Ground fault detection and calibration method and device for direct current system

A DC system, ground fault technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve problems such as relay protection malfunction, system collapse, equipment malfunction, refusal to operate, etc.

Inactive Publication Date: 2009-10-14

国网吉林省电力有限公司超高压公司

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In operation practice, it has been found that DC grounding will not only cause misoperation or refusal of relay protection, but may even cause misoperati

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The problem of correct wire selection of a branch with a ground fault of a direct current system of a power system is always a difficult problem for the power system. Comprehensive reasons on a plurality of aspects cause the phenomenon that the correct wire selection is difficult. The safety and the reliability of the direct current system affect the operation of power plants and transformer stations and are related to the safe production of the whole large power system. The ground fault detection and calibration method and the device for the direct current system improve the insulation supervision alarm value of a bus to the level of 100KO from 48KO. The ground fault detection and calibration method and the device are based on the requirements of (DL/T5044-95) technical regulations for design of direct current systems of fossil fuel power plants and transformer substations, and the corresponding branch insulating detection ability is improved to the level of 300KO from 20KO, and the branch insulating detection horizontally covers all the fault phenomena of the insulating alarm value of the direct current system. The calibration method and the device are used for detecting the calibration of a direct current insulating supervision device before access network. The invention aims at ensuring the safety of the system and the standards of access network.

Description

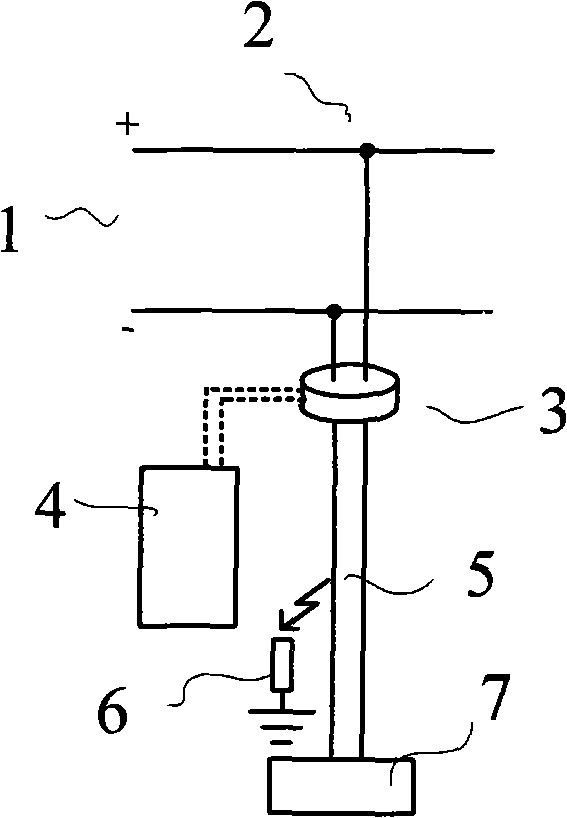

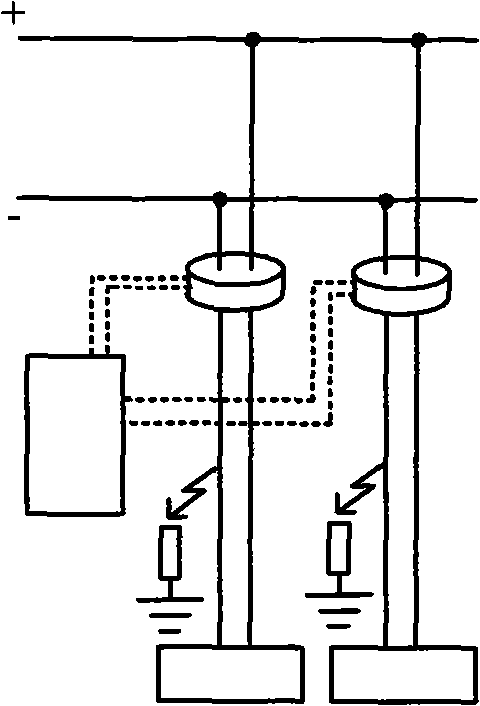

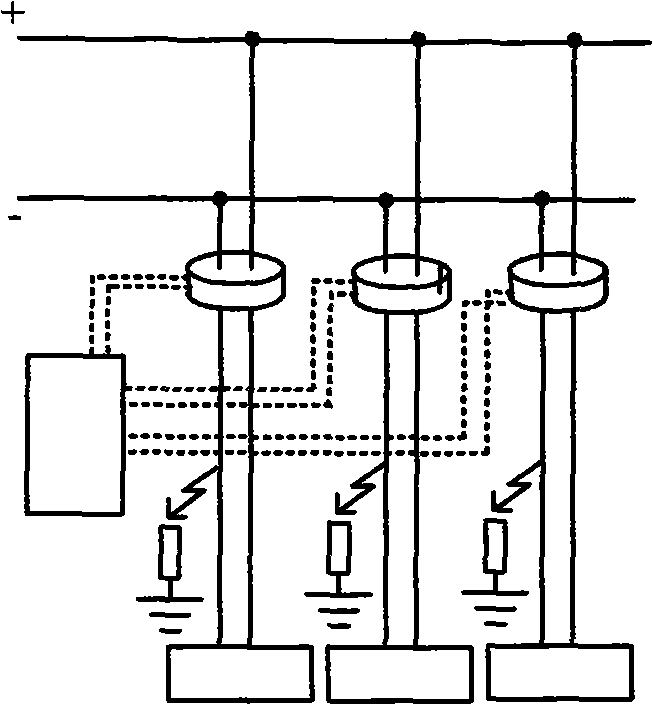

technical field [0001] The invention relates to a method for detecting and calibrating a DC system grounding fault in a power system, and belongs to the application category of DC system detection equipment. Background technique [0002] 1. The current monitoring level of DC system busbar insulation: [0003] DC power supply is one of the important power sources in power plants and substations. At present, the monitoring of DC bus insulation is based on the insulation monitoring current of 1.4mA. When the leakage current is greater than 1.4mA, the overall insulation level of the DC system has dropped below 48kΩ, and the resolution and accuracy of the DC bus insulation monitoring are judged. Ground fault, the basis for starting the next step of work. The current theoretical calculation is able to detect the phenomenon that the busbar insulation is less than 48KΩ, and the detection ability of the actual busbar insulation is less than the theoretical calculation value. [00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R35/00

Inventor 王鹏张连斌尹玉芳侯喜凤朱景明王兵李辉尹树峰李大鹏赵长春

Owner 国网吉林省电力有限公司超高压公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com