Method for growing photosynthetic organisms

A technology of photosynthetic organisms and biofuels, applied in separation methods, biofuels, biological raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

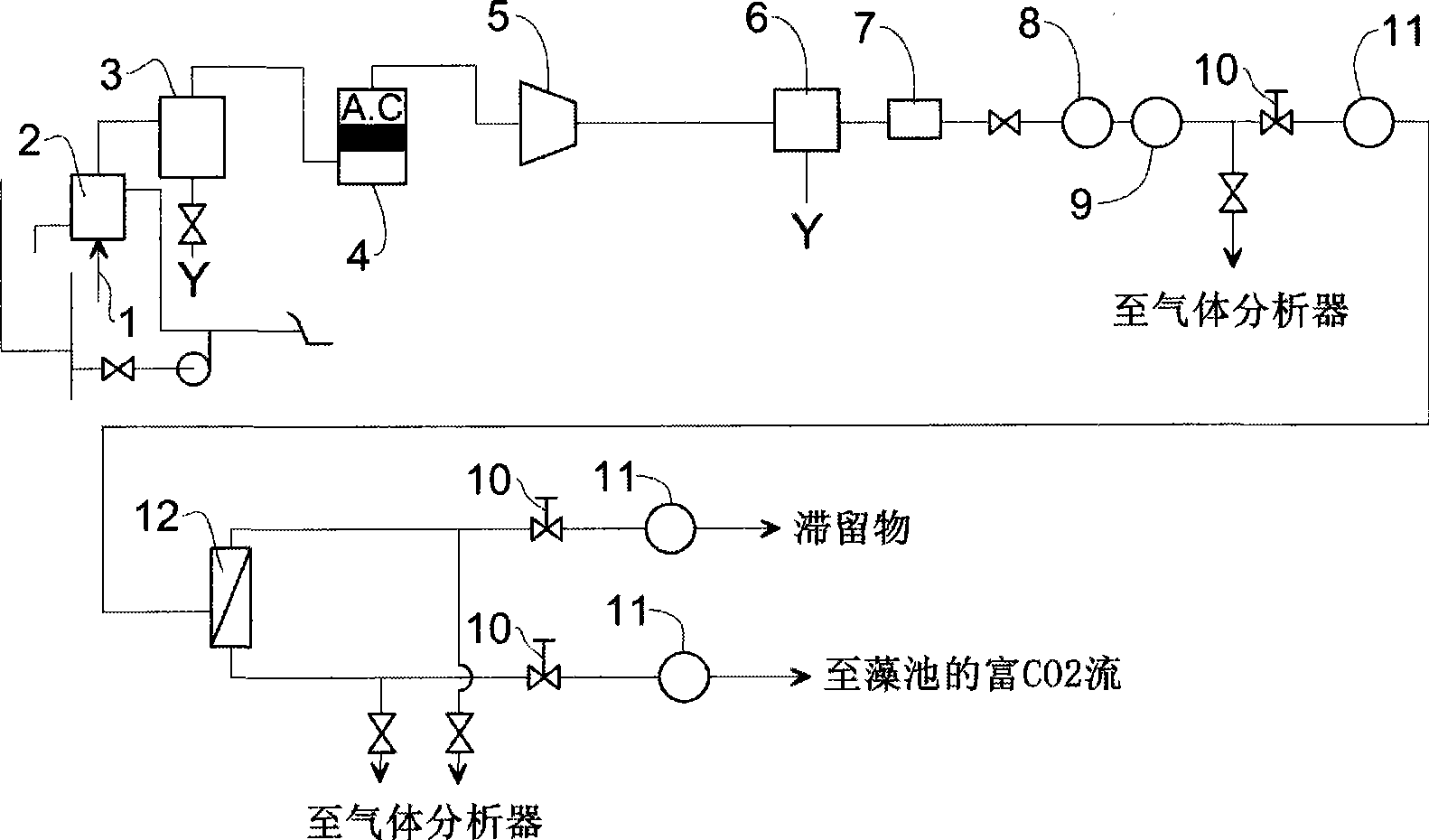

[0064] Example 1 - Membrane Separation

[0065] One of the unique features of CMSM fabrication technology is the ability to tightly control the membrane permeability / selectivity combination to suit various applications. In this regard, the membranes tested in this work were prepared to achieve the optimum permeability / selectivity combination for air separation.

[0066] The results stated below are based on an effective separation area of 3.4m made of approximately 10,000 carbon hollow fibers 2 Obtained from a test assembly open at one end.

[0067] Permeability assays and air enrichment assays are performed with a single gas: N 2 , O 2 , CO 2 and SF 6 . (The last gas is used to determine the molecular sieve properties of the membrane). The tests were carried out at room temperature and at feed pressures of up to 5 bar.

[0068] Two sets of experiments were performed:

[0069] - Permeability determination using pure gas;

[0070] - Air separation.

[0071] Consi...

Embodiment II

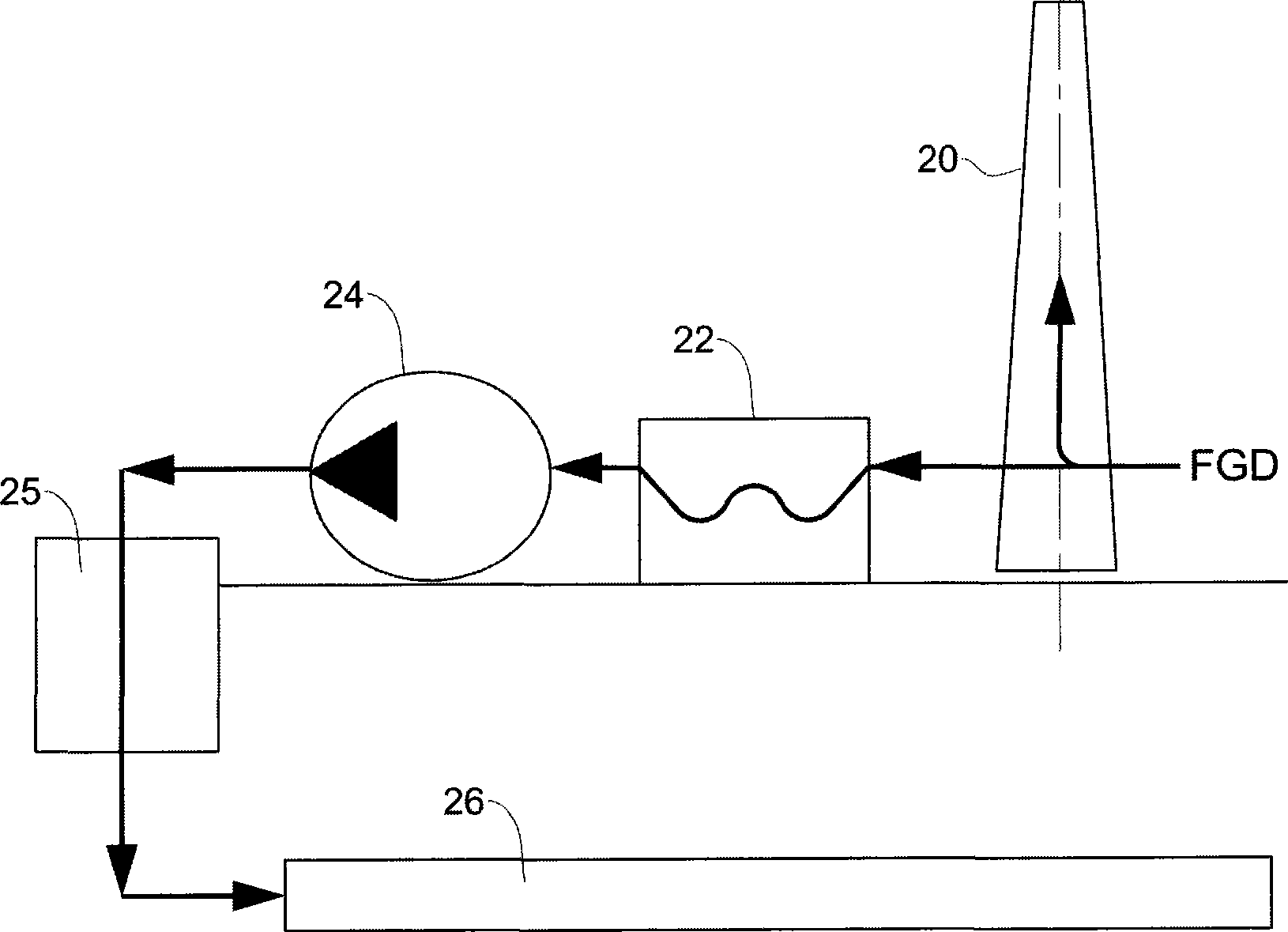

[0075] Example II - Transport System

[0076] In one embodiment of the transport system for transporting the treated flue gas to the microalgae cultivation area, the following components are required:

[0077] 1) Main gas pipelines suitable for transporting gases containing carbon dioxide;

[0078] 2) The primary gas manifold located close to the algae field;

[0079] 3) Mains for conveying carbon dioxide-containing gas from the main gas line to the primary gas manifold; and

[0080] 4) A plurality of secondary discharge lines extending from the primary gas manifold into the pond and including vents for delivering carbon dioxide rich gas to the algae.

[0081] One of the major commercial considerations is the supply of CO 2 The distance between the power plant and the seaweed field. This distance determines the selection to be made. The greater the amount of "parasitic" gas to be transferred, the more expensive the piping to use and the greater the energy consumption du...

Embodiment III

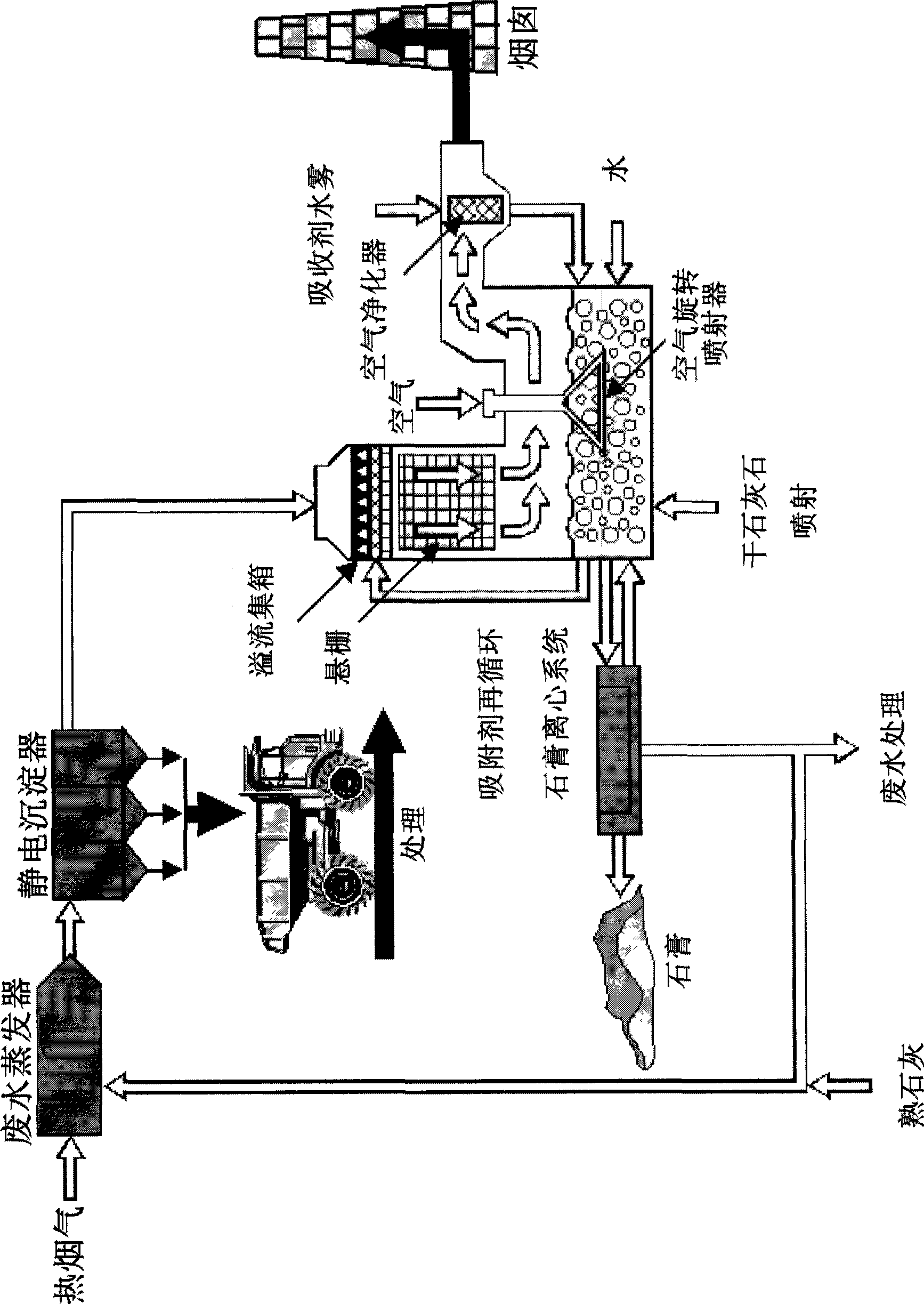

[0104] Example III - Inflation

[0105] The supply of flue gas into the pool is carried out by means of an aeration device.

[0106] The inflatable device is manufactured from a chemically stable polymeric material as the inflatable component. A preferred embodiment of the aerator is the KREAL tubular aerator (porous) (Russian Patent No. 32487). The inflator components are made in the form of LPP pipes (low pressure polyethylene), in which the inflators are fixed in pairs by polyamide T-tubes.

[0107] The inflatable assembly is implemented with LPP pipes (d=110-160mm), and the inflators are fixed in pairs on the LPP pipes through plastic trilling. The module width is 1.1m; the spacing between the aerators is 1.5-4m. Changing the spacing between the inflators allows varying the injection intensity over a wide range, ensuring optimum CO 2 model.

[0108] The use of polymeric materials in the inflator components reduces assembly time and increases the operational life of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com