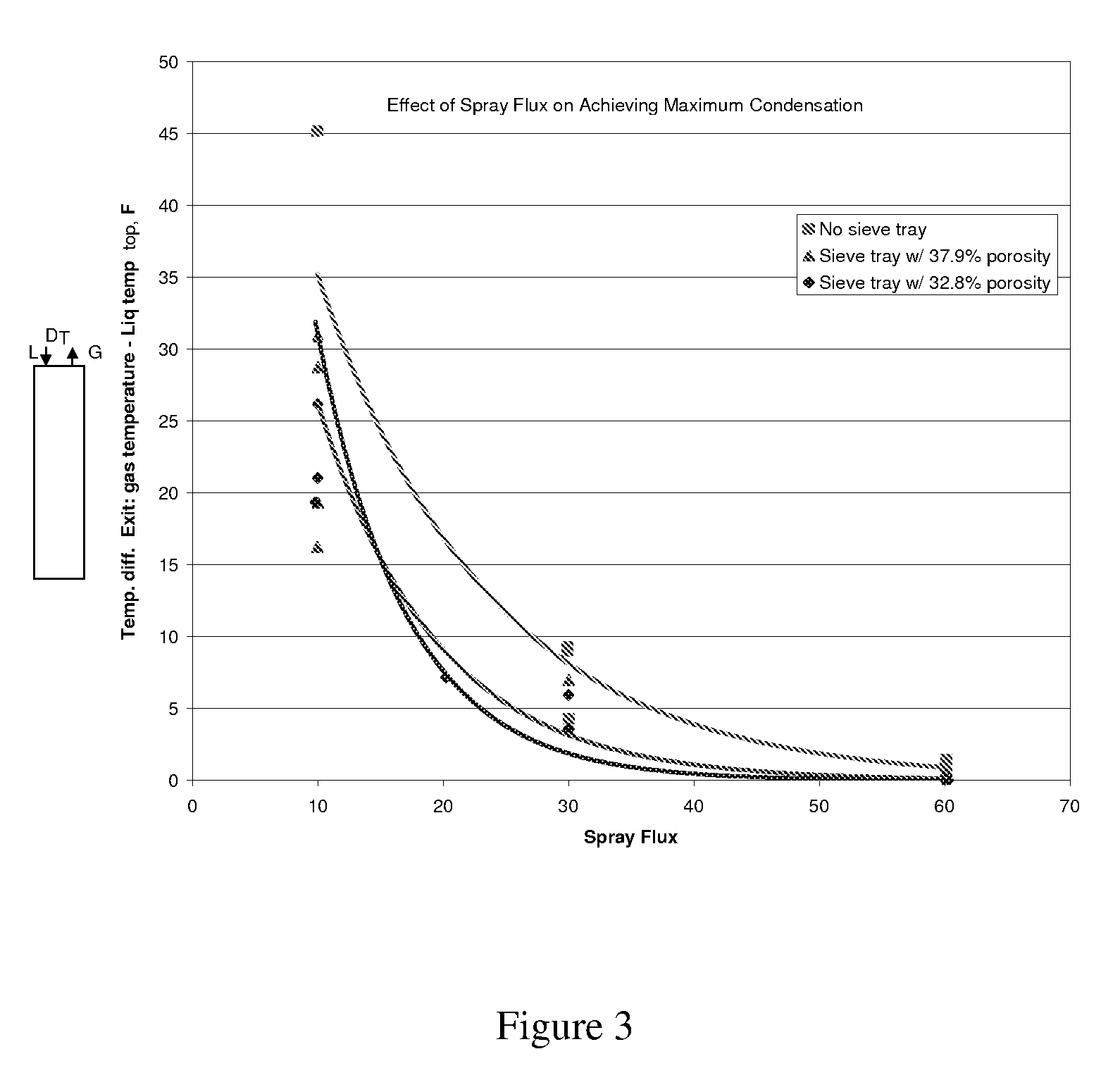

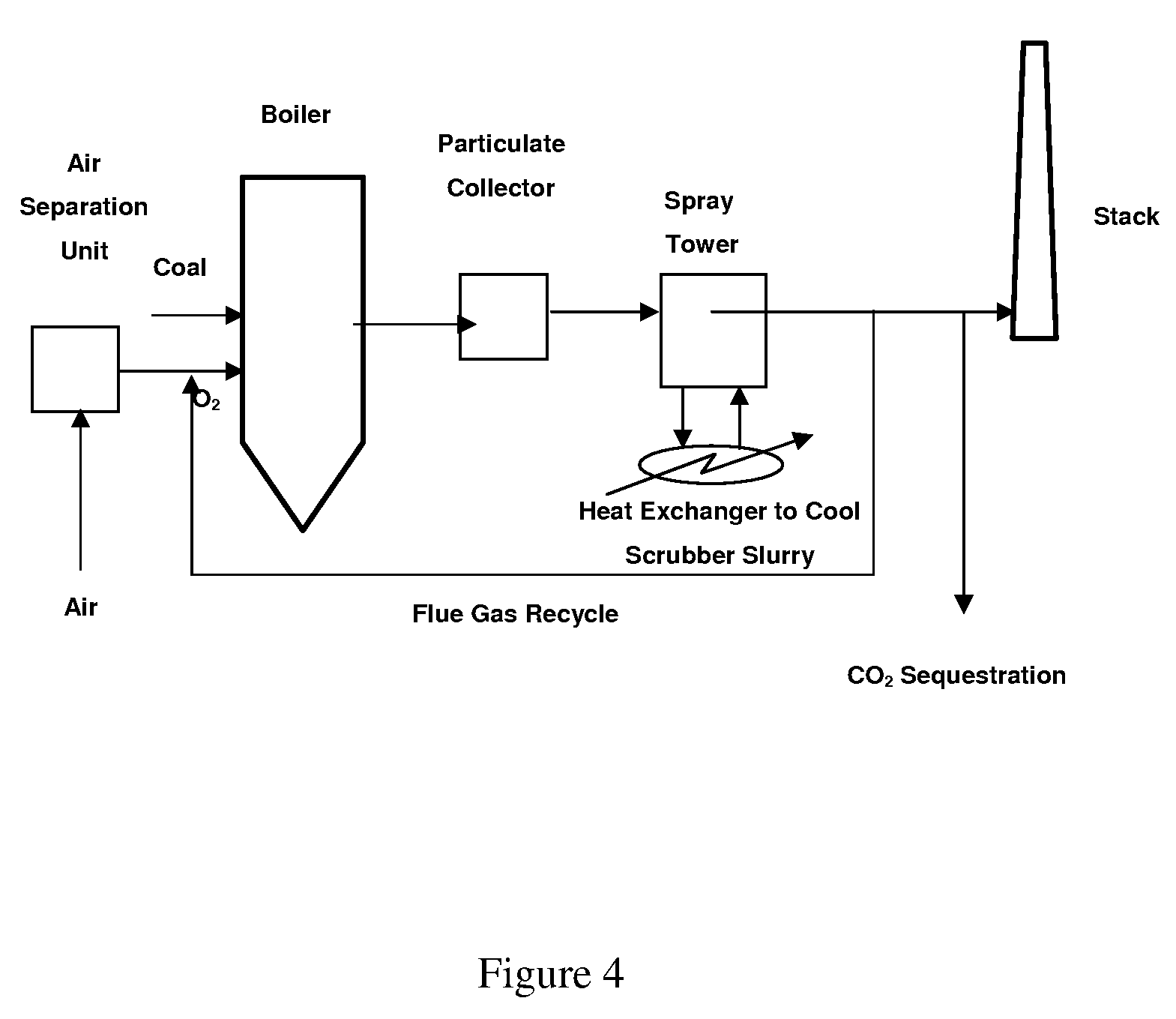

Process for controlling the moisture concentration of a combustion flue gas

InactiveUS20070243119A1Reduce concentrationReducing the moisture of the flue gasUsing liquid separation agentHydrogen sulfidesSprayerWater vapor

The invention is related to a system for removal of moisture and contaminants from recirculated flue gas which is used for combustion in fossil fuel power plants. The system includes a spray tower having an inlet at one end of the housing and an outlet at an opposite end of the housing for channeling the flue gas into and out of the housing. Sprayers are located in the housing for spraying the flue gas with a liquid reagent to remove contaminants, including SO2, from the flue gas. A heat exchanger is integrally connected to the housing. The heat exchanger cools the liquid reagent before the reagent is sprayed onto the flue gas stream. The sprayers quench the flue gas stream with the cooled liquid reagent. The cooling of the liquid reagent to a temperature below the flue gas water vapor dew point improves the condensation of the water vapor in the flue gas during the spraying process. The flue gas exits the system with a lower moisture content and is redirected to burner for combustion. As a result, the efficiency the combustion process will improve with less moisture in the flue gas.

Owner:THE BABCOCK & WILCOX CO

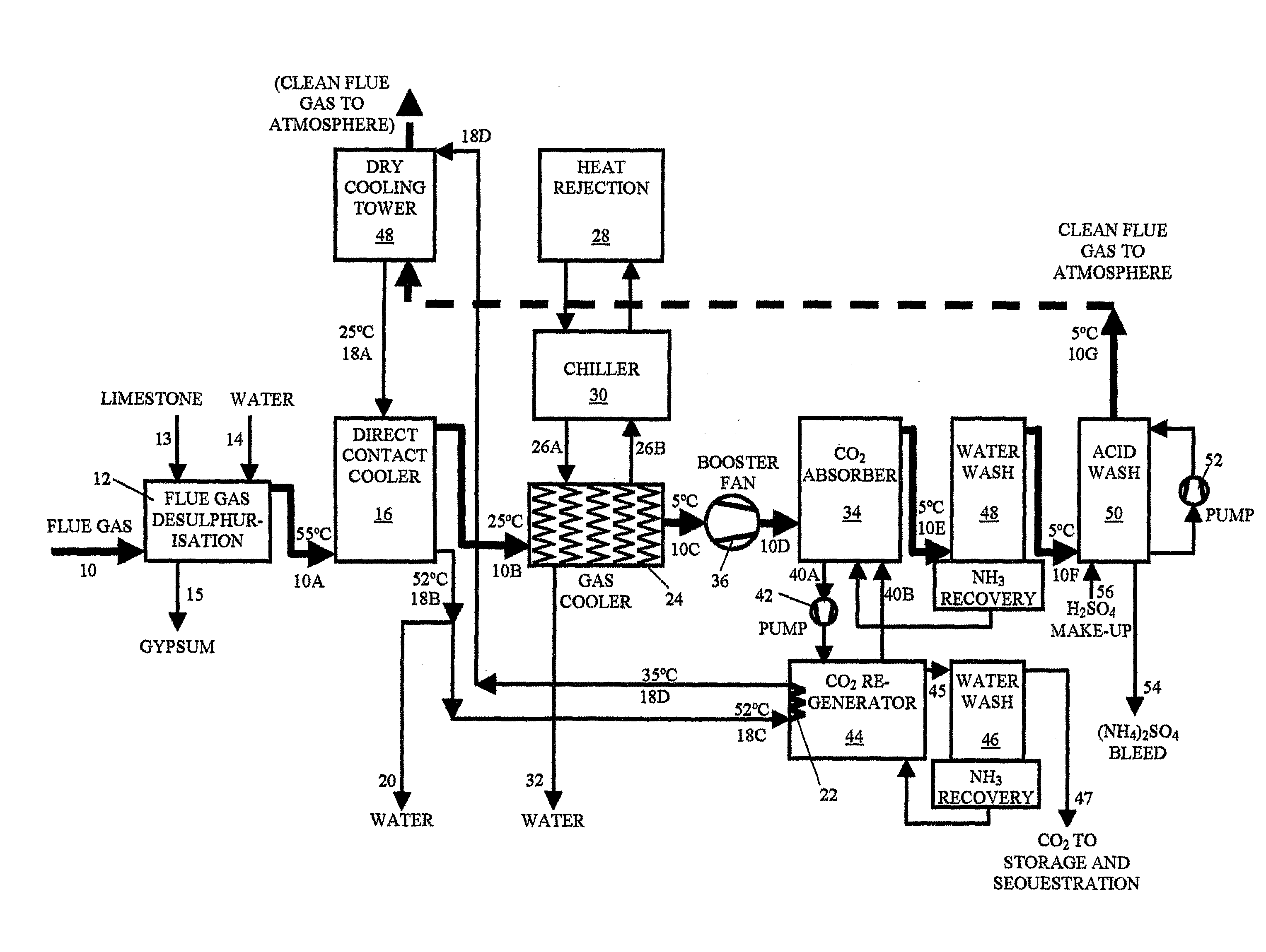

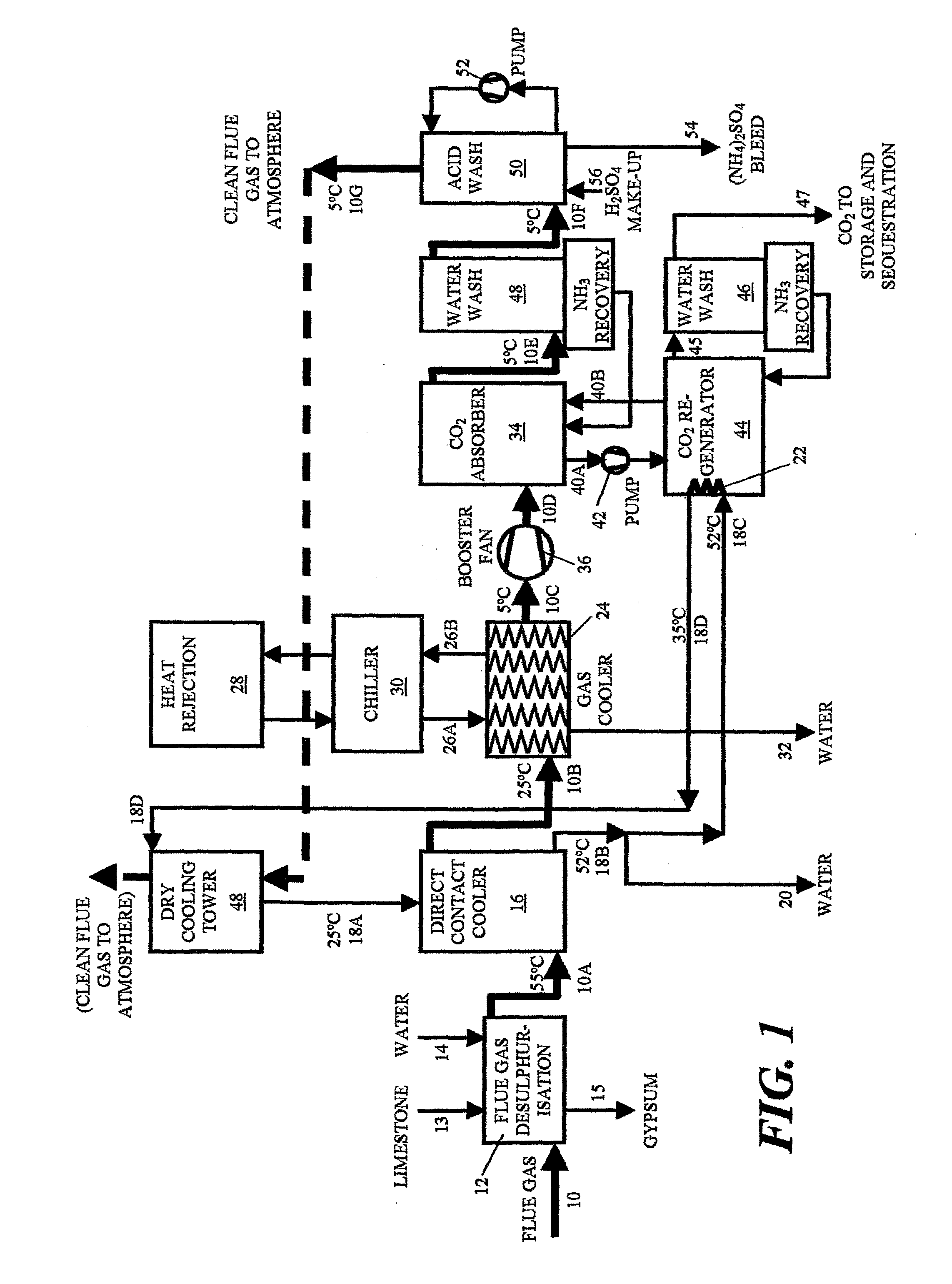

Carbon capture system and process

A system and process is provided primarily for use in hot climates, using ammonia solution to remove carbon dioxide from desulphurised water-vapour-containing flue gases of a fossil fuel power plant, while outputting useful streams of water and fertiliser.

Owner:GENERAL ELECTRIC TECH GMBH

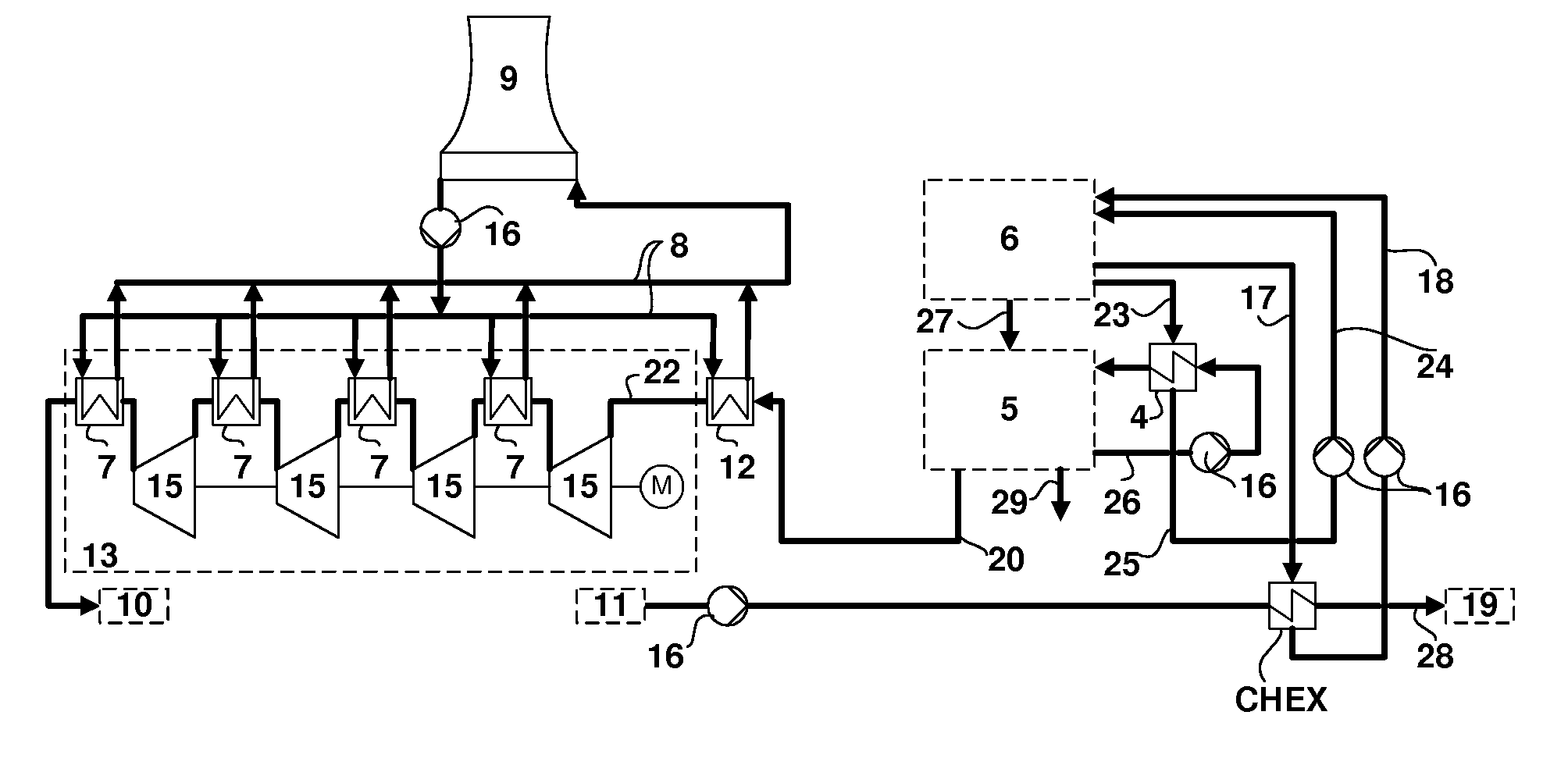

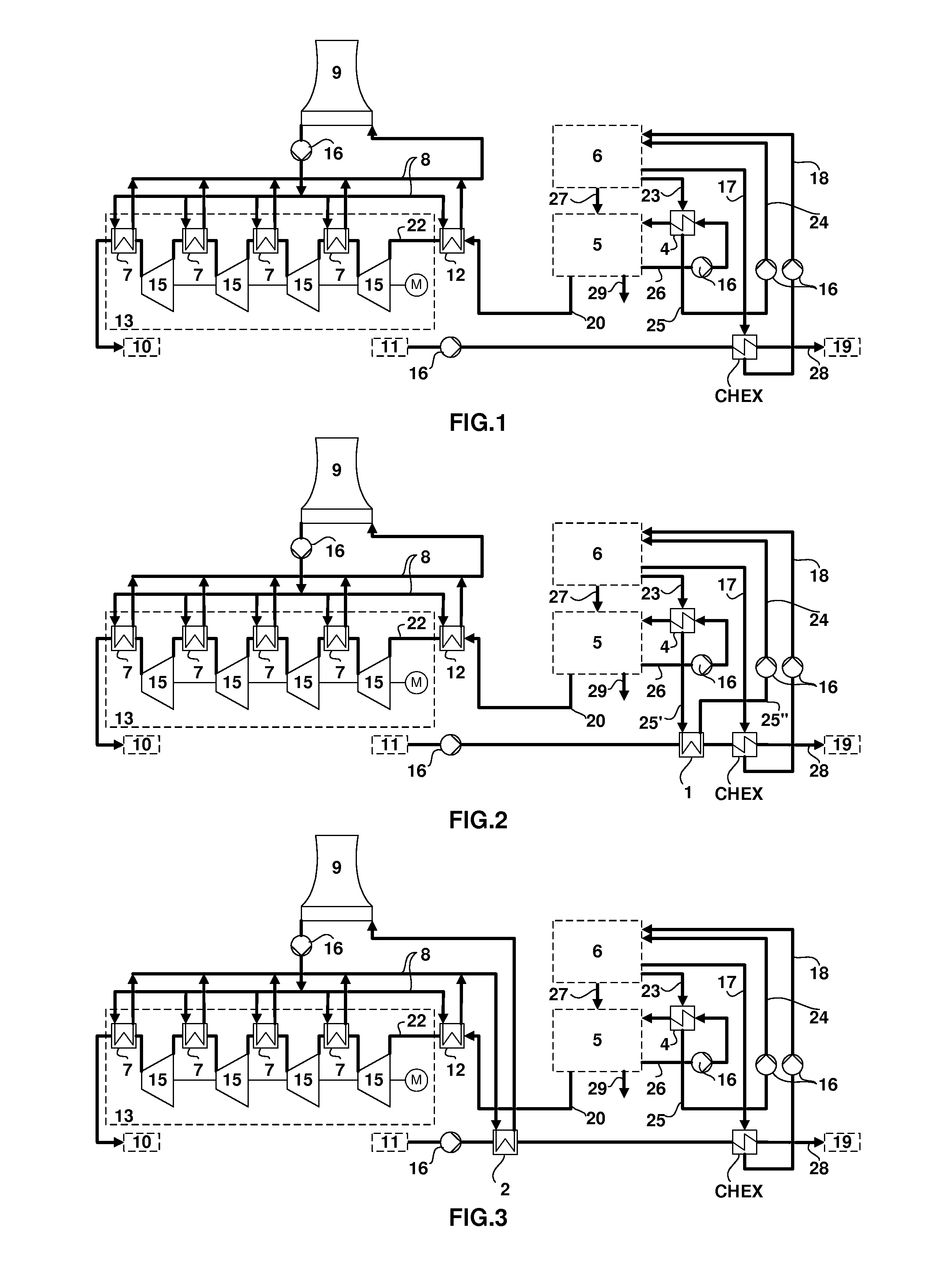

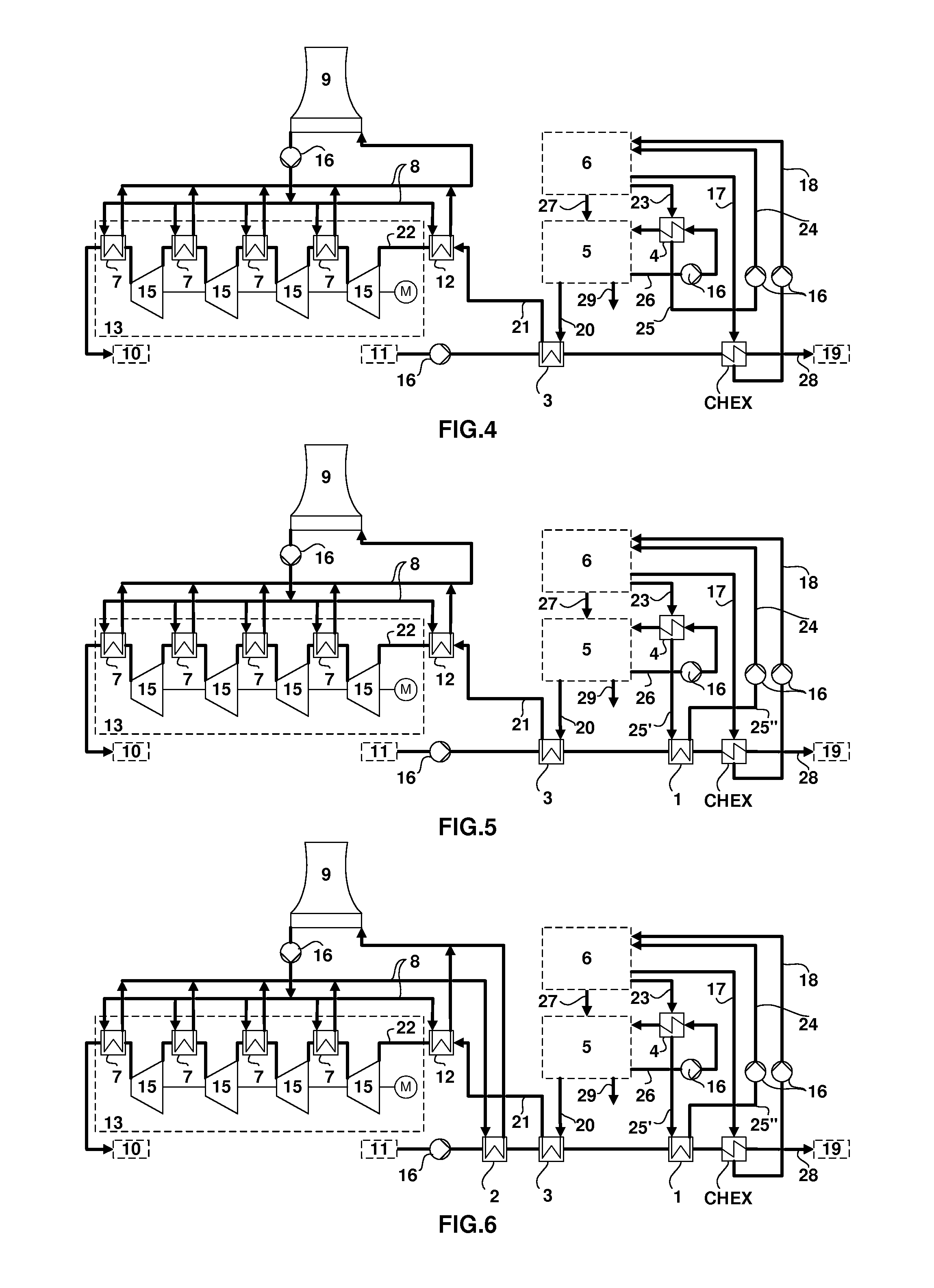

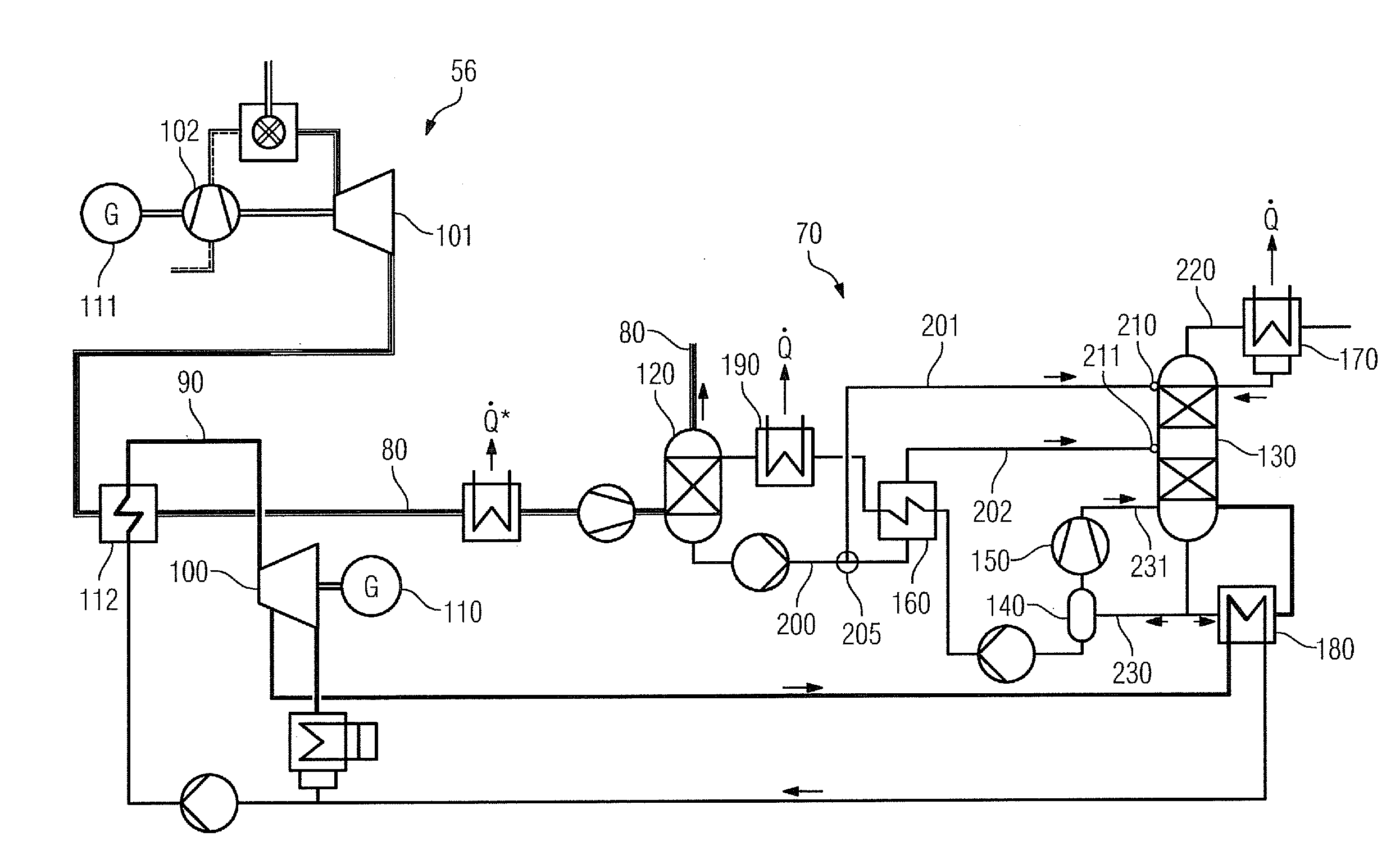

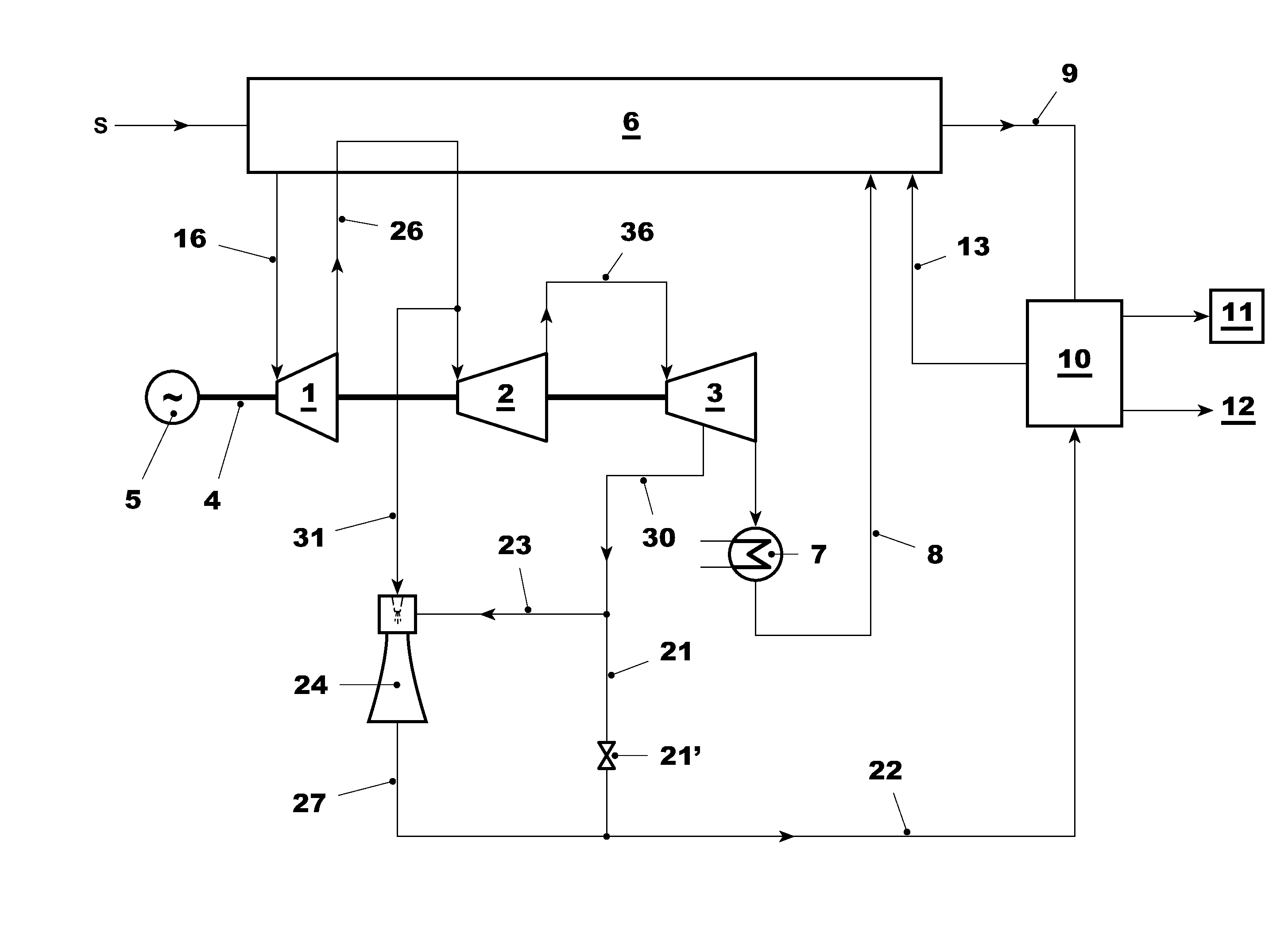

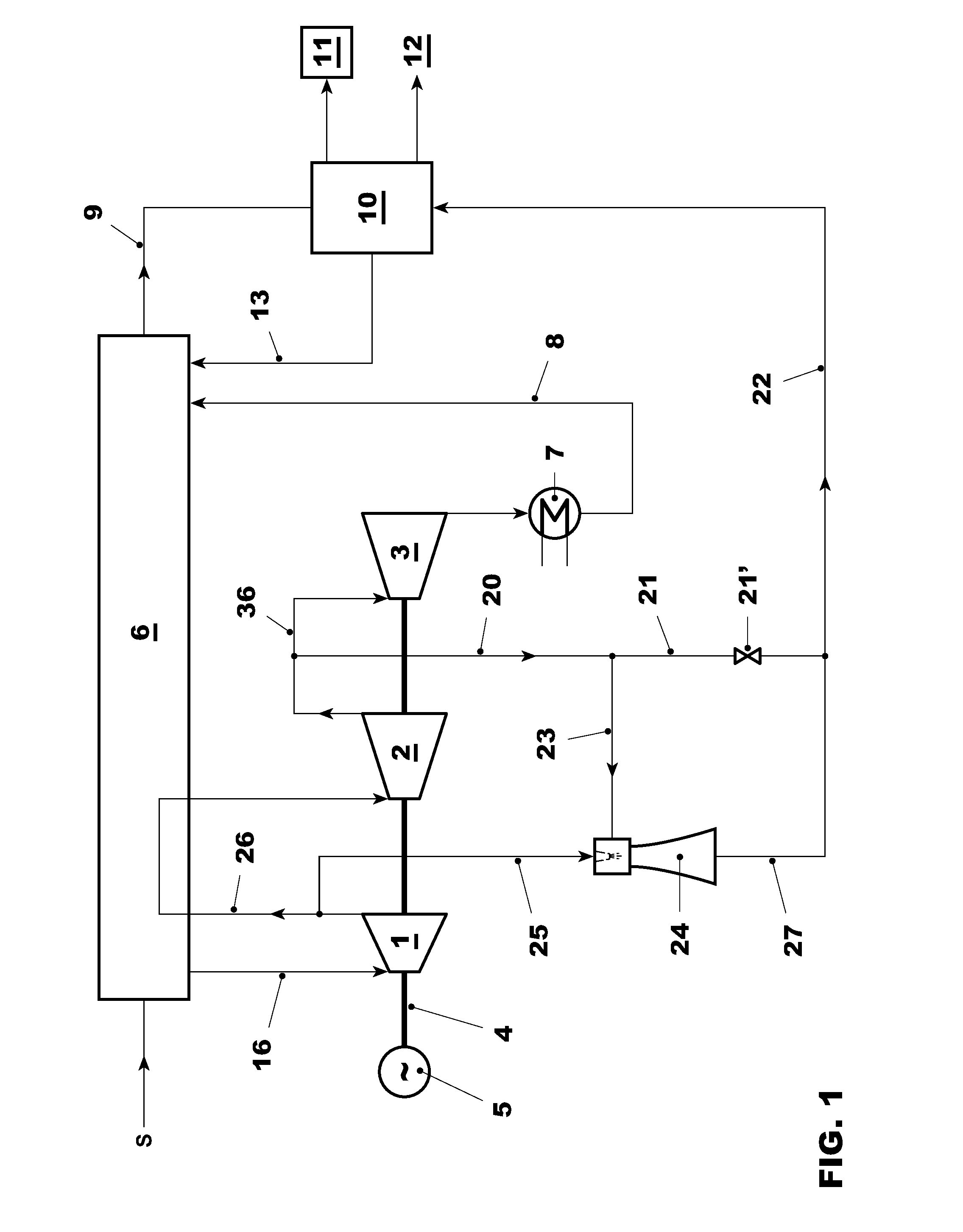

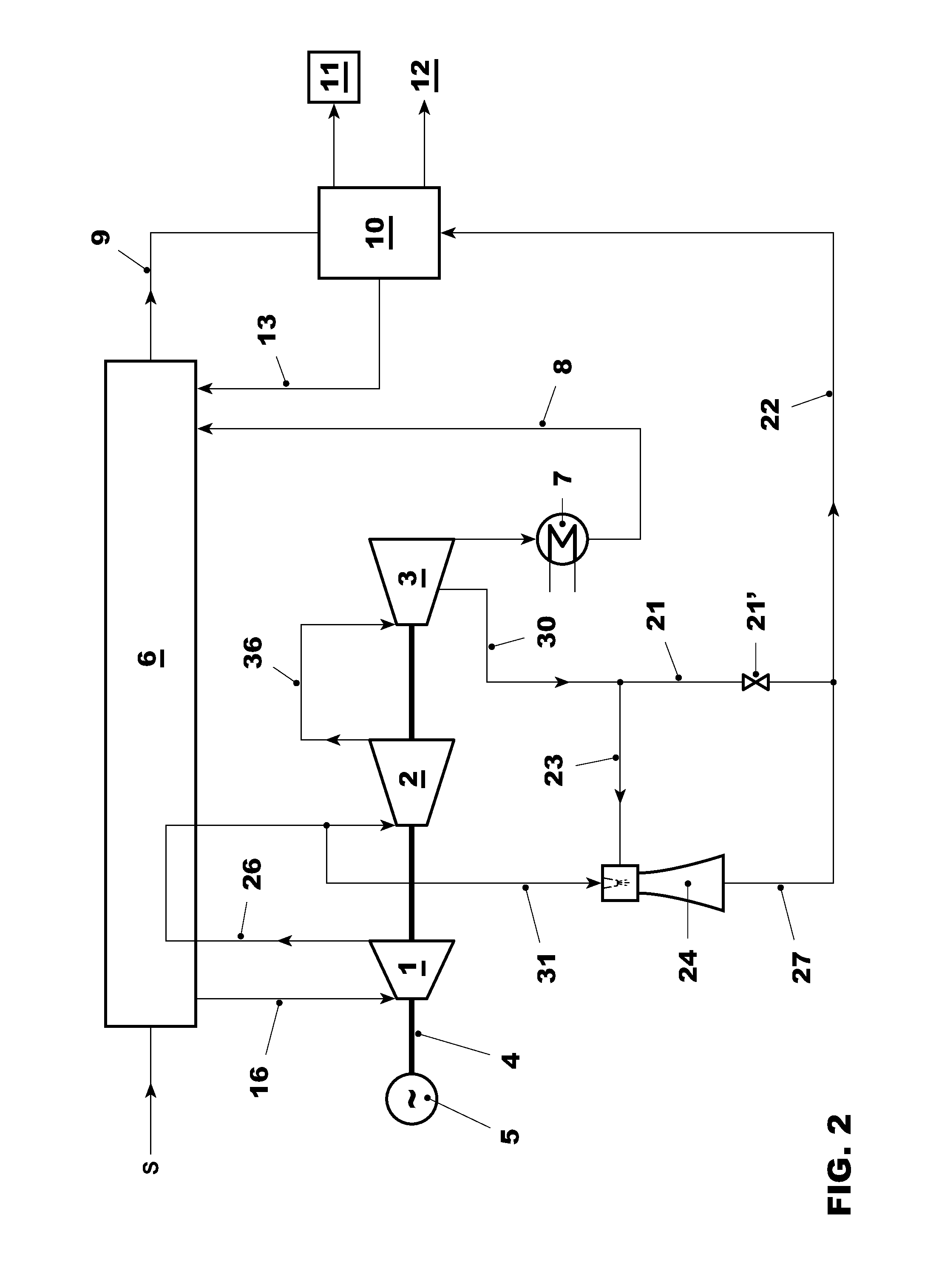

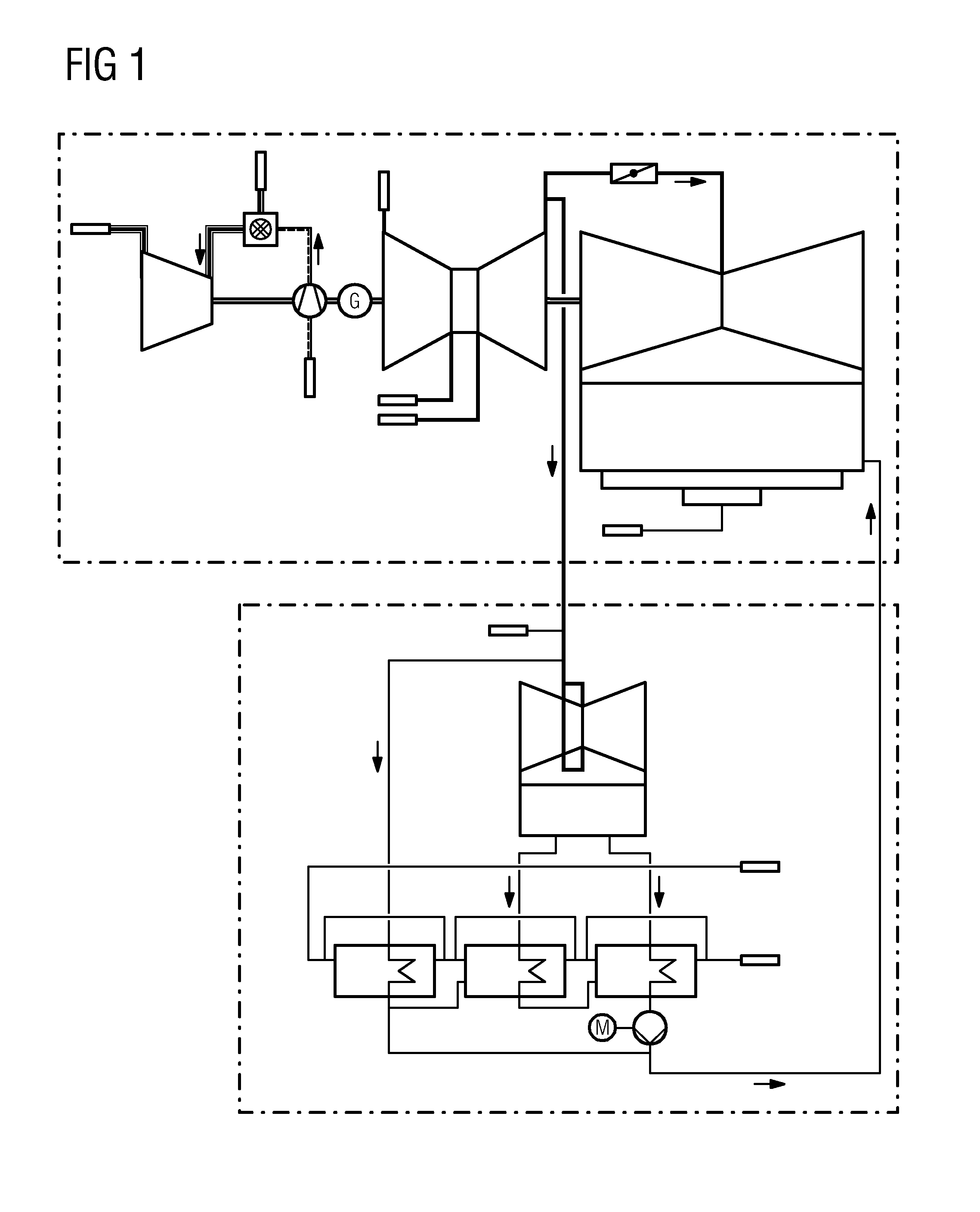

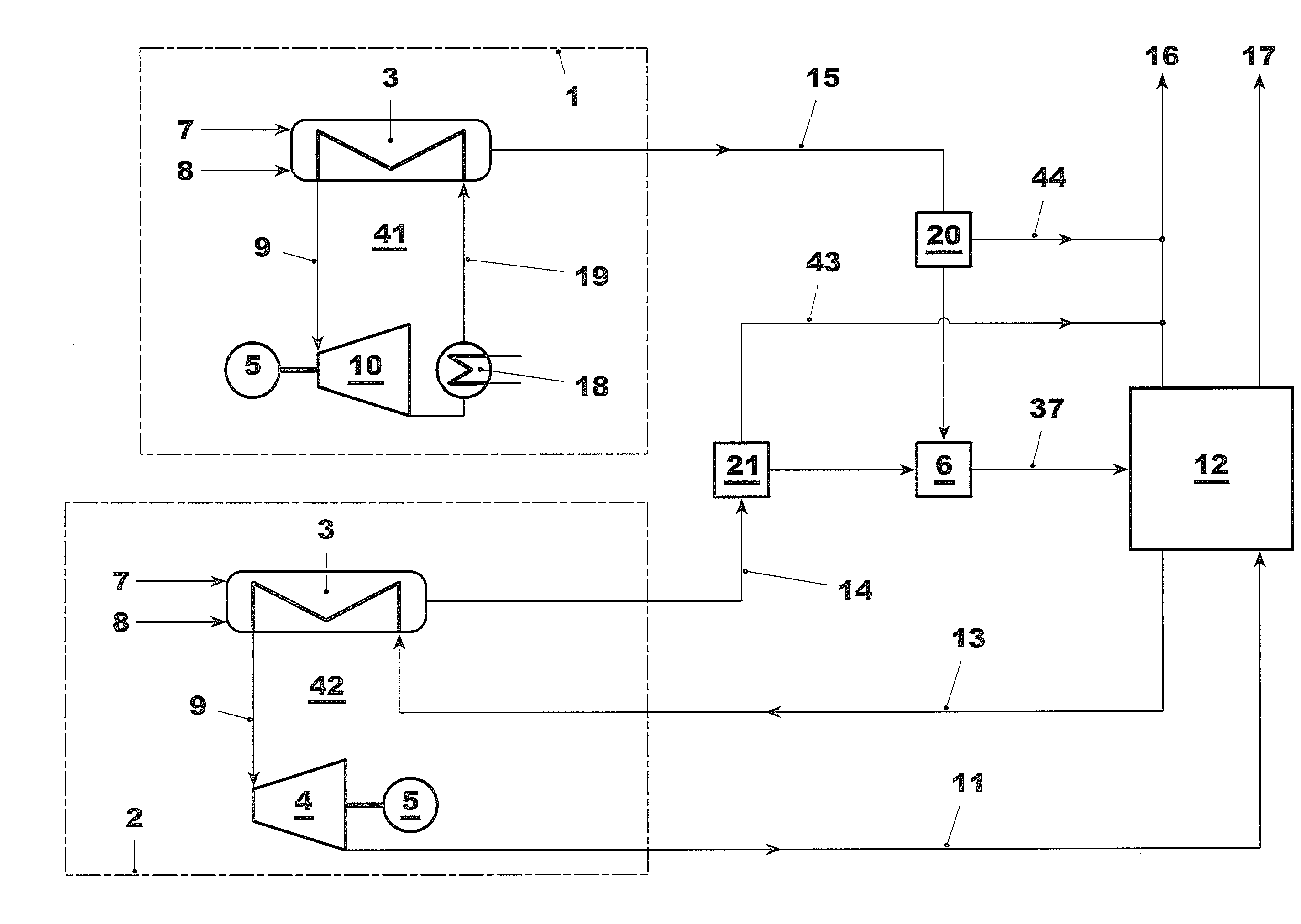

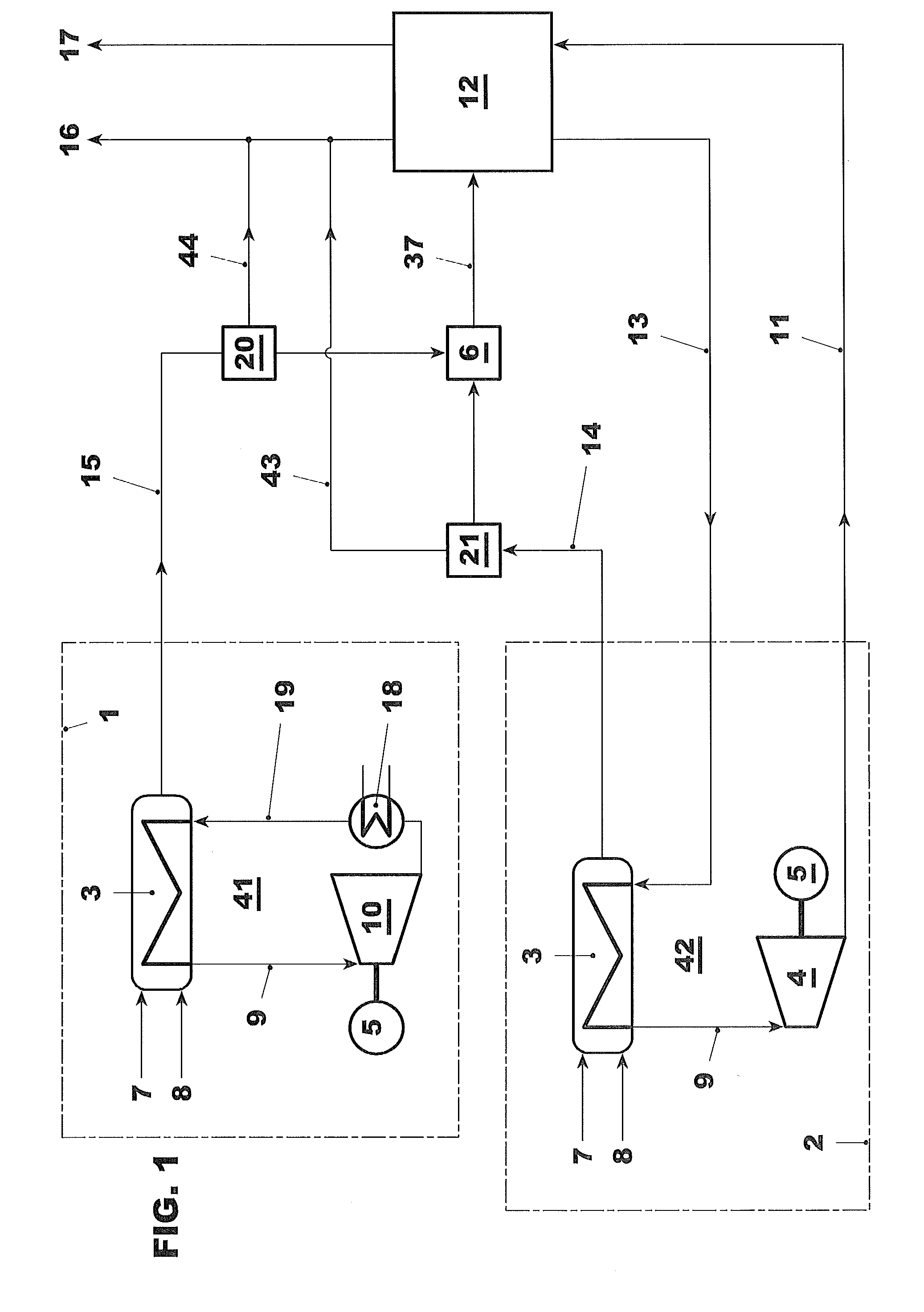

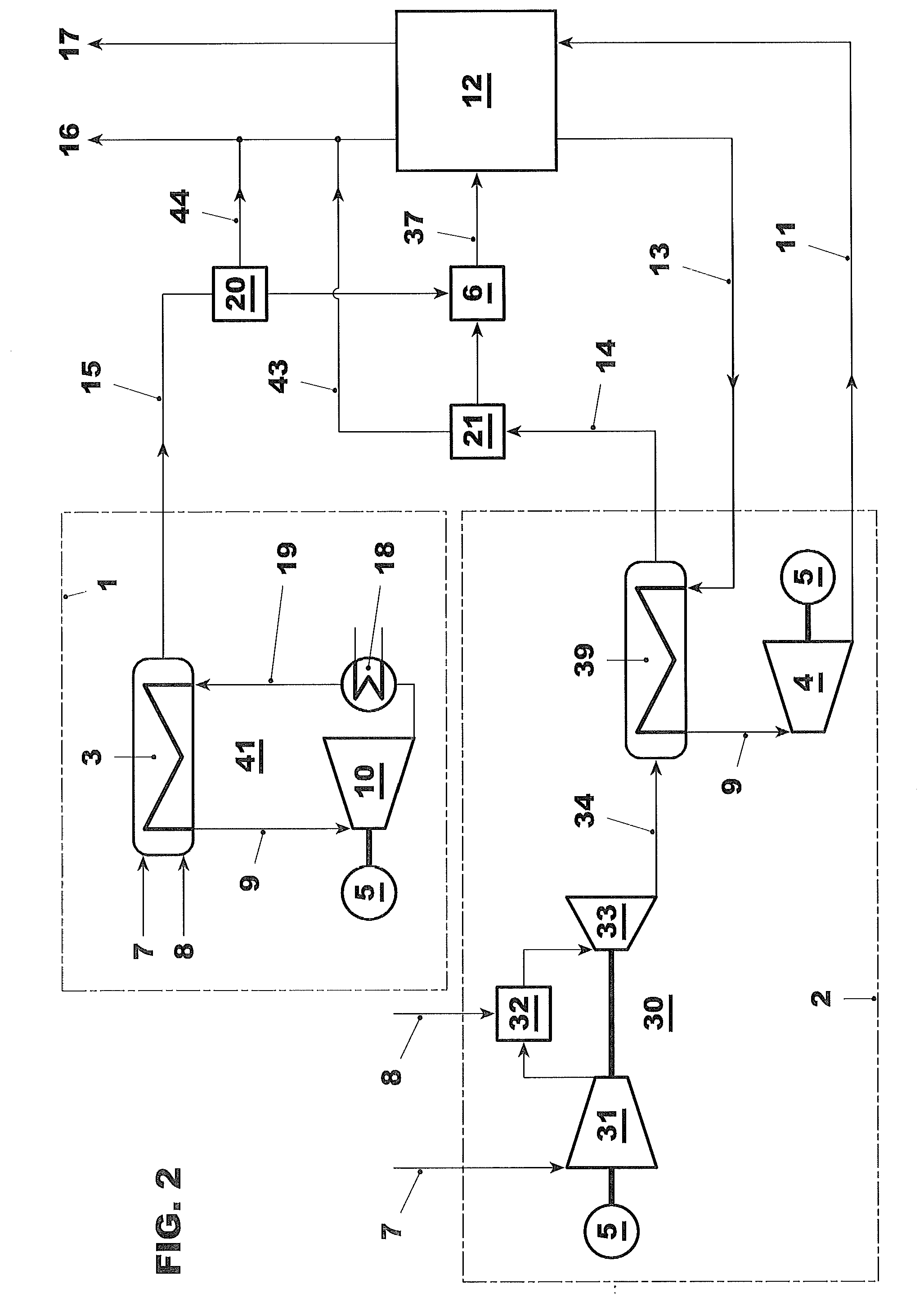

Thermal integration of a carbon dioxide capture and compression unit with a steam or combined cycle plant

ActiveUS20110265477A1Improve power efficiencyReduce extractionGas treatmentCarbon compoundsElectricityHeat flow

A power plant system including a fossil fuel fired power plant (6) for the generation of electricity, a carbon dioxide capture and compression system (5, 13), and an external heat cycle system has at least one heat exchanger (1,2,3) for the heating of the flow medium of the external heat cycle system. The heat exchanger (1,2,3) is connected to a heat flow from the CO2 capture plant (5) or a CO2 compression unit (13). A return flow from the heat exchanger (1,2,3) is led to the CO2 capture and compression system (5,13) or to the power plant (6). The power plant system allows an increase in overall efficiency of the system.

Owner:GENERAL ELECTRIC TECH GMBH

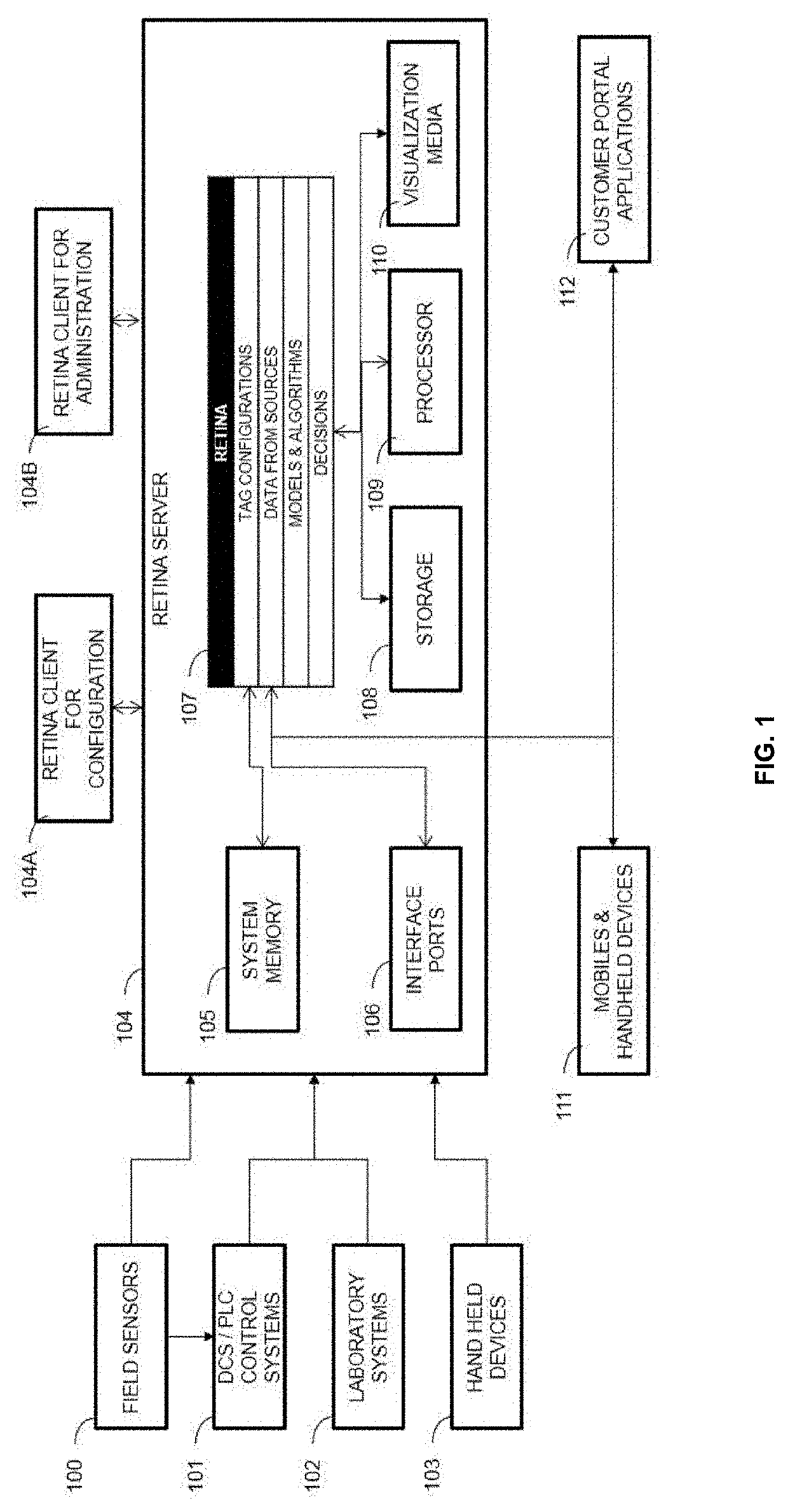

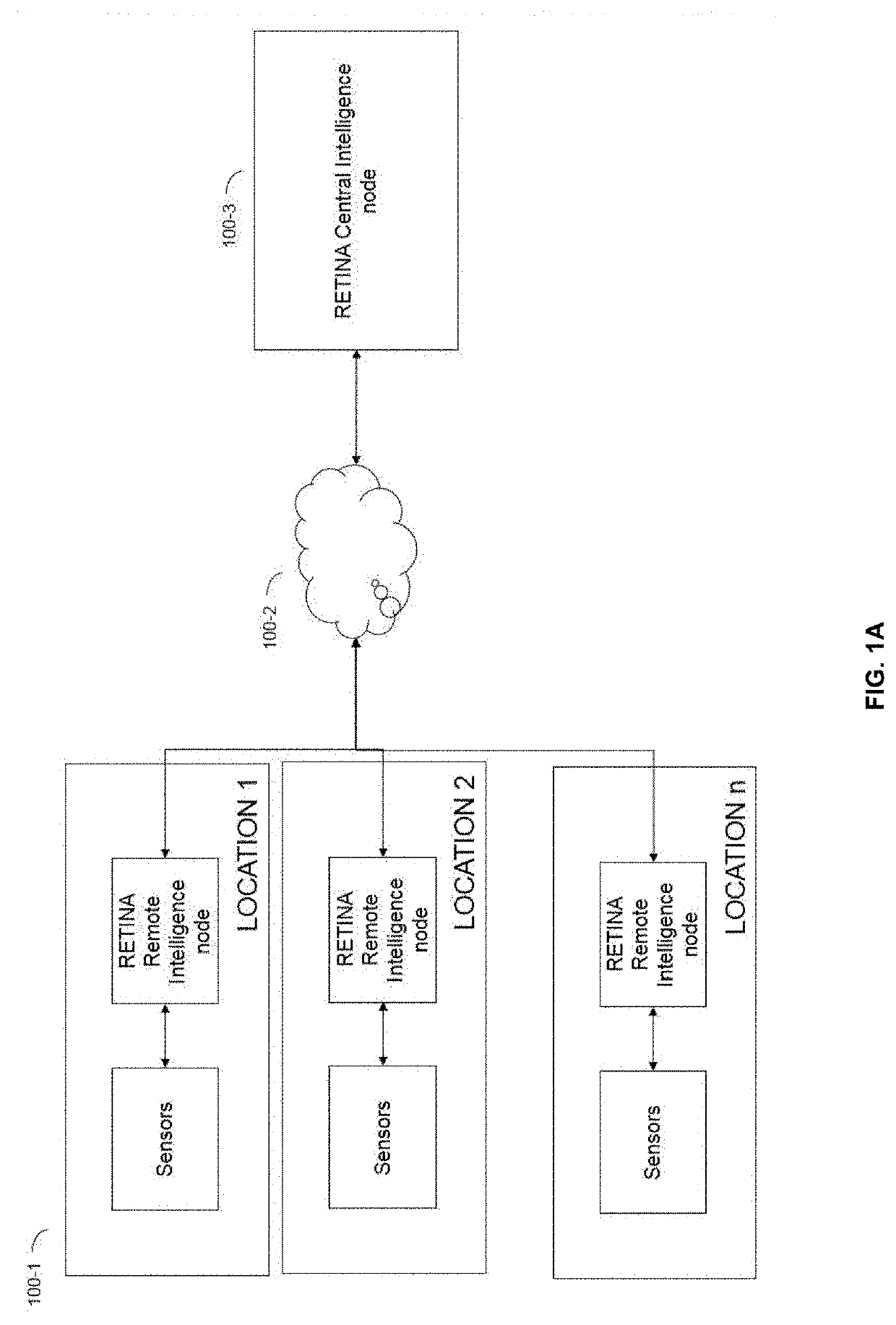

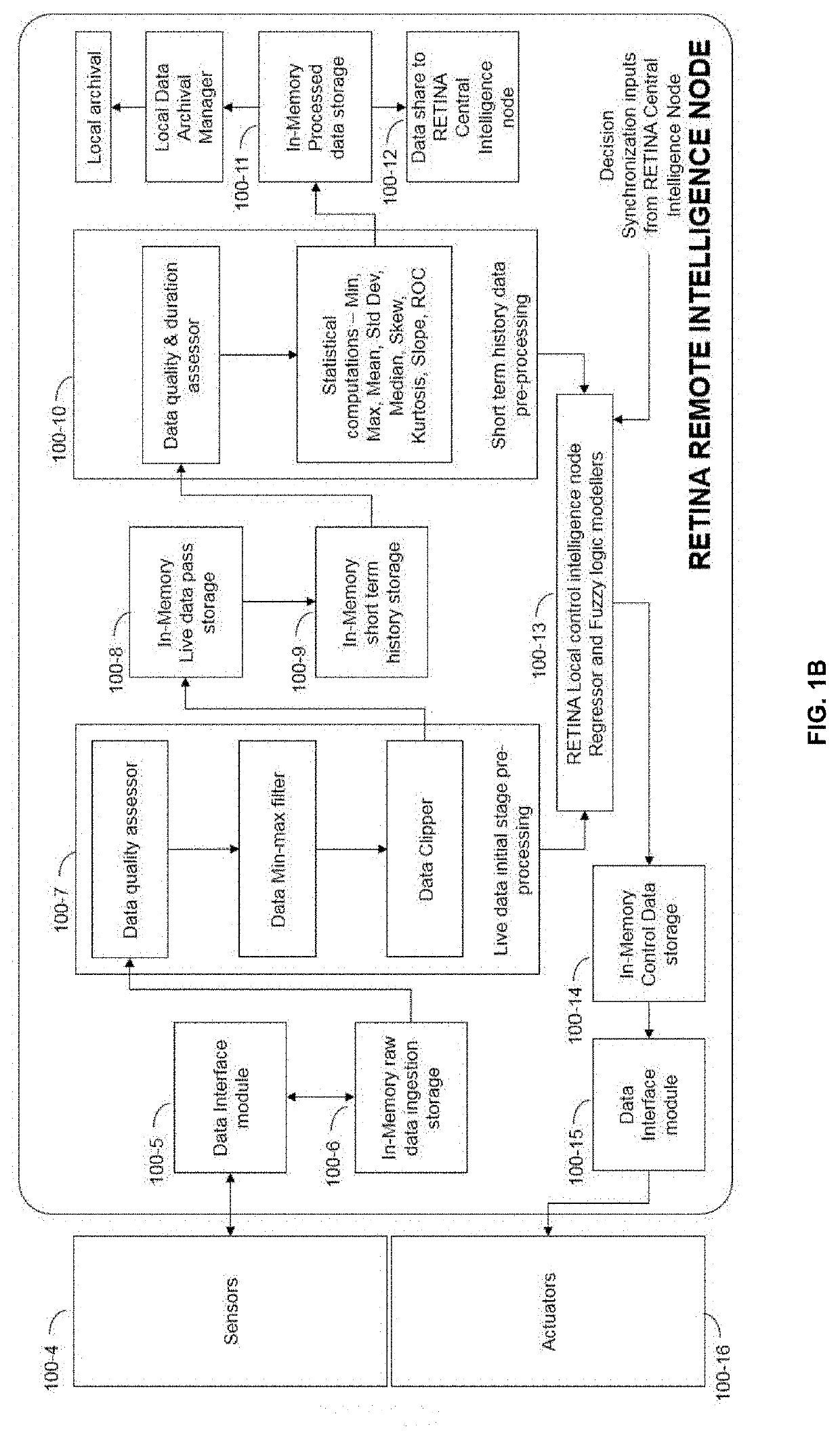

Intelligent Decision Synchronization in Real Time for both Discrete and Continuous Process Industries

ActiveUS20190347590A1Minimizes operation riskReduce operational riskResourcesInformation technology support systemData sourceOil and natural gas

This invention that provides system, method & apparatus for Real Time integration and Analytics (RETINA) to enable proactive decision synchronization in real time in order to minimize the operational risk and maximize the process productivity for process industries such as Oil & Gas Exploration and Fossil fuel power plants is disclosed. RETINA generates and synchronizes the decisions that affect the performance and profitability of business operations in real time and helps in analysis that are essential for any successful business operations. RETINA provides methods and apparatus that combines data from several types of data sources, build models for identifying impending failures, predicting a future state of the process from currently measured process data and provide decision options to business users so that any unwanted opportunity loss such as downtimes or critical equipment failures that are operations risks would be eliminated. RETINA provides methods and apparatus to ensure that correct decisions are taken at the appropriate instant of time with right amount of data to the pertinent personnel to eliminate inefficiencies in operations and performance resulting in tangible profitability.

Owner:DT360 INC

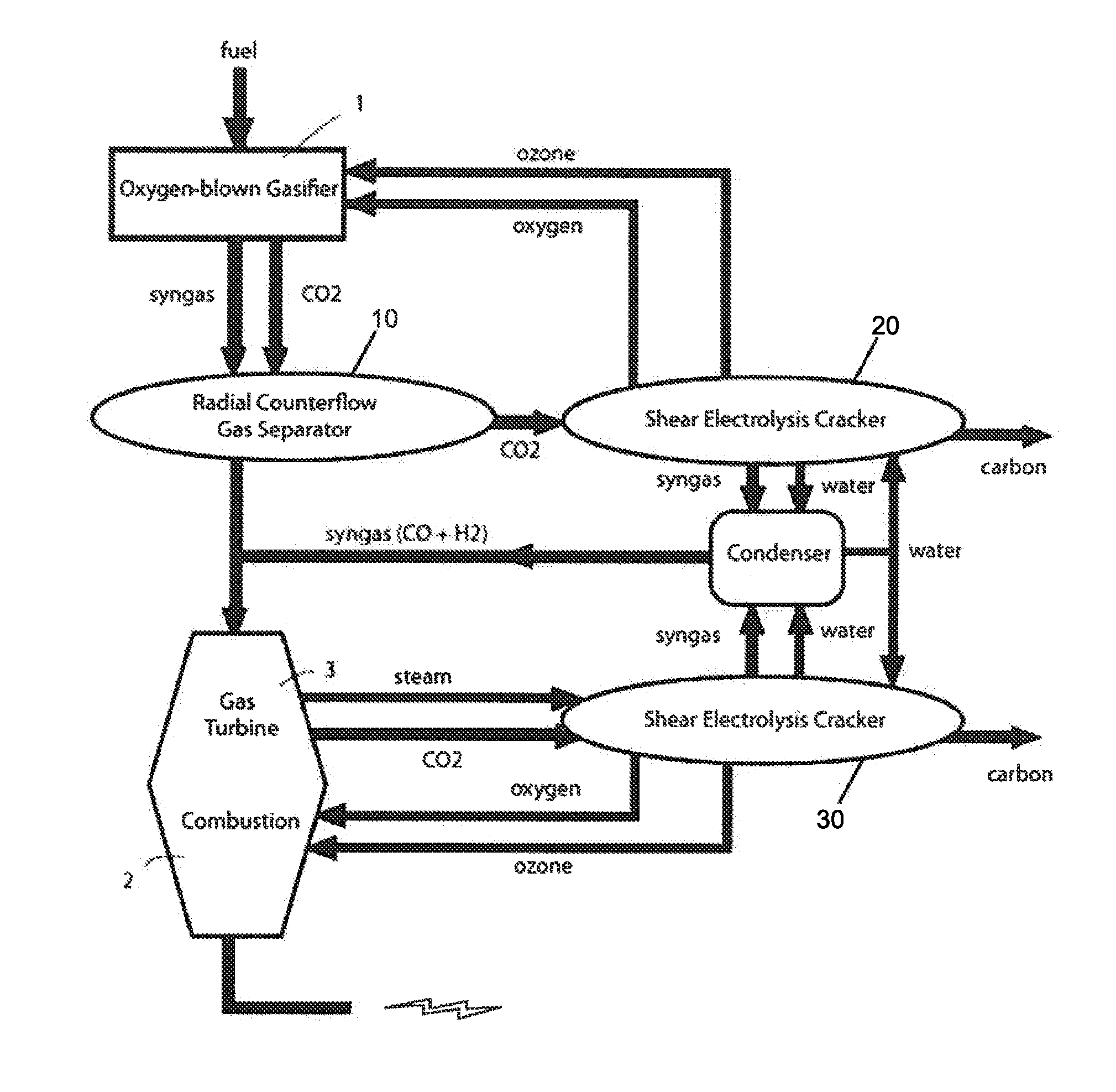

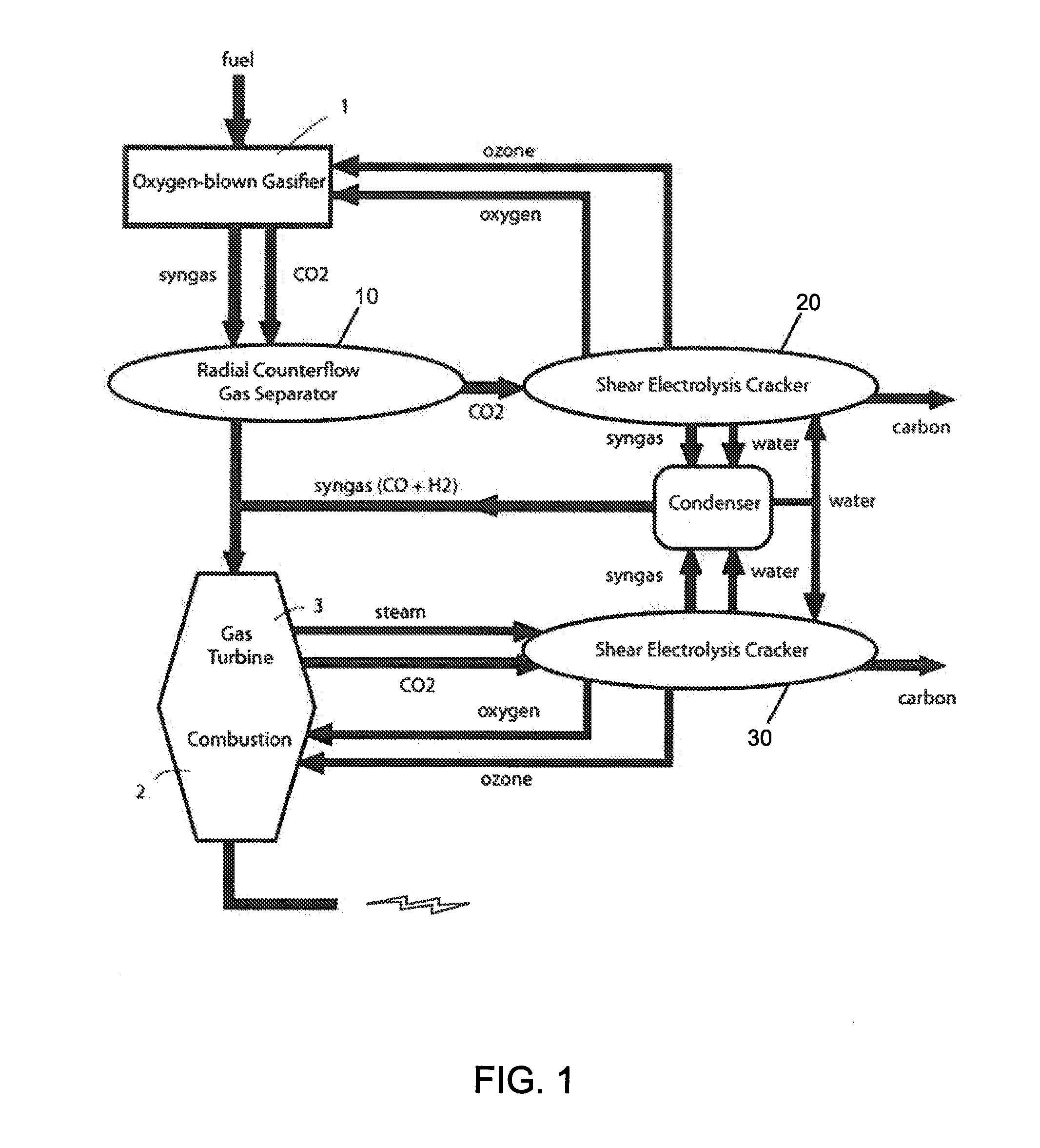

Hybrid power for cracking power plant co2

InactiveUS20100146927A1Engine fuctionsWind energy with garvitational potential energyElectric powerLoad following power plant

Power from wind, solar, and other intermittent energy sources cracks carbon dioxide, NOx, SOx, and other emissions from fossil fuel power plants, which provide baseload power to the grid. By this hybrid power system, intermittent sources can be integrated in power generation without compromising the reliability of the grid and without long power line connections. Carbon dioxide becomes, in effect, a storage medium for energy produced by intermittent sources. The CO2 can be pipelined to sites where wind, solar, tidal or and other intermittent energy sources are available, or power lines can be run from such intermittent sources to convenient sites for cracking.

Owner:MCCUTCHEN CO

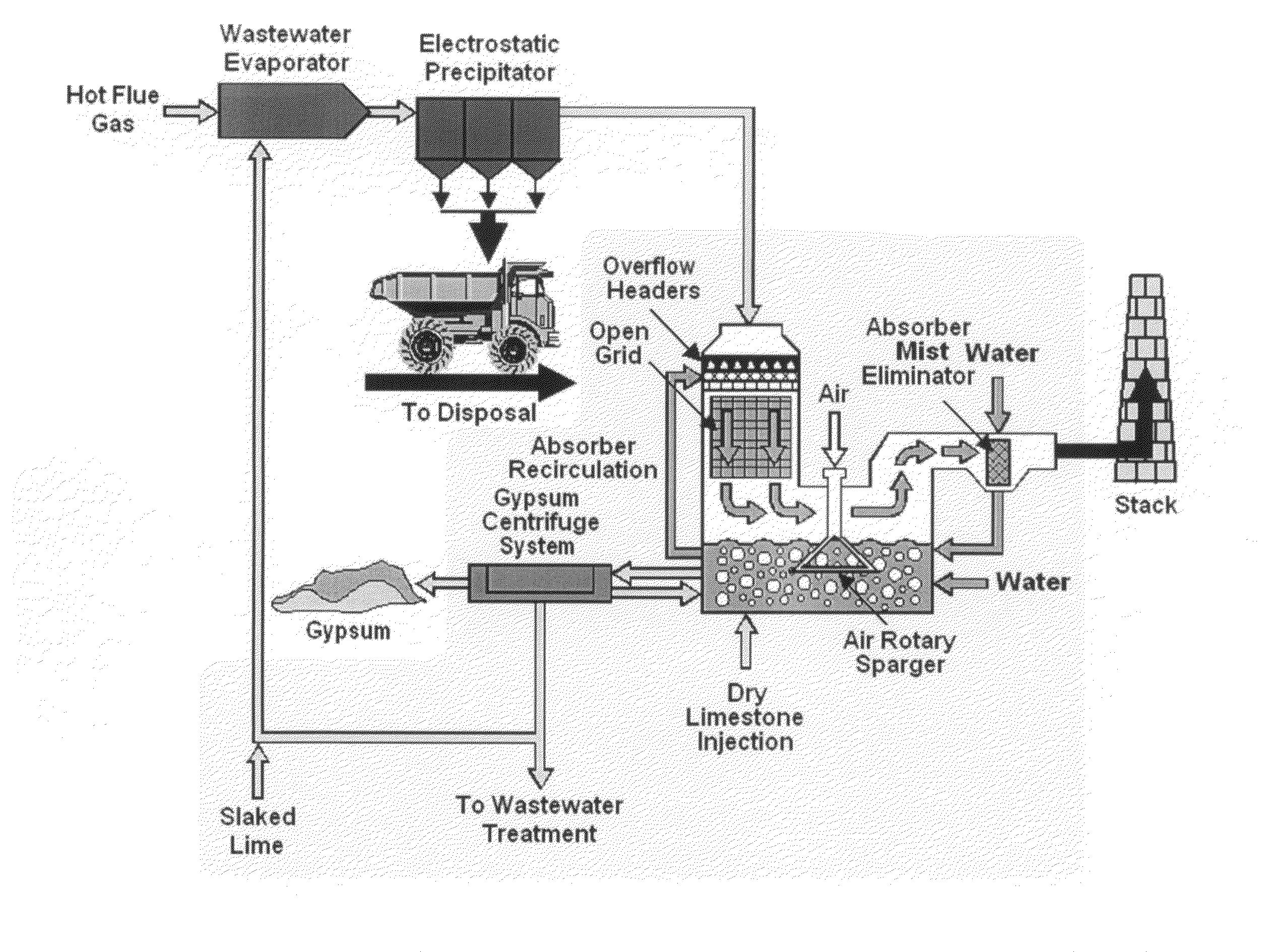

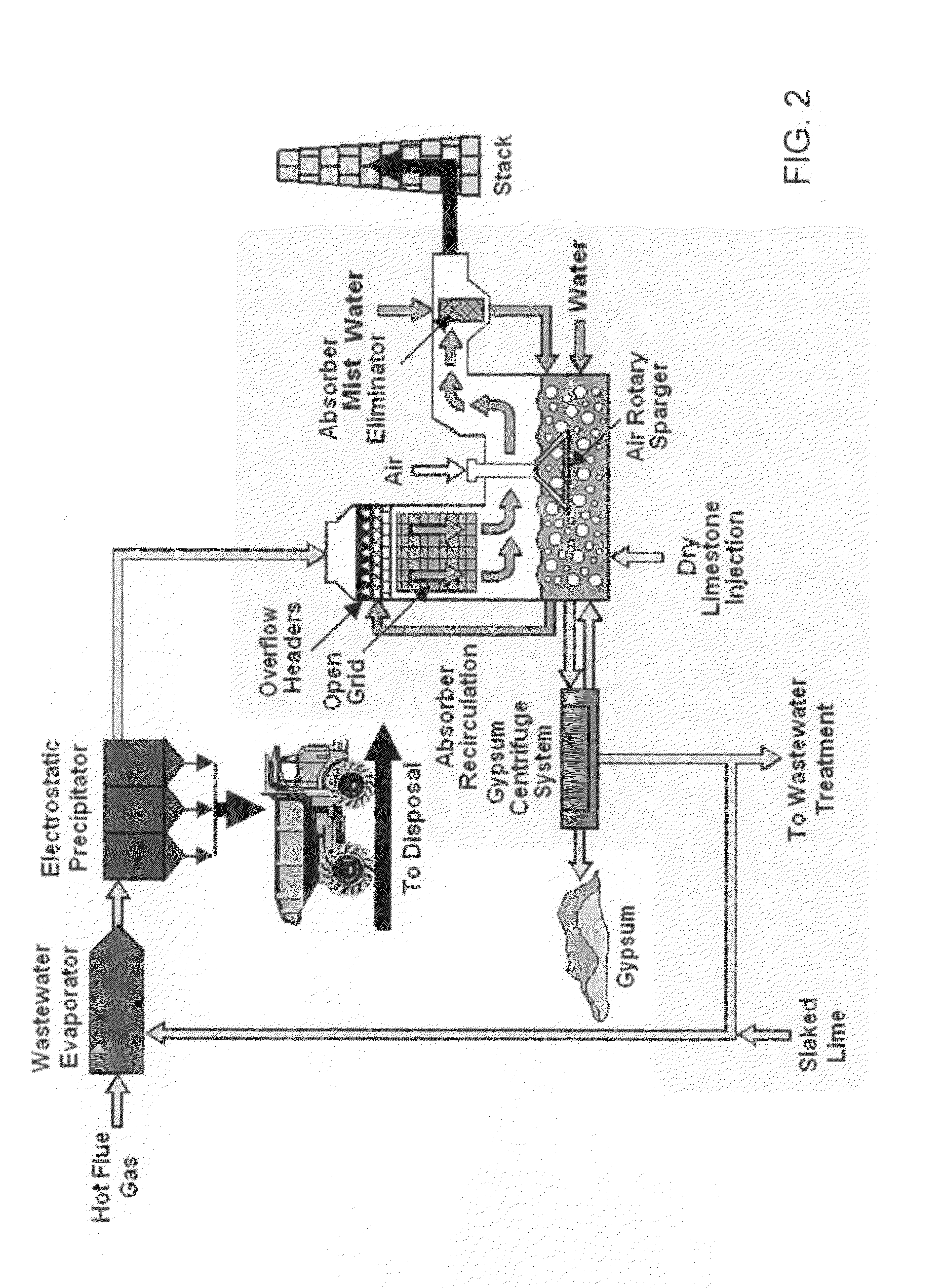

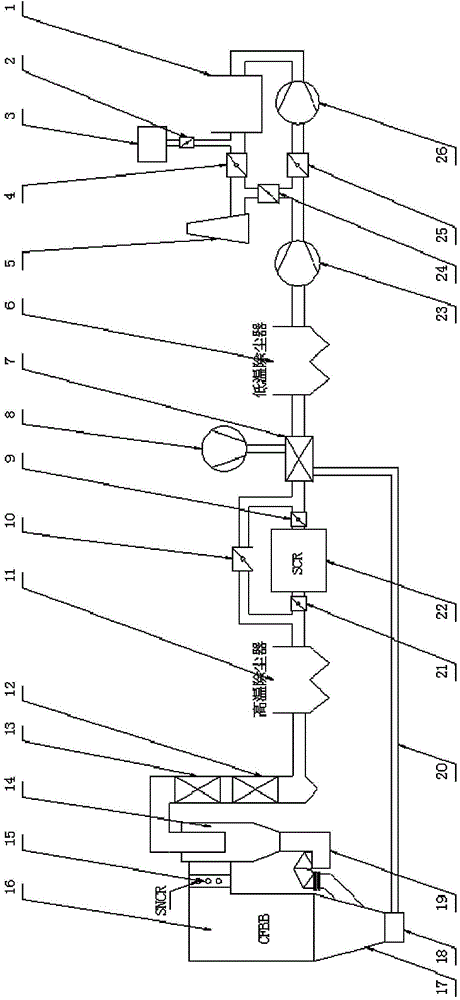

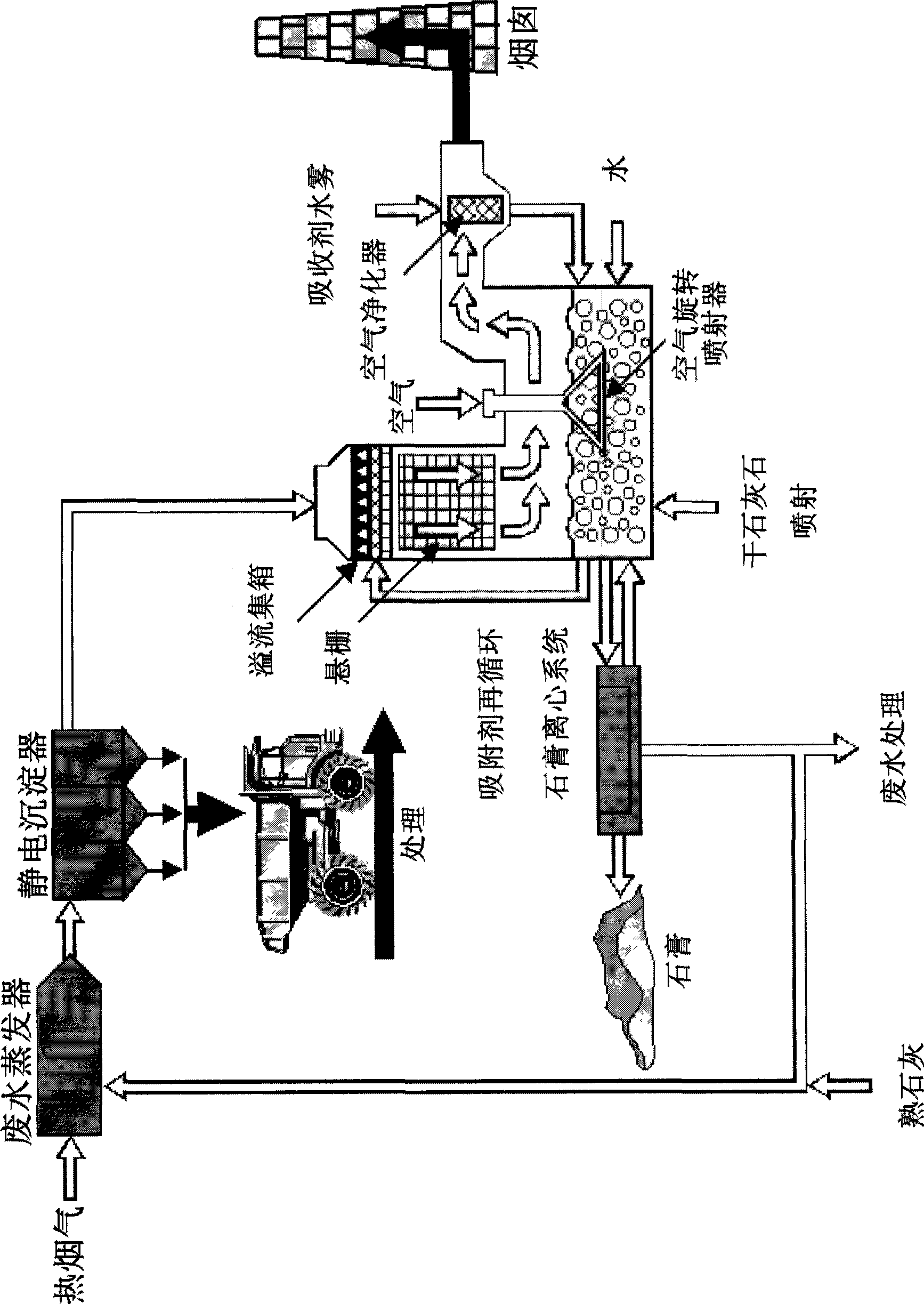

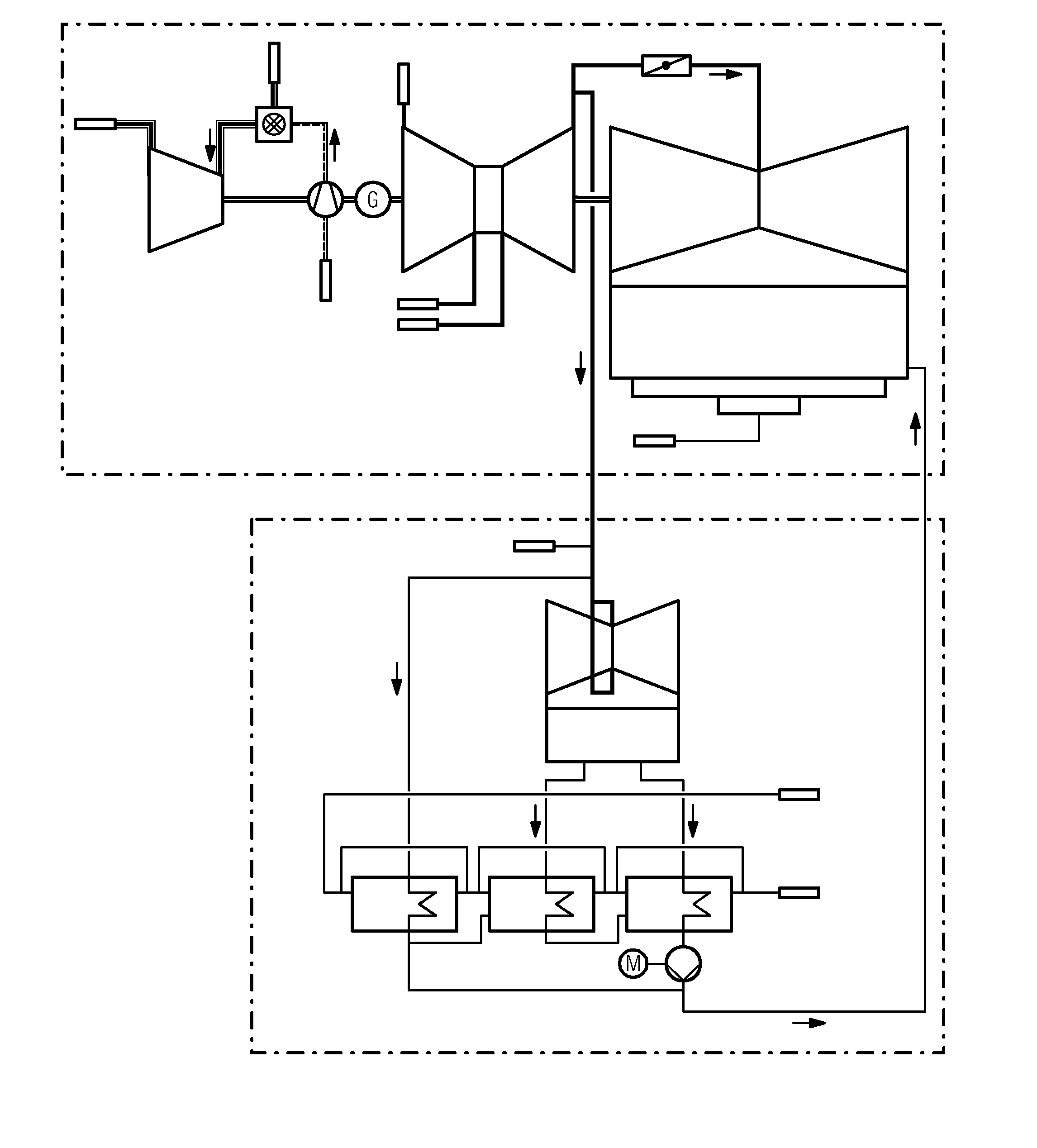

Ultra-clean discharge system and method for fluidized bed boiler

InactiveCN104437082AImprove working environmentExtend the life cycleNitrous oxide captureDispersed particle separationFluidized bedEmission standard

The invention relates to an ultra-clean discharge method for a fluidized bed boiler. The ultra-clean discharge method comprises the following steps of: carrying out in-furnace primary desulfurization in a dense-phase region of the fluidized bed boiler; carrying out primary denitration based on SNCR on the outlet of a furnace cavity; carrying out high-temperature dust removal on a smoke gas which is subjected to the in-furnace primary desulfurization and the primary denitration, and then carrying out secondary denitration based on SCR; carrying out heat exchange on the smoke gas subjected to the secondary denitration to normal smoke discharge temperature, and introducing the smoke gas into a low-temperature dust remover for secondary dust removal; delivering the smoke gas subjected to the secondary dust removal into a desulfurizing system for secondary desulfurization. The invention also provides a corresponding system. According to the method and the system provided by the invention, two-stage dust removal is performed by adopting high-low temperature dust removal devices, combined denitration is performed by combining SNCR and SCR manners, desulfurizing is realized by adopting in-furnace and out-of-furnace manners and accurate control is carried out through a combustion optimization technology and environmental-friendly system parameter, so that the discharge of NOx and SO2 reaches the discharge standard of a gas turbine unit in a key region of the 'fossil-fuel power plant atmospheric pollutant discharge standard' GB13223-2011; in addition, the corresponding system provided by the invention has the advantages of high denitration efficiency, high desulfurization effect, high system reliability, high working condition adaptability, good NOx and SO2 discharge controllability, long operation period, low operation cost and the like.

Owner:HUANENG CLEAN ENERGY RES INST

Method and device for separating of carbon dioxide from an exhaust gas of a fossil-fired power plant

ActiveUS20110277479A1Avoid Excessive CondensationFavorable plant efficiency of plantCombination devicesSolidificationDesorptionFossil fuel

A method and corresponding apparatus for separation of carbon dioxide from an exhaust gas of a fossil-fired power are provided. In an absorption process, the exhaust gas containing carbon dioxide is brought into contact with an absorption medium so that the absorption medium is laden with carbon dioxide. In a desorption process, vapor from a water / steam circuit of the fossil-fired power plant is heated, wherein a laden absorption medium is regenerated. In a subsequent expansion process, the regenerated absorption medium is expanded so that a vapor and an expanded absorption medium are formed, wherein the vapor is recirculated into the desorption process. The laden absorption medium is divided into a first part stream and a second part stream. Only the second part stream is brought into heat-exchanging contact with the expanded absorption medium. The first and second part streams are supplied to the desorption process at different process stages.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Method for growing photosynthetic organisms

Owner:SEAMBIOTIC LTD

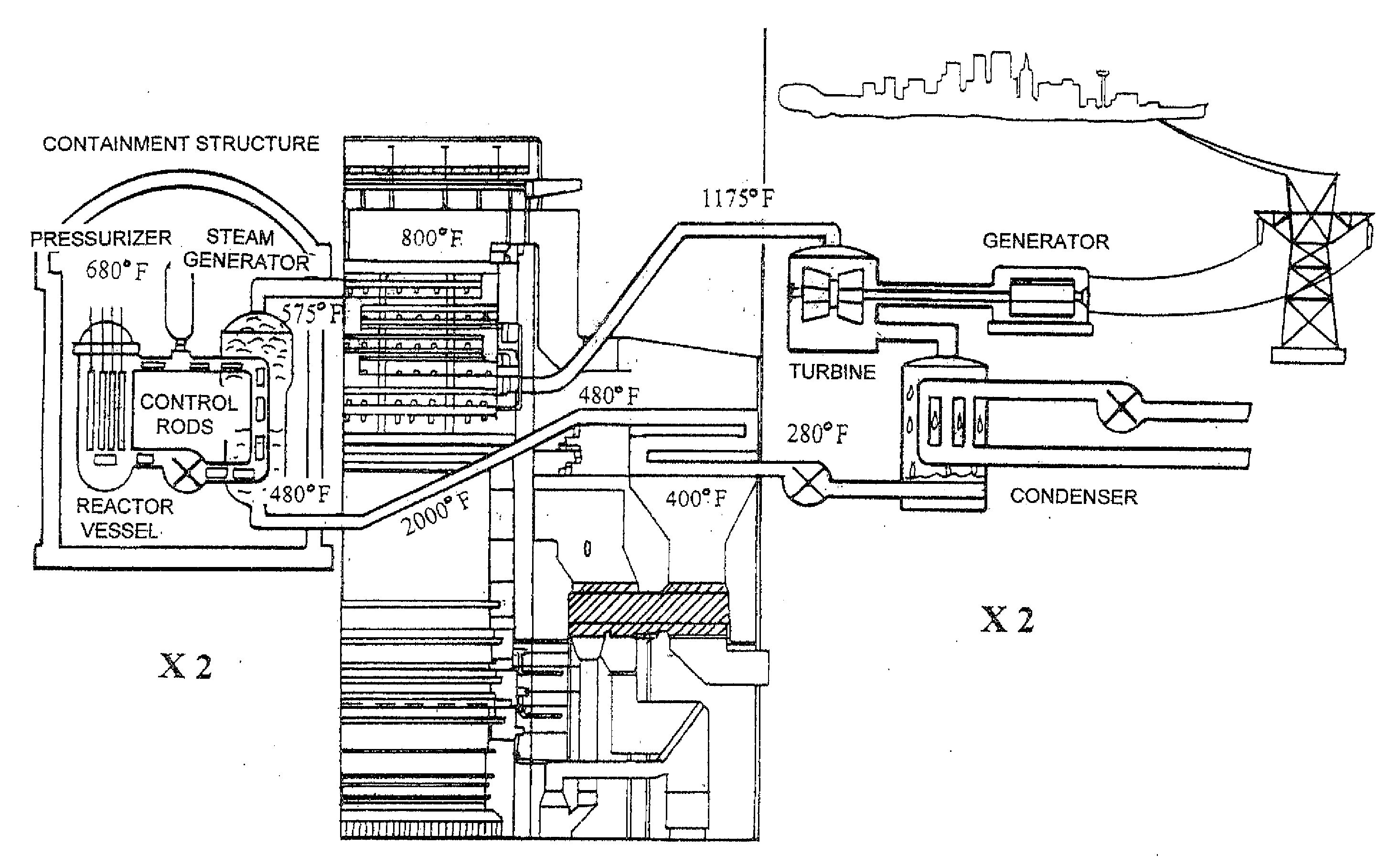

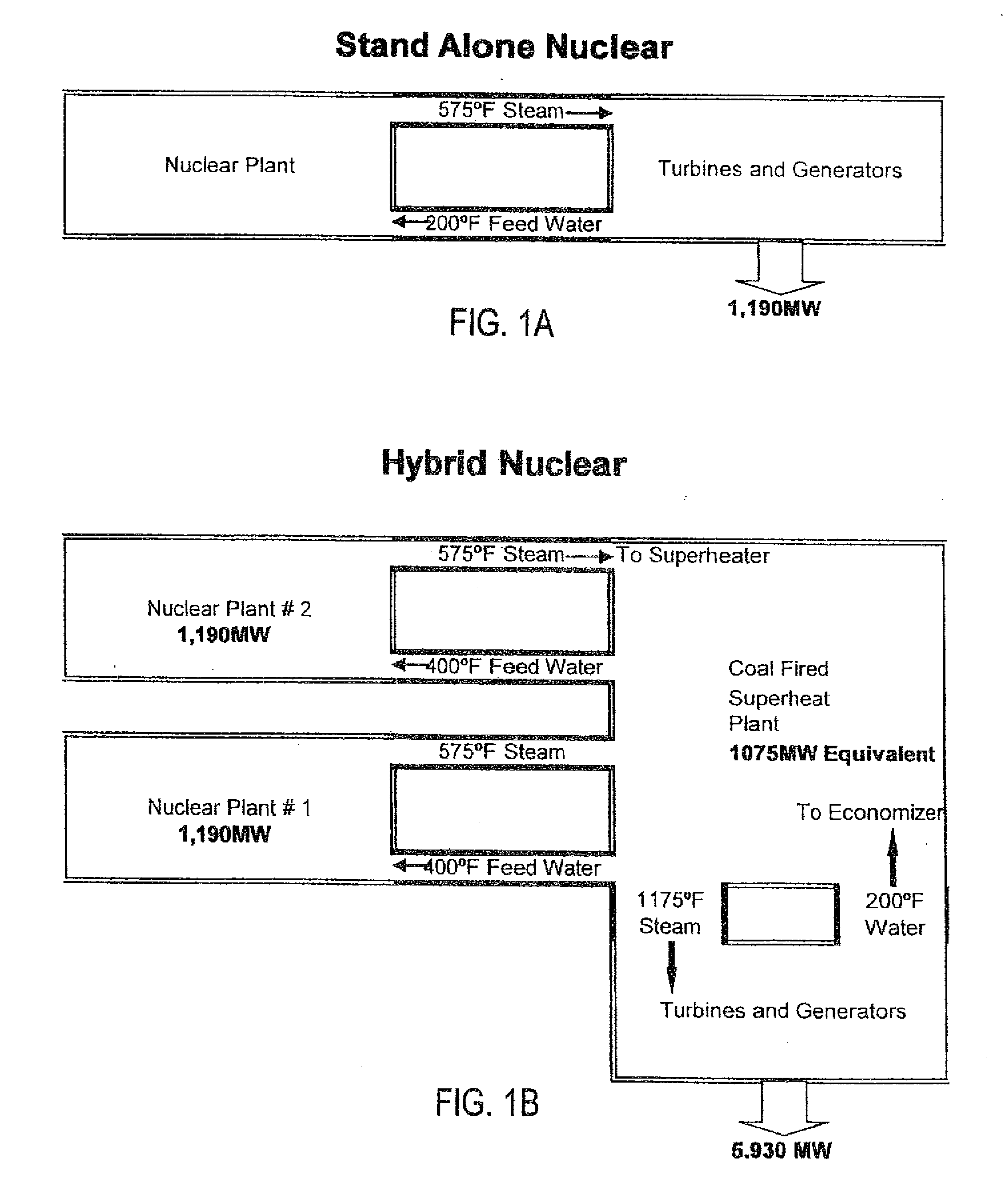

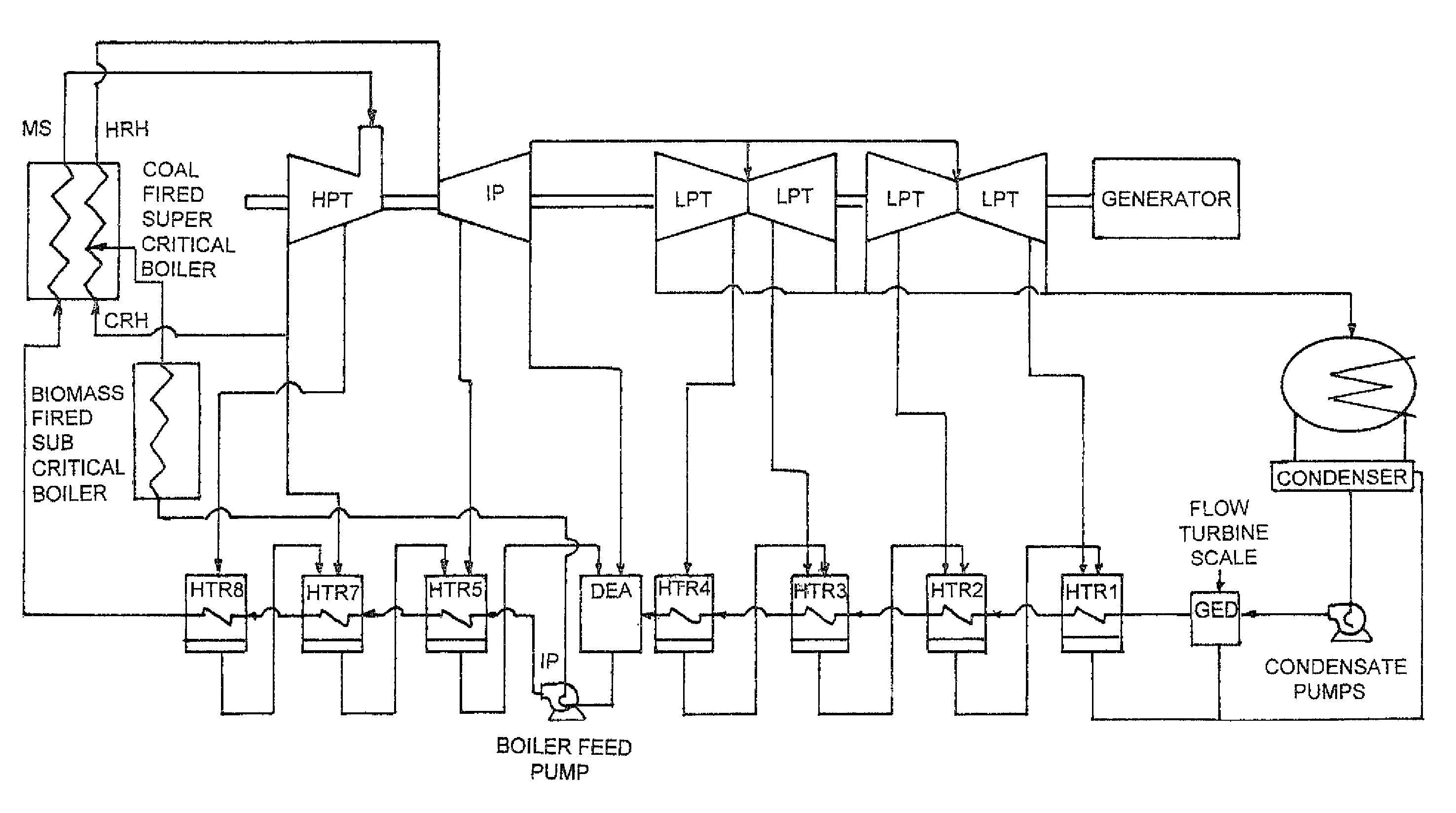

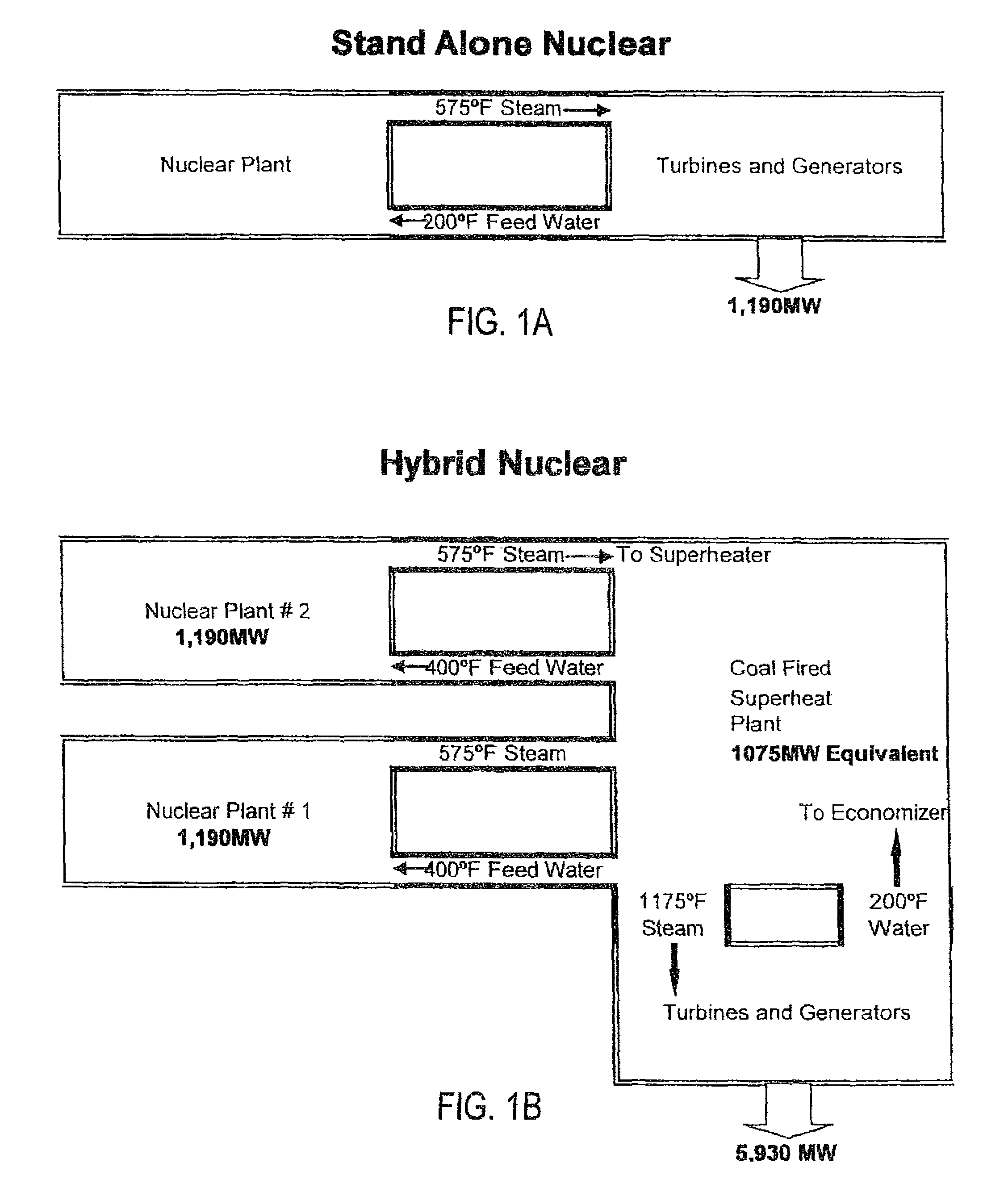

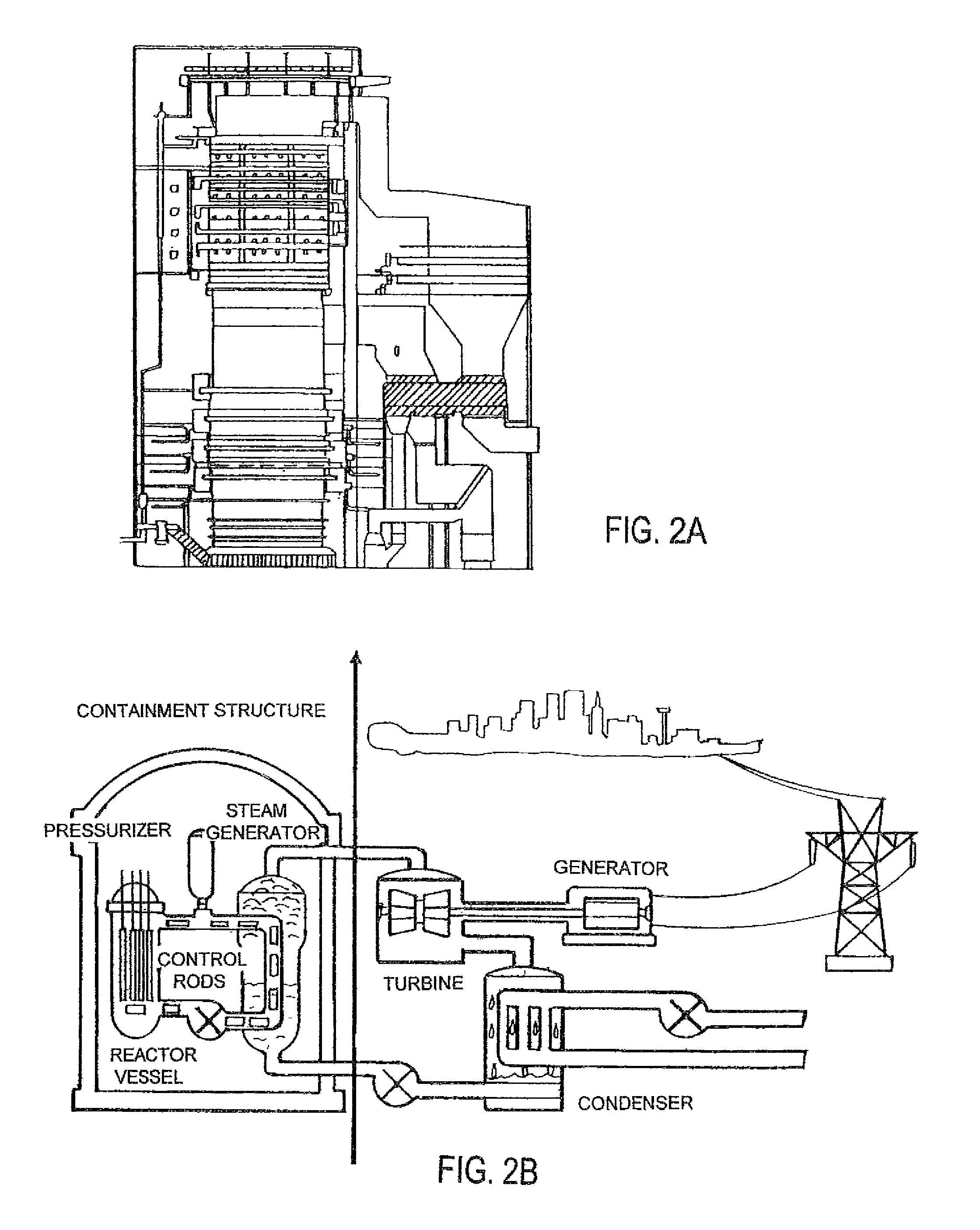

Hybrid Power Plant

A hybrid power plant is described in which a pressurized water nuclear reactor or a biomass-fueled power plant, which have a relatively low operating temperature, such as, is combined with a coal or other fossil fuel power plant having a higher operating temperature. Steam from the first plant is superheated in the second power plant to provide a hybrid plant with improved efficiencies and lower emissions.

Owner:HYBRID POWER

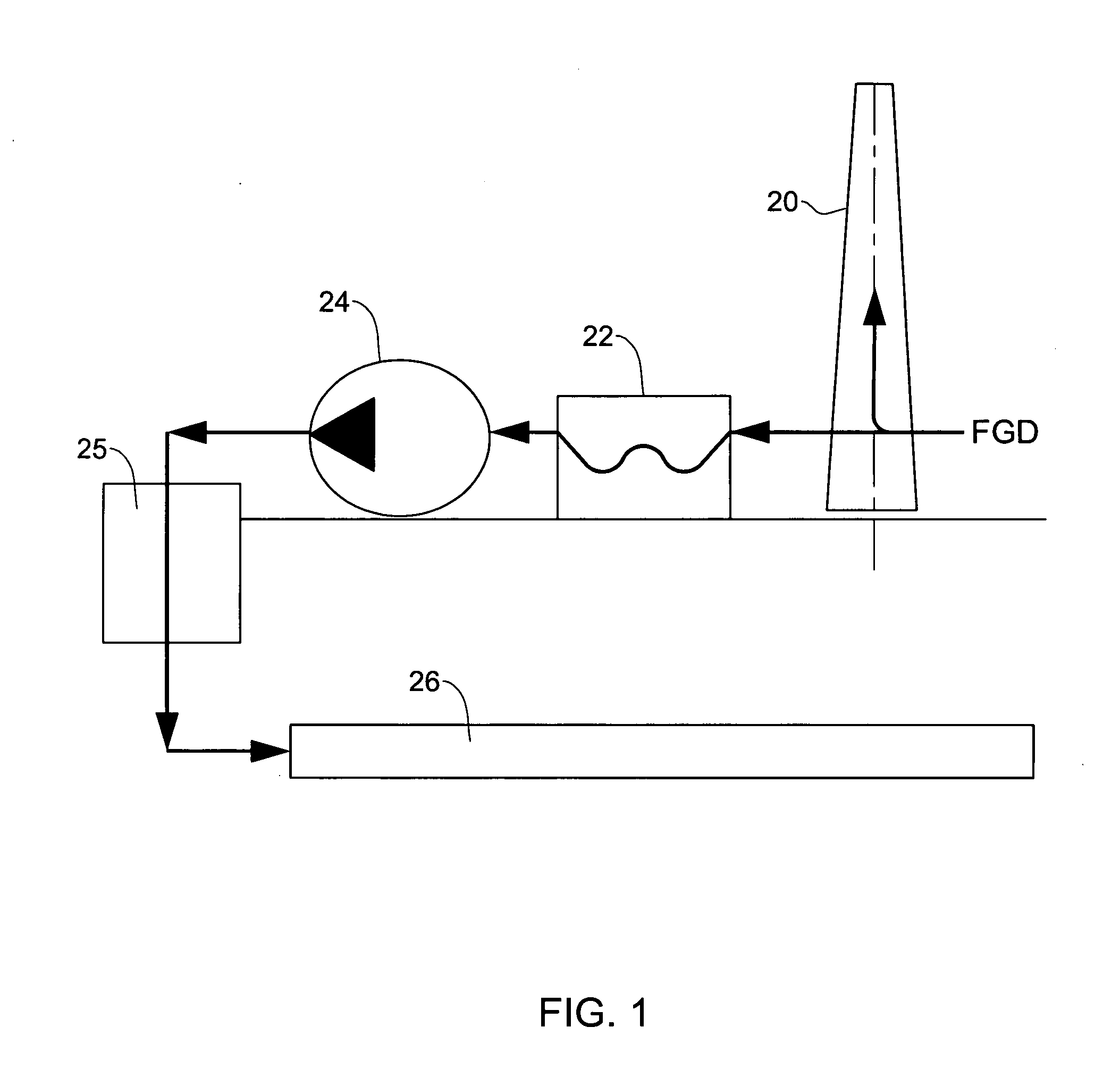

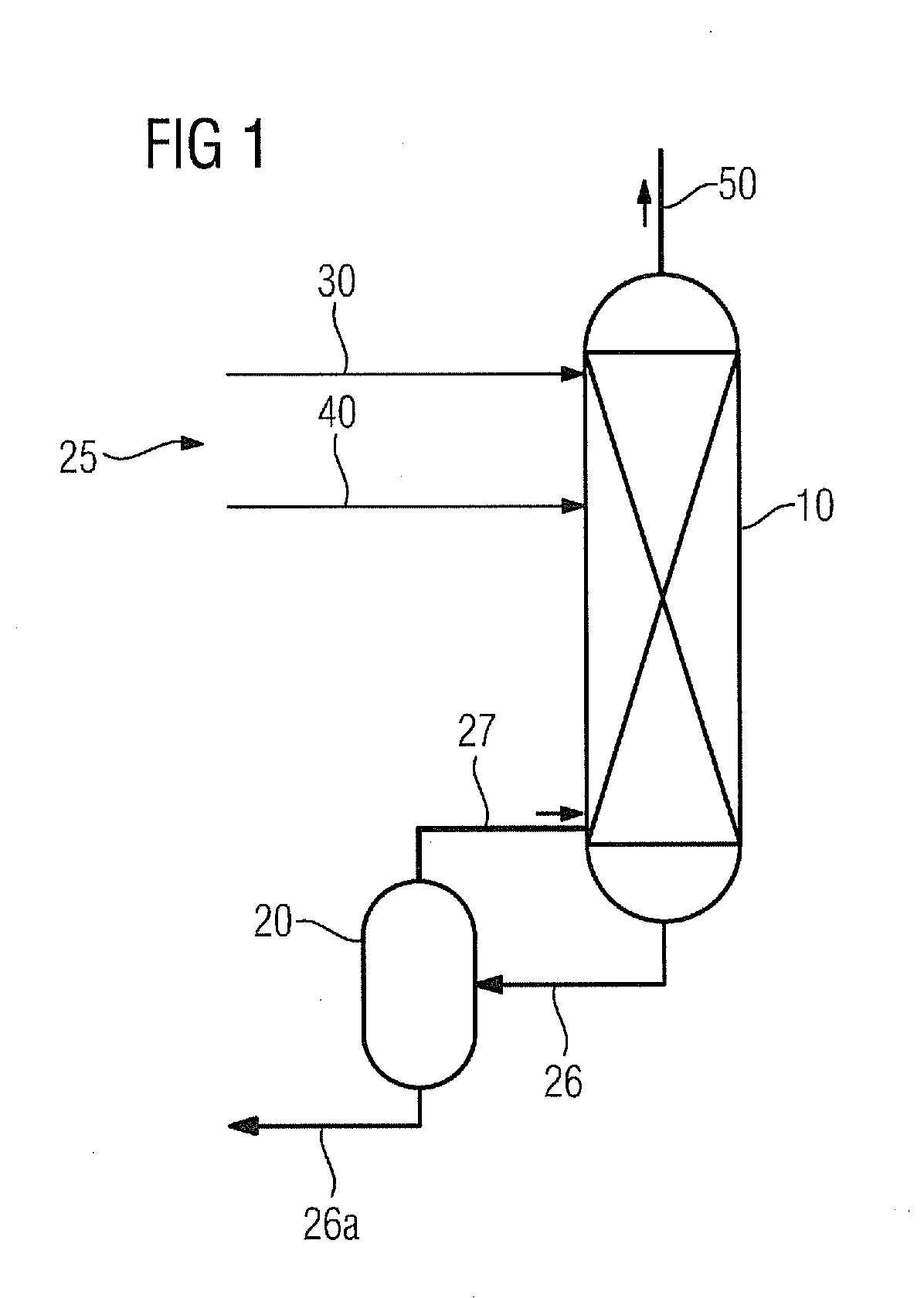

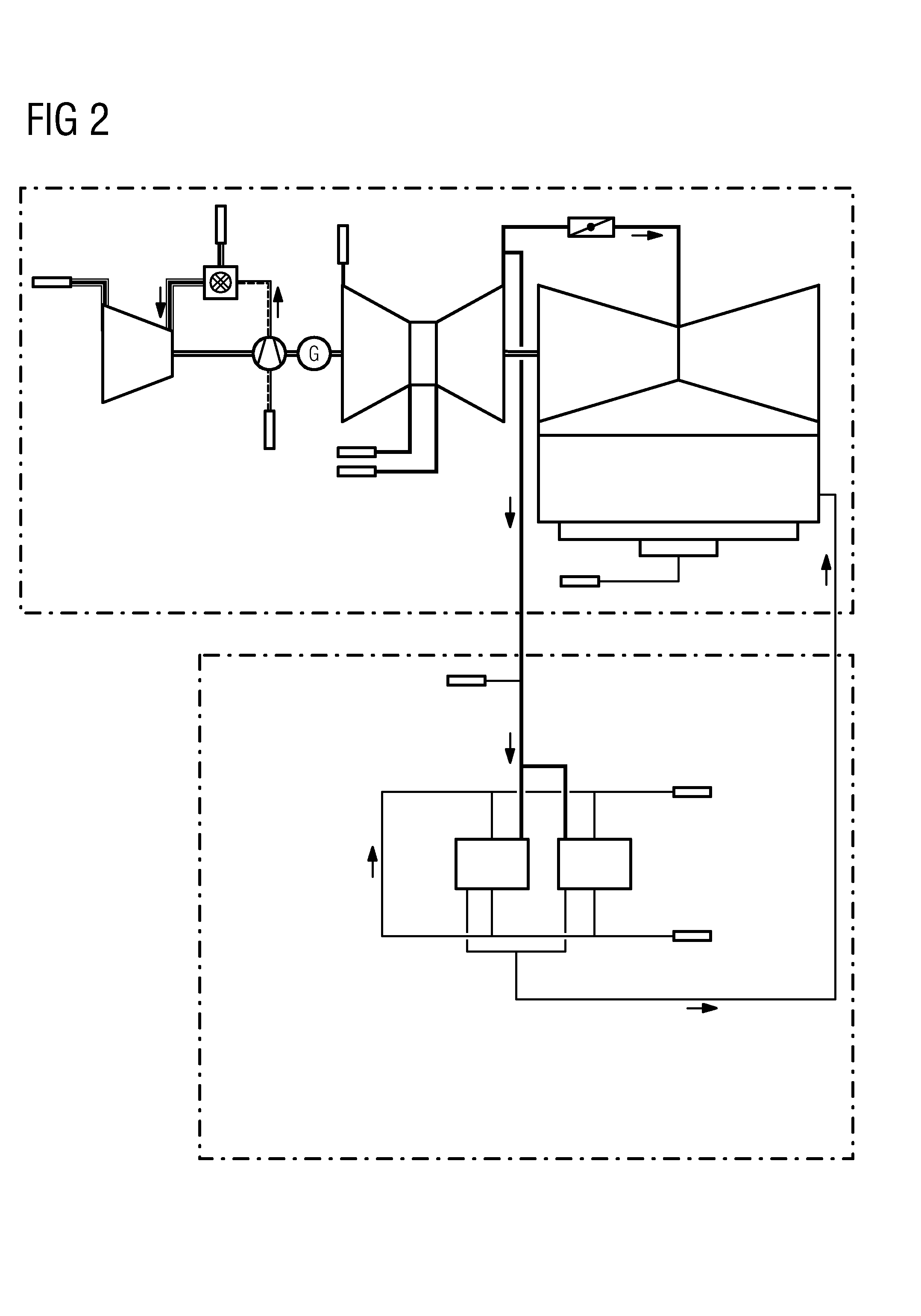

Power plant with co2 capture and method to operate such power plant

ActiveUS20130133326A1Improve efficiencyImprove reliabilitySteam useDirect carbon-dioxide mitigationNuclear engineeringElectric power

A fossil fuel fired power plant for the generation of electrical energy comprises a water steam cycle and a plant (10) for the capture of CO2 from exhaust gases emitted by the power plant and a steam jet ejector (24) configured and arranged to receive an input steam flow from a low- or intermediate pressure extraction point in the power plant and to increase its pressure. It is further arranged to receive motive steam (25) from a further extraction point in the power plant. A steam line (27, 22) directs the steam of increased pressure from the steam jet ejector (24) to the CO2 capture plant (10). The power plant according to this invention allows the use of low-pressure steam for the operation of the CO2 capture plant, where the extraction of such steam affects the overall efficiency of the power plant to a lesser degree than in power plant of the state of the art.

Owner:GENERAL ELECTRIC TECH GMBH

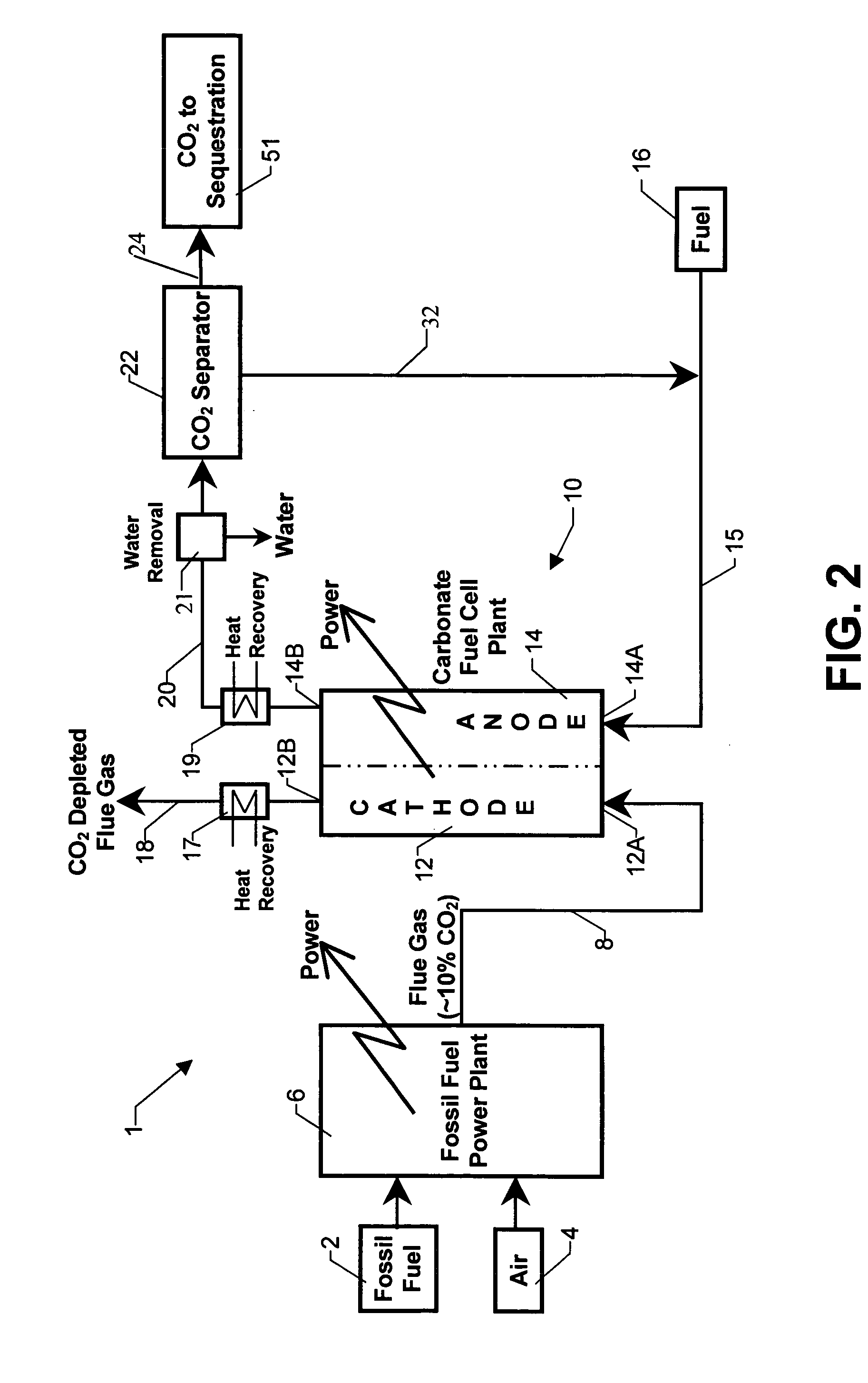

Power producing gas separation system and method

ActiveUS20160248110A1Efficient gas separationFuel cell combinationsFuel cell heat exchangeEngineeringOxygen

A power producing system adapted to be integrated with a flue gas generating assembly, the flue gas generating assembly including one or more of a fossil fueled installation, a fossil fueled facility, a fossil fueled device, a fossil fueled power plant, a boiler, a combustor, a furnace and a kiln in a cement factory, and the power producing system utilizing flue gas containing carbon dioxide and oxygen output by the flue gas generating assembly and comprising: a fuel cell comprising an anode section and a cathode section, wherein inlet oxidant gas to the cathode section of the fuel cell contains the flue gas output from the flue gas generating assembly; and a gas separation assembly receiving anode exhaust output from the anode section of the fuel cell and including a chiller assembly for cooling the anode exhaust to a predetermined temperature so as to liquefy carbon dioxide in the anode exhaust, wherein waste heat produced by the fuel cell is utilized to drive the chiller assembly.

Owner:FUELCELL ENERGY INC

Combustion emission estimation with flame sensing system

There is described a method and apparatus for controlling the combustion by-product formation rate in at least one burner of a fossil fuel fired power plant. The burner has an associated flame scanner which is focused on a small area of the burner flame to obtain an image signal of the flame. A flame signal that represents properties of temporal combustion in the visible light spectrum of the burner is generated from the image signal. Combustion turbulence at the burner is analyzed from the flame signal by a dynamic invariant that has a relationship to the combustion by-product values and different combustion by-product levels at the burner and the combustion turbulence is correlated to the combustion by-product formation rate at the burner. The method and apparatus can also be used to correlated the combustion turbulence at a multiplicity of burners to the associated combustion by-product formation rate.

Owner:ABB INC

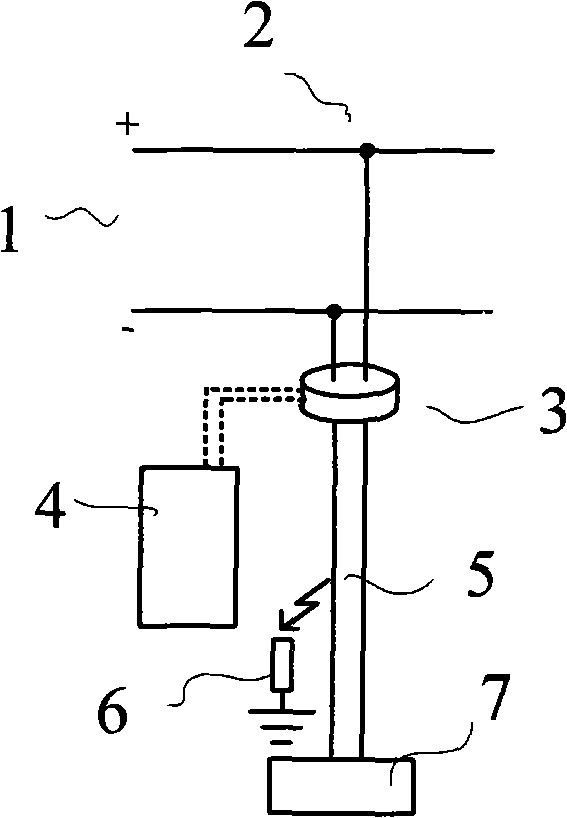

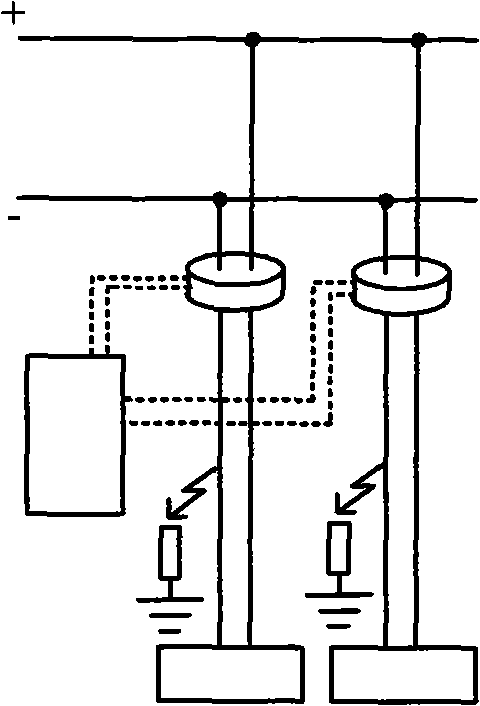

Ground fault detection and calibration method and device for direct current system

Owner:国网吉林省电力有限公司超高压公司

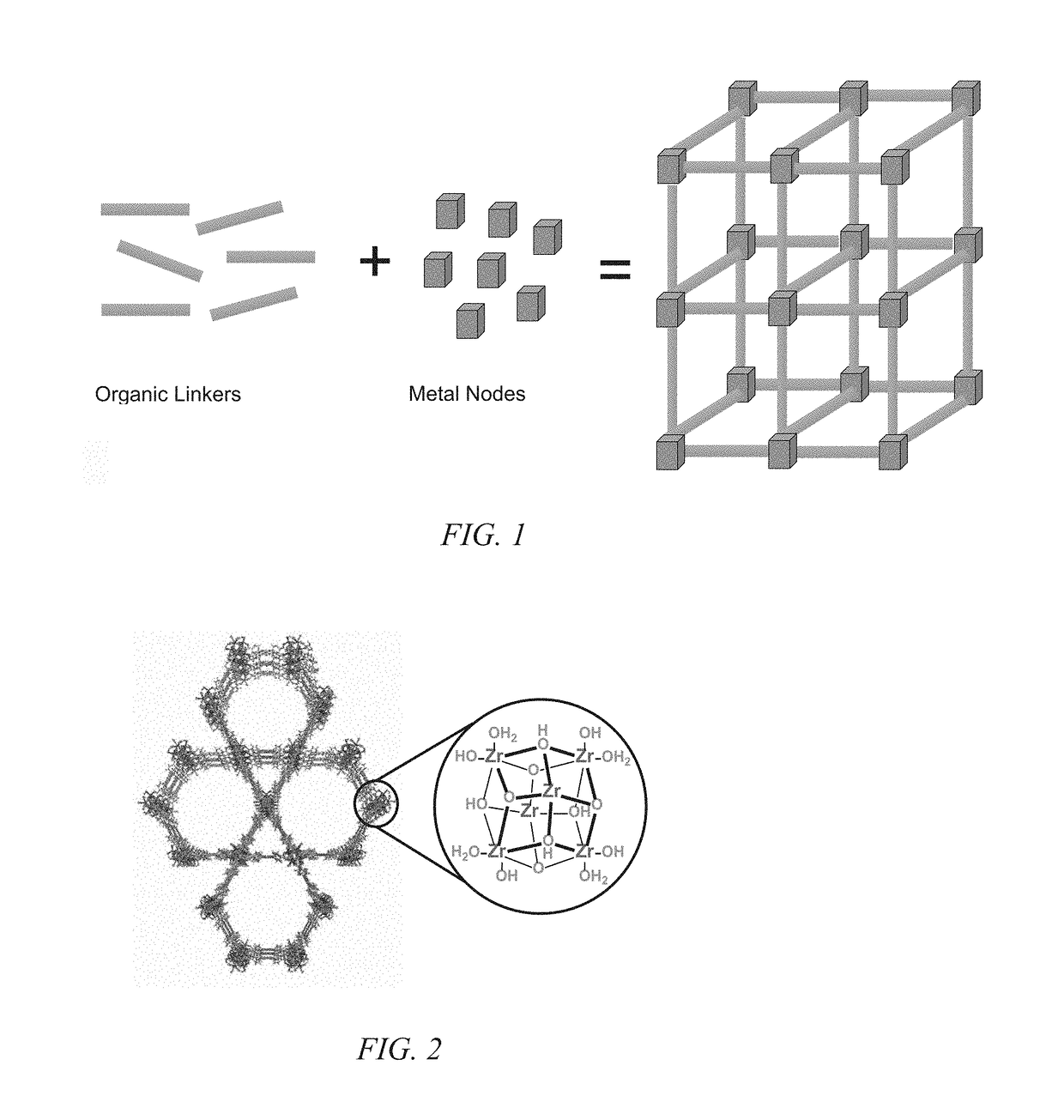

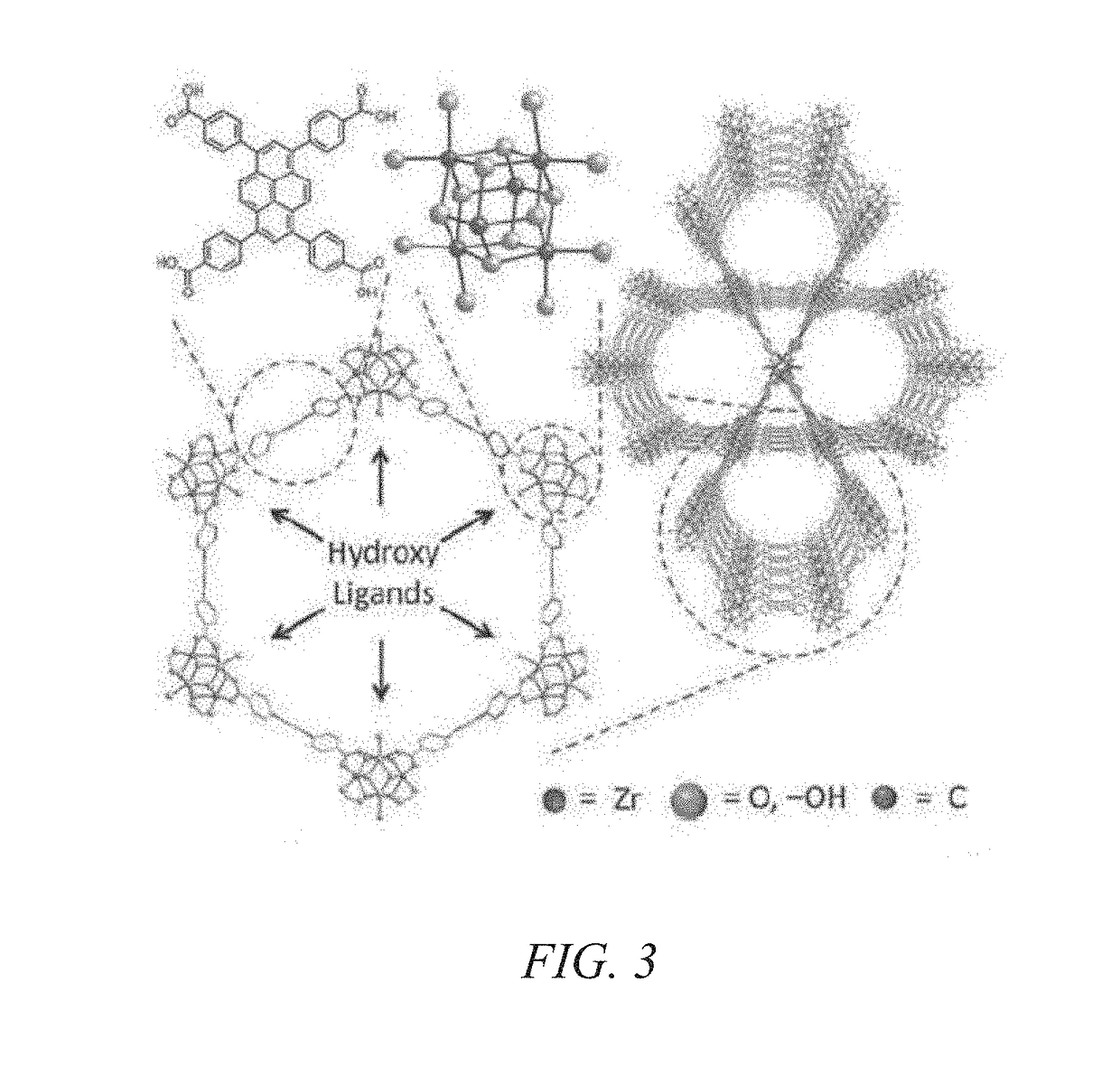

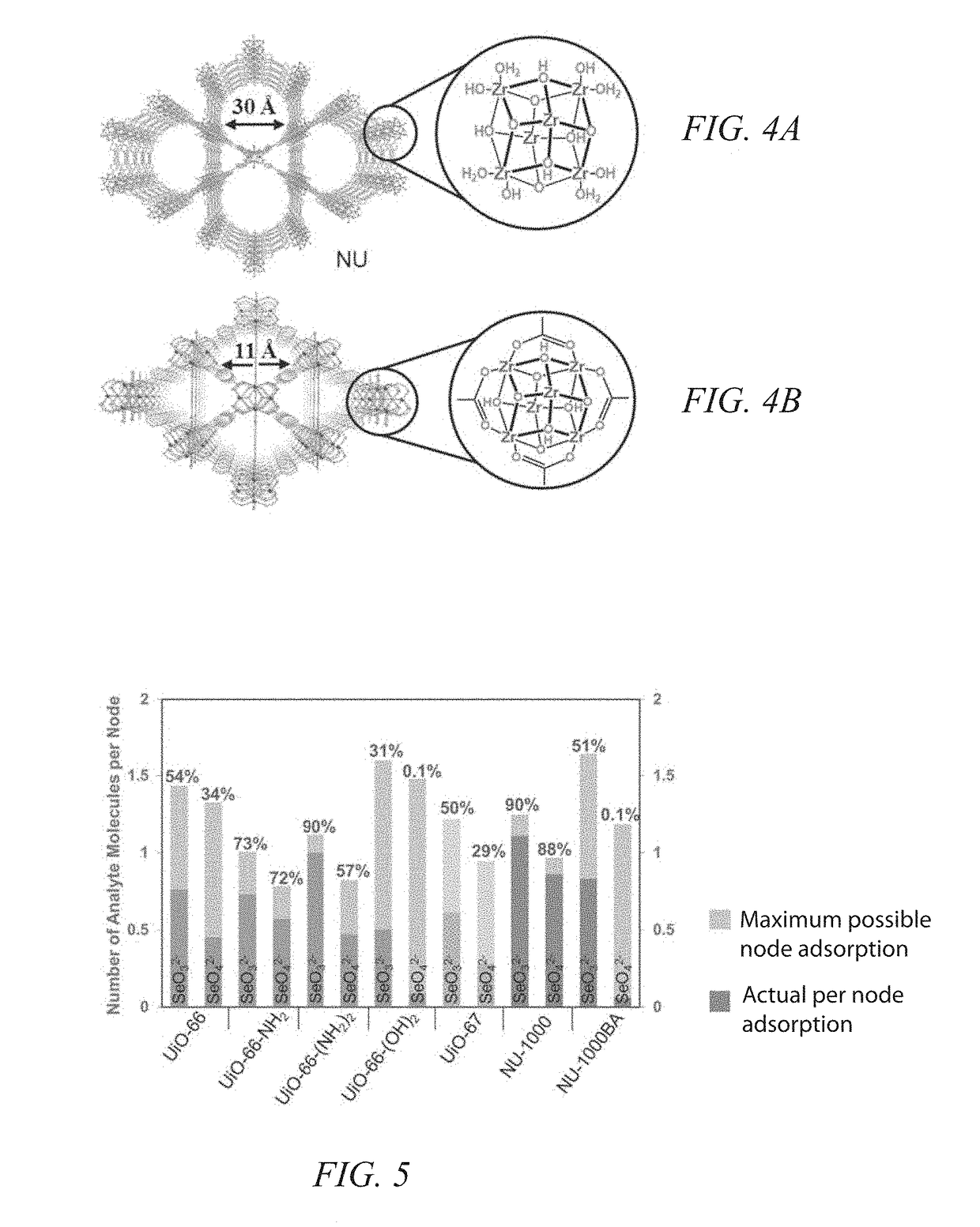

Metal-Organic Frameworks for Adsorption of Liquid Phase Compounds

ActiveUS20180134581A1Reduce concentrationReducing oxy-anion concentrationWater/sewage treatment by ion-exchangeWaste water treatment from gaseous effluentsChemical speciesMetal-organic framework

The present invention provides for the use of a metal-organic framework (MOF) in removing particular chemical species or compounds, in particular oxy-anions, from a liquid or liquid stream. In some embodiments, the MOF is a Zr-based MOF, such as NU-1000, and the oxy-anions that are removed include, include, for example, oxy-anions of selenium, including selenite (SeO32−) and selenate (SeO42−); oxy-anions of antimony, including oxy-anions in either the Sb[III] (antimonite) or the Sb[V] (antimonate) redox state; and oxy-anions of lead, including oxy-anions in either the Pb[II] or the Pb[IV] redox state, such as Pb(OH)62−, Pb(OH)64−, PbO32−, and PbO22−. The Zr-based MOF, including NU-1000 can be used to remove these oxy-anions from various liquid streams in industrial processes such as a nuclear and fossil fuel power plants, including the latter's flue gas desulfurization system.

Owner:NORTHWESTERN UNIV

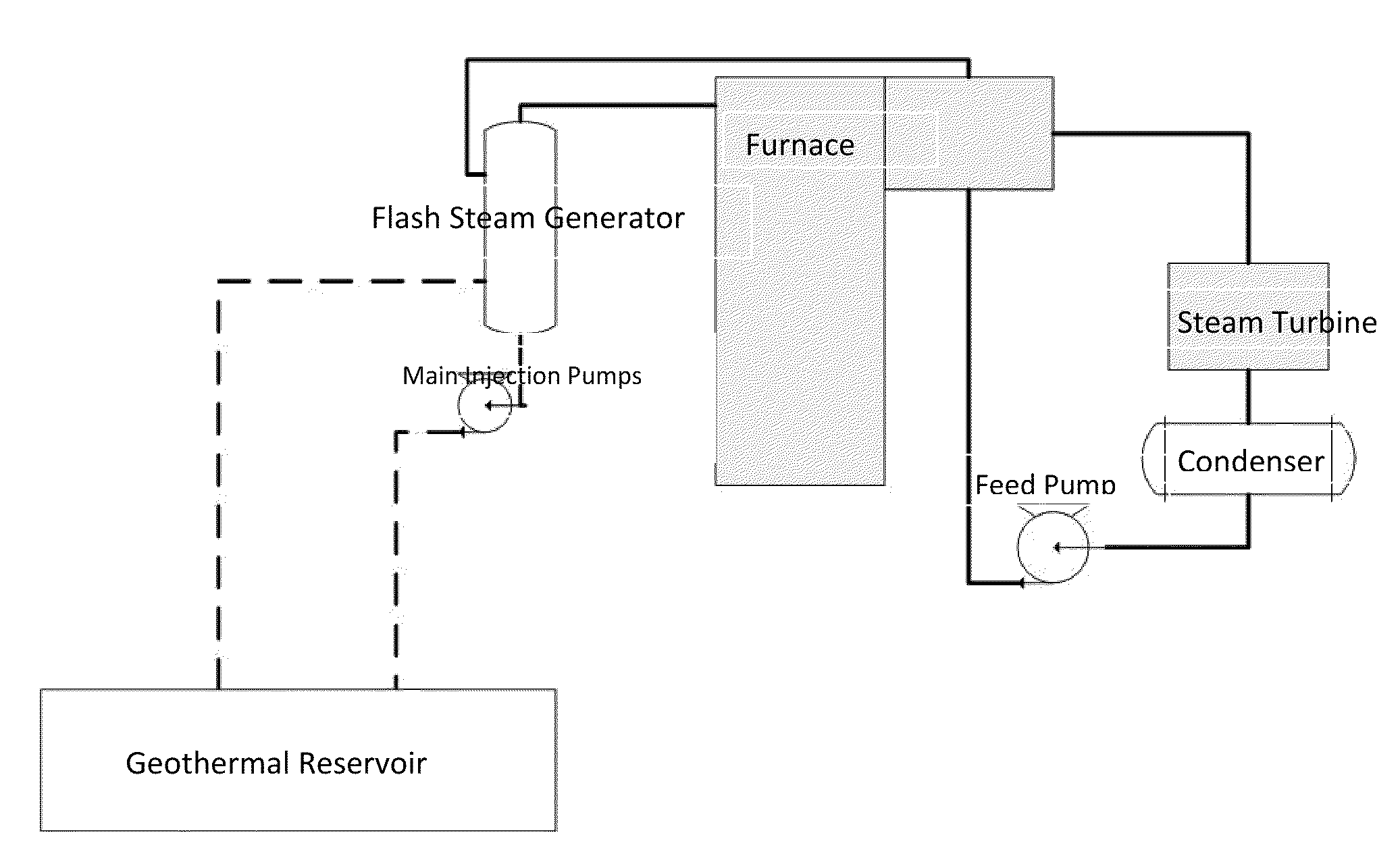

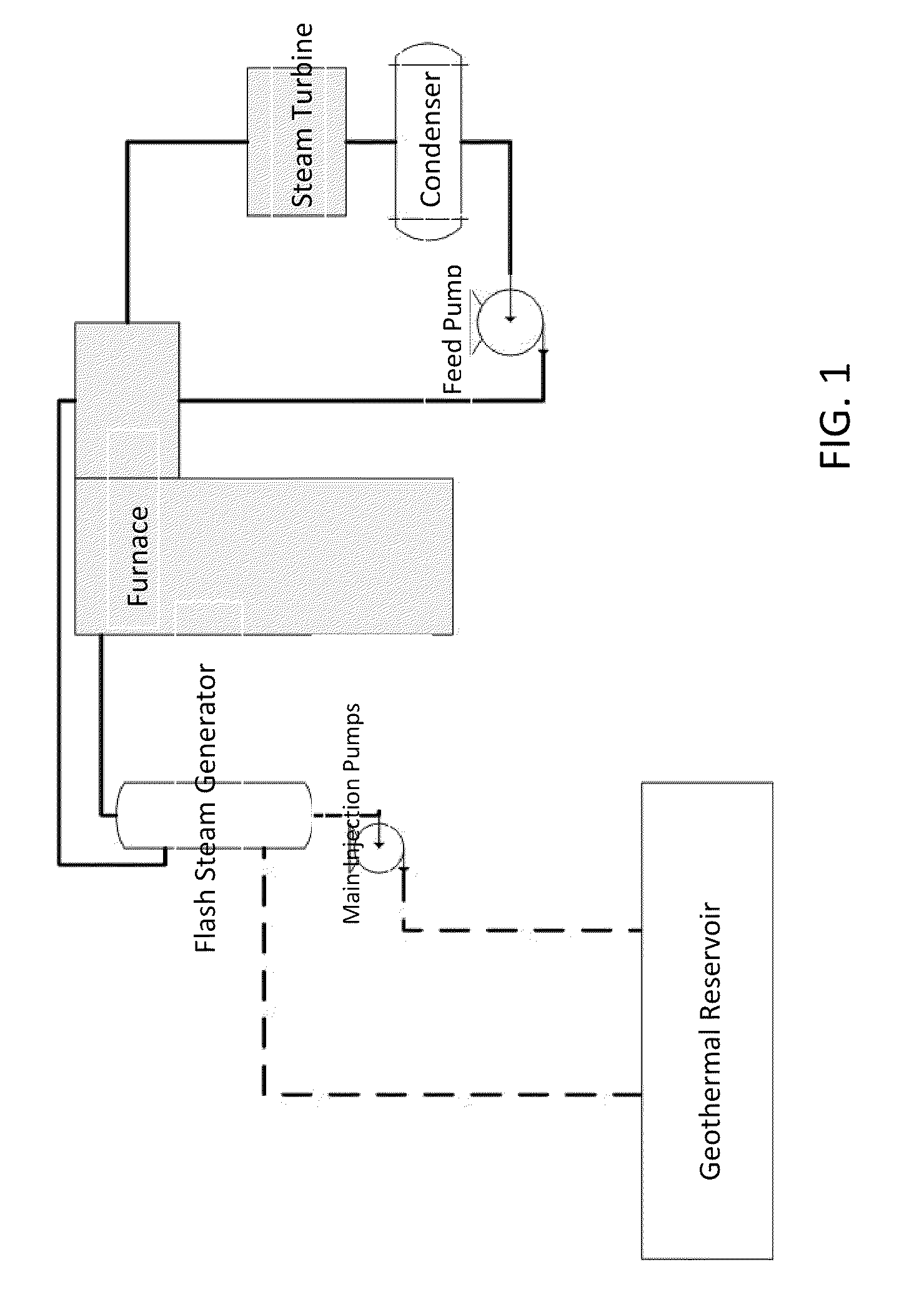

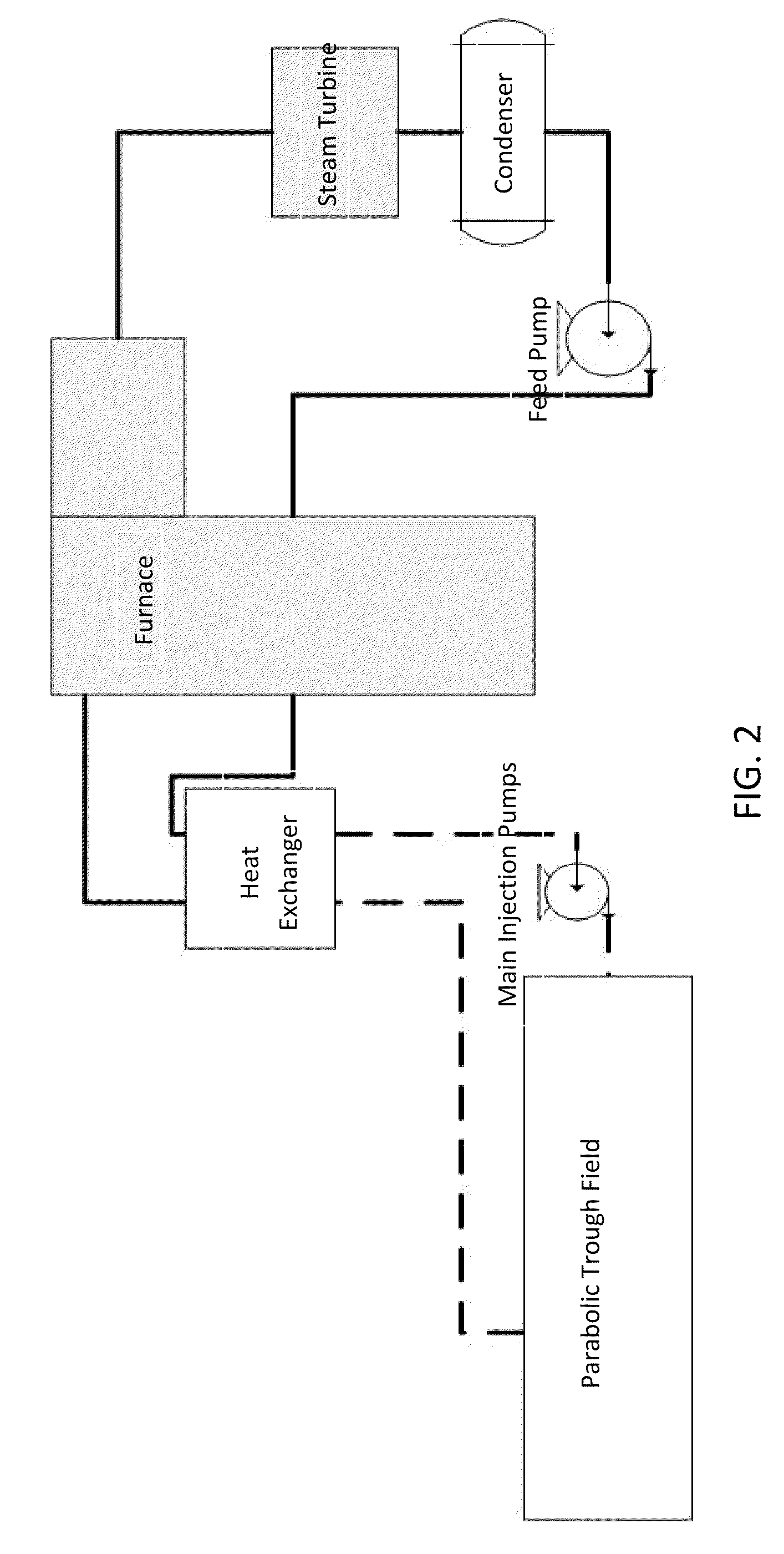

Hybrid Power Facilities

A hybrid power plant is disclosed wherein a first power plant produces secondary steam of a first, relatively low temperature using a renewable source of energy such as geothermal or solar. The steam from the renewable source plant is passed through a fossil fuel power plant that has an operating temperature higher than that of the first temperature which results in superheating the first temperature steam to the higher temperature in the fossil fuel power plant. Higher efficiencies and reductions in emissions are obtained.

Owner:HYBRID POWER

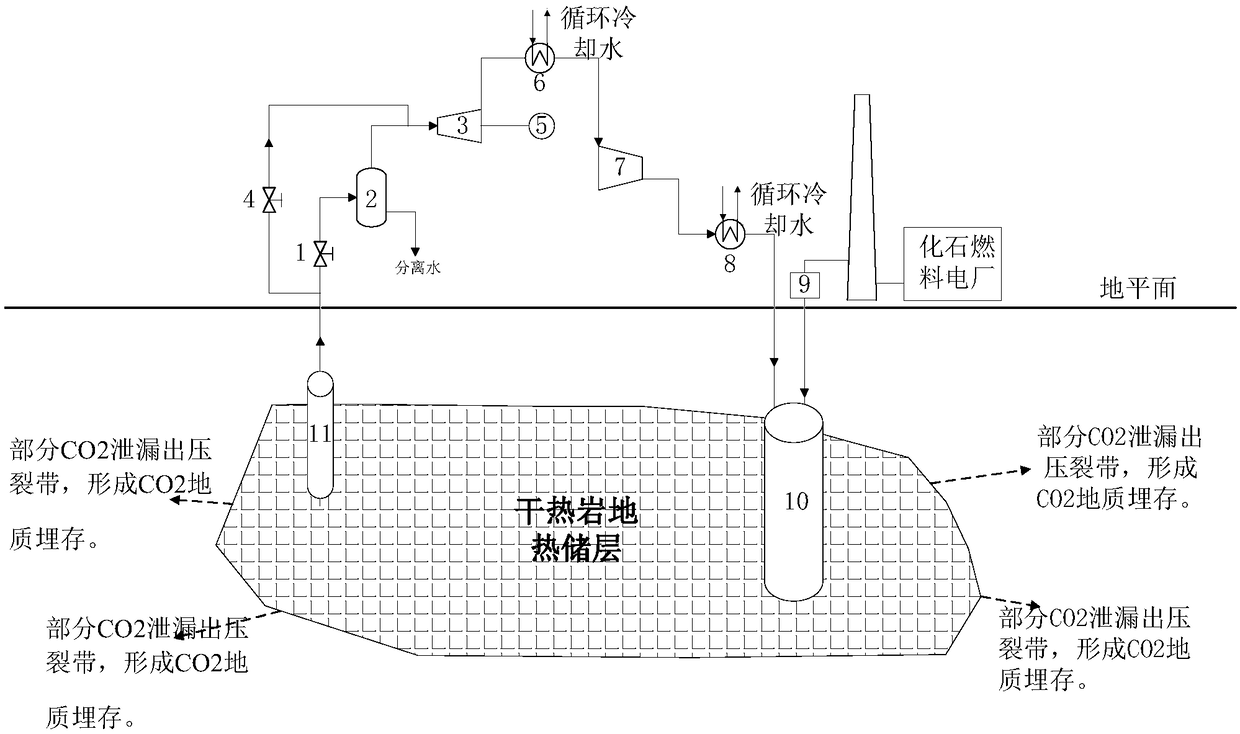

Supercritical carbon dioxide geothermal power generation system and method

PendingCN109185083AAchieve storageAchieving zero emissionsGeothermal energy generationGeothermal systemsEngineeringInjection well

The invention discloses a supercritical carbon dioxide geothermal power generation system and method. The system comprises a flashing loop valve, a flashing tank, a supercritical carbon dioxide loop valve, a turbine, an electric generator, a precooler, a compressor, an after-cooler, a fossil fuel power plant exhaust gas carbon dioxide collecting and treating device, an injection well, an output well and the like. The system can realize the purpose of developing geothermal resources and also can realize geological sequestration of carbon dioxide in exhaust gas of a fossil fuel power plant, so that the situation that the thermal power plant and geothermal exploitation are combined to generate electricity so as to realize zero emission of carbon dioxide becomes possible.

Owner:XIAN THERMAL POWER RES INST CO LTD

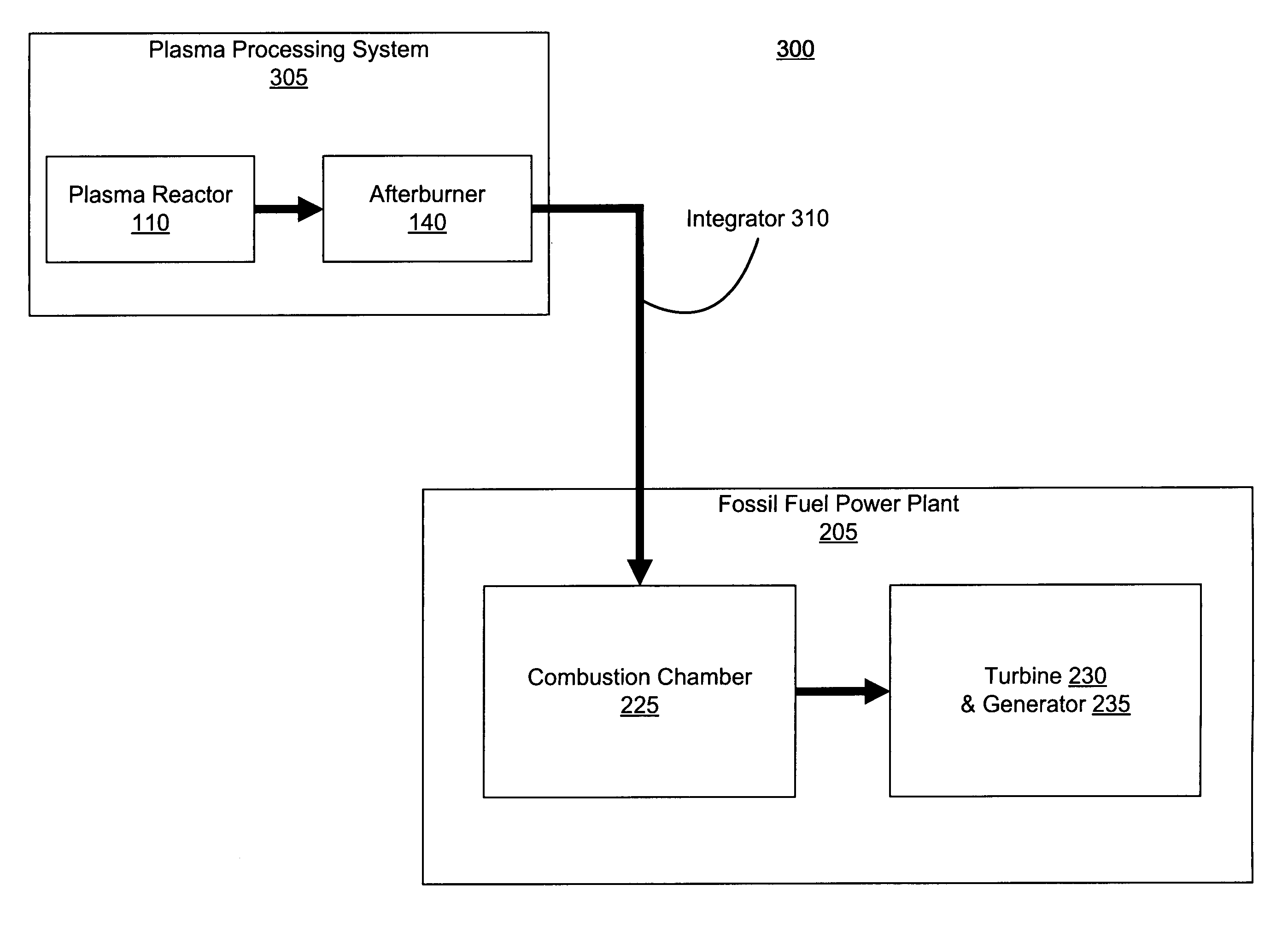

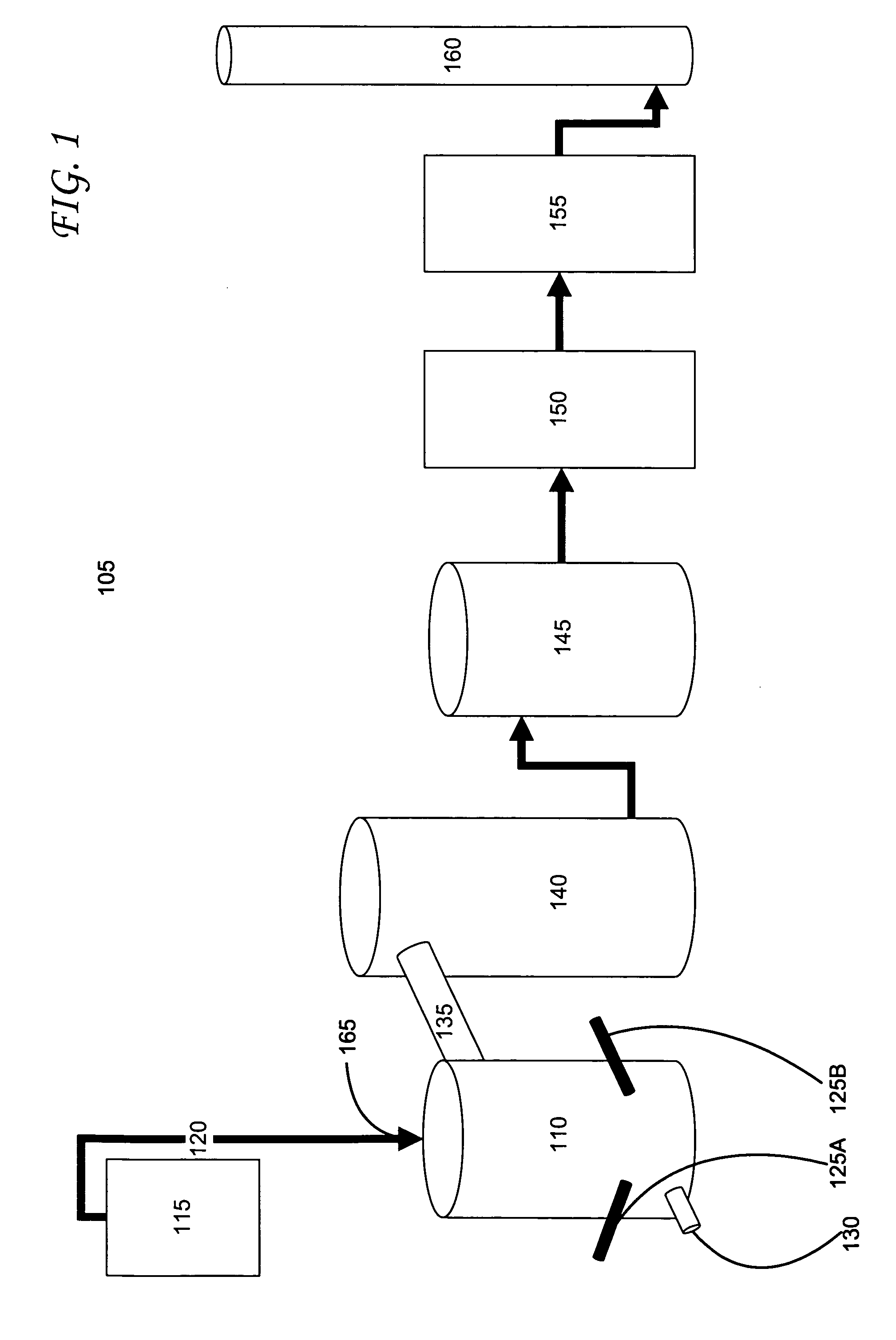

Systems and methods for integrated plasma processing of waste

ActiveUS20070012231A1Efficient propulsion technologiesGas turbine plantsThermal energyCombustion chamber

Systems and methods of integrating plasma waste processing are described. An integreted energy generation system provided with a fossil fuel power plant system having a combustion chamber and a plasma waste processing system having an output. The integrated energy generation system also including an integrator for combining the output of thermal energy from the plasma waste processing system with the combustion chamber of the fossil fuel power plant.

Owner:MARTIN ROBERT C JR +3

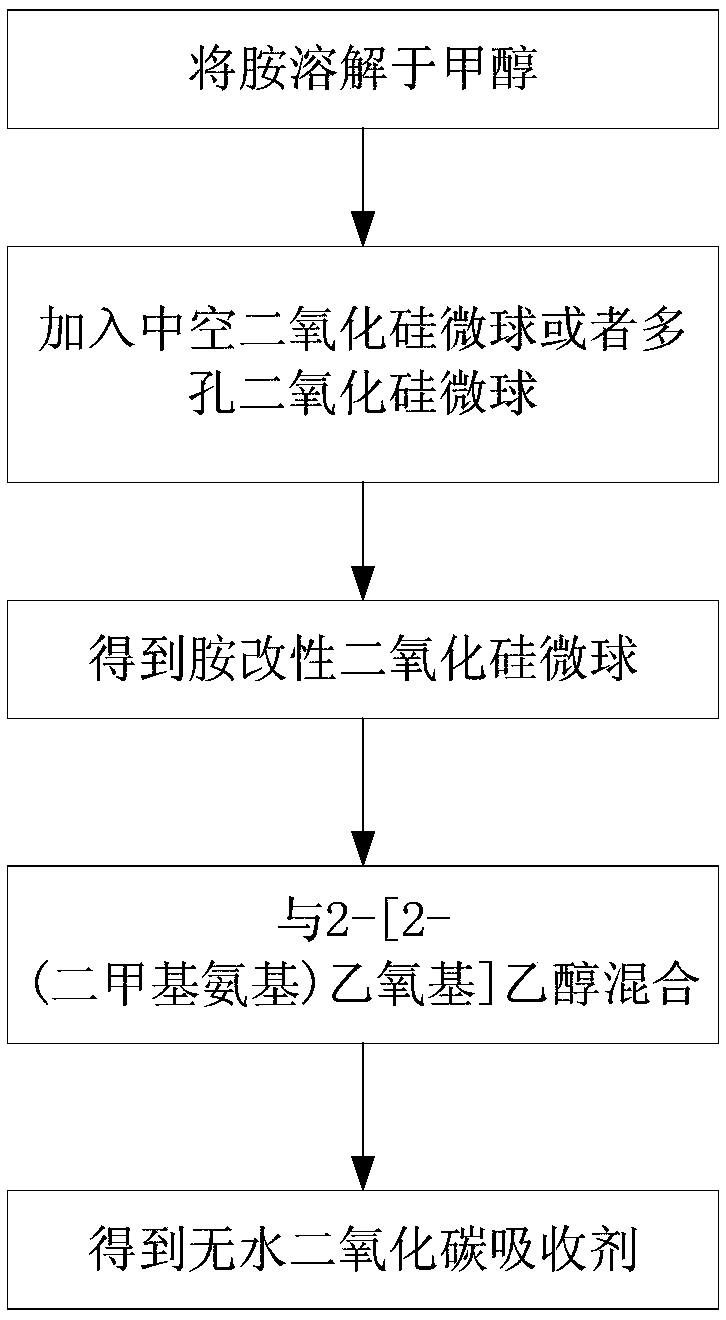

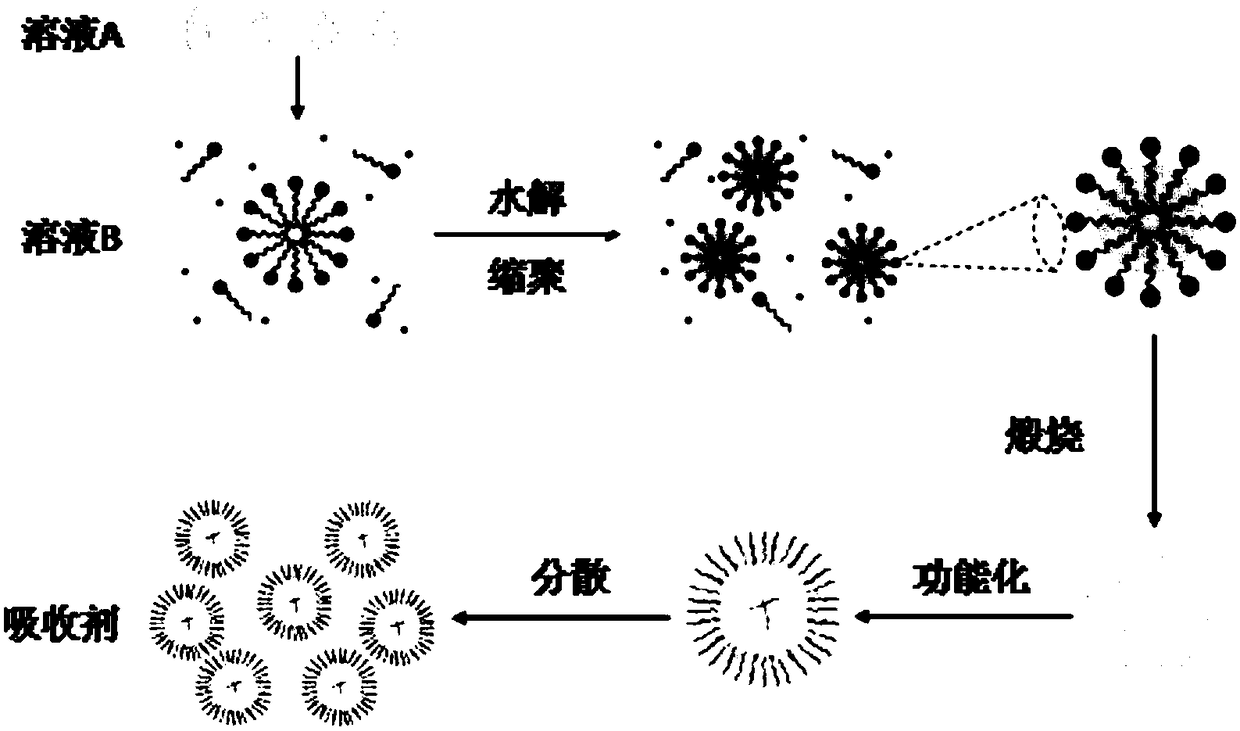

Anhydrous carbon dioxide absorbent and method for absorbing/desorbing carbon dioxide

InactiveCN108926963APromote absorptionLow regeneration energy consumptionDispersed particle separationAir quality improvementCo2 absorptionSilicon dioxide

The invention discloses an anhydrous carbon dioxide absorbent and a method for absorbing / desorbing carbon dioxide. A preparation method for the anhydrous carbon dioxide absorbent comprises the following steps: dissolving amine into methanol, and carrying out stirring until the amine is completely dissolved, so as to obtain a mixed solution; adding hollow silicon dioxide microspheres or porous silicon dioxide microspheres in the obtained mixed solution, continuing to carry out a reaction for 2 to 8 hours with stirring, and carrying out vacuum drying after the reaction ends up, so as to obtain amine modified silicon dioxide microspheres; and mixing the amine modified silicon dioxide microspheres with 2-[2-(dimethylamino)ethoxy]ethanol, thereby obtaining an amine modified silicon dioxide microsphere emulsion shaped anhydrous carbon dioxide absorbent, wherein the mass percent range of the amine modified silicon dioxide microspheres in the absorbent is 5wt% to 40wt%. The carbon dioxide absorption capacity of the anhydrous carbon dioxide absorbent is more than the double of the sum of absorption capacity of a pure solid adsorbent and absorption capacity of a pure liquid-phase absorbent,so that the anhydrous carbon dioxide absorbent can be applied to industries with high carbon dioxide emission such as fossil fuel power plants, cement plants, steel works and oil refineries.

Owner:CHONGQING UNIV

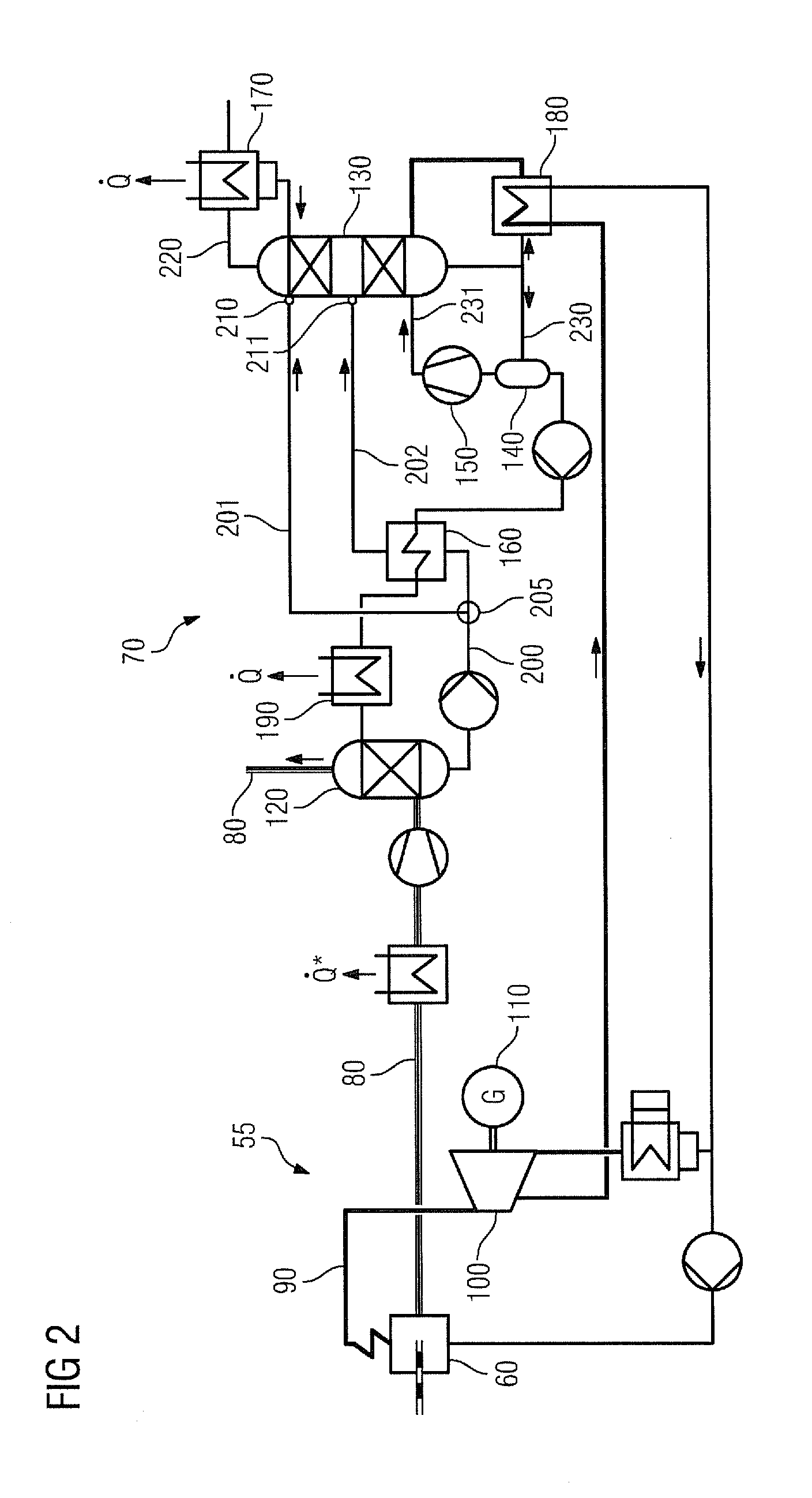

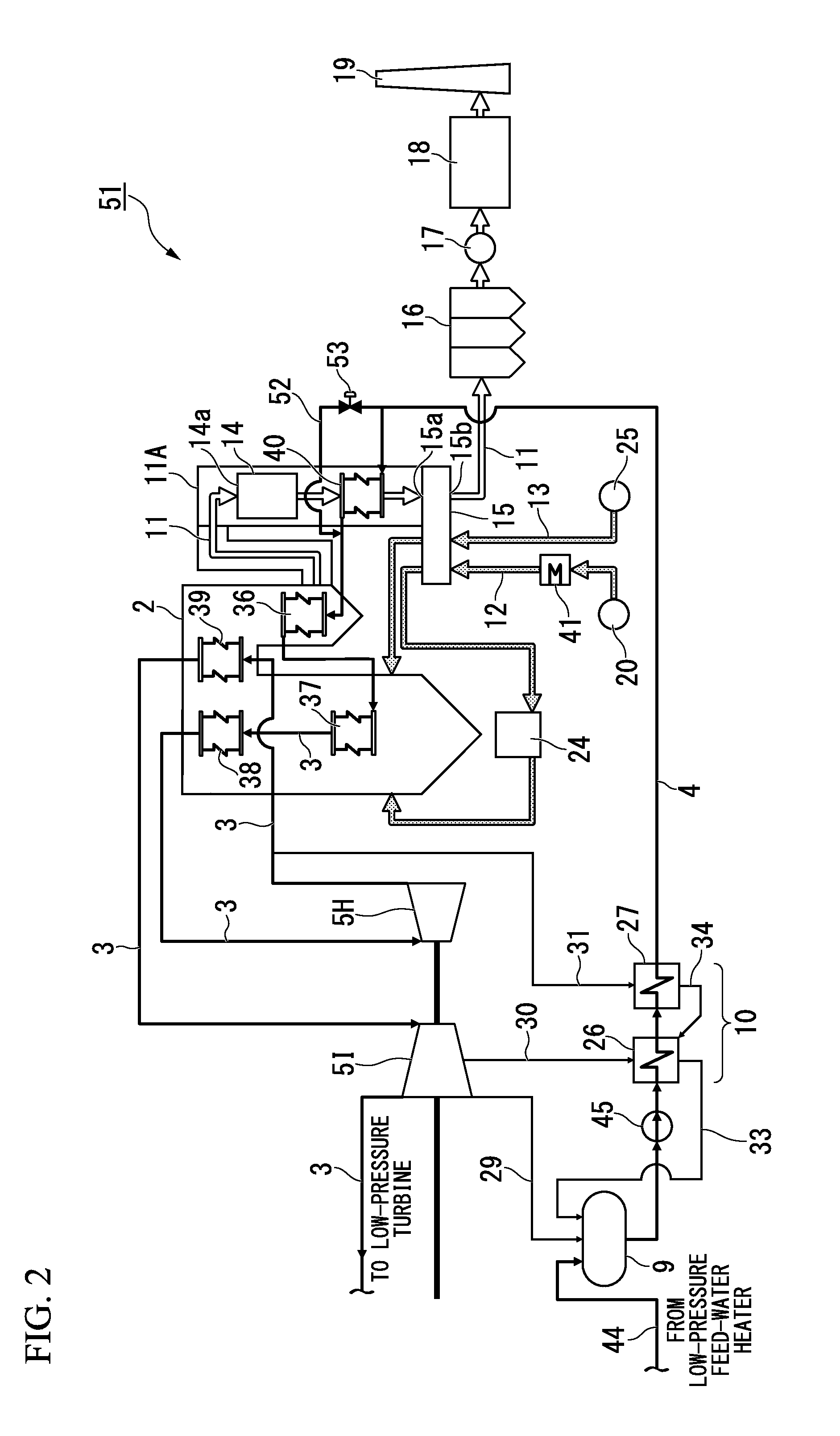

Retrofitting a heating steam extraction facility in a fossil-fired power plant

InactiveUS20130247571A1Simple and cost-effective mannerThermodynamically favorableSteam useCombined combustion mitigationSteam powerEngineering

A method for retrofitting an existing steam turbine with a steam extraction facility is provided. The stem turbine has a plurality of pressure stages and is integrated into a fossil-fired steam power plant. A steam extraction line is connected to one pressure stage or between two pressure stages of the steam turbine, and a heating steam turbine is connected into the steam extraction line.

Owner:SIEMENS AG

Hybrid power plant

A hybrid power plant is described in which a pressurized water nuclear reactor or a biomass-fueled power plant, which have a relatively low operating temperature, such as, is combined with a coal or other fossil fuel power plant having a higher operating temperature. Steam from the first plant is superheated in the second power plant to provide a hybrid plant with improved efficiencies and lower emissions.

Owner:HYBRID POWER

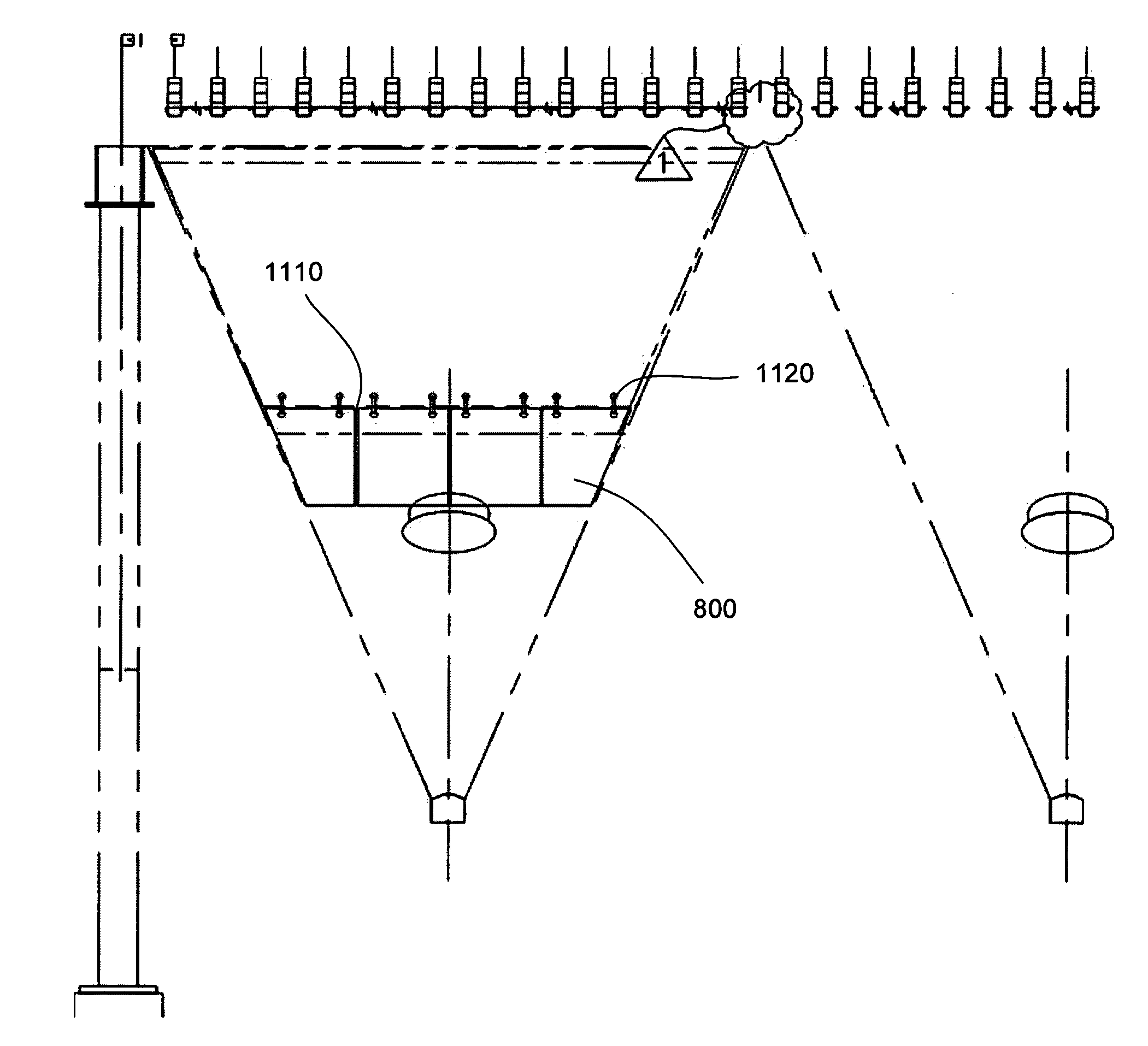

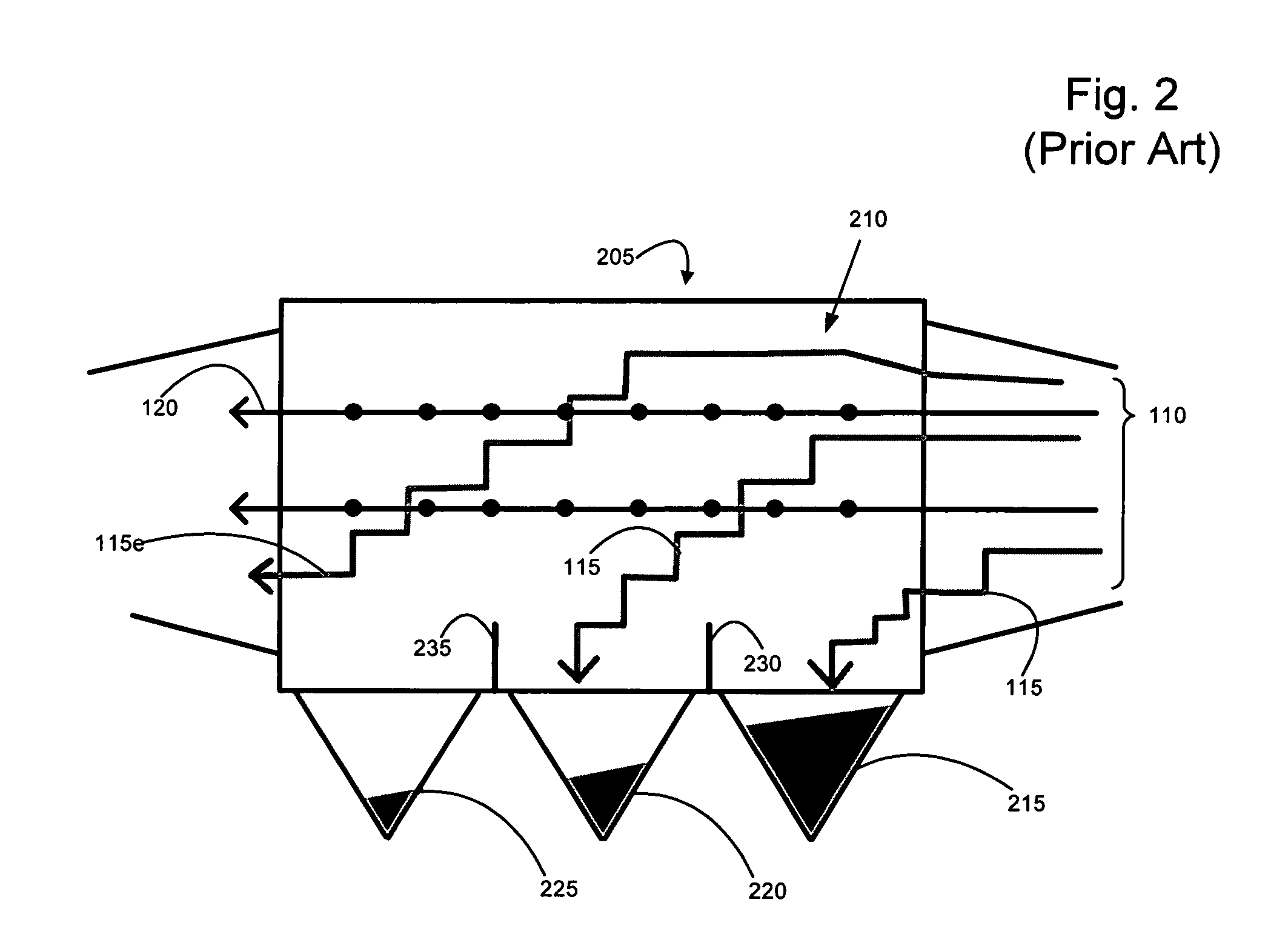

Systems and methods for organic particulate filtration

ActiveUS20080257148A1Reduce the amount requiredCombination devicesAuxillary pretreatmentParticulatesCombustion system

The present invention provides systems and methods for organic particulate filtration. An organic particulate filtration system is implemented within a fossil fuel power plant combustion system. The filtration system comprises a gas flow, in which gas are entrained particulates. The filtration system has a collection hopper located proximate a precipitator collection area. Within the collection hopper, a particulate baffle is provided in a downward-angled orientation. The particulate baffle is enabled to trap particulate, such as organic particulate, in the collection hopper, thereby preventing particulate re-entrainment in the gas flow.

Owner:THE SOUTHERN CO

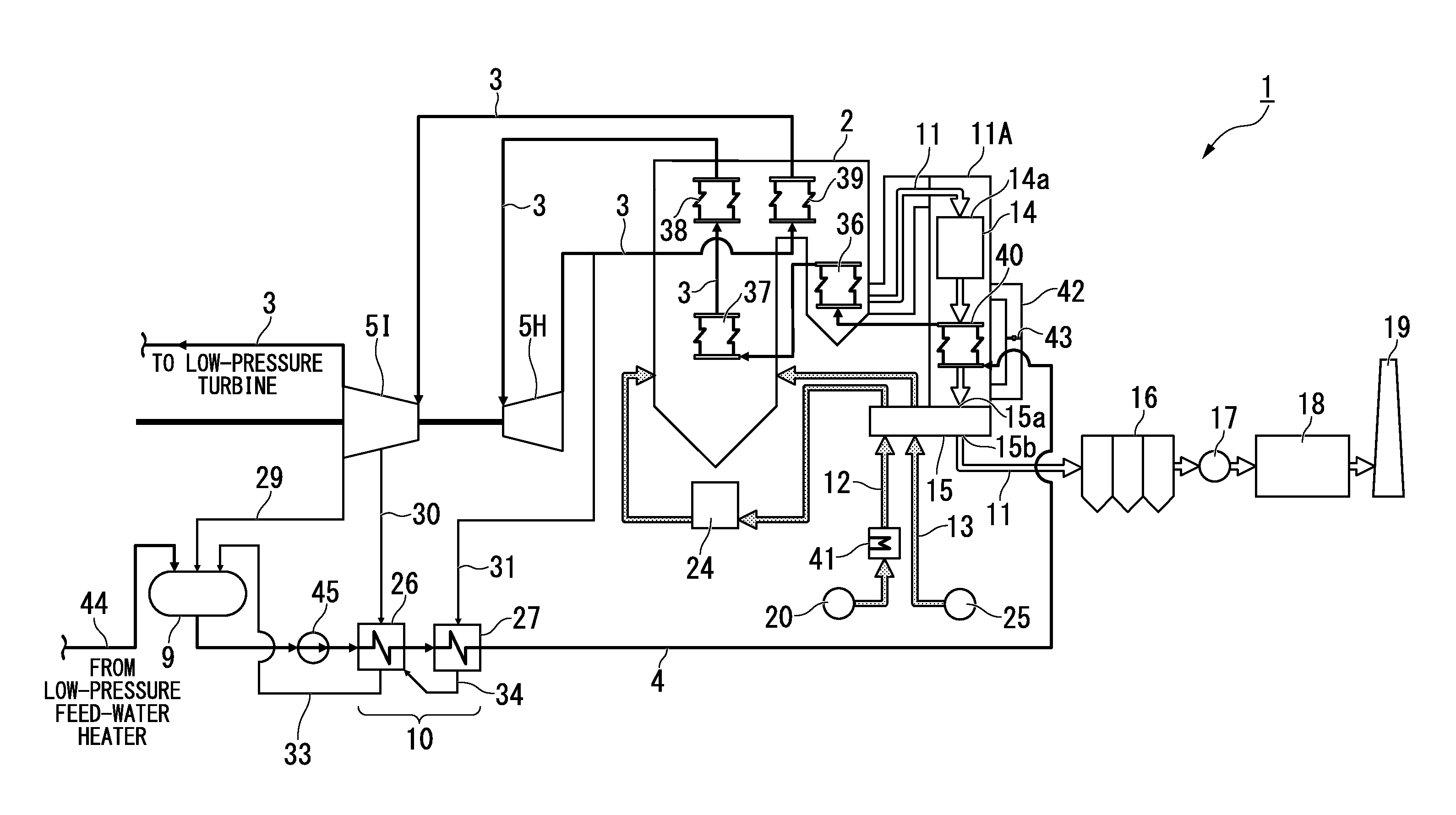

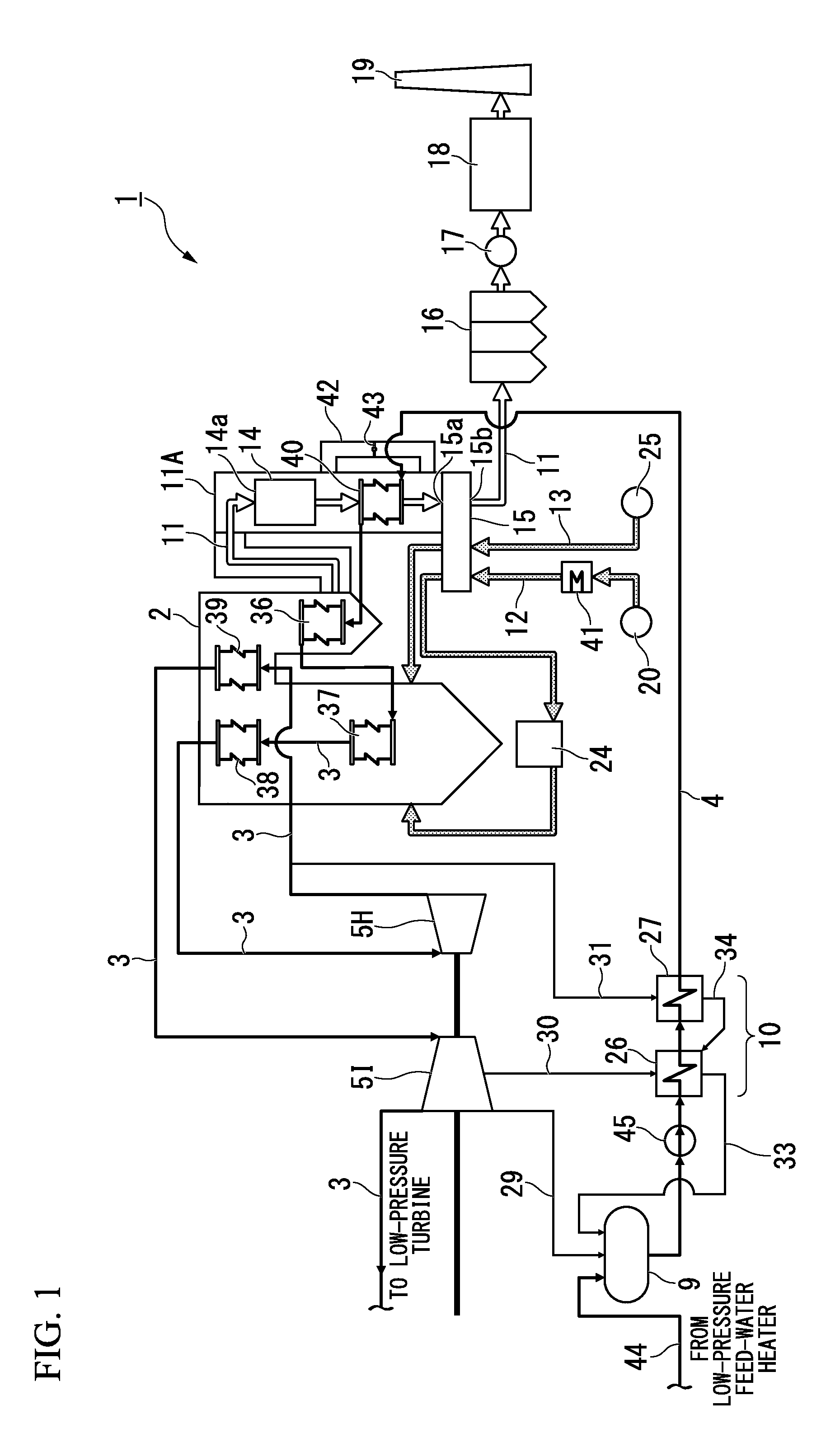

Fossil-fuel power plant and fossil-fuel power plant operation method

ActiveUS20160091197A1Improve power generation efficiencyHeat recoveryEmission preventionDamper arrangementCombustionEngineering

A thermal power plant has an exhaust gas system, a feed-water system, a high-pressure feed-water heater provided to the feed-water system, a main economizer, a catalytic NOx removal equipment, and a sub economizer. The main economizer is provided to the secondary side of the high-pressure feed-water heater of the feed-water system and increases the temperature of the feed-water by using the residual heat of the combustion gas from the boiler. The catalytic NOx removal equipment is provided to the secondary side of the main economizer of the exhaust gas system. The exhaust gas is supplied to the catalytic NOx removal equipment at a required temperature or higher. The sub economizer is provided between the high-pressure feed-water heater and the main economizer and increases the temperature of water by using the exhaust gas on the secondary side of the NOx removal equipment.

Owner:ELECTRIC POWER DEVELOPMENT COMPANY

Power plant for co2 capture

InactiveUS20120216547A1Optimize overall power plant operationExhaust apparatusEngine fuctionsFlue gasProcess engineering

An exemplary fossil fuel fired power plant is disclosed with minimum impact of the CO2 capture system on a power part of the plant. A power plant is disclosed which is ready for the retrofit of a CO2 capture plant, and a method is disclosed for retrofitting an existing plant into a power plant with CO2 capture. A power plant part is disclosed which can provide steam and power to operate CO2 capture system, and provide a CO2 capture system, which has the capacity to remove CO2 from flue gas flow of the power part, and of the additional power plant part.

Owner:GENERAL ELECTRIC TECH GMBH

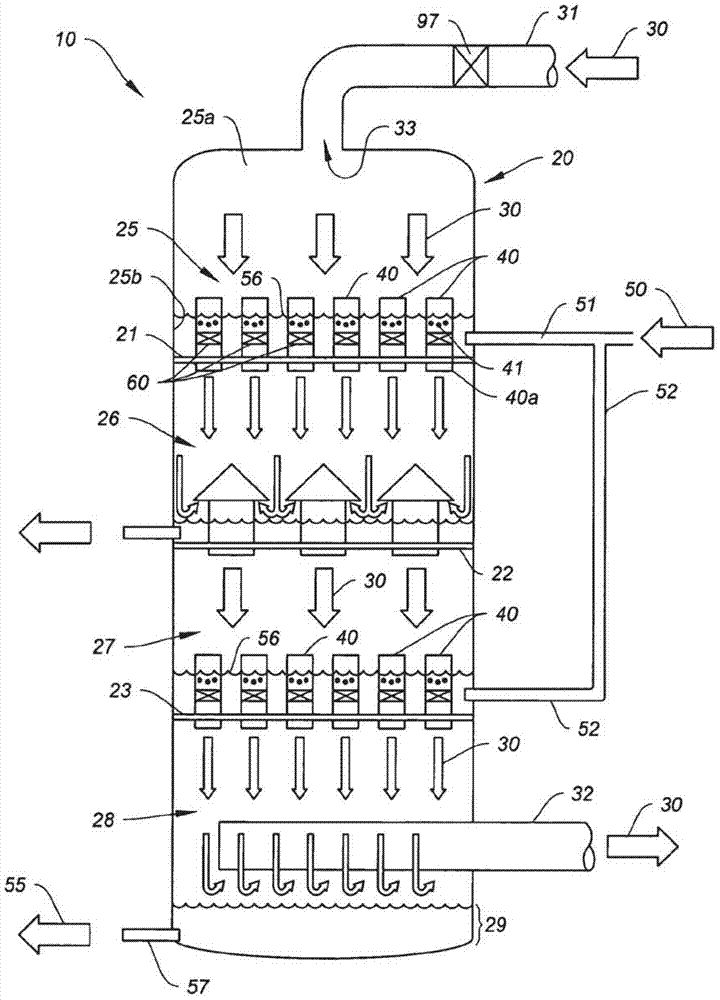

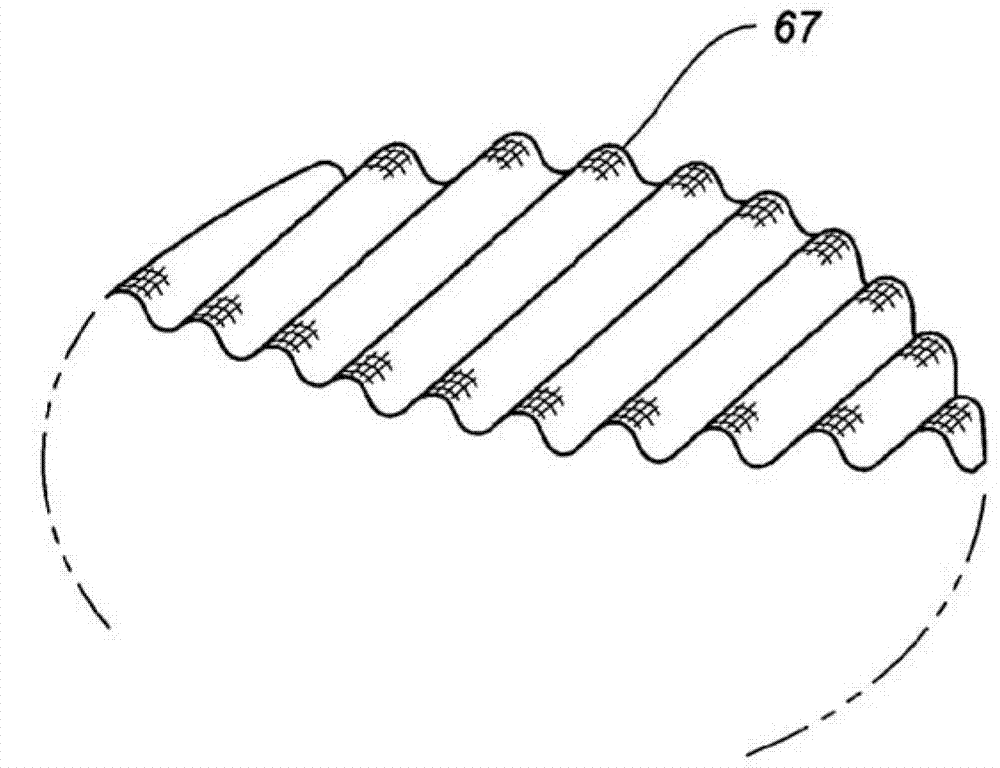

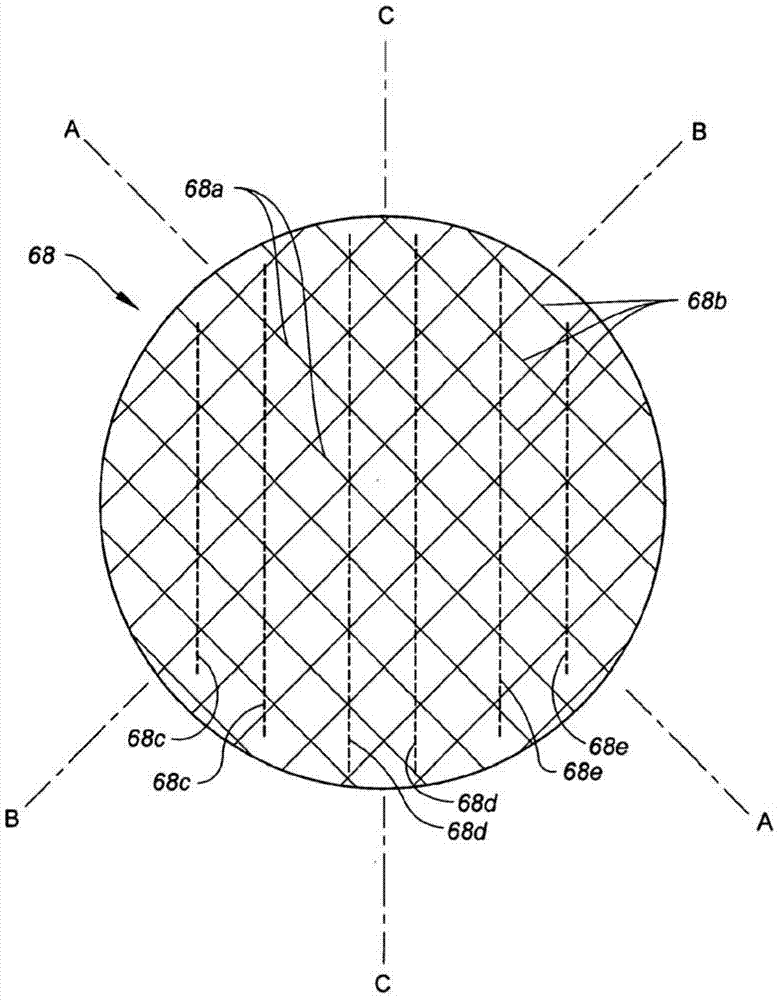

Absorber

InactiveCN103370119AIncreased surface areaImprove absorption efficiencyGas treatmentUsing liquid separation agentFlue gasMechanical engineering

An absorber is provided which utilizes a solvent froth to absorb a selected component, such as CO2 for example, from a flowing gas stream, such as flue gas from a fossil fuel power plant, for example. In one embodiment, a flooded tube gas absorber utilizes a bulkhead plate extending across a reaction chamber. The plate carries a plurality of vertical absorption tubes, each carrying a plurality of spaced apart screens. The incoming gas stream flows downwardly and at equal velocities through the tubes. Solvent is injected downwardly into the tubes. The screen array forms a froth and rapidly and repeatedly bursts the froth bubbles, forming a rapidly changing absorption surface. A second embodiment uses full diameter screens without a bulkhead plate. An option is to use ridge shaped screens to achieve solvent pulsing, increasing efficiency. Both vertical and horizontal reaction chambers are disclosed.

Owner:WESTEC ENVIRONMENTAL SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com